Phase Transition of Single-Layer Molybdenum Disulfide Nanosheets under Mechanical Loading Based on Molecular Dynamics Simulations

Abstract

:1. Introduction

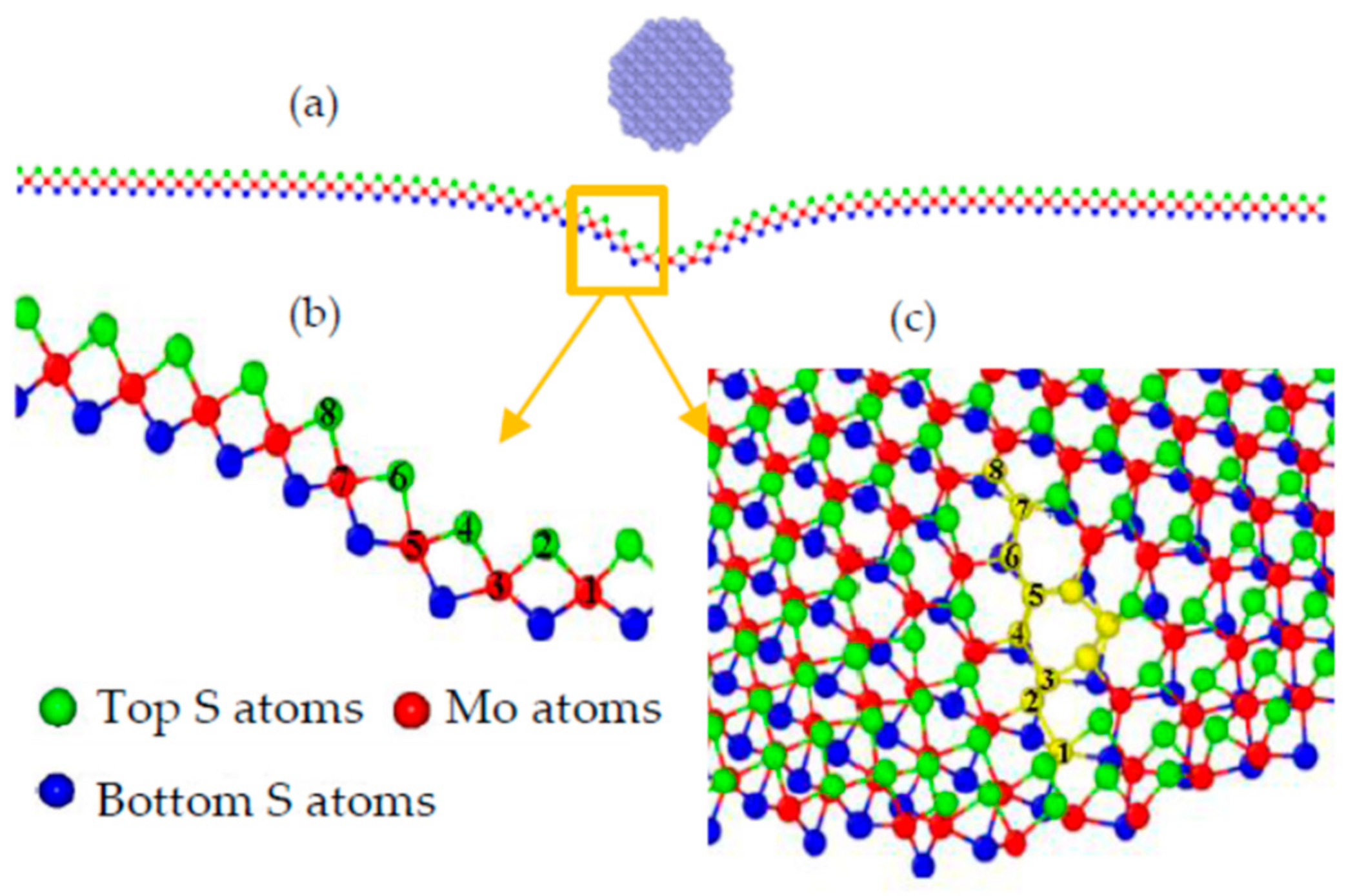

2. Theoretical Models and Methods

3. Results and Discussions

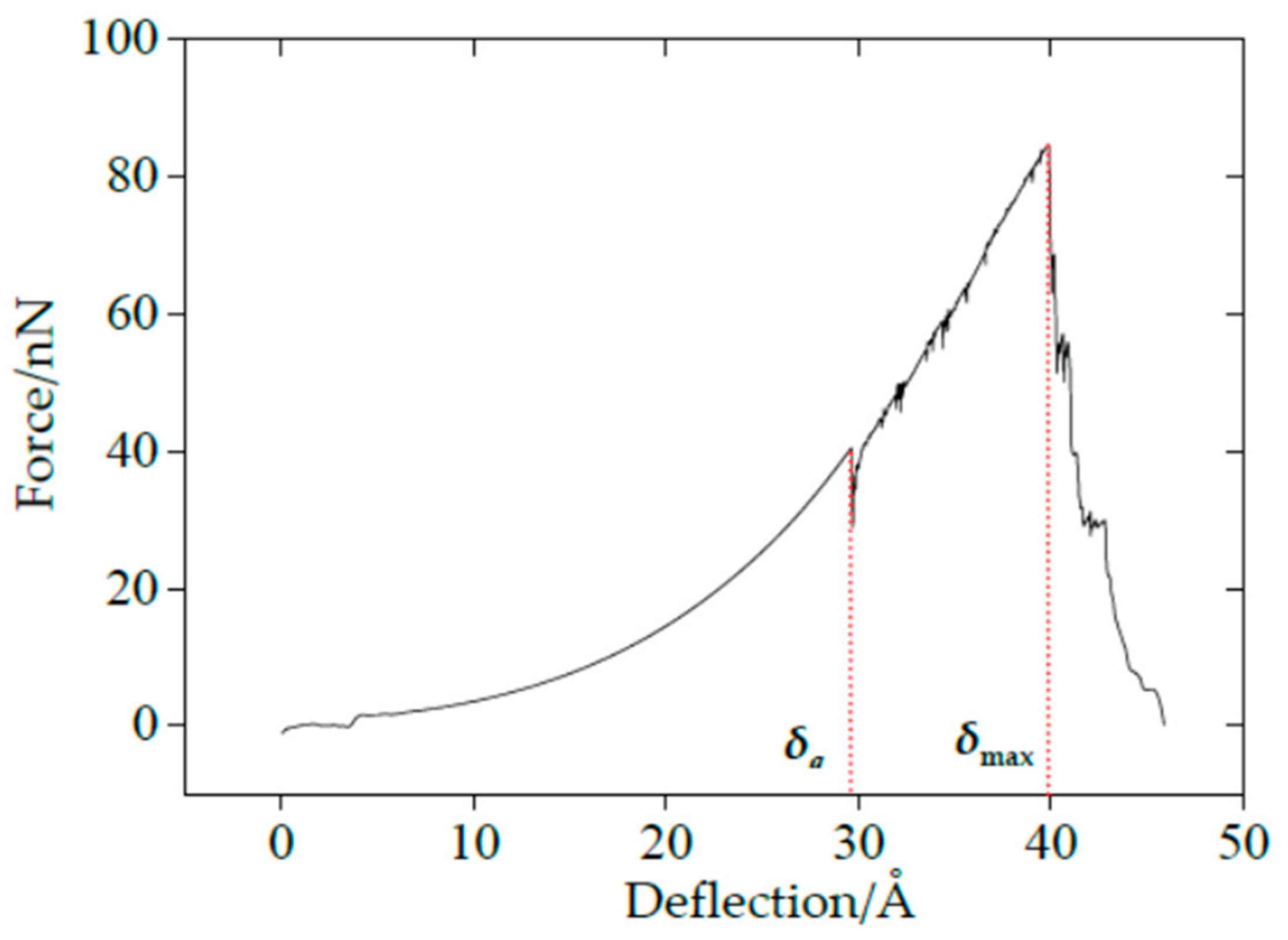

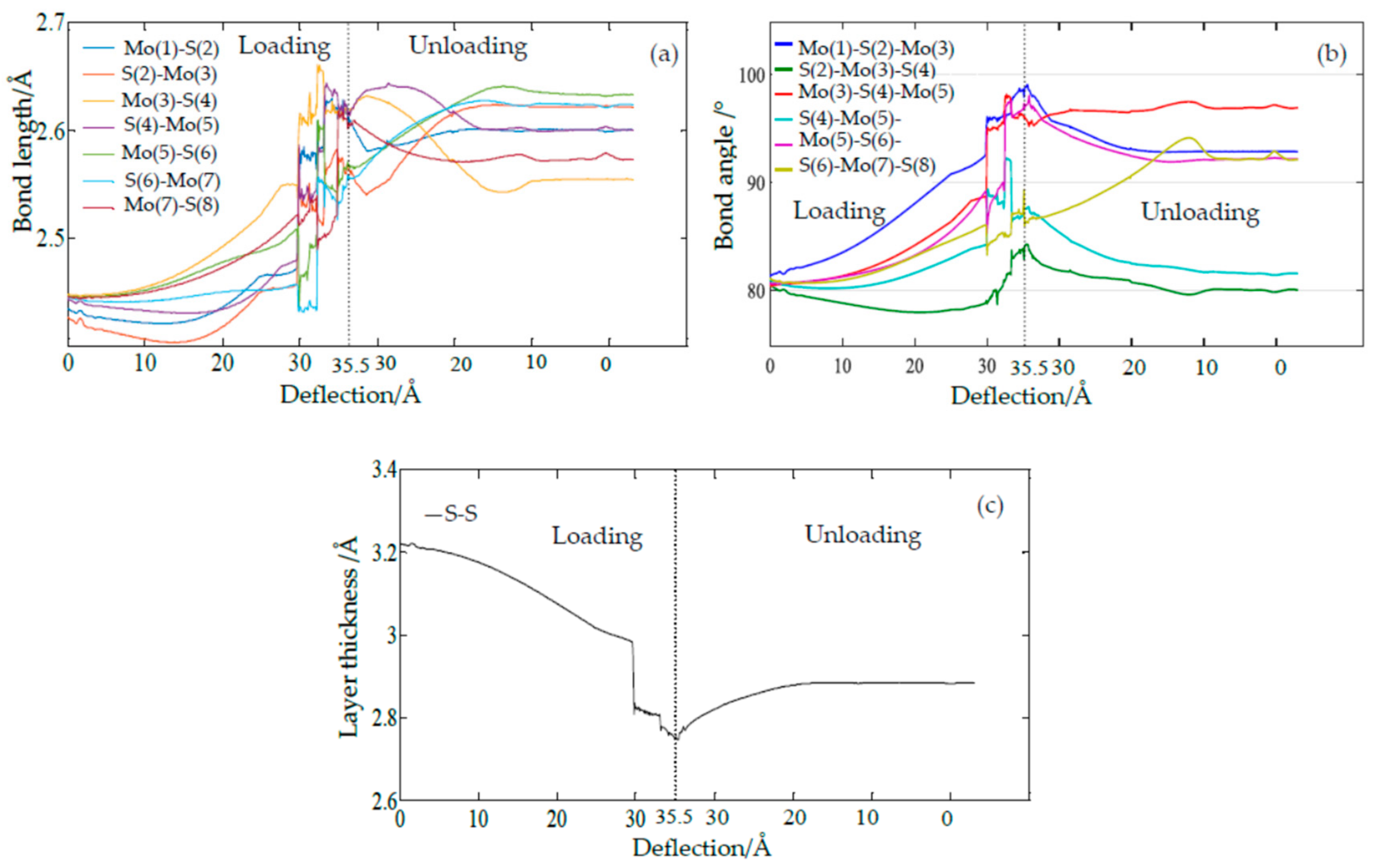

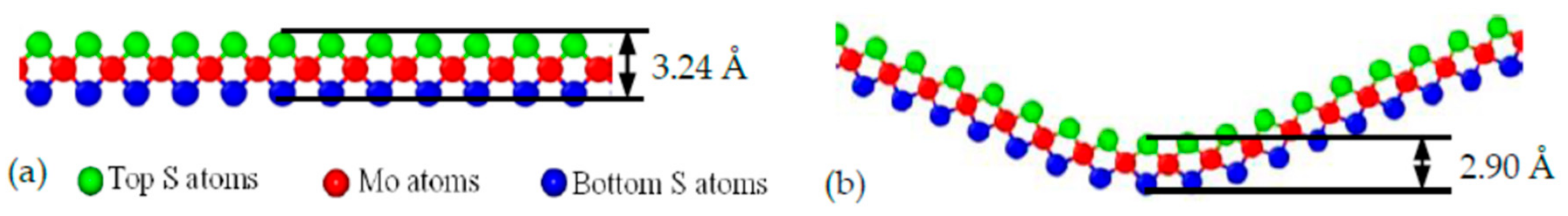

3.1. Nanoindentation of SLMoS2 Nanosheets

