Experimental Confirmation of the Reliability of Fanger’s Thermal Comfort Model—Case Study of a Near-Zero Energy Building (NZEB) Office Building

Abstract

:1. Introduction

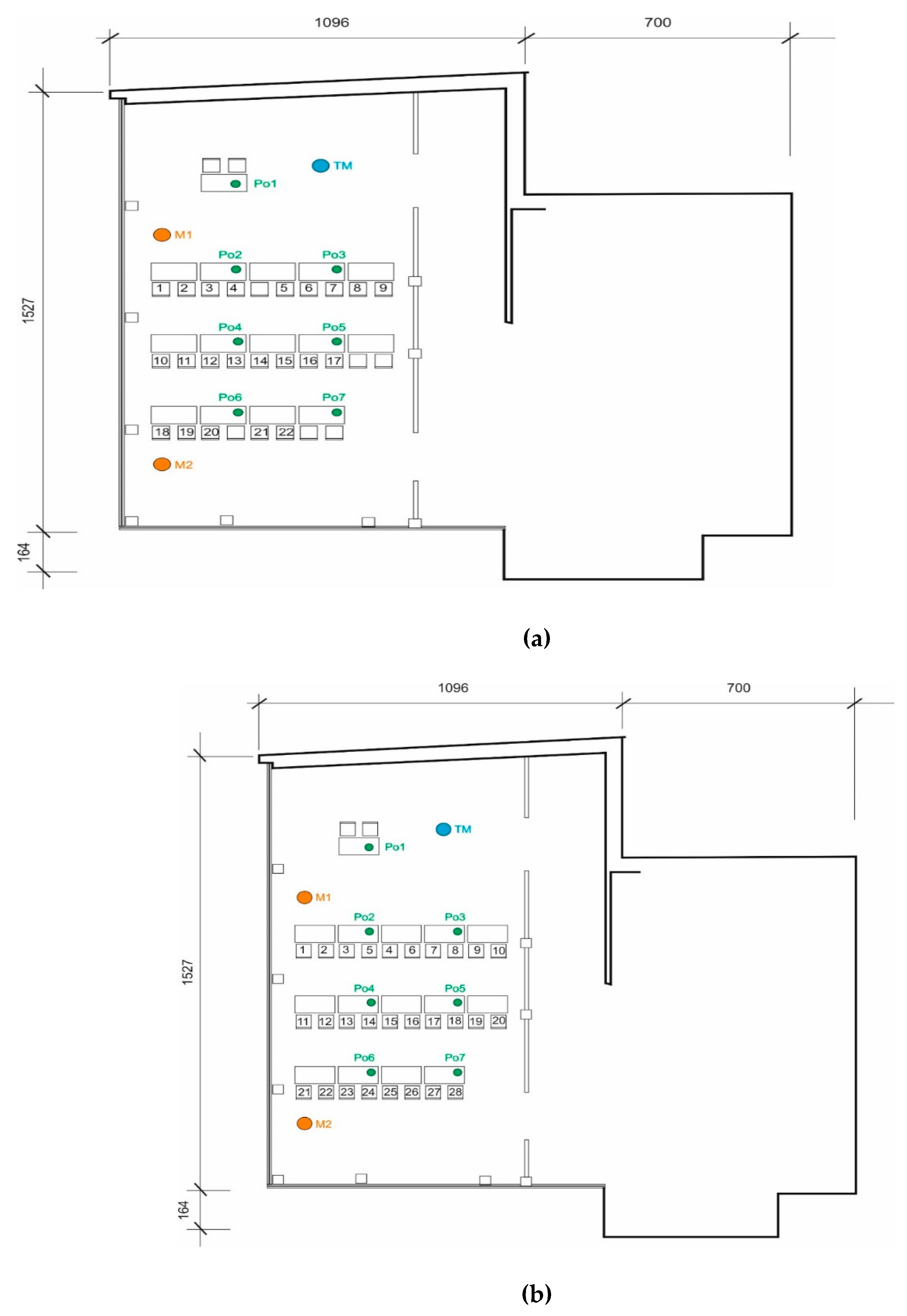

2. Materials and Methods

2.1. Goals of the Experiment

- -

- conducting an experiment to determine the lowest operating temperature giving thermal comfort (PMV = 0 and −0.5) in the experimental space of the MLBE building by way of physical measurements and sensory questionnaire surveys of a statistically representative panellist group (the size of the test group is 50),

