Effect of Dielectric Distributed Bragg Reflector on Electrical and Optical Properties of GaN-Based Flip-Chip Light-Emitting Diodes

Abstract

:1. Introduction

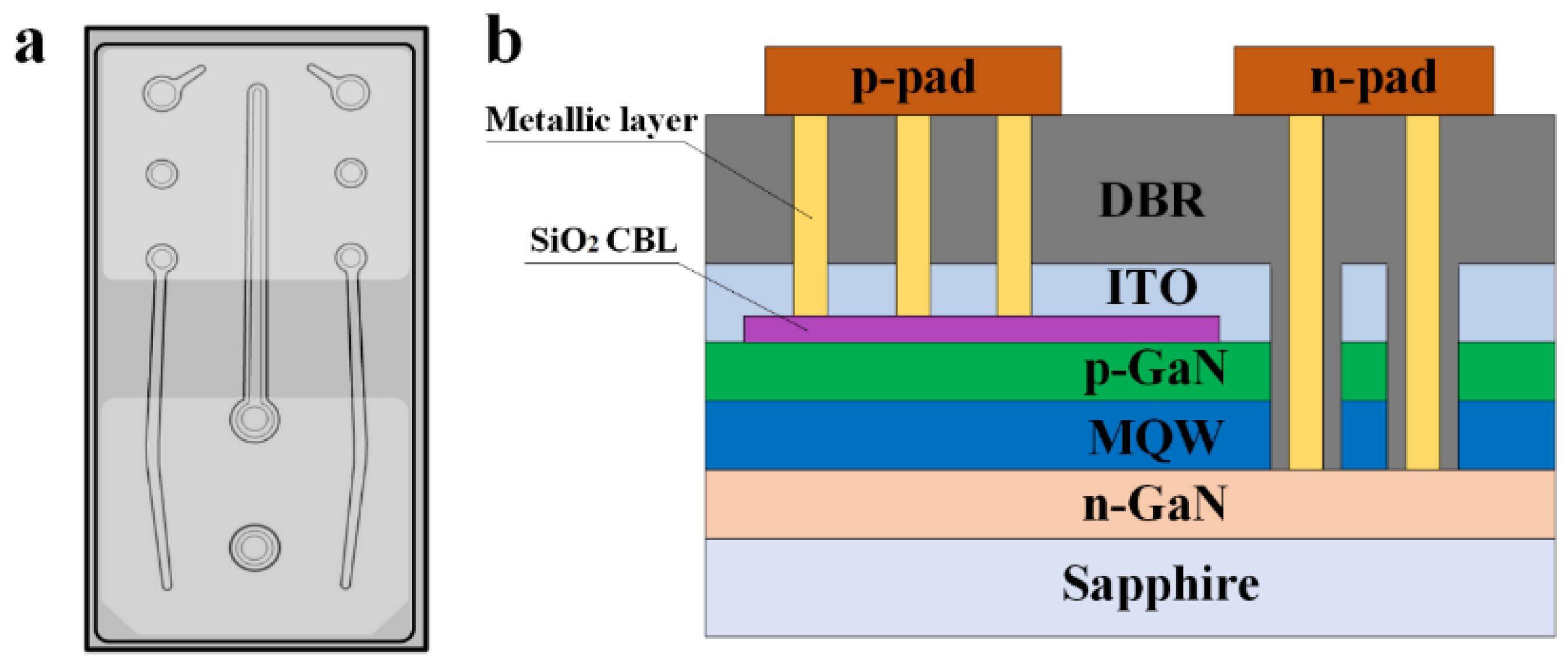

