Three-Dimensional Meso-Structure-Based Model for Evaluating the Complex Permittivity of Asphalt Concrete

Abstract

:1. Introduction

2. Objectives

3. Virtual Test Modelling for Complex Permittivity

3.1. Meso-Structure Modelling for Asphalt Concrete

- (1)

- Generation of 3-D aggregates

- (2)

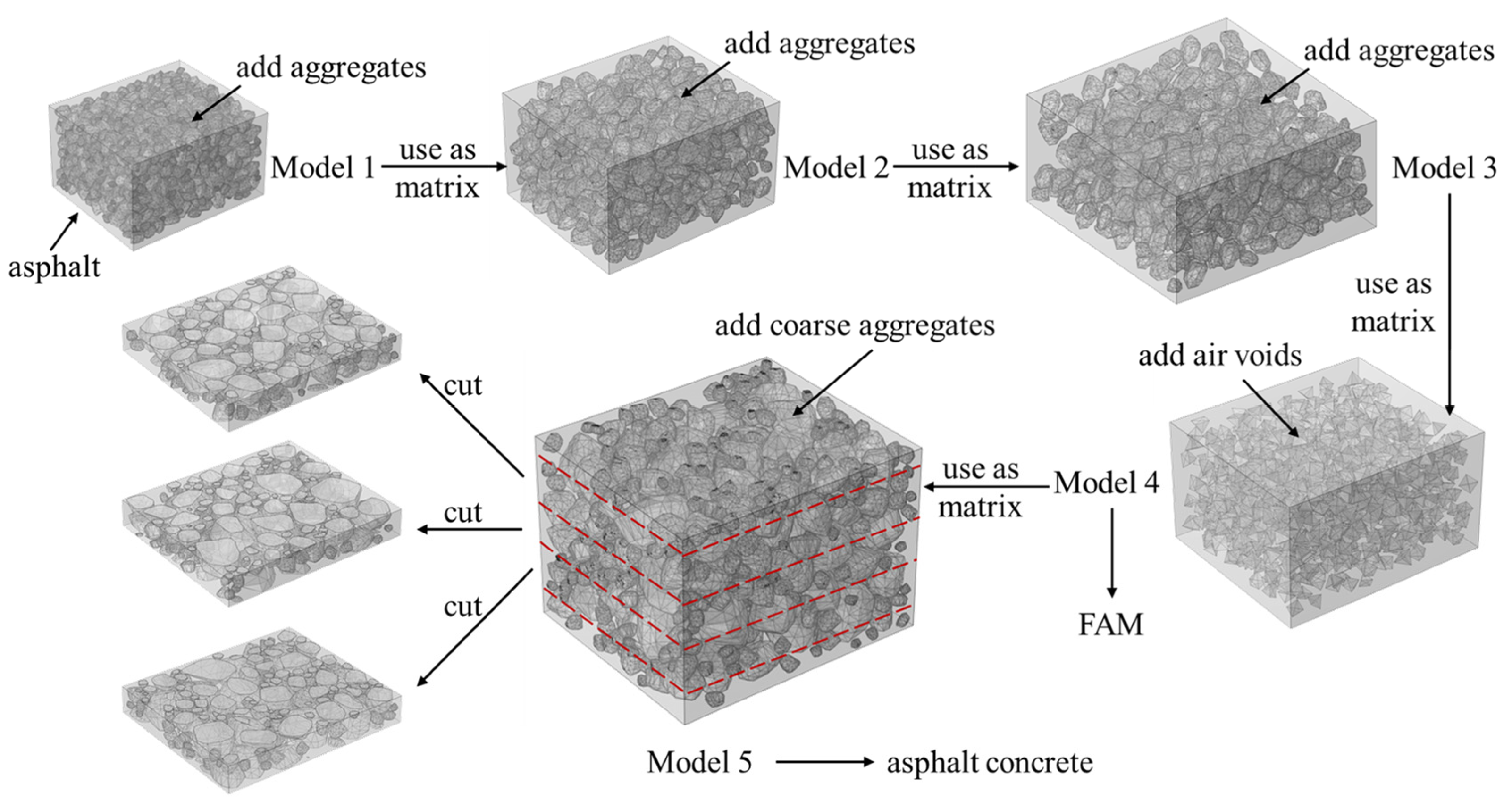

- Generation of 3-D asphalt concrete specimen

- (3)

