Analysis of the Effect of Surface Preparation of Aluminum Alloy Sheets on the Load-Bearing Capacity and Failure Energy of an Epoxy-Bonded Adhesive Joint

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sheet Metals and the Adhesive

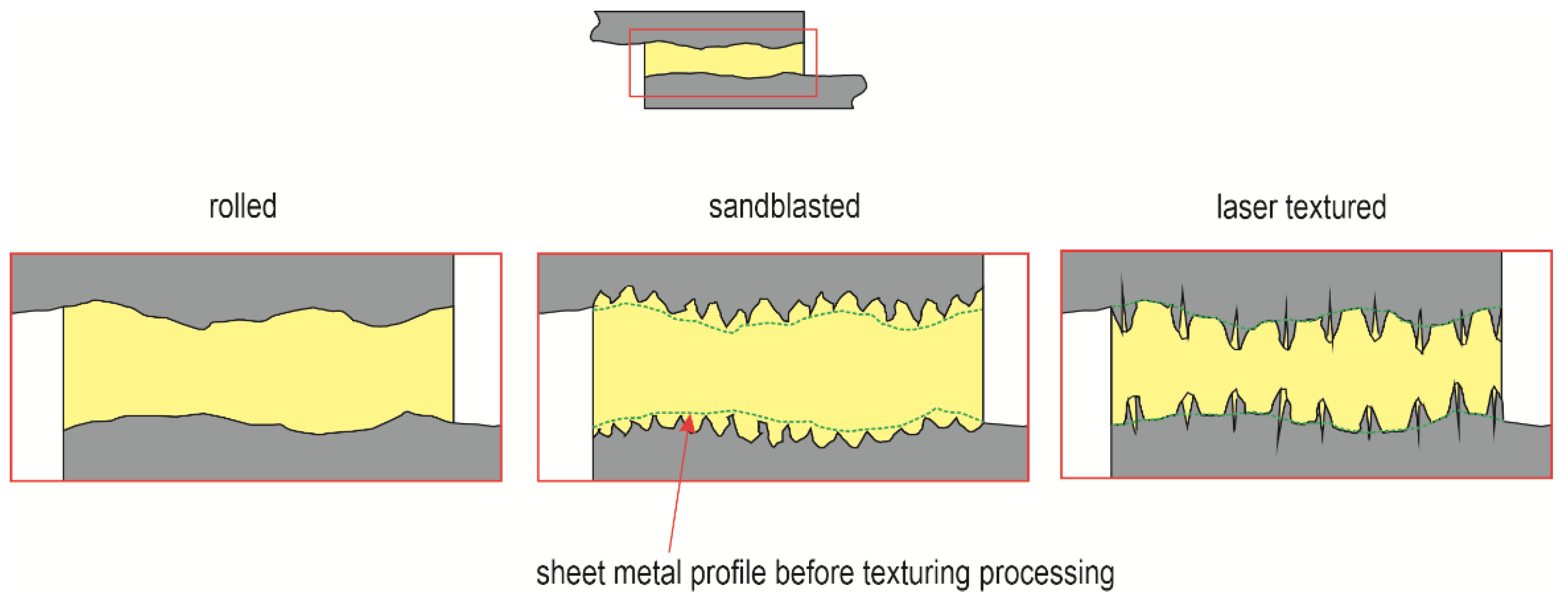

2.2. Surface Preparation for Adhesive Bonding

- -

- Sandblasting (T.I);

- -

- Laser beam surface treatment with fixed laser parameters and beam pass spacing (T.II).