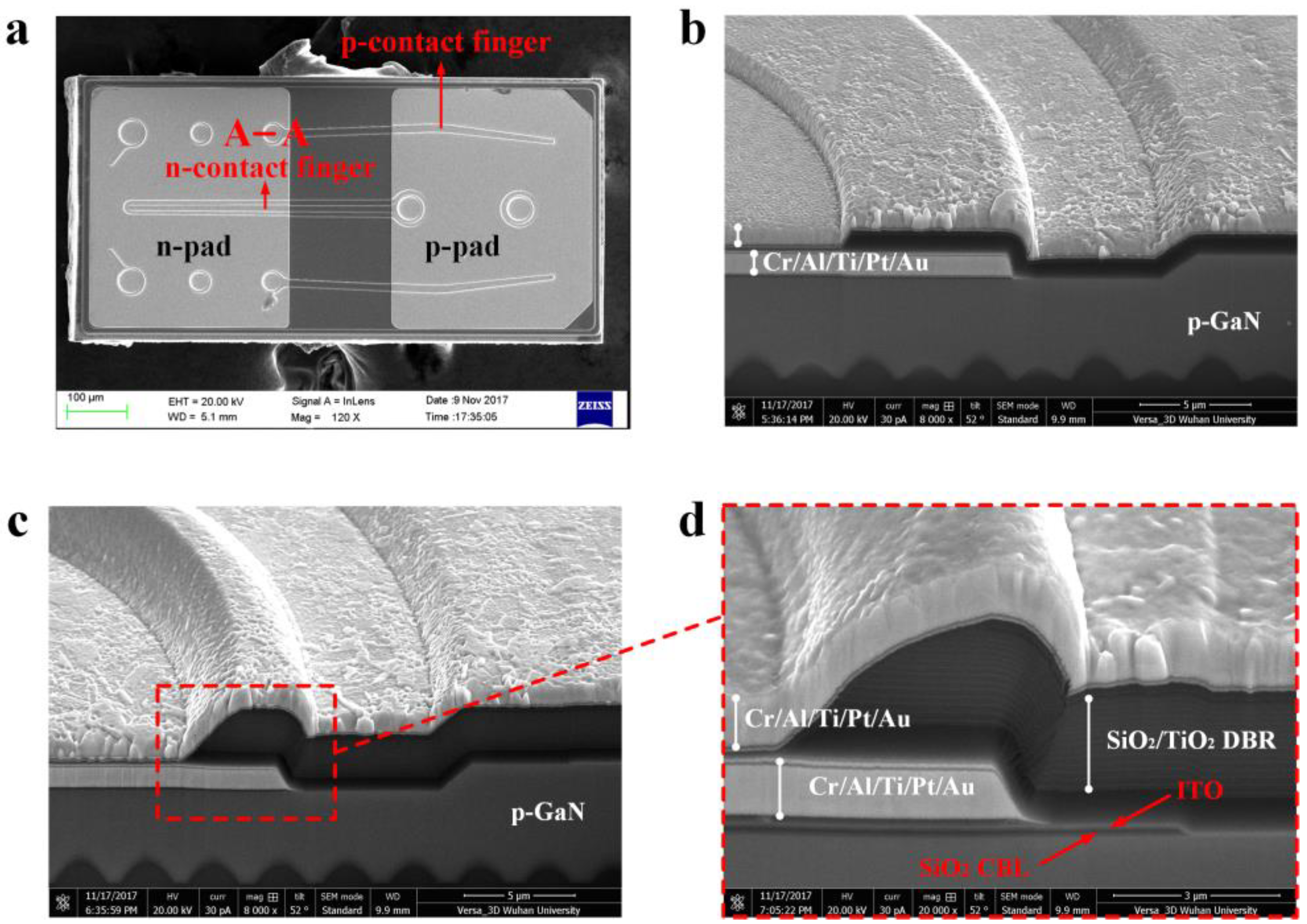

2. Materials and Methods

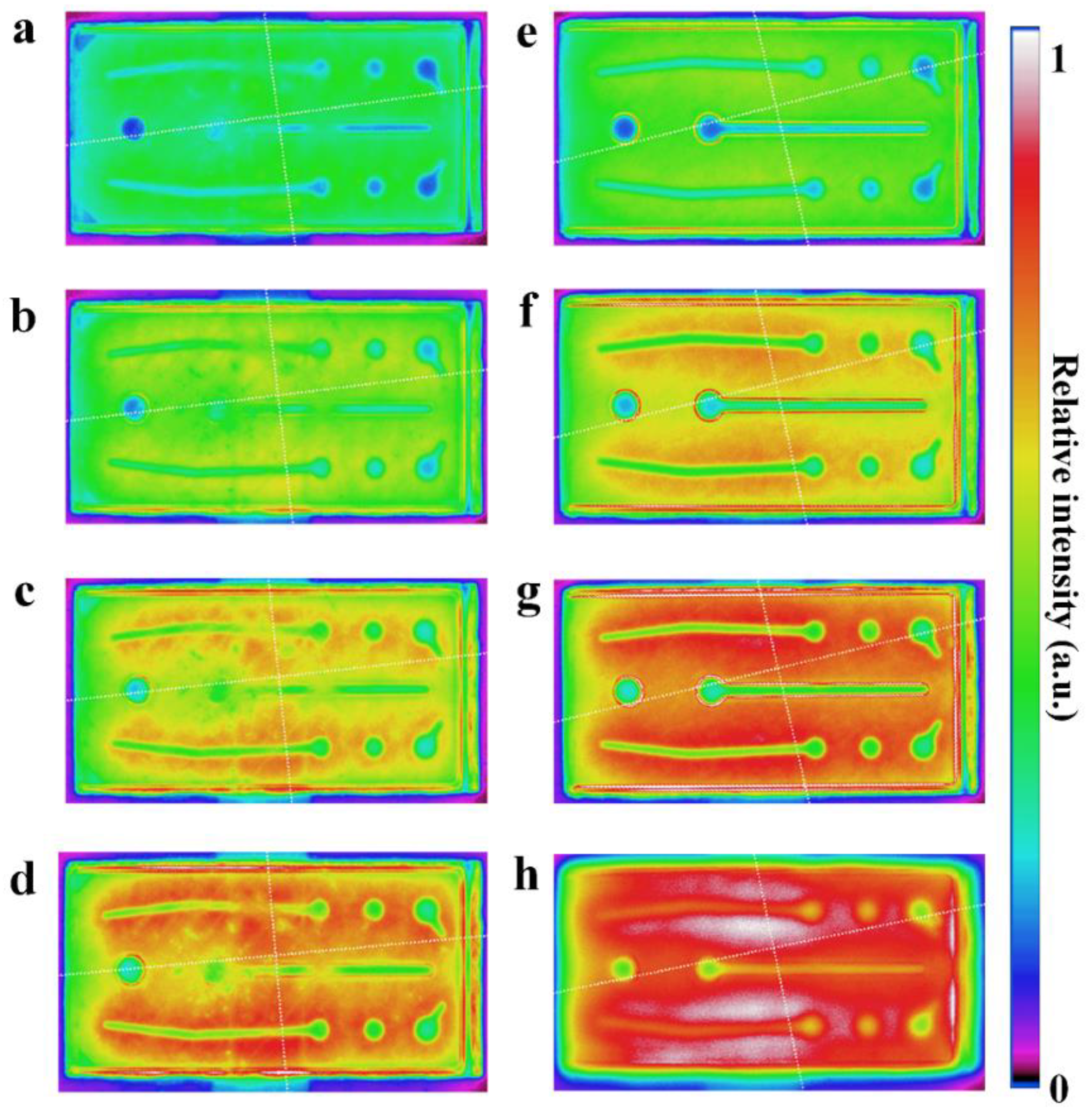

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, C.M.; Kong, D.J.; Shim, J.P.; Kim, S.; Choi, S.B.; Lee, J.Y.; Min, J.H.; Seo, D.J.; Choi, S.Y.; Lee, D.S. Fabrication of a vertically-stacked passive-matrix micro-LED array structure for a dual color display. Opt. Express 2017, 25, 2489–2495. [Google Scholar] [CrossRef] [PubMed]

