Heterogeneous Catalysts for Carbon Dioxide Methanation: A View on Catalytic Performance

Abstract

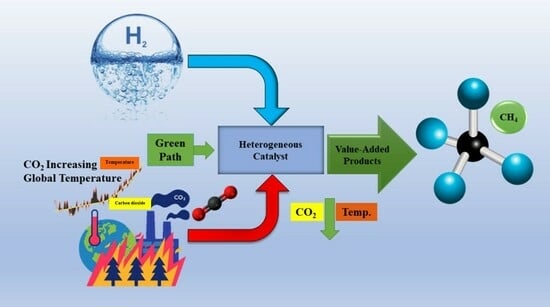

:1. Introduction

2. Reaction Mechanism and Thermodynamic Equilibrium

2.1. CO2 Methanation Reaction

2.2. Thermodynamic Equilibrium Conversion and Selectivity

3. The Catalytic Performance of Noble Metal Catalysts in CO2 Methanation

3.1. Ruthenium-Based Catalysts

| Catalyst | Preparation Methods | Metal Loading (%) | XCO2 (mol%) | SCH4 (mol%) | Period of Stable Running (h) | Reaction Conditions | Ref. | |

|---|---|---|---|---|---|---|---|---|

| GHSV h−1/WHSV (mL.g−1h−1) | T (°C) | |||||||

| Ruthenium-based catalysts | ||||||||

| Ru/Al2O3 | Commercial catalyst | 3 | 91 | 91 | 100 | 55,000 * H2:CO2 = 5:1 | 375 | [62] |

| Ru/CeO2 | Hydrothermal | 5 | 86 | 100 | 30 | 30,000 | 300 | [72] |

| Ru-Ni/Ce0.6Zr 0.4O2 | Deposition precipitation | 3/30 | 98 | 100 | 300 | 24,000 | 230 | [73] |

| Ru-CeO2/Al2O3 | Impregnation | 2 | 60 | 99 | - | 10,000 | 300 | [74] |

| Ru/TiO2 | Impregnation | 2.5 | 90 | 99 | 50 | 6000 | 350 | [75] |

| Ru/TiO2 | Impregnation | 5 | 68 | 98 | 34 | 7580 | 290 | [67] |

| Ru/UiO-66 | Impregnation | 1 | 60 | 100 | 160 | 19,000 | 250 ** 5 | [76] |

| Ru/TiO2 (001) | Solvothermal hydrolysis | 2.5 | 80 | 100 | 168 | 6000 | 325 | [66] |

| Ru/CeO2/r | Hydrothermal | 3.7 | 75 | 99 | 24 | 72,000 | 350 | [77] |

| Ru/CeO2 | Thermal deposition | - | 83 | 90 | 14 | - | 225 | [78] |

| Ru@MIL-101 | Hydrothermal | - | 90 | 99 | 48 | - | 225 | [69] |

| Rhodium-based catalysts | ||||||||

| Rh/TiO2 | Impregnation | 1 | 90 | 96 | 3 | 12,000 | 370 ** 2 | [79] |

| Rh/γAl2O3 | Wet impregnation | 1 | 25 | 100 | - | - | 125 | [80] |

| RhY | Ion-exchange | 6 | 59 | 99.8 | 2 | 60,000 * H2:CO2 = 3:1 | 150 | [81] |

| Rh/CeO2 | Impregnation | 3 | ~46 | ~100 | - | - | 350 | [82] |

| Rh/Al2O3 | Impregnation | 1 | 25 | 100 | - | - | 250 | [57] |

| Rh/PSAC | Impregnation | 2 | 54 | 73 | 2 | 10,000 | 207 | [83] |

| PdRuNi/Al2O3 | Impregnation | 2/8/90 | 53 | 40 | 5 | 400 | [84] | |

| RuRh-γ Al2O3 | Impregnation | 0.5/0.5 | 80 | 100 | - | 6000 | 250 | [85] |

| Ni-Rh/Al2O3 | Co-impregnation | 10/0.5 | 65 | 92 | 4 | 57,000 | 300 | [86] |

| Palladium-based catalysts | ||||||||

| Pd/UiO-66 | Sol–gel | 6 | 56 | 97.3 | - | 15,000 | 340 | [87] |

| Pd/Al2O3 | Impregnation | 5 | - | 40 | - | 45,000 | 280 | [88] |

| PdO/LaCoO3 | One-pot | 3 | 62 | 99 | 2 | 18,000 | 300 | [89] |

| PdO/LaCoO3 | Impregnation | 3 | 32 | 87 | 2 | 18,000 | 300 | [89] |

| Pd-Mg/SiO2 | Microemulsion | 6.2 | 59 | 95 | 9 | 7320 | 450 | [90] |

| Pd@FeO | Seeded growth | 5.2 | 98 | 100 | 20 Rounds | - | 180 | [91] |

| NiPd/Al2O3 | Co-impregnation | 10–0.5 | 91 | 99 | 4 | 57,000 | 300 | [86] |

3.2. Rhodium-Based Catalysts

3.3. Palladium-Based Catalysts

3.4. Summary of Performance of Noble Metal Catalysts

4. The Catalytic Performance of Non-Noble Metal Catalysts in CO2 Methanation

4.1. Nickel-Based Catalysts

| Catalyst | Preparation Methods | Metal Loading | XCO2 | SCH4 | Period of Stability | Reaction Conditions | Ref. | |

|---|---|---|---|---|---|---|---|---|

| (%) | (mol%) | (mol%) | (h) | GHSVh−1/WHSV mL.g−1h−1 | T (°C) | |||

| Nickel-based catalysts | ||||||||

| Ni/Al2O3 | Impregnation | 20 | 80 | 100 | 10 | 9000 | 350 | [133] |

| Ni/Al2O3 | Improved one-pot EISA | 10 | 60 | 95 | 60 | 10,000 | 400 | [134] |

| Ni/Al2O3 | Impregnation | 30 | 71 | 95 | 24 | 30,000 * H2:CO2:Ar = 61:15: 21 | 350 ** 2 | [135] |

| Ni/Al2O3-SiO2 | Sol–gel | 30/0.5 | 82 | 98 | 30 | 12,000 H2:CO2 = 3.5:1 | 350 | [128] |

| Ni-Co/Al2O3 | Improved one-pot EISA | 10/3 | 70 | 96 | 60 | 10,000 | 400 | [134] |

| NiFe/Al2O3 | One-pot-induction EISA | 84.1 | 100 | 150 | 420 | [136] | ||

| Ni-Pt/γ-Al2O3 | Co-impregnation | 10–0.5 | 83 | 97 | 60 | 5700 | 250 | [86] |

| Ni-Pd/γ-Al2O3 | Co-impregnation | 10–0.5 | 91 | 97 | 30 | 5700 | 250 | [86] |

| Ni/Al2O3-ZrO2 | Sol–gel | 20 | 76 | 100 | 100 | 20,000 | 300 | [137] |

| Mn-Ni/Al2O3 | Impregnation | 1.71 | 66 | 100 | - | 300 | [138] | |

| Ni-Pr/Al2O3 | Impregnation | 12–5 | 98 | 100 | 48 | 6000 | 300 | [139] |

| Ni-Ce/Al2O3 | Impregnation | 15–15 | 70 | 98 | 80 | 30,000 | 350 | [116] |

| NiO/SiO2 | Sol–gel | 60 | 86 | 95 | 48 | 10,000 | 350 | [140] |

| Ni-La2O3/SiO2 | Citric complex | 7.7 | 89 | 90 | 400 | 15,000 | 500 | [141] |

| NiLaMoO3/SiO2 | Citric complex | 6 | 87 | 100 | 320 | 15,000 | 350 | [121] |

| Ni/MSN | Sol–gel | 5 | 64 | 100 | 200 | 50,000 | 300 | [130] |

| Ni/MOF-5 | Impregnation | 10 | 75 | 100 | 100 | 2000 | 320 | [142] |

| Ni/MSN | Impregnation | 5 | 64 | 100 | 100 | 50,000 | 300 | [131] |

| Ni@HZSM-5 | Hydrothermal | 20 | 64 | 99 | 40 | 36,000 | 400 | [143] |

| Ni/OMA | Impregnation | 15 | 87 | 98 | 150 | 91,000 * H2:CO2 = 5:1 | 400 | [144] |

| Ni/CNT | Co-impregnation | 12 | 61 | 97 | 100 | 30,000 | 350 | [145] |

| Ni/3D-SBA-15 | Impregnation | 15 | 86 | 99 | 100 | 60,000 | 400 | [146] |

| Ni/C.Z. | Pseudo sol–gel | 5 | 80 | 99 | 90 | 43,000 | 350 | [37] |

| HTNiCu | Co-precipitation | 15 | 86 | 98 | 72 | 12,000 * H2:CO2:Ar = 6:1.5:2.5 | 350 | [147] |

