The Challenge of Integrating Seismic and Energy Retrofitting of Buildings: An Opportunity for Sustainable Materials?

Abstract

:1. Introduction

2. Integrated Retrofitting Solutions

2.1. Exoskeletons

2.2. Timber-Based Strategies

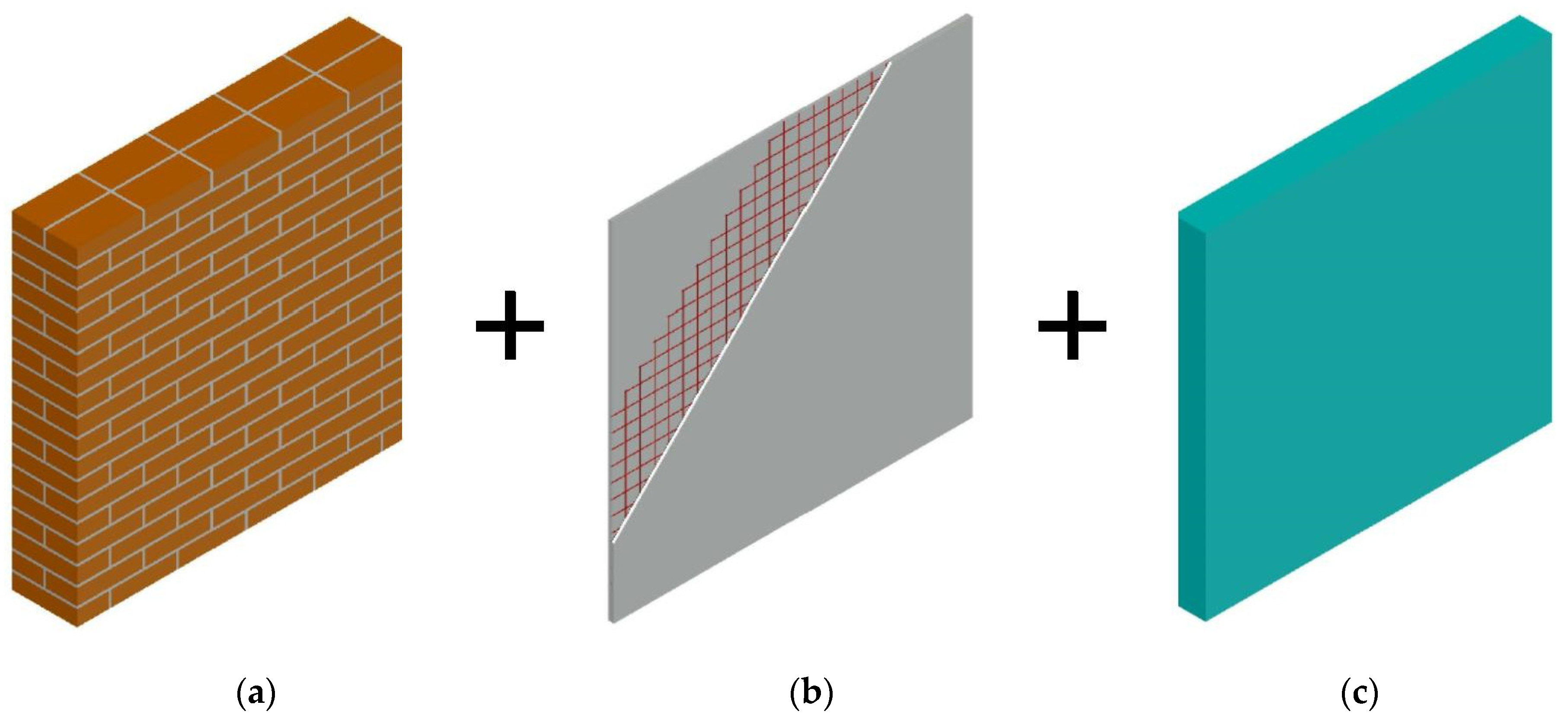

2.3. Composite Materials

2.4. Alternative Strategies for RC Buildings

3. Materials for Integrated Retrofitting

3.1. Sustainable Aggregates

3.1.1. Rice Husks

3.1.2. Hemp Hurds

3.1.3. Cork Granulates

3.1.4. Coffee Grounds

3.1.5. Other Types of Aggregates

| Material | Main Binder | Thermal Conductivity [W/mK] | Compressive Strength [MPa] | Refs. |