- -

- comparing the results of sensory tests obtained by means of three types of questionnaire questions with environmental measurement results and resulting from the Fanger-ISO 7730 comfort thermal model,

- -

- determining the impact of three question types on the results (seven-scale question, 0–100% scale question, yes/no question),

- -

- comparison and discussion of results obtained by measuring method and results of surveys (PPD = f(PMV),

- -

- comparing the raw results of surveys (PPD) obtained by other researchers with the authors’ own survey results,

- -

- proposing an equation for the experimental thermal comfort curve for given boundary conditions on the basis of the obtained results—a “limited scale” validation of the existing thermal comfort model

2.2. Thermal Comfort Model

2.3. Case Study Object and Boundary Conditions

2.4. Panel Group

2.5. Thermal Sensory Tests—Votes

- The first of them is: Determine the feeling of thermal sensation on a 7-degree scale, where the value −3 was marked as very cold, −2 as cold., −1 as quite cold, 0—neutral (comfortable), +1 quite warm, +2 warm, +3 hot (Fanger approach-based).

- The second of them is: Determine using a two-degree scale whether the prevailing conditions are comfortable for work (yes/no).

- The third of them is: Determine in what percentage the conditions are suitable for work (from 0% [absolutely not suitable] to 100% [the conditions are comfortable/neutral]).

2.6. The Measuring Equipment

- -

- ta—actual air temperature measurement,

- -

- tg—temperature of blackened sphere (heat radiation meter), 15 cm in diameter,

- -

- tnw—natural wet-bulb temperature measurement,

- -

- RH—measurement of relative air humidity,

- -

- va—measurement of air flow speed.

- -

- CO2 measurement range 0–5000 ppm CO2 accuracy 50 ppm +3% of the measured value

- -

- Measurement RH [%] range 0–100 %RH accuracy 3% (30–70%RH) /5%(70–90%RH)

- -

- Measurement t [°C] range −5–55 °C accuracy 0.3 °C (−5–20 °C)/0.4 oC (20–55 °C)