| Ni-Ce-Y/SBA-15 | CTAB-assisted impregnation | 15–10 | 61 | 97 | 26 | _ | 350 | [148] |

| NiMg/USY | Ion exchange | 13–9 | 65 | 92 | 10 | 12,000 * H2:CO2:Ar = 36:9:10 | 400 | [149] |

| Ni-Mn/Bn-U | Solution combustion synthesis | 85 | 100 | 150 | 36,000 | 270 | [150] | |

| Ni-La | Urea hydrolysis | 15 | 85 | 94 | 150 | 45,000 | 350 | [151] |

| Ni-La | Impregnation | 13.6–14 | 90 | 100 | 8 | 55,000 H2:CO2 = 5:1 | 350 | [152] |

| Ni/TiO2 | Deposition precipitation | 15 | 80 | 96 | 81 | 18,000 * H2:CO2:Ar = 12:3:5 | 340 | [153] |

| Ni/Y2O3 | Impregnation | 10 | 80 | 100 | 50 | 20,000 | 300 | [110] |

| Ni/ZrO2 | Impregnation | 15 | 60 | 100 | 50 | 48,000 | 300 | [154] |

| Ni/ZrO2 | Plasma decomposition | 5 | 79 | 77 | 70 | 60,000 | 350 | [45] |

| Ni/ZrO2 | Impregnation | 10 | 74 | 71 | 10 | 60,000 | 400 | [45] |

| Ni/CeO2 | Sol–gel | 20 | 81 | 96 | 106 | 40,000 | 250 | [155] |

| Ni/CeO2 | Hard template | 10 | 91 | 100 | 11 | 22,000 | 340 | [107] |

| Ni/CeO2- | Impregnation | 10 | 93 | 100 | 14 | 10,000 | 350 | [64] |

| Ni-Ce0.2Zr0.8O2 | Citric Complex | 15 | 71 | 100 | 200 | 15,000 | 250 | [108] |

| Ni-Ce0.72Zr0.28O2 | Sol–gel | 15/0.6 | 90 | 98 | 150 | 21,000 | 350 | [156] |

| Ni/CeO2-ZrO2 | Ammonia evaporation | 10 | 55 | 99.8 | 70 | 20,000 | 275 | [157] |

| Ni/CeO2-ZrO2 | Colloidal dispersion | 2 | 58 | 98 | 60 | 60,000 * H2:CO2:He = 12:3:5 | 350 | [158] |

| Ni/CeO2-ZrO2 | Pseudo-sol–gel | 5 | 68 | 98 | 43,000 | 350 | [37] | |

| Ni/Ce0.6O2Zr0.4O2 | Co-precipitation | 15/0.6 | 71 | 86 | 83 | 12,500 | 300 | [159] |

| Ni/Ce0.75Zr0.25 | 25 | 85 | — | 30. | 300 | [160] | ||

| Ni-La2O3CeO2/ZrO2 | Citric Complex | - | 80 | 100 | 160 | 15,000 | 350 | [161] |

| Ni/ZrO2-Al2O3 | Co-impregnation | 12 | 70 | 100 | 100 | 8100 | 360 | [113] |

| Ni/CeO2-Al2O3 | Co-impregnation | 15 | 71 | 99 | 120 | 15,000 | 350 | [116] |

| Ni/CeO2-Al2O3 | Co impregnation | 13 | 85 | 99 | 120 | 15,000 | 350 | [162] |

| Cobalt- and iron-based catalysts | ||||||||

| Co-Pt/Al2O3 | Double flame spray Pyrolysis | 0.03 | 70 | 98 | 210 | 36,000 | 400 | [163] |

| NiCo/Al2O3 | Impregnation | 20 | 90 | 100 | 200 | 13,000 | 325 | [164] |

| Ni-Co/Al2O3 | Solid-phase synthesis | 15–12.5 | 76 | 96 | 10 | 9000 | 400 | [165] |

| Ni-Co/Al2O3 | Impregnation | 10–10 | 61 | 95 | 200 | 13,000 | 350 | [164] |

| NiCoMgZnMn/Al2O4 | Citric complex | 6.8/9.8 | 64 | 100 | 320 | 15,000 | 350 | [166] |

| Co3O4 nanorod | Co-precipitation | 70 | 99 | 50 | 18,000 H2:CO2 = 4:6 | 330 ** 10 | [167] | |

| Co/KIT-6 | Excess impregnation | 20 | 48.9 | 100 | - | 22,000 | 280 | [33] |

| CoNR/TiO2 | Modular synthesis | - | 57 | 100 | 72 | 18,000 | 250 ** 10 | [168] |

| (Co0.95 Ru0.05)O4 | Modified wet chemistry protocol | - | 34.2 | 97.4 | 50 | 21,240 | 420 | [167] |

| PrCoPal | Impregnation | 68 | 95 | 200 | 150,000 | 350 | [169] | |

| Co/ZrO2 | Wetness impregnation | 10 | 92 | 99 | 300 | 3600 | 400 ** 30 | [170] |

| Co/ZrO2 | Citric complex | 2 | 85 | 99 | 300 | 7200 | 400 ** 30 | [171] |

| Co-Zr0.1B-O | Liquid-phase synthesis | - | 78 | 98 | 12 | 20,000 | 180 | [172] |

| NiFe/Al2O3 | Impregnation | 13–9 | 84.1 | 100 | 150 | 50,000 | 420 | [136] |

| NiFe/Al2O3 | One-pot sol–gel | 30–5 | 71 | 99 | 10 | 9000 | 350 | [173] |

| NiFe | Single-step co-precipitation | 3–0.5 | 78 | 30 | 20,000 | 200 | [174] | |

| Ni8Fe2 | Co-precipitation | 30 | 80 | 95 | 200 | 10,000 | 150 | [175] |

4.2. Cobalt-Based and Iron-Based Catalysts

4.3. Summary of Performance of Non-Noble Catalysts

5. Conclusions and Future Prospective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahn, J.; Chung, W. A Study on Activity of Coexistent CO Gas during the CO2 Methanation Reaction in Ni-Based Catalyst. Processes 2023, 11, 628. [Google Scholar] [CrossRef]

- Asim, M.; Maryam, B.; Zhang, S.; Sajid, M.; Kurbanov, A.; Pan, L.; Zou, J.J. Synergetic effect of Au nanoparticles and transition metal phosphides for enhanced hydrogen evolution from ammonia-borane. J. Colloid Interface Sci. 2023, 638, 14–25. [Google Scholar] [CrossRef] [PubMed]

- Mebrahtu, C.; Krebs, F.; Abate, S.; Perathoner, S.; Centi, G.; Palkovits, R. CO2 Methanation: Principles and Challenges, 1st ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 178, ISBN 9780444641274. [Google Scholar]

- Asim, M.; Zhang, S.; Maryam, B.; Xiao, J.; Shi, C.; Pan, L.; Zou, J.J. Pt loading to promote hydrogen evolution from ammonia-borane hydrolysis of Ni2P under visible light. Appl. Surf. Sci. 2023, 620, 156787. [Google Scholar] [CrossRef]

- Hassan, M.A.; Mehmood, T.; Liu, J.; Luo, X.; Li, X.; Tanveer, M.; Faheem, M.; Shakoor, A.; Dar, A.A.; Abid, M. A review of particulate pollution over Himalaya region: Characteristics and salient factors contributing ambient PM pollution. Atmos. Environ. 2023, 294, 119472. [Google Scholar] [CrossRef]

- Mehmood, T.; Hassan, M.A.; Li, X.; Ashraf, A.; Rehman, S.; Bilal, M.; Obodo, R.M.; Mustafa, B.; Shaz, M.; Bibi, S. Mechanism behind sources and sinks of major anthropogenic greenhouse gases. In Climate Change Alleviation for Sustainable Progression; CRC Press: Boca Raton, FL, USA, 2022; pp. 114–150. [Google Scholar]

- Bai, C.; Chen, Z.; Wang, D. Transportation carbon emission reduction potential and mitigation strategy in China. Sci. Total Environ. 2023, 873, 162074. [Google Scholar] [CrossRef]

- Zhu, Q. Developments on CO2-utilization technologies. Clean Energy 2019, 3, 85–100. [Google Scholar] [CrossRef]

- Petrovic, B.; Gorbounov, M.; Masoudi Soltani, S. Influence of surface modification on selective CO2 adsorption: A technical review on mechanisms and methods. Microporous Mesoporous Mater. 2021, 312, 110751. [Google Scholar] [CrossRef]

- IPCC. Summary for Policymakers Sixth Assessment Report (WG3); IPCC: Geneva, Switzerland, 2022; ISBN 9781107415416. [Google Scholar]

- Hassan, M.A.; Mehmood, T.; Lodhi, E.; Bilal, M.; Dar, A.A.; Liu, J. Lockdown Amid COVID-19 Ascendancy over Ambient Particulate Matter Pollution Anomaly. Int. J. Environ. Res. Public Health 2022, 19, 3540. [Google Scholar] [CrossRef]

- Hassan, M.A.; Faheem, M.; Mehmood, T.; Yin, Y.; Liu, J. Assessment of meteorological and air quality drivers of elevated ambient ozone in Beijing via machine learning approach. Environ. Sci. Pollut. Res. 2023, 30, 104086–104099. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, A.; Lougou, B.G.; Shuai, Y.; Wang, Z.; Tan, H. Current technology development for CO2 utilization into solar fuels and chemicals: A review. J. Energy Chem. 2020, 49, 96–123. [Google Scholar] [CrossRef]

- Dlugokencky, E.; Tans, P. Co2_Trend_Gl.Pdf. Available online: https://www.esrl.noaa.gov/gmd/ccgg/trends/global.html (accessed on 5 November 2023).

