Impact of Uneven Flow Wastewater Distribution on the Technological Efficiency of a Sequencing Batch Reactor

Abstract

:1. Introduction

2. Materials and Methods

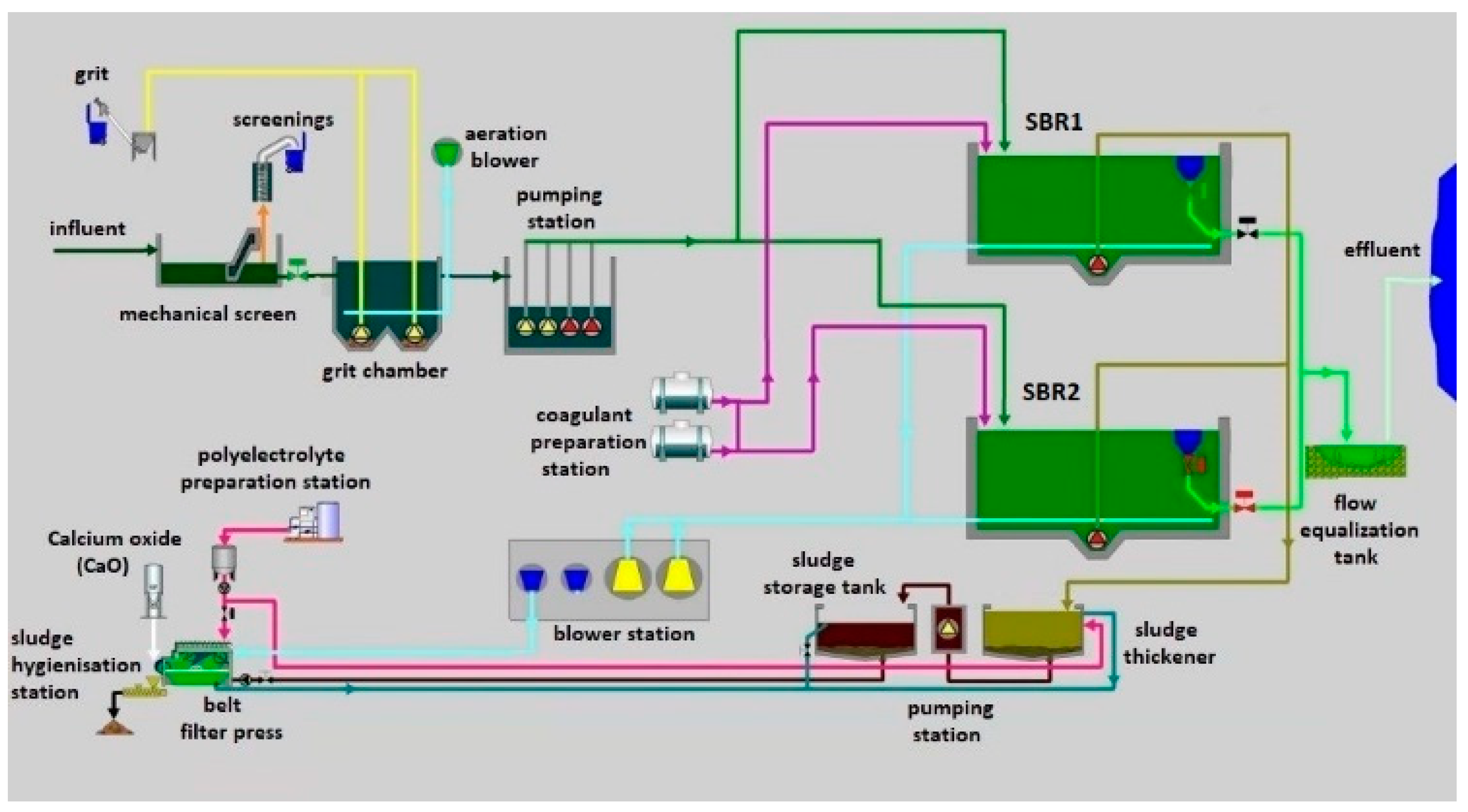

2.1. Characteristics of the Rabka-Zdrój WWTP

2.2. Sequencing Batch Reactor in the Rabka-Zdrój WWTP

- -

- Fine bubble aeration system with 1560 disc diffusers;

- -

- Two submersible mixers with a capacity of 10 kW;

- -

- Decanter of treated wastewater with a capacity of 1450 m3/h;

- -

- Excess sludge pump with a power of 9.0 kW and a capacity of 162 m3.

