Welding and Joining of Titanium Aluminides

Abstract

:1. Introduction

2. Brazing of Titanium Aluminides

2.1. Brazing of Titanium Aluminides Using Ti-Based Filler Metal

| Filler metal | Composition (wt%) | Solidus temperature (°C) | Liquidus temperature (°C) | Brazing temperature (°C) | References | |||

|---|---|---|---|---|---|---|---|---|

| Ti | Ni | Cu | Other | |||||

| Ti-Ni | 67 | 33 | – | – | 942 | 980 | 980–1000 | [33] |

| Ti-Cu-Ni | 60 | 25 | 15 | – | 901 | 914 | 930–970 | [17,32] |

| 70 | 15 | 15 | – | 910 | 960 | 1100–1200 | [17,22,31,32,34,36,43] | |

| Ti-Ni-Nb | 31 | 38 | – | 31-Nb | – | 1148 | 1160–1260 | [42] |

| Ti-Ni-V | 34 | 42 | – | 24-V | – | 1142 | 1180–1260 | [30] |

| Ti-Ni-B | 33 | 64 | – | 3-B | – | 1120 | 1180 | [44] |

| Ti-Ni-Cu-Zr | 52 | 23 | 12 | 13-Zr | 809 | 858 | 900 | [29] |

| Substrate | Filler Metal | Strength (MPa) | Brazing Parameters | Fracture Position | Brazing Method | References |

|---|---|---|---|---|---|---|

| Ti3Al/Ti-6Al-4V | Ti-15Cu-25Ni | 304 | 930 °C/180 s | Ti2Ni | Infrared | [17] |

| Ti-15Cu-15Ni | 373 | 970 °C/600 s | Ti2Ni | Infrared | ||

| Ti48Al-2Cr-2 Nb/40Cr steel | Ti-23Ni-12Cu-13Zr | 32 | 900 °C/900 s | brazed seam | Furnace | [29] |

| Ti-42.5Al-9V-0.3Y | Ti-42Ni-24V | 196 | 1220 °C/600 s | τ3-Al3NiTi2 | Furnace | [30] |

| Ti-46Al-4(Cr, Nb, B) | Ti-15Cu-15Ni | 220–230 | 1040 °C/600 s | – | Furnace | [31] |

| Ti50Al50/Ti-6Al-4V | Ti-15Cu-25Ni | 189 | 970 °C/300 s | Ti2Ni, Ti3Al | Infrared | [32] |

| Ti-15Cu-15Ni | 280 | 970 °C/1200 s | – | Infrared | ||

| Ti-48Al-2Nb-2Cr | Ti-15Cu-15Ni | 319–322 | 1100–1200 °C/30–60 s | Substrate | Infrared | [34] |

| Ti-45Al-5Nb-(W, B, Y) | Ti-38Ni-31Nb | 308 | 1220°C/600 s | Substrate | Furnace | [42] |

| Ti-43Al-9V-0.3Y/C/SiC composite | (TiH2-66Ni)97B3 | 105 | 1180 °C/600 s | C/SiC substrate | Furnace | [44] |

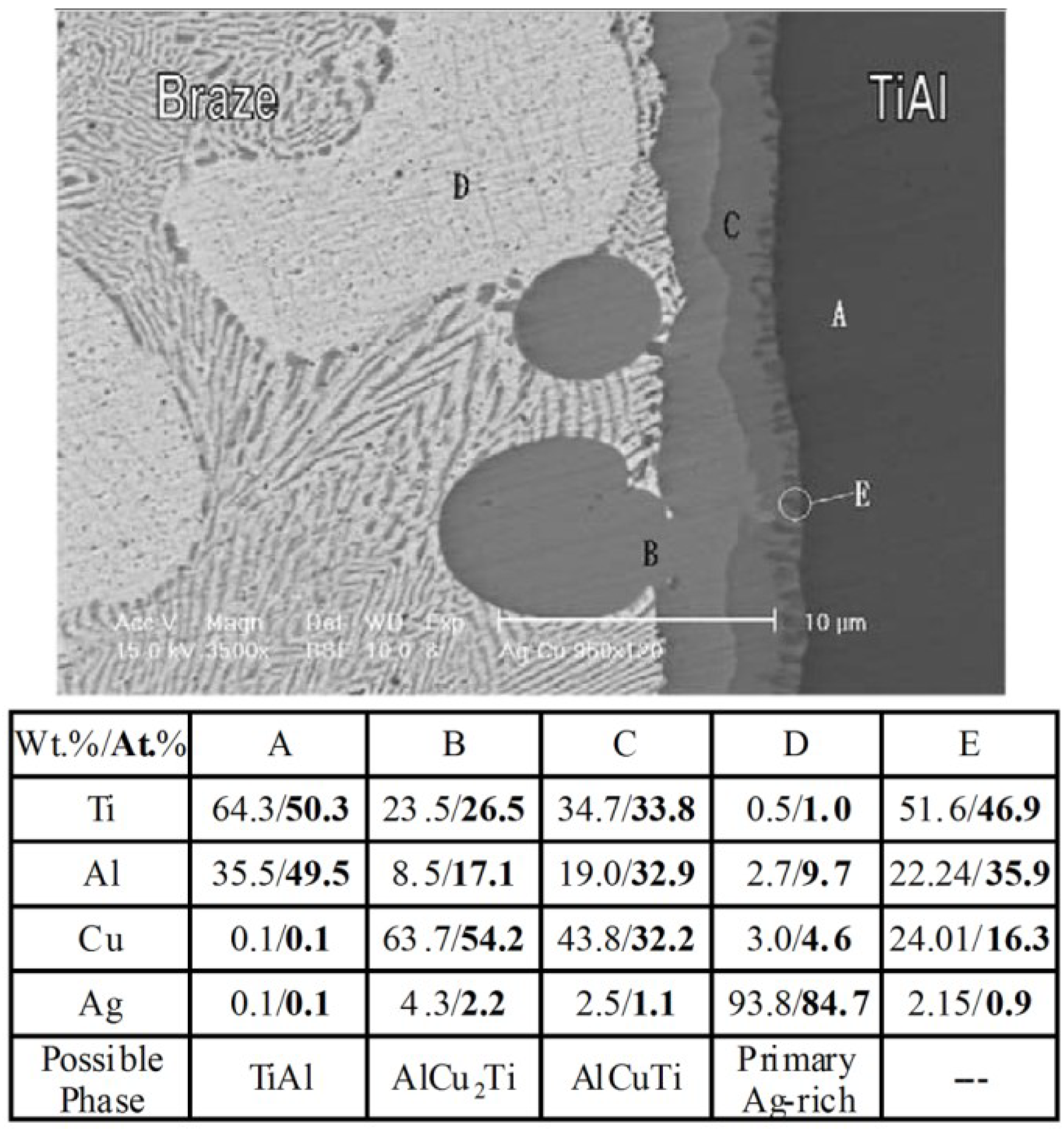

2.2. Brazing of Titanium Aluminides Using Ag-Based Filler Metal

| Substrate | Filler Metal | Strength (MPa) | Brazing Parameters | Fracture Position | Brazing Method | References |

