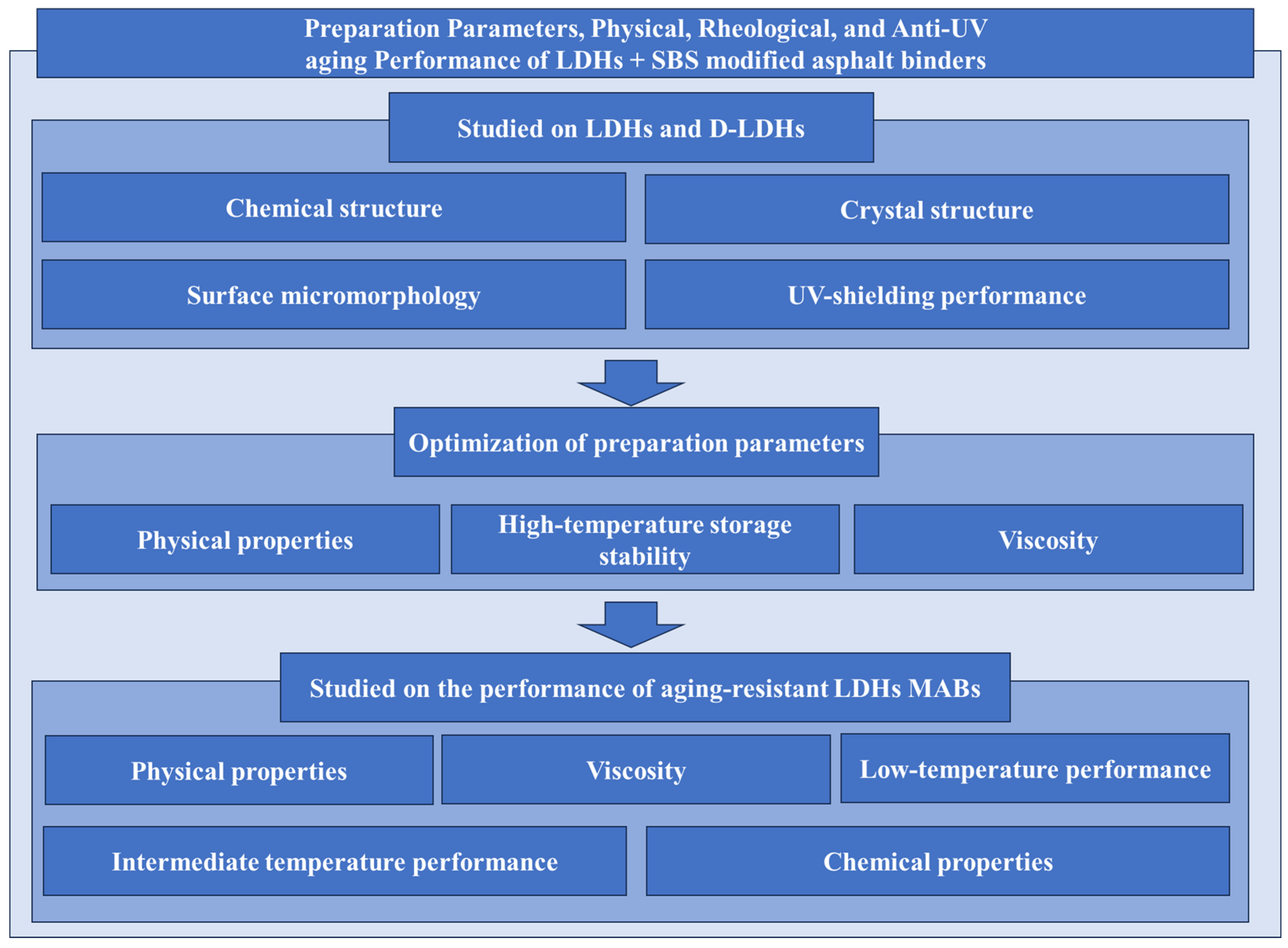

Physical, Rheological, and Anti-Ultraviolet Aging Performance of Layered Double Hydroxides + Styrene Block Copolymer-Modified Asphalt Binders