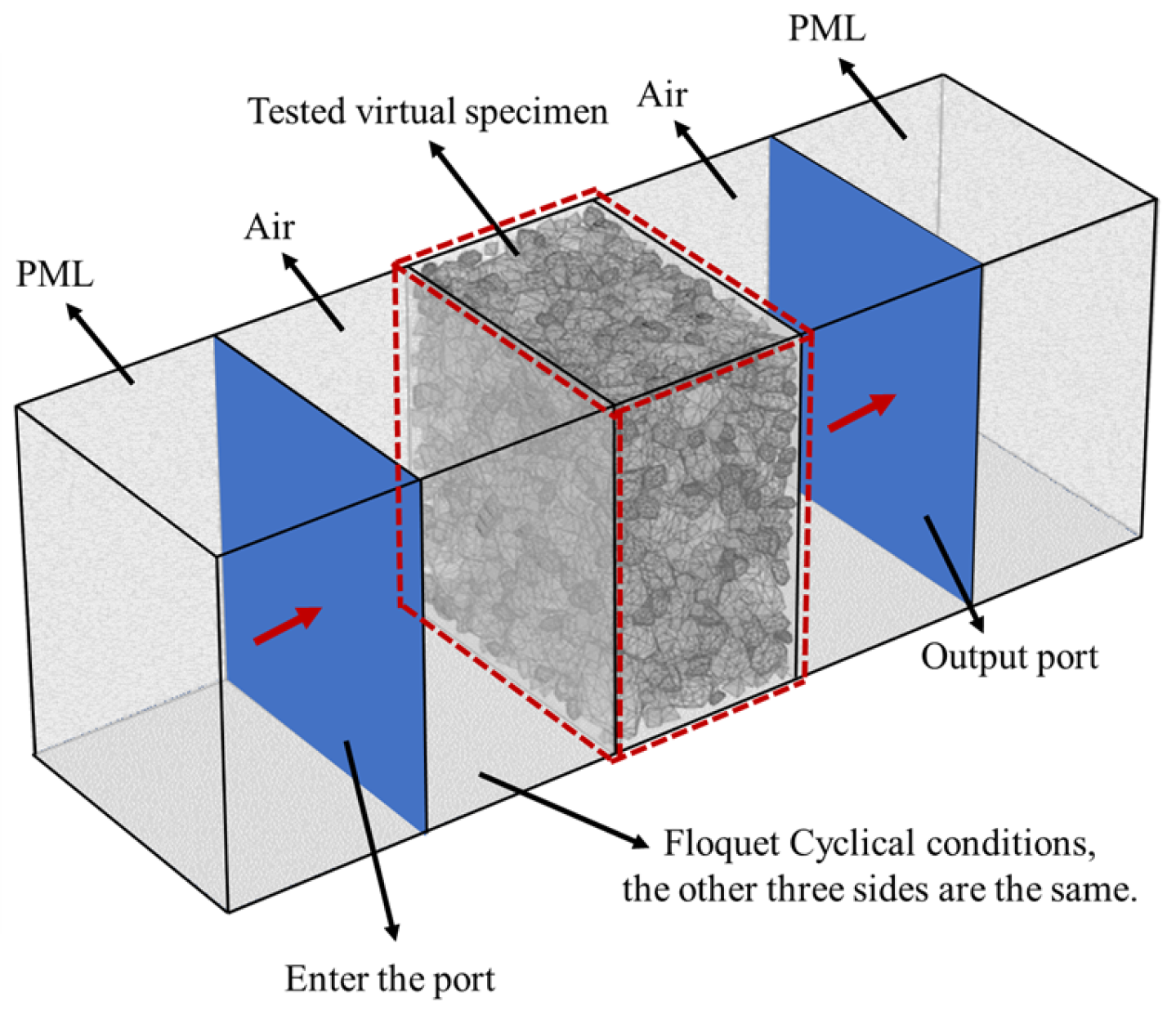

- The calculation of scattering parameter (S-parameter)

3.2. The Theory for Calculating Complex Permittivity with S-Parameter

- S21—Output reflection coefficient;

- S11m—Input reflection coefficient on the electromagnetic wave port;

- S21m—Output reflection coefficient on the electromagnetic wave port;

- c—The velocity of light, m/s;

- f—The frequency, GHz;

- l—The length of air shed from the tested material to the port, m.

- T—The propagation coefficient;

- θ—The phase of T;

- n—The refractive index;

- k0—The wave vector in vacuum;

- εr—The complex permittivity of the specimen;

- ε′—The real part of complex permittivity;

- ε″—The imaginary part of complex permittivity;

- μr—The relative magnetic permeability.