- Tsai, M.S.; Lee, X.H.; Lo, Y.C.; Sun, C.C. Optical design of tunnel lighting with white light-emitting diodes. Appl. Opt. 2014, 53, H114–H120. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Liu, S. Transient measurement of light-emitting diode characteristic parameters for production lines. Rev. Sci. Instrum. 2009, 80, 095102. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.K.; Sun, W.; Wierer, J.J., Jr.; Tansu, N. Effect of interface roughness on Auger recombination in semiconductor quantum wells. AIP Adv. 2017, 7, 035212. [Google Scholar] [CrossRef]

- Hu, H.; Zhou, S.; Liu, X.; Gao, Y.; Gui, C.; Liu, S. Effects of GaN/AlGaN/Sputtered AlN nucleation layers on performance of GaN-based ultraviolet light-emitting diodes. Sci. Rep. 2017, 7, 44627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, M.; Zhao, J.; Zhou, S.; Gao, Y.; Hu, J.; Liu, X.; Ding, X. An InGaN/GaN Superlattice to Enhance the Performance of Green LEDs: Exploring the Role of V-Pits. Nanomaterials 2018, 8, 450. [Google Scholar] [CrossRef]

- Hsu, W.Y.; Lian, Y.C.; Wu, P.Y.; Yong, W.M.; Sheu, J.K.; Lin, K.L.; Wu, Y.C.S. Suppressing the initial growth of sidewall GaN by modifying micron-sized patterned sapphire substrate with H3PO4-based etchant. Micromachines 2018, 9, 622. [Google Scholar] [CrossRef] [PubMed]

- Dadabayev, R.; Shabairou, N.; Zalevsky, Z.; Malka, D. A visible light RGB wavelength demultiplexer based on silicon-nitride multicore PCF. Opt. Laser. Technol. 2019, 111, 411–416. [Google Scholar] [CrossRef]

- Nikolaevsky, L.; Shchori, T.; Malka, D. Modeling a 1 × 8 MMI Green Light Power Splitter Based on Gallium-Nitride Slot Waveguide Structure. IEEE Photonic. Tech Lett. 2018, 15, 8. [Google Scholar] [CrossRef]

- Chang, S.J.; Kuo, C.H.; Su, Y.K.; Wu, L.W.; Sheu, J.K.; Wen, T.C.; Lai, W.C.; Chen, J.R.; Tsai, J.M. 400-nm InGaN-GaN and InGaN-AlGaN multi quantum well light-emitting diodes. IEEE J. Sel. Top. Quant. 2002, 8, 744–748. [Google Scholar] [CrossRef]

- Ge, P.; Li, Y.; Chen, Z.; Wang, H. LED high-beam headlamp based on free-form microlenses. Appl. Opt. 2014, 53, 5570–5575. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Liu, X.; Yan, H.; Gao, Y.; Xu, H.; Zhao, J.; Quan, Z.; Gui, C.; Liu, S. The effect of nanometre-scale V-pits on electronic and optical properties and efficiency droop of GaN-based green light-emitting diodes. Sci. Rep. 2018, 8, 11053. [Google Scholar] [CrossRef] [PubMed]

- Zhmakin, A.I. Enhancement of light extraction from light emitting diodes. Phys. Rep. 2011, 498, 189–241. [Google Scholar] [CrossRef]

- Krames, M.R.; Shchekin, O.B.; Mueller-Mach, R.; Mueller, G.O.; Zhou, L.; Harbers, G.; Craford, M.G. Status and future of high-power light-emitting diodes for solid-state lighting. J. Disp. Technol. 2007, 3, 160–175. [Google Scholar] [CrossRef]