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Experimental Methods

2.2.1. Preparation of LDH MABs

2.2.2. Reclaiming of LDHs

2.2.3. Characterization of LDHs and D-LDHs

2.2.4. UV Aging Simulation Tests

2.2.5. Evaluation of UV Aging Resistance

3. Results and Discussions

3.1. Structure and Performance Characterization of LDHs and D-LDHs

3.1.1. Chemical Structures of LDHs and D-LDHs

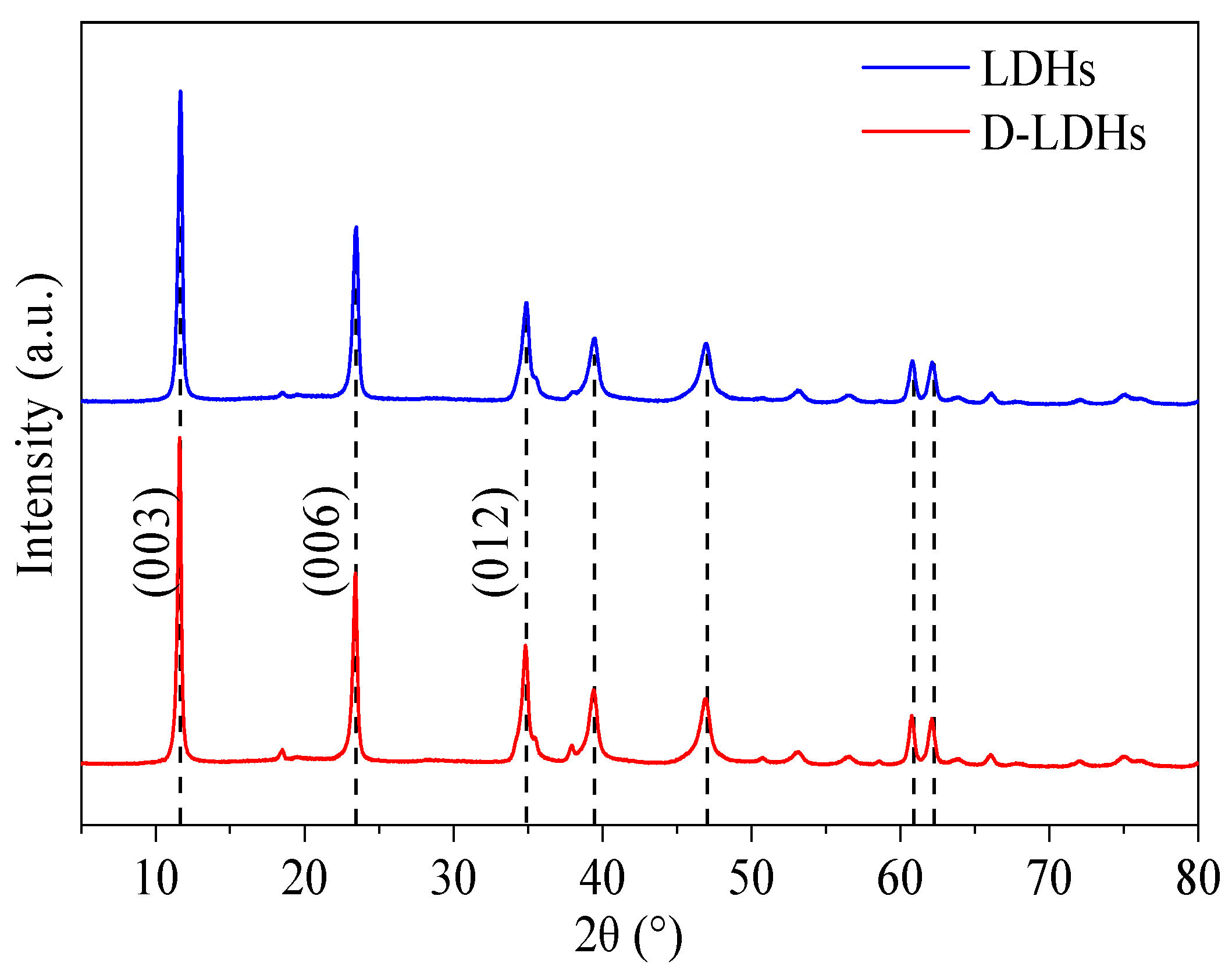

3.1.2. Crystal Structures of LDHs and D-LDHs

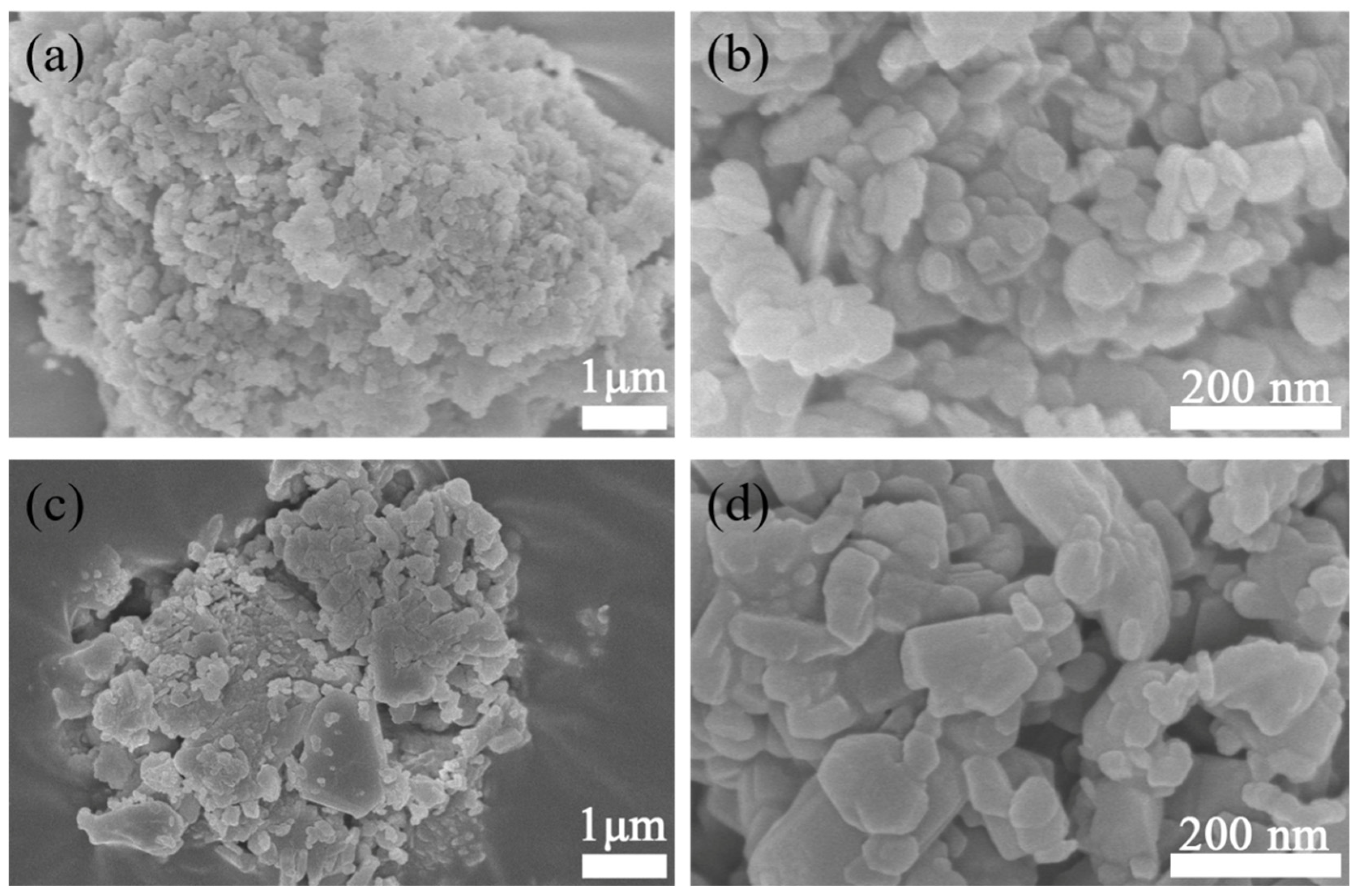

3.1.3. Surface Micromorphology of LDHs and D-LDHs

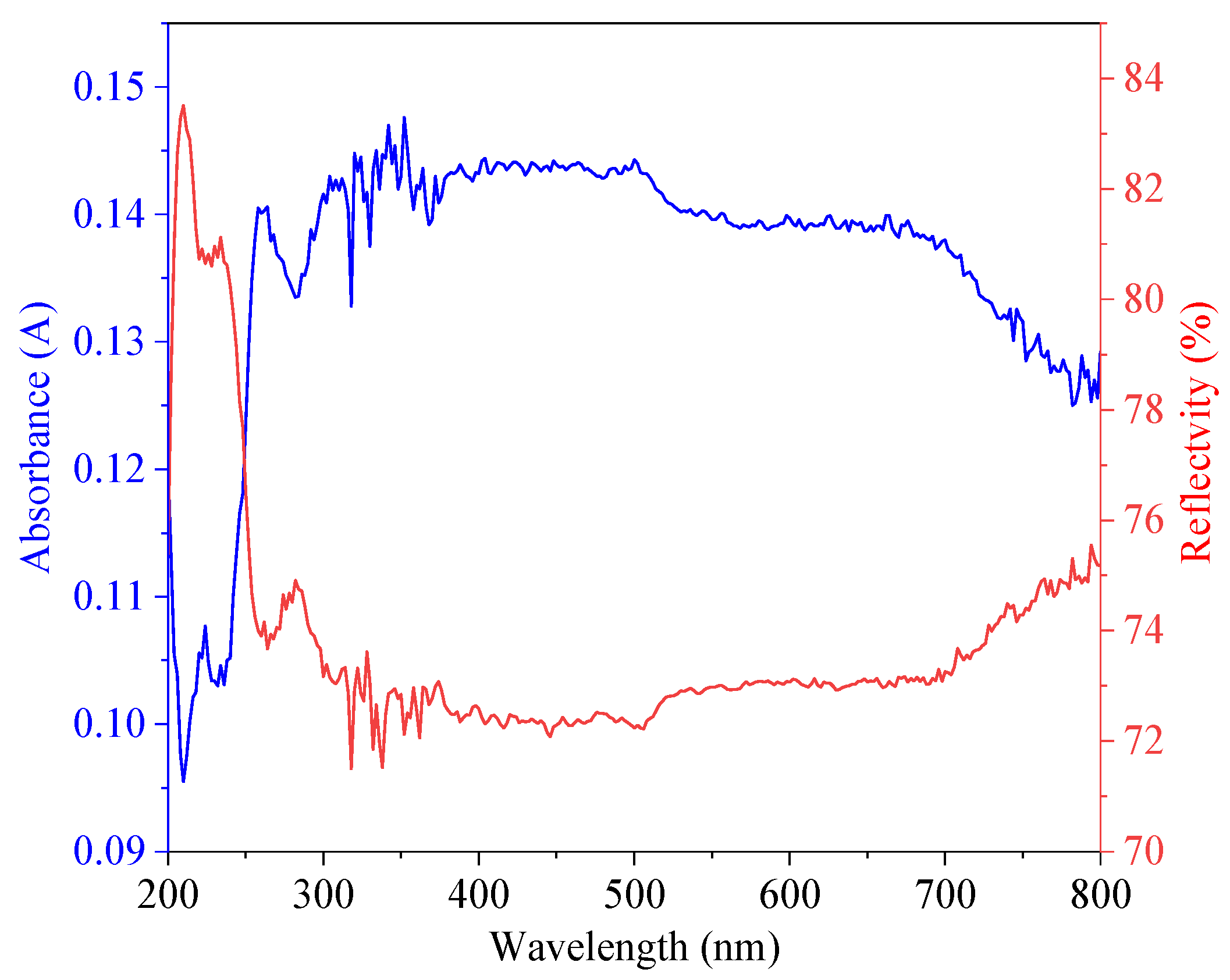

3.1.4. The UV-Shielding Properties of LDHs

3.2. Investigation of the Preparation Parameters of LDH MABs

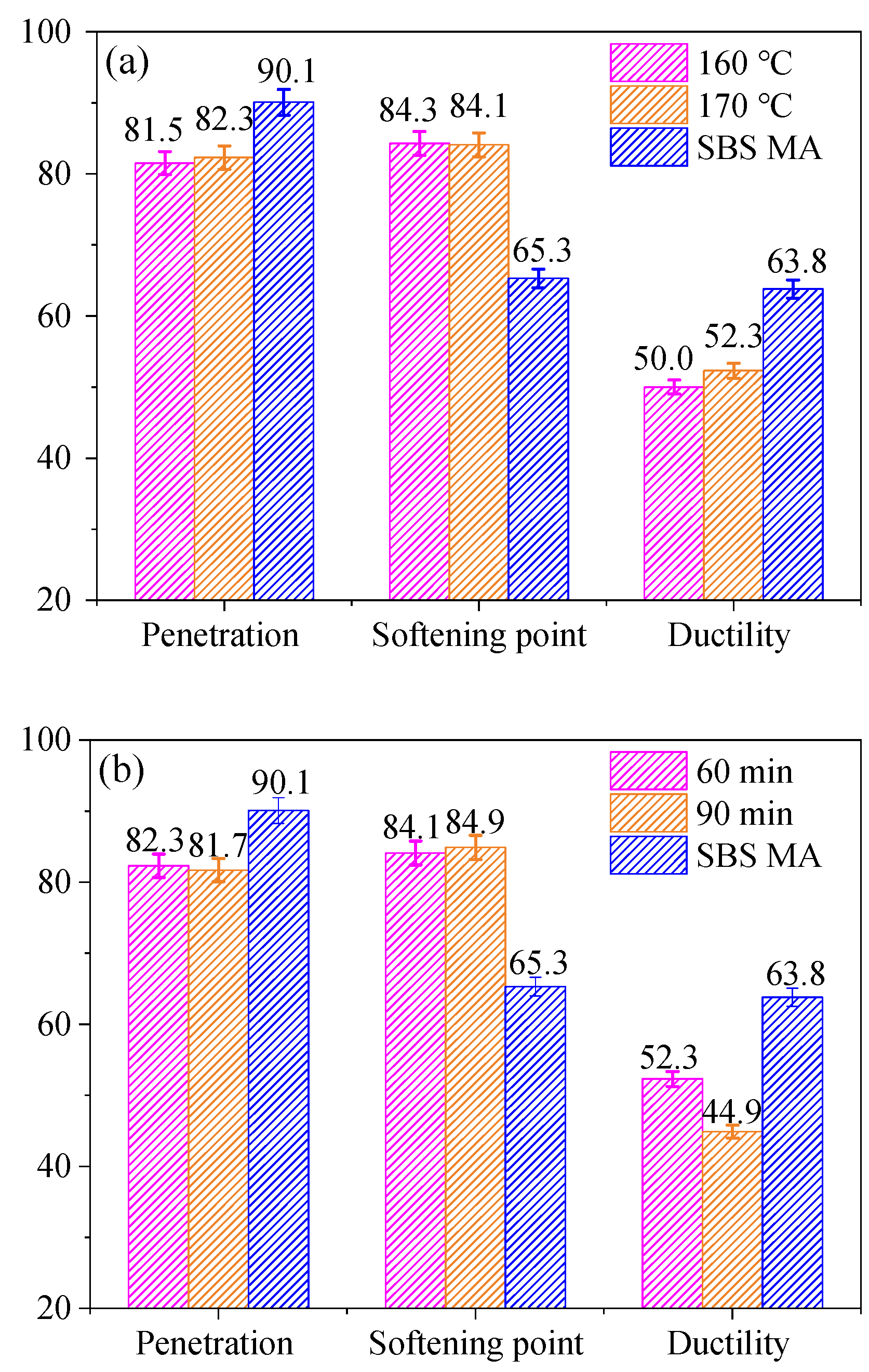

3.2.1. Effect of Preparation Parameters on the Physical Properties of LDH MABs