|---|---|---|---|---|

| Rice husk | Cement/hydraulic lime | 0.36–0.53 | 5.0–9.3 | [77,79] |

| Hemp hurds | Lime | 0.06–0.18 | 1.4–4.7 * | [85] |

| Cork granulates | Lime | 0.10–0.80 | 0.4–1.0 | [89] |

| Coffee grounds | Hydraulic lime | 0.29–0.46 | 2.2–12.4 | [94] |

| Expanded perlite | Cement + lime | 0.12–0.91 | 2.9–7.8 | [104] |

| Recycled concrete | Cement/lime | N/A | 5.0–8.0 | [97] |

| PCMs | Cement | 0.59–1.07 | 14.4–37.0 | [62] |

| PET waste | Cement/lime | 0.09–0.27 | 1.9–21.4 | [107] |

| EPS beads | Cement | 0.14–0.25 | 4.0 | [108] |

3.2. Traditional vs. Alternative Thermal Insulators

3.2.1. Ordinary Thermal Insulators

3.2.2. Alternative Insulators

| Material | Thermal Conductivity [W/mK] | Embodied Energy [MJ/kg] | Refs. |

|---|---|---|---|

| Expanded polystyrene (EPS) | 0.031–0.038 | 105.486 (CTGR) | [112,116] |

| Rock wool | 0.033–0.040 | 26.393 (CTGR) | [115,116] |

| Wood fibres | 0.038–0.050 | 25.0 (CTGA) | [113,142] |

| Cork | 0.037–0.050 | 51.517 (CTGR) | [101,116] |

| Hemp | 0.038–0.060 | 15.00 (CTGA) | [101,143] |

| Flax | 0.038–0.075 | 39.50 (CTGA) | [101,136,144] |

| Waste paper + textile fibres (wP and T) | 0.034–0.039 | 18.17 (CTGA) | [143] |

4. Final Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Menna, C.; Felicioni, L.; Negro, P.; Lupíšek, A.; Romano, E.; Prota, A.; Hájek, P. Review of methods for the combined assessment of seismic resilience and energy efficiency towards sustainable retrofitting of existing European buildings. Sustain. Cities Soc. 2022, 77, 103556. [Google Scholar] [CrossRef]

- Baek, C.; Park, S. Policy measures to overcome barriers to energy renovation of existing buildings. Renew. Sustain. Energy Rev. 2012, 16, 3939–3947. [Google Scholar] [CrossRef]

- Akadiri, P.O. Understanding barriers affecting the selection of sustainable materials in building projects. J. Build. Eng. 2015, 4, 86–93. [Google Scholar] [CrossRef]

- ECTP Materials and Sustainability Committee. Horizon Europe 2022–2027 Position Paper. 2022. Available online: https://www.ectp.org/fileadmin/user_upload/documents/ECTP/ECTP_Position-papers_and_SRIA/ECTP_M_S_Committee_Position_Paper__June_2022_.pdf (accessed on 2 February 2024).

- Marini, A.; Riva, P.; Negro, P.; Romano, E.; Passoni, C.; Taucer, F.; European Commission (Joint Research Centre); Institute for the Protection and the Security of the Citizen. Technology Options for Earthquake Resistant, Eco-Efficient Buildings in Europe: Research Needs; Publications Office: Luxembourg, 2014. [Google Scholar]

- Santamouris, M.; Vasilakopoulou, K. Present and future energy consumption of buildings: Challenges and opportunities towards decarbonisation, E-Prime—Advances in Electrical Engineering. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- Romano, E.; Negro, P.; Santarsiero, G.; Masi, A.; Butenweg, C. Identification of European Buildings Most Needing Seismic and Energy Retrofit with a Focus on the Italian Context; Publications Office: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Crowley, H.; Despotaki, V.; Silva, V.; Dabbeek, J.; Romão, X.; Pereira, N.; Castro, J.M.; Daniell, J.; Veliu, E.; Bilgin, H.; et al. Model of seismic design lateral force levels for the existing reinforced concrete European building stock. Bull. Earthq. Eng. 2021, 19, 2839–2865. [Google Scholar] [CrossRef]

- Economidou, M.; Todeschi, V.; Bertoldi, P.; Agostino, D.; Zangheri; Castellazzi, L. Review of 50 years of EU Energy Efficiency Policies for Buildings. Energy Build 2020, 225, 110322. [Google Scholar] [CrossRef]

- Gkatzogias, K.; Crowley, H.; Veljkovic, A.; Da, P.; Tsionis, G.; Da, B. Building Renovation in the EU: Scenarios and Impact Assessment; Publications Office: Luxembourg, 2022. [Google Scholar] [CrossRef]

- Decree of the President of the Italian Republic (DPR) of 26 August 1993, n. 412. Regolamento Recante Norme Per la Progettazione, L’installazione, L’esercizio e la Manutenzione degli Impianti Termici Degli Edifici ai Fini del Contenimento dei Consumi di Energia, in Attuazione Dell’art. 4, Comma 4, Della Legge 9 Gennaio 1991, n. 10; Official Gazette, Italy, General Series n. 242, Ordinary Supplement n. 96; 1993. Available online: https://www.gazzettaufficiale.it/eli/id/1993/10/14/093G0451/sg (accessed on 10 January 2024). (In Italian).

- Ordinance of the President of the Council of Ministers (OPCM) n. 3519 of 28 April 2006. Criteri Generali per L’individuazione Delle Zone Sismiche e per la Formazione e L’aggiornamento Degli Elenchi Delle Medesime Zone. Official Gazette, Italy, General Series n. 108; 2006. Available online: https://www.gazzettaufficiale.it/eli/id/2006/05/11/06A04427/sg (accessed on 10 January 2024). (In Italian).

