Investigation on Selective Laser Melting AlSi10Mg Cellular Lattice Strut: Molten Pool Morphology, Surface Roughness and Dimensional Accuracy

Abstract

:1. Introduction

2. Experimentals

2.1. Materials and SLM Process

2.2. Characterizations

3. Results and Discussion

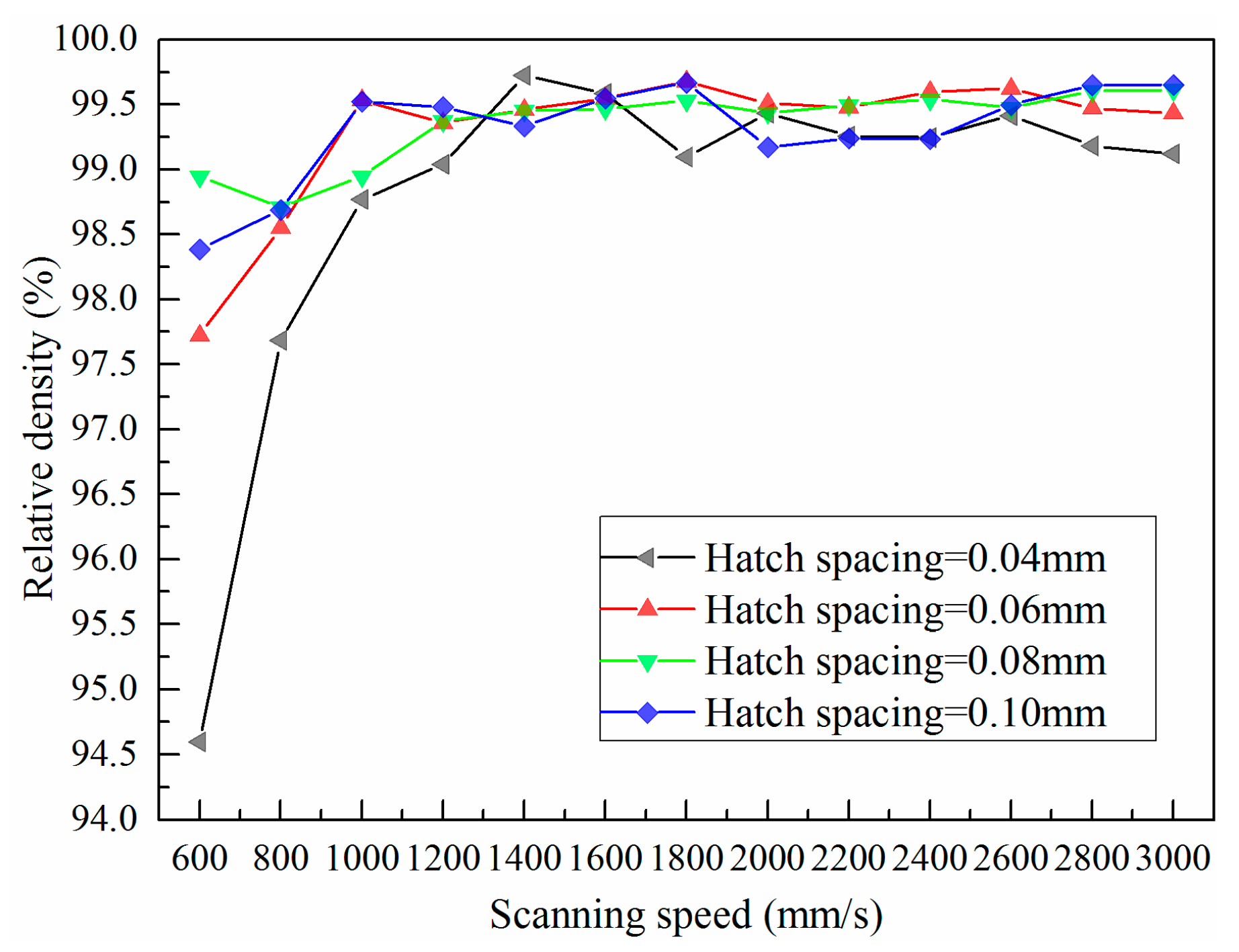

3.1. Density

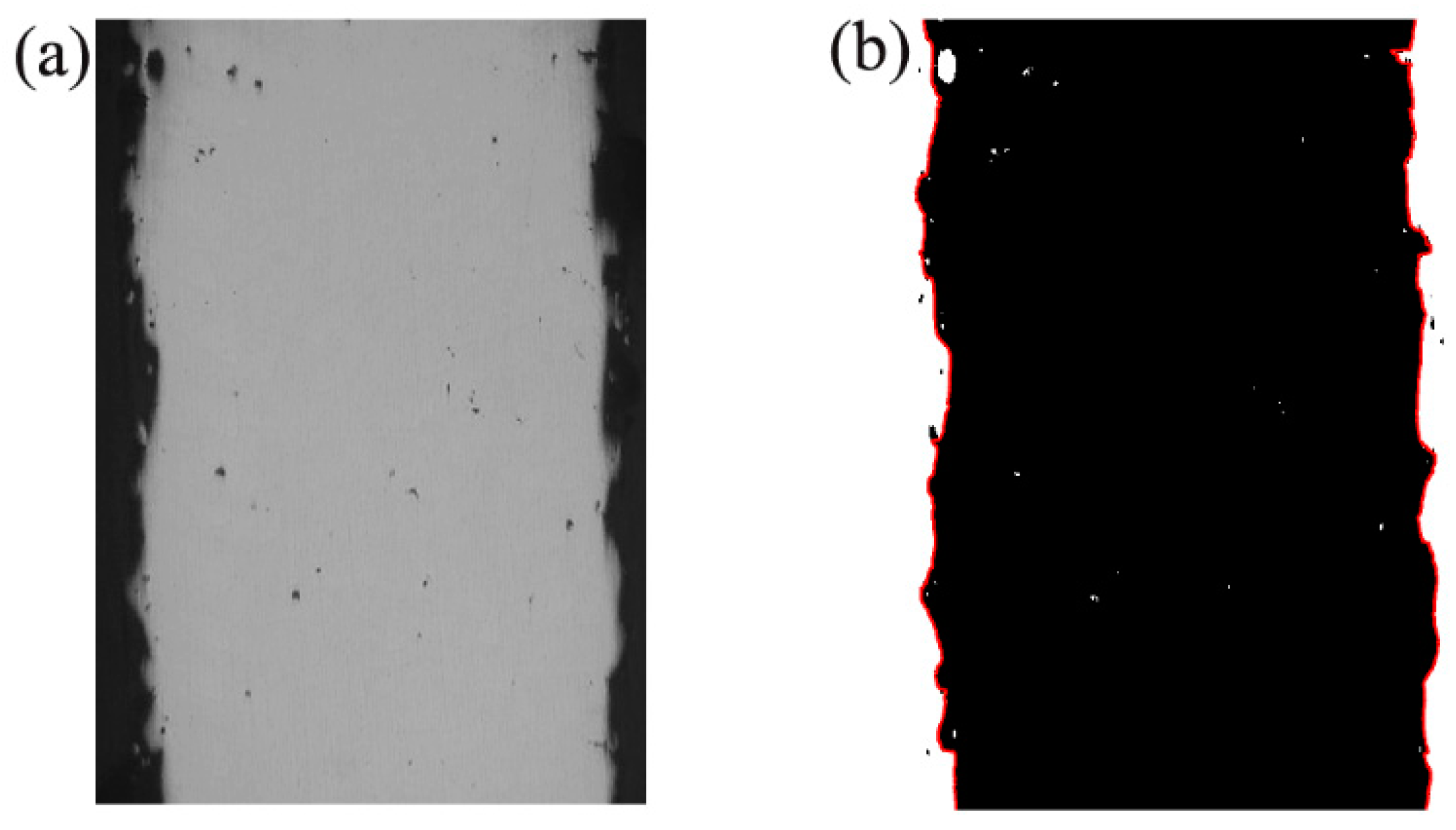

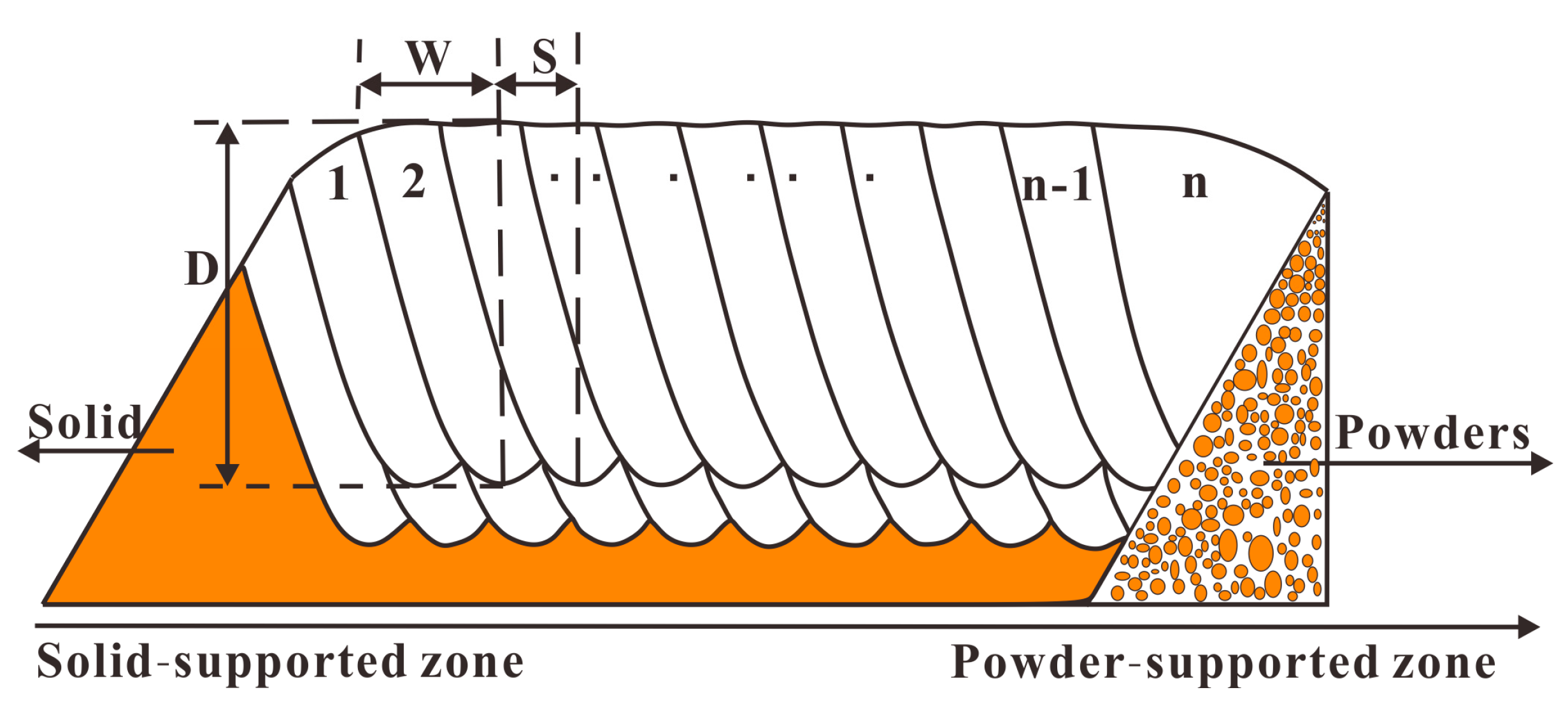

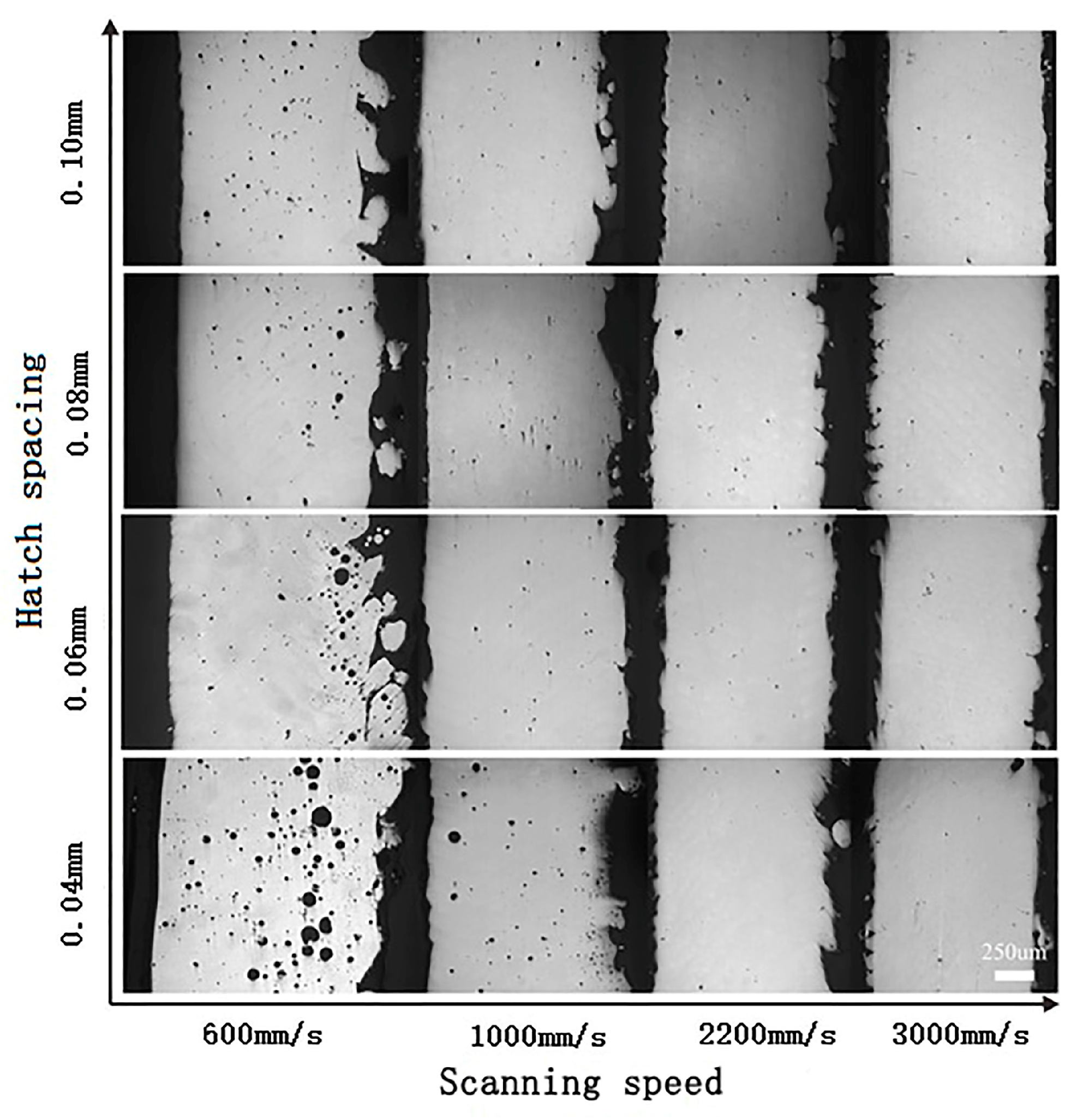