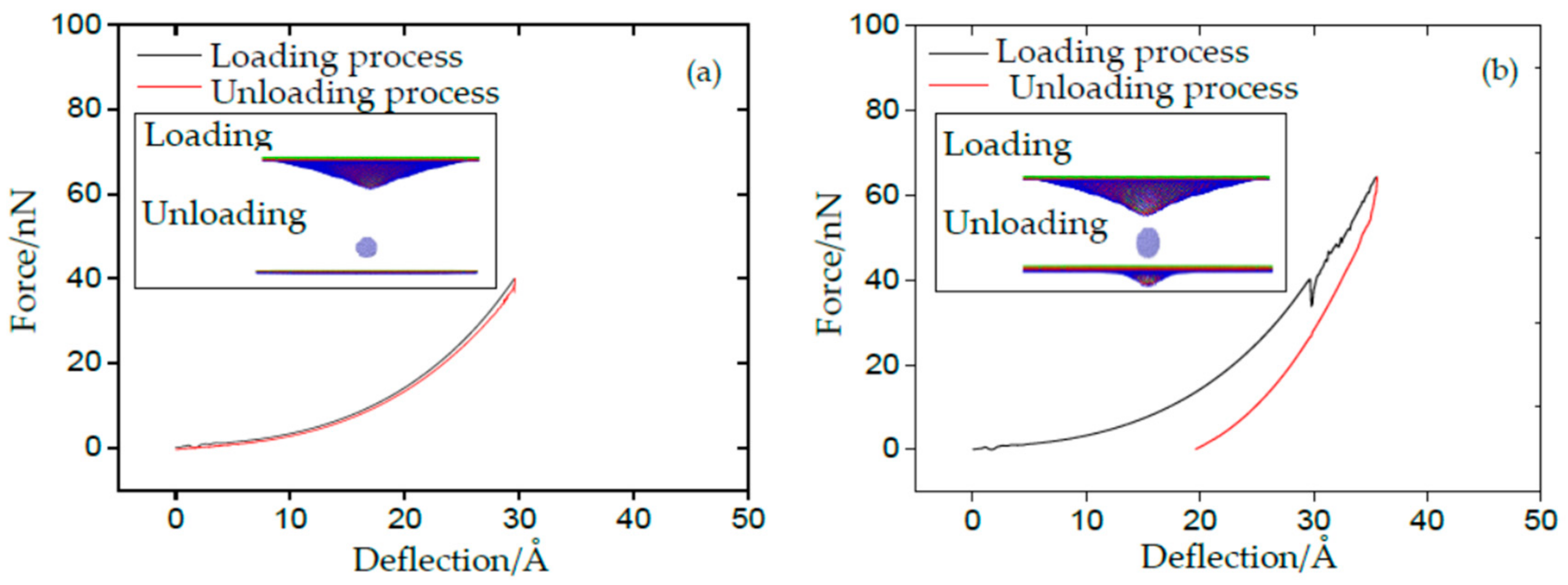

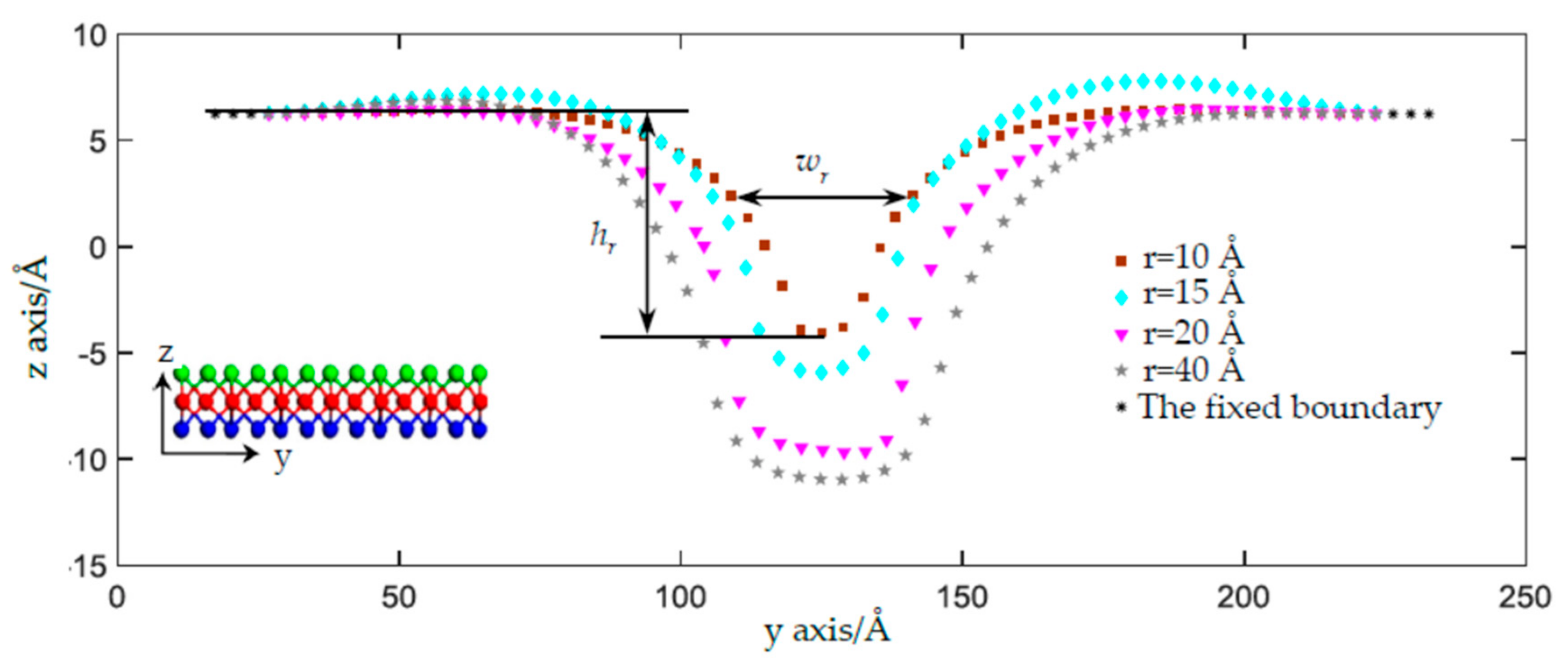

3.2. Effect of Indenter Size on the Plastic Deformation

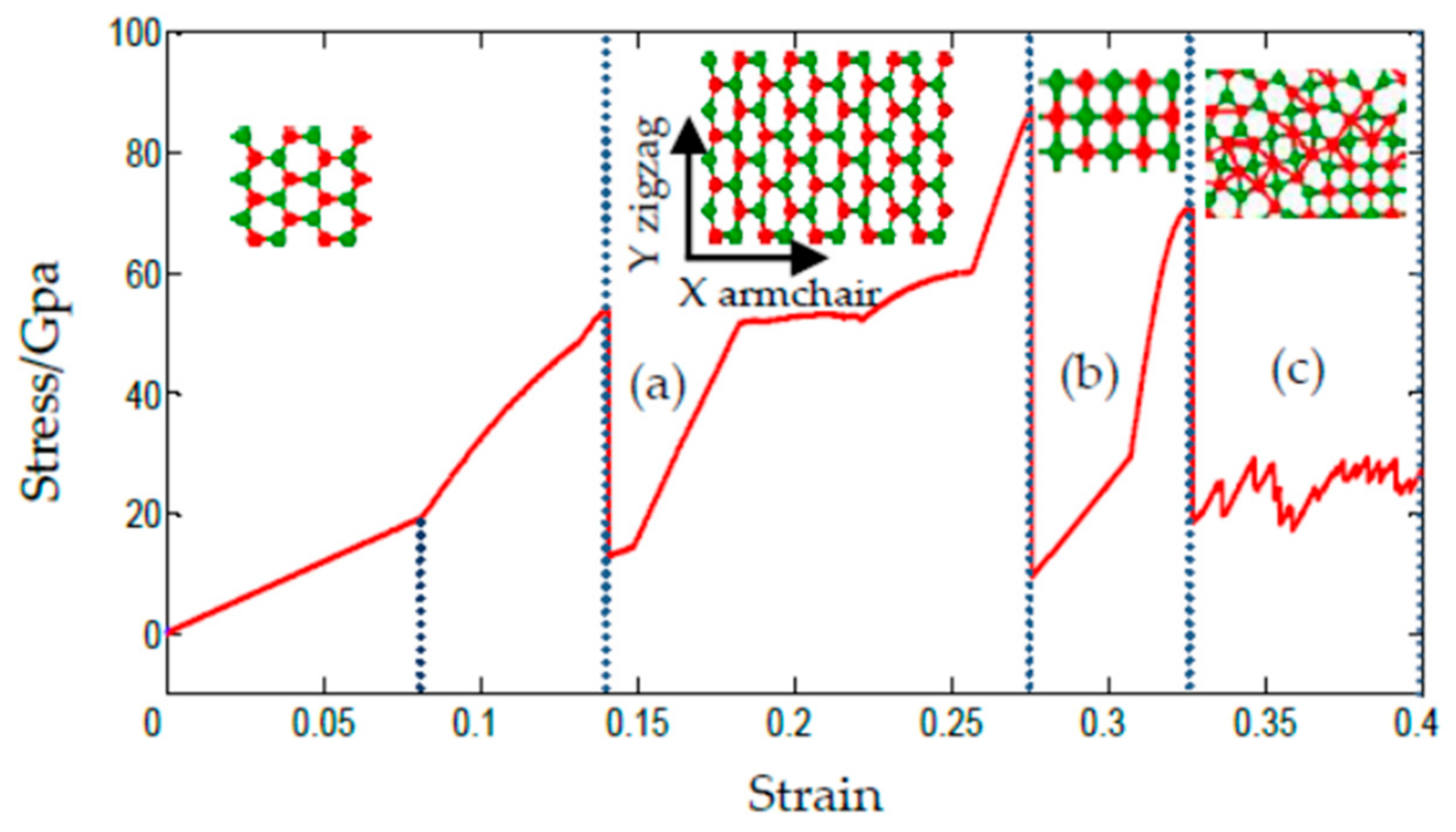

3.3. Uniaxial Compression of SLMoS2 Nanosheets

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Yang, K.; Tan, C.; Huang, X.; Huang, W.; Zhang, H. Preparation and applications of novel composites composed of metal-organic frameworks and two-dimensional materials. Chem. Commun. 