- Power, A. Housing sustainability: Demolition or refurbishment? Proc. Inst. Civ. Eng. Urban. Des. Plan. 2010, 163, 205–216. [Google Scholar] [CrossRef]

- Monteiro, H.; Fernández, J.E.; Freire, F. Comparative life-cycle energy analysis of a new and an existing house: The significance of occupant’s habits, building systems and embodied energy. Sustain. Cities Soc. 2016, 26, 507–518. [Google Scholar] [CrossRef]

- Corradi, M.; Mustafaraj, E.; Speranzini, E. Sustainability considerations in remediation, retrofit, and seismic upgrading of historic masonry structures. Environ. Sci. Pollut. Res. 2023, 30, 25274–25286. [Google Scholar] [CrossRef] [PubMed]

- Marini, A.; Passoni, C.; Belleri, A.; Feroldi, F.; Preti, M.; Metelli, G.; Riva, P.; Giuriani, E.; Plizzari, G. Combining seismic retrofit with energy refurbishment for the sustainable renovation of RC buildings: A proof of concept. Eur. J. Environ. Civ. Eng. 2022, 26, 2475–2495. [Google Scholar] [CrossRef]

- Ricci, P.; de Luca, F.; Verderame, G.M. 6th April 2009 L’Aquila earthquake, Italy: Reinforced concrete building performance. Bull. Earthq. Eng. 2011, 9, 285–305. [Google Scholar] [CrossRef]

- Cattari, S.; Abbati, S.D.; Ferretti, D.; Lagomarsino, S.; Cattari, S.; Abbati, S.D.; Ferretti, D.; Lagomarsino, S.; Ottonelli, D.; Rossi, M.; et al. The seismic behaviour of ancient masonry buildings after the earthquake in Emilia (Italy) on May 20th and 29th, 2012. Ing. Sismica 2012, 29, 87–119. [Google Scholar]

- Sisti, R.; Di Ludovico, M.; Borri, A.; Prota, A. Seismic performance of strengthened masonry structures: Actual behaviour of buildings in Norcia and Campi Alto during the 2016 Central Italy seismic sequence. Bull. Earthq. Eng. 2022, 20, 321–348. [Google Scholar] [CrossRef]

- European Commission. 2050 Long-Term Strategy. 2020. Available online: https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2050-long-term-strategy_en (accessed on 10 January 2024).

- Mastroberti, M.; Bournas, D.; Vona, M.; Manganelli, B.; Palermo, V. Combined seismic plus energy retrofitting for the existing RC buildings: Economic feasibility. In Proceedings of the 16th European Conference on Earthquake Engineering, Thessaloniki, Greece, 18–21 June 2018. [Google Scholar]

- Menna, C.; Vitiello, U.; Mauro, G.M.; Asprone, D.; Bianco, N.; Prota, A. Integration of Seismic Risk into Energy Retrofit Optimization Procedures: A Possible Approach Based on Life Cycle Evaluation. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Prague, Czech Republic, 2–4 July 2019. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Maduta, C.; Bournas, D.A.; Kouris, L.A. Energy Performance of Existing Residential Buildings in Europe: A Novel Approach Combining Energy with Seismic Retrofitting. Energy Build. 2020, 223, 110024. [Google Scholar] [CrossRef]

- Webb, A.L. Energy retrofits in historic and traditional buildings: A review of problems and methods. Renew. Sustain. Energy Rev. 2017, 77, 748–759. [Google Scholar] [CrossRef]

- Mazzarella, L. Energy retrofit of historic and existing buildings: The legislative and regulatory point of view. Energy Build. 2015, 95, 23–31. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Chen, H.M.; Sharmina, M.; Mendoza, J.M.F. Links between circular economy and climate change mitigation in the built environment. J. Clean. Prod. 2020, 260, 121115. [Google Scholar] [CrossRef]

- Santamouris, M. Innovating to zero the building sector in Europe: Minimising the energy consumption. eradication of the energy poverty and mitigating the local climate change. Sol. Energy 2016, 128, 61–94. [Google Scholar] [CrossRef]

- Ademovic, N.; Formisano, A.; Penazzato, L.; Oliveira, D.V. Seismic and energy integrated retrofit of buildings: A critical review. Front. Built Environ. 2022, 8, 963337. [Google Scholar] [CrossRef]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Gkournelos, P.D.; Triantafillou, T.C.; Bournas, D.A. Seismic upgrading of existing masonry structures: A state-of-the-art review. Soil. Dyn. Earthq. Eng. 2022, 161, 107428. [Google Scholar] [CrossRef]

- Gkatzogias, K.; Pohoryles, D.; Romano, E.; Bournas, D.; Negro, P.; Tsionis, G.; Dimova, S. Integrated Seismic and Energy Renovation of Buildings; Publications Office: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Bournas, D.A.; Da Porto, F.; Santarsiero, G.; Triantafillou, T.; Oliveira, D.; Jelle, B.P. Technologies for the Combined Seismic and Energy Upgrading of Existing Buildings; Publications Office: Luxembourg, 2022; Available online: https://data.europa.eu/doi/10.2760/86567 (accessed on 19 February 2024).