- Warsi, Y.; Kabanov, V.; Zhou, P.; Sinha, A. Novel Carbon Dioxide Utilization Technologies: A Means to an End. Front. Energy Res. 2020, 8, 574147. [Google Scholar] [CrossRef]

- Raheem, I.; Mubarak, N.M.; Karri, R.R.; Manoj, T.; Ibrahim, S.M.; Mazari, S.A.; Nizamuddin, S. Forecasting of energy consumption by G20 countries using an adjacent accumulation grey model. Sci. Rep. 2022, 12, 13417. [Google Scholar] [CrossRef]

- World Meteorological Organization (WMO). WMO Global Annual to Decadal Climate Update; World Meteorological Organization (WMO): Geneva, Switzerland, 2023. [Google Scholar]

- Monthly Average Mauna Loa CO2 Monthly Average Mauna Loa CO2.pdf. Available online: https://www.gml.noaa.gov/ccgg/trends/ (accessed on 21 November 2022).

- Khdary, N.H.; Alayyar, A.S.; Alsarhan, L.M.; Alshihri, S.; Mokhtar, M. Metal Oxides as Catalyst/Supporter for CO2 Capture and Conversion, Review. Catalysts 2022, 12, 300. [Google Scholar] [CrossRef]

- UNFCCC. UN Climate Change ANNUAL REPORT 2017; United Nations Framework Convention on Climate Change: Bonn, Germany, 2017; ISBN 9789292191757. [Google Scholar]

- Rafiee, A.; Rajab Khalilpour, K.; Milani, D.; Panahi, M. Trends in CO2 conversion and utilization: A review from process systems perspective. J. Environ. Chem. Eng. 2018, 6, 5771–5794. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil kumar, P.; Vo, D.V.N.; Jeevanantham, S.; Bhuvaneswari, V.; Anantha Narayanan, V.; Yaashikaa, P.R.; Swetha, S.; Reshma, B. A comprehensive review on different approaches for CO2 utilization and conversion pathways. Chem. Eng. Sci. 2021, 236, 116515. [Google Scholar] [CrossRef]

- Feng, X.; Wang, K.; Zhou, M.; Li, F.; Liu, J.; Zhao, M.; Zhao, L.; Song, X.; Zhang, P.; Gao, L. Metal organic framework derived Ni/CeO2 catalyst with highly dispersed ultra-fine Ni nanoparticles: Impregnation synthesis and the application in CO2 methanation. Ceram. Int. 2021, 47, 12366–12374. [Google Scholar] [CrossRef]

- Takht Ravanchi, M.; Sahebdelfar, S. Catalytic conversions of CO2 to help mitigate climate change: Recent process developments. Process Saf. Environ. Prot. 2021, 145, 172–194. [Google Scholar] [CrossRef]

- Liu, M.; Yi, Y.; Wang, L.; Guo, H.; Bogaerts, A. Hydrogenation of carbon dioxide to value-added chemicals by heterogeneous catalysis and plasma catalysis. Catalysts 2019, 9, 275. [Google Scholar] [CrossRef]

- Asim, M.; Zhang, S.; Wang, Y.; Maryam, B.; Sajid, M.; Shi, C.; Pan, L.; Zhang, X.; Zou, J.J. Self-supporting NiCoP for hydrogen generation via hydrolysis of ammonia borane. Fuel 2022, 318, 123544. [Google Scholar] [CrossRef]

- Garba, M.D.; Usman, M.; Khan, S.; Shehzad, F.; Galadima, A.; Ehsan, M.F.; Ghanem, A.S.; Humayun, M. CO2 towards fuels: A review of catalytic conversion of carbon dioxide to hydrocarbons. J. Environ. Chem. Eng. 2021, 9, 104756. [Google Scholar] [CrossRef]

- Italiano, C.; Llorca, J.; Pino, L.; Ferraro, M.; Antonucci, V.; Vita, A. CO and CO2 methanation over Ni catalysts supported on CeO2, Al2O3 and Y2O3 oxides. Appl. Catal. B Environ. 2020, 264, 118494. [Google Scholar] [CrossRef]

- Varvoutis, G.; Lampropoulos, A.; Oikonomou, P.; Andreouli, C.D.; Stathopoulos, V.; Lykaki, M.; Marnellos, G.E.; Konsolakis, M. Fabrication of highly active and stable Ni/CeO2-nanorods wash-coated on ceramic NZP structured catalysts for scaled-up CO2 methanation. J. CO2 Util. 2023, 70, 102425. [Google Scholar] [CrossRef]

- Varvoutis, G.; Karakoulia, S.A.; Lykaki, M.; Stefa, S.; Binas, V.; Marnellos, G.E.; Konsolakis, M. Support-induced modifications on the CO2 hydrogenation performance of Ni/CeO2: The effect of ZnO doping on CeO2 nanorods. J. CO2 Util. 2022, 61, 102057. [Google Scholar] [CrossRef]

- Refaat, Z.; El Saied, M.; El Naga, A.O.A.; Shaban, S.A.; Hassan, H.B.; Shehata, M.R.; Kady, F.Y.E. Efficient CO2 methanation using nickel nanoparticles supported mesoporous carbon nitride catalysts. Sci. Rep. 2023, 13, 4855. [Google Scholar] [CrossRef] [PubMed]

- Gholami, S.; Alavi, S.M.; Rezaei, M. Preparation of highly active and stable nanostructured Ni-Cr2O3 catalysts for hydrogen purification via CO2 methanation reaction. J. Energy Inst. 2021, 95, 132–142. [Google Scholar] [CrossRef]

- Zhou, G.; Wu, T.; Xie, H.; Zheng, X. Effects of structure on the carbon dioxide methanation performance of Co-based catalysts. Int. J. Hydrogen Energy 2013, 38, 10012–10018. [Google Scholar] [CrossRef]

- Nieß, S.; Armbruster, U.; Dietrich, S.; Klemm, M. Recent Advances in Catalysis for Methanation of CO2 from Biogas. Catalysts 2022, 12, 374. [Google Scholar] [CrossRef]

- Cárdenas-Arenas, A.; Quindimil, A.; Davó-Quiñonero, A.; Bailón-García, E.; Lozano-Castelló, D.; De-La-Torre, U.; Pereda-Ayo, B.; González-Marcos, J.A.; González-Velasco, J.R.; Bueno-López, A. Isotopic and in situ DRIFTS study of the CO2 methanation mechanism using Ni/CeO2 and Ni/Al2O3 catalysts. Appl. Catal. B Environ. 2020, 265, 118538. [Google Scholar] [CrossRef]

- Gao, J.; Liu, Q.; Gu, F.; Liu, B.; Zhong, Z.; Su, F. Recent advances in methanation catalysts for the production of synthetic natural gas. RSC Adv. 2015, 5, 22759–22776. [Google Scholar] [CrossRef]

- Aldana, P.A.U.; Ocampo, F.; Kobl, K.; Louis, B.; Thibault-Starzyk, F.; Daturi, M.; Bazin, P.; Thomas, S.; Roger, A.C. Catalytic CO2 valorization into CH4 on Ni-based ceria-zirconia. Reaction mechanism by operando IR spectroscopy. Catal. Today 2013, 215, 201–207. [Google Scholar] [CrossRef]

- Wang, S.; Pan, Q.; Peng, J.; Wang, S. In situ FTIR spectroscopic study of the CO2 methanation mechanism on Ni/Ce0.5Zr0.5O2. Catal. Sci. Technol. 2014, 4, 502–509. [Google Scholar] [CrossRef]

- Akamaru, S.; Shimazaki, T.; Kubo, M.; Abe, T. Density functional theory analysis of methanation reaction of CO2 on Ru nanoparticle supported on TiO2 (1 0 1). Appl. Catal. A Gen. 2014, 470, 405–411. [Google Scholar] [CrossRef]