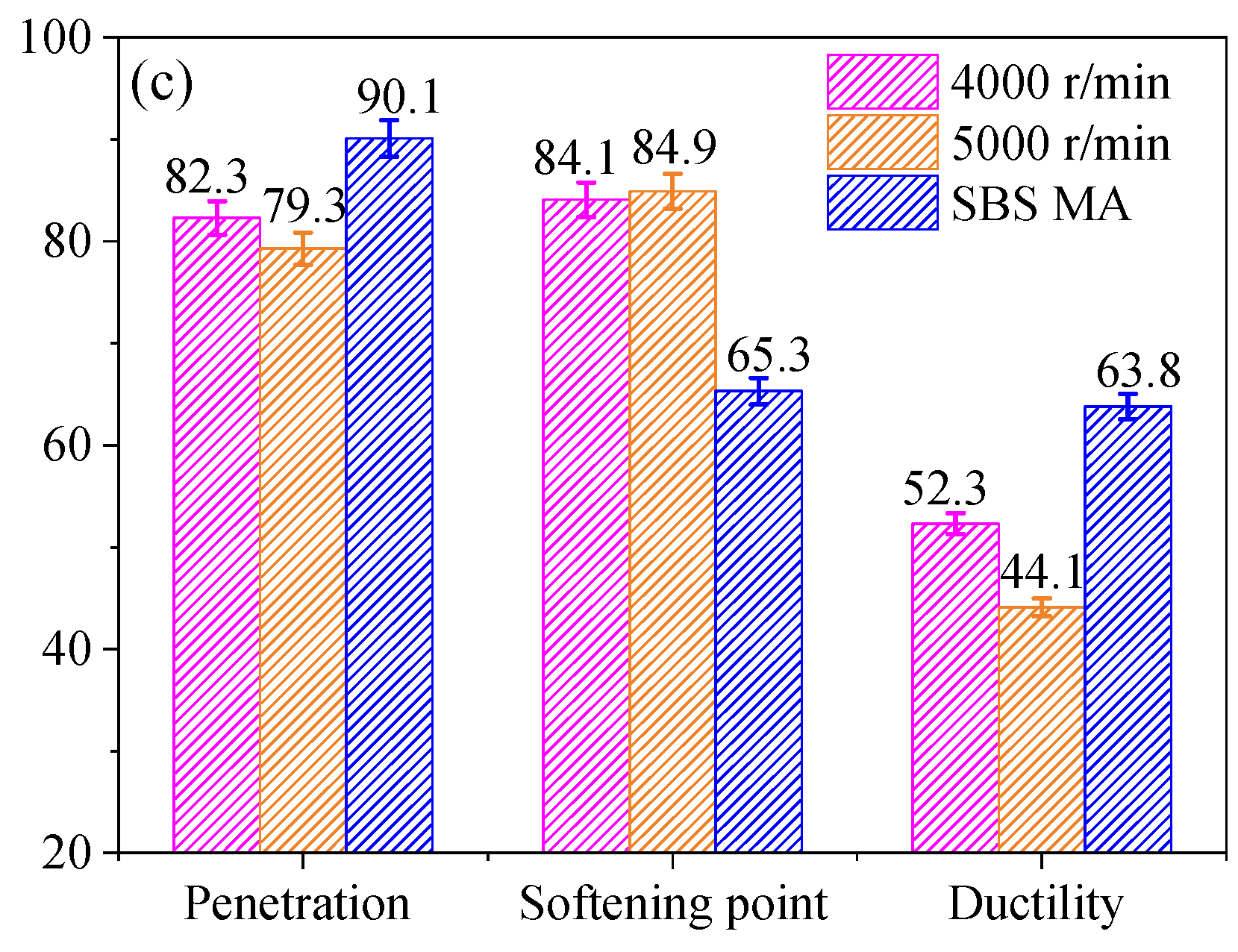

3.2.2. Effect of Preparation Parameters on the High-Temperature Storage Stability and Viscosity of LDH MABs

3.3. Investigation on the Anti-UV Aging Performance of LDH MABs

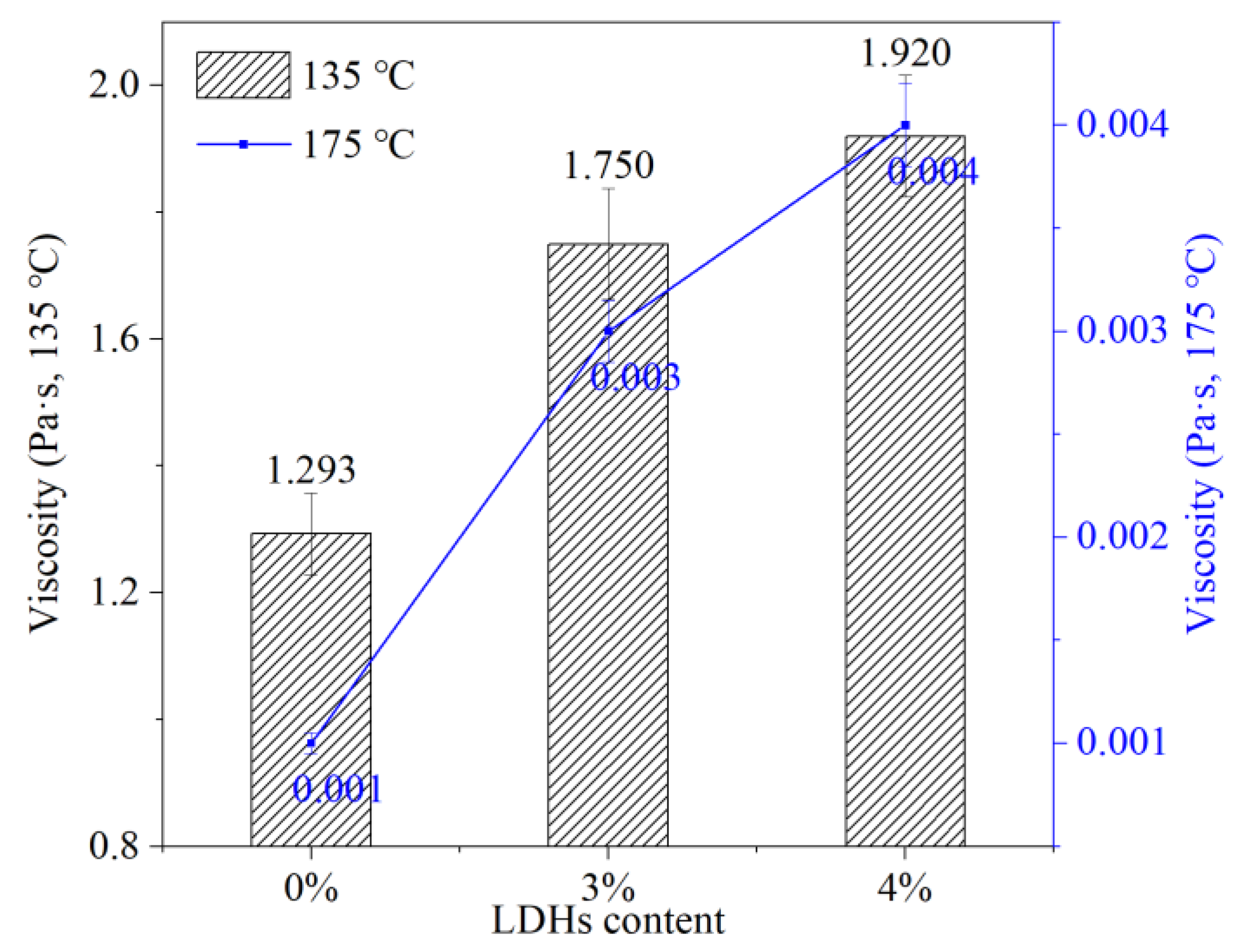

3.3.1. Effect of UV Aging on the Physical Properties of Aging-Resistant LDH MABs

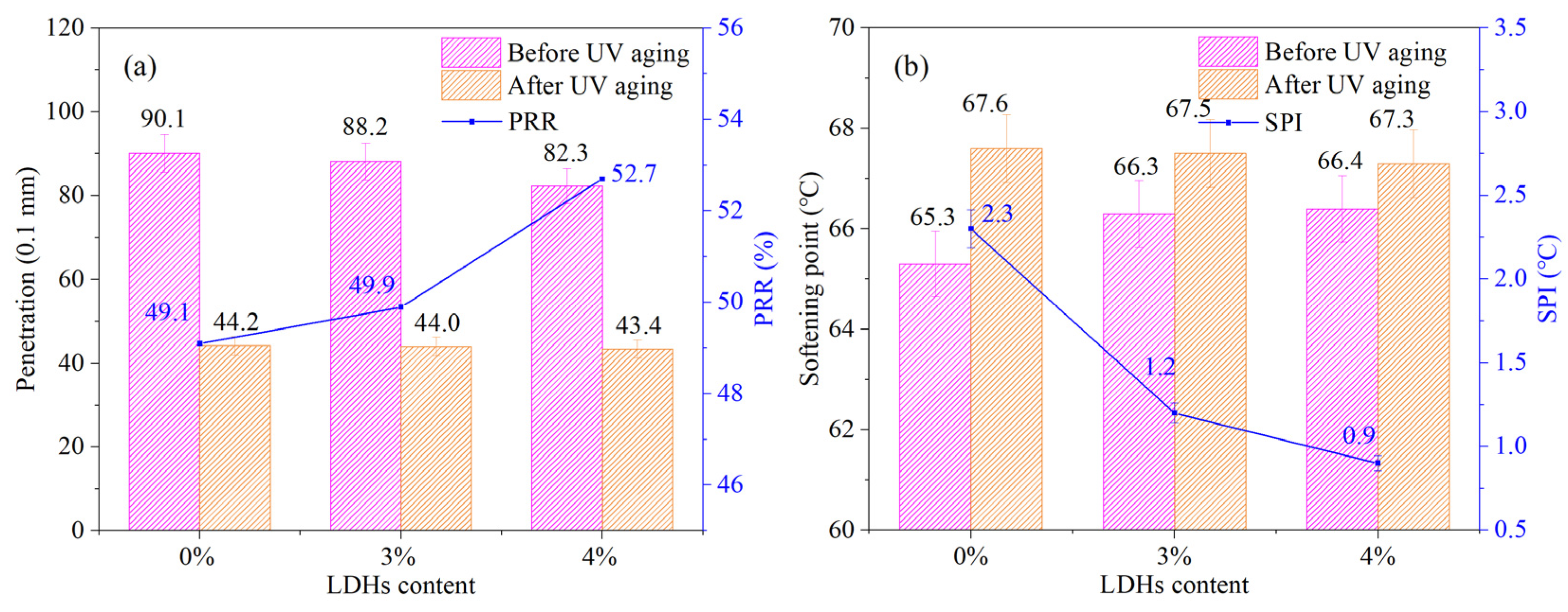