|---|---|---|---|---|---|---|

| Ti-46Al-2Cr-2Nb/C/C composite | Ag-26.7Cu-4.6Ti | 12.9 | 900 °C/600 s | TiC layer | Furnace | [13] |

| Ti-33.5Al-1.0Nb-0.5Cr-0.5Si/AISI4340 | Ag-35.2Cu-1.8Ti | 320 | – | – | Infrared | [14] |

| Ti50Al50 | BAg-8 | 343 | 950 °C/60 s | braze | Infrared | [15] |

| Pure Ag | >385 | 1050 °C/30–180 s | substrate | Infrared | [46] | |

| Ti-47Al/AISI 4140 | AgCu + Ti | 294 | 800°C/60 s | 84% AlCu2Ti + AlCuTi layers | Infrared | [37] |

| TiAl48Cr2Nb2 | Ag-28Cu | 149 | 900 °C/60 s | – | Furnace | [45] |

| Ti-47.5Al-2.5V/Si3N4 ceramics | AgCu | 124.6 | 850 °C/300 s | – | Furnace | [47] |

| Ti-48Al-2Cr-2Nb/35CrMo | Ag-Cu35.2-Ti1.8 | 320 | 870 °C/300 s | Al-Cu-Ti layer | Furnace | [48] |

| Ti-46.5Al-2.5V-1.0Cr/42CrMo | Ag-33Cu-4.5Ti | 347 | 900 °C/300 s | AlCu2Ti phase | Furnace | [49] |

2.3. Brazing of Titanium Aluminides Using Other Kinds of Filler Metal

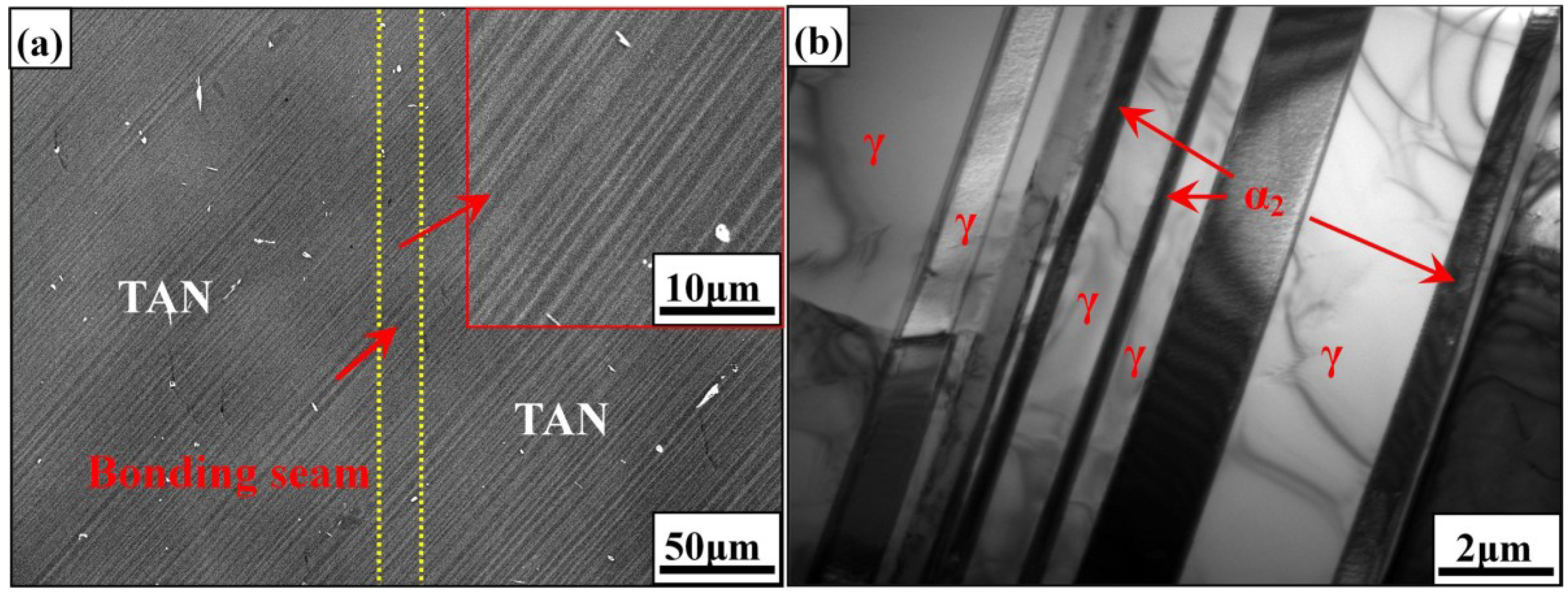

3. Diffusion Bonding of Titanium Aluminides

3.1. Diffusion Bonding of Titanium Aluminides to Themselves

| Substrate | Interlayer | Strength (MPa) | Bonding Parameters | Fracture Position | References | |

|---|---|---|---|---|---|---|

| Joint | Substrate | |||||

| Ti-47Al-4.5 (Cr, Mn, Nb, Si, B) | – | 373 | 430 | 1100 °C/20 MPa/10.8 ks | Substrate | [23] |

| 453 | 475 | 1100 °C/20 MPa/10.8 ks with 1430 °C/1.8 ks PBHT | Substrate | |||

| Ti-48Al-3.7 (Nb, Cr, C) | – | 388 | 1398 * | 1000 °C/10 MPa/18 ks | Substrate | [65] |