2.3. Analitycal and Statistical Methods

3. Results and Discussion

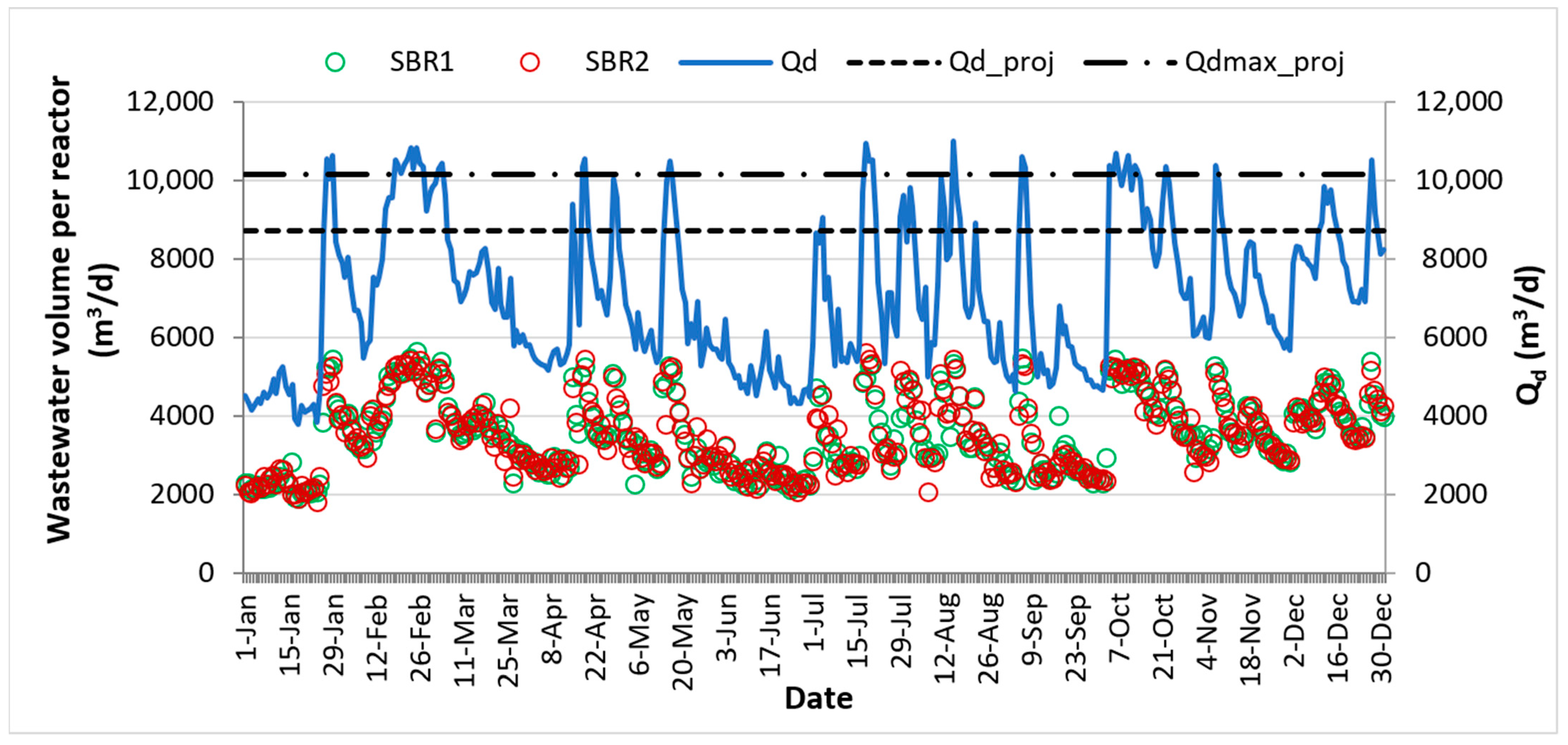

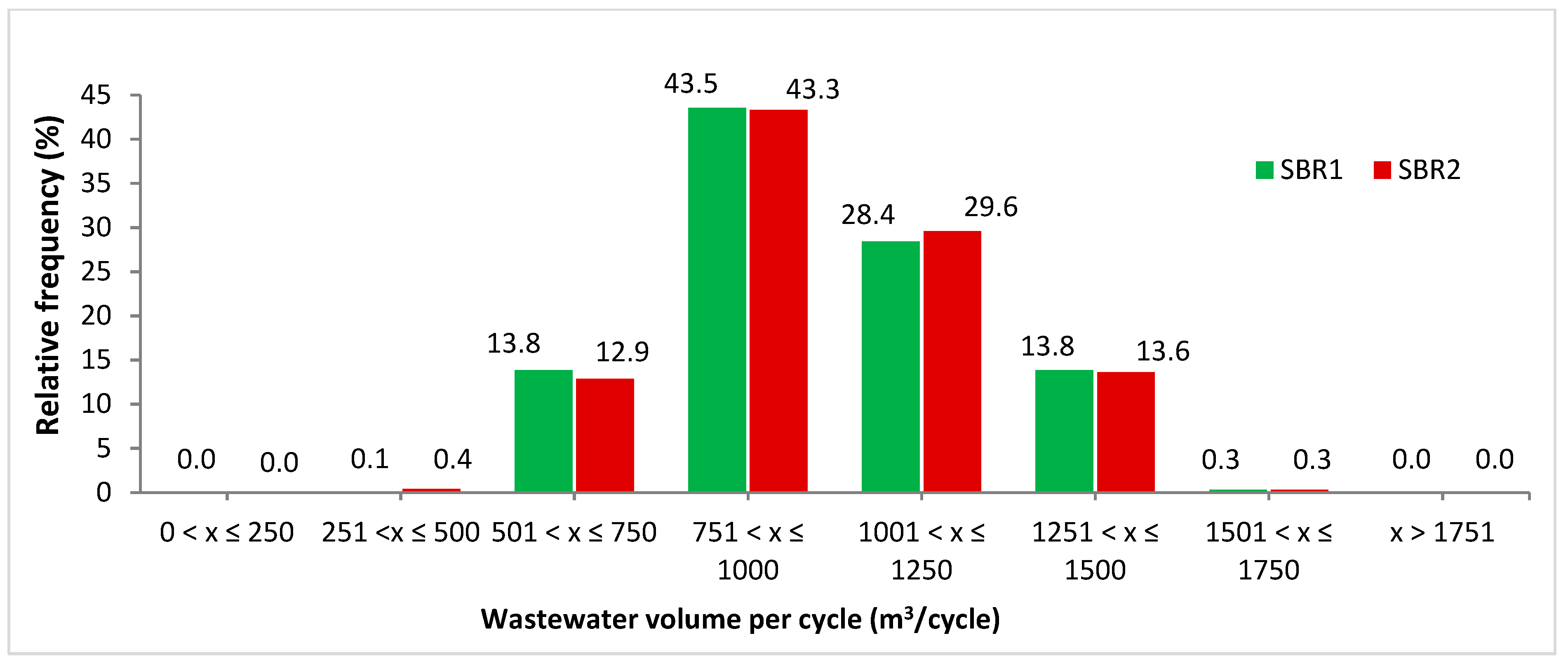

3.1. Characteristics of the Wastewater Inflow to SBR Reactors

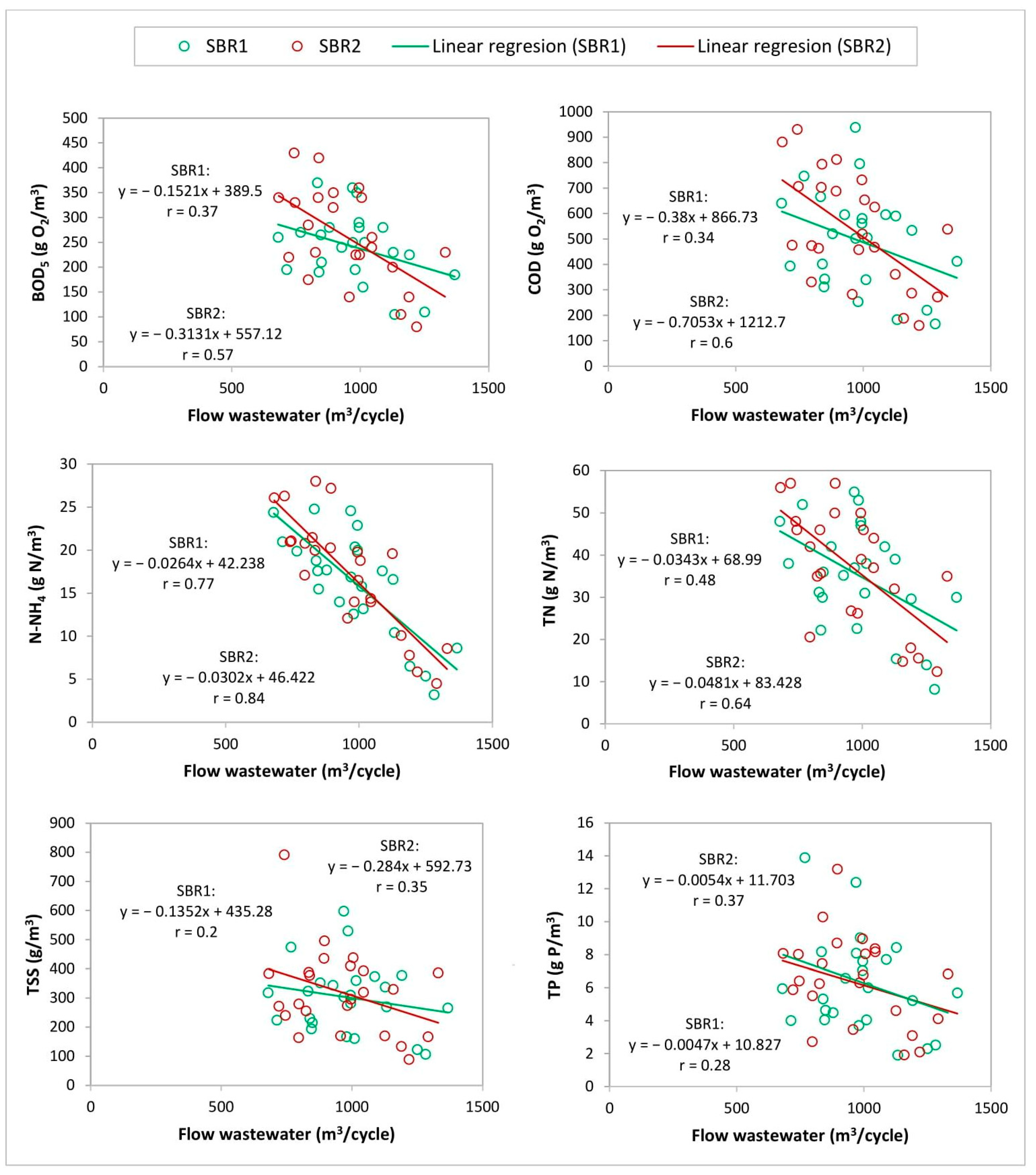

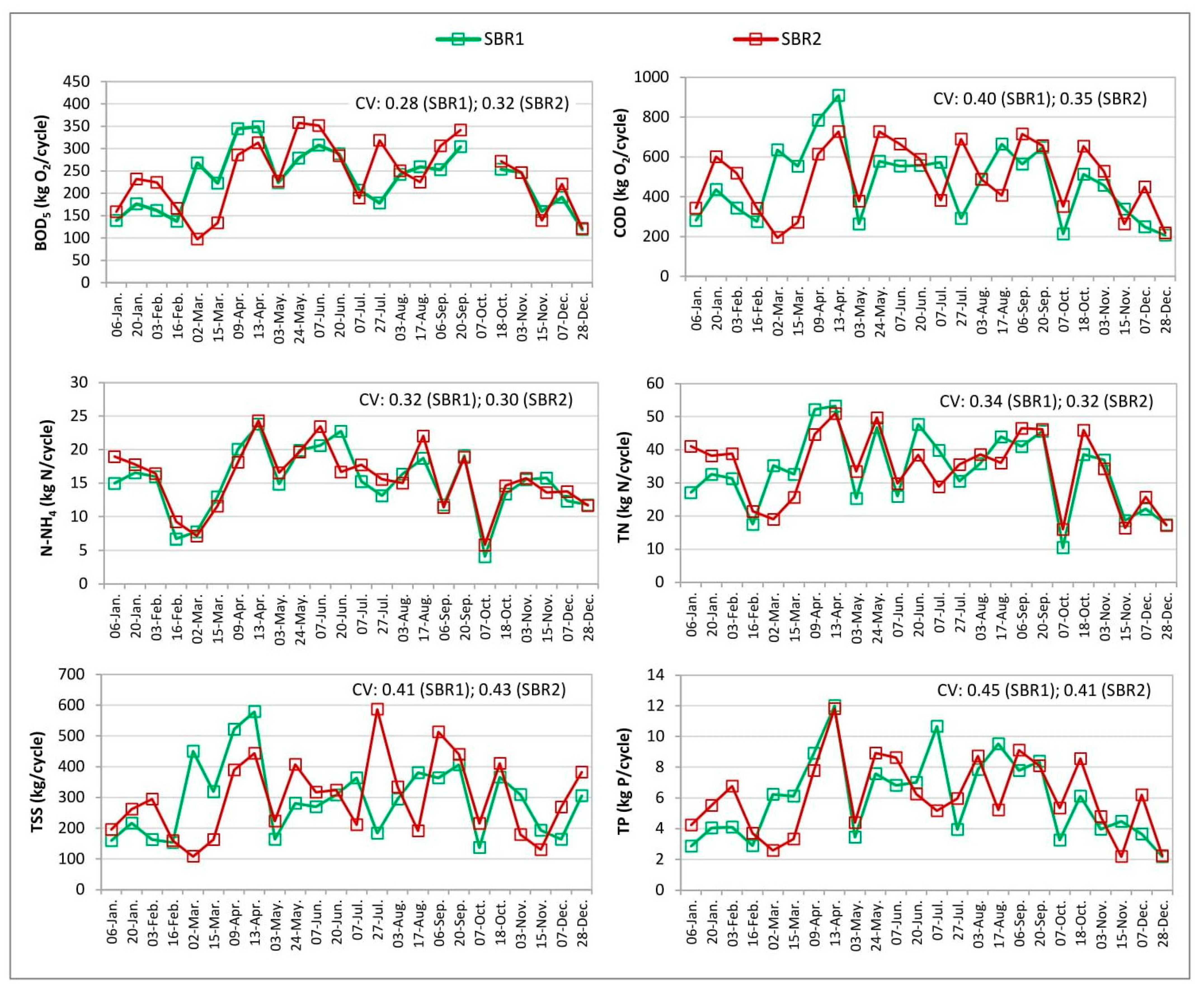

3.2. The Load of Pollutants in the Wastewater Flowing into the SBR Reactors

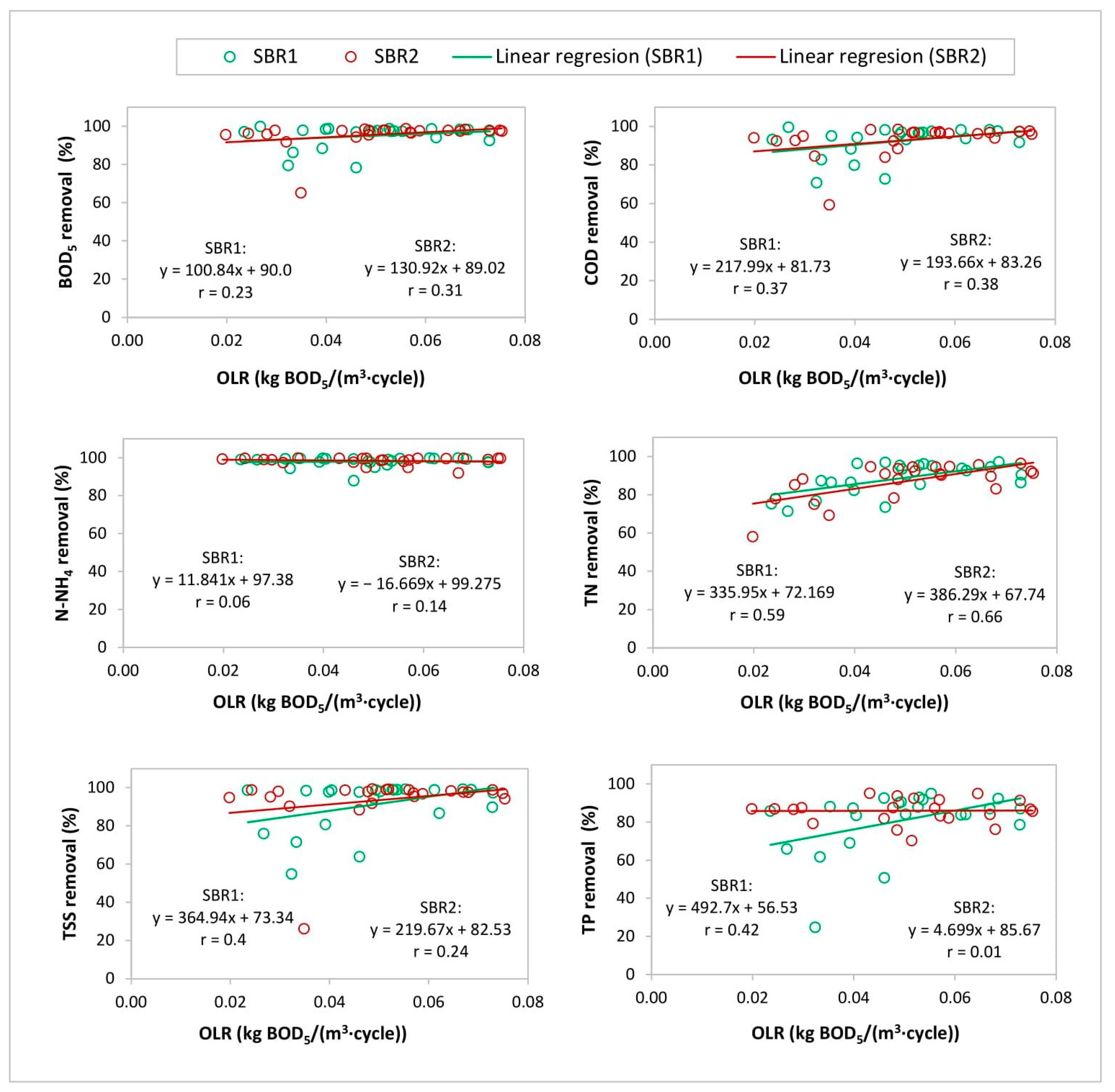

3.3. Influence of Uneven Wastewater Inflow on Technological Parameters of Sequencing Batch Reactors

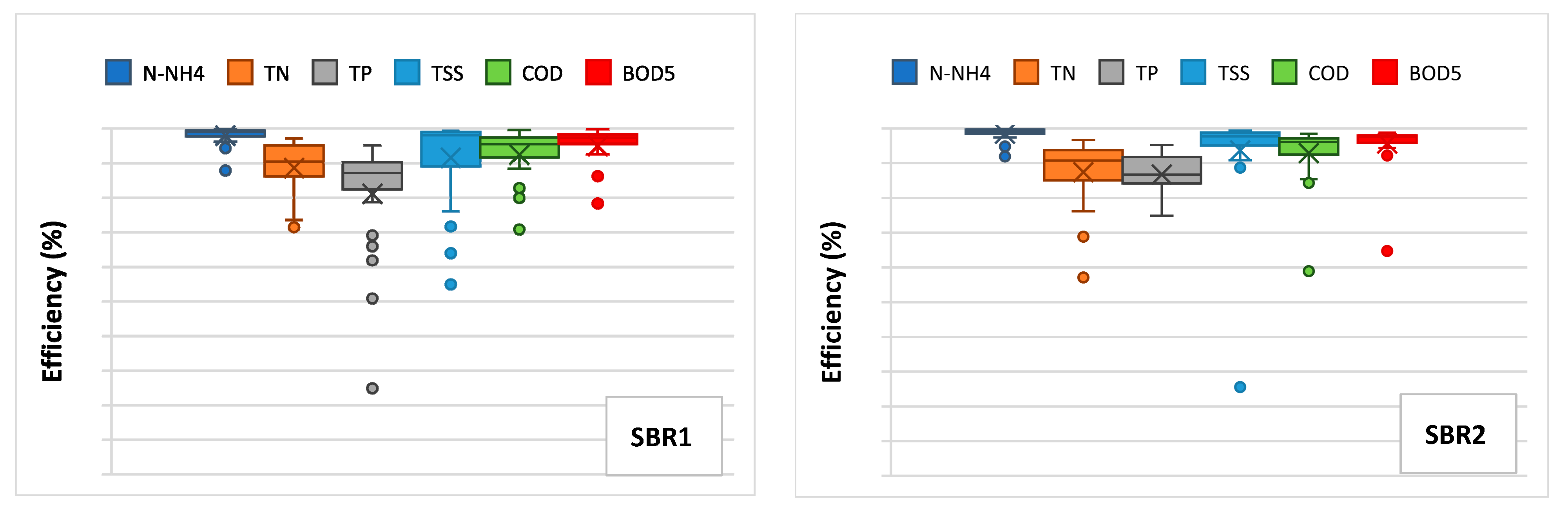

3.4. Assessment of the Efficiency of Sequencing Batch Reactors

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moretti, C.J.; Das, D.; Kistner, B.T.; Gullicks, H.; Hung, Y.-T. Activated Sludge and Other Aerobic Suspended Culture Processes. Water 2011, 3, 806–818. [Google Scholar] [CrossRef]

- Machineni, L. Review on biological wastewater treatment and resources recovery: Attached and suspended growth systems. Water Sci. Technol. 2019, 80, 2013–2026. [Google Scholar] [CrossRef] [PubMed]

- Goffi, A.S.; Trojan, F.; de Lima, J.D.; Lizot, M.; Thesari, S.S. Economic feasibility for selecting wastewater treatment systems. Water Sci. Technol. 2019, 78, 2518–2531. [Google Scholar] [CrossRef] [PubMed]