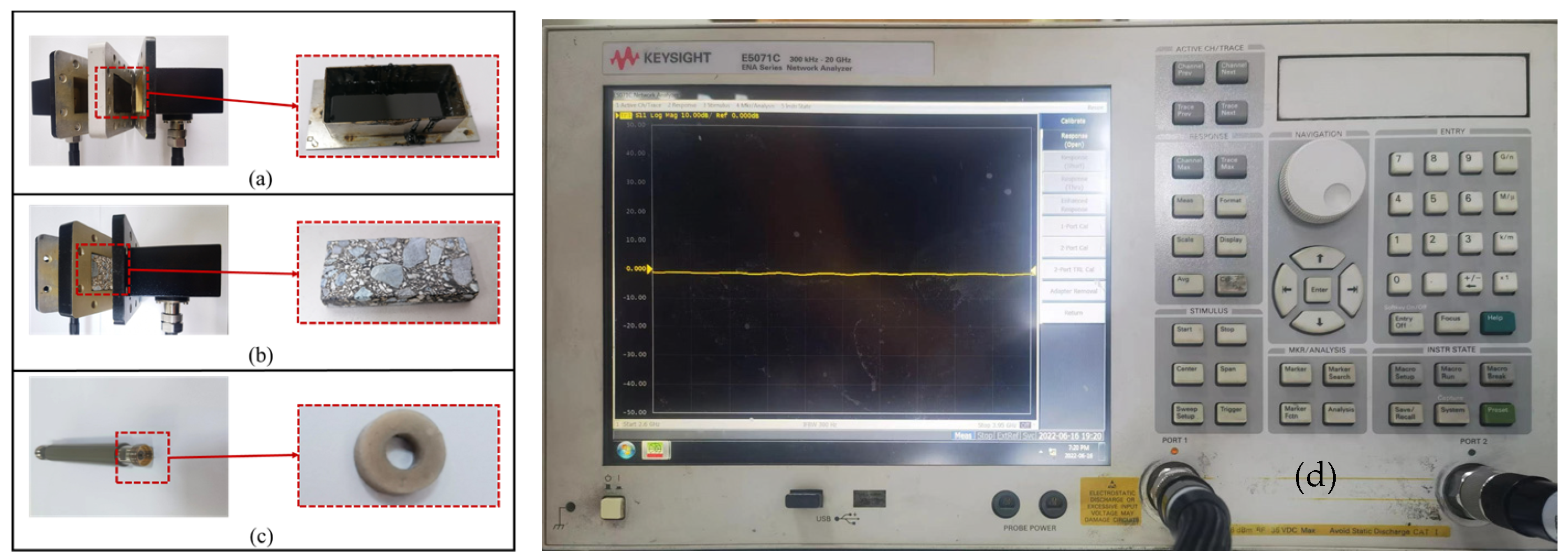

4. Experiment

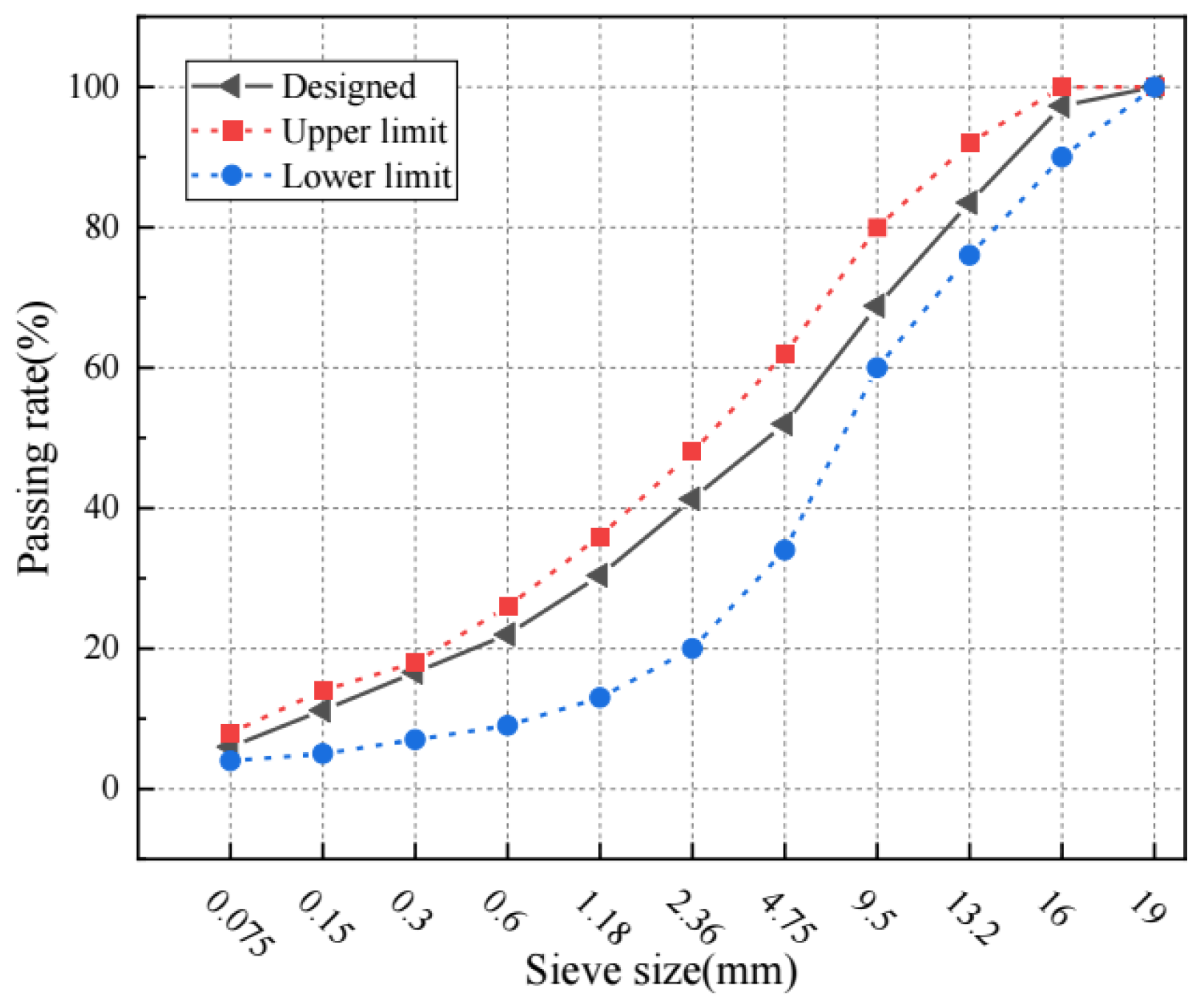

4.1. Materials and Specimens in the Experiment

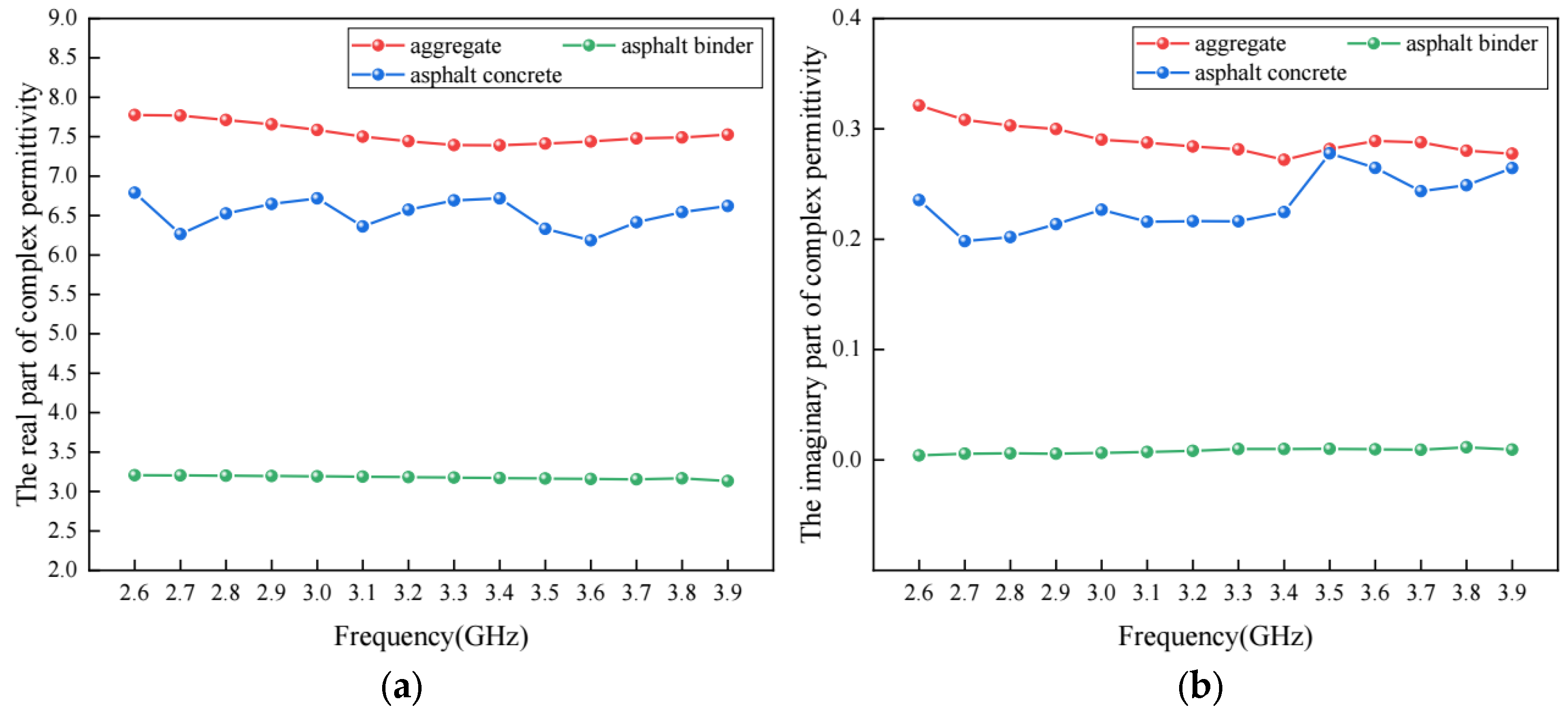

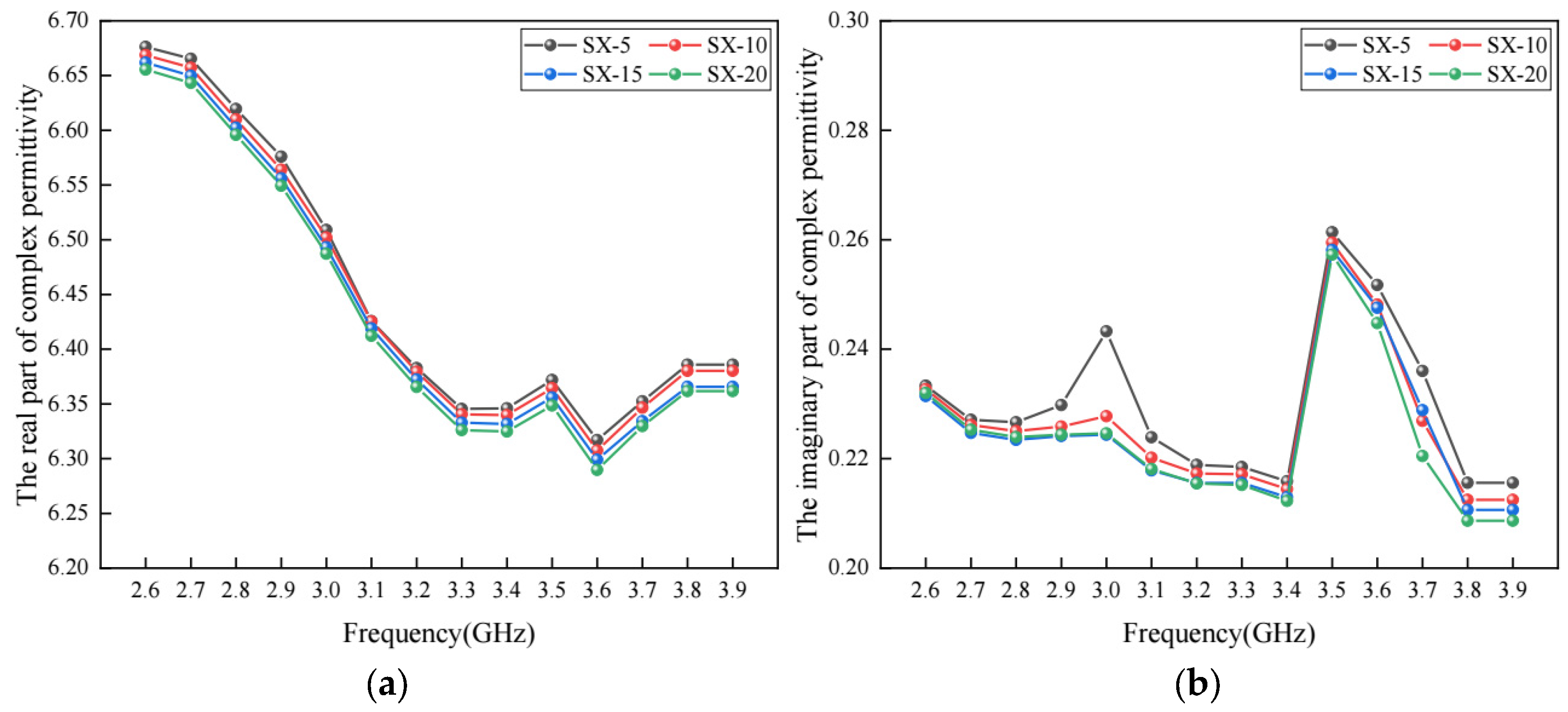

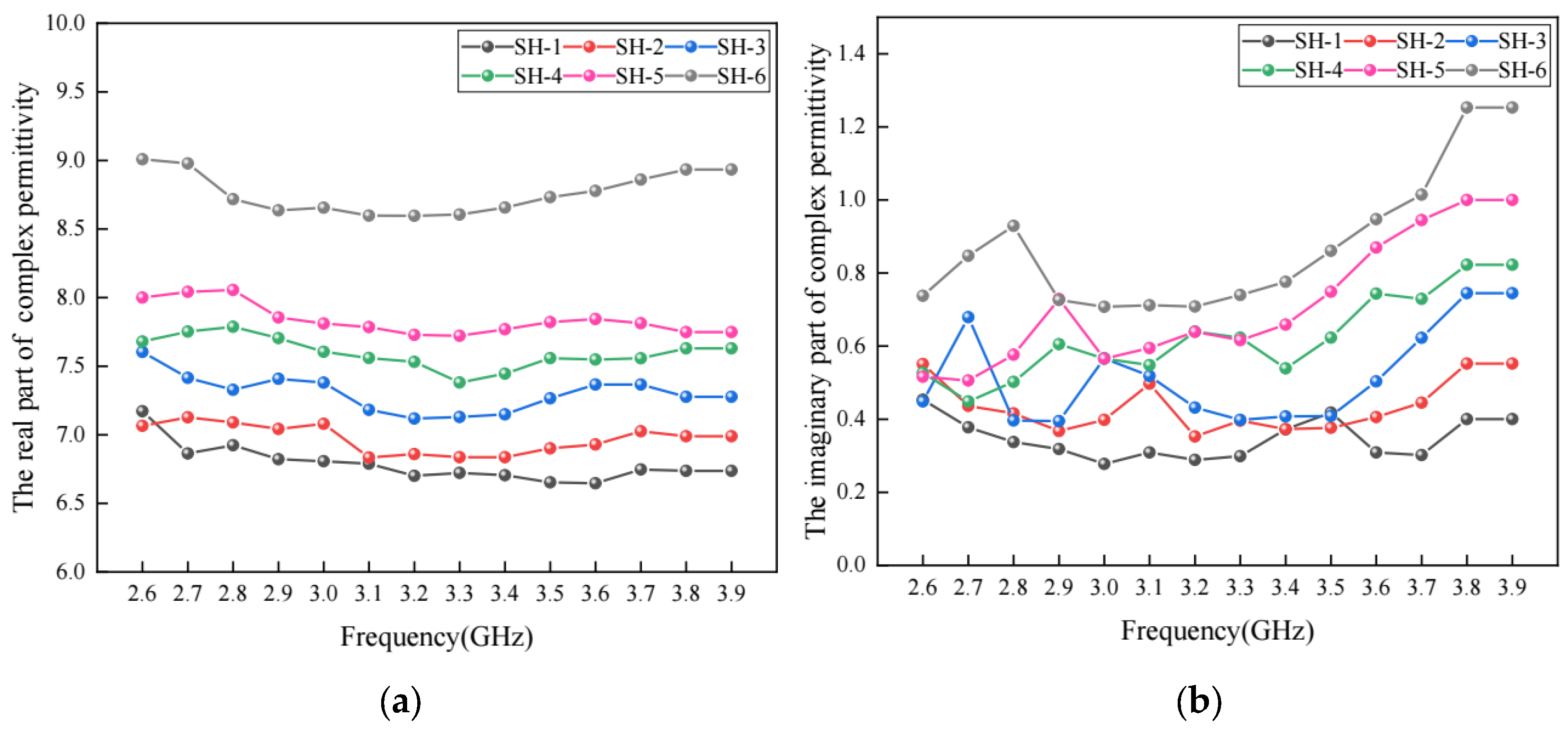

4.2. The Analysis of Experimental Result

5. Discussion

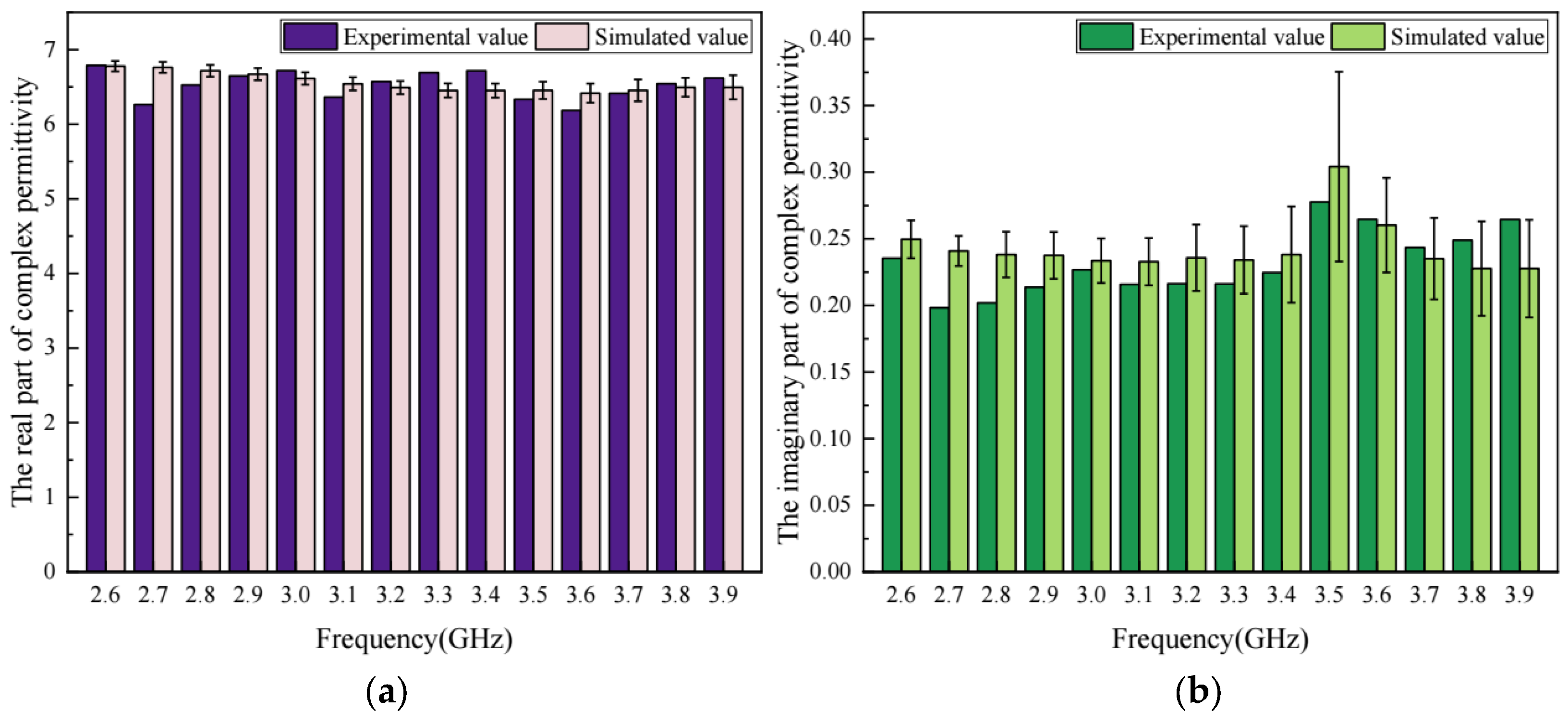

5.1. Model Validation

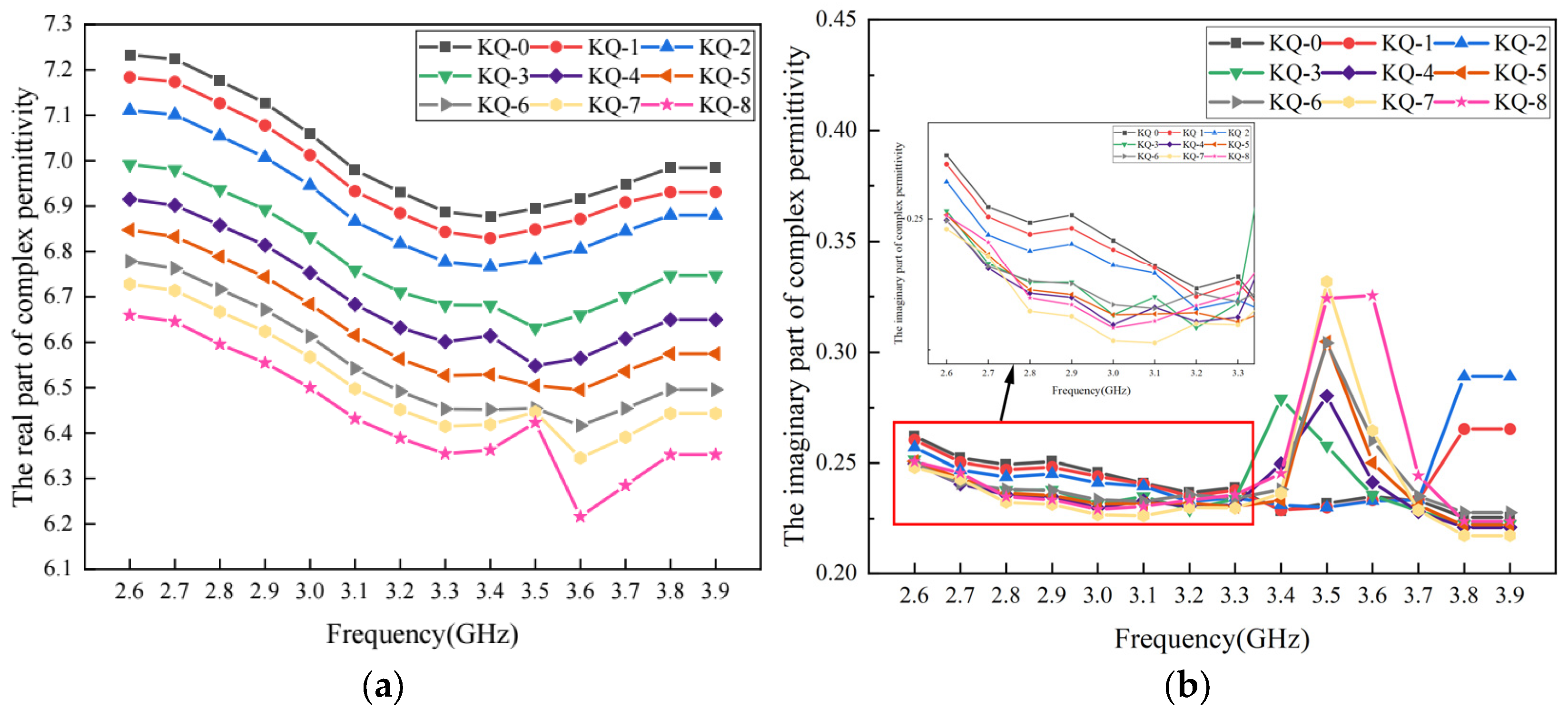

5.2. Effect of Porosity on Permittivity

5.3. Effect of Void Size on Permittivity

5.4. Effect of Aggregate Gradation on Permittivity

5.5. Effect of Moisture Content on Permittivity

