Effective Exploitation Potential of Shale Gas from Lower Cambrian Niutitang Formation, Northwestern Hunan, China

Abstract

:1. Introduction

2. Geological Setting

2.1. Overview

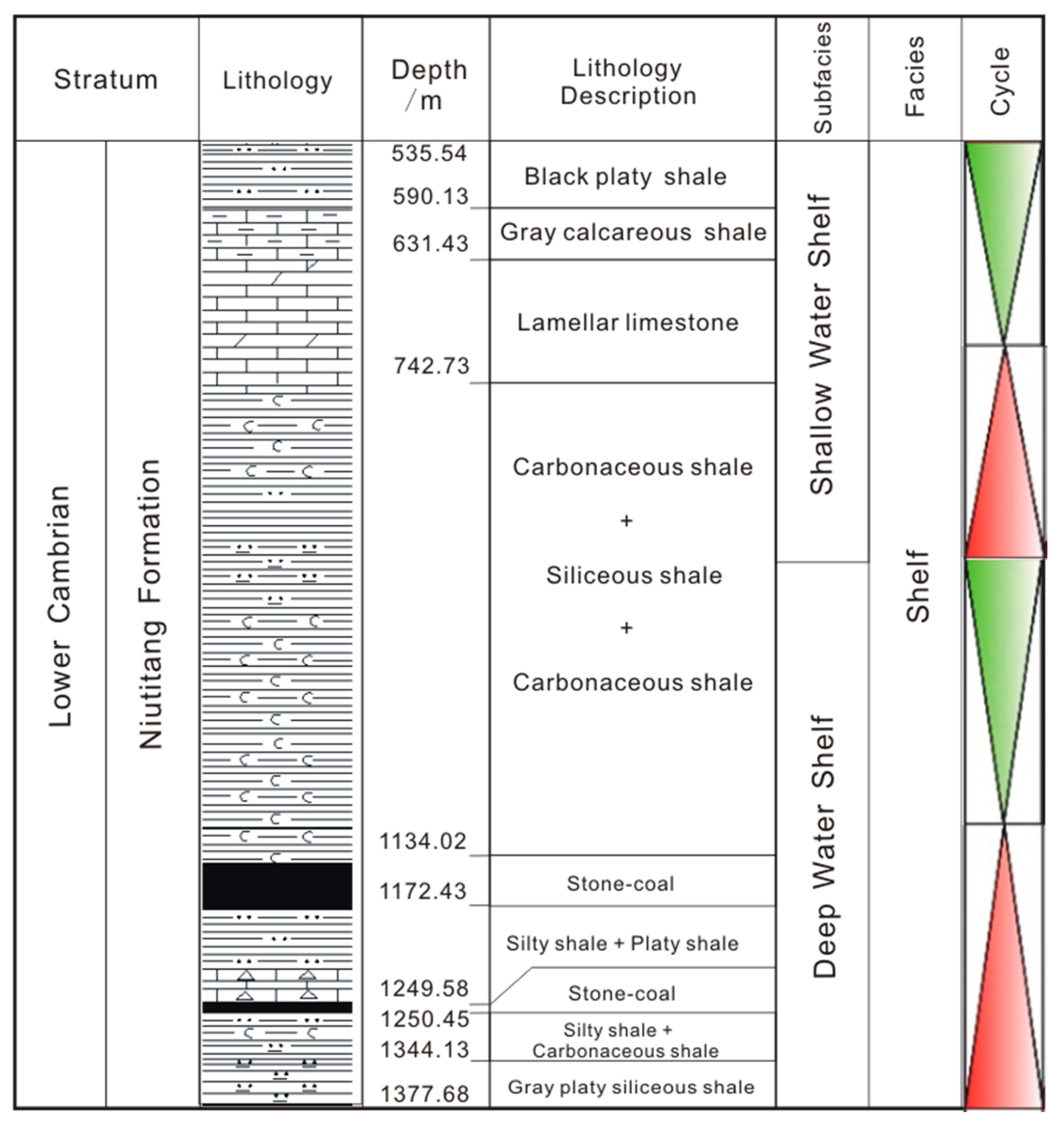

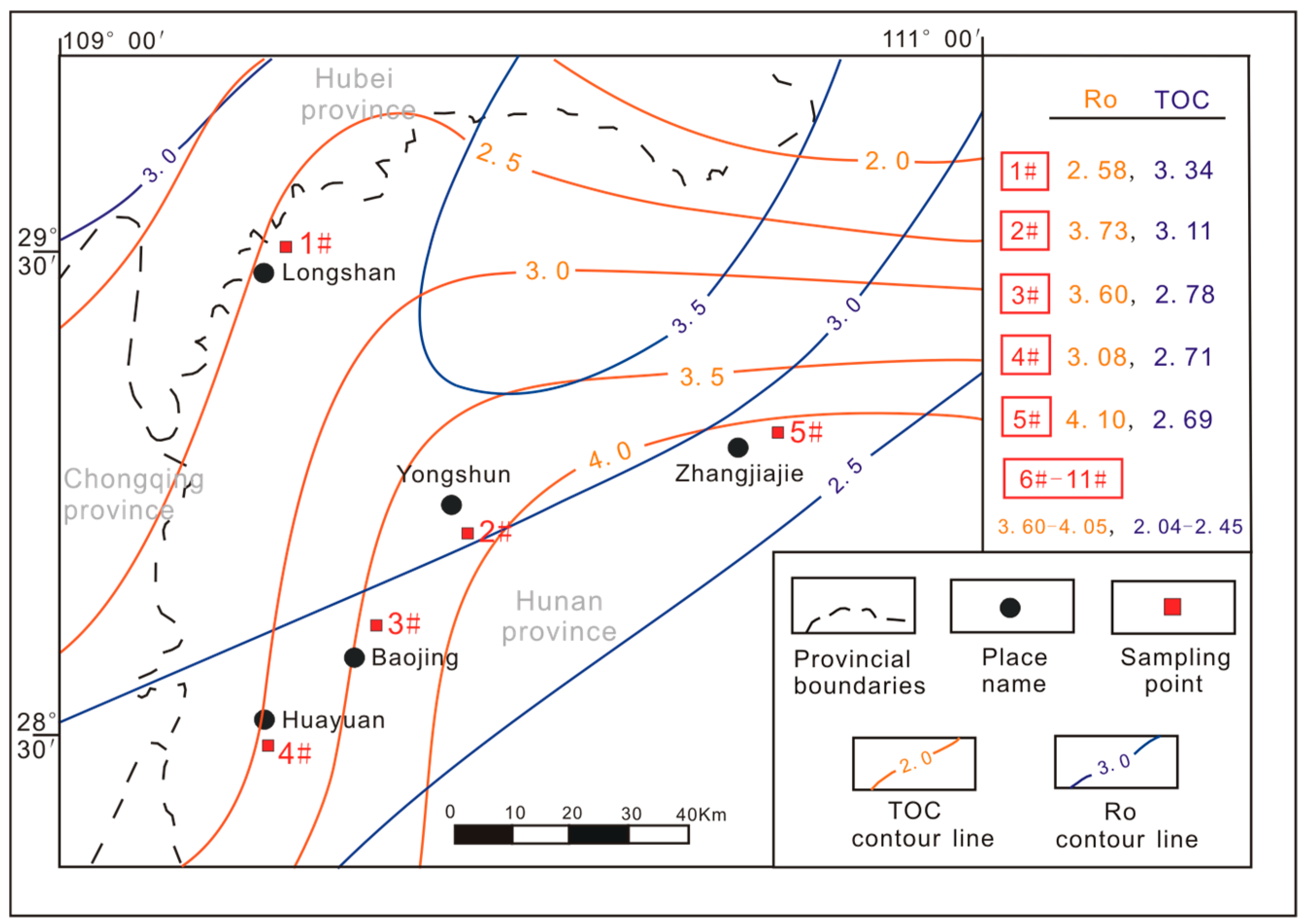

2.2. Shale-Distribution Characteristics