- Passoni, C.; Guo, J.; Christopoulos, C.; Marini, A.; Riva, P. Design of dissipative and elastic high-strength exoskeleton solutions for sustainable seismic upgrades of existing RC buildings. Eng. Struct. 2020, 221, 111057. [Google Scholar] [CrossRef]

- Di Lorenzo, G.; Tartaglia, R.; Prota, A.; Landolfo, R. Design procedure for orthogonal steel exoskeleton structures for seismic strengthening. Eng. Struct. 2023, 275, 115252. [Google Scholar] [CrossRef]

- Foti, D.; Fappani, D.; Marini, A.; Venturelli, G.; Feroldi, F. Riqualificazione Energetica e Strutturale di Edifici con Telaio in c.a.: Il Caso del Quartiere Casazza; Technical Report, DICATAM; University of Brescia: Brescia, Italy, 2014. [Google Scholar]

- Santarsiero, G.; D’Angola, A.; Ventura, G.; Masi, A.; Manfredi, V.; Picciano, V.; Digrisolo, A. Sustainable Renovation of Public Buildings through Seismic–Energy Upgrading: Methodology and Application to an RC School Building. Infrastructures 2023, 8, 168. [Google Scholar] [CrossRef]

- MacKenbach, S.; Zeller, J.C.; Osebold, R. A Roadmap towards Circularity—Modular Construction as a Tool for Circular Economy in the Built Environment. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 052027. [Google Scholar] [CrossRef]

- Labò, S.; Passoni, C.; Marini, A.; Belleri, A.; Camata, G.; Riva, P.; Spacone, E. Diagrid solutions for a sustainable seismic, energy, and architectural upgrade of European RC buildings. In Proceedings of the XII International Conference on Structural Repair and Rehabilitation, Porto, Portugal, 26–29 October 2016. [Google Scholar]

- Pertile, V.; Stella, A.; de Stefani, L.; Scotta, R. Seismic and energy integrated retrofitting of existing buildings with an innovative icf-based system: Design principles and case studies. Sustainability 2021, 13, 9363. [Google Scholar] [CrossRef]

- Hsiao, F.P.; Weng, P.W.; Li, Y.A.; Kawamoto, T.; Lin, Y.C.; Haryanto, Y. Study on retrofitting of existing reinforced concrete buildings with the exoskeleton design-U-frame method. Compos. Struct. 2023, 324, 117562. [Google Scholar] [CrossRef]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Badini, L.; Ott, S.; Aondio, P.; Winter, S. Seismic strengthening of existing RC buildings with external cross-laminated timber (CLT) walls hosting an integrated energetic and architectural renovation. Bull. Earthq. Eng. 2022, 20, 5963–6006. [Google Scholar] [CrossRef]

- Aloisio, A.; Boggian, F.; Tomasi, R. Design of a novel seismic retrofitting system for RC structures based on asymmetric friction connections and CLT panels. Eng. Struct. 2022, 254, 113807. [Google Scholar] [CrossRef]

- Tardo, C.; Margani, G. Technological analysis of a prefabricated timber-based system for the integrated renovation of RC framed buildings. Technol. Eng. Mater. Archit. 2022, 8. [Google Scholar] [CrossRef]

- Zanni, J.; Cademartori, S.; Marini, A.; Belleri, A.; Passoni, C.; Giuriani, E.; Riva, P.; Angi, B.; Brumana, G.; Marchetti, A.L. Integrated deep renovation of existing buildings with prefabricated shell exoskeleton. Sustainability 2021, 13, 11287. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; Saler, E.; Vignato, A.; Salvalaggio, M.; Croatto, G.; Dorigatti, G.; Turrini, U. Nested buildings: An innovative strategy for the integrated seismic and energy retrofit of existing masonry buildings with CLT panels. Sustainability 2021, 13, 1188. [Google Scholar] [CrossRef]

- Bertolazzi, A.; D’Agnolo, E.; Fattori, G.; Piccinato, A.; Croatto, G.; Turrini, U. Nested-building as an effective strategy for the reuse of reinforced concrete industrial buildings: The case of the ex-Manifattura Tabacchi factory in Verona (1930–65). Int. J. Archit. Technol. Sustain. 2023, 8, 56–65. [Google Scholar] [CrossRef]

- Kolaitis, D.I.; Malliotakis, E.; Kontogeorgos, D.A.; Mandilaras, I.; Katsourinis, D.I.; Founti, M.A. Comparative assessment of internal and external thermal insulation systems for energy efficient retrofitting of residential buildings. Energy Build. 2013, 64, 123–131. [Google Scholar] [CrossRef]

- Iuorio, O.; Dauda, J.; Lourenço, P. Flexural Resistance of Masonry Wall Retrofitted with Timber Panel under Out-Of-Plane Loading. In Proceedings of the 12th International Conference on Structural Analysis of Historical Constructions (SAHC), Barcelona, Spain, 29 September–1 October 2021. [Google Scholar] [CrossRef]

- Busselli, M.; Cassol, D.; Prada, A.; Giongo, I. Timber based integrated techniques to improve energy efficiency and seismic behaviour of existing masonry buildings. Sustainability 2021, 13, 10379. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Head, P.R. Composite Materials and Structures in Civil Engineering. Compr. Compos. Mater. 2000, 6, 489–527. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; Modena, C.; de Felice, G. Current practice and open issues in strengthening historical buildings with composites. Mater. Struct. 2014, 47, 1971–1985. [Google Scholar] [CrossRef]