2.7. Measurement Uncertainty

2.8. Other Assumptions and Boundary Conditions

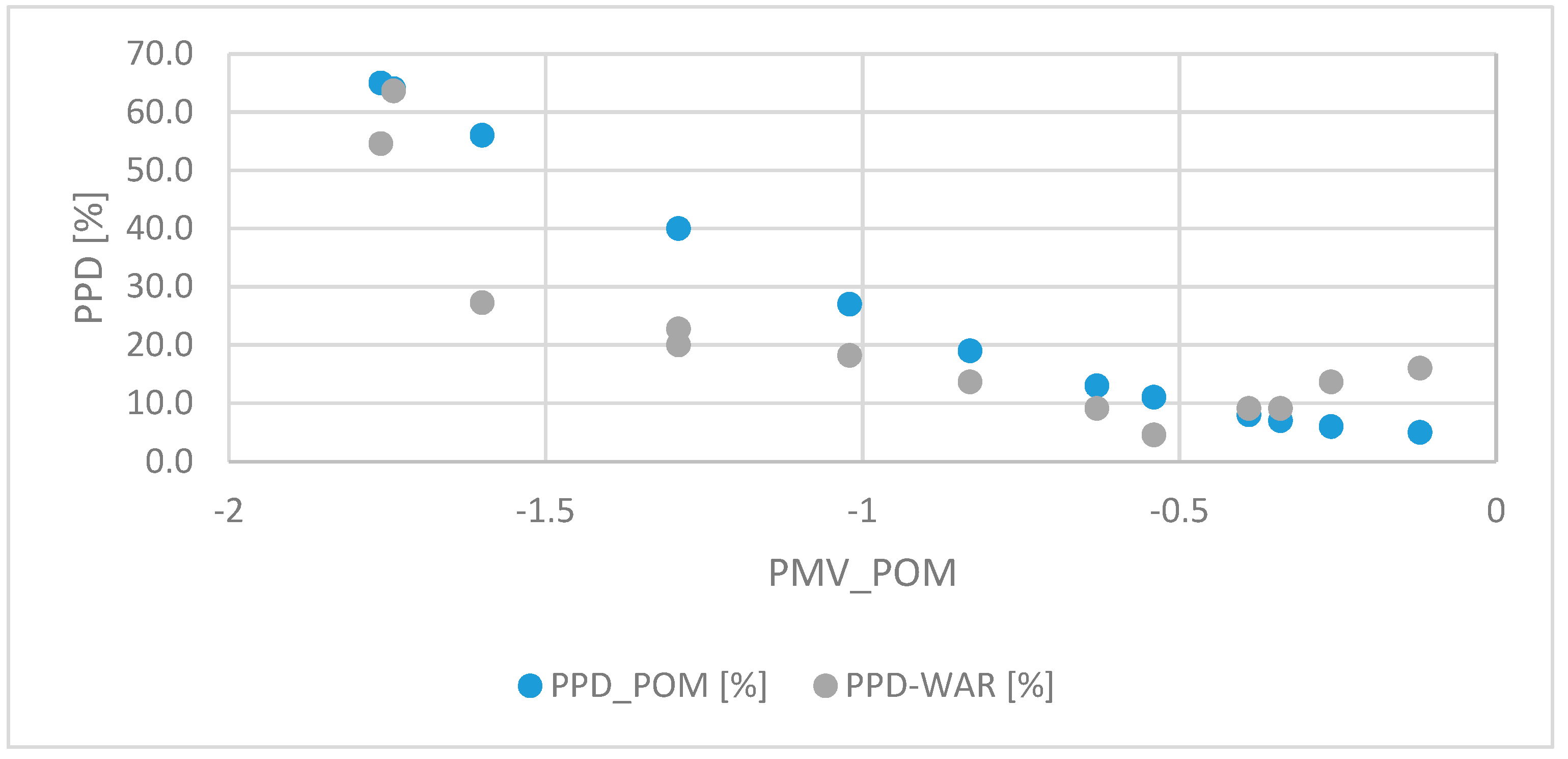

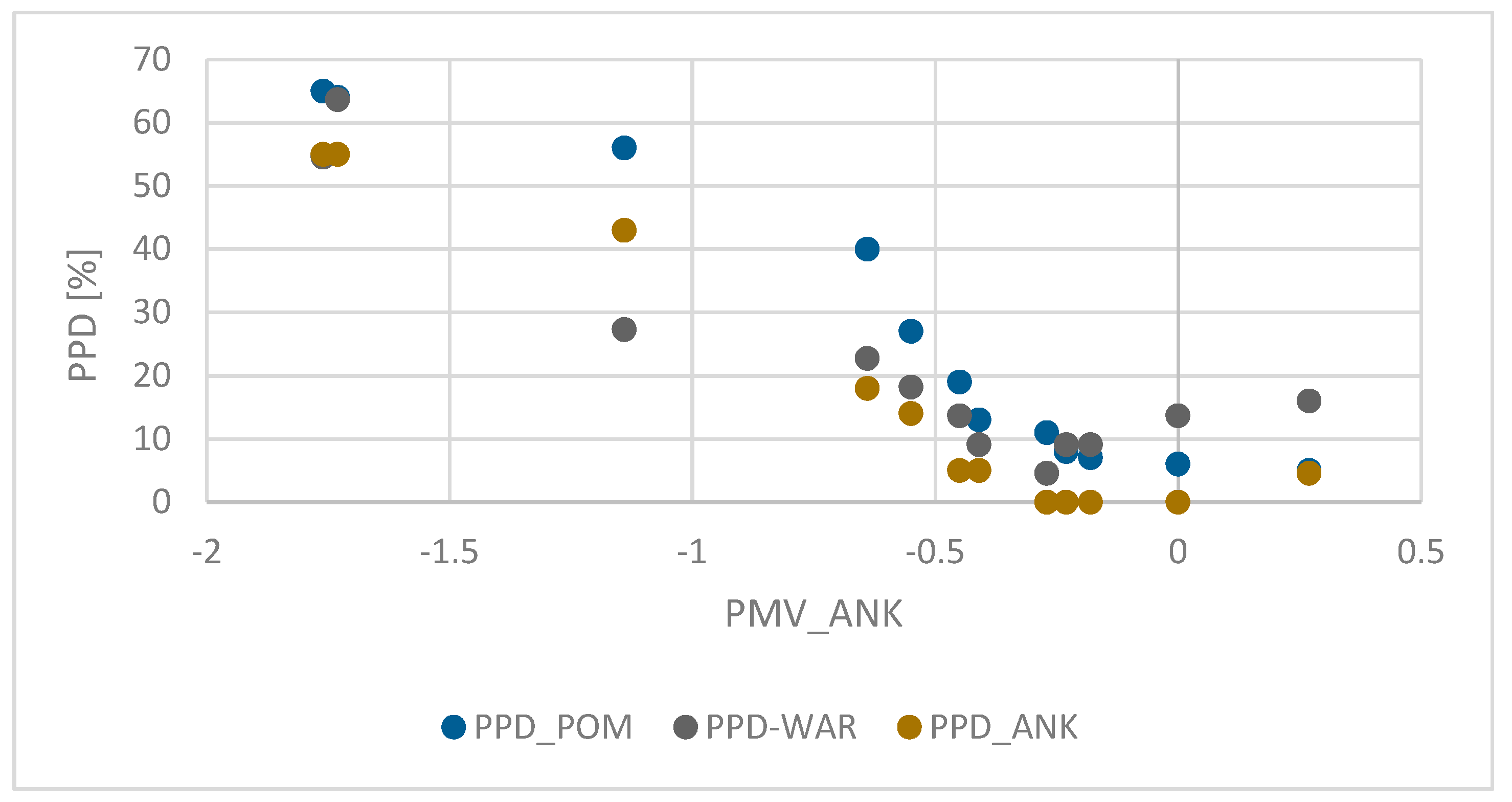

3. Results

- -

- PPD_ANK, a seven-point thermal sensation scale (−3 to 3),

- -

- PPD_WAR, a two-point thermal sensation scale (yes/no), a conditional question on whether you are satisfied with the thermal conditions,

- -

- PPD_ZAD_ANK, percentage scale (0–100%), a conditional question on what is the percentage of your satisfaction with the thermal conditions.

4. Discussion

4.1. Comparison of Results with the Fanger Model

4.2. Obtained Results in the Context of NZEB Buildings

4.3. Results in the Context of the Impact of the Question Type on PMV

4.4. Other

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fanger, P.O. Assessment of man’s thermal comfort in practice. Occup. Environ. Med. 1973, 30, 313–324. [Google Scholar] [CrossRef]

- BSI. ISO 7730: Ergonomics of the Thermal Environment Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- ANSI/ASHRAE Standard 55-2017, Thermal Environmental Conditions for Human Occupancy; ANSI: Piscataway, NJ, USA, 2017.

- Nagashima, K.; Tokizawa, K.; Marui, S. Thermal comfort. In Handbook of Clinical Neurology; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Djongyang, N.; Tchinda, R.; Njomo, D. Thermal comfort: A review paper. Renew. Sustain. Energy Rev. 2010, 14, 2626–2640. [Google Scholar] [CrossRef]

- Taleghani, M.; Tenpierik, M.; Kurvers, S.; van den Dobbelsteen, A. A review into thermal comfort in buildings. Renew. Sustain. Energy Rev. 2013, 26, 201–215. [Google Scholar] [CrossRef]