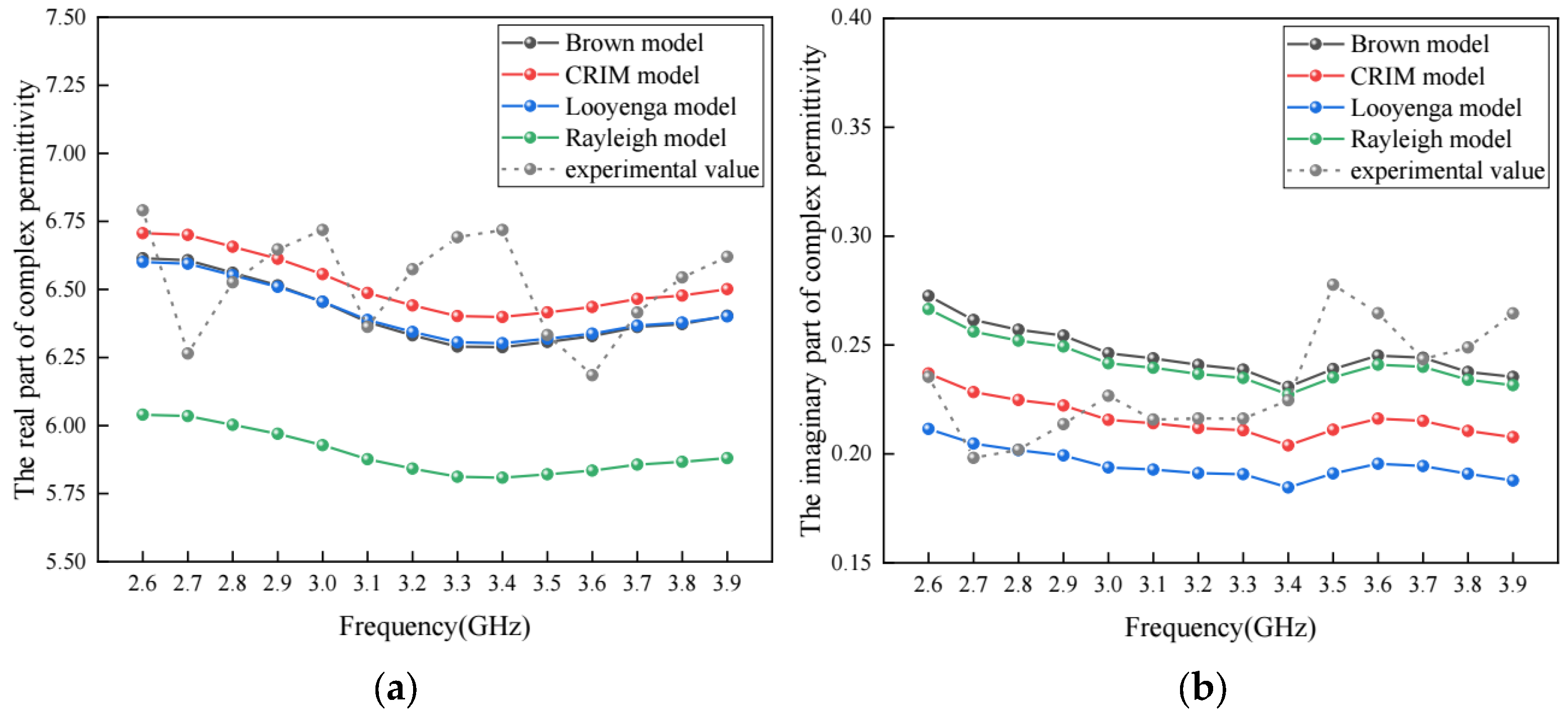

6. Modification of Dielectric Model

6.1. The Common Theoretical Models

- (1)

- Lichtenecker–Rother (LR) model

- (2)

- Rayleigh model

6.2. The Applicability Analysis for Classic Models

6.3. The Modified Equations Based on Meso-Scale Heterogeneous Model

- n—The value of 4, component 1–4 represents aggregate, asphalt binder, void and moisture content;

- f—The tested frequency, GHz;

- νi—The volume fraction of each component;

- εi—The complex permittivity of each component.

| Real Part of Complex Permittivity | Imaginary Part of Complex Permittivity | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Brown model | a1 | a2 | a3 | a4 | R2 | a1 | a2 | a3 | a4 | R2 |

| 0.338 | −0.303 | −1.538 | 0.073 | 0.922 | 0.285 | 0.552 | 0.171 | 0.171 | 0.980 | |

| CRIM model | b1 | b2 | b3 | b4 | R2 | b1 | b2 | b3 | b4 | R2 |

| 0.343 | −0.766 | −1.176 | 0.142 | 0.825 | 0.363 | −0.350 | 0.457 | 0.454 | 0.974 | |

| Looyenga model | c1 | c2 | c3 | c4 | R2 | c1 | c2 | c3 | c4 | R2 |

| 0.342 | 0.939 | 1.309 | 0.176 | 0.690 | 0.383 | −0.585 | 0.533 | 0.524 | 0.958 | |

7. Conclusions

- The maximum relative error between the calculated and measured real part of the complex permittivity was 7.9%, and the relative error at other frequencies was below 4%. The average relative error and maximum absolute error between the calculated and measured imaginary part of the complex permittivity were 9.01% and 0.04269, respectively. The accuracy of the meso-structure-based model is acceptable.

- The real part of the complex permittivity of asphalt concrete decreased with the increase in porosity. Some sudden change in the imaginary part of the complex permittivity was observed within the frequency range from 2.6 GHz to 3.9 GHz. A larger air void size would lead to a larger frequency at which sudden change occurs.