- Miao, B.; Ma, S.S.K.; Wang, X.; Su, H.; Chan, S.H. Catalysis mechanisms of CO2 and CO methanation. Catal. Sci. Technol. 2016, 6, 4048–4058. [Google Scholar] [CrossRef]

- Xu, X.; Tong, Y.; Huang, J.; Zhu, J.; Fang, X.; Xu, J.; Wang, X. Insights into CO2 methanation mechanism on cubic ZrO2 supported Ni catalyst via a combination of experiments and DFT calculations. Fuel 2021, 283, 118867. [Google Scholar] [CrossRef]

- Su, X.; Xu, J.; Liang, B.; Duan, H.; Hou, B.; Huang, Y. Catalytic carbon dioxide hydrogenation to methane: A review of recent studies. J. Energy Chem. 2016, 25, 553–565. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Liu, J.; Xiong, B. Mechanistic understanding of CO2 hydrogenation to methane over Ni/CeO2 catalyst. Appl. Surf. Sci. 2021, 558, 149866. [Google Scholar] [CrossRef]

- Ren, J.; Guo, H.; Yang, J.; Qin, Z.; Lin, J.; Li, Z. Insights into the mechanisms of CO2 methanation on Ni(111) surfaces by density functional theory. Appl. Surf. Sci. 2015, 351, 504–516. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, X.; Rui, N.; Hu, X.; Liu, C.j. Structural effect of Ni/ZrO2 catalyst on CO2 methanation with enhanced activity. Appl. Catal. B Environ. 2019, 244, 159–169. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Y.; Ping, Y.; Hu, D.; Xu, G.; Gu, F.; Su, F. A thermodynamic analysis of methanation reactions of carbon oxides for the production of synthetic natural gas. RSC Adv. 2012, 2, 2358–2368. [Google Scholar] [CrossRef]

- Pan, Q.; Peng, J.; Sun, T.; Wang, S.; Wang, S. Insight into the reaction route of CO2 methanation: Promotion effect of medium basic sites. Catal. Commun. 2014, 45, 74–78. [Google Scholar] [CrossRef]

- Ridzuan, N.D.M.; Shaharun, M.S.; Anawar, M.A.; Ud-Din, I. Ni-Based Catalyst for Carbon Dioxide Methanation: A Review. Catalysts 2022, 12, 469. [Google Scholar] [CrossRef]

- Lee, W.J.; Li, C.; Prajitno, H.; Yoo, J.; Patel, J.; Yang, Y.; Lim, S. Recent trend in thermal catalytic low temperature CO2 methanation: A critical review. Catal. Today 2021, 368, 2–19. [Google Scholar] [CrossRef]

- Martínez, J.; Hernández, E.; Alfaro, S.; Medina, R.L.; Aguilar, G.V.; Albiter, E.; Valenzuela, M.A. High selectivity and stability of nickel catalysts for CO2 Methanation: Support effects. Catalysts 2019, 9, 24. [Google Scholar] [CrossRef]

- Liang, C.; Zhang, L.; Zheng, Y.; Zhang, S.; Liu, Q.; Gao, G.; Dong, D.; Wang, Y.; Xu, L.; Hu, X. Methanation of CO2 over nickel catalysts: Impacts of acidic/basic sites on formation of the reaction intermediates. Fuel 2020, 262, 116521. [Google Scholar] [CrossRef]

- Razzaq, R.; Zhu, H.; Jiang, L.; Muhammad, U.; Li, C.; Zhang, S. Catalytic methanation of CO and CO2 in coke oven gas over Ni-Co/ZrO2-CeO2. Ind. Eng. Chem. Res. 2013, 52, 2247–2256. [Google Scholar] [CrossRef]

- Li, S.; Tang, H.; Gong, D.; Ma, Z.; Liu, Y. Loading Ni/La2O3 on SiO2 for CO methanation from syngas. Catal. Today 2017, 297, 298–307. [Google Scholar] [CrossRef]

- Stangeland, K.; Kalai, D.; Li, H.; Yu, Z. CO2 Methanation: The Effect of Catalysts and Reaction Conditions. Energy Procedia 2017, 105, 2022–2027. [Google Scholar] [CrossRef]

- Brooks, K.P.; Hu, J.; Zhu, H.; Kee, R.J. Methanation of carbon dioxide by hydrogen reduction using the Sabatier process in microchannel reactors. Chem. Eng. Sci. 2007, 62, 1161–1170. [Google Scholar] [CrossRef]

- Jürgensen, L.; Ehimen, E.A.; Born, J.; Holm-Nielsen, J.B. Dynamic biogas upgrading based on the Sabatier process: Thermodynamic and dynamic process simulation. Bioresour. Technol. 2015, 178, 323–329. [Google Scholar] [CrossRef] [PubMed]

- Yarbaş, T.; Ayas, N. A detailed thermodynamic analysis of CO2 hydrogenation to produce methane at low pressure. Int. J. Hydrogen Energy 2023, 49, 1134–1144. [Google Scholar] [CrossRef]

- Hofmann, A. Physical Chemistry Essentials; Springer: Cham, Switzerland, 2018; ISBN 9783319741673. [Google Scholar]

- Abdel-Mageed, A.M.; Wohlrab, S. Review of CO2 reduction on supported metals (Alloys) and single-atom catalysts (SACs) for the use of green hydrogen in power-to-gas concepts. Catalysts 2022, 12, 16. [Google Scholar] [CrossRef]

- Sharifian, S.; Asasian-Kolur, N. Studies on COx hydrogenation to methane over Rh-based catalysts. Inorg. Chem. Commun. 2020, 118, 108021. [Google Scholar] [CrossRef]

- Kuznecova, I.; Gusca, J. Property based ranking of CO and CO2 methanation catalysts. Energy Procedia 2017, 128, 255–260. [Google Scholar] [CrossRef]

- Garbarino, G.; Bellotti, D.; Riani, P.; Magistri, L.; Busca, G. Methanation of carbon dioxide on Ru/Al2O3 and Ni/Al2O3 catalysts at atmospheric pressure: Catalysts activation, behaviour and stability. Int. J. Hydrogen Energy 2015, 40, 9171–9182. [Google Scholar] [CrossRef]

- Park, S.J.; Wang, X.; Ball, M.R.; Proano, L.; Wu, Z.; Jones, C.W. CO2 methanation reaction pathways over unpromoted and NaNO3-promoted Ru/Al2O3 catalysts. Catal. Sci. Technol. 2022, 12, 4637–4652. [Google Scholar] [CrossRef]

- Tada, S.; Shimizu, T.; Kameyama, H.; Haneda, T.; Kikuchi, R. Ni/CeO2 catalysts with high CO2 methanation activity and high CH4 selectivity at low temperatures. Int. J. Hydrogen Energy 2012, 37, 5527–5531. [Google Scholar] [CrossRef]

- Aitbekova, A.; Wu, L.; Wrasman, C.J.; Boubnov, A.; Hoffman, A.S.; Goodman, E.D.; Bare, S.R.; Cargnello, M. Low-Temperature Restructuring of CeO2-Supported Ru Nanoparticles Determines Selectivity in CO2 Catalytic Reduction. J. Am. Chem. Soc. 2018, 140, 13736–13745. [Google Scholar] [CrossRef] [PubMed]

- Abe, T.; Tanizawa, M.; Watanabe, K.; Taguchi, A. CO2 methanation property of Ru nanoparticle-loaded TiO2 prepared by a polygonal barrel-sputtering method. Energy Environ. Sci. 2009, 2, 315–321. [Google Scholar] [CrossRef]

- Hatzisymeon, M.; Petala, A.; Panagiotopoulou, P. Carbon Dioxide Hydrogenation over Supported Ni and Ru Catalysts. Catal. Lett. 2021, 151, 888–900. [Google Scholar] [CrossRef]

- Martinez T, L.M.; Muñoz, A.; Pérez, A.; Laguna, O.H.; Bobadilla, L.F.; Centeno, M.A.; Odriozola, J.A. The effect of support surface hydroxyls on selective CO methanation with Ru based catalysts. Appl. Catal. A Gen. 2022, 641, 118678. [Google Scholar] [CrossRef]

- Loccufier, E.; Watson, G.; Zhao, Y.; Meledina, M.; Denis, R.; Derakhshandeh, P.G.; Van Der Voort, P.; Leus, K.; Debecker, D.P.; De Buysser, K.; et al. CO2 methanation with Ru@MIL-101 nanoparticles fixated on silica nanofibrous veils as stand-alone structured catalytic carrier. Appl. Catal. B Environ. 2023, 320, 121972. [Google Scholar] [CrossRef]

- Bobadilla, L.F.; Muñoz-Murillo, A.; Laguna, O.H.; Centeno, M.A.; Odriozola, J.A. Does shaping catalysts modify active phase sites? A comprehensive in situ FTIR spectroscopic study on the performance of a model Ru/Al2O3 catalyst for the CO methanation. Chem. Eng. J. 2019, 357, 248–257. [Google Scholar] [CrossRef]