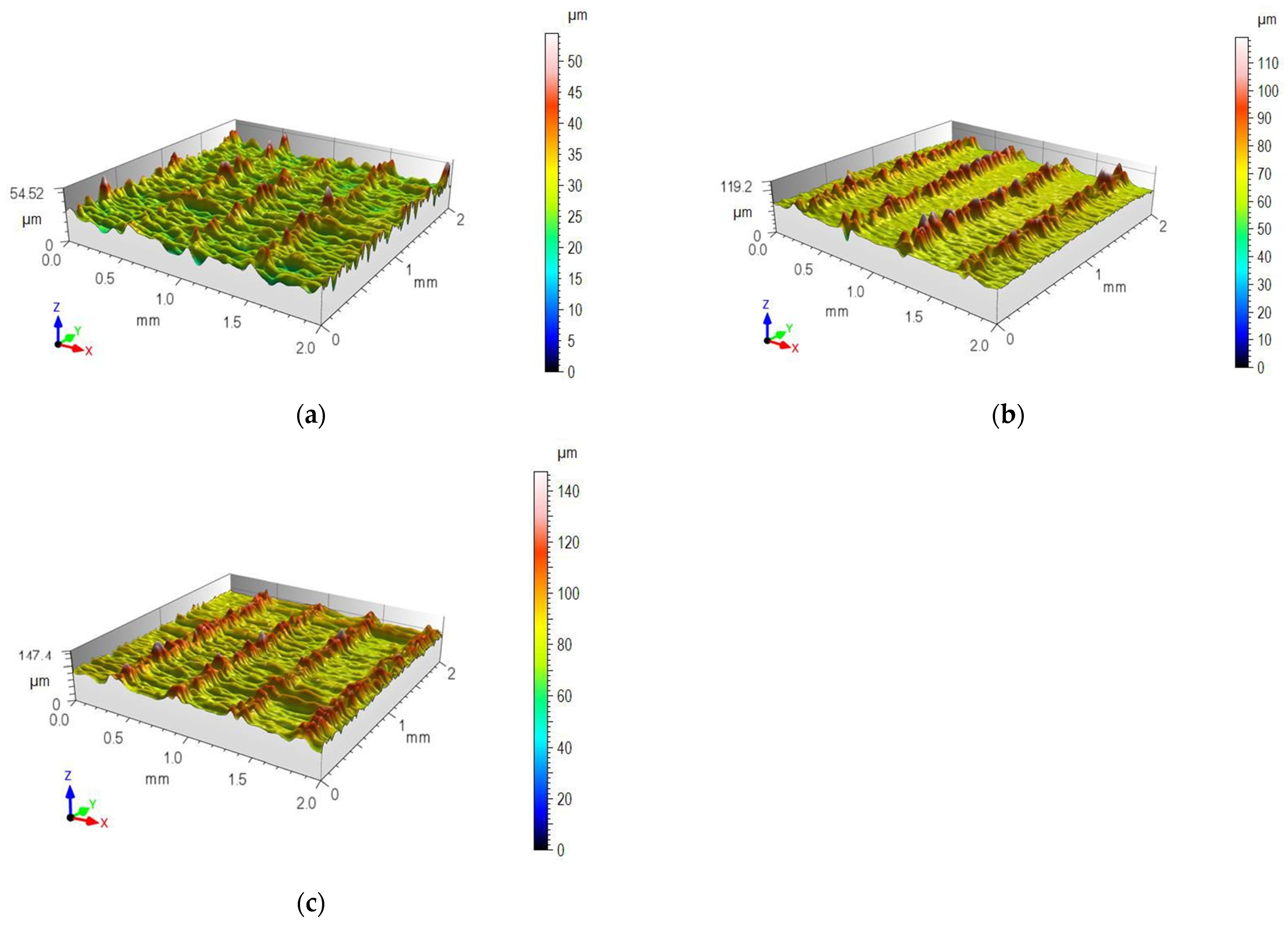

2.3. Evaluation of the Geometric Structure of the Surface

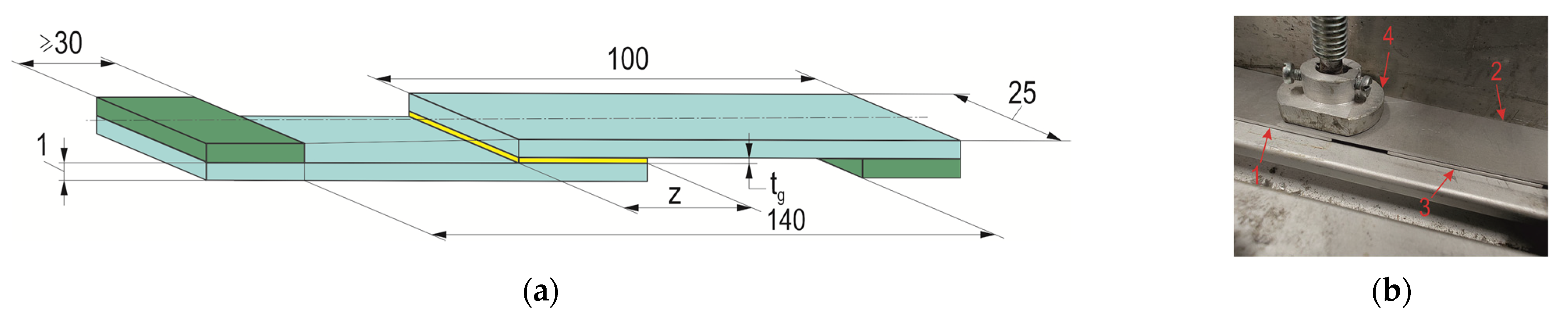

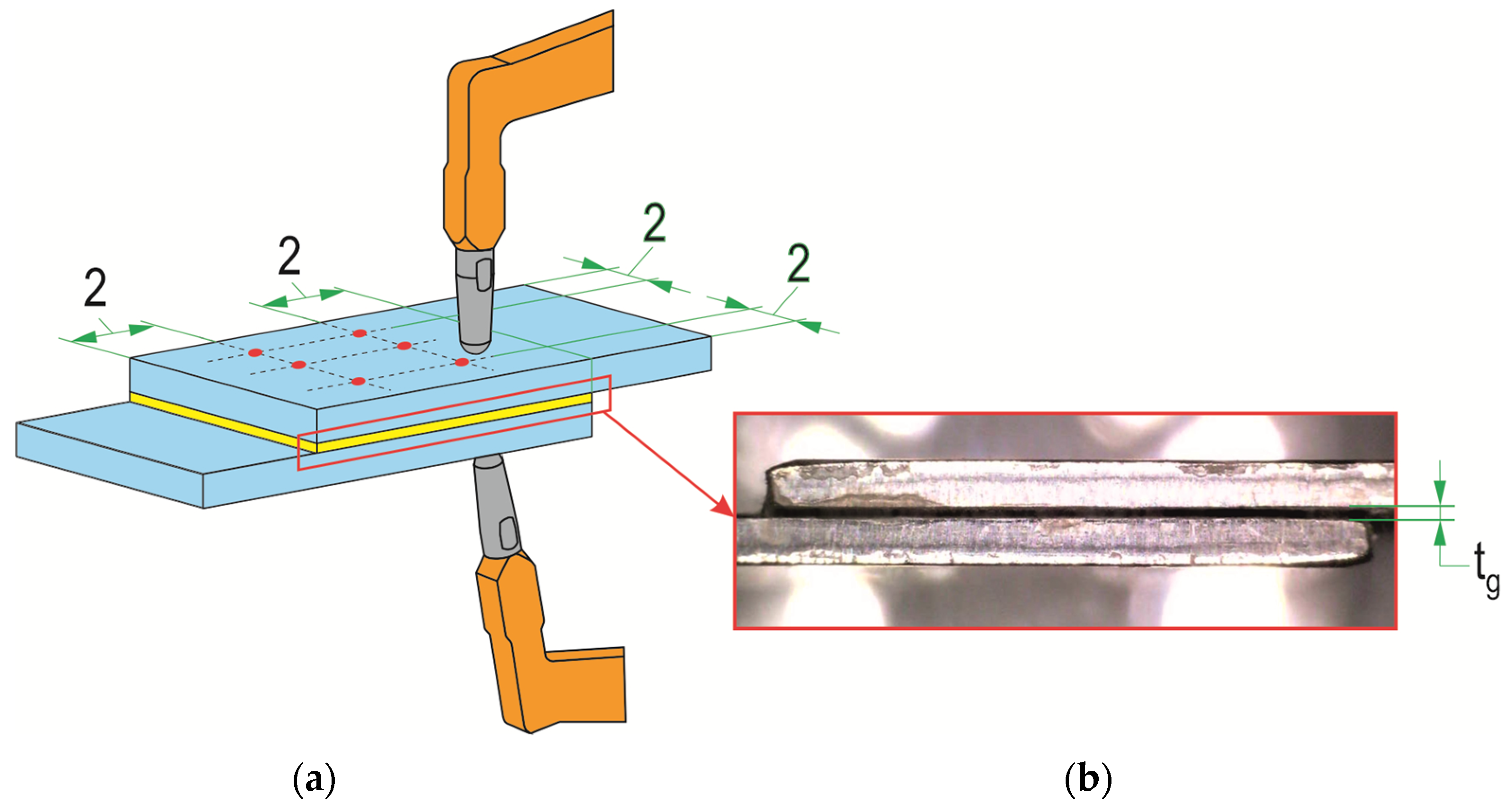

2.4. Sample Joint Preparation

2.5. Quasi-Static Lap-Shear Tensile Test

3. Results and Discussion

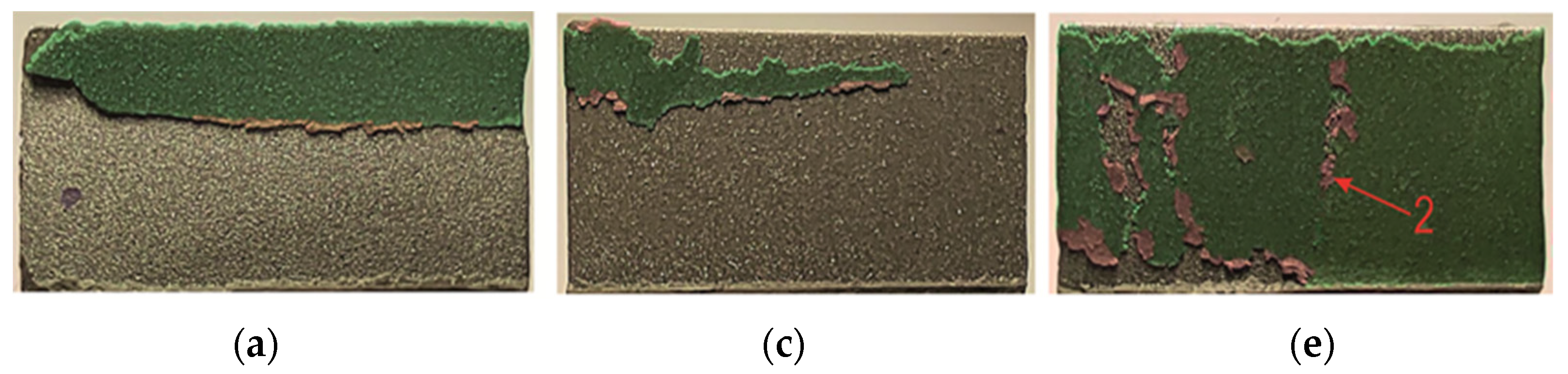

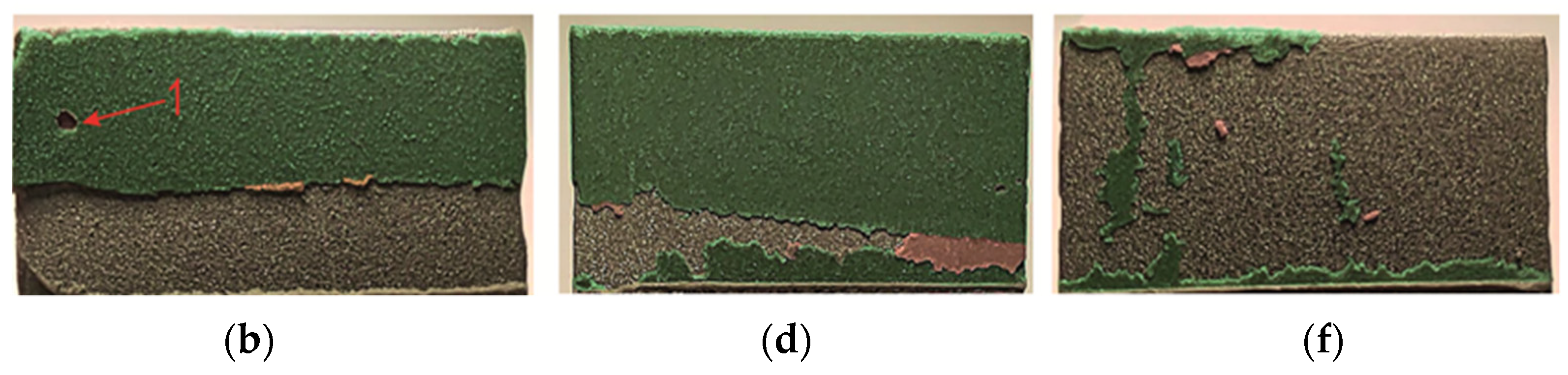

3.1. Surface Texture and Morphology of the Traces after Laser Treatment

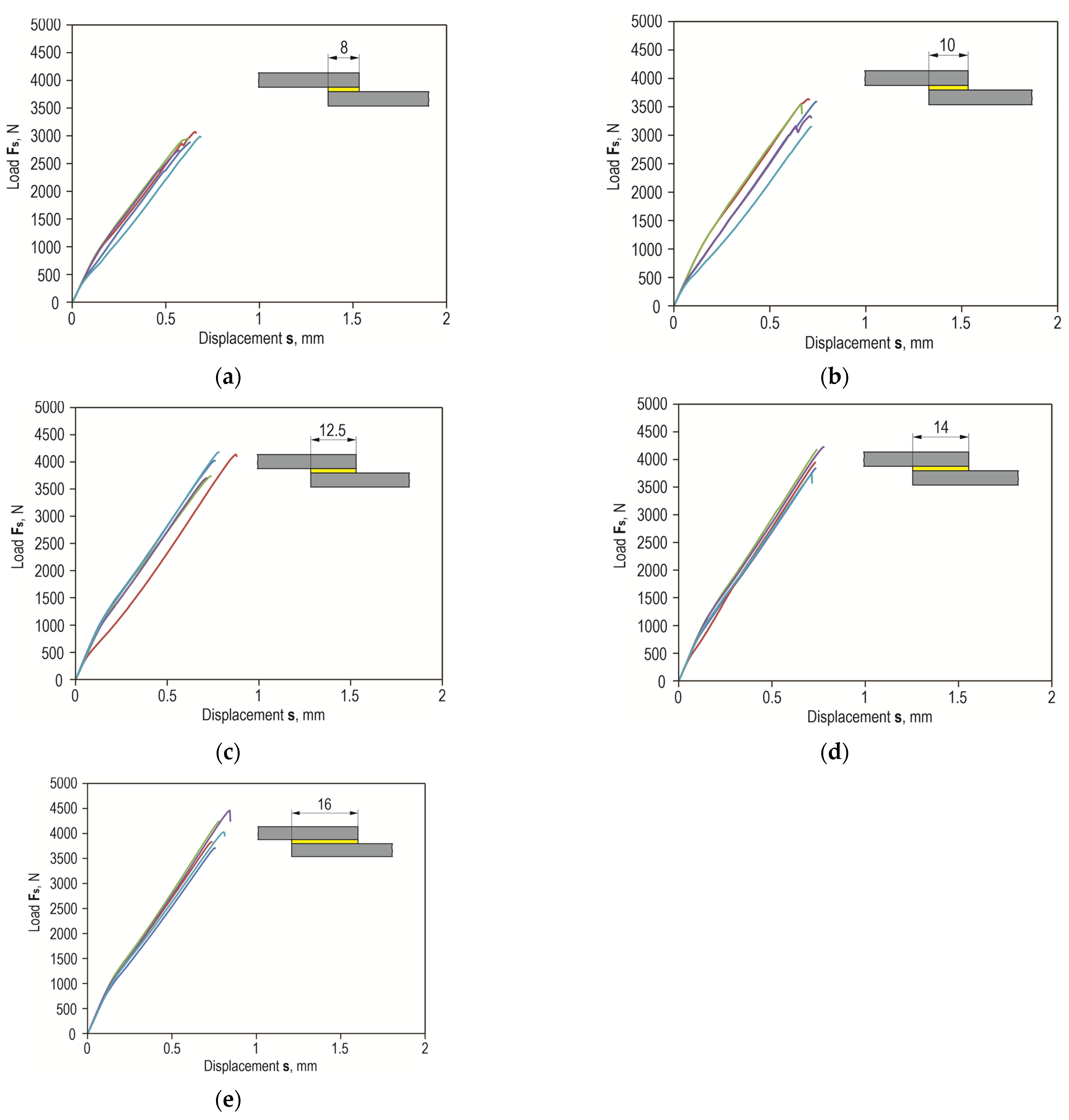

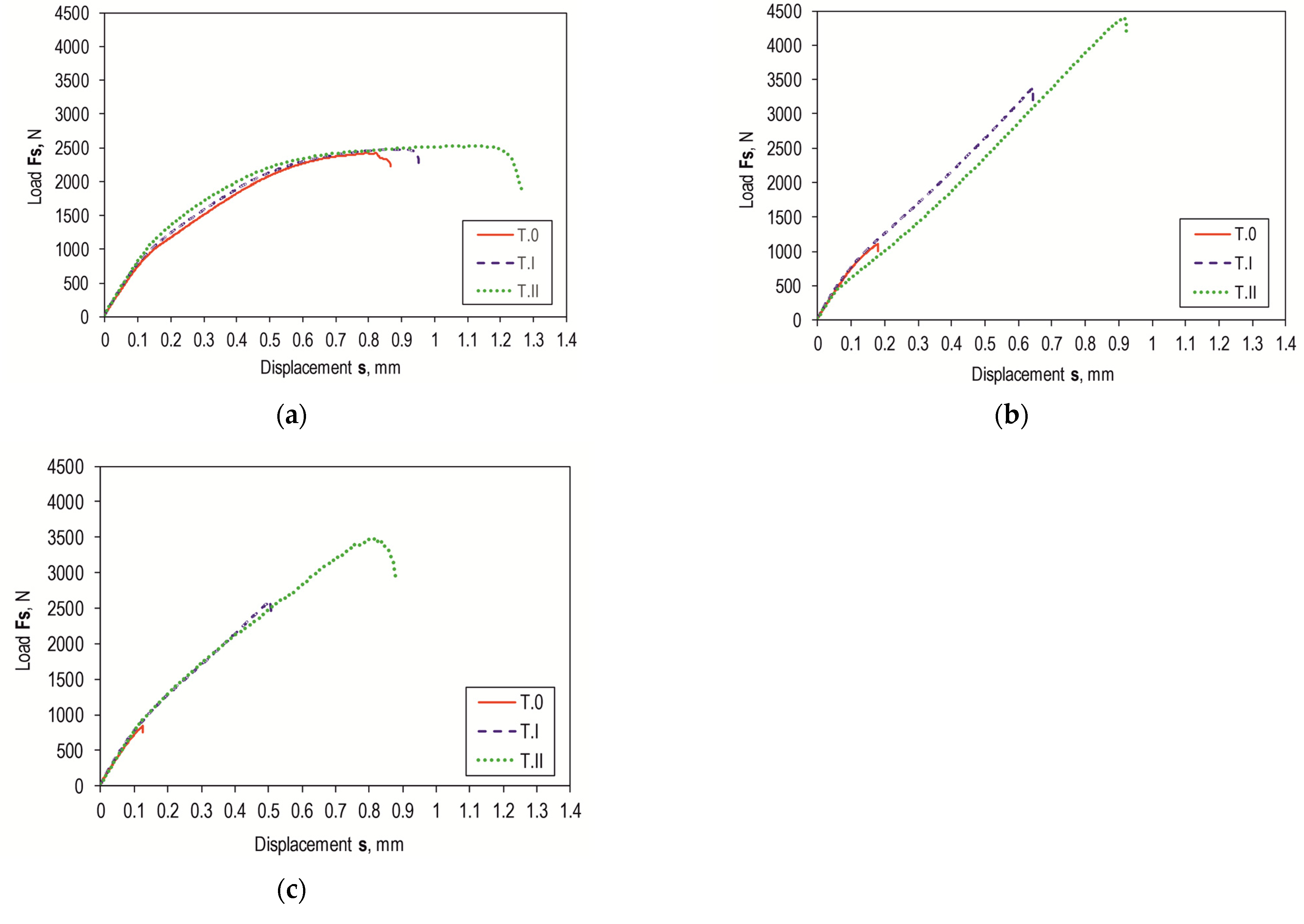

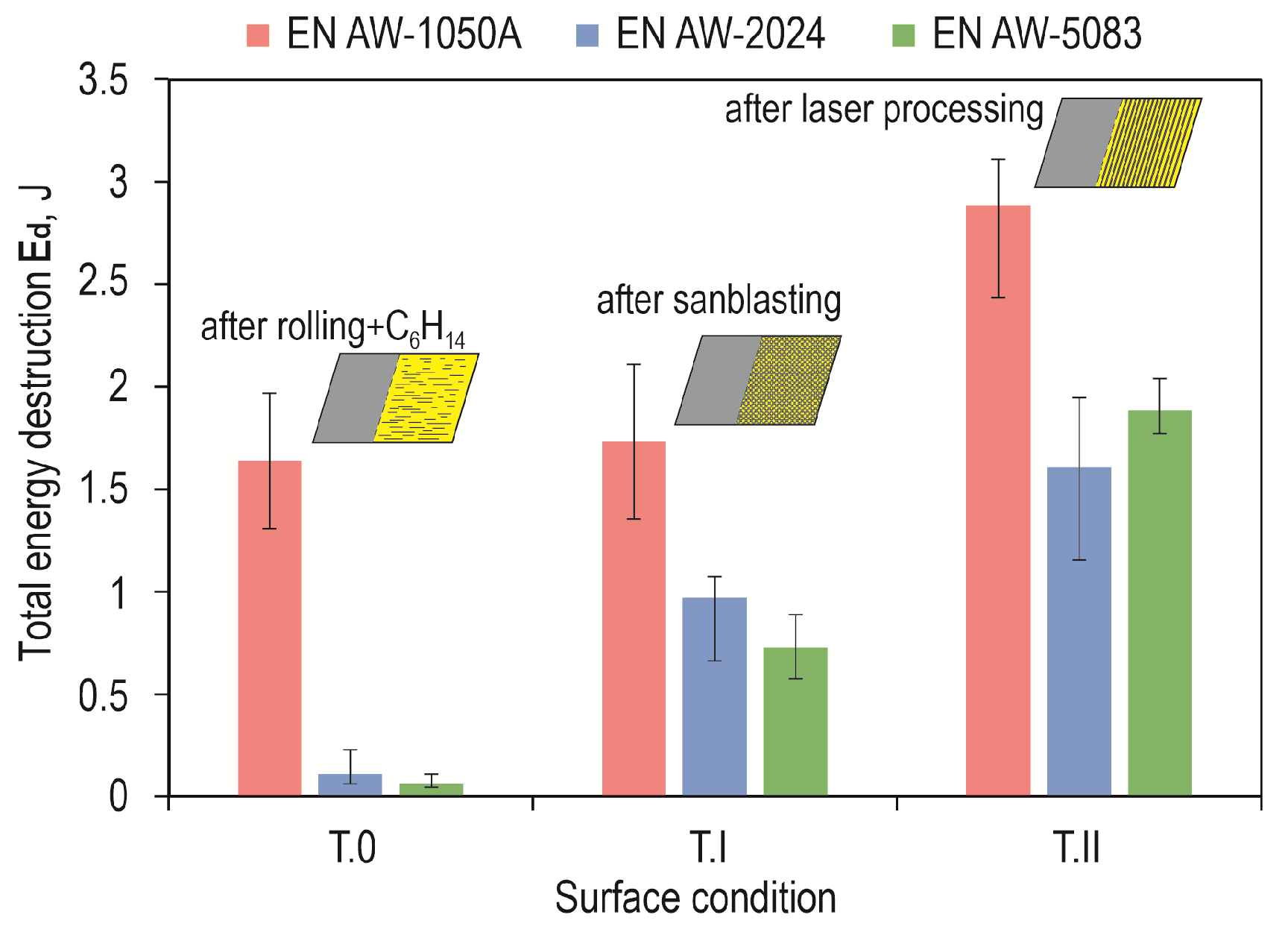

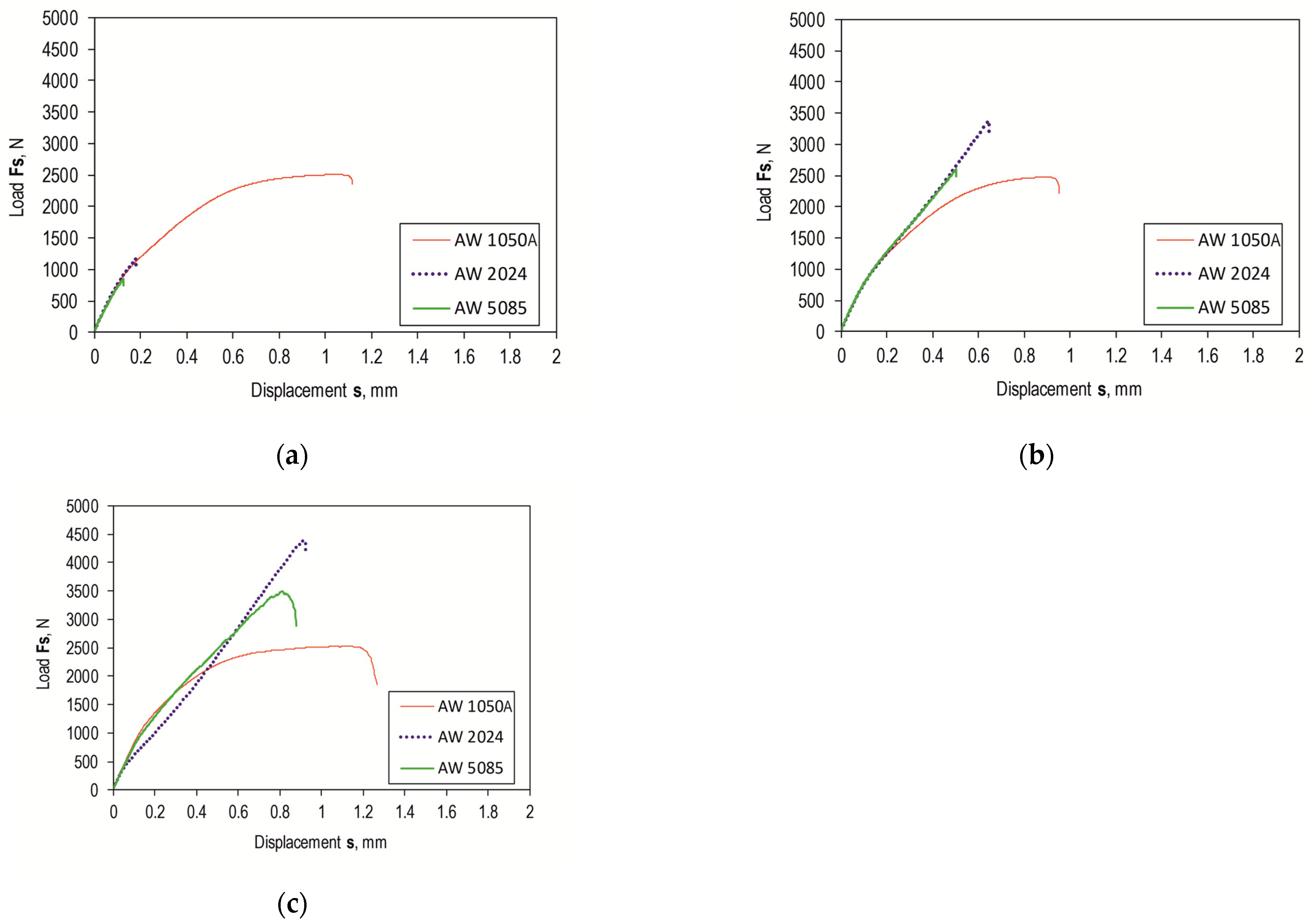

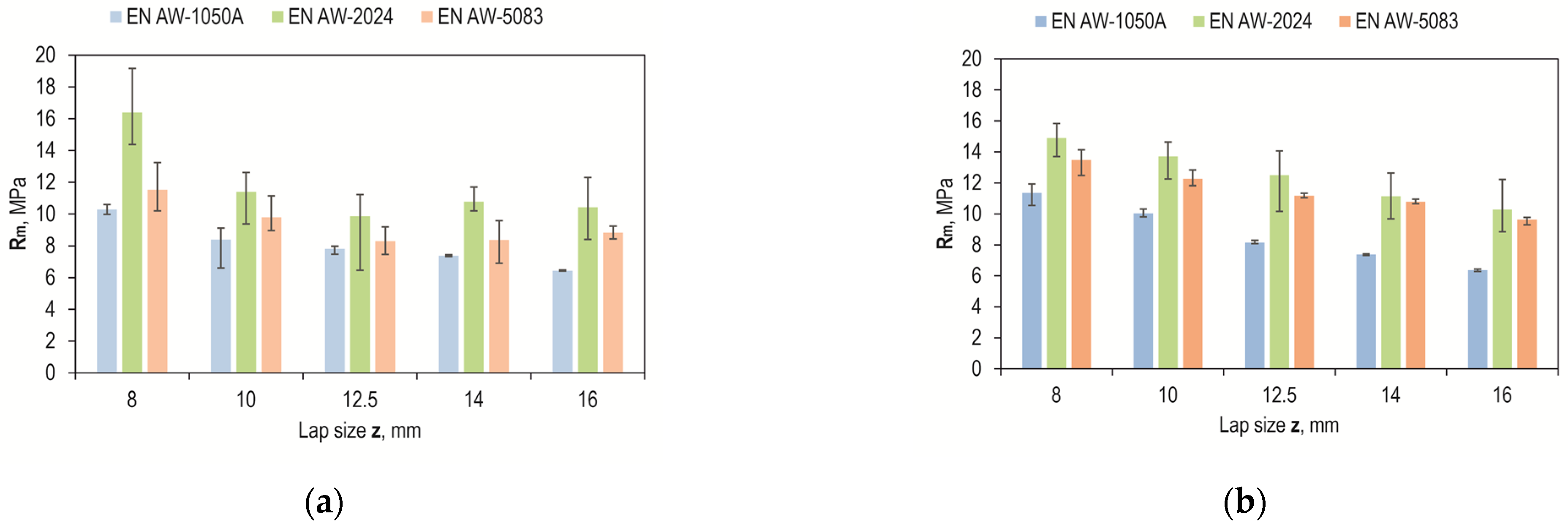