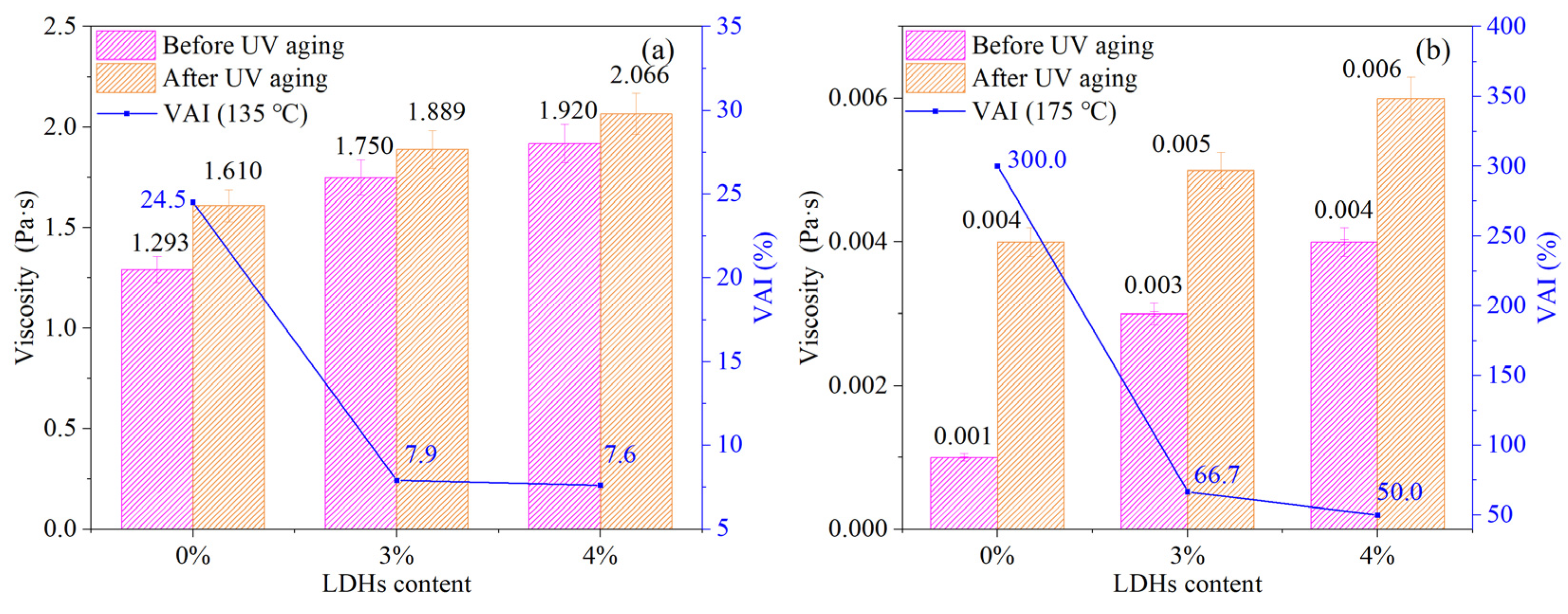

3.3.2. Effect of UV Aging on the Viscosity of Aging-Resistant LDH MABs

3.3.3. Effect of UV Aging on the Rheological Properties of Aging-Resistant LDH MABs

- (1)

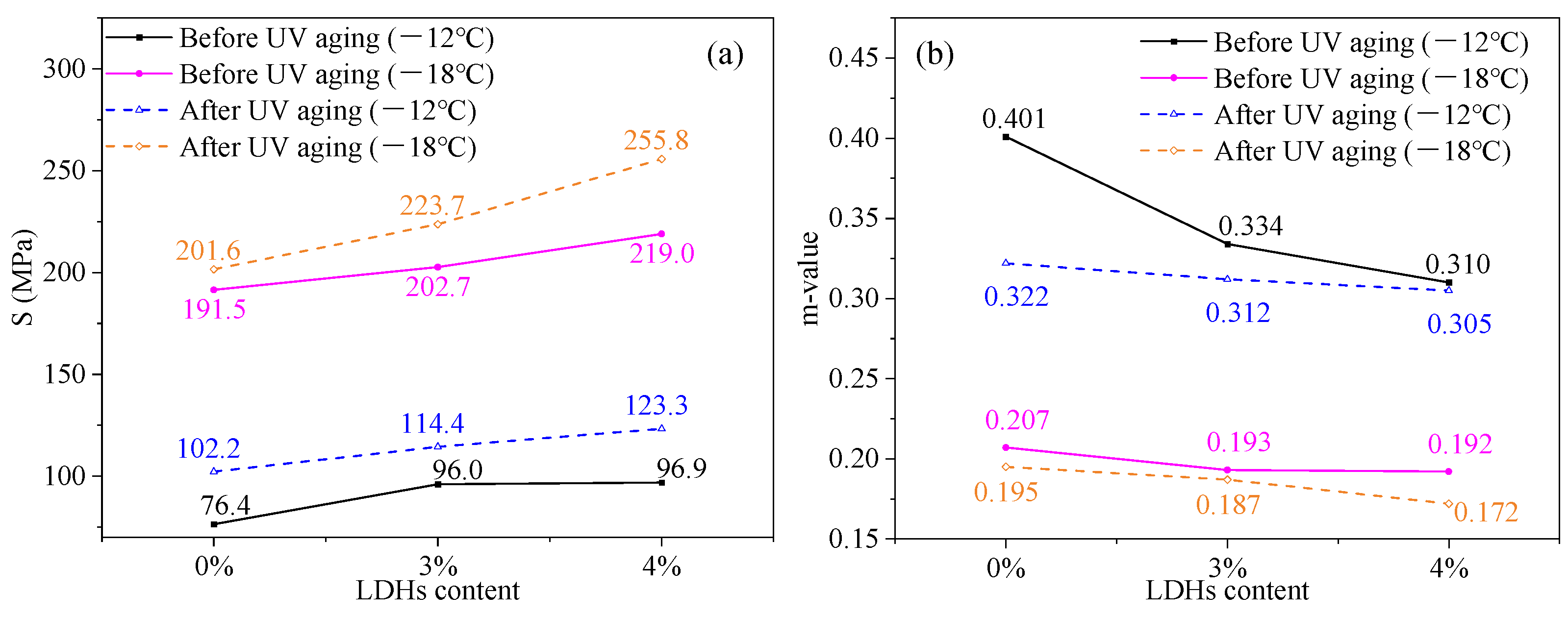

- Low-temperature rheological performance

- (2)

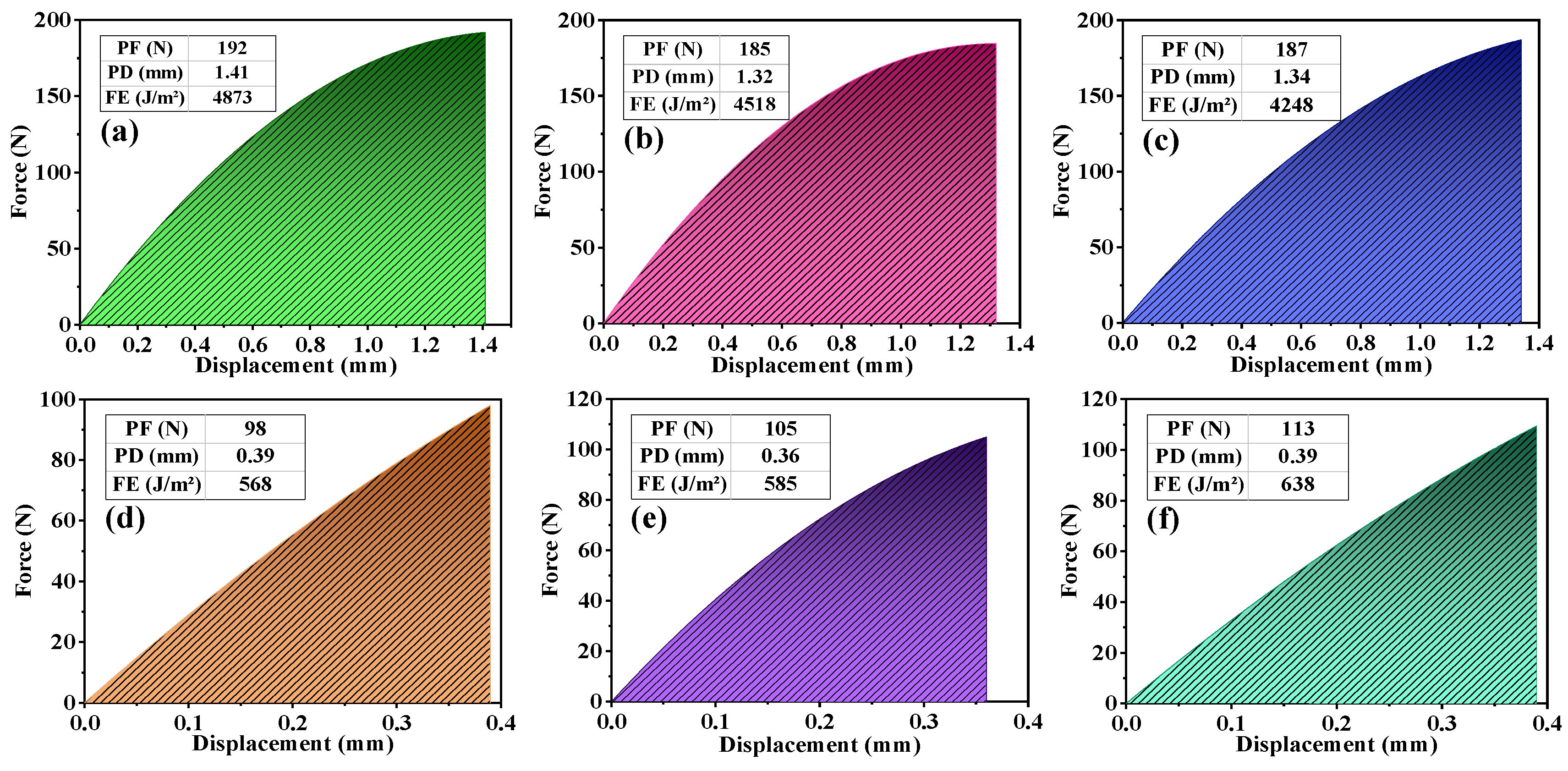

- Low-temperature cracking performance

- (3)