- Ghangrekar, M.M.; Behera, M. Suspended Growth Treatment Processes. In Comprehensive Water Quality and Purification; Ahuja, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 74–89. [Google Scholar] [CrossRef]

- Ontiveros, G.A.; Campanella, E.A. Environmental performance of biological nutrient removal processes from a life cycle perspective. Bioresour. Technol. 2013, 150, 506–512. [Google Scholar] [CrossRef]

- Orhon, D. Evolution of the activated sludge process: The first 50 years. J. Chem. Technol. Biol. 2015, 90, 608–640. [Google Scholar] [CrossRef]

- Kim, M.; Nakhla, G.; Keleman, M. Modeling the impact of food wastes on wastewater treatment plants. J. Environ. Manag. 2019, 237, 2344–2358. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.H.; Huang, Z.J.; Lu, S.J.; Zheng, J.; Zhang, X.X. Nutrients removal and bacterial community structure for low C/N municipal wastewater using a modified anaerobic/anoxic/oxic (mA2/O) process in North China. Bioresour. Technol. 2017, 243, 975–985. [Google Scholar] [CrossRef]

- Karczmarczyk, A.; Bus, A.; Baryła, A. Assessment of the Efficiency, Environmental and Economic Effects of Compact Type On-Site Wastewater Treatment Plants—Results from Random Testing. Sustainability 2021, 13, 982. [Google Scholar] [CrossRef]