- Fechete, I.; Vedrine, J.C. Nanoporous materials as new engineered catalysts for the synthesis of green fuels. Molecules 2015, 20, 5638–5666. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Lu, Y.; Zhang, Y.; Fu, H.; Sun, S.; Li, F.; Duan, Z.; Liu, Z.; Wu, C.; Wang, Y.; et al. Ru-based catalysts for efficient CO2 methanation: Synergistic catalysis between oxygen vacancies and basic sites. Nano Res. 2023, 16, 12153–12164. [Google Scholar] [CrossRef]

- Shang, X.; Deng, D.; Wang, X.; Xuan, W.; Zou, X.; Ding, W.; Lu, X. Enhanced low-temperature activity for CO2 methanation over Ru doped the Ni/CexZr(1−x)O2 catalysts prepared by one-pot hydrolysis method. Int. J. Hydrogen Energy 2018, 43, 7179–7189. [Google Scholar] [CrossRef]

- Tada, S.; Ochieng, O.J.; Kikuchi, R.; Haneda, T.; Kameyama, H. Promotion of CO2 methanation activity and CH4 selectivity at low temperatures over Ru/CeO2/Al2O3 catalysts. Int. J. Hydrogen Energy 2014, 39, 10090–10100. [Google Scholar] [CrossRef]

- Chai, S.; Men, Y.; Wang, J.; Liu, S.; Song, Q.; An, W.; Kolb, G. Boosting CO2 methanation activity on Ru/TiO2 catalysts by exposing (001) facets of anatase TiO2. J. CO2 Util. 2019, 33, 242–252. [Google Scholar] [CrossRef]

- Lippi, R.; Howard, S.C.; Barron, H.; Easton, C.D.; Madsen, I.C.; Waddington, L.J.; Vogt, C.; Hill, M.R.; Sumby, C.J.; Doonan, C.J.; et al. Highly active catalyst for CO2 methanation derived from a metal organic framework template. J. Mater. Chem. A 2017, 5, 12990–12997. [Google Scholar] [CrossRef]

- Sakpal, T.; Lefferts, L. Structure-dependent activity of CeO2 supported Ru catalysts for CO2 methanation. J. Catal. 2018, 367, 171–180. [Google Scholar] [CrossRef]

- Dreyer, J.A.H.; Li, P.; Zhang, L.; Beh, G.K.; Zhang, R.; Sit, P.H.L.; Teoh, W.Y. Influence of the oxide support reducibility on the CO2 methanation over Ru-based catalysts. Appl. Catal. B Environ. 2017, 219, 715–726. [Google Scholar] [CrossRef]

- Jiang, Y.; Lang, J.; Wu, X.; Hu, Y.H. Electronic structure modulating for supported Rh catalysts toward CO2 methanation. Catal. Today 2020, 356, 570–578. [Google Scholar] [CrossRef]

- Ocampo, F.; Louis, B.; Kiwi-Minsker, L.; Roger, A.C. Effect of Ce/Zr composition and noble metal promotion on nickel based CexZr1−xO2 catalysts for carbon dioxide methanation. Appl. Catal. A Gen. 2011, 392, 36–44. [Google Scholar] [CrossRef]

- Bando, K.K.; Soga, K.; Kunimori, K.; Ichikuni, N.; Okabe, K.; Kusama, H.; Sayama, K.; Arakawa, H. CO2 hydrogenation activity and surface structure of zeolite-supported Rh catalysts. Appl. Catal. A Gen. 1998, 173, 47–60. [Google Scholar] [CrossRef]

- Martin, N.M.; Hemmingsson, F.; Schaefer, A.; Ek, M.; Merte, L.R.; Hejral, U.; Gustafson, J.; Skoglundh, M.; Dippel, A.C.; Gutowski, O.; et al. Structure-function relationship for CO2 methanation over ceria supported Rh and Ni catalysts under atmospheric pressure conditions. Catal. Sci. Technol. 2019, 9, 1644–1653. [Google Scholar] [CrossRef]

- Younas, M.; Sethupathi, S.; Kong, L.L.; Mohamed, A.R. CO2 methanation over Ni and Rh based catalysts: Process optimization at moderate temperature. Int. J. Energy Res. 2018, 42, 3289–3302. [Google Scholar] [CrossRef]

- Bakar, W.A.W.A.; Ali, R.; Toemen, S. Catalytic methanation reaction over supported nickel-rhodium oxide for purification of simulated natural gas. J. Nat. Gas Chem. 2011, 20, 585–594. [Google Scholar] [CrossRef]

- Meloni, E.; Cafiero, L.; Renda, S.; Martino, M.; Pierro, M. Ru- and Rh-Based Catalysts for CO2 Methanation Assisted by Non-Thermal Plasma. Catalysts 2023, 13, 488. [Google Scholar] [CrossRef]

- Mihet, M.; Lazar, M.D. Methanation of CO2 on Ni/γ-Al2O3: Influence of Pt, Pd or Rh promotion. Catal. Today 2018, 306, 294–299. [Google Scholar] [CrossRef]

- Jiang, H.; Gao, Q.; Wang, S.; Chen, Y.; Zhang, M. The synergistic effect of Pd NPs and UiO-66 for enhanced activity of carbon dioxide methanation. J. CO2 Util. 2019, 31, 167–172. [Google Scholar] [CrossRef]

- Wang, X.; Shi, H.; Kwak, J.H.; Szanyi, J. Mechanism of CO2 Hydrogenation on Pd/Al2O3 Catalysts: Kinetics and Transient DRIFTS-MS Studies. ACS Catal. 2015, 5, 6337–6349. [Google Scholar] [CrossRef]

- Wang, K.; Li, W.; Huang, J.; Huang, J.; Zhan, G.; Li, Q. Enhanced active site extraction from perovskite LaCoO3 using encapsulated PdO for efficient CO2 methanation. J. Energy Chem. 2020, 53, 9–19. [Google Scholar] [CrossRef]

- Park, J.N.; McFarland, E.W. A highly dispersed Pd-Mg/SiO2 catalyst active for methanation of CO2. J. Catal. 2009, 266, 92–97. [Google Scholar] [CrossRef]

- Luo, L.; Wang, M.; Cui, Y.; Chen, Z.; Wu, J.; Cao, Y.; Luo, J.; Dai, Y.; Li, W.X.; Bao, J.; et al. Surface Iron Species in Palladium–Iron Intermetallic Nanocrystals that Promote and Stabilize CO2 Methanation. Angew. Chem.-Int. Ed. 2020, 59, 14434–14442. [Google Scholar] [CrossRef] [PubMed]

- Frontera, P.; Macario, A.; Ferraro, M.; Antonucci, P.L. Supported catalysts for CO2 methanation: A review. Catalysts 2017, 7, 59. [Google Scholar] [CrossRef]

- Karelovic, A.; Ruiz, P. Improving the hydrogenation function of Pd/γ-Al2O3 catalyst by Rh/γ-Al2O3 Addition in CO2 methanation at low temperature. ACS Catal. 2013, 3, 2799–2812. [Google Scholar] [CrossRef]

- Arandiyan, H.; Kani, K.; Wang, Y.; Jiang, B.; Kim, J.; Yoshino, M.; Rezaei, M.; Rowan, A.E.; Dai, H.; Yamauchi, Y. Highly Selective Reduction of Carbon Dioxide to Methane on Novel Mesoporous Rh Catalysts. ACS Appl. Mater. Interfaces 2018, 10, 24963–24968. [Google Scholar] [CrossRef]

- Debek, R. Novel Catalysts for Chemical CO2 Utilization. Doctoral Dissertation, Université Pierre et Marie Curie, Paris, France, AGH University of Science and Technology, Kraków, Poland, 2016; pp. 1–257. [Google Scholar]

- Dębek, R.; Azzolina-Jury, F.; Travert, A.; Maugé, F. A review on plasma-catalytic methanation of carbon dioxide—Looking for an efficient catalyst. Renew. Sustain. Energy Rev. 2019, 116, 109427. [Google Scholar] [CrossRef]

- Haneda, M.; Shinoda, K.; Nagane, A.; Houshito, O.; Takagi, H.; Nakahara, Y.; Hiroe, K.; Fujitani, T.; Hamada, H. Catalytic performance of rhodium supported on ceria-zirconia mixed oxides for reduction of NO by propene. J. Catal. 2008, 259, 223–231. [Google Scholar] [CrossRef]

- Phatak, A.A.; Koryabkina, N.; Rai, S.; Ratts, J.L.; Ruettinger, W.; Farrauto, R.J.; Blau, G.E.; Delgass, W.N.; Ribeiro, F.H. Kinetics of the water-gas shift reaction on Pt catalysts supported on alumina and ceria. Catal. Today 2007, 123, 224–234. [Google Scholar] [CrossRef]

