The Addition of Poly(Vinyl Alcohol) Fibers to Apatitic Calcium Phosphate Cement Can Improve Its Toughness

Abstract

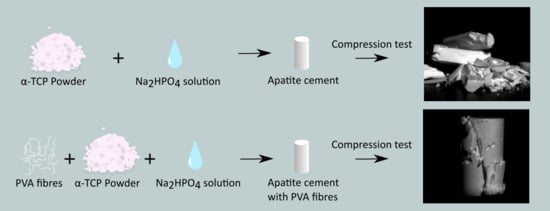

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cement Preparation

2.3. Setting Time Test

2.4. Mechanical Testing

2.5. Microstructural Analysis

2.6. Compositional Analysis

2.7. Statistical Analysis

3. Results

3.1. Mechanical Properties

3.2. Setting Time

3.3. Microstructure

3.4. Composition

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ginebra, M.-P.; Canal, C.; Español, M.; Pastorino, D.; Montufar, E.B. Calcium phosphate cements as drug delivery materials. Adv. Drug Deliv. Rev. 2012, 64, 1090–1110. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, W.; Schnitzler, V.; Tancret, F.; Bouler, J.-M. Calcium phosphate cements for bone substitution: Chemistry, handling and mechanical properties. Acta Biomater. 2014, 10, 1035–1049. [Google Scholar] [CrossRef] [PubMed]

- Dorozhkin, S.V. Calcium orthophosphate cements for biomedical application. J. Mater. Sci. 2008, 43(9), 3028–3057. [Google Scholar] [CrossRef]

- Hofmann, M.; Mohammed, A.-U.-R.; Perrie, Y.; Gbureck, U.; Barralet, J. High-strength resorbable brushite bone cement with controlled drug-releasing capabilities. Acta Biomater. 2009, 5, 43–49. [Google Scholar] [CrossRef] [PubMed]

- Friedman, C.D.; Costantino, P.D.; Takagi, S.; Chow, L.C. BoneSource™ hydroxyapatite cement: A novel biomaterial for craniofacial skeletal tissue engineering and reconstruction. J. Biomed. Mater. Res Part A 1998, 43(4), 428–432. [Google Scholar] [CrossRef]

- Canal, C.; Ginebra, M.-P. Fibre-reinforced calcium phosphate cements: A review. J. Mech. Behav. Biomed. Mater. 2011, 4, 1658–1671. [Google Scholar] [CrossRef]

- Krüger, R.; Groll, J. Fiber reinforced calcium phosphate cements – On the way to degradable load bearing bone substitutes? Biomaterials 2012, 33, 5887–5900. [Google Scholar] [CrossRef] [PubMed]

- Gallinetti, S.; Mestres, G.; Canal, C.; Persson, C.; Ginebra, M.-P. A novel strategy to enhance interfacial adhesion in fiber-reinforced calcium phosphate cement. J. Mech. Behav. Biomed. Mater. 2017, 75, 495–503. [Google Scholar] [CrossRef] [Green Version]

- Motisuke, M.; Santos, V.R.; Bazanini, N.C.; Bertran, C.A. Apatite bone cement reinforced with calcium silicate fibers. J. Mater. Sci. Mater. Med. 2014, 25, 2357–2363. [Google Scholar] [CrossRef]

- Xu, H.H.K.; Eichmiller, F.C.; Giuseppetti, A.A. Reinforcement of a self-setting calcium phosphate cement with different fibers. J. Biomed. Mater. Res. 2000, 52, 107–114. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, H.H. Effects of synergistic reinforcement and absorbable fiber strength on hydroxyapatite bone cement. J. Biomed. Mater. Res. Part A 2005, 75, 832–840. [Google Scholar] [CrossRef]

- Gorst, N.; Perrie, Y.; Gbureck, U.; Hutton, A.; Hofmann, M.; Grover, L.; Barralet, J. Effects of fibre reinforcement on the mechanical properties of brushite cement. Acta Biomater. 2006, 2, 95–102. [Google Scholar] [CrossRef]

- Burguera, E.F.; Xu, H.H.K.; Takagi, S.; Chow, L.C. High early strength calcium phosphate bone cement: Effects of dicalcium phosphate dihydrate and absorbable fibers. J. Biomed. Mater. Res. Part A 2005, 75, 966–975. [Google Scholar] [CrossRef]

- Ambard, A.J.; Mueninghoff, L. Calcium Phosphate Cement: Review of Mechanical and Biological Properties. J. Prosthodont. 2006, 15, 321–328. [Google Scholar] [CrossRef]