- Triantafillou, T. (Ed.) Textile Fibre Composites in Civil Engineering; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Valluzzi, M.R.; Tinazzi, D.; Modena, C. Shear behavior of masonry panels strengthened by FRP laminates. Constr. Build. Mater. 2002, 16, 409–416. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Karlos, K.; Kapsalis, P.; Georgiou, L. Innovative Structural and Energy Retrofitting System for Masonry Walls Using Textile Reinforced Mortars Combined with Thermal Insulation: In-Plane Mechanical Behavior. J. Compos. Constr. 2018, 22, 04018029. [Google Scholar] [CrossRef]

- Christis, Z.C.; Renos, V.; Nicholas, K.; Rogiros, I.; Christiana, A.F.; Stathis, B. Seismic and energy upgrading of existing buildings—Full-scale testing of retrofitted masonry-infilled RC frames. Earthq. Eng. Struct. Dyn. 2023, 52, 4489–4517. [Google Scholar] [CrossRef]

- Bournas, D.A. Concurrent seismic and energy retrofitting of RC and masonry building envelopes using inorganic textile-based composites combined with insulation materials: A new concept. Compos. Part B Eng. 2018, 148, 166–179. [Google Scholar] [CrossRef]

- Baek, E.; Pohoryles, D.A.; Kallioras, S.; Bournas, D.A.; Choi, H.; Kim, T. Innovative seismic and energy retrofitting of wall envelopes using prefabricated textile-reinforced concrete panels with an embedded capillary tube system. Eng. Struct. 2022, 265, 114453. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Sannino, A.; Aiello, M.A. Mechanical and thermal characterization of FRCM-matrices. Key Eng. Mater. 2019, 817, 189–194. [Google Scholar] [CrossRef]

- Illampas, R.; Rigopoulos, I.; Ioannou, I. Influence of microencapsulated Phase Change Materials (PCMs) on the properties of polymer modified cementitious repair mortar. J. Build. Eng. 2021, 40, 102328. [Google Scholar] [CrossRef]

- Longo, F.; Lassandro, P.; Moshiri, A.; Phatak, T.; Aiello, M.A.; Krakowiak, K.J. Lightweight geopolymer-based mortars for the structural and energy retrofit of buildings. Energy Build. 2020, 225, 110352. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J.; Structures, G. Processing, Properties and Industrial Applications; Woodhead Publishing: Sawston, UK, 2008. [Google Scholar]

- Miranda, T.; Silva, R.A.; Oliveira, D.V.; Leitão, D.; Cristelo, N.; Oliveira, J.; Soares, E. ICEBs stabilised with alkali-activated fly ash as a renewed approach for green building: Exploitation of the masonry mechanical performance. Constr. Build. Mater. 2017, 155, 65–78. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Cholostiakow, S.; Skyrianou, I.; Koutas, L.; Papakonstantinou, C. Out-of-plane performance of structurally and energy retrofitted masonry walls: Geopolymer versus cement-based textile-reinforced mortar combined with thermal insulation. Open Res. Eur. 2023, 3, 186. [Google Scholar] [CrossRef]

- Artino, A.; Evola, G.; Margani, G.; Marino, E.M. Seismic and energy retrofit of apartment buildings through autoclaved aerated concrete (AAC) blocks infill walls. Sustainability 2019, 11, 3939. [Google Scholar] [CrossRef]

- Stylianou, P.; Chatzidakis, A.; Coughlan, P.; Brandner, A.; Zadnik, B.; Theodotou, A.; Kyriakides, N.; Paska, I.; Karanasiou, M. The need for integrating Structural/Seismic Upgrade of Existing Buildings, with Energy Efficiency Improvements, ECCE Position Paper, European Council of Civil Engineers. 2020. Available online: http://www.ecceengineers.eu/position_papers/files/3S_PP_Full_per-page.pdf (accessed on 29 February 2024).

- de Sousa, C.; Barros, J.A.O.; Correia, J.R.; Valente, T.D.S. Development of sandwich panels for multi-functional strengthening of RC buildings: Characterization of constituent materials and shear interaction of panel assemblies. Constr. Build. Mater. 2021, 267, 120849. [Google Scholar] [CrossRef]

- Lopes, L.; Penazzato, L.; Reis, D.C.; Almeida, M.; Oliveira, D.V.; Lourenço, P.B. A Holistic Modular Solution for Energy and Seismic Renovation of Buildings Based on 3D-Printed Thermoplastic Materials. Sustainability 2024, 16, 2166. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment—A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Habert, G.; Bouzidi, Y.; Chen, C.; Jullien, A. Development of a depletion indicator for natural resources used in concrete. Resour. Conserv. Recycl. 2010, 54, 364–376. [Google Scholar] [CrossRef]

- UNEP 2019. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global sand Resources; GRID-Geneva, United Nations Environment Programme: Geneva, Switzerland, 2019; Available online: https://wedocs.unep.org/handle/20.500.11822/28163 (accessed on 8 February 2024).