- van Hoof, J. Forty years of Fanger’s model of thermal comfort: Comfort for all? Indoor Air 2008, 18, 182–201. [Google Scholar] [CrossRef] [PubMed]

- Rupp, R.F.; Vásquez, N.G.; Lamberts, R. A review of human thermal comfort in the built environment. Energy Build. 2015, 105, 178–205. [Google Scholar] [CrossRef]

- Peeters, L.; de Dear, R.; Hensen, J.; D’haeseleer, W. Thermal comfort in residential buildings: Comfort values and scales for building energy simulation. Appl. Energy 2009, 86, 772–780. [Google Scholar] [CrossRef] [Green Version]

- Frontczak, M.; Wargocki, P. Literature survey on how different factors influence human comfort in indoor environments. Build. Environ. 2011, 46, 922–937. [Google Scholar] [CrossRef]

- van Hoof, J. Thermal comfort: Research and practice. Front. Biosci. 2010, 15, 765–788. [Google Scholar] [CrossRef]

- Cheng, Y.; Niu, J.; Gao, N. Thermal comfort models: A review and numerical investigation. Build. Environ. 2012, 47, 13–22. [Google Scholar] [CrossRef]

- de Dear, R.J.; Akimoto, T.; Arens, E.A.; Brager, G.; Candido, C.; Cheong, K.W.D.; Li, B.; Nishihara, N.; Sekhar, S.C.; Tanabe, S.; et al. Progress in thermal comfort research over the last twenty years. Indoor Air 2013, 23, 442–461. [Google Scholar] [CrossRef]

- Mors, S.T.; Hensen, J.L.M.; Loomans, M.G.L.C.; Boerstra, A.C. Adaptive thermal comfort in primary school classrooms: Creating and validating PMV-based comfort charts. Build. Environ. 2011, 46, 2454–2461. [Google Scholar] [CrossRef] [Green Version]