- Paradossi, G.; Cavalieri, F.; Chiessi, E.; Spagnoli, C.; Cowman, M.K. Poly(vinyl alcohol) as versatile biomaterial for potential biomedical applications. J. Mater. Sci. Mater. Med. 2003, 14, 687–691. [Google Scholar] [CrossRef]

- Hassan, C.M.; Trakampan, P.; Peppas, N.A. Water solubility characteristics of poly (vinyl alcohol) and gels prepared by freezing/thawing processes, Water Soluble Polymers; Springer: Boston, MA, USA, 2002; pp. 31–40. [Google Scholar]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Gombert, Y. Non-degradable ceramic bone cements - investigation of processability and mechanical performance. Master’s Thesis, ETH Zurïch, Zürich, Switzerland, 2014. [Google Scholar]

- Bohner, M.; Luginbühl, R.; Reber, C.; Doebelin, N.; Baroud, G.; Conforto, E. A physical approach to modify the hydraulic reactivity of α-tricalcium phosphate powder. Acta Biomater. 2009, 5, 3524–3535. [Google Scholar] [CrossRef]

- ASTM C266–03– Standard Test Method for Time of Setting of Hydraulic-Cement Paste by Gillmore Needles; ASTM International: West Conshohocken, PA, USA, 2003.

- Jonsén, P.; Häggblad, H.-Å. Fracture energy based constitutive models for tensile fracture of metal powder compacts. Int. J. Solids Struct. 2007, 44, 6398–6411. [Google Scholar] [CrossRef] [Green Version]

- Council on Dental Materials and Devices. New American Dental Association specification no. 27 for direct filling resins. J. Am. Dent. Assoc. 1977, 94, 1191–1194. [Google Scholar]

- Nezafati, N.; Moztarzadeh, F.; Hesaraki, S.; Mozafari, M. Synergistically reinforcement of a self-setting calcium phosphate cement with bioactive glass fibers. Ceram. Int. 2011, 37, 927–934. [Google Scholar] [CrossRef]

- López, A.; Mestres, G.; Ott, M.K.; Engqvist, H.; Ferguson, S.J.; Persson, C.; Helgason, B. Compressive mechanical properties and cytocompatibility of bone-compliant, linoleic acid-modified bone cement in a bovine model. J. Mech. Behav. Biomed. Mater. 2014, 32, 245–256. [Google Scholar] [CrossRef] [Green Version]

- Taut, T.; Kleeberg, R.; Bergmann, J. Seifert Software: The new Seifert Rietveld program BGMN and its application to quantitative phase analysis. Mater. Struct. 1998, 5(1), 57–66. [Google Scholar]

- Bergmann, J.; Friedel, P.; Kleeberg, R. A new fundamental parameter based Rietveld program for laboratory X-ray sources, its use in quantitative analysis and structure investigations., Commission of Powder Diffraction. Int. Union Crystallogr. CPD Newsl. 1998, 20, 4. [Google Scholar]

- Doebelin, N.; Kleeberg, R. Profex: A graphical user interface for the Rietveld refinement program BGMN. J. Appl. Crystallogr. 2015, 48, 1573–1580. [Google Scholar] [CrossRef]

- Mathew, M.; Schroeder, L.; Dickens, B.; Brown, W. The crystal structure of α-Ca3 (PO4) 2. Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1977, 33, 1325–1333. [Google Scholar] [CrossRef]

- Sudarsanan, K.t.; Young, R. Significant precision in crystal structural details. Holly Springs hydroxyapatite. Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1969, 25, 1534–1543. [Google Scholar] [CrossRef] [Green Version]

- Nazarian, A.; Von Stechow, D.; Zurakowski, D.; Müller, R.; Snyder, B.D. Bone Volume Fraction Explains the Variation in Strength and Stiffness of Cancellous Bone Affected by Metastatic Cancer and Osteoporosis. Calcif. Tissue Int. 2008, 83, 368–379. [Google Scholar] [CrossRef]

- Kopperdahl, D.L.; Keaveny, T.M. Yield strain behavior of trabecular bone. J. Biomech. 1998, 31, 601–608. [Google Scholar] [CrossRef]

- Dos Santos, L.A.; Carrodeguas, R.G.; Boschi, A.O.; De Arruda, A.C.F. Fiber-enriched double-setting calcium phosphate bone cement. J. Biomed. Mater. Res. Part A 2003, 65, 244–250. [Google Scholar] [CrossRef]