3. Materials and Methods

4. Experimental Results

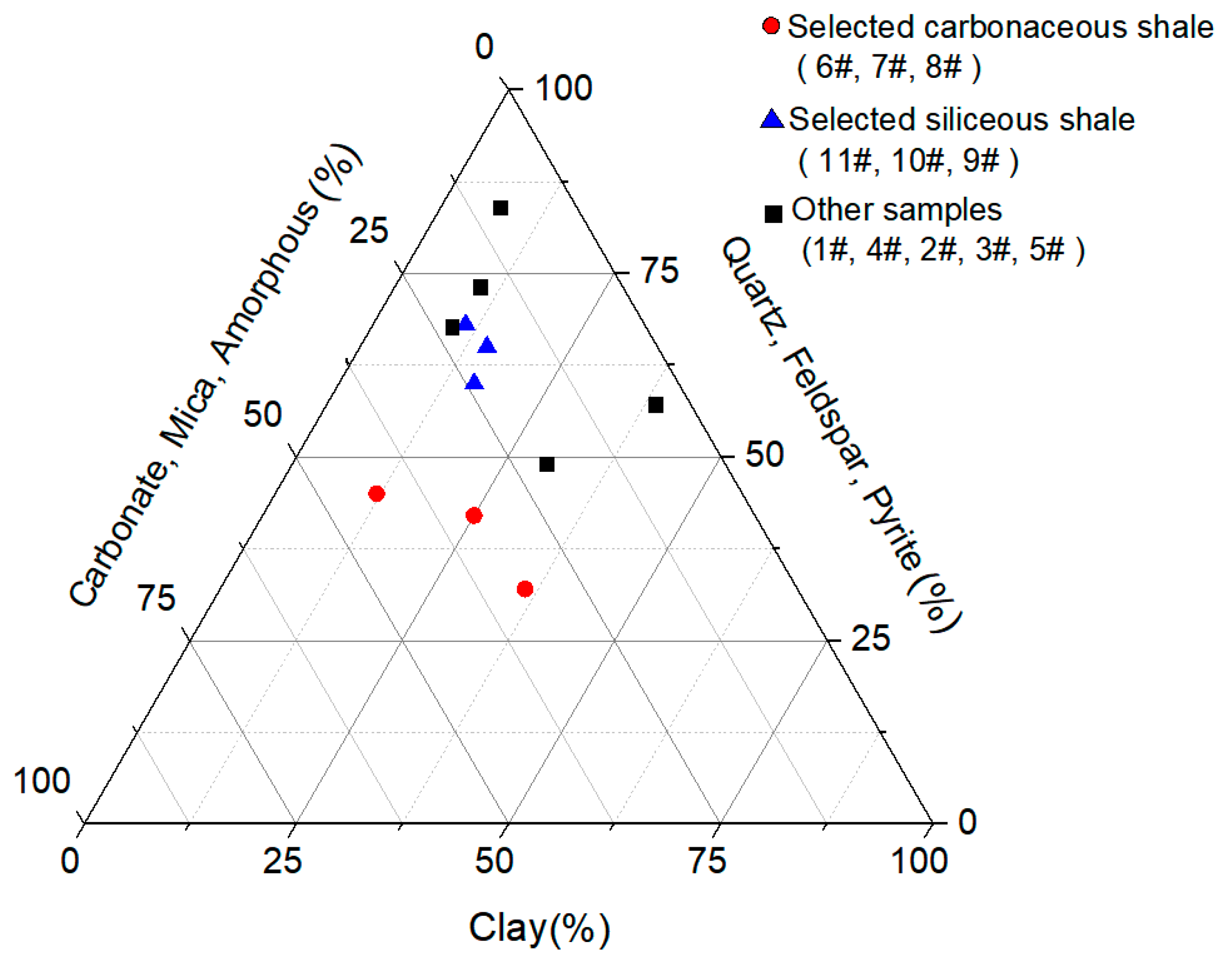

4.1. Mineral Composition

4.2. Organic Matter Characteristics

4.3. Mechanical Parameters

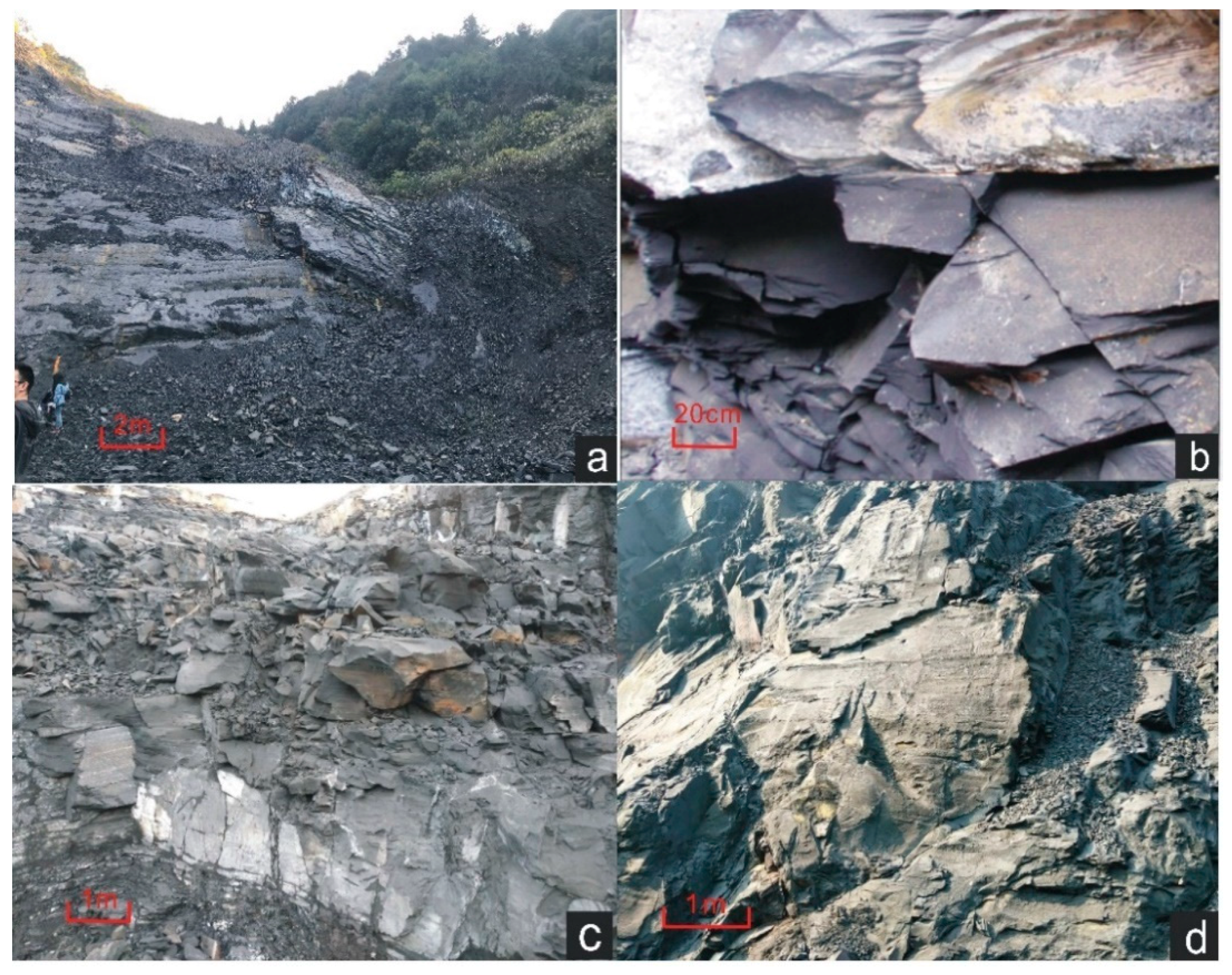

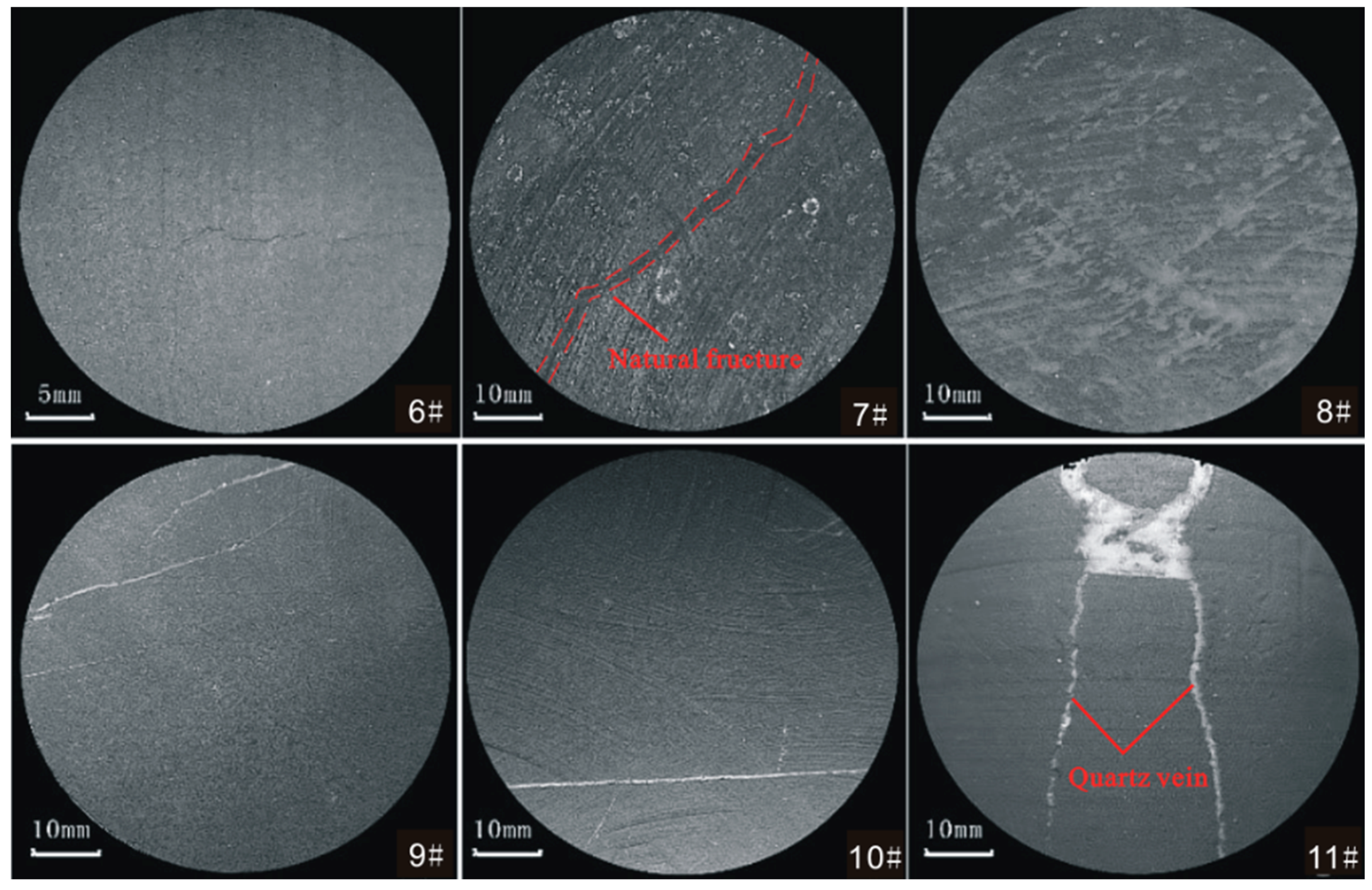