- Halawa, E.; van Hoof, J. The adaptive approach to thermal comfort: A critical overview. Energy Build. 2012, 51, 101–110. [Google Scholar] [CrossRef]

- Enescu, D. A review of thermal comfort models and indicators for indoor environments. Renew. Sustain. Energy Rev. 2017, 79, 1353–1379. [Google Scholar] [CrossRef]

- Nicol, J.F.; Roaf, S. Rethinking thermal comfort. Build. Res. Inf. 2017, 45, 711–716. [Google Scholar] [CrossRef] [Green Version]

- Yao, R.; Li, B.; Liu, J. A theoretical adaptive model of thermal comfort—Adaptive Predicted Mean Vote (aPMV). Build. Environ. 2009, 44, 2089–2096. [Google Scholar] [CrossRef]

- Mora, R.; Bean, R. Thermal comfort: Designing for people. Ashrae J. 2018, 60, 2. [Google Scholar]

- Final draft EN 16798-1, Energy performance of buildings—Ventilation of buildings—Part 1: Indoor environmental input parameters for design and assessment of energy performance of buildings addressing indoor air quality, thermal environment, lighting and acoustics (Module M1–6). 2018. Available online: https://www.cibse.org/getmedia/bb1c34b1-19fe-4199-a44f-acb981077ab0/Draft-BS-EN-16798-1-Energy-performance-of-buildings.pdf.aspx (accessed on 24 April 2019).

- ISO 15251, Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; ISO: Geneva, Switzerland, 2007.

- de Dear, R. Thermal comfort in practice. Indoor Air. 2004, (Suppl. 7), 32–39. [Google Scholar] [CrossRef]

- Charles, K.E. Fanger’s Thermal Comfort and Draught Models; National Research Council Canada: Halifax, NS, Canada, 2003.

- Ormandy, D.; Ezratty, V. Health and thermal comfort: From WHO guidance to housing strategies. Energy Policy 2012, 49, 116–121. [Google Scholar] [CrossRef] [Green Version]

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings; Official Journal of the European Union: Brussels, Belgum, 2010.

- Fedorczak-Cisak, M.; Furtak, M.; Gintowt, J.; Kowalska-Koczwara, A.; Pachla, F.; Stypuła, K.; Tatara, T. Thermal and vibration comfort analysis of a nearly zero-energy building in Poland. Sustainability 2018, 10, 3774. [Google Scholar] [CrossRef]

- Fassio, F.; Fanchiotti, A.; Vollaro, R.D. Linear, non-linear and alternative algorithms in the correlation of IEQ factors with global comfort: A case study. Sustainability 2014, 6, 8113–8127. [Google Scholar] [CrossRef]

- Ncube, M. The Development of a Methodology for a Tool for Rapid Assessment of Indoor Environment Quality in Office Buildings in the UK; University of Nottingham: Nottingham, UK, 2012. [Google Scholar]

- Heinzerling, D. Commercial Building Indoor Environmental Quality Evaluation: Methods and Tools; UC Berkeley: Berkeley, CA, USA, 2012. [Google Scholar]

- Piasecki, M.; Kozicki, M. The Approach of Including TVOCs Concentration in the Indoor Environmental Quality Model (IEQ)—Case Studies of BREEAM Certified Office Buildings. Sustainability 2018, 10, 3902. [Google Scholar] [CrossRef]

- Interactions Affecting the Achievement of Acceptable Indoor Environments; ASHRAE Standard: Atlanta, GA, USA, 2011.

- Piasecki, M.; Kostyrko, K.B. Indoor environmental quality assessment, part 2: Model reliability analysis. J. Build. Phys. 2018, 5, 288–315. [Google Scholar] [CrossRef]

- Liang, H.H.; Chen, C.P.; Hwang, R.L.; Shih, W.M.; Lo, S.C.; Liao, H.Y. Satisfaction of occupants toward indoor environment quality of certified green office buildings in Taiwan. Build. Environ. 2014, 72, 232–242. [Google Scholar] [CrossRef]

- Mihai, T.; Iordache, V. Determining the Indoor Environment Quality for an Educational Building. Energy Procedia 2016, 85, 566–574. [Google Scholar] [CrossRef] [Green Version]

- Pei, Z.; Lin, B.; Liu, Y.; Zhu, Y. Comparative study on the indoor environment quality of green office buildings in China with a long-term field measurement and investigation. Build. Environ. 2015, 84, 80–88. [Google Scholar] [CrossRef]