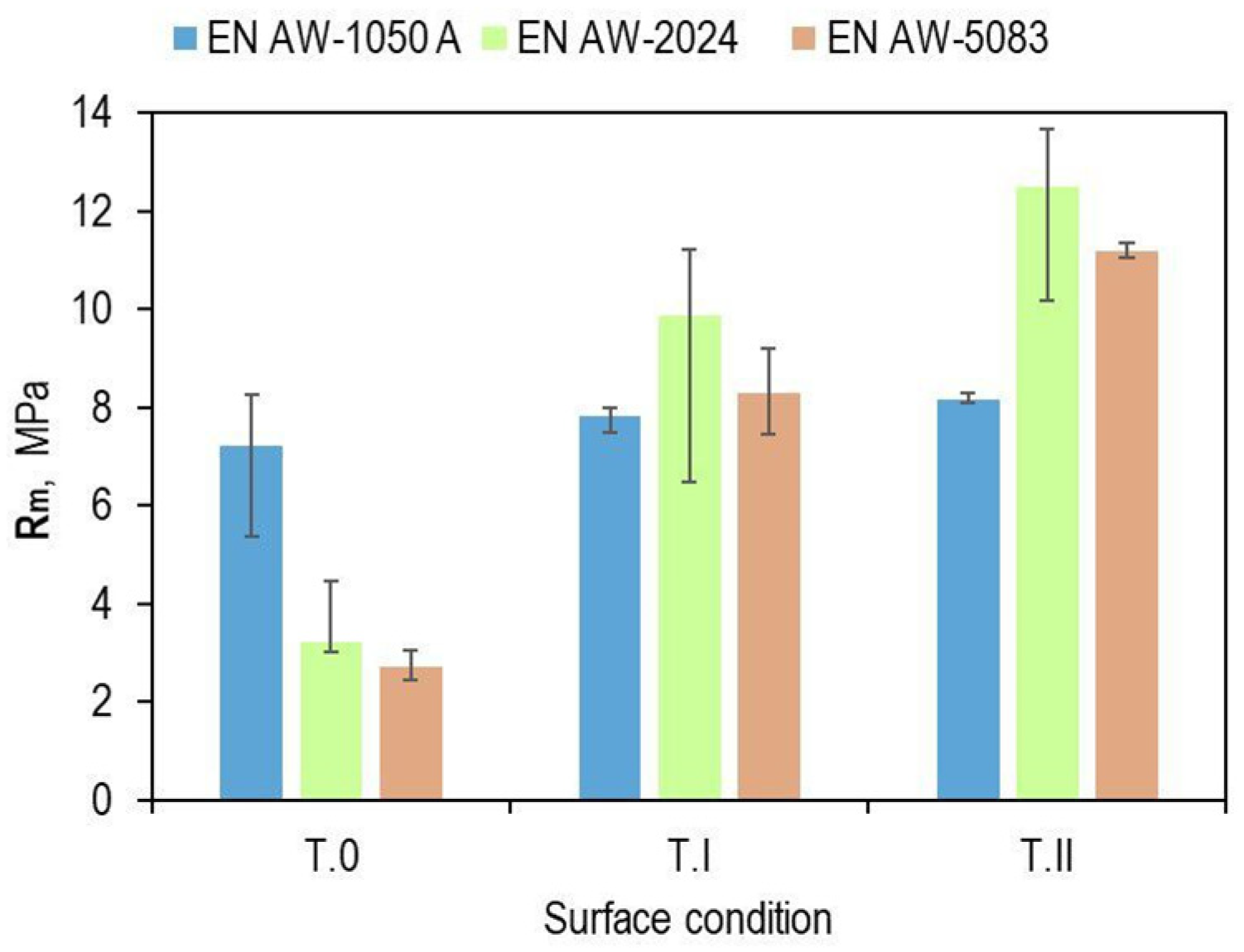

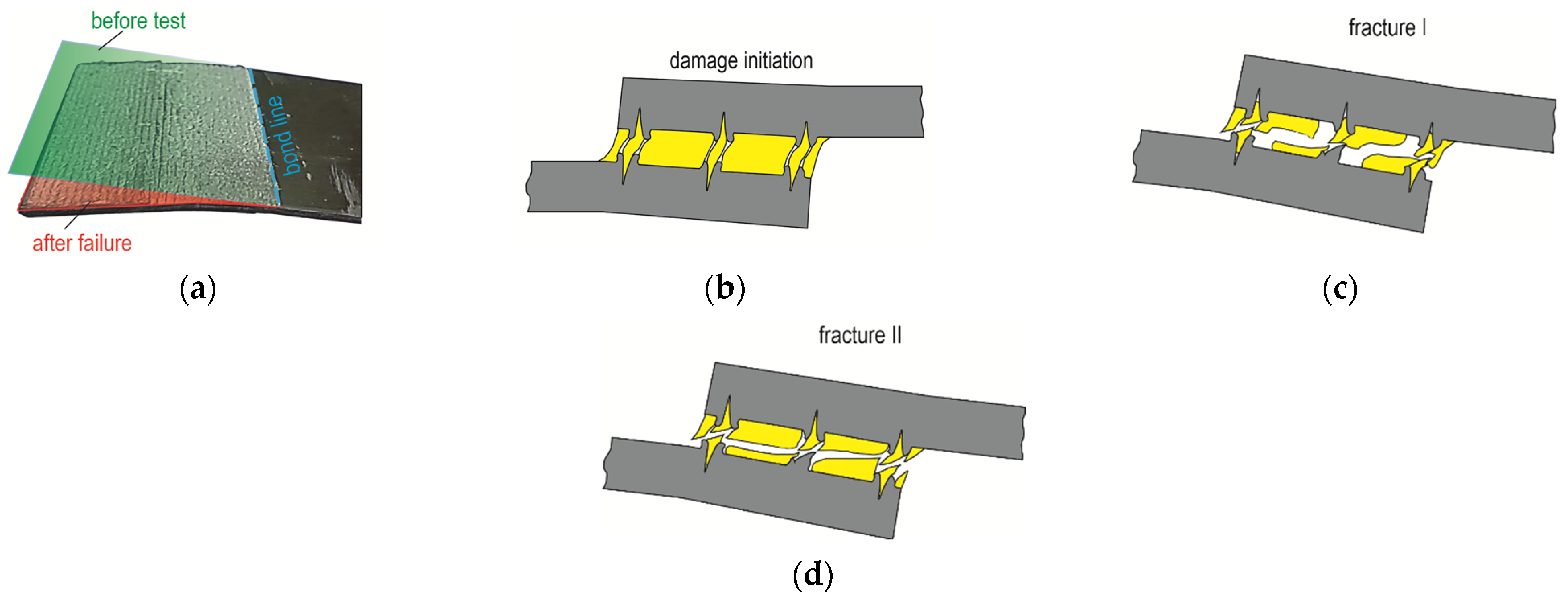

3.2. Load-Bearing Capacity of Lap Joints

3.3. Surface Characterization

4. Conclusions

- (1)

- The most reproducible shape of the material outflow at the edge of the created gap after laser treatment was obtained for the substrate from EN AW-5083. In this material, the gap was also the widest. The largest variation in the irregularity of the melt overflow occurred for the substrate with EN AW-1050A. The molten material moved back into the microcavity formed. The formed changes had the lowest repeatability.

- (2)