2015, 52, 1555–1562. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.-W.; Xie, D.; Xu, J.-L.; Sun, Y.; Li, X.; Zhang, C.; Dai, R.-X.; Zhao, Y.-F.; Li, X.; Li, X.; et al. MoS2 field-effect transistors with lead zirconate-titanate ferroelectric gating. IEEE Electron Device Lett. 2015, 36, 784–786. [Google Scholar] [CrossRef]

- Pang, Y.; Xue, F.; Wang, L.; Chen, J.; Luo, J.; Jiang, T.; Zhang, C.; Wang, Z.-L. Tribotronic enhanced photoresponsivity of a MoS2 phototransistor. Adv. Sci. 2016, 3, 1500419. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.A.; Kim, S.J.; Song, W.; Chang, S.J.; Park, C.Y.; Myung, S.; Lim, J.; Lee, S.S.; An, K.S. Fabrication of flexible optoelectronic devices based on MoS2/graphene hybrid patterns by a soft lithographic patterning method. Carbon 2017, 116, 167–173. [Google Scholar] [CrossRef]

- Zhou, R.; Wang, J.G.; Liu, H.Z.; Liu, H.Y.; Jin, D.D.; Liu, X.R.; Shen, C.; Xie, K.; Wei, B.Q. Coaxial MoS2@carbon hybrid fibers: A low-cost anode material for high-performance Li-ion batteries. Materials 2017, 10, 174. [Google Scholar] [CrossRef] [PubMed]

- Brumme, T.; Calandra, M.; Mauri, F. First-principles theory of field-effect doping in transition-metal dichalcogenides: Structural properties, electronic structure, hall coefficient, and electrical conductivity. Phys. Rev. B 2015, 91, 123–128. [Google Scholar] [CrossRef]

- Chhowalla, M.; Shin, H.S.; Eda, G.; Li, L.-J.; Loh, K.P.; Zhang, H. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 2013, 5, 263–275. [Google Scholar] [CrossRef] [PubMed]

- Gordon, R.A.; Yang, D.; Crozier, E.D.; Jiang, D.T.; Frindt, R.F. Structures of exfoliated single layers of WS2, MoS2, and MoSe2 in aqueous suspension. Phys. Rev. B 2002, 65, 125407. [Google Scholar] [CrossRef]