- Van Den Heede, P.; De Belie, N. Environmental impact; life cycle assessment (LCA) of traditional and “green” concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Quintaliani, C.; Merli, F.; Fiorini, C.V.; Corradi, M.; Speranzini, E.; Buratti, C. Vegetal Fiber Additives in Mortars: Experimental Characterization of Thermal and Acoustic Properties. Sustainability 2022, 14, 1260. [Google Scholar] [CrossRef]

- Chabannes, M.; Bénézet, J.C.; Clerc, L.; Garcia-Diaz, E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: An innovative application. Constr. Build. Mater. 2014, 70, 428–438. [Google Scholar] [CrossRef]

- Marques, B.; Almeida, J.; Tadeu, A.; António, J.; Santos, M.I.; de Brito, J.; Oliveira, M. Rice husk cement-based composites for acoustic barriers and thermal insulating layers. J. Build. Eng. 2021, 39, 102297. [Google Scholar] [CrossRef]

- Park, B.D.; Wi, S.G.; Lee, K.H.; Singh, A.P.; Yoon, T.H.; Kim, Y.S. Characterization of anatomical features and silica distribution in rice husk using microscopic and micro-analytical techniques. Biomass Bioenergy 2003, 25, 319–327. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Gamage, J.C.P.H.; de Silva, G.I.P.; Navaratnam, S. Development of sustainable mortar using waste rice husk ash from rice mill plant: Physical and thermal properties. J. Build. Eng. 2021, 43, 102614. [Google Scholar] [CrossRef]

- Tronet, P.; Lecompte, T.; Picandet, V.; Baley, C. Study of lime hemp concrete (LHC)—Mix design. casting process and mechanical behaviour. Cem. Concr. Compos. 2016, 67, 60–72. [Google Scholar] [CrossRef]

- Çomak, B.; Bideci, A.; Bideci, Ö.S. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. A review of the factors affecting the properties and performance of hemp aggregate concretes. J. Build. Eng. 2020, 31, 101323. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Seng, B.; Magniont, C.; Lorente, S. Characterization of a precast hemp concrete. Part I: Physical and thermal properties. J. Build. Eng. 2019, 24, 100540. [Google Scholar] [CrossRef]

- Delannoy, G.; Marceau, S.; Glé, P.; Gourlay, E.; Guéguen-Minerbe, M.; Amziane, S.; Farcas, F. Durability of hemp concretes exposed to accelerated environmental aging. Constr. Build. Mater. 2020, 252, 119043. [Google Scholar] [CrossRef]

- Panesar, D.K.; Shindman, B. The mechanical, transport and thermal properties of mortar and concrete containing waste cork. Cem. Concr. Compos. 2012, 34, 982–992. [Google Scholar] [CrossRef]

- Brás, A.; Leal, M.; Faria, P. Cement-cork mortars for thermal bridges correction. Comparison with cement-EPS mortars performance. Constr. Build. Mater. 2013, 49, 315–327. [Google Scholar] [CrossRef]

- Matos, A.M.; Nunes, S.; Sousa-Coutinho, J. Cork waste in cement based materials. Mater. Des. 2015, 85, 230–239. [Google Scholar] [CrossRef]

- Jerónimo, A.; Soares, C.; Aguiar, B.; Lima, N. Hydraulic lime mortars incorporating micro cork granules with antifungal properties. Constr. Build. Mater. 2020, 255, 119368. [Google Scholar] [CrossRef]

- Kovalcik, A.; Obruca, S.; Marova, I. Valorization of spent coffee grounds: A review. Food Bioprod. Process. 2018, 110, 104–119. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Martínez-García, C.; Martínez-Cartas, M.L.; Cotes-Palomino, M.T.; Pérez-Villarejo, L.; Cruz-Pérez, N.; Corpas-Iglesias, F.A. The use of different forms of waste in the manufacture of ceramic bricks. Appl. Clay Sci. 2011, 52, 270–276. [Google Scholar] [CrossRef]

- la Scalia, G.; Saeli, M.; Miglietta, P.P.; Micale, R. Coffee biowaste valorization within circular economy: An evaluation method of spent coffee grounds potentials for mortar production. Int. J. Life Cycle Assess. 2021, 26, 1805–1815. [Google Scholar] [CrossRef] [PubMed]

- Roychand, R.; Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Zhang, G.; Li, C.Q. Transforming spent coffee grounds into a valuable resource for the enhancement of concrete strength. J. Clean. Prod. 2023, 419, 138205. [Google Scholar] [CrossRef]

- González-Fonteboa, B.; Seara-Paz, S.; de Brito, J.; González-Taboada, I.; Martínez-Abella, F.; Vasco-Silva, R. Recycled concrete with coarse recycled aggregate: An overview and analysis. Mater. Constr. 2018, 68, 13317. [Google Scholar] [CrossRef]

- Samiei, R.R.; Daniotti, B.; Pelosato, R.; Dotelli, G. Properties of cement-lime mortars vs. cement mortars containing recycled concrete aggregates. Constr. Build. Mater. 2015, 84, 84–94. [Google Scholar] [CrossRef]