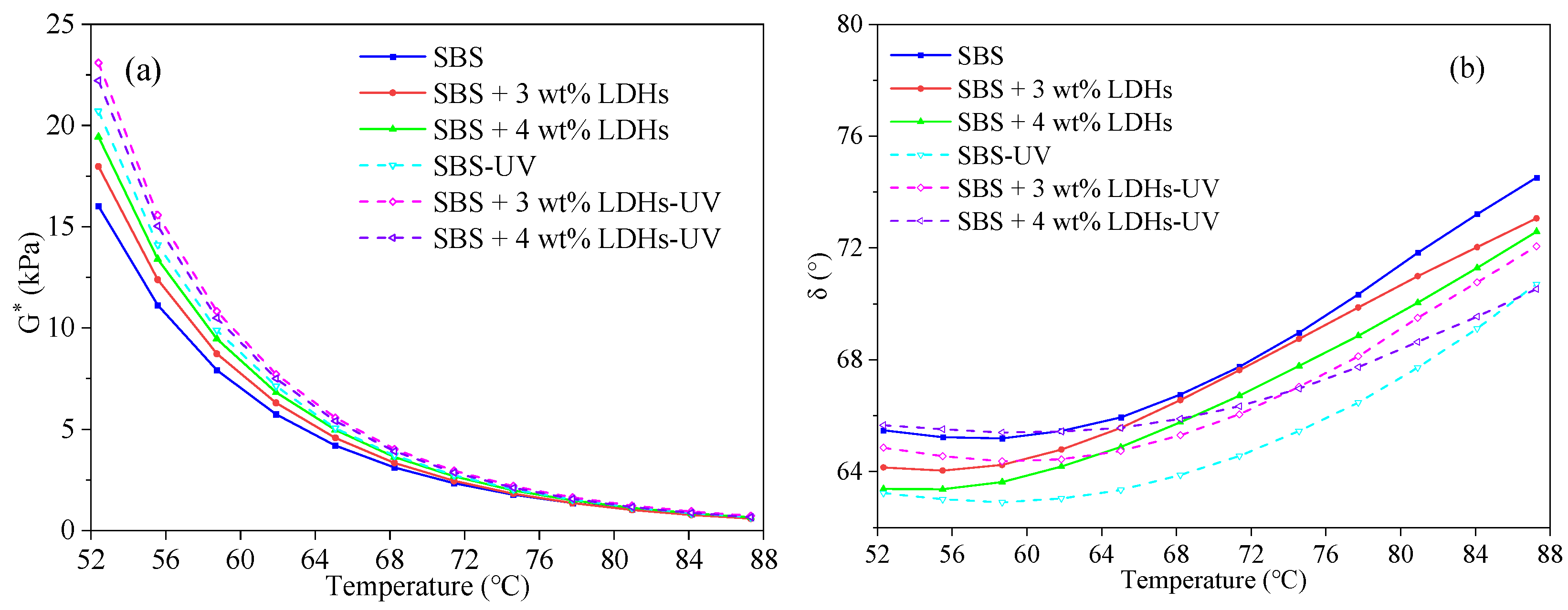

- Intermediate-temperature rheological performance

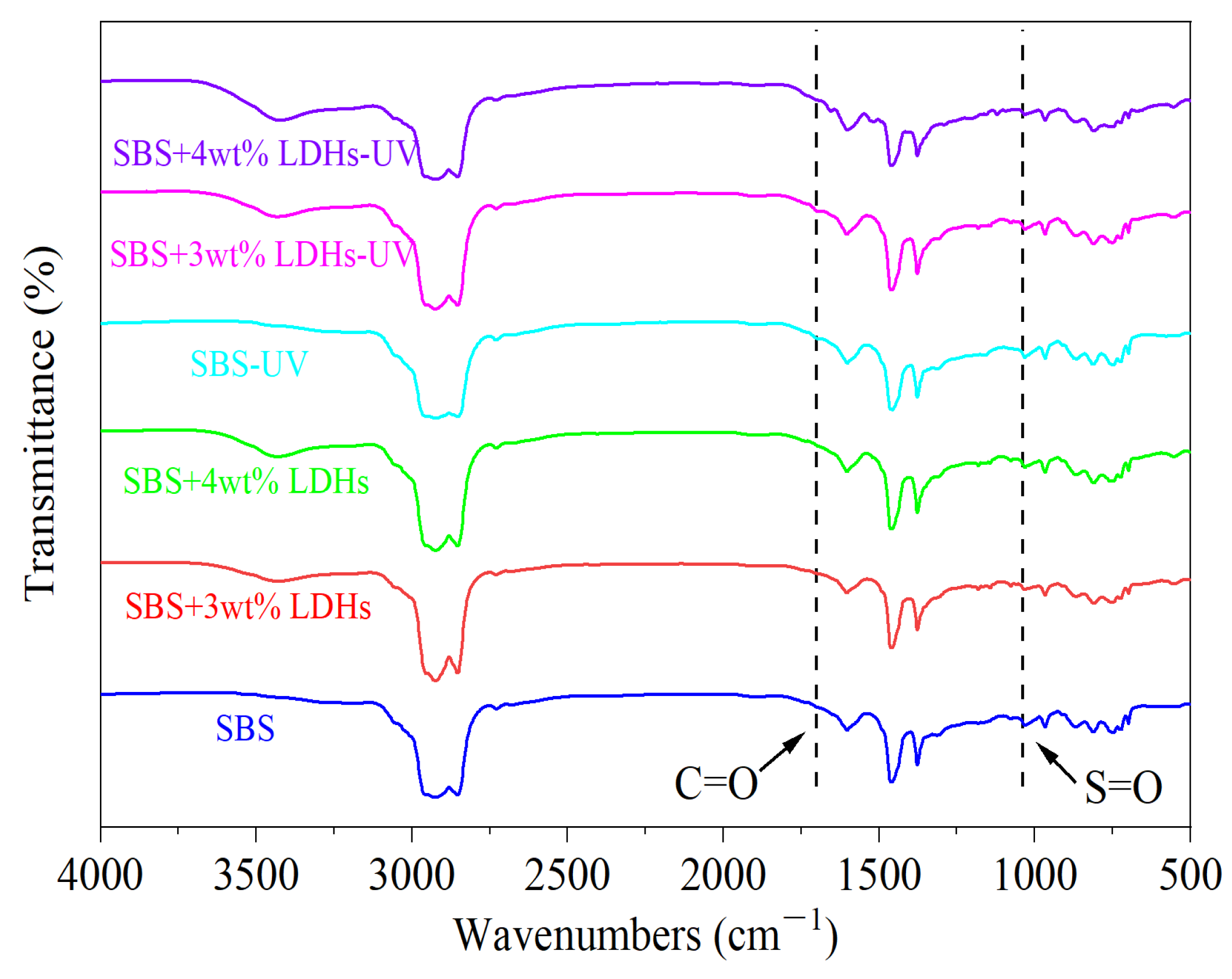

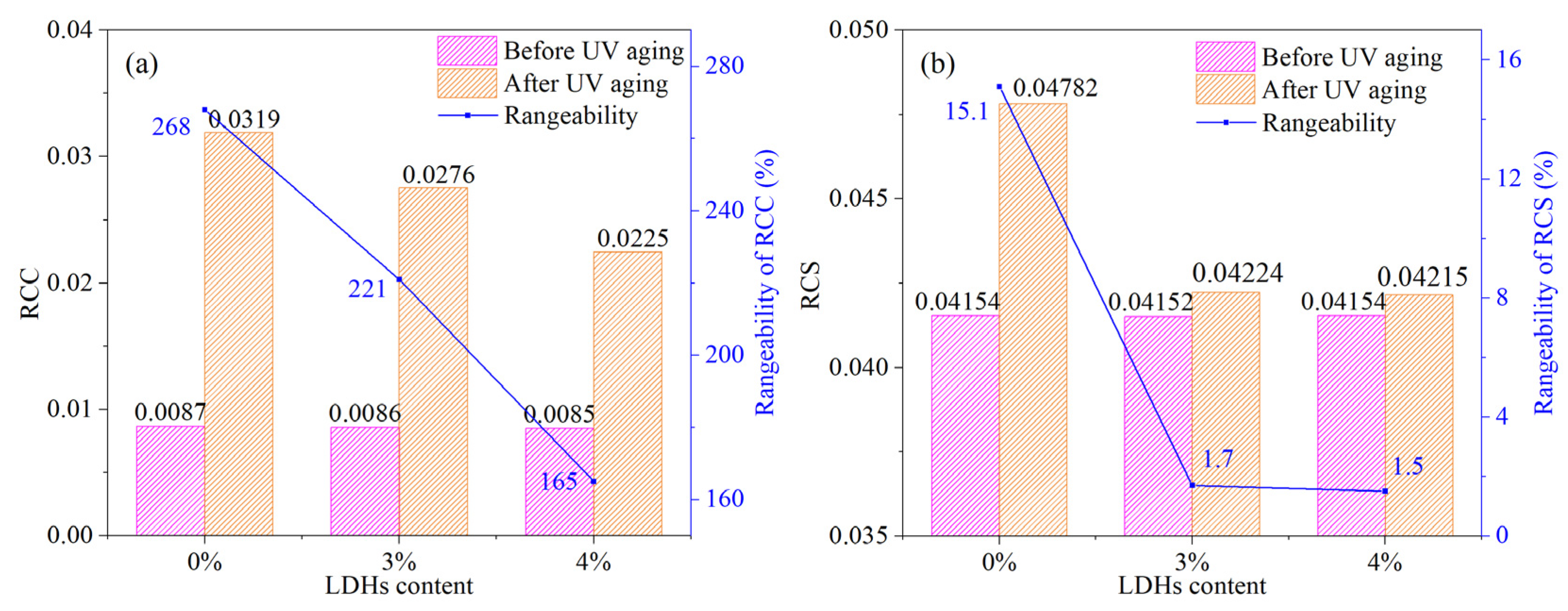

3.3.4. Effect of UV Aging on the Chemical Properties of Aging-Resistant LDH MABs

4. Conclusions

- (1)

- FTIR, XRD, and SEM results demonstrate that the structure of LDHs remained unchanged before and after use in asphalt modification. This means that LDHs have stable physical and chemical properties under the preparation conditions in this paper, which can confirm their preeminent anti-UV properties in engineering applications.

- (2)

- The optimal preparation parameters are a preparation temperature of 170 °C, shearing time of 60 min, and shearing rate of 4000 r/min. And the optimal doping of LDHs is 3 wt%. Under this condition, the low-temperature properties of LDHs + SBS MABs partially decrease, while the high-temperature performance increases significantly. Noticeably, the softening point of LDHs + SBS MABs increases immensely, which is 28.8% higher than that of SBS MABs. And 3 wt% LDHs + SBS MABs have the best high-temperature storage stability.

- (3)

- LDHs significantly affect MABs, and the aging index (PRR, SPI, and VAI) and FTIR results demonstrate that the UV aging resistance of LDHs + SBS MABs grows with the LDHs added. Compared with SBS MABs, the RCC and RCS rangeability of 3 wt% LDHs +SBS MABs are reduced by 47% and 13.4%, respectively, demonstrating a significant enhancement in anti-UV aging performance.

- (4)

- The results of the BBR, DTT, and DSR indicate that the rheological properties of LDHs + SBS MABs obtained under the optimal preparation conditions are markedly improved at high temperatures, and LDHs have a positive effect on the low-temperature performance of the UV-aged binders. After UV aging, the S of SBS MABs increases by 33.8%, and the m-value decreases by 19.7%, while those of the ABs doped with 3 wt% LDHs are just 19.2% and 6.6%, showing a preferable anti-UV aging performance.

- (5)

- LDHs have stable physical and chemical properties; LDHs + SBS MABs, obtained with the optimal preparation parameters, have a fine anti-UV aging performance and adequate high- and low-temperature rheological properties and thus have meaningful reference values for practical engineering applications. The results of this study on the optimal preparation parameters of LDHs + SBS-modified asphalt are of great significance for practical engineering applications, and the results of this study on the performance of modified asphalt with different LDH dosages provide a guiding basis for the design of asphalt pavements.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, C.; Zhao, B.; Xue, Y.; He, Y.; Ding, S.; Wen, Y.; Lv, S. Synchronous method and mechanism of asphalt-aggregate separation and regeneration of reclaimed asphalt pavement. Constr. Build. Mater. 2023, 378, 131127. [Google Scholar] [CrossRef]