- The real part and the imaginary part of the complex permittivity tend to be smaller when more coarse aggregates are replaced with fine aggregates. This is mainly caused by the stronger absorption and loss capacity of coarse aggregates.

- Both the real part and the imaginary part of the complex permittivity increase with higher moisture content due to the stronger dielectric property of water. Before all the air voids are filled with water, each 1% increase in moisture content leads to about a 3~4% increase in the real part of the complex permittivity. When all the air voids are filled with water, the above phenomenon is more significant.

- The determination coefficients R2 for the real part and the imaginary part of the complex permittivity fitted by the modified Brown model were the maximum values, which were 0.922 and 0.980, respectively. The modified equations were more applicable for the calculation of the complex permittivity of asphalt concrete in the future.

- Actually, temperature is a significant factor in the 3-D meso-scale modeling construction. However, the influence of temperature on the complex permittivity of asphalt concrete is not considered in this study. Moreover, the frequency range is relatively narrow. Therefore, these limitations will be taken into consideration in future work.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sha, A.; Lou, B.; Barbieri, D.M.; Hoff, I. Microwave heating as an innovative road maintenance technology: Aging effect on binder and feasibility evaluation. Materials 2022, 15, 316. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. The prospect of microwave heating: Towards a faster and deeper crack healing in asphalt pavement. Processes 2021, 9, 507. [Google Scholar] [CrossRef]

- Ho, I.H.; Dickson, M. Numerical modeling of heat production using geothermal energy for a snow-melting system. Geomech. Energy Environ. 2017, 10, 42–51. [Google Scholar] [CrossRef]

- Acevedo, L.; Ferreira, G.; López-Sabirón, A.M. Exergy transfer principles of microwavable materials under electromagnetic effects. Mater. Today Commun. 2021, 27, 102313. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H.; Jiang, B.; Venkiteela, G. Evaluation of microwave heating for potential application in hot in-place recycling of asphalt pavement. Transport. Res. Rec. 2022, 2676, 256–268. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Punathil, L.; Basak, T. A theoretical analysis on the effect of containers on the microwave heating of materials. Int. Commun. Heat Mass 2017, 82, 145–153. [Google Scholar] [CrossRef]

- Írnek, A. Influences of different reaction mediums on the properties of high-voltage LiNiPO4@ C cathode material in terms of dielectric heating efficiency. Electrochim. Acta 2017, 258, 524–534. [Google Scholar] [CrossRef]

- Zhong, Y.; Wang, Y.; Zhang, B.; Li, X.; Li, S.; Zhong, Y.; Gao, Y. Prediction model of asphalt content of asphalt mixture based on dielectric properties. Adv. Civ. Eng. 2020, 2020, 6661593. [Google Scholar] [CrossRef]

- Shoaib, N.; Sellone, M.; Brunetti, L.; Oberto, L. Uncertainty analysis for material measurements using the vector network analyzer. Microw. Opt. Techn. Let. 2016, 58, 1841–1844. [Google Scholar] [CrossRef]

- Loizos, A.; Plati, C. Field and laboratory test for assigning dielectric constants of asphalt pavement materials. Road Mater. Pavement 2006, 7, 513–532. [Google Scholar] [CrossRef]

- Yu, X.; Luo, R.; Huang, T.; Wang, J.; Ruan, L. Development of relative humidity–frequency equivalence principle for the dielectric properties of asphalt mixtures. J. Mater. Civ. Eng. 2021, 33, 04021197. [Google Scholar] [CrossRef]

- Frid, A.; Frid, V. Moisture effect on asphalt dielectric permittivity: Simulating, sensitivity analysis and experimental validation. Int. J. Pavement Res. Technol. 2023, 1–15. [Google Scholar] [CrossRef]

- Yu, X.; Luo, R.; Huang, T. Influence of temperature on the dielectric properties of asphalt mixtures. Int. J. Pavement Eng. 2023, 24, 2046273. [Google Scholar] [CrossRef]

- Jaselskis, E.J.; Grigas, J.; Brilingas, A. Dielectric properties of asphalt pavement. J. Mater. Civ. Eng. 2003, 15, 427–434. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Wei, Z.; Zhang, D. Microwave absorption enhancement of asphalt concrete with SiC-Fe3O4 mixtures modifier. Constr. Build. Mater. 2020, 254, 119209. [Google Scholar] [CrossRef]

- Kaya, O.; Annagur, H.M.; Altintas, O. Experimental Investigation of Mechanical and Electromagnetic performance of asphalt concrete containing different ratios of graphite powder as a filler to be potentially used as part of wireless electric roads. Balt. J. Road Bridge Eng. 2023, 18, 19–41. [Google Scholar] [CrossRef]

- Trigos, L.; Gallego, J.; Escavy, J.I.; Picado-Santos, L. Dielectric properties versus microwave heating susceptibility of aggregates for self-healing asphalt mixtures. Constr. Build. Mater. 2021, 293, 123475. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, Y.; Zhang, B.; Li, X. Investigating the sensitivity of mineral aggregate size on the dielectric response of asphalt concrete based on a multiscale experiment. Aip Adv. 2022, 12, 035314. [Google Scholar] [CrossRef]

- Zhang, B.; Zhong, Y.H.; Liu, H.X.; Wang, F.M. Experimental research on dielectric constant model for asphalt concrete Material. Adv. Mater. Res. 2011, 250, 2760–2764. [Google Scholar] [CrossRef]

- Piuzzi, E.; Cannazza, G.; Cataldo, A.; Chicarella, S.; De Benedetto, E.; Frezza, F.; Timpani, F. Measurement system for evaluating dielectric permittivity of granular materials in the 1.7–2.6-GHz band. IEEE Trans. Instrum. Meas. 2015, 65, 1051–1059. [Google Scholar] [CrossRef]

- Cao, Q.; Al-Qadi, I.L. Effect of moisture content on calculated dielectric properties of asphalt concrete pavements from ground-penetrating radar measurements. Remote Sens. 2021, 14, 34. [Google Scholar] [CrossRef]

- Zhong, Y.; Wang, Y.; Yang, Z.; Zhang, B.; Wang, P. Dielectric model of asphalt mastics considering temperature influence. J. Mater. Civ. Eng. 2023, 35, 04023249. [Google Scholar] [CrossRef]

- Zhong, Y.; Gao, Y.; Zhang, B.; Li, S.; Cui, H.; Li, X.; Zhao, H. Experimental study on the dielectric model of common asphalt pavement surface materials based on the LR model. Adv. Civ. Eng. 2021, 2021, 6667101. [Google Scholar] [CrossRef]