- Henze, M.; van Loosdrecht, M.C.M.; Ekama, G.A.; Brdjanovic, D. Biological Wastewater Treatment: Principles, Modeling, and Design; IWA Publishing: London, UK, 2008. [Google Scholar] [CrossRef] [Green Version]

- Hauduc, H.; Rieger, L.; Oehmen, A.; van Loosdrecht, M.C.; Comeau, Y.; Héduit, A.; Vanrolleghem, P.A.; Gillot, S. Critical review of activated sludge modeling: State of process knowledge, modeling concepts, and limitations. Biotechnol. Bioeng. 2013, 110, 24–46. [Google Scholar] [CrossRef]

- Wilderer, P.A.; Irvine, R.L.; Gronszy, M.C. Sequencing Batch Reactor Technology; IWA Scientific and Technical Report No. 10; IWA Publishing: London, UK, 2001. [Google Scholar]

- Artan, N.; Orhon, D. Mechanism and Design of Sequencing Batch Reactors for Nutrient Removal; Scientific and Technical Report Series, No. 19; IWA Publishing: London, UK, 2005. [Google Scholar]

- Gerardi, M. Troubleshooting the Sequencing Batch Reactor; John Wiley and Sons, Inc.: New York, NY, USA, 2010. [Google Scholar]

- Tomaszek, J.A. Comparison between Sequencing Batch and Continuous Flow Activated Sludge Systems. In Chemistry for the Protection of the Environment 4. Environmental Science Research; Mournighan, R., Dudzińska, M.R., Barich, J., Gonzalez, M.A., Black, R.K., Eds.; Springer: Boston, MA, USA, 2005; Volume 59. [Google Scholar] [CrossRef]