- Zuo, Y.; Yang, F.; Wolke, J.G.; Li, Y.; Jansen, J.A. Incorporation of biodegradable electrospun fibers into calcium phosphate cement for bone regeneration. Acta Biomater. 2010, 6, 1238–1247. [Google Scholar] [CrossRef]

- Dunne, N.; O’Hara, R.; Palmer, I.; Orr, J.; Buchanan, F. Optimisation of calcium phosphate cements for bone augmentation through vertebroplasty. In 6th World Congress of Biomechanics (WCB 2010), Singapore, 1–6 August 2010; Lim, C.T., Goh, J.C.H., Eds.; IFMBE Proceedings; Springer: Berlin/Heidelberg, Germany, 2010; Volume 31. [Google Scholar]

- Low, K.L.; Zein, S.H.S.; Tan, S.H.; McPhail, D.S.; Boccaccini, A.R. The effect of interfacial bonding of calcium phosphate cements containing bio-mineralized multi-walled carbon nanotube and bovine serum albumin on the mechanical properties of calcium phosphate cements. Ceram. Int. 2011, 37, 2429–2435. [Google Scholar] [CrossRef]

- Leplay, P.; Rethore, J.; Meille, S.; Baietto, M.-C. Damage law identification of a quasi brittle ceramic from a bending test using Digital Image Correlation. J. Eur. Ceram. Soc. 2010, 30, 2715–2725. [Google Scholar] [CrossRef] [Green Version]

- Ping, Z.; Nguyen, Q.; Chen, S.; Zhou, J.; Ding, Y. States of water in different hydrophilic polymers—DSC and FTIR studies. Polymer 2001, 42, 8461–8467. [Google Scholar] [CrossRef]

- Ginebra, M.-P.; Driessens, F.C.M.; Boltong, M.G.; Muntasell, J.; Font, J.; Planell, J.A. The effects of temperature on the behaviour of an apatitic calcium phosphate cement. J. Mater. Sci. Mater. Med. 1995, 6, 857–860. [Google Scholar] [CrossRef]

- Beckmann, J.; Springorum, R.; Vettorazzi, E.; Bachmeier, S.; Lüring, C.; Tingart, M.; Puschel, K.; Stark, O.; Grifka, J.; Gehrke, T.; et al. Fracture prevention by femoroplasty-cement augmentation of the proximal femur. J. Orthop. Res. 2011, 29, 1753–1758. [Google Scholar] [CrossRef] [Green Version]

- Pittet, C.; Lemaître, J. Mechanical characterization of brushite cements: A Mohr circles’ approach. J. Biomed. Mater. Res. 2000, 53, 769–780. [Google Scholar] [CrossRef]

| Group | Initial (min) | Final (min) |

|---|---|---|

| CPC | 24.0 ± 2.0 | 84 ± 7.0 |

| CPC-2.5 PVA | 13.5 ± 2.0 | 77.0 ± 9.0 |

| CPC-5.0 PVA | 11.5 ± 1.0 | 64.0 ± 6.0 |

| CPC-7.5 PVA | 8.5 ± 1.0 | 53.0 ± 9.0 |

| Group | α-TCP (wt %) | Apatite (wt %) |

|---|---|---|

| CPC | 3.2 (± 0.1) | 96.8 (± 0.1) |

| CPC-2.5 PVA | 2.6 (± 0.3) | 97.4 (± 0.3) |

| CPC-5.0 PVA | 3.1 (± 0.7) | 96.9 (± 0.7) |

| CPC-7.5 PVA | 2.7 (± 0.3) | 97.3 (± 0.3) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, J.; Faivre, J.; Engqvist, H.; Persson, C. The Addition of Poly(Vinyl Alcohol) Fibers to Apatitic Calcium Phosphate Cement Can Improve Its Toughness. Materials 2019, 12, 1531. https://doi.org/10.3390/ma12091531

Luo J, Faivre J, Engqvist H, Persson C. The Addition of Poly(Vinyl Alcohol) Fibers to Apatitic Calcium Phosphate Cement Can Improve Its Toughness. Materials. 2019; 12(9):1531. https://doi.org/10.3390/ma12091531

Chicago/Turabian StyleLuo, Jun, Julien Faivre, Håkan Engqvist, and Cecilia Persson. 2019. "The Addition of Poly(Vinyl Alcohol) Fibers to Apatitic Calcium Phosphate Cement Can Improve Its Toughness" Materials 12, no. 9: 1531. https://doi.org/10.3390/ma12091531