- Hu, D.; Gao, J.; Ping, Y.; Jia, L.; Gunawan, P.; Zhong, Z.; Xu, G.; Gu, F.; Su, F. Enhanced investigation of CO methanation over Ni/Al2O3 catalysts for synthetic natural gas production. Ind. Eng. Chem. Res. 2012, 51, 4875–4886. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, Y.H.; Moon, D.H.; Ahn, J.Y.; Nguyen, D.D.; Chang, S.W.; Kim, S.S. Reaction Mechanism and Catalytic Impact of Ni/CeO2−x Catalyst for Low-Temperature CO2 Methanation. Ind. Eng. Chem. Res. 2019, 58, 8656–8662. [Google Scholar] [CrossRef]

- Wu, H.C.; Chen, T.C.; Wu, J.H.; Pao, C.W.; Chen, C.S. Influence of sodium-modified Ni/SiO2 catalysts on the tunable selectivity of CO2 hydrogenation: Effect of the CH4 selectivity, reaction pathway and mechanism on the catalytic reaction. J. Colloid Interface Sci. 2021, 586, 514–527. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Liu, Q.; Liang, L.; Ouyang, J. Surface hydroxyls mediated CO2 methanation at ambient pressure over attapulgite-loaded Ni-TiO2composite catalysts with high activity and reuse ability. J. CO2 Util. 2021, 47, 101489. [Google Scholar] [CrossRef]

- Zhou, R.; Rui, N.; Fan, Z.; Liu, C. jun Effect of the structure of Ni/TiO2 catalyst on CO2 methanation. Int. J. Hydrogen Energy 2016, 41, 22017–22025. [Google Scholar] [CrossRef]

- Zeng, L.; Wang, Y.; Li, Z.; Song, Y.; Zhang, J.; Wang, J.; He, X.; Wang, C.; Lin, W. Highly Dispersed Ni Catalyst on Metal-Organic Framework-Derived Porous Hydrous Zirconia for CO2 Methanation. ACS Appl. Mater. Interfaces 2020, 12, 17436–17442. [Google Scholar] [CrossRef] [PubMed]

- Foraita, S.; Fulton, J.L.; Chase, Z.A.; Vjunov, A.; Xu, P.; Baráth, E.; Camaioni, D.M.; Zhao, C.; Lercher, J.A. Impact of the oxygen defects and the hydrogen concentration on the surface of tetragonal and monoclinic ZrO2 on the reduction rates of stearic acid on Ni/ZrO2. Chem.-A Eur. J. 2015, 21, 2423–2434. [Google Scholar] [CrossRef] [PubMed]

- Ratchahat, S.; Sudoh, M.; Suzuki, Y.; Kawasaki, W.; Watanabe, R.; Fukuhara, C. Development of a powerful CO2 methanation process using a structured Ni/CeO2 catalyst. J. CO2 Util. 2018, 24, 210–219. [Google Scholar] [CrossRef]

- Zhou, G.; Liu, H.; Cui, K.; Jia, A.; Hu, G.; Jiao, Z.; Liu, Y.; Zhang, X. Role of surface Ni and Ce species of Ni/CeO2 catalyst in CO2 methanation. Appl. Surf. Sci. 2016, 383, 248–252. [Google Scholar] [CrossRef]

- Sun, H.; Wang, H.; Liu, X.; Zhang, Z.; Zhang, S.; Wang, X.; Liu, Y. Stable and Highly Dispersed Nickel Catalysts on Ce-Zr-O Solid Solutions for CO2 Methanation. ChemistrySelect 2022, 7, 2–10. [Google Scholar] [CrossRef]

- Takano, H.; Kirihata, Y.; Izumiya, K.; Kumagai, N.; Habazaki, H.; Hashimoto, K. Highly active Ni/Y-doped ZrO2 catalysts for CO2 methanation. Appl. Surf. Sci. 2016, 388, 653–663. [Google Scholar] [CrossRef]

- Muroyama, H.; Tsuda, Y.; Asakoshi, T.; Masitah, H.; Okanishi, T.; Matsui, T.; Eguchi, K. Carbon dioxide methanation over Ni catalysts supported on various metal oxides. J. Catal. 2016, 343, 178–184. [Google Scholar] [CrossRef]

- Vita, A.; Italiano, C.; Pino, L.; Frontera, P.; Ferraro, M.; Antonucci, V. Activity and stability of powder and monolith-coated Ni/GDC catalysts for CO2 methanation. Appl. Catal. B Environ. 2018, 226, 384–395. [Google Scholar] [CrossRef]

- Liu, Y.; Zong, X.; Patra, A.; Caratzoulas, S.; Vlachos, D.G. Propane Dehydrogenation on PtxSny (x, y ≤ 4) Clusters on Al2O3(110). ACS Catal. 2023, 13, 2802–2812. [Google Scholar] [CrossRef]

- Cai, M.; Wen, J.; Chu, W.; Cheng, X.; Li, Z. Methanation of carbon dioxide on Ni/ZrO2-Al2O3 catalysts: Effects of ZrO2 promoter and preparation method of novel ZrO2-Al2O3 carrier. J. Nat. Gas Chem. 2011, 20, 318–324. [Google Scholar] [CrossRef]

- Dias, Y.R.; Bernardi, F.; Perez-Lopez, O.W. Improving Low-Temperature CO2 Methanation by Promoting Ni-Al LDH-Derived Catalysts with Alkali Metals. ChemCatChem 2023, 202300834. [Google Scholar] [CrossRef]

- Riani, P.; Garbarino, G.; Lucchini, M.A.; Canepa, F.; Busca, G. Unsupported versus alumina-supported Ni nanoparticles as catalysts for steam/ethanol conversion and CO2 methanation. J. Mol. Catal. A Chem. 2014, 383–384, 10–16. [Google Scholar] [CrossRef]

- Kim, M.J.; Youn, J.R.; Kim, H.J.; Seo, M.W.; Lee, D.; Go, K.S.; Lee, K.B.; Jeon, S.G. Effect of surface properties controlled by Ce addition on CO2 methanation over Ni/Ce/Al2O3 catalyst. Int. J. Hydrogen Energy 2020, 45, 24595–24603. [Google Scholar] [CrossRef]

- Liu, Y.; McGill, C.J.; Green, W.H.; Deshlahra, P. Effects of surface species and homogeneous reactions on rates and selectivity in ethane oxidation on oxide catalysts. AIChE J. 2021, 67, e17483. [Google Scholar] [CrossRef]

- Velty, A.; Corma, A. Advanced zeolite and ordered mesoporous silica-based catalysts for the conversion of CO2 to chemicals and fuels. Chem. Soc. Rev. 2023, 52, 1773–1946. [Google Scholar] [CrossRef] [PubMed]

- Ye, R.P.; Ding, J.; Gong, W.; Argyle, M.D.; Zhong, Q.; Wang, Y.; Russell, C.K.; Xu, Z.; Russell, A.G.; Li, Q.; et al. CO2 hydrogenation to high-value products via heterogeneous catalysis. Nat. Commun. 2019, 10, 5698. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.J.; Ye, J.; Jiang, J.; Pan, Y. Progresses in the preparation of coke resistant Ni-based catalyst for steam and CO2 reforming of methane. ChemCatChem 2011, 3, 529–541. [Google Scholar] [CrossRef]

- Li, S.; Guo, S.; Gong, D.; Kang, N.; Fang, K.G.; Liu, Y. Nano composite composed of MoOx-La2O3–Ni on SiO2 for storing hydrogen into CH4 via CO2 methanation. Int. J. Hydrogen Energy 2019, 44, 1597–1609. [Google Scholar] [CrossRef]

- Ma, H.; Ma, K.; Ji, J.; Tang, S.; Liu, C.; Jiang, W.; Yue, H.; Liang, B. Graphene intercalated Ni-SiO2/GO-Ni-foam catalyst with enhanced reactivity and heat-transfer for CO2 methanation. Chem. Eng. Sci. 2019, 194, 10–21. [Google Scholar] [CrossRef]

- Guo, M.; Lu, G. The difference of roles of alkaline-earth metal oxides on silica-supported nickel catalysts for CO2 methanation. RSC Adv. 2014, 4, 58171–58177. [Google Scholar] [CrossRef]

- Guo, M.; Lu, G. The effect of impregnation strategy on structural characters and CO2 methanation properties over MgO modified Ni/SiO2 catalysts. Catal. Commun. 2014, 54, 55–60. [Google Scholar] [CrossRef]

- Gac, W.; Zawadzki, W.; Słowik, G.; Sienkiewicz, A.; Kierys, A. Nickel catalysts supported on silica microspheres for CO2 methanation. Microporous Mesoporous Mater. 2018, 272, 79–91. [Google Scholar] [CrossRef]