- Restuccia, L.; Spoto, C.; Ferro, G.A.; Tulliani, J.M. Recycled Mortars with C&D Waste. Procedia Struct. Integr. 2016, 2, 2896–2904. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Pellegrini-Cervantes, M.J.; Castro-Beltrán, A.; Rodríguez-Rodríguez, M.; Orozco-Carmona, V.M.; Peinado-Guevara, H.J. Properties of Mortar with Recycled Aggregates. and Polyacrylonitrile Microfibers Synthesized by Electrospinning. Materials 2019, 12, 3849. [Google Scholar] [CrossRef]

- Shoukry, H.; Kotkata, M.F.; Abo-EL-Enein, S.A.; Morsy, M.S.; Shebl, S.S. Thermo-physical properties of nanostructured lightweight fiber reinforced cementitious composites. Constr. Build. Mater. 2016, 102, 167–174. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Rashad, A.M. Insulating and fire-resistant behaviour of metakaolin and fly ash geopolymer mortars. Proc. Inst. Civ. Eng. Constr. Mater. 2019, 172, 37–44. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Pokorný, J.; Pavlíková, M.; Pavlík, Z. Properties of cement-lime render containing perlite as lightweight aggregate. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar] [CrossRef]

- Govaerts, Y.; Hayen, R.; de Bouw, M.; Verdonck, A.; Meulebroeck, W.; Mertens, S.; Grégoire, Y. Performance of a lime-based insulating render for heritage buildings. Constr. Build. Mater. 2018, 159, 376–389. [Google Scholar] [CrossRef]

- Yu, L.H.; Ou, H.; Lee, L.L. Investigation on pozzolanic effect of perlite powder in concrete. Cem. Concr. Res. 2003, 33, 73–76. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Donnini, J.; Nardinocchi, A. Lightweight plasters containing plastic waste for sustainable and energy-efficient building. Constr. Build. Mater. 2015, 94, 337–345. [Google Scholar] [CrossRef]

- Maaroufi, M.; Belarbi, R.; Abahri, K.; Benmahiddine, F. Full characterization of hygrothermal. mechanical and morphological properties of a recycled expanded polystyrene-based mortar. Constr. Build. Mater. 2021, 301, 124310. [Google Scholar] [CrossRef]

- Le, D.L.; Salomone, R.; Nguyen, Q.T. Circular bio-based building materials: A literature review of case studies and sustainability assessment methods. Build. Environ. 2023, 244, 110774. [Google Scholar] [CrossRef]

- Spósito, F.A.; Higuti, R.T.; Tashima, M.M.; Akasaki, J.L.; Melges, J.L.P.; Assunção, C.C.; Bortoletto, M.; Silva, R.G.; Fioriti, C.F. Incorporation of PET wastes in rendering mortars based on Portland cement/hydrated lime. J. Build. Eng. 2020, 32, 101506. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Lakatos, Á.; Kalmár, F. Analysis of water sorption and thermal conductivity of expanded polystyrene insulation materials. Build. Serv. Eng. Res. Technol. 2013, 34, 407–416. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Manos, G.C.; Melidis, L.; Katakalos, K.; Kotoulas, L.; Anastasiadis, A.; Chatziastrou, C. Masonry panels with external thermal insulation subjected to in-plane diagonal compression. Case Stud. Constr. Mater. 2021, 14, 00538. [Google Scholar] [CrossRef]

- Karamanos, A.; Hadiarakou, S.; Papadopoulos, A.M. The impact of temperature and moisture on the thermal performance of stone wool. Energy Build. 2008, 40, 1402–1411. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Env. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Piñeiro, S.R.; del Río Merino, M.; García, C.P. New Plaster Composite with Mineral Wool Fibres from CDW Recycling. Adv. Mater. Sci. Eng. 2015, 2015, 854192. [Google Scholar] [CrossRef]

- Serrano, A.; Borreguero, A.M.; Garrido, I.; Rodríguez, J.F.; Carmona, M. Reducing heat loss through the building envelope by using polyurethane foams containing thermoregulating microcapsules. Appl. Therm. Eng. 2016, 103, 226–232. [Google Scholar] [CrossRef]

- McKenna, S.T.; Hull, T.R. The fire toxicity of polyurethane foams. Fire Sci. Rev. 2016, 5, 3. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Dickson, T.; Pavía, S. Energy performance, environmental impact and cost of a range of insulation materials. Renew. Sustain. Energy Rev. 2021, 140, 110752. [Google Scholar] [CrossRef]

- Korjenic, A.; Klaric, S.; Hadžic, A.; Korjenic, S. Sheep wool as a construction material for energy efficiency improvement. Energies 2015, 8, 5765–5781. [Google Scholar] [CrossRef]

- Bianco, L.; Pollo, R.; Serra, V. Wood Fiber vs Synthetic Thermal Insulation for Roofs Energy Retrofit: A Case Study in Turin, Italy. Energy Procedia 2017, 111, 347–356. [Google Scholar] [CrossRef]

- Pal, R.K.; Goyal, P.; Sehgal, S. Effect of cellulose fibre based insulation on thermal performance of buildings. Mater. Today Proc. 2021, 45, 5778–5781. [Google Scholar] [CrossRef]

- Troppová, E.; Švehlík, M.; Tippner, J.; Wimmer, R. Influence of temperature and moisture content on the thermal conductivity of wood-based fibreboards. Mater. Struct. 2015, 48, 4077–4083. [Google Scholar] [CrossRef]