- Dutta, A.; Sarkar, S. Sequencing Batch Reactor for Wastewater Treatment: Recent Advances. Curr. Pollut. Rep. 2015, 1, 177–190. [Google Scholar] [CrossRef]

- Smyth, M.; Horan, N.J. Sequence Batch Reactors–past, present and future. In Proceedings of the 8th European Waste Water Management Conference, Manchester, UK, 7–8 October 2014. [Google Scholar]

- Steinmetz, H.; Wiese, J.; Schmitt, T.G. Efficiency of SBR technology in municipal wastewater treatment plants. Water Sci. Technol. 2002, 46, 293–299. [Google Scholar] [CrossRef]

- Al-Rekabi, W.S.; Qiang, H.; Qiang, W.W. Review on Sequencing Batch Reactors. Pak. J. Nutr. 2007, 6, 11–19. [Google Scholar]

- Mahvi, A.H. Sequencing batch reactor: A promising technology in wastewater treatment. J. Environ. Health Sci. 2008, 5, 79–90. [Google Scholar]

- Benavides-Sanchez, J.; Vuono, M.; Dionisi, D. Model-based comparison of sequencing batch reactors and continuous-flow activated sludge processes for biological wastewater treatment. Comput. Chem. Eng. 2021, 144, 107127. [Google Scholar] [CrossRef]

- Khalaf, A.; Ibrahim, W.A.; Fayed, M.; Eloffy, M.G. Comparison between the performance of activated sludge and sequence batch reactor systems for dairy wastewater treatment under different operating conditions. Alex. Eng. J. 2021, 60, 1433–1445. [Google Scholar] [CrossRef]