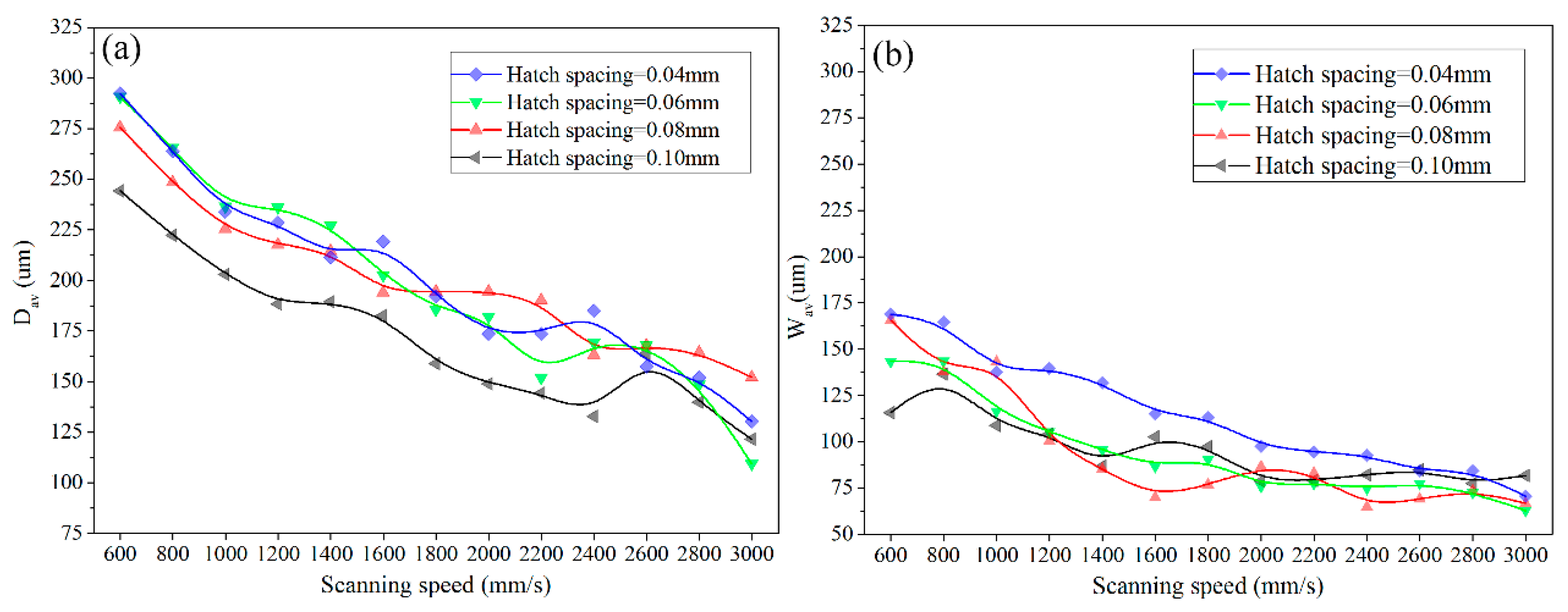

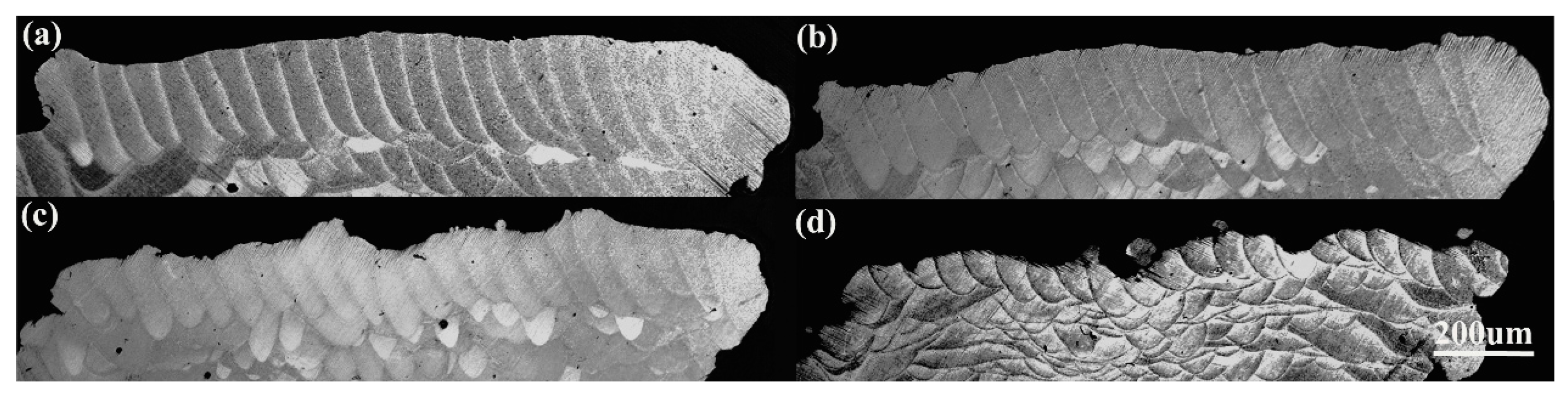

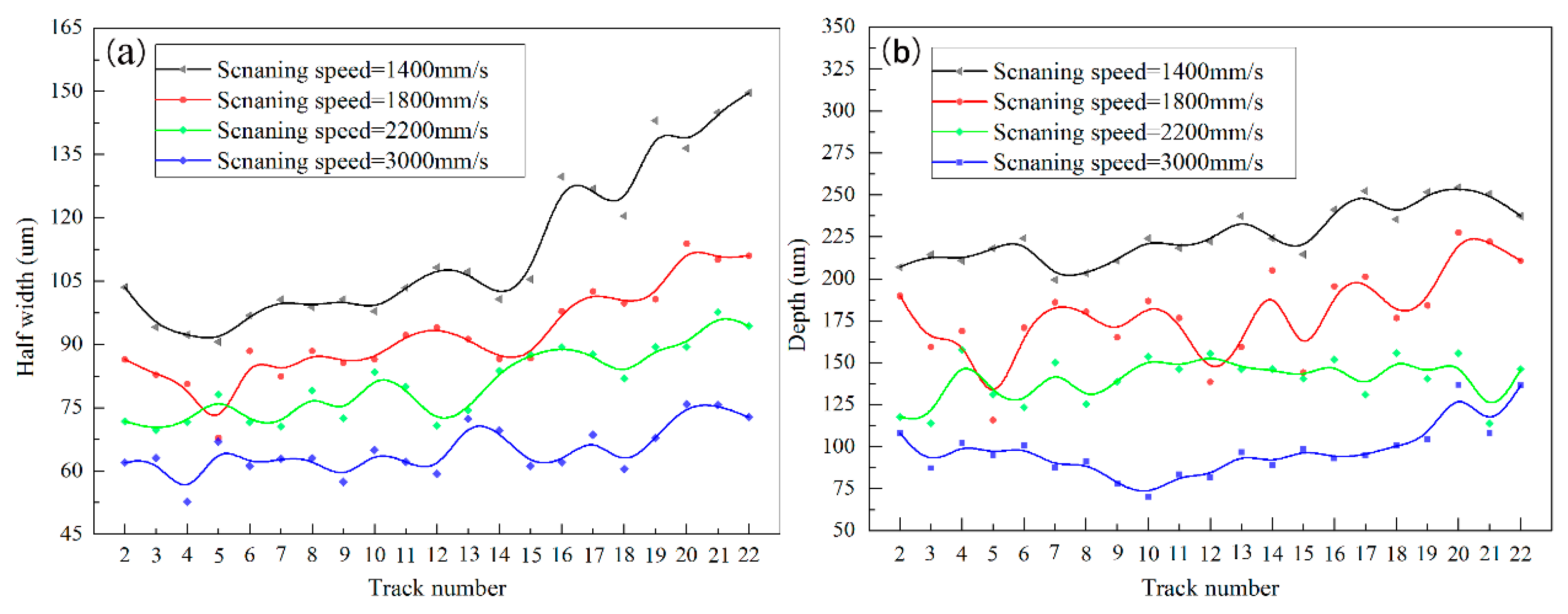

3.2. Molten Pool Morphology

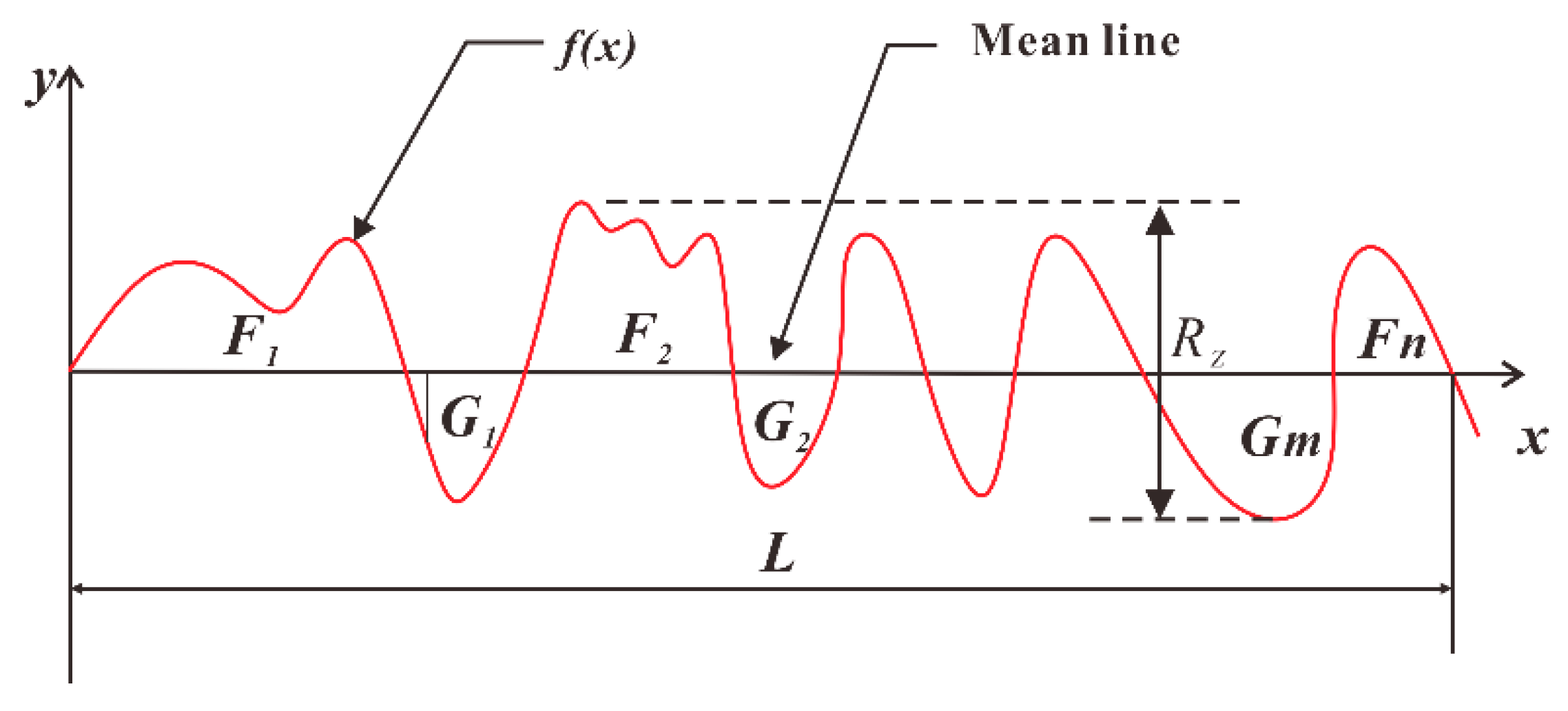

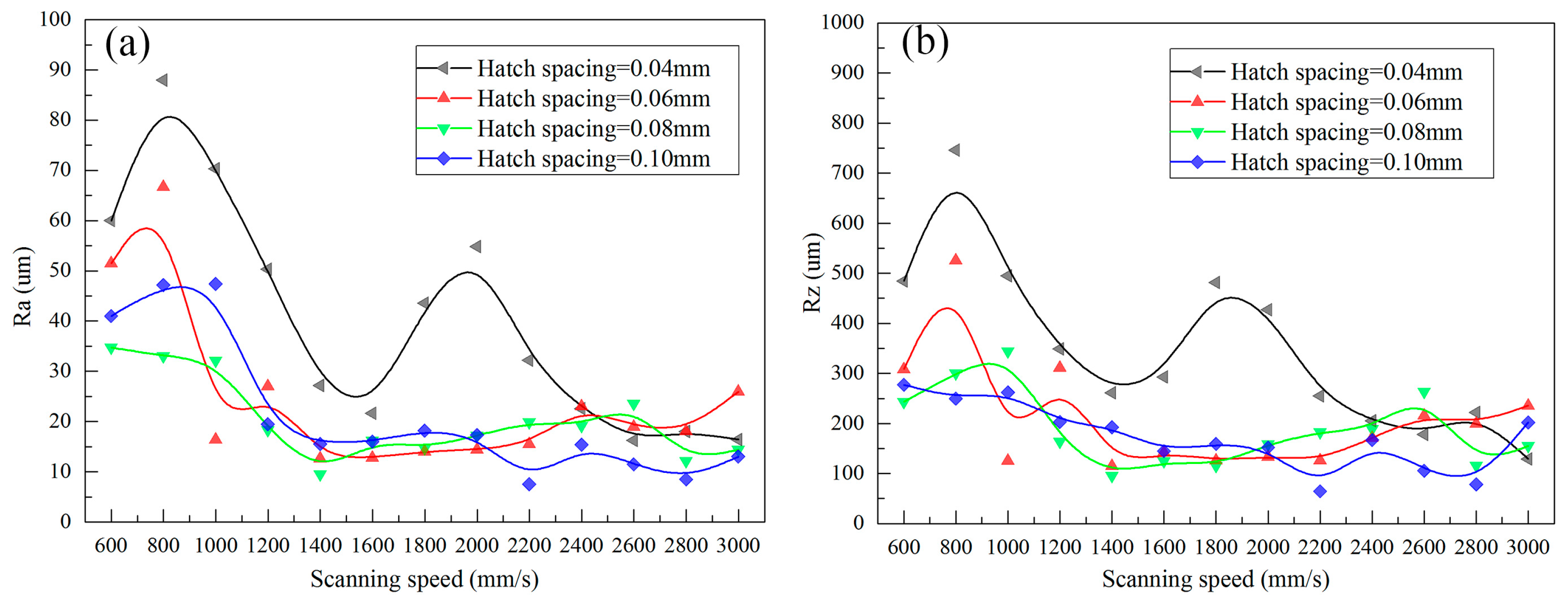