| 580 | – | 1000 °C/20 MPa/3.6 ks with 1430 °C for 1.8 ks PBHT | Substrate | |||

| Ti-46.5Al-2Cr-1.5 Nb-1V | – | 384 | 468 | laser surface melting 900 °C/60 MPa/7.2 ks | Substrate | [72] |

| γ-TiAl | 14 nm period Ni/Al multilayer | 314 | – | 900 °C/5 MPa/3.6 ks | Reaction layer | [73] |

| TiAl | hydrogenated Ti6Al4V interlayer | 290 | – | 850 °C/15 MPa/900 s | Bonding zone | [74] |

| Ti-45Al-5Nb | 14 nm period Ni/Al multilayer with Ti and Ni foils | 38 | – | 900 °C/5 MPa/1.8 ks | Interface | [76] |

| Ti-47Al-2Cr-0.2Si | – | 555 * | 602 * | 1000 °C/40 MPa/18 ks | Outside of bonding zone | [78] |

3.2. Diffusion Bonding of Titanium Aluminides to Other Materials

| Substrate | Interlayer | Joint Strength (MPa) | Bonding Parameters | Fracture Position | References |

|---|---|---|---|---|---|

| IMI 384 Ti alloy/IHI 01A γ-TiAl | – | >400 * | 900 °C/200 MPa/3.6 ks | Interface | [85] |

| TiAl/Ti-17 | – | >410 * | 1000 °C/9.8 MPa/3.6 ks | TiAl substrate | [87] |

| Ti-36Al/Eutectoid Steel | – | 160 | 800 °C/3.6 ks | Interface | [89] |

| TiAl/Steel | – | 420 * | 1000 °C/20 MPa/1.2 ks | TiAl3 and TiAl layer | [90] |

| Ti-46Al-2Cr-2Nb/Ti3AlC2 | Ti/Ni foils | 151.6 | 920 °C/30 MPa/3.6 ks | Intermetallic layer | [92] |

| Zr/Ni foils | 103.6 | 850 °C/30 MPa/3.6 ks | Ceramic substrate | [93] | |

| Ti-46.5Al-2.5V-2Cr-1.5Nb/Ti-6Al-4V | – | BSR > 80% # | 900 °C/100 MPa/7.2 ks | Outside of bonding zone | [99] |

| Ti-43Al-1.7Cr-1.7Nb/SiC | – | 240 | 1300 °C/35 MPa/900 s | (Ti5Si3Cx + TiC) layer | [100] |

| Ti-37.8Al-1.4Cr-1.4V/GH99 | Ti6Al4V-0.5H foil | 259 | 850 °C/20 MPa/1.8 ks | Bonding zone | [101] |

4. Fusion Welding of Titanium Aluminides

5. Joining of Titanium Aluminides by Other Methods

6. Conclusions

Acknowledgments

Conflicts of Interest

References

- Loria, E.A. Quo vadis gamma titanium aluminide. Intermetallics 2001, 9, 997–1001. [Google Scholar] [CrossRef]

- Noda, T. Application of cast gamma TiAl for automobiles. Intermetallics 1998, 6, 709–713. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Jia, Y.; Xiao, S.L.; Tian, J.; Xu, L.J. Review of the investment casting of TiAl-based intermetallic alloys. Acta Metall. Sin. 2013, 49, 1281–1285. [Google Scholar]

- Liu, B.; Liu, Y.; Li, Y.P.; Zhang, W.; Chiba, A. Thermomechanical characterization of beta-stabilized Ti-45Al-7Nb-0.4W-0.15B alloy. Intermetallics 2011, 19, 1184–1190. [Google Scholar] [CrossRef]

- Tetsui, T. Development of a TiAl turbocharger for passenger vehicles. Mater. Sci. Eng. A 2002, 329, 582–588. [Google Scholar] [CrossRef]

- Yang, J.R.; Chen, R.R.; Ding, H.S.; Guo, J.J.; Han, J.C.; Fu, H.Z. Heat transfer and macrostructure formation of Nb containing TiAl alloy directionally solidified by square cold crucible. Intermetallics 2013, 42, 184–191. [Google Scholar] [CrossRef]

- Lasalmonie, A. Intermetallics: Why is it so difficult to introduce them in gas turbine engines? Intermetallics 2006, 14, 1123–1129. [Google Scholar] [CrossRef]

- Ding, X.F.; Lin, J.P.; Zhang, L.Q.; Su, Y.Q.; Chen, G.L. Microstructural control of TiAl-Nb alloys by directional solidification. Acta Mater. 2012, 60, 498–506. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.; Zhang, W.; Huang, J.S. Hot deformation behavior of TiAl alloys prepared by blended elemental powders. Intermetallics 2011, 19, 154–159. [Google Scholar] [CrossRef]

- Threadgill, P.L. The prospects for joining titanium aluminides. Mater. Sci. Eng. A 1995, 192, 640–646. [Google Scholar] [CrossRef]

- Cam, G.; Clemens, H.; Gerling, R.; Kocak, M. Diffusion bonding of gamma-TiAl sheets. Intermetallics 1999, 7, 1025–1031. [Google Scholar] [CrossRef]

- Lee, W.B.; Kim, M.G.; Koo, J.M.; Kim, K.K.; Quesnel, D.J.; Kim, Y.J.; Jung, S.B. Friction welding of TiAl and AISI4140. J. Mater. Sci. 2004, 39, 1125–1128. [Google Scholar] [CrossRef]

- Wang, H.Q.; Cao, J.; Feng, J.C. Brazing mechanism and infiltration strengthening of CC composites to TiAl alloys joint. Scr. Mater. 2010, 63, 859–862. [Google Scholar] [CrossRef]

- Noda, T.; Shimizu, T.; Okabe, M.; Iikubo, T. Joining of TiAl and steels by induction brazing. Mater. Sci. Eng. A 1997, 240, 613–618. [Google Scholar]

- Shiue, R.K.; Wu, S.K.; Chen, S.Y. Infrared brazing of TiAl intermetallic using BAg-8 braze alloy. Acta Mater. 2003, 51, 1991–2004. [Google Scholar] [CrossRef]