- DenBaars, S.P.; Feezell, D.; Kelchner, K.; Pimputkar, S.; Pan, C.C.; Yen, C.C.; Tanaka, S.; Zhao, Y.; Pfaff, N.; Farrell, R.; et al. Development of gallium-nitride-based light-emitting diodes (LEDs) and laser diodes for energy-efficient lighting and displays. Acta Mater. 2013, 61, 945–951. [Google Scholar] [CrossRef]

- Tansu, N.; Zhao, H.; Liu, G.; Li, X.H.; Zhang, J.; Tong, H.; Ee, Y.K. III-nitride photonics. IEEE Photonics J. 2010, 2, 241–248. [Google Scholar] [CrossRef]

- Sun, W.; Al Muyeed, S.A.; Song, R.; Wierer, J.J., Jr.; Tansu, N. Integrating AlInN interlayers into InGaN/GaN multiple quantum wells for enhanced green emission. Appl. Phys. Lett. 2018, 112, 201106. [Google Scholar] [CrossRef] [Green Version]

- Arif, R.A.; Ee, Y.K.; Tansu, N. Polarization engineering via staggered InGaN quantum wells for radiative efficiency enhancement of light emitting diodes. Appl. Phys. Lett. 2007, 91, 091110. [Google Scholar] [CrossRef]

- Mitchell, B.; Dierolf, V.; Gregorkiewicz, T.; Fujiwara, Y. Perspective: Toward efficient GaN-based red light emitting diodes using europium doping. J. Appl. Phys. 2018, 123, 160901. [Google Scholar] [CrossRef] [Green Version]

- Tan, C.K.; Borovac, D.; Sun, W.; Tansu, N. InGaN/Dilute-As GaNAs interface quantum well for red emitters. Sci. Rep. 2016, 6, 19271. [Google Scholar] [CrossRef]

- Zhou, S.; Yuan, S.; Liu, S.; Ding, H. Improved light output power of LEDs with embedded air voids structure and SiO2 current blocking layer. Appl. Surf. Sci. 2014, 305, 252–258. [Google Scholar] [CrossRef]

- Teng, D.; Wu, M.; Liu, L.; Wang, G. Size-and current-density-controlled tunable wavelength in GaN-based LEDs for potential dense wavelength-division multiplexing application. IEEE Wirel. Commun. 2015, 22, 74–79. [Google Scholar] [CrossRef]

- Shoresh, T.; Katanov, N.; Malka, D. 1 × 4 MMI visible light wavelength demultiplexer based on a GaN slot-waveguide structure. Photonic. Nanostruct. 2018, 30, 45–49. [Google Scholar] [CrossRef]

- Tawfik, W.Z.; Hyun, G.Y.; Lee, S.J.; Ryu, S.W.; Ha, J.S.; Lee, J.K. Enhanced performance of GaN-based LEDs via electroplating of a patterned copper layer on the backside. J. Mater. Sci. 2018, 53, 8878–8886. [Google Scholar] [CrossRef]

- Han, N.; Cuong, T.V.; Han, M.; Ryu, B.D.; Chandramohan, S.; Park, J.B.; Kang, J.H.; Park, Y.J.; Ko, K.B.; Kim, H.Y.; et al. Improved heat dissipation in gallium nitride light-emitting diodes with embedded graphene oxide pattern. Nat. Commun. 2013, 4, 1452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huh, C.; Lee, K.S.; Kang, E.J.; Park, S.J. Improved light-output and electrical performance of InGaN-based light-emitting diode by microroughening of the p-GaN surface. J. Appl. Phys. 2003, 93, 9383–9385. [Google Scholar] [CrossRef]

- Wierer, J.J.; Krames, M.R.; Epler, J.E.; Gardner, N.F.; Craford, M.G.; Wendt, J.R.; Simmons, J.A.; Sigalas, M.M. InGaN/GaN quantum-well heterostructure light-emitting diodes employing photonic crystal structures. Appl. Phys. Lett. 2004, 84, 3885–3887. [Google Scholar] [CrossRef]