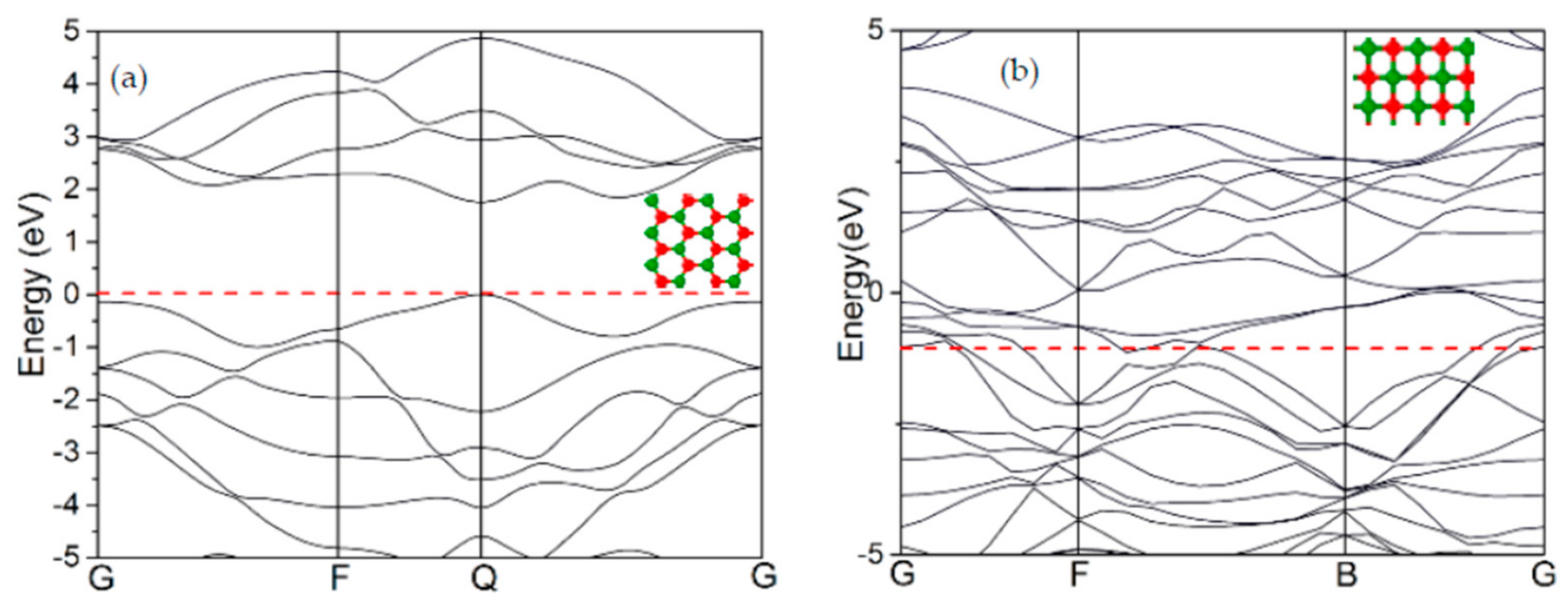

- Zhang, L.Y.; Fang, L.; Peng, X.Y. First-principles study on multiphase property and phase transition of monolayer MoS2. Acta Phys. Sin. 2016, 65, 229–236. [Google Scholar]

- Acerce, M.; Voiry, D.; Chhowalla, M. Metallic 1T phase MoS2 nanosheets as supercapacitor electrode materials. Nat. Nanotechnol. 2015, 10, 313–318. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.C.; Dumcenco, D.O.; Huang, Y.S.; Suenaga, K. Atomic mechanism of the semiconducting-to-metallic phase transition in single-layered MoS2. Nat. Nanotechnol. 2014, 9, 391–396. [Google Scholar] [CrossRef] [PubMed]

- Voiry, D.; Goswami, A.; Kappera, R.; Kaplan, D.; Fujita, T.; Chen, M.; Asefa, T.; Chhowalla, M. Covalent functionalization of monolayered transition metal dichalcogenides by phase engineering. Nat. Chem. 2014, 7, 45–49. [Google Scholar] [CrossRef] [PubMed]

- Kappera, R.; Voiry, D.; Yalcin, S.E.; Branch, B.; Gupta, G.; Mohite, A.; Chhowalla, M. Phase-engineered low-resistance contacts for ultrathin MoS2 transistors. Nat. Mater. 2014, 13, 1128–1134. [Google Scholar] [CrossRef] [PubMed]

- Eda, G.; Yamaguchi, H.; Viory, D.; Fujita, T.; Chen, M.; Chhowalla, M. Photoluminescence from chemically exfoliated MoS2. Nano Lett. 2011, 11, 5111–5116. [Google Scholar] [CrossRef] [PubMed]

- Gao, P.; Wang, L.; Zhang, Y.; Huang, Y.; Liu, K. Atomic-scale probing the dynamics of sodium transport and intercalation induced phase transformations in MoS2. ACS Nano 2015, 9, 11296–11301. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Zhou, H.; Zhang, G.; Zhang, Y.W. Modulating carrier density and transport properties of MoS2 by organic molecular doping and defect engineering. Chem. Mater. 2016, 28, 8611–8621. [Google Scholar] [CrossRef]

- Madauß, L.; Ochedowski, O.; Lebius, H.; Ban-d’Etat, B.; Naylor, C.H.; Johnson, A.T.C.; Kotakoski, J.; Schleberger, M. Defect engineering of single- and few-layer MoS2 by swift heavy ion irradiation. 2D Mater. 2017, 4, 015034. [Google Scholar] [CrossRef]