- Bai, X.; Wang, L. Study on mesoscopic model of low-temperature cracking of steel slag asphalt mixture based on random aggregate. Constr. Build. Mater. 2023, 364, 129974. [Google Scholar] [CrossRef]

- Onifade, I.; Jelagin, D.; Guarin, A.; Birgisson, B.; Kringos, N. Effect of micro-scale morphological parameters on meso-scale response of asphalt concrete. Asph. Pavements 2014, 2, 1775–1784. [Google Scholar] [CrossRef]

- Sun, Z.; Qi, H.; Li, S.; Tan, Y.; Yue, Z.; Lv, H. Estimating the effect of coarse aggregate meso-structure on the thermal contraction of asphalt mixture by a hierarchical prediction approach. Constr. Build. Mater. 2022, 342, 128048. [Google Scholar] [CrossRef]

- Mo, L.T.; Huurman, M.; Woldekidan, M.F.; Wu, S.P.; Molenaar, A.A. Investigation into material optimization and development for improved ravelling resistant porous asphalt concrete. Mater. Des. 2010, 31, 3194–3206. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, C.; Song, Z.; Zhou, S.; Chen, W. Mesodamage mechanism of asphalt mixtures with different structural types under frost heaving of ice crystals. J. Mater. Civ. Eng. 2023, 35, 04022377. [Google Scholar] [CrossRef]

- Cao, Q.; Al-Qadi, I.L. Development of a numerical model to predict the dielectric properties of heterogeneous asphalt concrete. Sensors 2021, 21, 2643. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, L.; Du, Y.; Wang, H.; Dan, H. Three-dimensional microstructure-based model for evaluating the coefficient of thermal expansion and contraction of asphalt concrete. Constr. Build. Mater. 2021, 284, 122764. [Google Scholar] [CrossRef]

- Baker-Jarvis, J.R.; Janezic, M.D.; Riddle, B.F.; Johnk, R.T.; Holloway, C.L.; Geyer, R.G.; Grosvenor, C.A. Measuring the Permittivity and Permeability of Lossy Materials: Solids, Liquids, Metals, and Negative-Index Materials; NIST Technical Note 1536; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2005. [Google Scholar]

- ASTM D5568-14; Standard Test Method for Measuring Relative Complex Permittivity and Relative Magnetic Permeability of Solid Materials at Microwave Frequencies Using Waveguide. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM D7449M-14; Standard Test Method for Measuring Relative Complex Permittivity and Relative Magnetic Permeability of Solid Materials at Microwave Frequencies Using Coaxial Air Line. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- Feng, H.T.; Zhuo, R.F.; Chen, J.T.; Yan, D.; Feng, J.J.; Li, H.J.; Cheng, S.; Wu, Z.G.; Wang, J.; Yan, P.X. Synthesis, characterization, and microwave absorption property of the SnO2 nanowire/paraffin composites. Nano Express 2009, 4, 1452–1457. [Google Scholar] [CrossRef]

- Fu, C.; Liu, K.; Liu, Q.; Xu, P.; Dai, D.; Tong, J. Exploring directional energy conversion behavior of electromagnetic-based multifunctional asphalt pavement. Energy 2023, 268, 126573. [Google Scholar] [CrossRef]

- Haq, T.; Koziel, S.; Pietrenko-Dabrowska, A. Resonator-Loaded Waveguide Notch Filters with Broad Tuning Range and Additive-Manufacturing-Based Operating Frequency Adjustment Procedure. Electronics 2023, 12, 4486. [Google Scholar] [CrossRef]

- Bakam Nguenouho, O.S.; Chevalier, A.; Potelon, B.; Benedicto, J.; Quendo, C. Dielectric characterization and modelling of aqueous solutions involving sodium chloride and sucrose and application to the design of a bi-parameter RF-sensor. Sci. Rep. 2022, 12, 7209. [Google Scholar] [CrossRef] [PubMed]

| Model Number | Composition | Model Dimension |

|---|---|---|

| Model 1 | Asphalt binder + aggregates (smaller than 0.15 mm) | 2 mm × 1.6 mm × 1.2 mm |

| Model 2 | Asphalt binder + aggregates (smaller than 1.18 mm) | 8 mm × 7 mm × 6 mm |

| Model 3 | Asphalt binder + aggregates (smaller than 2.36 mm) | 32 mm × 28 mm × 20 mm |

| Model 4 | Asphalt binder + air void + aggregates (smaller than 2.36 mm) | 70 mm × 60 mm × 10 mm |

| Model 5 | Asphalt binder + air void + aggregates (in all sizes) | 70 mm × 60 mm × 50 mm |

| Condition | Conditional Variant | Condition | Conditional Variant |

|---|---|---|---|

| 1 | Basic condition | 2 | Porosity of 0% |

| 3 | Porosity of 1% | 4 | Porosity of 2% |

| 5 | Porosity of 3% | 6 | Porosity of 4% |

| 7 | Porosity of 5% | 8 | Porosity of 6% |

| 9 | Porosity of 7% | 10 | Porosity of 8% |

| 11 | Porosity of 5%, moisture content of 1% | 12 | Porosity of 4%, moisture content of 2% |

| 13 | Porosity of 3%, moisture content of 3% | 14 | Porosity of 2%, moisture content of 4% |

| 15 | Porosity of 1%, moisture content of 5% | 16 | Porosity of 0%, moisture content of 6% |

| 17 | Heterogeneous distribution of 1–4 mm in void size | 18 | Heterogeneous distribution of 1–6 mm in void size |

| 19 | Heterogeneous distribution of 1–8 mm in void size | 20 | 5% increasement in fine aggregate content |

| 21 | 10% increasement in fine aggregate content | 22 | 15% increasement in fine aggregate content |

| 23 | 20% increasement in fine aggregate content | 24 | Same complex permittivity for each component |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Z.; Chen, X.; Wang, J.; Chen, J. Three-Dimensional Meso-Structure-Based Model for Evaluating the Complex Permittivity of Asphalt Concrete. Materials 2024, 17, 1900. https://doi.org/10.3390/ma17081900

Xie Z, Chen X, Wang J, Chen J. Three-Dimensional Meso-Structure-Based Model for Evaluating the Complex Permittivity of Asphalt Concrete. Materials. 2024; 17(8):1900. https://doi.org/10.3390/ma17081900

Chicago/Turabian StyleXie, Zhenwen, Xingzao Chen, Jing Wang, and Jiaqi Chen. 2024. "Three-Dimensional Meso-Structure-Based Model for Evaluating the Complex Permittivity of Asphalt Concrete" Materials 17, no. 8: 1900. https://doi.org/10.3390/ma17081900