- Masłoń, A.; Tomaszek, J.A. A study on the use of the BioBall® as a biofilm carrier in a sequencing batch reactor. Bioresour. Technol. 2015, 196, 577–585. [Google Scholar] [CrossRef]

- Podedworna, J.; Zubrowska-Sudol, M.; Sytek-Szmeichel, K.; Gnida, A.; Surmacz-Górska, J.; Marciocha, D. Impact of multiple wastewater feedings on the efficiency of nutrient removal in an IFAS-MBSBBR: Number of feedings vs. efficiency of nutrient removal. Water Sci. Technol. 2016, 74, 1457–1468. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Miao, Y.; Sun, Y.; Li, X.; Zhang, Q.; Peng, Y. Feasibility of in situ enriching anammox bacteria in a sequencing batch biofilm reactor (SBBR) for enhancing nitrogen removal of real domestic wastewater. Chem. Eng. J. 2018, 352, 847–854. [Google Scholar] [CrossRef]

- Chen, W.; Lu, Y.; Jin, Q.; Zhang, M.; Wu, J. A novel feedforward control strategy for simultaneous nitrification and denitrification (SND) in aerobic granular sludge sequential batch reactor (AGS-SBR). J. Environ. Manag. 2020, 260, 110103. [Google Scholar] [CrossRef]

- Li, D.; Zhang, S.; Li, S.; Zeng, H.; Zhang, J. Aerobic granular sludge operation and nutrients removal mechanism in a novel configuration reactor combined sequencing batch reactor and continuous-flow reactor. Bioresour. Technol. 2019, 292, 122024. [Google Scholar] [CrossRef]

- Czarnota, J.; Masłoń, A.; Zdeb, M.; Łagód, G. The Impact of Different Powdered Mineral Materials on Selected Properties of Aerobic Granular Sludge. Molecules 2020, 25, 386. [Google Scholar] [CrossRef] [Green Version]

- He, W.; Wang, Q.; Zhu, Y.; Wang, K.; Mao, J.; Xue, X.; Shi, Y. Innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material. Bioresour. Technol. 2021, 324, 124675. [Google Scholar] [CrossRef] [PubMed]

- Nowobilska-Majewska, E.; Bugajski, P.M. The Analysis of the Amount of Pollutants in Wastewater after Mechanical Treatment in the Aspect of their Susceptibility to Biodegradation in the Treatment Plant in Nowy Targ. J. Ecol. Eng. 2019, 20, 135–143. [Google Scholar] [CrossRef]

- Bugajski, P.M.; Pawełek, J.; Jóźwiakowska, K. The Interdependence of Organic and Biogenic Pollutants Concentrations in the Aspect of their Susceptibility to Biodegradation – A Case Study. J. Ecol. Eng. 2021, 22, 138–147. [Google Scholar] [CrossRef]

- Mucha, Z.; Kułakowski, P. Turbidity measurements as a tool of monitoring and control of the SBR effluent at the small wastewater treatment plant–preliminary study. Arch. Environ. Prot. 2016, 42, 33–36. [Google Scholar] [CrossRef] [Green Version]

- Puig, S.; Vives, M.T.; Corominas, L.; Balaguer, M.; Colprim, J. Wastewater nitrogen removal in SBRs, applying a step-feed strategy: From lab-scale to pilot-plant operation. Water Sci. Technol. 2004, 50, 89–96. [Google Scholar] [CrossRef]

- Mahvi, A.; Mesdaghinia, A.; Karakani, F. Feasibility of continuous flow sequencing batch reactor in domestic wastewater treatment. J. Appl. Sci. 2005, 1, 348–353. [Google Scholar] [CrossRef]

- Simon, J.; Wiese, J.; Steinmetz, H. A comparison of continuous flow and sequencing batch reactor plants concerning integrated operation of sewer systems and wastewater treatment plants. Water Sci. Technol. 2006, 54, 241–248. [Google Scholar] [CrossRef]

- Jafarinejad, S. Cost estimation and economical evaluation of three configurations of activated sludge process for a wastewater treatment plant (WWTP) using simulation. Appl. Water Sci. 2017, 7, 2513–2521. [Google Scholar] [CrossRef] [Green Version]

- Masłoń, A. The dynamics of wastewater flow to the wastewater treatment plant in the aspect of the sequencing batch reactors functioning. Instal 2017, 10, 57–62. (In Polish) [Google Scholar]

- Stanisz, A. An Affordable Statistic Course with the Use of STATISTICA PL on the Examples of Tom 1 Medicine. Basic Statistics; Publisher: Cracow, Poland, 2006. (In Polish) [Google Scholar]

- Chmielowski, K.; Satora, S.; Wałega, A. The efficiency of the sewage treatment based on the example of the sewage treatment plant for the city of Krynica-Zdrój. Infr. Ecol. Rural Areas 2009, 9, 73–83. (In Polish) [Google Scholar]

- Masłoń, A. Dual system of wastewater treatment in the Gorlice WWTP. Gas Water Sanit. Eng. 2015, 8, 295–300. (In Polish) [Google Scholar] [CrossRef]

- Bartkowska, I. Variation of purified wastewater effluent. Ecol. Eng. 2016, 48, 1–8. (In Polish) [Google Scholar] [CrossRef] [Green Version]

- Widera, D.; Pawęska, K. Characteristics of the wastewater inflow to the wastewater treatment plant in the tourist resort. Ecol. Eng. 2018, 19, 53–60. [Google Scholar] [CrossRef] [Green Version]

- Wąsik, E.; Chmielowski, K.; Młyński, D.; Bedla, B. Selected aspects of functioning of the sewage sludge treatment plant in Szczawnica in terms of receiver water quality. Ecol. Eng. 2017, 18, 41–51. [Google Scholar] [CrossRef]

- Masłoń, A. Hydraulic operating conditions of sequencing batch reactor. Gas Water Sanit. Eng. 2017, 12, 496–500. (In Polish) [Google Scholar] [CrossRef]

- Chmielowski, K.; Bugajski, P.; Kaczor, G. Comparative analysis of the quality of sewage discharged from selected agglomeration sewerage systems. J. Water Land Dev. 2016, 30, 35–42. [Google Scholar] [CrossRef]