- Despite the preservation of the initial surface condition (without additional chemical cleaning) between the laser-textured grooves, the load-bearing capacity of the joint (the average maximum force that the joint can carry) was 10% for EN AW-1050A, 285% for EN AW-2024, and 296% for EN AW-5083.

- (3)

- Joints from EN AW-1050A showed the highest values of total joint failure energy. The mentioned material has the lowest yield strength. Adhesion bonds formed between the adhesive phase and the substrate were so strong that gradual bending of the overlap occurred during loading. As a result of the bending of the overlap in the adhesive layer, a normal force was generated in addition to the tangential force. The work of these forces during the load test of laser-treated joints was smallest for EN AW-2024.

- (4)

- Joints with EN AW-1050A, the surfaces of which were prepared via sandblasting, showed a strength (Rm) decreasing with the increasing overlap size. For the other two alloys, EN AW-2024 and EN AW-5083 had the lowest strength with a 12.5 mm overlap. In all cases, joints with an 8 mm overlap had the highest strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brockmann, W.; Geiß, P.L.; Klingen, J.; Schröder, B. Adhesive Bonding. Materials, Applications and Technology; Wiley-VCH Verlag GmbH & Co: Weinheim, Germany, 2009. [Google Scholar]

- Borselino, C.; Di Bella, G.; Ruisi, V.F. Adhesive joining of aluminium AA6082: The effects of resin and surface treatment. Int. J. Adhes. Adhes. 2009, 29, 36–44. [Google Scholar] [CrossRef]

- Adams, R.D. (Ed.) Adhesive Bonding: Science, Technology and Applications; Woodhead Publishing: Cambridge, UK, 2021. [Google Scholar]

- Klingen, J. Adhesive Bonging in Five Steps. Achieving Safe and High-Quality Bonds; Viley-VCH: Weinheim, Germany, 2022. [Google Scholar]

- Deb, A.; Malvade, I.; Biswa, P.; Schroeder, J. An experimental and analytical study of the mechanical behavior of adhesively bonded joints for variable extension rates and temperatures. Int. J. Adhes. Adhes. 2007, 29, 1–15. [Google Scholar]