4.4. Fractures Observation

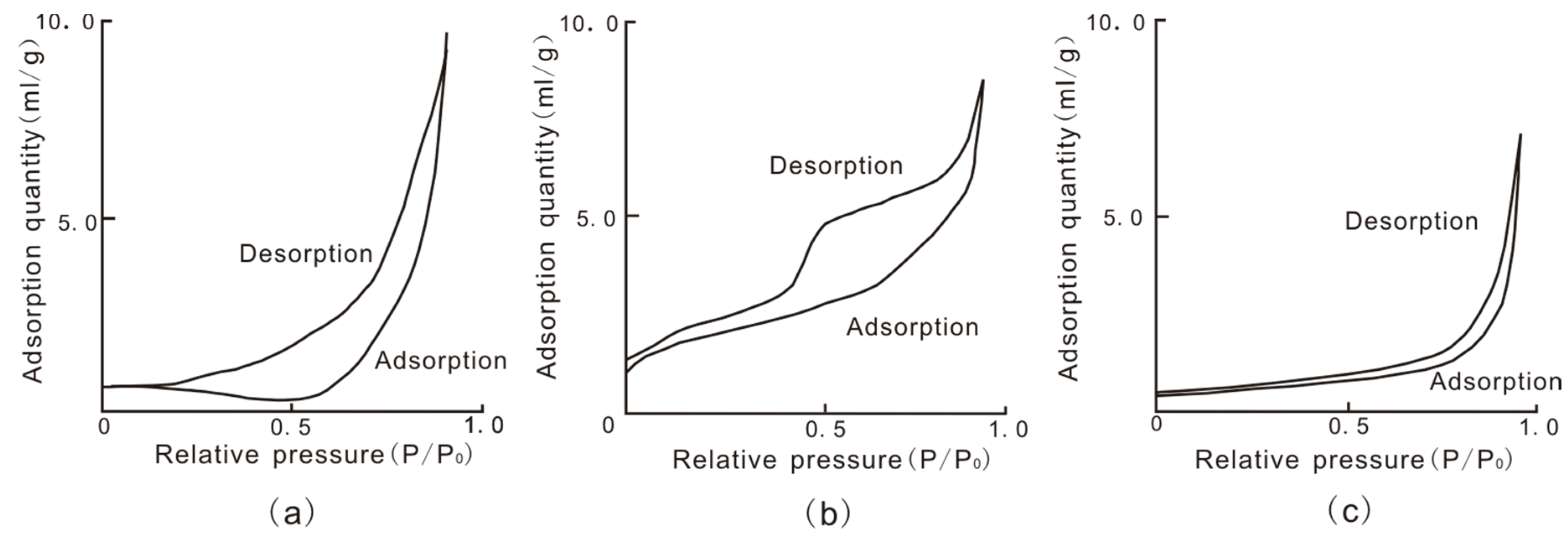

4.5. Microstructure of Shales

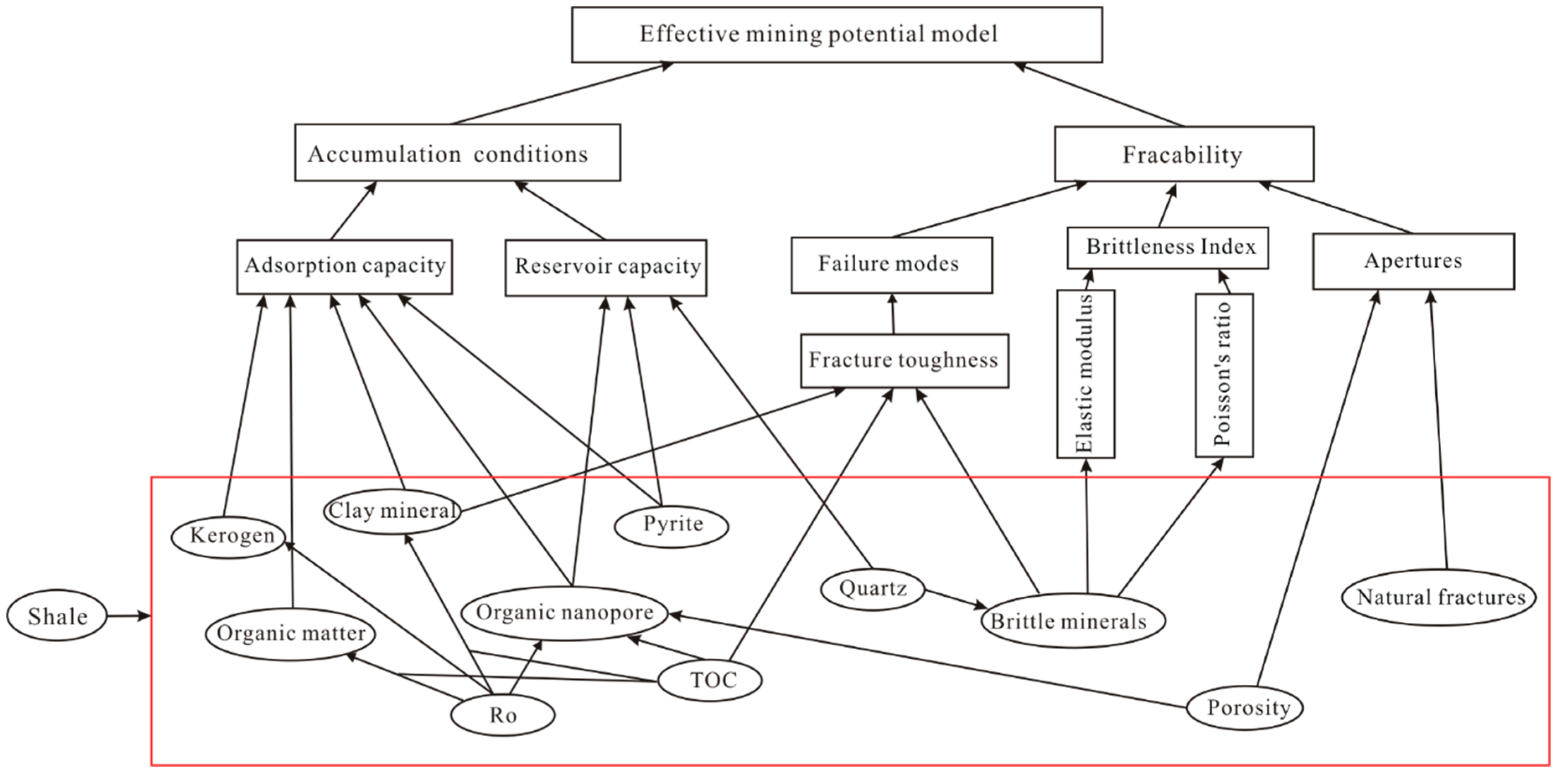

5. Discussion

5.1. Accumulation Conditions

5.1.1. Adsorption Capacity

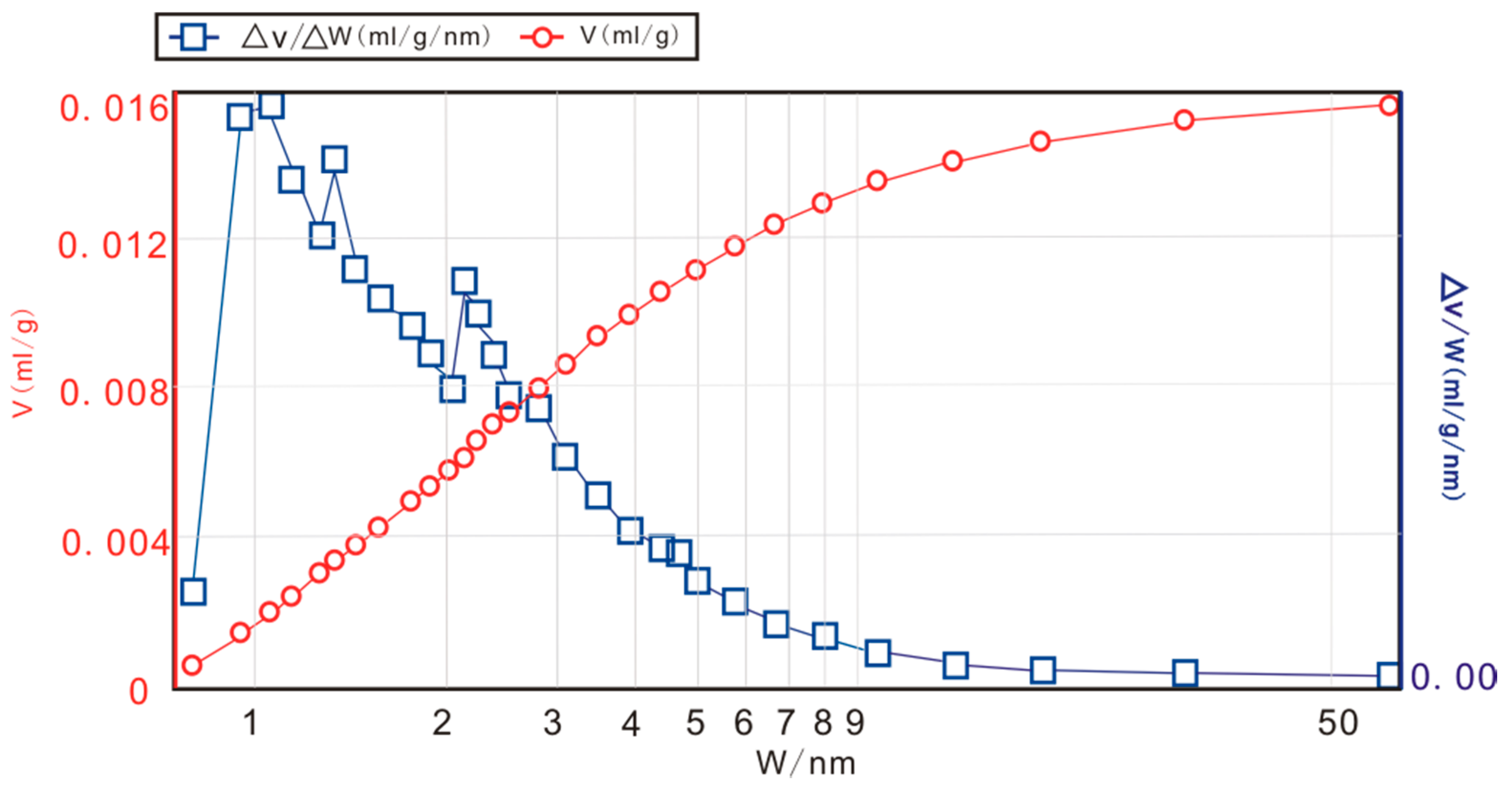

5.1.2. Reservoir Capacity

5.2. Fracability

5.2.1. Uniaxial Compression Failure Modes

5.2.2. Brittleness Index

5.2.3. Natural Fractures

5.3. The Recommendation of a Comprehensive Framework for Exploitation Potential

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Curtis, M.; Ambrose, R.; Sondergeld, C. Structural Characterization of Gas Shales on the Micro and Nano-Scales. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Kale, S.; Rai, C.; Sondergeld, C. Petrophysical Characterization of Barnett Shale. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010. [Google Scholar]