- Xing, C.; Li, M.; Liu, L.; Lu, R.; Liu, N.; Wu, W.; Yuan, D. A comprehensive review on the blending condition between virgin and RAP asphalt binders in hot recycled asphalt mixtures: Mechanisms, evaluation methods, and influencing factors. J. Clean. Prod. 2023, 398, 136515. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Chen, Q.; Zhang, L. Basic performance and asphalt smoke absorption effect of environment-friendly asphalt to improve pavement construction environment. J. Clean. Prod. 2022, 333, 130142. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Zhuang, C.Y.; Li, N.; Zhao, W.; Cai, C.F. Iop, Effects of SBS Content on the Performance of Modified Asphalt. In Proceedings of the 2nd International Conference on Civil Engineering and Materials Science (ICCEMS), Seoul, Republic of Korea, 26–28 May 2017. [Google Scholar]

- Mo, Z. Study on the performance and aging low temperature performance of GO/SBS modified asphalt. Matéria 2023, 28, e20230151. [Google Scholar] [CrossRef]

- Ameli, A.; Khabbaz, E.H.; Babagoli, R.; Norouzi, N.; Valipourian, K. Evaluation of the effect of carbon nano tube on water damage resistance of Stone matrix asphalt mixtures containing polyphosphoric acid and styrene butadiene rubber. Constr. Build. Mater. 2020, 261, 119946. [Google Scholar] [CrossRef]

- Si, J.; Wang, J.; Yu, X.; Ding, G.; Ruan, W.; Xing, M.; Xie, R. Influence of thermal-oxidative aging on the mechanical performance and structure of cold-mixed epoxy asphalt. J. Clean. Prod. 2022, 337, 130482. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Evaluation of aging behaviors of asphalt binders through different rheological indices. Fuel 2018, 221, 78–88. [Google Scholar] [CrossRef]

- Li, J.; Yang, J.; Liu, Y.; Zhenxia, Z.; Tang, X.; Luo, J. Fabrication of IPDI-LDHs/SBS modified asphalt with enhanced thermal aging and UV aging resistance. Constr. Build. Mater. 2021, 302, 124131. [Google Scholar] [CrossRef]

- Ma, F.; Zhu, C.; Fu, Z.; Li, C.; Hou, Y.; Jiang, X.; Wu, M. Analysis of rheological behavior and anti-aging properties of SBS modified asphalt incorporating UV absorbent and naphthenic oil (NPO). Constr. Build. Mater. 2023, 377, 130958. [Google Scholar] [CrossRef]

- Wu, Y.T. Low-temperature rheological behavior of ultraviolet irradiation aged matrix asphalt and rubber asphalt binders. Constr. Build. Mater. 2017, 157, 708–717. [Google Scholar] [CrossRef]

- Yu, H.N.; Bai, X.P.; Qian, G.P.; Wei, H.; Gong, X.B.; Jin, J.; Li, Z.J. Impact of Ultraviolet Radiation on the Aging Properties of SBS-Modified Asphalt Binders. Polymers 2019, 11, 1111. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Yin, X.; Liang, M.; Du, X. Study on effect of thermal, oxidative and ultraviolet coupled aging on rheological properties of asphalt binder and their contribution rates. Int. J. Pavement Eng. 2023, 24, 2239426. [Google Scholar] [CrossRef]

- Zhong, Y.; Gao, Y.; Zhang, B.; Li, X.; Wang, X. Effect of ultraviolet radiation on dielectric properties of asphalt mixture. Int. J. Pavement Eng. 2023, 24, 2157004. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.H.; Hong, L.L.; Huang, Y. Effect of ultraviolet absorber (UV-531) on the properties of SBS-modified asphalt with different block ratios. Constr. Build. Mater. 2020, 234, 117388. [Google Scholar] [CrossRef]