- Feng, J.C.; Wu, H.Q.; He, J.S.; Zhang, B.G. Microstructure evolution of electron beam welded Ti3Al-Nb joint. Mater. Charact. 2005, 54, 99–105. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, Y.T. Strong bonding of infrared brazed alpha(2)-Ti3Al and Ti-6Al-4V using Ti-Cu-Ni fillers. Intermetallics 2010, 18, 107–114. [Google Scholar] [CrossRef]

- Acoff, V.L.; Wilkerson, S.; Arenas, M. The effect of rolling direction on the weld structure and hardness of gamma-TiAl sheet material. Mater. Sci. Eng. A 2002, 329, 763–767. [Google Scholar]

- Kuwahara, G.; Yamaguchi, S.; Nanri, K.; Ootani, M.; Seto, S.; Arai, M.; Fujioka, T. CO2 laser welding of titanium aluminide intermetallic compound. Proc. SPIE 2000, 3888, 411–417. [Google Scholar] [CrossRef]

- Reisgen, U.; Olschok, S.; Backhaus, A. Electron beam welding of titanium aluminides—Influence of the welding parameters on the weld seam and microstructure. Mater. Werkst. 2010, 41, 897–907. [Google Scholar] [CrossRef]

- Cao, J.; He, P.; Wang, M. Mechanical milling of Ti-Ni-Si filler metal for brazing TiAl intermetallics. Intermetallics 2011, 19, 855–859. [Google Scholar] [CrossRef]

- Guedes, A.; Pinto, A.M.P.; Vieira, M.F.; Viana, F. Joining Ti-47Al-2Cr-2Nb with a Ti/(Cu,Ni)/Ti clad-laminated braze alloy. J. Mater. Sci. 2003, 38, 2409–2414. [Google Scholar] [CrossRef] [Green Version]

- Cam, G.; Kocak, M. Diffusion bonding of investment cast gamma-TiAl. J. Mater. Sci. 1999, 34, 3345–3354. [Google Scholar] [CrossRef]

- Ustinov, A.I.; Falchenko, Y.V.; Ishchenko, A.Y.; Kharchenko, G.K.; Melnichenko, T.V.; Muraveynik, A.N. Diffusion welding of gamma-TiAl based alloys through nano-layered foil of Ti/Al system. Intermetallics 2008, 16, 1043–1045. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater. Des. 2009, 30, 469–474. [Google Scholar] [CrossRef]

- Lee, W.B.; Kim, Y.J.; Jung, S.B. Effects of copper insert layer on the properties of friction welded joints between TiAl and AISI 4140 structural steel. Intermetallics 2004, 12, 671–678. [Google Scholar] [CrossRef]

- Cao, J.; Feng, J.C.; Li, Z.R. Effect of reaction heat on reactive joining of TiAl intermetallics using Ti-Al-C interlayers. Scr. Mater. 2007, 57, 421–424. [Google Scholar] [CrossRef]

- Uenishi, K.; Sumi, H.; Kobayashi, K.F. Joining of the intermetallic compound Tial using self-propagating high-temperature synthesis reaction. Z. Metallkd 1995, 86, 64–68. [Google Scholar]

- Dong, H.G.; Yang, Z.L.; Yang, G.S.; Dong, C. Vacuum brazing of TiAl alloy to 40Cr steel with Ti60Ni22Cu10Zr8 alloy foil as filler metal. Mater. Sci. Eng. A 2013, 561, 252–258. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Chen, H.Y.; Wang, Y.F.; Feng, J.C. Brazing TiAl intermetallics using TiNi-V eutectic brazing alloy. Mater. Sci. Eng. A 2012, 551, 133–139. [Google Scholar] [CrossRef]

- Wallis, I.C.; Ubhi, H.S.; Bacos, M.P.; Jossob, P.; Lindqvistc, J.; Lundstromc, D.; Wisbeya, A. Brazed joints in gamma TiAl sheet: Microstructure and properties. Intermetallics 2004, 12, 303–316. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, Y.T.; Shiue, C.Y. Infrared brazing of Ti50Al50 and Ti-6Al-4V using two Ti-based filler metals. Intermetallics 2008, 16, 1083–1089. [Google Scholar] [CrossRef]

- Tetsui, T. Effects of brazing filler on properties of brazed joints between TiAl and metallic materials. Intermetallics 2001, 9, 253–260. [Google Scholar] [CrossRef]

- Lee, S.J.; Wu, S.K. Infrared joining strength and interfacial microstructures of Ti-48Al-2Nb-2Cr intermetallics using Ti-15Cu-15Ni foil. Intermetallics 1999, 7, 11–21. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, S.Y. Infrared brazing of TiAl using Al-based braze alloys. Intermetallics 2003, 11, 661–671. [Google Scholar] [CrossRef]

- Blue, C.A.; Blue, R.A.; Lin, R.Y. Microstructural evolution in joining of tial with a liquid Ti Alloy. Scr. Metall. Mater. 1995, 32, 127–132. [Google Scholar] [CrossRef]

- Koo, J.M.; Lee, W.B.; Kim, M.G.; Kim, D.U.; Kim, Y.J.; Jung, S.B. Induction brazing of gamma-TiAl to alloy steel AISI 4140 using filler metal of eutectic Ag-Cu alloy coated with Ti film. Mater. Trans. 2005, 46, 303–308. [Google Scholar] [CrossRef]

- Liu, H.J.; Feng, J.C.; Qian, Y.Y. Microstructure and strength of the SiC/TiAl joint brazed with Ag-Cu-Ti filler metal. J. Mater. Sci. Lett. 2000, 19, 1241–1242. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Wang, Y.F.; Feng, J.C. Effect of Si3N4-particles addition in Ag-Cu-Ti filler alloy on Si3N4/TiAl brazed joint. Mater. Sci. Eng. A 2011, 528, 5135–5140. [Google Scholar] [CrossRef]

- He, P.; Feng, J.C.; Zhou, H. Microstructure and strength of brazed joints of Ti3Al-base alloy with NiCrSiB. Mater. Charact. 2004, 52, 309–318. [Google Scholar] [CrossRef]

- He, P.; Feng, J.C.; Xu, W. Interfacial microstructure of induction brazed joints of TiAl-based intermetallics to steel 35CrMo with AgCuNiLi filler. Mater. Sci. Eng. A 2005, 408, 195–201. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Liu, Y.Z.; Feng, J.C. Brazing high Nb containing TiAl alloy using TiNi-Nb eutectic braze alloy. Intermetallics 2012, 22, 136–141. [Google Scholar] [CrossRef]