- Sokolov, S.; Kondratenko, E.V.; Pohl, M.M.; Barkschat, A.; Rodemerck, U. Stable low-temperature dry reforming of methane over mesoporous La2O3-ZrO2 supported Ni catalyst. Appl. Catal. B Environ. 2012, 113–114, 19–30. [Google Scholar] [CrossRef]

- Rossetti, I.; Biffi, C.; Bianchi, C.L.; Nichele, V.; Signoretto, M.; Menegazzo, F.; Finocchio, E.; Ramis, G.; Di Michele, A. Ni/SiO2 and Ni/ZrO2 catalysts for the steam reforming of ethanol. Appl. Catal. B Environ. 2012, 117–118, 384–396. [Google Scholar] [CrossRef]

- Moghaddam, S.V.; Rezaei, M.; Meshkani, F.; Daroughegi, R. Synthesis of nanocrystalline mesoporous Ni/Al2O3–SiO2 catalysts for CO2 methanation reaction. Int. J. Hydrogen Energy 2018, 43, 19038–19046. [Google Scholar] [CrossRef]

- Li, Y.; Lu, G.; Ma, J. Highly active and stable nano NiO-MgO catalyst encapsulated by silica with a core-shell structure for CO2 methanation. RSC Adv. 2014, 4, 17420–17428. [Google Scholar] [CrossRef]

- Aziz, M.A.A.; Jalil, A.A.; Triwahyono, S.; Mukti, R.R.; Taufiq-Yap, Y.H.; Sazegar, M.R. Highly active Ni-promoted mesostructured silica nanoparticles for CO2 methanation. Appl. Catal. B Environ. 2014, 147, 359–368. [Google Scholar] [CrossRef]

- Aziz, M.A.A.; Jalil, A.A.; Triwahyono, S.; Saad, M.W.A. CO2 methanation over Ni-promoted mesostructured silica nanoparticles: Influence of Ni loading and water vapor on activity and response surface methodology studies. Chem. Eng. J. 2015, 260, 757–764. [Google Scholar] [CrossRef]

- Aziz, M.A.A.; Jalil, A.A.; Triwahyono, S.; Ahmad, A. CO2 methanation over heterogeneous catalysts: Recent progress and future prospects. Green Chem. 2015, 17, 2647–2663. [Google Scholar] [CrossRef]

- Rahmani, S.; Rezaei, M.; Meshkani, F. Preparation of highly active nickel catalysts supported on mesoporous nanocrystalline γ-Al2O3 for CO2 methanation. J. Ind. Eng. Chem. 2014, 20, 1346–1352. [Google Scholar] [CrossRef]

- Liu, Q.; Bian, B.; Fan, J.; Yang, J. Cobalt doped Ni based ordered mesoporous catalysts for CO2 methanation with enhanced catalytic performance. Int. J. Hydrogen Energy 2018, 43, 4893–4901. [Google Scholar] [CrossRef]

- Gac, W.; Zawadzki, W.; Rotko, M.; Greluk, M.; Słowik, G.; Kolb, G. Effects of support composition on the performance of nickel catalysts in CO2 methanation reaction. Catal. Today 2020, 357, 468–482. [Google Scholar] [CrossRef]

- Li, W.; Wang, H.; Jiang, X.; Zhu, J.; Liu, Z.; Guo, X.; Song, C. A short review of recent advances in CO2 hydrogenation to hydrocarbons over heterogeneous catalysts. RSC Adv. 2018, 8, 7651–7669. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Ma, C.; Wang, Q.; Xu, Y.; Ma, G.; Wang, J.; Wang, H.; Dong, C.; Zhang, C.; Ding, M. Enhanced low-temperature performance of CO2 methanation over mesoporous Ni/Al2O3-ZrO2 catalysts. Appl. Catal. B Environ. 2019, 243, 262–272. [Google Scholar] [CrossRef]

- Zhao, K.; Li, Z.; Bian, L. CO2 methanation and co-methanation of CO and CO2 over Mn-promoted Ni/Al2O3 catalysts. Front. Chem. Sci. Eng. 2016, 10, 273–280. [Google Scholar] [CrossRef]

- Ahmad, W.; Younis, M.N.; Shawabkeh, R.; Ahmed, S. Synthesis of lanthanide series (La, Ce, Pr, Eu & Gd) promoted Ni/Γ-Al2O3 catalysts for methanation of CO2 at low temperature under atmospheric pressure. Catal. Commun. 2017, 100, 121–126. [Google Scholar] [CrossRef]

- Müller, K.; Fleige, M.; Rachow, F.; Schmeißer, D. Sabatier based CO2-methanation of flue gas emitted by conventional power plants. Energy Procedia 2013, 40, 240–248. [Google Scholar] [CrossRef]

- Gong, D.; Li, S.; Guo, S.; Tang, H.; Wang, H.; Liu, Y. Lanthanum and cerium co-modified Ni/SiO2 catalyst for CO methanation from syngas. Appl. Surf. Sci. 2018, 434, 351–364. [Google Scholar] [CrossRef]

- Zhen, W.; Li, B.; Lu, G.; Ma, J. Enhancing catalytic activity and stability for CO2 methanation on Ni@MOF-5 via control of active species dispersion. Chem. Commun. 2015, 51, 1728–1731. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Qiu, B.; Liu, Y.; Zhang, Y. An active and stable nickel-based catalyst with embedment structure for CO2 methanation. Appl. Catal. B Environ. 2020, 269, 118801. [Google Scholar] [CrossRef]

- Aljishi, A.; Veilleux, G.; Lalinde, J.A.H.; Kopyscinski, J. The effect of synthesis parameters on ordered mesoporous nickel alumina catalyst for CO2 methanation. Appl. Catal. A Gen. 2018, 549, 263–272. [Google Scholar] [CrossRef]

- Wang, W.; Chu, W.; Wang, N.; Yang, W.; Jiang, C. Mesoporous nickel catalyst supported on multi-walled carbon nanotubes for carbon dioxide methanation. Int. J. Hydrogen Energy 2016, 41, 967–975. [Google Scholar] [CrossRef]

- Dong, H.; Liu, Q. Three-Dimensional Networked Ni-Phyllosilicate Catalyst for CO2 Methanation: Achieving High Dispersion and Enhanced Stability at High Ni Loadings. ACS Sustain. Chem. Eng. 2020, 8, 6753–6766. [Google Scholar] [CrossRef]

- Summa, P.; Samojeden, B.; Motak, M.; Wierzbicki, D.; Alxneit, I.; Świerczek, K.; Da Costa, P. Investigation of Cu promotion effect on hydrotalcite-based nickel catalyst for CO2 methanation. Catal. Today 2022, 384–386, 133–145. [Google Scholar] [CrossRef]

- Sun, C.; Świrk Da Costa, K.; Wang, Y.; Scheidl, K.S.; Breiby, D.W.; Rønning, M.; Hu, C.; Da Costa, P. Tailoring the yttrium content in Ni-Ce-Y/SBA-15 mesoporous silicas for CO2 methanation. Catal. Today 2021, 382, 104–119. [Google Scholar] [CrossRef]

- Bacariza, M.C.; Graça, I.; Bebiano, S.S.; Lopes, J.M.; Henriques, C. Magnesium as Promoter of CO2 Methanation on Ni-Based USY Zeolites. Energy and Fuels 2017, 31, 9776–9789. [Google Scholar] [CrossRef]

- Jiang, Y.; Huang, T.; Dong, L.; Su, T.; Li, B.; Luo, X.; Xie, X.; Qin, Z.; Xu, C.; Ji, H. Mn modified Ni/bentonite for CO2 methanation. Catalysts 2018, 8, 646. [Google Scholar] [CrossRef]

- Zhang, L.; Bian, L.; Zhu, Z.; Li, Z. La-promoted Ni/Mg-Al catalysts with highly enhanced low-temperature CO2 methanation performance. Int. J. Hydrogen Energy 2018, 43, 2197–2206. [Google Scholar] [CrossRef]

- Garbarino, G.; Wang, C.; Cavattoni, T.; Finocchio, E.; Riani, P.; Flytzani-Stephanopoulos, M.; Busca, G. A study of Ni/La-Al2O3 catalysts: A competitive system for CO2 methanation. Appl. Catal. B Environ. 2019, 248, 286–297. [Google Scholar] [CrossRef]

- Liu, J.; Li, C.; Wang, F.; He, S.; Chen, H.; Zhao, Y.; Wei, M.; Evans, D.G.; Duan, X. Enhanced low-temperature activity of CO2 methanation over highly-dispersed Ni/TiO2 catalyst. Catal. Sci. Technol. 2013, 3, 2627–2633. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, W.; Li, Z. Highly efficient Ni/ZrO2 catalysts prepared via combustion method for CO2 methanation. J. CO2 Util. 2016, 16, 236–244. [Google Scholar] [CrossRef]