- Chmielowski, K.; Bugajski, P.; Kaczor, G. Compositional analysis of the sewage incoming to and discharged from the sewage treatment plant in Kolbuszowa Dolna. J. Ecol. Eng. 2016, 17, 9–16. [Google Scholar] [CrossRef] [Green Version]

- Orchowski, M.; Masłoń, A.; Heidrich, Z. Energy consumption of the Sandomierz wastewater treatment plant. Gas Water Sanit. Eng. 2018, 2, 68–73. (In Polish) [Google Scholar] [CrossRef]

- Czarnota, J.; Masłoń, A. Analysis of technological effectiveness of wastewater treatment plant in Nisko. JCEEA 2015, 62, 75–86. [Google Scholar] [CrossRef]

- Szczerbińska, N.; Gałczyńska, M.; Ulas, K.; Burczyk, P.; Mikołajczak, M.; Busko, M. Efficiency of sewage treatment plant in Gryfino. Water Environ. Rural Areas 2018, 18, 85–98. (In Polish) [Google Scholar]

- Langergraber, G.; Alex, J.; Weissenbacher, N.; Woerner, D.; Ahnert, M.; Frehmann, T.; Halft, N.; Hobus, I.; Plattes, M.; Spering, V.; et al. Generation of diurnal variation for influent data for dynamic simulation. Water Sci. Technol. 2008, 57, 1483–1486. [Google Scholar] [CrossRef] [PubMed]

- Dzubur, A.; Serdarevic, A. Daily influent variation for dynamic modeling of wastewater treatment plants. Coupled Syst. Mech. 2020, 9, 111–123. [Google Scholar] [CrossRef]

- Martin, C.; Vanrolleghem, P.A. Analysing, completing, and generating influent data for WWTP modelling: A critical review. Environ. Model. Softw. 2014, 60, 188–201. [Google Scholar] [CrossRef] [Green Version]

- Masłoń, A.; Tomaszek, J.A. Sequencing Batch Reactors. Fundamentals of Technology, Design Principles and Examples of Applications; Publishing House Seidel Przywecki: Warszawa, Poland, 2017. [Google Scholar]

- Lee, S.-H.; Kang, H.-J.; Park, H.-D. Influence of influent wastewater communities on temporal variation of activated sludge communities. Water Res. 2015, 73, 132–144. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, H.; Jungles, M.K.; Hoffmann, H.; Antonio, R.V.; Costa, R.H. Full-scale sequencing batch reactor (SBR) for domestic wastewater: Performance and diversity of microbial communities. Bioresour. Technol. 2013, 132, 262–268. [Google Scholar] [CrossRef] [Green Version]

- Ignatowicz, K.; Struk-Sokołowska, J.; Kazimierowicz, J. Assessment of the removal of carbon, nitrogen and phosphorus in municipal wastewater treatment plants in Sokółka. Econ. Environ. 2013, 4, 158–168. [Google Scholar]

- Bartkowska, I.; Dzienis, L.; Wawrentowicz, D. Effectiveness of wastewater treatment plants in Hajnówka and its modernization proposal. Ecol. Eng. 2011, 24, 226–235. [Google Scholar]

- Bartkowska, I.; Klaus, W. Performance analysis of sewage sludge treatment plant working in the SBR system. Econ. Environ. 2013, 4, 107–117. [Google Scholar]

- Piotrowski, R.; Ujazdowski, T. Designing Control Strategies of Aeration System in Biological WWTP. Energies 2020, 13, 3619. [Google Scholar] [CrossRef]

- Zaburko, J.; Głowienka, R.; Widomski, M.K.; Szulżyk-Cieplak, J.; Babko, R.; Łagód, G. Modeling of the Aeration System of a Sequencing Batch Reactor. J. Ecol. Eng. 2020, 21, 249–256. [Google Scholar] [CrossRef]

| 8 h Cycle | ||||||||||||||||||||

| Filling | ||||||||||||||||||||

| Anoxic stirring | ||||||||||||||||||||

| Aeration | ||||||||||||||||||||

| Settling | ||||||||||||||||||||

| Decantation | ||||||||||||||||||||

| Hour of cycle | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||||||||||

| 6 h Cycle | ||||||||||||||||||||

| Filling | ||||||||||||||||||||

| Anoxic stirring | ||||||||||||||||||||

| Aeration | ||||||||||||||||||||

| Settling | ||||||||||||||||||||

| Decantation | ||||||||||||||||||||

| Hour of cycle | 0 | 1 | 2 | 3 | 4 | 5 | 6 | |||||||||||||

| Parameter | SBR1 | SBR2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Average | SD | CV | Min. | Max. | Average | SD | CV | |

| pH | 7.0 | 7.6 | 7.3 | 0.1 | 0.02 | 7.0 | 7.6 | 7.3 | 0.1 | 0.02 |

| COD (g O2/m3) | 166.0 | 939.0 | 491.7 | 196.8 | 0.40 | 160.0 | 931.0 | 533.7 | 220.0 | 0.41 |

| BOD5 (g O2/m3) | 105.0 | 370.0 | 241.3 | 69.1 | 0.29 | 80.0 | 430.0 | 260.2 | 96.1 | 0.37 |

| TSS (g/m3) | 107.0 | 598.0 | 301.8 | 120.0 | 0.40 | 89.0 | 792.0 | 319.3 | 148.7 | 0.47 |

| TN (g N/m3) | 8.2 | 55.0 | 35.2 | 12.5 | 0.36 | 12.4 | 57.0 | 37.1 | 13.8 | 0.37 |

| N-NH4 (g N/m3) | 3.2 | 24.8 | 16.2 | 6.0 | 0.37 | 4.5 | 28.0 | 17.3 | 6.7 | 0.39 |

| N-NO2 (g N/m3) | 0.07 | 0.24 | 0.12 | 0.04 | 0.36 | 0.06 | 0.24 | 0.12 | 0.05 | 0.37 |

| N-NO3 (g N/m3) | 0.25 | 2.88 | 0.83 | 0.78 | 0.94 | 0.20 | 2.80 | 0.79 | 0.78 | 0.99 |

| P-PO4 (g P/m3) | 1.02 | 4.89 | 2.5 | 1.1 | 0.47 | 0.54 | 6.57 | 2.7 | 1.3 | 0.49 |

| TP (g P/m3) | 1.92 | 13.9 | 6.2 | 2.9 | 0.44 | 1.94 | 13.2 | 6.5 | 2.7 | 0.42 |