- Piasecki, M.; Kostyrko, K.; Pykacz, S. Indoor environmental quality assessment: Part 1: Choice of the indoor environmental quality sub-component models. J. Build. Phys. 2017, 41, 264–289. [Google Scholar] [CrossRef]

- Freire, R.Z.; Oliveira, G.H.C.; Mendes, N. Predictive controllers for thermal comfort optimization and energy savings. Energy Build. 2008, 40, 1353–1365. [Google Scholar] [CrossRef]

- Spagnolo, J.; de Dear, R. A field study of thermal comfort in outdoor and semi-outdoor environments in subtropical Sydney Australia. Build. Environ. 2003, 38, 721–738. [Google Scholar] [CrossRef] [Green Version]

- Zomorodian, Z.S.; Tahsildoost, M.; Hafezi, M. Thermal comfort in educational buildings: A review article. Renew. Sustain. Energy Rev. 2016, 59, 895–906. [Google Scholar] [CrossRef]

- Trebilcock, M.; Soto-Muñoz, J.; Yañez, M.; Martin, R.F. The right to comfort: A field study on adaptive thermal comfort in free-running primary schools in Chile. Build. Environ. 2017, 114, 455–469. [Google Scholar] [CrossRef]

- Zeiler, W.; Boxem, G. Effects of thermal activated building systems in schools on thermal comfort in winter. Build. Environ. 2009, 44, 2308–2317. [Google Scholar] [CrossRef]

- Khodakarami, J.; Nasrollahi, N. Thermal comfort in hospitals—A literature review. Renew. Sustain. Energy Rev. 2012, 16, 4071–4077. [Google Scholar] [CrossRef]

- Fanger, P.O. Assessment of thermal comfort practice. Br. J. Ind. Med. 1973, 30, 313–324. [Google Scholar]

- Rohles, F.; Nevins, G.R. Nature of thermal comfort for sedentary man. ASHRAE Trans. 1971, 77, 239–246. [Google Scholar]

- Alfano, F.R.D.; Ianniello, E.; Palella, B.I.; Riccio, G. Thermal comfort design in indoor environments: A comparison between EU and USA approaches. In Proceedings of the HB 2006—Healthy Buildings: Creating a Healthy Indoor Environment for People, Lisboa, Portugal, 4–8 June 2006. [Google Scholar]

- de Dear, R.J.; Brager, G.S. Thermal comfort in naturally ventilated buildings: Revisions to ASHRAE Standard 55. Energy Build. 2002, 34, 549–561. [Google Scholar] [CrossRef]

- de Dear, R.; Kim, J.; Candido, C.; Deuble, M. Adaptive thermal comfort in australian school classrooms. Build. Res. Inf. 2015, 43, 383–398. [Google Scholar] [CrossRef]

- Olesen, B.W. Revision of EN 15251: Indoor Environmental Criteria. Rehva J. 2012, 49, 6–12. [Google Scholar]

- BSI. Ergonomics of the Thermal Environment—Instruments for Measuring Physical Quantities; Bs En Iso 77262001; ISO: Geneva, Switzerland, 2002. [Google Scholar]

- Alfano, F.R.D.A.; Palella, B.I.; Riccio, G. Notes on the Calculation of the PMV Index by Means of Apps. Energy Procedia 2016, 101, 249–256. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; de Dear, R.; Luo, M.; Ghahramani, A.; Lin, B. The uncertainty of subjective thermal comfort measurement. Energy Build. 2018, 181, 38–49. [Google Scholar] [CrossRef]

- Kim, J.; de Dear, R. Thermal comfort expectations and adaptive behavioural characteristics of primary and secondary school students. Build. Environ. 2018, 127, 13–22. [Google Scholar] [CrossRef]

- Buratti, C.; Ricciardi, P. Adaptive analysis of thermal comfort in university classrooms: Correlation between experimental data and mathematical models. Build. Environ. 2009, 44, 674–687. [Google Scholar] [CrossRef]

- Carlucci, S.; Bai, L.; de Dear, R.; Yang, L. Review of adaptive thermal comfort models in built environmental regulatory documents. Build. Environ. 2018, 137, 73–89. [Google Scholar] [CrossRef]

- Teli, D.; Jentsch, M.F.; James, P.A.B. Naturally ventilated classrooms: An assessment of existing comfort models for predicting the thermal sensation and preference of primary school children. Energy Build. 2012, 53, 166–182. [Google Scholar] [CrossRef]

- Haddad, S.; King, S.; Osmond, P. Enhancing thermal comfort in school buildings. Proc. Heal. Build. 2012. Available online: https://www.isiaq.org/docs/PDF%20Docs%20for%20Proceedings/7F.2.pdf (accessed on 24 April 2019).