- Lee, S.J.; Wu, S.K.; Lin, R.Y. Infrared joining of TiAl intermetallics using Ti-15Cu-15Ni foil—I. The microstructure morphologies of joint interfaces. Acta Mater. 1998, 46, 1283–1295. [Google Scholar] [CrossRef]

- Yang, Z.W.; Zhang, L.X.; Tian, X.Y.; Liu, Y.Z.; He, P.; Peng, J.C. Interfacial microstructure and mechanical properties of TiAl and C/SiC joint brazed with TiH2-Ni-B brazing powder. Mater. Charact. 2013, 79, 52–59. [Google Scholar] [CrossRef]

- Mirski, Z.; Rozanski, M. Diffusion brazing of titanium aluminide alloy based on TiAl (gamma). Arch. Civ. Mech. Eng. 2013, 13, 415–421. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, S.Y. Infrared brazing of TiAl intermetallic using pure silver. Intermetallics 2004, 12, 929–936. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Li, C.; Feng, J.C. Interfacial microstructure and joining properties of TiAl/Si3N4 brazed joints. Mater. Sci. Eng. A 2011, 528, 7030–7035. [Google Scholar] [CrossRef]

- He, P.; Feng, J.C.; Xu, W. Mechanical property of induction brazing TiAl-based intermetallics to steel 35CrMo using AgCuTi filler metal. Mater. Sci. Eng. A 2006, 418, 45–52. [Google Scholar] [CrossRef]

- Li, Y.L.; He, P.; Feng, J.C. Interface structure and mechanical properties of the TiAl/42CrMo steel joint vacuum brazed with Ag-Cu/Ti/Ag-Cu filler metal. Scr. Mater. 2006, 55, 171–174. [Google Scholar] [CrossRef]

- Li, Y.L.; Liu, W.; Sekulic, D.P.; He, P. Reactive wetting of AgCuTi filler metal on the TiAl-based alloy substrate. Appl. Surf. Sci. 2012, 259, 343–348. [Google Scholar] [CrossRef]

- Gale, W.F.; Butts, D.A. Transient liquid phase bonding. Sci. Technol. Weld. Join. 2004, 9, 283–300. [Google Scholar] [CrossRef]

- Duan, H.; Kocak, M.; Bohm, K.H.; Ventzke, V. Transient liquid phase (TLP) bonding of TiAl using various insert foils. Sci. Technol. Weld. Join. 2004, 9, 513–518. [Google Scholar] [CrossRef]

- Lin, T.S.; Li, H.X.; He, P.; Wei, H.M.; Li, L.; Feng, J.C. Microstructure evolution and mechanical properties of transient liquid phase (TLP) bonded joints of TiAl intermetallics. Intermetallics 2013, 37, 59–64. [Google Scholar] [CrossRef]

- Butts, D.A.; Gale, W.F. Transient liquid phase bonding of Gamma Met PX: Microstructure and mechanical properties. Mater. Sci. Technol. 2008, 24, 1492–1500. [Google Scholar] [CrossRef]

- Zhou, T.; Gale, W.F. Modelling wide gap TLP bonding of Ti-48 at%Al-2 at%Cr-2 at%Nb alloys. Mater. Sci. Technol. 2003, 19, 1084–1090. [Google Scholar] [CrossRef]

- Zou, G.S.; Me, E.H.; Bai, H.L.; Wu, A.P.; Wang, Q.; Ren, J.L. A study on transient liquid phase diffusion bonding of Ti-22Al-25Nb alloy. Mater. Sci. Eng. A 2009, 499, 101–105. [Google Scholar] [CrossRef]

- Xiong, H.-P.; Mao, W.; Xie, Y.-H.; Ma, W.-L.; Chen, Y.-F.; Li, X.-H.; Li, J.-P.; Cheng, Y.-Y. Liquid-phase siliconizing by Al-Si alloys at the surface of a TiAl-based alloy and improvement in oxidation resistance. Acta Mater. 2004, 52, 2605–2620. [Google Scholar] [CrossRef]

- Chaudhari, G.P.; Acoff, V.L. Titanium aluminide sheets made using roll bonding and reaction annealing. Intermetallics 2010, 18, 472–478. [Google Scholar] [CrossRef]

- Zhang, J.L. Synthesis of gamma-TiAl foils and sheets by innovative reactive diffusion methods from elemental Ti and Al. Intermetallics 2010, 18, 2292–2300. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Liu, J.K.; Zhao, L.Y.; Feng, J.C. Reaction-diffusion bonding of high Nb containing TiAl alloy. Rare Met. Mater. Eng. 2014, 43, 28–31. [Google Scholar] [CrossRef]

- Uenishi, K.; Kobayashi, K.F. Processing of intermetallic compounds for structural applications at high temperature. Intermetallics 1996, 4, S95–S101. [Google Scholar] [CrossRef]

- Shapiro, A.E.; Ivanov, E.Y. Heat-Resistant Brazing Filler Metals for Joining Titanium Aluminide and Titanium Alloys. In Proceedings of the 3rd International Brazing and Soldering Conference (IBSC), San Antonio, TX, USA, 23–26 April 2006; pp. 12–17.

- Reisgen, U.; Olschok, S.; Backhaus, A. Microstructure analysis of electron-beam brazed gamma-titanium aluminide. Light Met. Technol. V 2011, 690, 153–156. [Google Scholar]

- He, P.; Feng, J.C.; Zhou, H. Microstructure and strength of brazed joints of Ti3Al base alloy with Cu-P filler metal. J. Mater. Sci. Technol. 2005, 21, 493–498. [Google Scholar]

- Cam, G.; Ipekoglu, G.; Bohm, K.H.; Kocak, M. Investigation into the microstructure and mechanical properties of diffusion bonded TiAl alloys. J. Mater. Sci. 2006, 41, 5273–5282. [Google Scholar] [CrossRef]

- Cao, J.; Song, X.G.; Wu, L.Z.; Qi, J.L.; Feng, J.C. Characterization of Al/Ni multilayers and their application in diffusion bonding of TiAl to TiC cermet. Thin Solid Films 2012, 520, 3528–3531. [Google Scholar] [CrossRef]