- Dillard, D.A. (Ed.) Advances in Structural Adhesive Bonding; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Arenas, J.M.; Alía, C.; Narbón, J.J.; Ocaña, R.; González, C. Considerations for the industrial application of structural adhesive joints in the aluminium-composite material bonding. Compos. Part B 2013, 44, 417–423. [Google Scholar] [CrossRef]

- Encinas, N.; Oakley, B.R.; Belcher, M.A.; Blohowiak, K.Y.; Dillingham, R.G.; Abenojar, J.; Martínez, M.A. Surface modification of aircraft used composites for adhesive bonding. Int. J. Adhes. Adhes. 2014, 50, 157–163. [Google Scholar] [CrossRef]

- Miturska-Barańska, I.; Rudawska, A.; Doluk, E. The influence of sandblasting process parameters of aerospace aluminium alloy sheets on adhesive joints strength. Materials 2021, 14, 6626. [Google Scholar] [CrossRef]

- Maggiore, S.; Banea, M.D.; Stagnaro, P.; Luciano, G. A review of structural adhesive joints in hybrid joining processes. Polymers 2021, 13, 3961. [Google Scholar] [CrossRef]

- Habenicht, G. Applied Adhesive Bonding. A Practical Guide for Flawless Results; Viley-VCH: Weinheim, Germany, 2009. [Google Scholar]

- Petrie, E.M. Handbook of Adhesives and Sealants; McGraw-Hill Companies Inc.: New York, NY, USA, 2007. [Google Scholar]

- Antelo, J.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; Goyal, R.; da Silva, L.F.M. Replacing welding with adhesive bonding: An industrial case study. Int. J. Adhes. Adhes. 2022, 113, 103064. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Sinke, J. Adhesion properties of bonded composite-to-aluminium joints using peel tests. J. Adhes. 2014, 90, 511–525. [Google Scholar] [CrossRef]

- Zheng, R.; Lin, J.; Wang, P.-C.; Zhu, C.; Wu, Y. Effect of adhesive characteristics on static strength of adhesive-bonded aluminum alloys. Int. J. Adhes. Adhes. 2015, 57, 85–94. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Y. Influence of surface roughness and bondline thickness on the bonding performance of epoxy adhesive joints on mild steel substrates. Prog. Org. Coat. 2021, 153, 106135. [Google Scholar] [CrossRef]

- Paschek, D.; Luminosu, C.T.; Ocakci, E. Industry 5.0 challenges and perspectives for manufacturing systems in the society 5.0. In Sustainability and Innovation in Manufacturing Enterprises: Indicators, Models and Assessment for Industry 5.0; Draghici, A., Ivascu, L., Eds.; Springer: Singapore, 2022. [Google Scholar]

- Bayramoglu, S.; Demir, K.; Akpinar, S. Investigation of internal step and metal part reinforcement on joint strength in the adhesively bonded joint: Experimental and numerical analysis. Theor. Appl. Fract. Mech. 2020, 108, 102613. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, H.S.; Kwon, H. Effects of surface pre-treatment and void content on GLARE laminate process characteristics. J. Mater. Process. Technol. 2010, 210, 1008–1016. [Google Scholar] [CrossRef]

- Salgin, B.; Özkanat, O.; Mol, J.M.; Terryn, H.; Rohwerder, M. Role of surface oxide properties on the aluminum/epoxy interfacial bonding. J. Phys. Chem. C 2013, 117, 4480–4487. [Google Scholar] [CrossRef]

- Comyn, J. Adhesion Science; Royal Society of Chemistry, Croydon: London, UK, 2021. [Google Scholar]

- Xu, Y.; Li, H.; Shen, Y.; Liu, S.; Wang, W.; Tao, J. Improvement of adhesion performance between aluminum alloy sheet and epoxy based on anodizing technique. Int. J. Adhes. Adhes. 2016, 70, 74–80. [Google Scholar] [CrossRef]

- Zakaria, A.Z.; Shelesh-Nezhad, K.; Chakherlou, T.N.; Olad, A. Effects of aluminum surface treatments on the interfacial fracture toughness of carbon-fiber aluminum laminates. Eng. Fract. Mech. 2017, 172, 139–151. [Google Scholar] [CrossRef]

- Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/EC and repealing Council Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX%3A32006R1907 (accessed on 27 March 2024).

- Marques, A.C.; Mocanu, A.; Tomić, N.Z.; Balos, S.; Stammen, E.; Lundevall, A.; Abrahami, S.T.; Günter, R.; de Kok, J.M.M.; Teixeira de Freitas, S. Review on adhesives and surface treatments for structural applications: Recent developments on sustainability and implementation for metal and composite substrates. Materials 2020, 13, 5590. [Google Scholar] [CrossRef] [PubMed]

- Hamdi, M.; Saleh, M.N.; Poulis, J.A. Improving the adhesion strength of polymers: Effect of surface treatments. J. Adhes. Sci. Technol. 2020, 34, 1853–1870. [Google Scholar] [CrossRef]

- Ebnesajjad, S. Plasma treatment of polymeric materials. In Surface Treatment of Materials for Adhesive Bonding; William Andrew Publishing: New York, NY, USA, 2014; pp. 227–269. [Google Scholar]

- Kłonica, M. Application of the Ozonation Process for Shaping the Energy Properties of the Surface Layer of Polymer Construction Materials. J. Ecol. Eng. 2022, 23, 212–219. [Google Scholar] [CrossRef]

- Rudawska, A. The impact of the seasoning conditions on mechanical properties of modified and unmodified epoxy adhesive compounds. Polymers 2019, 11, 804. [Google Scholar] [CrossRef]

- Ciecińska, B.; Kubit, A. Analysis of selected properties of adhesive compositions with nanofillers. Assem Tech. Technol. 2017, 1, 34–38. [Google Scholar]

- Jojibabu, P.; Zhang, Y.X.; Prusty, B.G. A review of research advances in epoxy-based nanocomposites as adhesive materials. Int. J. Adhes. Adhes. 2020, 96, 102454. [Google Scholar] [CrossRef]

- Autumn, K.; Peattie, A. Mechanisms of Adhesion in Geckos. Integr. Comp. Biol. 2002, 42, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Tao, D.; Lu, H.; Bai, P.; Liu, Z.; Ma, L.; Meng, Y.; Tian, Y. Recent developments in gecko-inspired dry adhesive surfaces from fabrication to application. Surf. Topogr. Metrol. Prop. 2019, 7, 023001. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, S.; Li, B.; Yu, B.; Lee, H.; Cai, M.; Gorb, S.N.; Zhou, F.; Liu, W. Gecko’s Feet-Inspired Self-Peeling Switchable Dry/Wet Adhesive. Chem. Mater. 2021, 33, 2785–2795. [Google Scholar] [CrossRef]

- Tajti, F.; Berczeli, M.; Weltsch, Z. Optimizing Adhesion in Aluminum Alloys: A Cross-Disciplinary Approach to Surface Treatment and Bond Strength. SSRN. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4767278 (accessed on 25 March 2024).