- EIA. International Energy Outlook; EIA: Washington, DC, USA, 2018. [Google Scholar]

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Klett, T.R.; Charpentier, R.R. FORSPAN Model Users Guide; Center for Integrated Data Analytics Wisconsin Science Center: Reston, VA, USA, 2003. [Google Scholar]

- Ewing, J.; Jackson, G. Barnett Shale Creates Win-Win Situation for Homeowners and Energy Companies; Fort Worth Business Press: Fort Worth, TX, USA, 2005; Volume 18, p. 28. [Google Scholar]

- Hill, R.J. Modeling of gas generation from the Barnett Shale, Fort Worth Basin, Texas. AAPG Bull. 2007, 91, 501–521. [Google Scholar] [CrossRef]

- Burnaman, M.D.; Shelton, J. Shale Gas Play Screening and Evaluatiosn Criteria. China Pet. Explor. 2009, 14, 51–64. [Google Scholar]

- Editorial Committee of Shale Gas Geology and Exploration Practice Series. New Progress in Shale Gas Exploration and Development in North America; Petroleum Industry Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Macquaker, J.; Davies, S. Lithofacies Variability in Fine-Grained Mixed Clastic Carbonate Successions: Implications for Identifying Shale-Gas Reservoirs. In Proceedings of the AAPG Annual Meeting, San Antonio, TX, USA, 20–23 April 2008. [Google Scholar]

- Bowker, K.A. Barnett Shale gas production, Fort Worth Basin: Issues and discussion. AAPG Bull. 2007, 91, 523–533. [Google Scholar] [CrossRef]

- ANON. Marcellus Shale-Appalachian Basin Natural Gas Play [EB/OL]. Available online: http://geology.com/articles/ marcellusshale.shtml (accessed on 2 December 2018).

- He, J.L.; Wang, J.; Yu, Q. Pore structure of shale and its effects on gas storage and transmission capacity in well HD-1 eastern Sichuan Basin, China. Fuel 2018, 226, 709–720. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Hu, Q.H. Pore characterization and methane sorption capacity of over-mature organic-rich Wufeng and Longmaxi shales in the southeast Sichuan Basin, China. Mar. Pet. Geol. 2016, 77, 247–261. [Google Scholar] [CrossRef]

- Yong, T.; Fan, Y.; Lv, Q.Q. Analysis of the Tectonic Stress Field of SE Sichuan and its Impact on the Preservation of Shale Gas in Lower Silurian Longmaxi Formation of the Dingshan Region, China. J. Geol. Soc. India 2018, 92, 92–100. [Google Scholar] [CrossRef]

- Li, S.R.; Zeng, L.; Wang, Z.P. A New Insight into Shale-Gas Accumulation Conditions and Favorable Areas of the Xinkailing Formation in the Wuning Area, North-West Jiangxi, China. Energies 2018, 11, 12. [Google Scholar] [CrossRef]

- Wang, R.; Sang, S.; Zhu, D. Pore characteristics and controlling factors of the Lower Cambrian Hetang Formation shale in Northeast Jiangxi, China. Energy Explor. Exploit. 2017, 36, 43–65. [Google Scholar] [CrossRef]

- Zhang, L.T.; Guo, J.H.; Jiao, P. Accumulation conditions and resource potential of shale gas in Lower Cambrian Niutitang Formation, northwestern Hunan. J. Cent. South Univ. (Sci. Technol.) 2014, 45, 1163–1173. [Google Scholar]

- Lin, T.; Zhang, J.C.; Li, B. Shale gas accumulation conditions and gas-bearing properties of the Lower Cambrian Niutitang Formation in Well Changye 1, northwestern Hunan. Acta Pet. Sin. 2014, 35, 839–846. [Google Scholar]

- Zhou, Q.H.; Song, N.; Wang, C.Z. Characteristics of shale and gas content of Niutitang Formation in Changde region of Hunan Province. Nat. Gas Geosci. 2015, 26, 301–311. [Google Scholar]

- Wang, Y.; Zhu, Y.M.; Chen, S.B. Formation conditions of shale gas in Lower Cambrian Niutitang Formation, northwestern Hunan. J. China Univ. Min. Technol. 2013, 42, 586–594. [Google Scholar]

- Jiang, W.; Tang, S.H.; Gong, Y.H. The Reservoir Characteristics and Favorable Areas of Shale Gas in Northwestern Hunan Lower Cambrian Niutitang. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2014, 36, 16–24. [Google Scholar]

- Xiao, Z.H.; Yang, R.F.; Feng, T. Reservoir-forming conditions and exploration potential of shale gas in Lower Cambrian Niutitang Formation, Northwestern Hunan. J. Hunan Univ. Sci. Technol. (Nat. Sci. Ed.) 2012, 27, 50–53. [Google Scholar]

- Wu, J.J.; Zhang, S.H.; Cao, H. Fracability evaluation of shale gas reservoir—A case study in the Lower Cambrian Niutitang Formation, northwestern Hunan, China. J. Pet. Sci. Eng. 2018, 164, 675–684. [Google Scholar] [CrossRef]

- Wan, Y.; Tang, S.H.; Pan, Z.J. Evaluation of the shale gas potential of the lower Silurian Longmaxi Formation in northwest Hunan Province, China. Mar. Pet. Geol. 2017, 79, 159–175. [Google Scholar] [CrossRef]

- Hou, B.; Chen, M.; Li, Z.M. Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs. Pet. Explor. Dev. 2014, 41, 763–768. [Google Scholar] [CrossRef]

- Jin, X.C.; Shah, S.N.; Roegiers, J.C. An Integrated Petrophysics and Geomechanics Approach for Fracability Evaluation in Shale Reservoirs. SPE J. 2015, 20, 518–526. [Google Scholar] [CrossRef]