- Luo, X.; Li, J.W.; Huo, X.K.; Wang, Y.C.; Yang, Y.Q.; Wang, X.R.; Zhang, W.; Luo, X. New lightweight mirror billet: Connection of gamma-TiAl and K9 glass with Ti6Al4V foil as interlayer. Mater. Sci. Technol. 2013, 29, 250–254. [Google Scholar] [CrossRef]

- Tenyama, K.; Maeda, M.; Shibayanagi, T.; Naka, M. Interfacial microstructure of silicon carbide and titanium aluminide joints produced by solid-state diffusion bonding. Mater. Trans. 2004, 45, 2734–2739. [Google Scholar] [CrossRef]

- Wang, X.R.; Yang, Y.Q.; Luo, X.; Zhang, W.; Zhao, G.M.; Huang, B. An investigation of Ti-43Al-9V/Ti-6Al-4V interface by diffusion bonding. Intermetallics 2013, 36, 127–132. [Google Scholar] [CrossRef]

- Chen, H.Y.; Cao, J.; Song, X.G.; Feng, J.C. Contributions of atomic diffusion and plastic deformation to the plasma surface activation assisted diffusion bonding of zirconium-based bulk metallic glass. Appl. Phys. Lett. 2012, 100. [Google Scholar] [CrossRef]

- Wu, G.Q.; Huang, Z. Superplastic forming/diffusion bonding of laser surface melted TiAl intermetallic alloy. Scr. Mater. 2001, 45, 895–899. [Google Scholar] [CrossRef]

- Wu, G.Q.; Huang, Z.; Chen, C.Q.; Ruan, Z.J.; Zhang, Y. Superplastic diffusion bonding of gamma-TiAl-based alloy. Mater. Sci. Eng. A 2004, 380, 402–407. [Google Scholar] [CrossRef]

- Simoes, S.; Viana, F.; Ventzke, V.; Koçak, M.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Diffusion bonding of TiAl using Ni/Al multilayers. J. Mater. Sci. 2010, 45, 4351–4357. [Google Scholar] [CrossRef]

- He, P.; Fan, L.; Liu, H.; Feng, J.C. Effects of hydrogen on diffusion bonding of TiAl-based intermetallics using hydrogenated Ti6Al4V interlayer. Int. J. Hydrog. Energy 2010, 35, 13317–13321. [Google Scholar] [CrossRef]

- Cao, J.; Feng, J.C.; Li, Z.R. Microstructure and fracture properties of reaction-assisted diffusion bonding of TiAl intermetallic with Al/Ni multilayer foils. J. Alloy Compd. 2008, 466, 363–367. [Google Scholar] [CrossRef]

- Simoes, S.; Viana, F.; Kocak, M.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Diffusion bonding of TiAl using reactive Ni/Al nanolayers and Ti and Ni foils. Mater. Chem. Phys. 2011, 128, 202–207. [Google Scholar] [CrossRef]

- Simoes, S.; Viana, F.; Kocak, M.; Ramos, A.S.; Vieira, M.T.; Vieira, M.F. Microstructure of reaction zone formed during diffusion bonding of TiAl with Ni/Al multilayer. J. Mater. Eng. Perform. 2012, 21, 678–682. [Google Scholar] [CrossRef]

- Glatz, W.; Clemens, H. Diffusion bonding of intermetallic Ti-47Al-2Cr-0.2Si sheet material and mechanical properties of joints at room temperature and elevated temperatures. Intermetallics 1997, 5, 415–423. [Google Scholar] [CrossRef]

- Duckham, A.; Spey, S.J.; Wang, J.; Reiss, M.E.; Weihs, T.P.; Besnoin, E.; Knio, O.M. Reactive nanostructured foil used as a heat source for joining titanium. J. Appl. Phys. 2004, 96, 2336–2342. [Google Scholar] [CrossRef]

- Wang, J.; Besnoin, E.; Duckham, A.; Spey, S.J.; Reiss, M.E.; Knio, O.M.; Weihs, T.P. Joining of stainless-steel specimens with nanostructured Al/Ni foils. J. Appl. Phys. 2004, 95, 248–256. [Google Scholar] [CrossRef]

- Wang, J.; Besnoin, E.; Knio, O.M.; Weihs, T.P. Investigating the effect of applied pressure on reactive multilayer foil joining. Acta Mater. 2004, 52, 5265–5274. [Google Scholar] [CrossRef]

- Duarte, L.I.; Ramos, A.S.; Vieira, M.F.; Viana, F.; Vieira, M.T.; Kocak, M. Solid-state diffusion bonding of gamma-TiAl alloys using Ti/Al thin films as interlayers. Intermetallics 2006, 14, 1151–1156. [Google Scholar] [CrossRef]

- Duarte, L.I.; Viana, F.; Ramos, A.S.; Vieira, M.T.; Leinenbach, C.; Klotz, U.E.; Vieira, M.F. Diffusion bonding of gamma-TiAl using modified Ti/Al nanolayers. J. Alloy Compd. 2012, 536, S424–S427. [Google Scholar] [CrossRef]

- Ramos, A.S.; Vieira, M.T.; Duarte, L.I.; Vieira, M.F.; Viana, F.; Calinas, R. Nanometric multilayers: A new approach for joining TiAl. Intermetallics 2006, 14, 1157–1162. [Google Scholar] [CrossRef]

- Holmquist, M.; Recina, V.; Pettersson, B. Tensile and creep properties of diffusion bonded titanium alloy IMI 834 to gamma titanium aluminide IHI alloy 01A. Acta Mater. 1999, 47, 1791–1799. [Google Scholar] [CrossRef]

- Liu, H.J.; Feng, J.C.; Qian, Y.Y. Interface structure and formation mechanism of diffusion-bonded joints of SiC ceramic to TiAl-based alloy. Scr. Mater. 2000, 43, 49–53. [Google Scholar] [CrossRef]

- Kanai, S.; Seto, S.; Sugiura, H. Tensile properties of diffusion bonds between TiAl intermetallic compound and titanium alloy. Mater. Trans. 2005, 46, 2484–2489. [Google Scholar] [CrossRef]

- Wang, X.F.; Ma, M.; Liu, X.B.; Lin, J.G. Interface characteristics in diffusion bonding of a gamma-TiAl alloy to Ti-6Al-4V. J. Mater. Sci. 2007, 42, 4004–4008. [Google Scholar] [CrossRef]