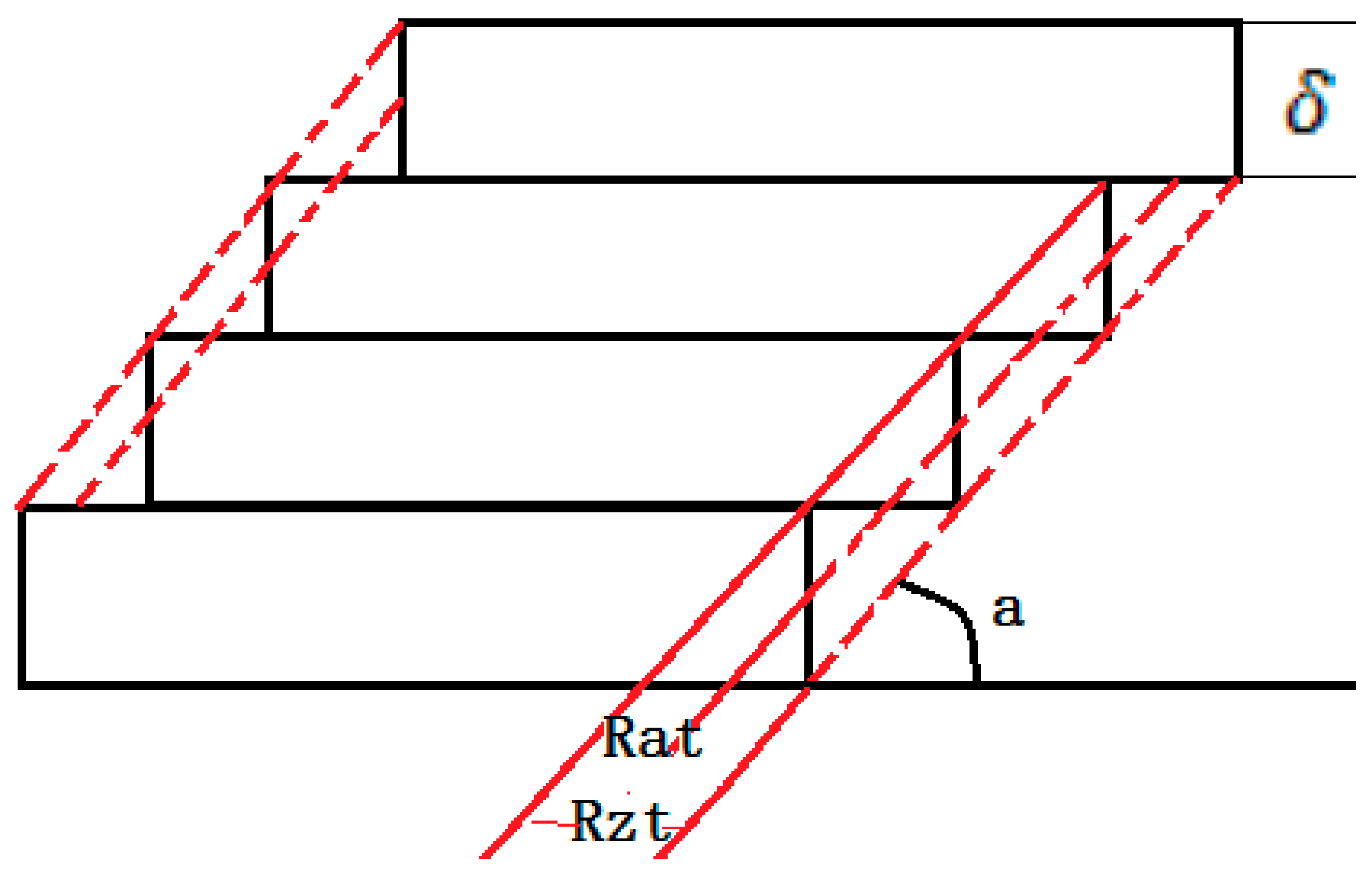

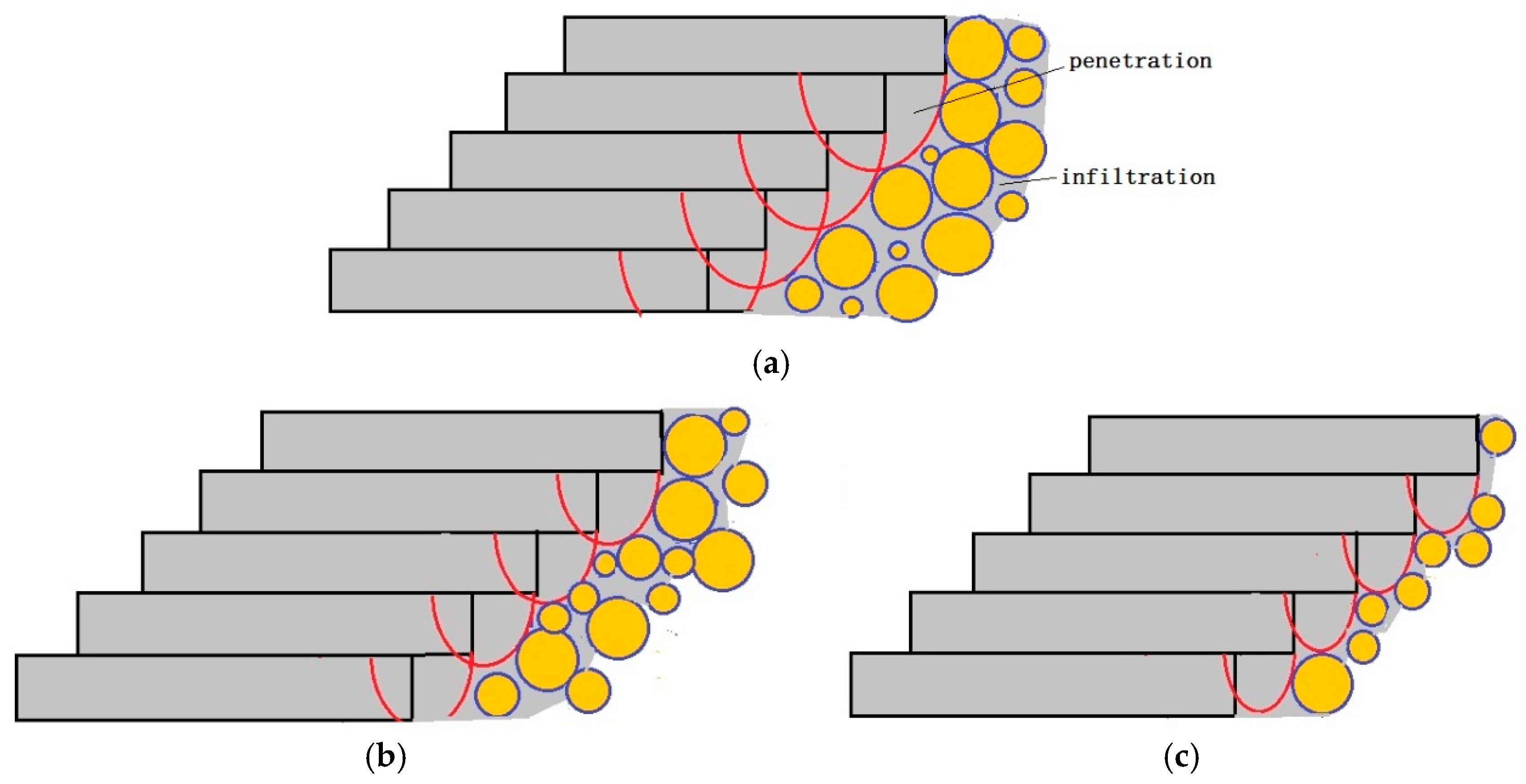

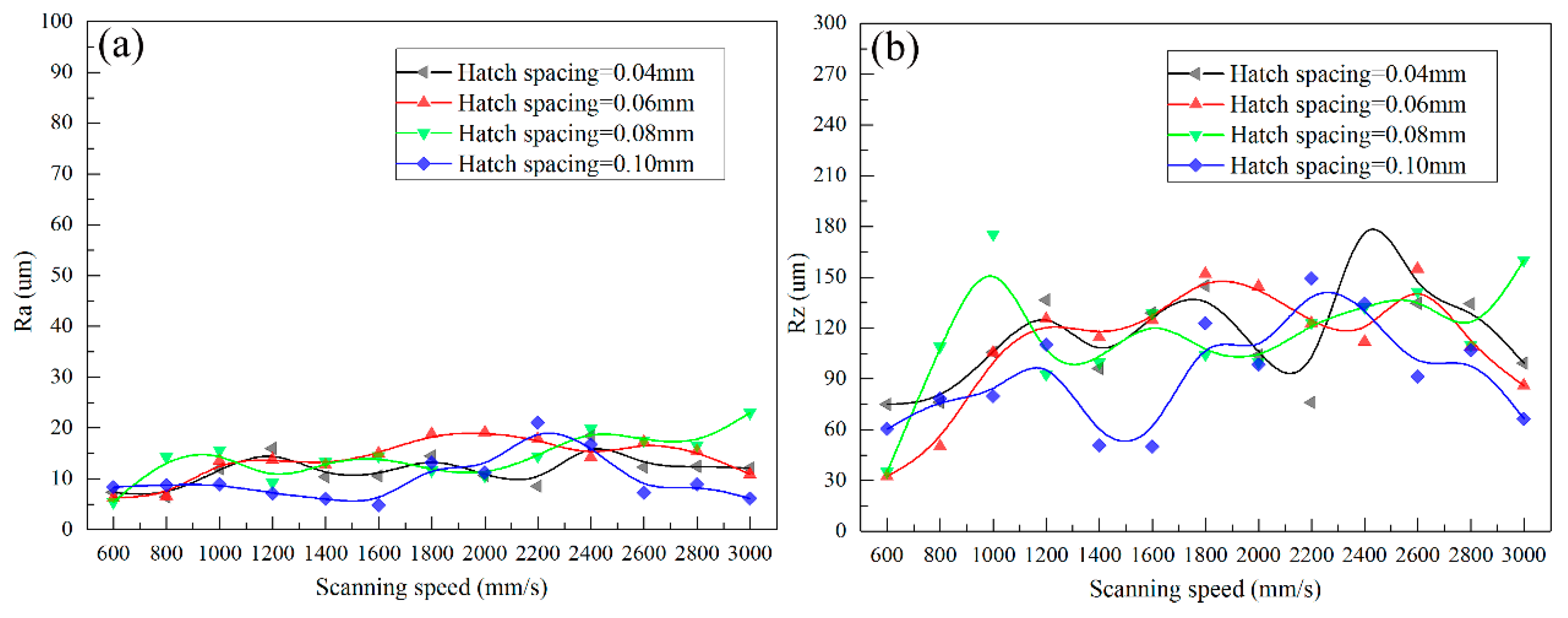

3.3. Surface Roughness

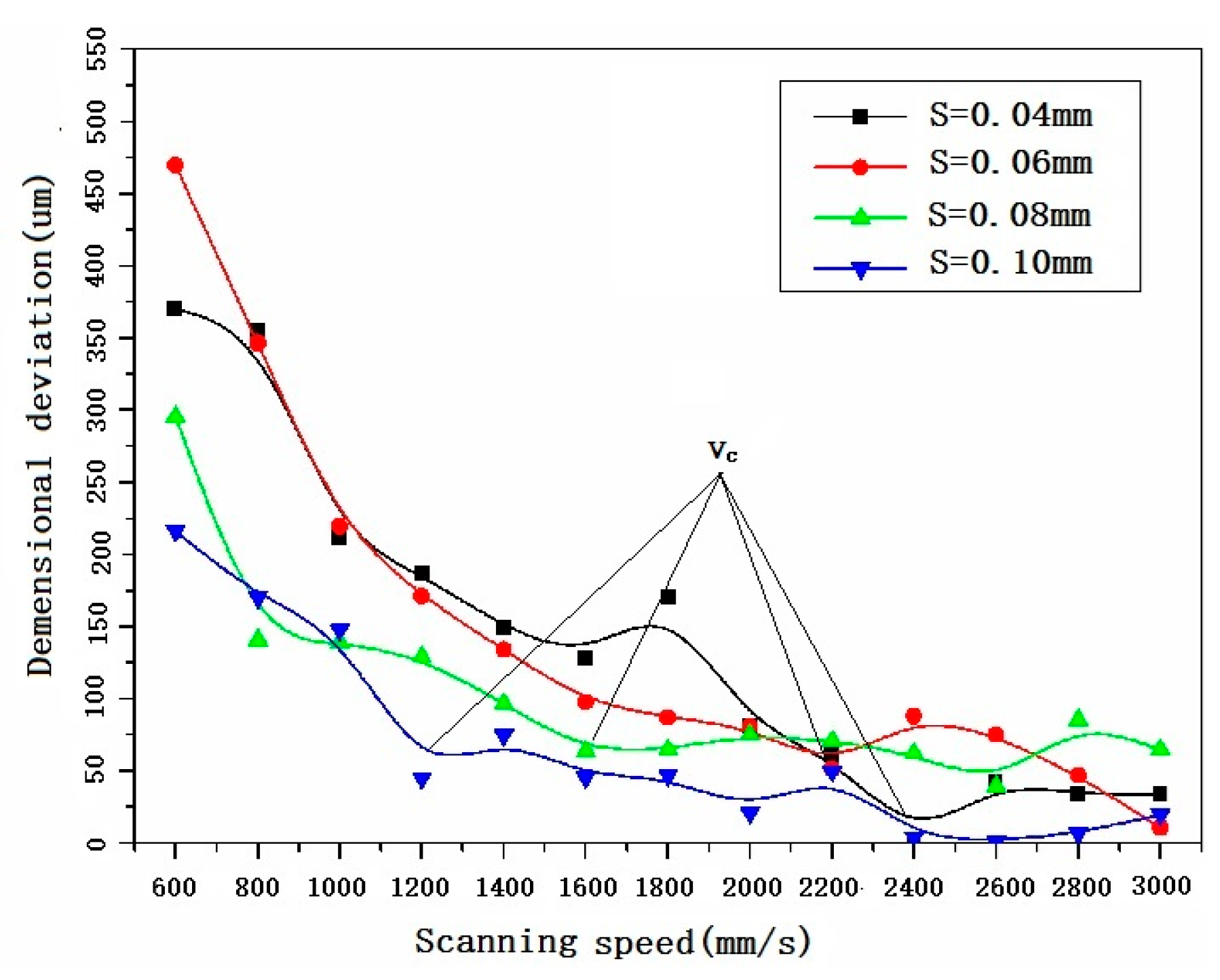

3.4. Dimensional Accuracy

4. Conclusions

- (1)