- Jin, X.C. An integrated geomechanics and petrophysics study of hydraulic fracturing in naturally fractured reservoirs. Ph.D. Thesis, The University of Oklahoma, Norman, Oklahoma, 2014. [Google Scholar]

- Perez, A.R. Brittleness estimation from seismic measurements in unconventional reservoirs: Application to the Barnett shale. SEG Tech. Progr. Expand. 2013, 2258–2262. [Google Scholar] [CrossRef]

- Feng, A.F.; Zhang, Y.J. Application of image J software for image processing and fabric porosity analyzing. Knitt. Ind. 2015, 1, 9–11. [Google Scholar]

- Enderlin, M.B.; Alsleben, H.; Breyer, J.A. Predicting fracability in shale reservoirs. In Proceedings of the AAPG Hedberg Conference, Napa, CA, USA, 14–18 March 2011; pp. 1–4. [Google Scholar]

- Rickman, R.; Mullen, M.J.; Petre, J.E. A Practical Use of Shale Petrophysics for Stimulation Design Optimization: All Shale Plays Are Not Clones of the Barnett Shale. In Proceedings of the SPE Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Pu, B.L.; Jiang, Y.L.; Wang, Y. Reservoir-forming conditions and favorable exploration zones of shale gas in Lower Silurian Longmaxi Formation of Sichuan Basin. Acta Pet. Sin. 2010, 31, 225–230. [Google Scholar]

- Wang, G.K.; Jiao, P. Accumulation Condition of Niutitang Formation of Lower Cambrian Shale Gas Resource in Northwestern Hunan Region. Energy and Energy Conserv. 2013, 1, 35–51. [Google Scholar]

- Yan, J.P.; Yan, Y.; Sima, L.Q. Relationship between fracture characteristics and “five-property” of shale reservoir. Lithol. Reserv. 2015, 27, 87–93. [Google Scholar]

- Han, X.X.; Jiang, X.M.; Wang, D.Z. Effect of combustion process on pore structure of oil shale ash. J. Chem. Ind. Eng. (China) 2007, 58, 1296–1300. [Google Scholar]

- Gao, Z.Y.; Yang, S.; Jiang, Z.X. Investigating the spontaneous imbibition characteristics of continental Jurassic Ziliujing Formation shale from the northeastern Sichuan Basin and correlations to pore structure and composition. Mar. Pet. Geol. 2018, 98, 697–705. [Google Scholar] [CrossRef]

- Liu, C.L.; Dong, Y.X.; Che, P. Pyrite Formation and Its Controls in Black Shales of the Buxin Formation (Lower Eocene) from the Sanshui Basin, Guangdong. Acta Sedimentol. Sin. 2006, 24, 75–80. [Google Scholar]

- Hickey, J.J.; Bo, H. Lithofacies summary of the Mississippian Barnett Shale, Mitchell 2 T.P. Sims well, Wise County, Texas. AAPG Bull. 2007, 91, 437–443. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. Sediment geochemistry of the Lower Jurassic Gordondale Member, northeastern British Columbia. Bull. Can. Pet. Geol. 2006, 54, 337–365. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, J.C.; Tang, X. Main controlling factors on shale adsorption capacity of the Lower Silurian Longmaxi Formation in western Hunan-Hubei area. Oil Gas Geol. 2016, 37, 23–29. [Google Scholar]

- Chalmers, G.R.L.; Bustin, R.M. The organic matter distribution and methane capacity of the Lower Cretaceous strata of Northeastern British Columbia, Canada. Int. J. Coal Geol. 2007, 70, 223–239. [Google Scholar] [CrossRef]

- Zhao, J.B.; Tang, S.H.; Zhang, S.H. Analysis on Characteristics and Influence Factors of Shale Pore in Niutitang Formation of Northwestern Hunan. Coal Sci. Technol. 2014, S1, 261–265. [Google Scholar]

- Li, Y.W.; Zuo, L.H.; Yu, W. A Fully Three Dimensional Semianalytical Model for Shale Gas Reservoirs with Hydraulic Fractures. Energies 2018, 11, 436. [Google Scholar] [CrossRef]

- Javadpour, F.; Fisher, D.; Unsworth, M. Nanoscale Gas Flow in Shale Gas Sediments. J. Can. Pet. Technol. 2007, 46, 55–61. [Google Scholar] [CrossRef]

- Liu, H.L.; Wang, Y.M.; Liu, X.N. Nanopore characteristics of Longmaxi Formation and forming mechanism of bubble to pore in marine shale of Sichuan Basin. Nat. Gas Ind. 2017, 37, 11–16. [Google Scholar]

- Liang, L.X.; He, S.P.; Zhang, A.D. Test of shale type I fracture toughness by CCNBD specimen. West-China Explor. Eng. 2016, 11, 41–43. (In Chinese) [Google Scholar]

- Liu, J.; Wang, J.G.; Leung, C.F. A Multi-Parameter Optimization Model for the Evaluation of Shale Gas Recovery Enhancement. Energies 2018, 11, 654. [Google Scholar] [CrossRef]

- Chen, J.G.; Deng, J.G.; Yuan, J.L. Determination of fracture toughness of modes I and II of shale formation. Chin. J. Rock Mech. Eng. 2015, 6, 1101–1105. [Google Scholar]

- Zou, C.N.; Dong, D.Z.; Wang, S.J. Geological characteristics, formation mechanism and resource potential of shale gas in China. Pet. Explor. Dev. 2010, 37, 641–653. [Google Scholar] [CrossRef]

- Kahraman, S.; Altindag, R. A brittleness index to estimate fracture toughness. Int. J. Rock Mech. Min. Sci. 2004, 41, 343–348. [Google Scholar] [CrossRef]

- Ding, W.L.; Li, C.; Li, C.Y. Dominant factor of fracture development in shale and its relationship to gas accumulation. Earth Sci. Front. 2012, 19, 212–220. [Google Scholar]

- Tang, Y.; Xing, Y.; Li, L.Z. Influence factors and evolution methods of the gas shale fracability. Earth Sci. Front. 2012, 19, 356–363. [Google Scholar]