- McGroddy, K.; David, A.; Matioli, E.; Iza, M.; Nakamura, S.; DenBaars, S.; Speck, J.S.; Hu, E.L. Directional emission control and increased light extraction in GaN photonic crystal light emitting diodes. Appl. Phys. Lett. 2008, 93, 103502. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Yuan, S.; Liu, Y.; Guo, L.J.; Liu, S.; Ding, H. Highly efficient and reliable high power LEDs with patterned sapphire substrate and strip-shaped distributed current blocking layer. Appl. Surf. Sci. 2015, 355, 1013–1019. [Google Scholar] [CrossRef]

- Wong, W.S.; Sands, T.; Cheung, N.W.; Kneissl, M.; Bour, D.P.; Mei, P.; Romano, L.T.; Johnson, N.M. InxGa1−xN light emitting diodes on Si substrates fabricated by Pd-In metal bonding and laser lift-off. Appl. Phys. Lett. 2000, 77, 2822–2824. [Google Scholar] [CrossRef]

- Hui, K.N.; Wang, X.H.; Li, Z.L.; Lai, P.T.; Choi, H.W. Design of vertically-stacked polychromatic light-emitting diodes. Opt. Express 2009, 17, 9873–9878. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, S.; Liu, S. Study on sapphire removal for thin-film LEDs fabrication using CMP and dry etching. Appl. Surf. Sci. 2009, 255, 9469–9473. [Google Scholar] [CrossRef]

- Lee, S.Y.; Choi, K.K.; Jeong, H.H.; Choi, H.S.; Oh, T.H.; Song, J.O.; Seong, T.Y. Wafer-level fabrication of GaN-based vertical light-emitting diodes using a multi-functional bonding material system. Semicond. Sci. Tech. 2009, 24, 092001. [Google Scholar] [CrossRef] [Green Version]

- Wierer, J.J.; Steigerwald, D.A.; Krames, M.R.; O’shea, J.J.; Ludowise, M.J.; Christenson, G.; Shen, Y.C.; Lowery, C.; Martin, P.S.; Subramanya, S.; et al. High-power AlGaInN flip-chip light-emitting diodes. Appl. Phys. Lett. 2001, 78, 3379–3381. [Google Scholar] [CrossRef]

- Liu, M.; Zhou, S.; Liu, X.; Gao, Y.; Ding, X. Comparative experimental and simulation studies of high-power AlGaN-based 353 nm ultraviolet flip-chip and top-emitting LEDs. Jpn. J. Appl. Phys. 2018, 57, 031001. [Google Scholar] [CrossRef]

- Horng, R.H.; Chuang, S.H.; Tien, C.H.; Lin, S.C.; Wuu, D.S. High performance GaN-based flip-chip LEDs with different electrode patterns. Opt. Express 2014, 22, A941–A946. [Google Scholar] [CrossRef] [PubMed]

- Lv, J.; Zheng, C.; Chen, Q.; Zhou, S.; Liu, S. High power InGaN/GaN flip-chip LEDs with via-hole-based two-level metallization electrodes. Phys. Status Solidi A 2016, 213, 3150–3156. [Google Scholar] [CrossRef]

- Lee, J.R.; Na, S.I.; Jeong, J.H.; Lee, S.N.; Jang, J.S.; Lee, S.H.; Jung, J.J.; Song, T.Y.; Seong, J.O.; Park, S.J. Low resistance and high reflectance Pt/Rh contacts to p-type GaN for GaN-based flip chip light-emitting diodes. J. Electrochem. Soc. 2005, 152, G92–G94. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Gao, Y.; Liu, Y.; Liu, M.; Liu, Z.; Gui, C.; Liu, S. Numerical simulation and experimental investigation of GaN-based flip-chip light-emitting diodes with highly reflective Ag/TiW and ITO/DBR Ohmic contacts. Opt. Express 2017, 25, 26615–26627. [Google Scholar] [CrossRef]