- Both the average depth and half width of molten pool decrease as the scanning speed increases. But, the dependence of the half width becomes weak when the scanning speed is high enough.

- (2)

- Bigger molten pool is formed and the half width changed greatly than that of the depth when laser irradiates from solid-supported zone to powder-supported zone.

- (3)

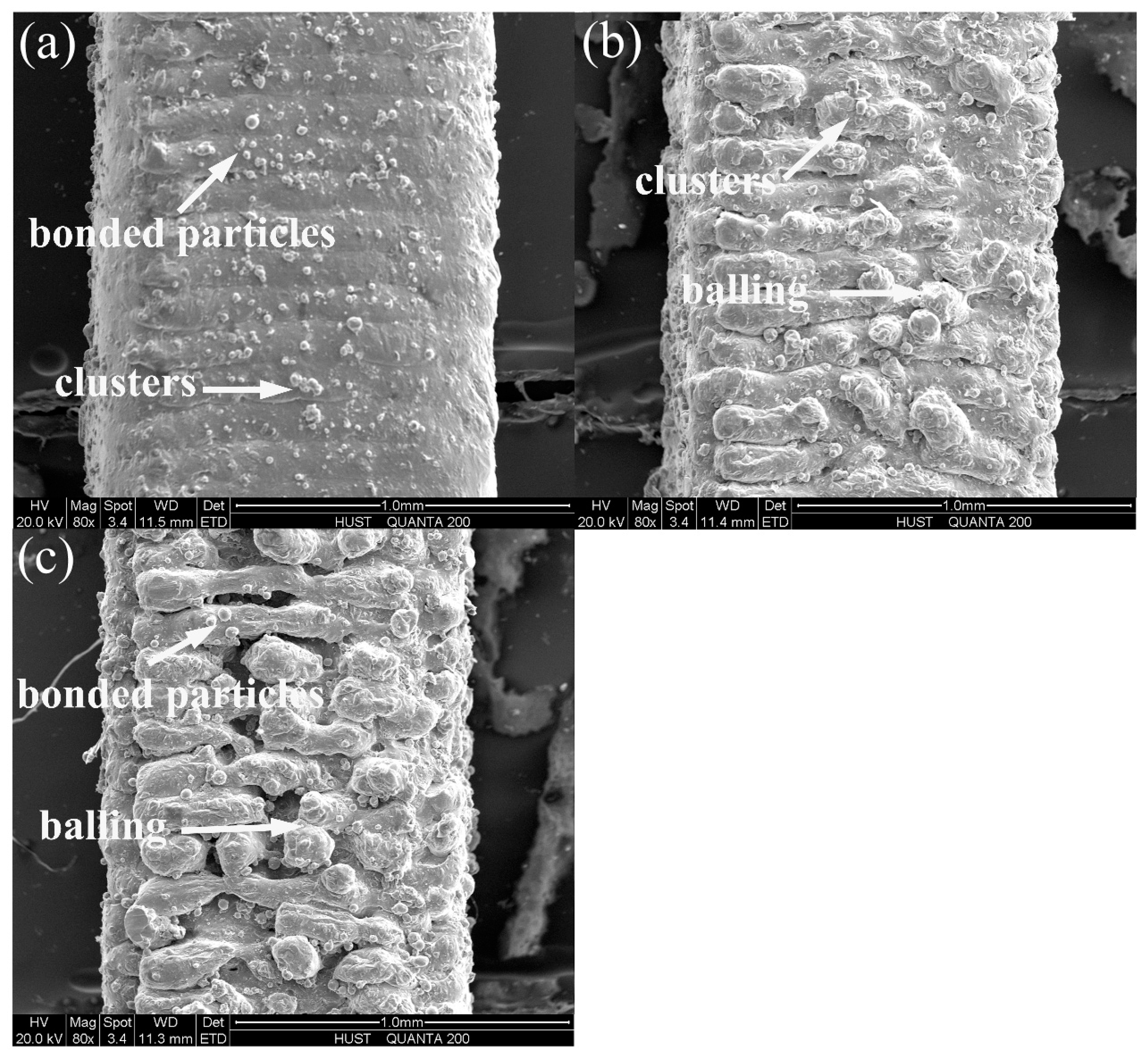

- The lower surface quality is deteriorated under low scanning speed due to infiltration effect. The upper surface roughness has small fluctuation under different hatch spacing and scanning speed due to the bonded particles and balling on stair step. The surface roughness of lower is larger than that of upper.