| Input load (kg/cycle) | Output load (kg/cycle) | ||||||||||||

| BOD5 | COD | TSS | TN | N-NH4 | TP | BOD5 | COD | TSS | TN | N-NH4 | TP | ||

| Input load | BOD5 | 1 | |||||||||||

| (kg/cycle) | COD | 0.882 | 1 | ||||||||||

| TSS | 0.771 | 0.908 | 1 | ||||||||||

| TN | 0.813 | 0.880 | 0.783 | 1 | |||||||||

| N-NH4 | 0.634 | 0.618 | 0.445 | 0.709 | 1 | ||||||||

| TP | 0.775 | 0.909 | 0.807 | 0.815 | 0.596 | 1 | |||||||

| Output load (kg/cycle) | BOD5 | 0.007 | 0.192 | 0.095 | 0.205 | 0.184 | 0.033 | 1 | |||||

| COD | −0.098 | 0.037 | 0.026 | 0.044 | 0.026 | −0.098 | 0.944 | 1 | |||||

| TSS | −0.144 | 0.061 | −0.033 | 0.074 | 0.030 | −0.088 | 0.938 | 0.900 | 1 | ||||

| TN | −0.076 | 0.143 | 0.173 | 0.064 | 0.009 | −0.070 | 0.761 | 0.485 | 0.808 | 1 | |||

| N-NH4 | 0.059 | 0.155 | 0.113 | 0.140 | 0.086 | 0.056 | 0.700 | 0.696 | 0.631 | 0.507 | 1 | ||

| TP | 0.071 | 0.278 | 0.131 | 0.277 | 0.273 | 0.152 | 0.901 | 0.841 | 0.914 | 0.775 | 0.656 | 1 | |

| Input load (kg/cycle) | Output load (kg/cycle) | ||||||||||||

| BOD5 | COD | TSS | TN | N-NH4 | TP | BOD5 | COD | TSS | TN | N-NH4 | TP | ||

| Input load | BOD5 | 1 | |||||||||||

| (kg/cycle) | COD | 0.953 | 1 | ||||||||||

| TSS | 0.738 | 0.778 | 1 | ||||||||||

| TN | 0.765 | 0.822 | 0.625 | 1 | |||||||||

| N-NH4 | 0.624 | 0.563 | 0.296 | 0.646 | 1 | ||||||||

| TP | 0.852 | 0.875 | 0.690 | 0.797 | 0.543 | 1 | |||||||

| Output load (kg/cycle) | BOD5 | −0.283 | −0.229 | −0.250 | 0.142 | 0.139 | −0.174 | 1 | |||||

| COD | −0.365 | −0.298 | −0.281 | 0.041 | −0.062 | −0.219 | 0.925 | 1 | |||||

| TSS | −0.268 | −0.211 | −0.227 | 0.131 | 0.106 | −0.172 | 0.988 | 0.938 | 1 | ||||

| TN | −0.486 | −0.389 | −0.276 | −0.179 | −0.232 | −0.305 | 0.481 | 0.763 | 0.481 | 1 | |||

| N-NH4 | 0.239 | 0.301 | 0.214 | 0.408 | 0.405 | 0.463 | 0.006 | 0.014 | −0.051 | 0.017 | 1 | ||

| TP | 0.014 | 0.060 | 0.061 | 0.368 | 0.403 | 0.091 | 0.881 | 0.784 | 0.888 | 0.388 | 0.206 | 1 | |

| Parameter | SBR1 | SBR2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Average | SD | CV | Min. | Max. | Average | SD | CV | |

| HRT (h) | 0.96 | 2.21 | 1.4 | 0.3 | 0.25 | 0.95 | 2.1 | 1.5 | 0.4 | 0.25 |

| MLSS (kg/m3) | 1.98 | 3.27 | 2.5 | 0.4 | 0.14 | 1.96 | 3.29 | 2.48 | 0.3 | 0.14 |

| OLR (kg BOD5/m3·d) | 0.060 | 0.164 | 0.118 | 0.03 | 0.28 | 0.040 | 0.181 | 0.121 | 0.04 | 0.31 |

| F/M ratio (kg BOD5/kg MLSS·d) | 0.022 | 0.071 | 0.048 | 0.015 | 0.31 | 0.013 | 0.085 | 0.05 | 0.017 | 0.35 |

| OLR per cycle (g BOD5/m3 ·cycle) | 23.5 | 73.0 | 49.1 | 14.1 | 0.29 | 19.8 | 75.3 | 50.3 | 16.4 | 0.33 |

| F/M ratio (g BOD5/kg MLSS·cycle) | 10.6 | 31.5 | 20.0 | 6.0 | 0.30 | 6.8 | 31.9 | 20.5 | 7.1 | 0.35 |

| Parameter | Statistical Model | |

|---|---|---|

| SBR1 | SBR2 | |

| BOD5 | Y = 0.048x1 − 0.21x2 + 8.46 | Y = 0.051x1 − 0.18x2 + 3.22 |

| COD | Y = 0.23x1 − 0.45x2 + 10.44 | Y = 0.26x1 − 0.51x2 + 12.61 |

| TSS | Y = 0.06x1 + 0.02x2 − 28.16 | Y = 0.05x1 + 0.015x2 − 34.25 |

| TN | Y = 0.01x1 − 0.07x2 + 0.88 | Y = 0.012x1 − 0.1x2 + 0.66 |

| N-NH4 | Y = 0.01x1 − 0.64x2 + 1.14 | Y = 0.01x1 − 0.58x2 + 064 |

| TP | Y = 0.01x1 − 1.6x2 + 0.43 | Y = 0.01x1 − 1.3x2 + 0.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masłoń, A. Impact of Uneven Flow Wastewater Distribution on the Technological Efficiency of a Sequencing Batch Reactor. Sustainability 2022, 14, 2405. https://doi.org/10.3390/su14042405

Masłoń A. Impact of Uneven Flow Wastewater Distribution on the Technological Efficiency of a Sequencing Batch Reactor. Sustainability. 2022; 14(4):2405. https://doi.org/10.3390/su14042405

Chicago/Turabian StyleMasłoń, Adam. 2022. "Impact of Uneven Flow Wastewater Distribution on the Technological Efficiency of a Sequencing Batch Reactor" Sustainability 14, no. 4: 2405. https://doi.org/10.3390/su14042405