- Xie, Y.; Tong, Q.; Chen, Y.; Liu, J.; Lin, M. Manufacture and properties of ultra-low density fibreboard from wood fibre. Bioresources 2011, 6, 4055–4066. [Google Scholar] [CrossRef]

- Segovia, F.; Blanchet, P.; Auclair, N.; Essoua, G.G.E. Thermo-mechanical properties of a wood fiber insulation board using a bio-based adhesive as a binder. Buildings 2020, 10, 152. [Google Scholar] [CrossRef]

- Horvathova, M. Facade Insulation from Wood-Fiber Boards in the Burning Process. Transp. Res. Procedia 2021, 55, 1415–1422. [Google Scholar] [CrossRef]

- Simões, N.; Fino, R.; Tadeu, A. Uncoated medium density expanded cork boards for building façades and roofs: Mechanical. hygrothermal and durability characterization. Constr. Build. Mater. 2019, 200, 447–464. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A Review of Sustainable Materials for Acoustic Applications. Build. Acoust. 2012, 19, 283–312. [Google Scholar] [CrossRef]

- Malanho, S.; Veiga, R.; Farinha, C.B. Global Performance of Sustainable Thermal Insulating Systems with Cork for Building Facades. Buildings 2021, 11, 83. [Google Scholar] [CrossRef]

- Tadeu, A.; Škerget, L.; Simões, N.; Fino, R. Simulation of heat and moisture flow through walls covered with uncoated medium density expanded cork. Build. Env. 2018, 142, 195–210. [Google Scholar] [CrossRef]

- Barreca, F.; Arcuri, N.; Cardinali, G.D.; di Fazio, S. A bio-based render for insulating agglomerated cork panels. Coatings 2021, 11, 1478. [Google Scholar] [CrossRef]

- Silvestre, J.D.; Pargana, N.; de Brito, J.; Pinheiro, M.D.; Durão, V. Insulation cork boards-environmental life cycle assessment of an organic construction material. Materials 2016, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, T.J.F.; Parresol, B.R. A new model for cork weight estimation in Northern Portugal with methodology for construction of confidence intervals. For. Ecol. Manag. 2001, 152, 131–139. [Google Scholar]

- Kymäläinen, H.R.; Sjöberg, A.M. Flax and hemp fibres as raw materials for thermal insulations. Build. Env. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Lascaro, E.; Merli, F.; Ricciardi, P. Rice husk panels for building applications: Thermal. acoustic and environmental characterization and comparison with other innovative recycled waste materials. Constr. Build. Mater. 2018, 171, 338–349. [Google Scholar] [CrossRef]

- António, J.; Tadeu, A.; Marques, B.; Almeida, J.A.S.; Pinto, V. Application of rice husk in the development of new composite boards. Constr. Build. Mater. 2018, 176, 432–439. [Google Scholar] [CrossRef]

- Marques, B.; Tadeu, A.; António, J.; Almeida, J.; de Brito, J. Mechanical, thermal and acoustic behaviour of polymer-based composite materials produced with rice husk and expanded cork by-products. Constr. Build. Mater. 2020, 239, 117851. [Google Scholar] [CrossRef]

- Intini, F.; Kühtz, S. Recycling in buildings: An LCA case study of a thermal insulation panel made of polyester fiber. recycled from post-consumer PET bottles. Int. J. Life Cycle Assess. 2011, 16, 306–315. [Google Scholar] [CrossRef]

- Valverde, I.C.; Castilla, L.H.; Nuñez, D.F.; Rodriguez-Senín, E.R. de La Mano Ferreira. Development of new insulation panels based on textile recycled fibers. Waste Biomass Valorization 2013, 4, 139–146. [Google Scholar] [CrossRef]

- STEICO Das Naturbausystem. Available online: https://www.steico.com (accessed on 29 January 2024).

- Ricciardi, P.; Belloni, E.; Cotana, F. Innovative panels with recycled materials: Thermal and acoustic performance and Life Cycle Assessment. Appl. Energy 2014, 134, 150–162. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C.; Lowrie, F.; Tse, P. Building Services Research and Information Association and University of Bath. In Embodied Carbon: The Inventory of Carbon and Energy (ICE); BSRIA: Bath, UK, 2011. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Penazzato, L.; Illampas, R.; Oliveira, D.V. The Challenge of Integrating Seismic and Energy Retrofitting of Buildings: An Opportunity for Sustainable Materials? Sustainability 2024, 16, 3465. https://doi.org/10.3390/su16083465

Penazzato L, Illampas R, Oliveira DV. The Challenge of Integrating Seismic and Energy Retrofitting of Buildings: An Opportunity for Sustainable Materials? Sustainability. 2024; 16(8):3465. https://doi.org/10.3390/su16083465

Chicago/Turabian StylePenazzato, Luca, Rogiros Illampas, and Daniel V. Oliveira. 2024. "The Challenge of Integrating Seismic and Energy Retrofitting of Buildings: An Opportunity for Sustainable Materials?" Sustainability 16, no. 8: 3465. https://doi.org/10.3390/su16083465