- Morizono, Y.; Nishida, M.; Chiba, A.; Yamamuro, T.; Kanamori, Y.; Terai, T. Diffusion bonding of TiAl alloy to eutectoid steel and its interfacial self-destruction behavior. Mater. Trans. 2004, 45, 527–531. [Google Scholar] [CrossRef]

- He, P.; Feng, J.C.; Zhang, B.G.; Qian, Y.Y. A new technology for diffusion bonding intermetallic TiAl to steel with composite barrier layers. Mater. Charact. 2003, 50, 87–92. [Google Scholar] [CrossRef]

- Gong, H.R.; He, Y.H.; Huang, B.Y. Bond strength and interface energy between Pd membranes and TiAl supports. Appl. Phys. Lett. 2008, 93. [Google Scholar] [CrossRef]

- Cao, J.; Liu, J.K.; Song, X.G.; Lin, X.T.; Feng, J.C. Diffusion bonding of TiAl intermetallic and Ti3AlC2 ceramic: Interfacial microstructure and joining properties. Mater. Des. 2014, 56, 115–121. [Google Scholar] [CrossRef]

- Liu, J.K.; Cao, J.; Lin, X.T.; Chen, H.Y.; Wang, J.; Feng, J.C. Interfacial microstructure and joining properties of TiAl/Ti3AlC2 diffusion bonded joints using Zr and Ni foils as interlayer. Vacuum 2014, 102, 16–25. [Google Scholar] [CrossRef]

- Djanarthany, S.; Viala, J.C.; Bouix, J. Development of SiC/TiAl composites: Processing and interfacial phenomena. Mater. Sci. Eng. A 2001, 300, 211–218. [Google Scholar] [CrossRef]

- Suzuki, T.; Guo, X.L.; Umehara, H.; Terauchi, S. Cross-sectional characterization of the interfacial zone of SiTiCf/C/TiAl composites by transmission electron microscope. J. Mater. Sci. Lett. 1999, 18, 1799–1801. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Y.Q.; Zhao, G.M.; Huang, B.; Feng, Z.Q.; Luo, X.; Li, M.H.; Lou, J.H. Investigation of interfacial reaction in SiC fiber reinforced Ti-43Al-9V composites. Intermetallics 2013, 33, 54–59. [Google Scholar] [CrossRef]

- Paransky, Y.; Gotman, I.; Gutmanas, E.Y. Reactive phase formation at AlN-Ti and AlN-TiAl interfaces. Mater. Sci. Eng. A 2000, 277, 83–94. [Google Scholar] [CrossRef]

- Li, H.Q.; Wang, Q.M.; Gong, J.; Sun, C. Interfacial reactions and oxidation behavior of Al2O3 and Al2O3/Al coatings on an orthorhombic Ti2AlNb alloy. Appl. Surf. Sci. 2011, 257, 4105–4112. [Google Scholar] [CrossRef]

- Wang, X.F.; Ma, M.; Liu, X.B.; Wu, X.Q.; Tan, C.G.; Shi, R.K.; Lin, J.G. Diffusion bonding of gamma-TiAl alloy to Ti-6Al4V alloy under hot pressure. Trans. Nonferrous Met. Soc. 2006, 16, 1059–1063. [Google Scholar] [CrossRef]

- Liu, H.J.; Feng, J.C. Diffusion bonding of SiC ceramic to TiAl-based alloy. J. Mater. Sci. Lett. 2001, 20, 815–817. [Google Scholar] [CrossRef]

- He, P.; Wang, J.; Lin, T.S.; Li, H.X. Effect of hydrogen on diffusion bonding of TiAl-based intermetallics and Ni-based superalloy using hydrogenated Ti6Al4V interlayer. Int. J. Hydrog. Energy 2014, 39, 1882–1887. [Google Scholar] [CrossRef]

- Chaturvedi, M.C.; Richards, N.L.; Xu, Q. Electron beam welding of a Ti-45Al-2Nb-2Mn + 0.8 vol% TiB2 XD alloy. Mater. Sci. Eng. A 1997, 240, 605–612. [Google Scholar] [CrossRef]

- Chen, G.Q.; Zhang, B.G.; Liu, W.; Feng, J.C. Crack formation and control upon the electron beam welding of TiAl-based alloys. Intermetallics 2011, 19, 1857–1863. [Google Scholar] [CrossRef]

- Chen, G.Q.; Zhang, B.G.; Liu, W.; Feng, J.C. Influence of aluminum content on the microstructure and properties of electron beam welded joints of TiAl/TC4 alloy. Rare Met. Mater. Eng. 2013, 42, 452–456. [Google Scholar] [CrossRef]

- Lei, Z.L.; Dong, Z.J.; Chen, Y.B.; Zhang, J.; Zhu, R.C. Microstructure and tensile properties of laser beam welded Ti-22Al-27Nb alloys. Mater. Des. 2013, 46, 151–156. [Google Scholar] [CrossRef]

- Liu, J.; Dahmen, M.; Ventzke, V.; Kashaev, N.; Poprawe, R. The effect of heat treatment on crack control and grain refinement in laser beam welded beta-solidifying TiAl-based alloy. Intermetallics 2013, 40, 65–70. [Google Scholar] [CrossRef]

- Chaturvedi, M.C.; Xu, Q.; Richards, N.L. Development of crack-free welds in a TiAl-based alloy. J. Mater. Process. Technol. 2001, 118, 74–78. [Google Scholar] [CrossRef]

- Tan, L.J.; Yao, Z.K.; Zhou, W.; Guo, H.Z.; Zhao, Y. Microstructure and properties of electron beam welded joint of Ti-22Al-25Nb/TC11. Aerosp. Sci. Technol. 2010, 14, 302–306. [Google Scholar]

- Xu, Q.; Chaturvedi, M.C.; Richards, N.L. The role of phase transformation in electron-beam welding of TiAl-based alloys. Metall. Mater. Trans. A 1999, 30, 1717–1726. [Google Scholar]

- Zhang, H.T.; He, P.; Feng, J.C.; Wu, H.Q. Interfacial microstructure and strength of the dissimilar joint Ti3Al/TC4 welded by the electron beam process. Mater. Sci. Eng. A 2006, 425, 255–259. [Google Scholar] [CrossRef]