- Ma, C.F.; Elsworth, D.; Dong, C.M. Controls of hydrocarbon generation on the development of expulsion fractures in organic-rich shale: Based on the Paleogene Shahejie Formation in the Jiyang Depression, Bohai Bay Basin, East China. Mar. Pet. Geol. 2017, 86, 1406–1414. [Google Scholar] [CrossRef]

| Location (Coordinates) | Samples Number | Quartz (%) | Feldspar (%) | Pyrite (%) | Calcite (%) | Mica (‰) | Anatase (%) | Clay Mineral (%) | Amorphous (%) |

|---|---|---|---|---|---|---|---|---|---|

| Longshan (109.401417, 29.43082) | 1# | 35 | 13 | 12 | 5 | 0 | 0 | 35 | 0 |

| Yongshun (109.892638, 28.994641) | 2# | 47 | 14 | 13 | 2 | 2 | 0 | 12 | 10 |

| Baojing (109.700429, 28.712333) | 3# | 36 | 9 | 27 | 4 | 13 | 0 | 11 | 0 |

| Huayuan (109.467028 28.556155) | 4# | 23 | 18 | 8 | 5 | 6 | 3 | 29 | 8 |

| Zhangjiajie (110.555208, 29.075137) | 5# | 56 | 13 | 16 | 0 | 8 | 0 | 7 | 0 |

| Changde (111.686879, 29.192547) | 6# | 25 | 16 | 0 | 0 | 13 | 5 | 12 | 29 |

| 7# | 28 | 15 | 0 | 3 | 7 | 0 | 26 | 21 | |

| 8# | 19 | 15 | 0 | 2 | 8 | 0 | 36 | 20 | |

| 9# | 36 | 16 | 11 | 0 | 2 | 2 | 15 | 18 | |

| 10# | 27 | 5 | 18 | 0 | 13 | 2 | 15 | 20 | |

| 11# | 42 | 16 | 13 | 0 | 2 | 0 | 12 | 15 |

| Sample Number | Sapropelite and Vitrinite (%) | Exinite (%) | Inertinite (%) | Type Index | δ13C (‰) | Organic Matter Type |

|---|---|---|---|---|---|---|

| 3# | 92.0 | 8.0 | 0 | 86.0 | −32.92 | Ⅰ |

| 5# | 96.6 | 0.7 | 2.7 | 93.2 | −32.28 | Ⅰ |

| 9# | 95.3 | 4.3 | 0.3 | 91.8 | −30.57 | Ⅰ |

| Sample Number | Uniaxial Compressive Strength (MPa) | Young’s Modulus (GPa) | Poisson’s Ratio | Tensile Strength (MPa) |

|---|---|---|---|---|

| 1# | 40 | 27.54 | 0.20 | 6.3 |

| 2# | 44 | 30.28 | 0.17 | 13.7 |

| 3# | 37 | 25.43 | 0.21 | 7.4 |

| 4# | 36 | 27.11 | 0.24 | 5.6 |

| 5# | 65 | 31.36 | 0.20 | 14.1 |

| 6# | 8 | 1.37 | 0.23 | 2.1 |

| 7# | 6 | 1.25 | 0.24 | 1.9 |

| 8# | 17 | 3.86 | 0.19 | 4.3 |

| 9# | 25 | 14.15 | 0.29 | 6.2 |

| 10# | 30 | 21.33 | 0.16 | 8.9 |

| 11# | 42 | 25.60 | 0.15 | 12.5 |

| Index | Burial Depth(m) | Thickness (m) | TOC (%) | RO (%) | Total Gas Content (m3/t) | Porosity (%) |

|---|---|---|---|---|---|---|

| Locality | 100–4000 * | ≥30 * | ≥1.2 * | ≥1.75 * | ≥1 * | ≥ 2 * |

| Antrim | 200–800 | 20 | 0.3–24.0 | 0.4–0.6 | 1.5–3.7 | 9 |

| Ohio | 670–1670 | 100–330 | 0–4.7 | 0.4–1.3 | 2.2–3.7 | 4.7 |

| New Albany | 200–1630 | 33–133 | 1.0–25.0 | 0.4–1.0 | 1.5–3.0 | 10–14 |

| Barnett | 1980–2590 | 76 | 4.5 | 1.0–2.1 | 11.1–13.0 | 4–5 |

| Lewis | 914–1829 | 152–579 | 0.5–2.5 | 1.6–1.9 | 0.6–1.8 | 3–5.5 |

| Longmaxi (northwestern Hunan) | 0–3300 | 50–150 | 0.12–3.86 | 1.0–4.3 | 2.34 | 1.7 |

| Niutitang (northwestern Hunan) | 0–1300 | 70–110 | 2.6–4.1 | 2.7–3.5 | 0.5–2.1 | 3.2–7.5 |

| Area | Clay% | Quartz% | Feldspar% | Poisson Ratio | Young’s Modulus (GPa) | Average Brittleness Index |

|---|---|---|---|---|---|---|

| Siliceous shale (Barnett) | 27 | 35-50 | 7 | 0.2~0.3 | 33.0 | 0.67 |

| Siliceous shale (9#–11#) | 12–26 | 28–42 | 15–16 | 0.15~0.29 | 14.15–25.60 | 0.63 |

| Carbonaceous shale (6#–8#) | 12–36 | 19–27 | 5–16 | 0.19–0.24 | 1.25–3.86 | 0.29 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, H.; Wang, T.; Bao, T.; Sun, P.; Zhang, Z.; Wu, J. Effective Exploitation Potential of Shale Gas from Lower Cambrian Niutitang Formation, Northwestern Hunan, China. Energies 2018, 11, 3373. https://doi.org/10.3390/en11123373

Cao H, Wang T, Bao T, Sun P, Zhang Z, Wu J. Effective Exploitation Potential of Shale Gas from Lower Cambrian Niutitang Formation, Northwestern Hunan, China. Energies. 2018; 11(12):3373. https://doi.org/10.3390/en11123373

Chicago/Turabian StyleCao, Han, Tianyi Wang, Ting Bao, Pinghe Sun, Zheng Zhang, and Jingjing Wu. 2018. "Effective Exploitation Potential of Shale Gas from Lower Cambrian Niutitang Formation, Northwestern Hunan, China" Energies 11, no. 12: 3373. https://doi.org/10.3390/en11123373