- Sattayakorn, S.; Ichinose, M.; Sasaki, R. Clarifying thermal comfort of healthcare occupants in tropical region: A case of indoor environment in Thai hospitals. Energy Build. 2017, 149, 45–57. [Google Scholar] [CrossRef]

| Group | Gender | Group Size | Age [Years] | Height [cm] | Body Weight [kg] | Skin Surface “DuBois” [m2] | Body Mass Index | Clo [m2 K/W] |

|---|---|---|---|---|---|---|---|---|

| Academic youth- Author’s test | Man | 12 | 23 ± 2.4 | 175 ± 8.0 | 74 ± 13.0 | 1.8 ± 0.25 | 24.2 ± 3.0 | 0.7 ± 0.05 |

| Woman | 38 | 22 ± 2.0 | 162 ± 6.0 | 58 ± 15.0 | 1.6 ± 0.22 | 22.1 ± 2.4 | 0.7 ± 0.05 | |

| Mean | 50 | 22 ± 2.2 | 165 ± 16.0 | 62 ± 18.4 | 1.6 ± 0.23 | 21.2 ± 2.4 | 0.7 ± 0.05 | |

| Academic youth- Fanger’s test | Man | 64 | 24 ± 4.6 | 180 ± 12.0 | 71 ± 13.0 | 1.9 ± 0.24 | 22.2 ± 3.0 | 0.6 ± 0.05 |

| Woman | 64 | 23 ± 2.4 | 168 ± 7.0 | 57 ± 14.8 | 1.6 ± 0.24 | 20.2 ± 2.2 | 0.6 ± 0.05 | |

| Mean | 128 | 23 ± 4.4 | 174 ± 16.0 | 64 ± 21.0 | 1.8 ± 0.34 | 21.2 ± 2.6 | 0.6 ± 0.05 |

| Type of Sensor | Measurement Range | Scale | Producer Accuracy |

|---|---|---|---|

| Temperature sensors | –20 °C –50 °C | 0.01 °C | 0.5 °C |

| Humidity sensors | 0–100% | 0.1% RH | 1% |

| Air speed | 0.01–10 m/s | 0.01 m/s | 2% |

| Radiant temp. measurement | 0–50 °C | 0.01 °C | 2% |

| Parameter | Standard Deviation% | Range |

|---|---|---|

| Air temperature ta °C | 0.5 °C ⇒ 0.08 PMV ⇒ 0.6% PPD | −20 °C–50 °C |

| Radiant temperature tmr °C | 2 °C ⇒ 0.28 PMV ⇒ 3% PPD | 0–50 °C |

| Relative humidity RH % | 5% RH ⇒ 0.07 PMV ⇒ 0.5% PPD | 0–90% |

| Relative air velocity va m/s | |0.01 + 0.01va|m/s ⇒ 0.03 PMV ⇒0.2%PPD | 0.01–10 m/s |

| PPD- table error | 0.1 PMV ⇒ 0.73% PPD | |

| SDreal(PPD) = (0.36+9+0.25+0.04+ 0.54)0.5 = 3.2% | ||

| Parameters | SDrealPPD% | SDvotePPD% | Uoverall% |

|---|---|---|---|

| PPD(PMV) | 3.2 | 11.9 | 2·(10.24 + 141.6)0.5=24.6 |

| ta | tmr | RH | va | met | clo | PMV_POM | PPD_POM | PPD_ZAD_ANK | PPD-WAR | PPD_ANK |