- Ventzke, V.; Bohm, K.H.; Kocak, M.; Riekehr, S.; Horstmann, M.; Merhof, P.; Watzlaw, M. Microstructure and mechanical properties of friction welded gamma-TiAl based alloy Ti-47Al-3.5(Mn+Cr+Nb)-0.8(B+Si) in investment cast condition. Mater. Werkst. 2006, 37, 649–660. [Google Scholar] [CrossRef]

- Ventzke, V.; Brokmeier, H.G.; Merhof, P.; Kocak, M. Microstructural characterization of friction welded TiAl-Ti6Al4V hybrid joints. Solid State Phenom. 2010, 160, 319–326. [Google Scholar] [CrossRef]

- Cai, D.T.; Chen, J.C.; Mao, X.F.; Hao, C.Y. Reheat cracking in Ti2AlNb alloy resistance spot weldments. Intermetallics 2013, 38, 63–69. [Google Scholar] [CrossRef]

- Kahraman, N. The influence of welding parameters on the joint strength of resistance spot-welded titanium sheets. Mater. Des. 2007, 28, 420–427. [Google Scholar] [CrossRef]

- Kaya, Y.; Kahraman, N. The effects of electrode force, welding current and welding time on the resistance spot weldability of pure titanium. Int. J. Adv. Manuf. Technol. 2012, 60, 127–134. [Google Scholar] [CrossRef]

- Qiu, R.F.; Zhang, X.; Shi, H.X.; Yu, H.; Zhang, K.K. Joining phenomena of resistance spot welded joint between titanium and aluminum alloy. Adv. Mater. Res. 2011, 230–232, 982–986. [Google Scholar] [CrossRef]

- Zhao, D.W.; Wang, Y.X.; Sheng, S.N.; Lin, Z.G. Real time monitoring weld quality of small scale resistance spot welding for titanium alloy. Measurement 2013, 46, 1957–1963. [Google Scholar] [CrossRef]

- Zuhailawati, H.; Saeed, A.M.; Ismail, A.B.; Samad, Z.; Ariga, T. Spot resistance welding of a titanium/nickel joint with filler metal. Weld. J. 2010, 89, 101s–104s. [Google Scholar]

- Baeslack, W.A.; Broderick, T.F.; Juhas, M.; Fraser, H.L. Characterization of solid-phase welds between Ti-6A1-2Sn-4Zr-2Mo-0.1Si and Ti-13.5A1-21.5Nb titanium aluminide. Mater. Charact. 1994, 33, 357–367. [Google Scholar] [CrossRef]

- Tu, Y.M.; Qiu, R.F.; Shi, H.X.; Zhang, X.; Zhang, K.K. Resistance spot welding between titanium and stainless steel with an aluminum alloy insert. Adv. Mater. Res. 2011, 291–294, 964–967. [Google Scholar] [CrossRef]

- Cao, J.; Feng, J.C.; Li, Z.R. Joining of TiAl intermetallic by self-propagating high-temperature synthesis. J. Mater. Sci. 2006, 41, 4720–4274. [Google Scholar] [CrossRef]

- Cao, J.; Wang, H.Q.; Qi, J.L.; Lin, X.C.; Feng, J.C. Combustion synthesis of TiAl intermetallics and their simultaneous joining to carbon/carbon composites. Scr. Mater. 2011, 65, 261–264. [Google Scholar] [CrossRef]

- Feng, J.C.; Cao, J.; Li, Z.R. Microstructure evolution and reaction mechanism during reactive joining of TiAl intermetallic to TiC cermet using Ti-Al-C-Ni interlayer. J. Alloy Compd. 2007, 436, 298–302. [Google Scholar] [CrossRef]

- Chen, S.P.; Dong, F.; Fan, W.H.; Meng, Q.S.; Munir, Z.A. Interface kinetics of combustion-diffusion bonding of Ni3Al/Ni and TiAl/Ti under direct current field. J. Mater. Sci. 2013, 48, 1268–1274. [Google Scholar]

- Chen, S.P.; Meng, Q.S.; Zhang, N.; Xue, P.F.; Munir, Z.A. In situ synthesis and bonding of Ti-TiAl-TiC/Ni functionally graded materials by field-activated pressure-assisted synthesis process. Mater. Sci. Eng. A 2012, 538, 103–109. [Google Scholar] [CrossRef]

- Romankov, S.; Sha, W.; Kaloshkin, S.D.; Kaevitser, K. Fabrication of Ti-Al coatings by mechanical alloying method. Surf. Coat. Technol. 2006, 201, 3235–3245. [Google Scholar] [CrossRef] [Green Version]

- Roman’kov, S.E.; Sagdoldina, Z.B.; Kaloshkin, S.D.; Kaevitser, E.V. Fabrication of Ti-Al composite coatings by the mechanical alloying method. Phys. Met. Metallogr. 2008, 106, 67–75. [Google Scholar] [CrossRef]

- Yang, F.; Lin, J.P.; He, Y.H.; Du, H.; Chen, G.L. Innovative fabrication of Ti-48Al-6Nb porous coating by cold gas spraying and reactive sintering. Mater. Lett. 2012, 76, 190–193. [Google Scholar] [CrossRef]

- Yoruk, G.; Ozdemir, O. The evaluation of NiAl- and TiAl-based intermetallic coatings produced on the AISI 1010 steel by an electric current-activated sintering method. Intermetallics 2012, 25, 60–65. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Cao, J.; Qi, J.; Song, X.; Feng, J. Welding and Joining of Titanium Aluminides. Materials 2014, 7, 4930-4962. https://doi.org/10.3390/ma7074930

Cao J, Qi J, Song X, Feng J. Welding and Joining of Titanium Aluminides. Materials. 2014; 7(7):4930-4962. https://doi.org/10.3390/ma7074930

Chicago/Turabian StyleCao, Jian, Junlei Qi, Xiaoguo Song, and Jicai Feng. 2014. "Welding and Joining of Titanium Aluminides" Materials 7, no. 7: 4930-4962. https://doi.org/10.3390/ma7074930

APA StyleCao, J., Qi, J., Song, X., & Feng, J. (2014). Welding and Joining of Titanium Aluminides. Materials, 7(7), 4930-4962. https://doi.org/10.3390/ma7074930