- Bhat, F.S.; Mir, M.S. A study investigating the influence of nano Al2O3 on the performance of SBS modified asphalt binder. Constr. Build. Mater. 2021, 271, 121499. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Wu, S.P.; Liu, Q.T.; Yang, C.; Zou, Y.X.; Wan, P. Feasibility assessment of CeO2 nanoparticles as aging-resistant agent of asphalt. Constr. Build. Mater. 2022, 330, 127245. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, Z.Q.; Xie, J.Q.; Gui, Z.J.; Li, N.Q.; Xu, Y.F. Analysis of OMMT strengthened UV aging-resistance of Sasobit/SBS modified asphalt: Its preparation, characterization and mechanism. J. Clean. Prod. 2021, 315, 128139. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.M.; Wu, S.J.; Wang, H.R.; Liu, X.C.; Sun, H.D.; Fan, L. Effect of montmorillonite modification on resistance to thermal oxidation aging of asphalt binder. Case Stud. Constr. Mater. 2022, 16, e00971. [Google Scholar] [CrossRef]

- Li, J.S.; Yu, J.Y.; Wu, S.P.; Pang, L.; Amirkhanian, S.; Zhao, M.L. Effect of inorganic ultraviolet resistance nanomaterials on the physical and rheological properties of bitumen. Constr. Build. Mater. 2017, 152, 832–838. [Google Scholar] [CrossRef]

- Pizzoferrato, R.; Richetta, M. Layered Double Hydroxides (LDHs). Crystals 2020, 10, 1121. [Google Scholar] [CrossRef]

- Crucho, J.; Neves, J. Effect of Nano Hydrotalcite on the Aging Resistance of a High Binder Content Stone Mastic Asphalt. Appl. Sci. 2021, 11, 9971. [Google Scholar] [CrossRef]

- Ma, L.; Wang, F.; Cui, P.; Yunusa, M. Effect of aging on the constitutive models of asphalt and their mixtures. Constr. Build. Mater. 2021, 272, 121611. [Google Scholar] [CrossRef]

- Zhang, C.L.; Chen, M.X.; Yu, M.; Wang, T.; Chen, G.C.; He, J.; Hu, C.B. Preparation of dodecyltrimethoxysilane surface organic LDHs and application in aging resistance of SBS modified bitumen. Mater. Res. Express 2021, 8, 075101. [Google Scholar] [CrossRef]

- Xu, S.; Dang, L.; Yu, J.; Xue, L.; Hu, C.; Que, Y. Evaluation of ultraviolet aging resistance of bitumen containing different organic layered double hydroxides. Constr. Build. Mater. 2018, 192, 696–703. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Liu, Q. Investigation of the effect of layer double hydroxides on comprehensive properties of SBS-modified asphalt mixture. Mater. Res. Innov. 2015, 19, 764–768. [Google Scholar] [CrossRef]

- Li, Y.Y.; Wu, S.P.; Liu, Q.T.; Nie, S.; Li, H.C.; Dai, Y.; Pang, L.; Li, C.M.; Zhang, A.M. Field evaluation of LDHs effect on the aging resistance of asphalt concrete after four years of road service. Constr. Build. Mater. 2019, 208, 192–203. [Google Scholar] [CrossRef]

- Yang, X.L.; Shen, A.Q.; Guo, Y.C.; Wu, H.S.; Wang, H. A review of nano layered silicate technologies applied to asphalt materials. Road Mater. Pavement Des. 2021, 22, 1708–1733. [Google Scholar] [CrossRef]

- Li, R.Y.; Xiao, F.P.; Amirkhanian, S.; You, Z.P.; Huang, J. Developments of nano materials and technologies on asphalt materials—A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Zhang, C.; Dong, H.; Wang, T.; Li, Y.; Xu, S.; Zheng, Y.; Que, Y.; Chen, Y. Effect of different organic layered double hydroxides on the anti-aging property of bitumen. Constr. Build. Mater. 2023, 367, 130316. [Google Scholar] [CrossRef]

- Huang, Y.F.; Feng, Z.G.; Zhang, H.L.; Yu, J.Y. Effect of Layered Double Hydroxides (LDHs) on Aging Properties of Bitumen. J. Test. Eval. 2012, 40, 734–739. [Google Scholar] [CrossRef]

- Wang, J.S.; Wu, S.P.; Han, J.; Liu, X. Study on Preparation and UV Ageing Resistance Effect of LDHs Modified Asphalt. In Proceedings of the 3rd Mainland, Taiwan and Hong Kong Conference on Green Building Materials, Wuhan, China, 25–27 November 2011; pp. 194–202. [Google Scholar]

- Xu, S.; Sun, Y.B.; Yu, J.Y. The Effect of Zinc Doped Mg-Al LDHs on Ultraviolet Aging Resistance of Asphalt. Pet. Sci. Technol. 2015, 33, 335–343. [Google Scholar] [CrossRef]

- JTGE20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Hou, X.; Lv, S.; Chen, Z.; Xiao, F. Applications of Fourier transform infrared spectroscopy technologies on asphalt materials. Measurement 2018, 121, 304–316. [Google Scholar] [CrossRef]

- Tao, X.; Shi, L.S.; Sun, M.J.; Li, N. Synthesis of lignin amine asphalt emulsifier and its investigation by online FTIR spectrophotometry. Adv. Mater. Res. 2014, 909, 72–76. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Dai, Y.; Pang, L.; Liu, Q.; Xie, J.; Kong, D. Investigation of sodium stearate organically modified LDHs effect on the anti aging properties of asphalt binder. Constr. Build. Mater. 2018, 172, 509–518. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, M.; He, B.; Han, X.; Yu, J.; Xue, L. Investigation of ultraviolet aging resistance of bitumen modified by layered double hydroxides with different particle sizes. Constr. Build. Mater. 2019, 196, 166–174. [Google Scholar] [CrossRef]

- Lin, Q.; Zhang, Z.-Q.; Sha, A.-M.; Yang, H. Research on relationship between aging state and low-temperature performance of asphalt mixture. J. Test. Eval. 2009, 37, 486–489. [Google Scholar]

| Properties | Results | Methods [35] |

|---|---|---|

| Penetration (25 °C, 100 g, 5 s; 0.1 mm) | 90.1 | T 0604 |

| Softening point (°C) | 65.3 | T 0606 |

| Ductility (15 °C; cm) | 63.8 | T 0605 |

| Viscosity (135 °C; Pa·s) | 1.293 | T 0625 |

| Chemical Compositions | CO2 | Na2O | MgO | Al2O3 | SiO2 | SO3 | Cl | CaO | ZnO |

|---|---|---|---|---|---|---|---|---|---|

| Weight (%) | 44.203 | 0.105 | 33.344 | 22.199 | 0.015 | 0.011 | 0.017 | 0.099 | 0.007 |

| Sample | Shear Temperature (°C) | Shear Time (min) | Shear Rate (r/min) |

|---|---|---|---|

| 1 | 170 | 60 | 4000 |

| 2 | 160 | 60 | 4000 |

| 3 | 170 | 90 | 4000 |

| 4 | 170 | 60 | 5000 |

| LDH Content | CMAI |

|---|---|

| 0% | 30.2% |

| 3% | 21.9% |

| 4% | 14.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Wu, S.; Chen, A.; Li, Y. Physical, Rheological, and Anti-Ultraviolet Aging Performance of Layered Double Hydroxides + Styrene Block Copolymer-Modified Asphalt Binders. Sustainability 2023, 15, 15246. https://doi.org/10.3390/su152115246

Song Y, Wu S, Chen A, Li Y. Physical, Rheological, and Anti-Ultraviolet Aging Performance of Layered Double Hydroxides + Styrene Block Copolymer-Modified Asphalt Binders. Sustainability. 2023; 15(21):15246. https://doi.org/10.3390/su152115246

Chicago/Turabian StyleSong, Yu, Shaopeng Wu, Anqi Chen, and Yuanyuan Li. 2023. "Physical, Rheological, and Anti-Ultraviolet Aging Performance of Layered Double Hydroxides + Styrene Block Copolymer-Modified Asphalt Binders" Sustainability 15, no. 21: 15246. https://doi.org/10.3390/su152115246