- Sachs, B.; Britnell, L.; Wehling, T.O.; Eckmann, A.; Jalil, R.; Belle, B.D.; Lichtenstein, A.I.; Katsnelson, M.; Novoselov, K.S. Doping mechanisms in graphene-MoS2 hybrids. Appl. Phys. Lett. 2013, 103, 10451. [Google Scholar] [CrossRef]

- Xu, E.Z.; Liu, H.M.; Park, K.; Li, Z.; Losovyj, Y.; Starr, M.; Werbianskyj, M.; Fertig, H.A.; Zhang, S.X. p-Type transition-metal doping of large-area MoS2 thin films grown by chemical vapor deposition. Nanoscale 2017, 9, 3576–3584. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.D.; Li, L.; Yang, C.; Soler-Crespo, R.A.; Meng, Z.; Li, M.L.; Zhang, X.; Keten, S.; Horacio, D. Plasticity resulted from phase transformation for monolayer molybdenum disulfide film during nanoindentation simulations. Nanotechnology 2017, 28, 164005. [Google Scholar] [CrossRef] [PubMed]

- Dang, K.Q.; Simpson, J.P.; Spearot, D.E. Phase transformation in monolayer molybdenum disulphide (MoS2) under tension predicted by molecular dynamics simulations. Scr. Mater. 2014, 76, 41–44. [Google Scholar] [CrossRef]

- Li, M.L.; Wan, Y.L.; Hu, J.Y.; Wang, W.D. Molecular dynamics simulation of effects of temperature and chirality on the mechanical properties of single-layer molybdenum disulfide. Acta Phys. Sin. 2016, 65, 176201. [Google Scholar]

- Zhao, J.; Kou, L.; Jiang, J.W.; Rabczuk, T. Tension-induced phase transition of single-layer molybdenum disulphide (MoS2) at low temperatures. Nanotechnology 2014, 25, 295701. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.D.; Hao, Y.; Yi, C.; Ji, X.; Niu, X. Relaxation properties of graphene nanoribbons at different ambient temperatures: A molecular dynamics study. Acta Phys. Sin. 2012, 61, 2021–2036. [Google Scholar]

- Xiong, S.; Gao, G. Molecular dynamics simulations of mechanical properties of monolayer MoS2. Nanotechnology 2015, 26, 185705. [Google Scholar] [CrossRef] [PubMed]

- Li, M.L.; Wan, Y.L.; Tu, L.P.; Yang, Y.C.; Lou, J. The effect of VMoS3 point defect on the elastic properties of monolayer MoS2 with REBO potentials. Nanoscale Res. Lett. 2016, 11, 155. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.D.; Li, S.; Min, J.J.; Yi, C.L.; Zhan, Y.J.; Li, M.L. Nanoindentation experiments for single-layer rectangular graphene films: A molecular dynamics study. Nanoscale Res. Lett. 2014, 9, 41. [Google Scholar] [CrossRef] [PubMed]

- Kieffer, W.F. The theory of the properties of metals and alloys.; Elasticity, plasticity, and structure of matter. Nature 1958, 139, 348–349. [Google Scholar] [CrossRef]

- Zhang, H.T.; Tersoff, J.; Xu, S.; Chen, H.X.; Zhang, Q.B.; Zhang, K.L.; Yang, Y.; Lee, C.-S.; Tu, K.-N.; Li, J.; et al. Approaching the ideal elastic strain limit in silicon nanowires. Sci. Adv. 2016, 2, e1501382. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, H.; Li, M.; Gao, C.; Huang, H.; Zhuo, W.; Hu, J.; Wan, Y.; Luo, J.; Wang, W. Phase Transition of Single-Layer Molybdenum Disulfide Nanosheets under Mechanical Loading Based on Molecular Dynamics Simulations. Materials 2018, 11, 502. https://doi.org/10.3390/ma11040502

Pang H, Li M, Gao C, Huang H, Zhuo W, Hu J, Wan Y, Luo J, Wang W. Phase Transition of Single-Layer Molybdenum Disulfide Nanosheets under Mechanical Loading Based on Molecular Dynamics Simulations. Materials. 2018; 11(4):502. https://doi.org/10.3390/ma11040502

Chicago/Turabian StylePang, Haosheng, Minglin Li, Chenghui Gao, Haili Huang, Weirong Zhuo, Jianyue Hu, Yaling Wan, Jing Luo, and Weidong Wang. 2018. "Phase Transition of Single-Layer Molybdenum Disulfide Nanosheets under Mechanical Loading Based on Molecular Dynamics Simulations" Materials 11, no. 4: 502. https://doi.org/10.3390/ma11040502