|---|---|---|---|---|---|---|---|---|---|---|

| [°C] | [°C] | [%] | [m/s] | [met] | [clo] | [-] | [%] | [%] | [%] | [%] |

| 17.2 | 16.8 | 30.8 | 0.01 | 1.2 | 0.7 | −1.8 | 65 | 57 | 55 | 55 |

| 17.4 | 16.6 | 32.1 | 0.02 | 1.2 | 0.7 | −1.7 | 64 | 55 | 64 | 55 |

| 18.0 | 17.2 | 32,3 | 0.02 | 1.2 | 0.7 | −1.6 | 56 | 44 | 27 | 43 |

| 19.5 | 17.9 | 33.7 | 0.08 | 1.2 | 0.7 | −1.3 | 40 | 26 | 23 | 18 |

| 20.4 | 19.1 | 33.7 | 0.01 | 1.2 | 0.7 | −1.0 | 27 | 25 | 18 | 14 |

| 21.4 | 19.6 | 31.2 | 0.01 | 1.2 | 0.7 | −0.8 | 19 | 23 | 14 | 5 |

| 22.2 | 20.2 | 32.1 | 0.01 | 1.2 | 0.7 | −0.6 | 13 | 21 | 9 | 5 |

| 22.7 | 20.4 | 31.6 | 0.01 | 1.2 | 0.7 | −0.5 | 11 | 19 | 5 | 0.0 |

| 23.2 | 21.1 | 31.5 | 0.01 | 1.2 | 0.7 | −0.4 | 8 | 18 | 9 | 0.0 |

| 23.7 | 20.9 | 31.3 | 0.02 | 1.2 | 0.7 | −0.3 | 7 | 17 | 9 | 0.0 |

| 24.1 | 21.2 | 30.9 | 0.02 | 1.2 | 0.7 | −0.2 | 6 | 19 | 13 | 0.0 |

| 24.6 | 21.7 | 31.1 | 0.01 | 1.2 | 0.7 | −0.1 | 5 | 23 | 16 | 4 |

| TA | PMV_POM | Thermal Sensation Answers-Sensory Result [%] | PPD_ANK | ||||||

|---|---|---|---|---|---|---|---|---|---|

| [°C] | [-] | −3 | −2 | −1 | 0 | 1 | 2 | 3 | [%] |

| 17.2 | −1.8 | 9.1 | 45.5 | 45.5 | 0 | 0 | 0 | 0 | 55 |

| 17.4 | −1.7 | 18.2 | 36.4 | 45.5 | 0 | 0 | 0 | 0 | 55 |

| 17.9 | −1.6 | 4.5 | 38.2 | 43.6 | 13.6 | 0 | 0 | 0 | 43 |

| 19.5 | −1.3 | 4.5 | 13.6 | 22.7 | 59.1 | 0 | 0 | 0 | 18 |

| 20.4 | −1.0 | 4.5 | 9.1 | 22.7 | 63.6 | 0 | 0 | 0 | 14 |

| 21.4 | −0.8 | 0 | 4.5 | 31.8 | 63.6 | 0 | 0 | 0 | 5 |

| 22.2 | −0.6 | 0 | 4.5 | 40.9 | 50 | 4.5 | 0 | 0 | 5 |

| 22.7 | −0.5 | 0 | 0 | 31.8 | 63.6 | 4.5 | 0 | 0 | 0 |

| 23.2 | −0.4 | 0 | 0 | 31.8 | 59.1 | 9.1 | 0 | 0 | 0 |

| 23.7 | −0.3 | 0 | 0 | 31.8 | 54.5 | 13.6 | 0 | 0 | 0 |

| 24.1 | −0.3 | 0 | 0 | 31.8 | 36.4 | 31.8 | 0 | 0 | 0 |

| 24.6 | −0.1 | 0 | 0 | 22.7 | 31.8 | 40.9 | 4.5 | 0 | 5 |

| Room Category | Coefficients: | |||

|---|---|---|---|---|

| PMV [-] | PPD [%] | ta_pom | ta_ank | |

| Best (A) | −0.2 < PMV | <6 | 24.2 °C | 22.2 °C |

| Min. (C) | −0.7 < PMV | <15 | 21.6 °C | 20.4 °C |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piasecki, M.; Fedorczak-Cisak, M.; Furtak, M.; Biskupski, J. Experimental Confirmation of the Reliability of Fanger’s Thermal Comfort Model—Case Study of a Near-Zero Energy Building (NZEB) Office Building. Sustainability 2019, 11, 2461. https://doi.org/10.3390/su11092461

Piasecki M, Fedorczak-Cisak M, Furtak M, Biskupski J. Experimental Confirmation of the Reliability of Fanger’s Thermal Comfort Model—Case Study of a Near-Zero Energy Building (NZEB) Office Building. Sustainability. 2019; 11(9):2461. https://doi.org/10.3390/su11092461

Chicago/Turabian StylePiasecki, Michał, Małgorzata Fedorczak-Cisak, Marcin Furtak, and Jacek Biskupski. 2019. "Experimental Confirmation of the Reliability of Fanger’s Thermal Comfort Model—Case Study of a Near-Zero Energy Building (NZEB) Office Building" Sustainability 11, no. 9: 2461. https://doi.org/10.3390/su11092461