- Correia, S.; Anes, V.; Reis, L. Effect of surface treatment on adhesively bonded aluminium-aluminium joints regarding aeronautical structures. Eng. Fail. Anal. 2018, 84, 34–45. [Google Scholar] [CrossRef]

- Grant, L.D.R.; Adams, R.D.; da Silva, L. Effect of the temperature on the strength of adhesively bonded single lap and T joints for the automotive industry. Int. J. Adhes. Adhes. 2009, 29, 535–542. [Google Scholar] [CrossRef]

- Zhu, C.; Wan, H.; Min, J.; Mei, Y.; Lin, J.; Carlson, B.E.; Maddela, S. Application of pulsed Yb: Fiber laser to surface treatment of Al alloys for improved adhesive bonded performance. Opt. Lasers Eng. 2019, 119, 65–76. [Google Scholar] [CrossRef]

- Min, J.; Wan, H.; Carlson, B.E.; Lin, J.; Sun, C. Application of laser ablation in adhesive bonding of metallic materials: A review. Opt. Laser Technol. 2020, 128, 106188. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, H.; Tan, C.; Zhu, B.; Xia, F.; Wang, Q.; Song, X. Effect of laser texturing on the surface characteristics and bonding property of 30CrMnSiA steel adhesive joints. J. Manuf. Process. 2019, 47, 219–228. [Google Scholar] [CrossRef]

- Andrabi, A.A.; Shelesh-Nezhad, K.; Chakherlou, T.N. The effect of laser surface structuring patterns on the interfacial resistance of aluminum joints bonded with epoxy adhesive. Int. J. Adhes. Adhes. 2022, 114, 103101. [Google Scholar] [CrossRef]

- Tang, M.; Shi, Y.; Zhu, W.; Zhang, N.; Zhang, L. A Convenient and High-Efficient Laser Micro-Engraving Treatment for Controllable Preparation of Microstructure on Al Alloy. Materials 2018, 11, 2297. [Google Scholar] [CrossRef] [PubMed]

- Ghobakhloo, M.; Iranmanesh, M.; Tseng, M.L.; Grybauskas, A.; Stefanini, A.; Amran, A. Behind the definition of Industry 5.0: A systematic review of technologies, principles, components, and values. J. Ind. Prod. Eng. 2023, 40, 432–447. [Google Scholar] [CrossRef]

- EN 573-3:2019; Aluminium and Aluminium Alloys—Chemical Composition and form of Wrought Products—Part 3: Chemical Composition and Form of Products. European Standard: Brussels, Belgium, 2019.

- EN 485-4:2000; Aluminium and Aluminium Alloys—Sheet, Strip and Plate—Part 4: Tolerances on Shape and Dimensions for Cold-Rolled Products. Technical Committee CEN/TC 132. European Standard: Brussels, Belgium, 2000.

- Technical Data Sheet—Araldite 2014-2 Structural Adhesives. Available online: https://www.huntsman.com (accessed on 23 February 2024).

- ISO 4288:2011; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. ISO: Geneva, Switzerland, 2011.

- Ciecińska, B.E. Using Lasers as Safe Alternatives for Adhesive Bonding. Emerging Research and Opportunities; IGI Global: Hershey, PA, USA, 2020. [Google Scholar]

- ISO 25178-2:2012; Geometrical Product Specifications (GPS). In Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2012.

- EN 2243-1:2006; Aerospace series—Non-Metallic Materials—Structural Adhesives—Test Method—Part 1: Single Lap Shear. European Standard: Brussels, Belgium, 2006.

| Material Designation | Element (Max Value) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mg | Mn | Fe | Si | Cu | Zn | Cr | Ti | Zr+Ti | Others | |

| EN AW-1050A | 0.05 | 0.05 | 0.4 | 0.25 | 0.05 | 0.07 | - | 0.05 | - | 0.03 |

| EN AW-2024 | 1.8 | 0.9 | 0.5 | 0.5 | 4.9 | 0.25 | 0.1 | 0.15 | 0.2 | 0.15 |

| EN AW-5083 | 4.9 | 1.0 | 0.4 | 0.4 | 0.1 | 0.25 | 0.25 | 0.15 | - | 0.15 |

| Material Designation | Heat-Treated Condition | Brinell Hardness, HB | Young’s Modulus E, GPa | Poisson’s Ratio ν | Yield Strength Rp0.2 (min.), MPa | Tensile Strength Rm (min.), MPa | Elongation after Fracture A50, % |

|---|---|---|---|---|---|---|---|

| EN AW-1050A | H24 | 33 | 69 | 0.33 | 75 | 105 | 4 |

| EN AW-2024 | T351 | 120 | 74 | 0.33 | 290 | 435 | 20 |

| EN AW-5083 | H111 | 75 | 71 | 0.33 | 125 | 275 | 12 |

| Adhesive | Young Modulus E, GPa | Shear Modulus G, GPa | Tensile Yield Strength Rm, MPa | Shear Yield Strength, MPa | Poisson Ratio, ν | Elongation at Break, % |

|---|---|---|---|---|---|---|

| Araldite 2014-2 | 3.1 | 1.2 | 30 | 22 | 0.33 | 0.9 |

| Al2O3 | SiO2 | Fe2O3 | Na2O |

|---|---|---|---|

| 99.20 | 0.08 | 0.06 | 0.35 |

| Material Grade | Lap z, mm | Surface Treatment | ||

|---|---|---|---|---|

| Without Texturing T.0 | Texturing | |||

| Electrocorundum T.I | Laser T.II | |||

| EN AW-1050A | 8 | - | x | x |

| 10 | - | x | x | |

| 12.5 | x | x | x | |

| 14 | - | x | x | |

| 16 | - | x | x | |

| EN AW-2024 | 8 | - | x | x |

| 10 | - | x | x | |

| 12.5 | x | x | x | |

| 14 | - | x | x | |

| 16 | - | x | x | |

| EN AW-5083 | 8 | - | x | x |

| 10 | - | x | x | |

| 12.5 | x | x | x | |

| 14 | - | x | x | |

| 16 | - | x | x | |

| Parameter | Material | Values of Parameters, μm | |||

|---|---|---|---|---|---|

| Standard Value | Mean Deviation | Standard Deviation | Standard Deviation of the Mean Value | ||

| Ra | EN AW-1050A | 0.186 | 0.171 | 0.005 | 0.002 |

| EN AW-2024 | 0.181 | 0.176 | 0.004 | 0.001 | |

| EN AW-5083 | 0.136 | 0.131 | 0.003 | 0.002 | |

| Rz | EN AW-1050A | 1.681 | 1.495 | 0.038 | 0.017 |

| EN AW-2024 | 2.341 | 2.123 | 0.012 | 0.008 | |

| EN AW-5083 | 1.28 | 1.16 | 0.006 | 0.003 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciecińska, B.; Mucha, J.; Bąk, Ł. Analysis of the Effect of Surface Preparation of Aluminum Alloy Sheets on the Load-Bearing Capacity and Failure Energy of an Epoxy-Bonded Adhesive Joint. Materials 2024, 17, 1948. https://doi.org/10.3390/ma17091948

Ciecińska B, Mucha J, Bąk Ł. Analysis of the Effect of Surface Preparation of Aluminum Alloy Sheets on the Load-Bearing Capacity and Failure Energy of an Epoxy-Bonded Adhesive Joint. Materials. 2024; 17(9):1948. https://doi.org/10.3390/ma17091948

Chicago/Turabian StyleCiecińska, Barbara, Jacek Mucha, and Łukasz Bąk. 2024. "Analysis of the Effect of Surface Preparation of Aluminum Alloy Sheets on the Load-Bearing Capacity and Failure Energy of an Epoxy-Bonded Adhesive Joint" Materials 17, no. 9: 1948. https://doi.org/10.3390/ma17091948