- Liu, X.; Li, N.; Hu, J.; Gao, Y.; Wang, R.; Zhou, S. Comparative Study of Highly Reflective ITO/DBR and Ni/Ag ohmic Contacts for GaN-Based Flip-Chip Light-Emitting Diodes. ECS J. Solid State Sci. Technol. 2018, 7, Q116–Q122. [Google Scholar] [CrossRef]

- Yamae, K.; Fukshima, H.; Fujimoto, K. Omnidirectional Reflector with Total Internal Reflective Interface for Light Extraction Enhancement of Solid-State Light Source. Phys. Status Solidi A 2018. [Google Scholar] [CrossRef]

- Hsu, Y.P.; Chang, S.J.; Su, Y.K.; Chang, C.S.; Shei, S.C.; Lin, Y.C.; Chen, S.C. InGaN/GaN light-emitting diodes with a reflector at the backside of sapphire substrates. J. Electron. Mater. 2003, 32, 403–406. [Google Scholar] [CrossRef]

- Lu, T.C.; Wu, T.T.; Chen, S.W.; Tu, P.M.; Li, Z.Y.; Chen, C.K.; Chen, C.H.; Kuo, H.C.; Wang, S.C.; Zan, H.W.; et al. Characteristics of current-injected GaN-based vertical-cavity surface-emitting lasers. IEEE J. Sel. Top. Quant. 2011, 17, 1594–1602. [Google Scholar]

- Leonard, J.T.; Young, E.C.; Yonkee, B.P.; Cohen, D.A.; Margalith, T.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Demonstration of a III-nitride vertical-cavity surface-emitting laser with a III-nitride tunnel junction intracavity contact. Appl. Phys. Lett. 2015, 107, 091105. [Google Scholar] [CrossRef]

- Zhou, S.; Zheng, C.; Lv, J.; Gao, Y.; Wang, R.; Liu, S. GaN-based flip-chip LEDs with highly reflective ITO/DBR p-type and via hole-based n-type contacts for enhanced current spreading and light extraction. Opt. Laser Technol. 2017, 92, 95–100. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, S.; Gao, Y.; Hu, H.; Liu, Y.; Gui, C.; Liu, S. Numerical simulation and experimental investigation of GaN-based flip-chip LEDs and top-emitting LEDs. Appl. Opt. 2017, 56, 9502–9509. [Google Scholar] [CrossRef]

- Zhou, S.; Cao, B.; Yuan, S.; Liu, S. Enhanced luminous efficiency of phosphor-converted LEDs by using back reflector to increase reflectivity for yellow light. Appl. Opt. 2014, 53, 8104–8110. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Xu, H.; Liu, M.; Liu, X.; Zhao, J.; Li, N.; Liu, S. Effect of Dielectric Distributed Bragg Reflector on Electrical and Optical Properties of GaN-Based Flip-Chip Light-Emitting Diodes. Micromachines 2018, 9, 650. https://doi.org/10.3390/mi9120650

Zhou S, Xu H, Liu M, Liu X, Zhao J, Li N, Liu S. Effect of Dielectric Distributed Bragg Reflector on Electrical and Optical Properties of GaN-Based Flip-Chip Light-Emitting Diodes. Micromachines. 2018; 9(12):650. https://doi.org/10.3390/mi9120650

Chicago/Turabian StyleZhou, Shengjun, Haohao Xu, Mengling Liu, Xingtong Liu, Jie Zhao, Ning Li, and Sheng Liu. 2018. "Effect of Dielectric Distributed Bragg Reflector on Electrical and Optical Properties of GaN-Based Flip-Chip Light-Emitting Diodes" Micromachines 9, no. 12: 650. https://doi.org/10.3390/mi9120650