- (4)

- Dimensional accuracy has strong correlation with lower surface quality and width of molten pool. The dimensional accuracy can be improved by applying high scanning speed when the inclined strut was fabricated.

- (5)

- SLMed AlSi10Mg inclined strut with low surface roughness and high dimensional accuracy as well as high density can be achieved simultaneously by using high scanning speed.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Attar, H.; Löber, L.; Funk, A.; Calin, M.; Zhang, L.C.; Prashanth, K.G.; Scudino, S.; Zhang, Y.S.; Eckert, J. Mechanical behavior of porous commercially pure Ti and Ti–TiB composite materials manufactured by selective laser melting. Mater. Sci. Eng. A 2015, 625, 350–356. [Google Scholar] [CrossRef]

- Schwab, H.; Prashanth, K.; Löber, L.; Kühn, U.; Eckert, J. Selective laser melting of Ti-45Nb alloy. Metals 2015, 5, 686–694. [Google Scholar] [CrossRef]

- Fang, M.; Chen, B. Fabrication of high porosity Cu-based structure using direct laser sintering. Rapid Prototyp. J. 2016, 22, 207–214. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zhang, H.; Yin, J.; Ke, L.; Zeng, X. Selective laser melting of Al7050 powder: Melting mode transition and comparison of the characteristics between the keyhole and conduction mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 2017, 126, 25–35. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Brenne, F.; Niendorf, T.; Maier, H.J. Additively manufactured cellular structures: Impact of microstructure and local strains on the monotonic and cyclic behavior under uniaxial and bending load. J. Mater. Process. Technol. 2013, 213, 1558–1564. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Delroisse, P.; Jacques, P.J.; Maire, E.; Rigo, O.; Simar, A. Effect of strut orientation on the microstructure heterogeneities in AlSi10Mg lattices processed by selective laser melting. Scr. Mater. 2017, 141, 32–35. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, X.; Wei, L. Parameters and surface performance of laser removal of rust layer on A3 steel. Surf. Coat. Technol. 2003, 116, 10–16. [Google Scholar] [CrossRef]

- Yang, J.; Han, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti-6Al-4V alloy. Mater. Des. 2016, 110, 558–570. [Google Scholar] [CrossRef]

- Pérez, C.L.; Calvet, J.V.; Pérez, M.S. Geometric roughness analysis in solid free-form manufacturing processes. J. Mater. Process. Technol. 2001, 119, 52–57. [Google Scholar] [CrossRef]

- Prashanth, K.; Löber, L.; Klauss, H.-J.; Kühn, U.; Eckert, J. Characterization of 316L steel cellular dodecahedron structures produced by selective laser melting. Technologies 2016, 4, 34. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Van Bael, S.; Kerckhofs, G.; Moesen, M.; Pyka, G.; Schrooten, J.; Kruth, J.P. Micro-ct-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures. Mater. Sci. Eng. A 2011, 528, 7423–7431. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (slm) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Qiu, C.; Yue, S.; Adkins, N.J.E.; Ward, M.; Hassanin, H.; Lee, P.D.; Withers, P.J.; Attallah, M.M. Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater. Sci. Eng. A 2015, 628, 188–197. [Google Scholar] [CrossRef]

- Mahshid, R.; Hansen, H.N.; Højbjerre, K.L. Strength analysis and modeling of cellular lattice structures manufactured using selective laser melting for tooling applications. Mater. Des. 2016, 104, 276–283. [Google Scholar] [CrossRef] [Green Version]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Zhu, H.; Nie, X.; Yin, J.; Hu, Z.; Zeng, X. Effect of zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy. Scr. Mater. 2017, 134, 6–10. [Google Scholar] [CrossRef]

- Hu, Z.; Zhu, H.; Zhang, H.; Zeng, X. Experimental investigation on selective laser melting of 17-4ph stainless steel. Opt. Laser Technol. 2017, 87, 17–25. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Bäuerle, D.W. Laser Processing and Chemistry; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Kruth, J.P.; Merceils, P.; Van Vaerenbergh, J. Feedback control of selective laser melting. In Proceedings of the 3rd International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 24–29 September 2007. [Google Scholar]

- Bacchewar, P.B.; Singhal, S.K.; Pandey, P.M. Statistical modelling and optimization of surface roughness in the selective laser sintering process. J. Eng. Manuf. 2007, 221. [Google Scholar] [CrossRef]

| Element | Al | Si | Mg | Fe | Ti | Ni | Cu | Zn | Pb | Sn | Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt % | Balance | 10.04 | 0.47 | 1.42 | 0.018 | 0.043 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Processing Parameters | Value |

|---|---|

| Laser power | 200 |

| Scanning speed | 600–3000 |

| Layer thickness | 20 |

| Hatch spacing | 0.04−0.10 |

| Magnification | um/Pixel (x Axis) | um/Pixel (y Axis) |

|---|---|---|

| 1.92926 | 1.92926 | |

| 0.4761905 | 0.4746836 |

| Pearson’s Correlation | of Upper Surface | of Lower Surface | ||

|---|---|---|---|---|

| −0.03063976 | 0.7003351 | 0.7395423 | 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Zhu, H.; Nie, X.; Wang, G.; Zeng, X. Investigation on Selective Laser Melting AlSi10Mg Cellular Lattice Strut: Molten Pool Morphology, Surface Roughness and Dimensional Accuracy. Materials 2018, 11, 392. https://doi.org/10.3390/ma11030392

Han X, Zhu H, Nie X, Wang G, Zeng X. Investigation on Selective Laser Melting AlSi10Mg Cellular Lattice Strut: Molten Pool Morphology, Surface Roughness and Dimensional Accuracy. Materials. 2018; 11(3):392. https://doi.org/10.3390/ma11030392

Chicago/Turabian StyleHan, Xuesong, Haihong Zhu, Xiaojia Nie, Guoqing Wang, and Xiaoyan Zeng. 2018. "Investigation on Selective Laser Melting AlSi10Mg Cellular Lattice Strut: Molten Pool Morphology, Surface Roughness and Dimensional Accuracy" Materials 11, no. 3: 392. https://doi.org/10.3390/ma11030392