- Ye, R.P.; Li, Q.; Gong, W.; Wang, T.; Razink, J.J.; Lin, L.; Qin, Y.Y.; Zhou, Z.; Adidharma, H.; Tang, J.; et al. High-Performance of Nanostructured Ni/CeO2 Catalyst on CO2 Methanation; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 268, ISBN 0000000175. [Google Scholar]

- Ocampo, F.; Louis, B.; Roger, A.C. Methanation of carbon dioxide over nickel-based Ce0.72Zr0.28O2 mixed oxide catalysts prepared by sol-gel method. Appl. Catal. A Gen. 2009, 369, 90–96. [Google Scholar] [CrossRef]

- Ashok, J.; Ang, M.L.; Kawi, S. Enhanced activity of CO2 methanation over Ni/CeO2-ZrO2 catalysts: Influence of preparation methods. Catal. Today 2017, 281, 304–311. [Google Scholar] [CrossRef]

- Vrijburg, W.L.; Van Helden, J.W.A.; Parastaev, A.; Groeneveld, E.; Pidko, E.A.; Hensen, E.J.M. Ceria-zirconia encapsulated Ni nanoparticles for CO2 methanation. Catal. Sci. Technol. 2019, 9, 5001–5010. [Google Scholar] [CrossRef]

- Pastor-Pérez, L.; Le Saché, E.; Jones, C.; Gu, S.; Arellano-Garcia, H.; Reina, T.R. Synthetic natural gas production from CO2 over Ni-x/CeO2-ZrO2 (x = Fe, Co) catalysts: Influence of promoters and space velocity. Catal. Today 2018, 317, 108–113. [Google Scholar] [CrossRef]

- Atzori, L.; Rombi, E.; Meloni, D.; Sini, M.F.; Monaci, R.; Cutrufello, M.G. CO and CO2 Co-Methanation on Ni/CeO2-ZrO2 Soft-Templated Catalysts. Catalysts 2019, 9, 415. [Google Scholar] [CrossRef]

- Li, S.; Liu, G.; Zhang, S.; An, K.; Ma, Z.; Wang, L.; Liu, Y. Cerium-modified Ni-La2O3/ZrO2 for CO2 methanation. J. Energy Chem. 2020, 43, 155–164. [Google Scholar] [CrossRef]

- Liu, H.; Zou, X.; Wang, X.; Lu, X.; Ding, W. Effect of CeO2 addition on Ni/Al2O3 catalysts for methanation of carbon dioxide with hydrogen. J. Nat. Gas Chem. 2012, 21, 703–707. [Google Scholar] [CrossRef]

- Schubert, M.; Pokhrel, S.; Thomé, A.; Zielasek, V.; Gesing, T.M.; Roessner, F.; Mädler, L.; Bäumer, M. Highly active Co-Al2O3-based catalysts for CO2 methanation with very low platinum promotion prepared by double flame spray pyrolysis. Catal. Sci. Technol. 2016, 6, 7449–7460. [Google Scholar] [CrossRef]

- Alrafei, B.; Polaert, I.; Ledoux, A.; Azzolina-Jury, F. Remarkably stable and efficient Ni and Ni-Co catalysts for CO2 methanation. Catal. Today 2020, 346, 23–33. [Google Scholar] [CrossRef]

- Chen, H.; Fu, J.; Zhang, P.; Peng, H.; Abney, C.W.; Jie, K.; Liu, X.; Chi, M.; Dai, S. Entropy-stabilized metal oxide solid solutions as CO oxidation catalysts with high-temperature stability. J. Mater. Chem. A 2018, 6, 11129–11133. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Sun, H.; Zhang, Z.; Song, P.; Liu, Y. Highly Stable Bimetal Ni-Co on Alumina-Covered Spinel Oxide Derived from High Entropy Oxide for CO2 Methanation. Ind. Eng. Chem. Res. 2023, 62, 341–354. [Google Scholar] [CrossRef]

- Jimenez, J.D.; Wen, C.; Lauterbach, J. Design of highly active cobalt catalysts for CO2 hydrogenation: Via the tailoring of surface orientation of nanostructures. Catal. Sci. Technol. 2019, 9, 1970–1978. [Google Scholar] [CrossRef]

- Jimenez, J.; Bird, A.; Santos Santiago, M.; Wen, C.; Lauterbach, J. Supported Cobalt Nanorod Catalysts for Carbon Dioxide Hydrogenation. Energy Technol. 2017, 5, 884–891. [Google Scholar] [CrossRef]

- Liang, L.; Miao, C.; Chen, S.; Zheng, X.; Ouyang, J. Effective CO2 methanation at ambient pressure over Lanthanides (La/Ce/Pr/Sm) modified cobalt-palygorskite composites. J. CO2 Util. 2022, 63, 102114. [Google Scholar] [CrossRef]

- Li, W.; Nie, X.; Jiang, X.; Zhang, A.; Ding, F.; Liu, M.; Liu, Z.; Guo, X.; Song, C. ZrO2 support imparts superior activity and stability of Co catalysts for CO2 methanation. Appl. Catal. B Environ. 2018, 220, 397–408. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Mu, M.; Ding, F.; Liu, Z.; Guo, X.; Song, C. Organic acid-assisted preparation of highly dispersed Co/ZrO2 catalysts with superior activity for CO2 methanation. Appl. Catal. B Environ. 2019, 254, 531–540. [Google Scholar] [CrossRef]

- Tu, J.; Wu, H.; Qian, Q.; Han, S.; Chu, M.; Jia, S.; Feng, R.; Zhai, J.; He, M.; Han, B. Low temperature methanation of CO2 over an amorphous cobalt-based catalyst. Chem. Sci. 2021, 12, 3937–3943. [Google Scholar] [CrossRef]

- Valinejad Moghaddam, S.; Rezaei, M.; Meshkani, F.; Daroughegi, R. Carbon dioxide methanation over Ni-M/Al2O3 (M: Fe, CO, Zr, La and Cu) catalysts synthesized using the one-pot sol-gel synthesis method. Int. J. Hydrogen Energy 2018, 43, 16522–16533. [Google Scholar] [CrossRef]

- Yin, L.; Chen, X.; Sun, M.; Zhao, B.; Chen, J.; Zhang, Q.; Ning, P. Insight into the role of Fe on catalytic performance over the hydrotalcite-derived Ni-based catalysts for CO2 methanation reaction. Int. J. Hydrogen Energy 2022, 47, 7139–7149. [Google Scholar] [CrossRef]

- Lan, P.W.; Wang, C.C.; Chen, C.Y. Effect of Ni/Fe ratio in Ni–Fe catalysts prepared under external magnetic field on CO2 methanation. J. Taiwan Inst. Chem. Eng. 2021, 127, 166–174. [Google Scholar] [CrossRef]

- Everett, O.E.; Zonetti, P.C.; Alves, O.C.; de Avillez, R.R.; Appel, L.G. The role of oxygen vacancies in the CO2 methanation employing Ni/ZrO2 doped with Ca. Int. J. Hydrogen Energy 2020, 45, 6352–6359. [Google Scholar] [CrossRef]

- Yamasaki, M.; Habazaki, H.; Yoshida, T.; Akiyama, E.; Kawashima, A.; Asami, K.; Hashimoto, K.; Komori, M.; Shimamura, K. Compositional dependence of the CO2 methanation activity of Ni/ZrO2 catalysts prepared from amorphous Ni-Zr alloy precursors. Appl. Catal. A Gen. 1997, 163, 187–197. [Google Scholar] [CrossRef]

- Tan, J.; Wang, J.; Zhang, Z.; Ma, Z.; Wang, L.; Liu, Y. Highly dispersed and stable Ni nanoparticles confined by MgO on ZrO2 for CO2 methanation. Appl. Surf. Sci. 2019, 481, 1538–1548. [Google Scholar] [CrossRef]

- Ren, J.; Qin, X.; Yang, J.Z.; Qin, Z.F.; Guo, H.L.; Lin, J.Y.; Li, Z. Methanation of carbon dioxide over Ni-M/ZrO2 (M = Fe, Co, Cu) catalysts: Effect of addition of a second metal. Fuel Process. Technol. 2015, 137, 204–211. [Google Scholar] [CrossRef]

- Tian, J.; Zheng, P.; Zhang, T.; Han, Z.; Xu, W.; Gu, F.; Wang, F.; Zhang, Z.; Zhong, Z.; Su, F.; et al. CO2 methanation over Ni nanoparticles inversely loaded with CeO2 and Cr2O3: Catalytic functions of metal oxide/Ni interfaces. Appl. Catal. B Environ. 2023, 339, 123121. [Google Scholar] [CrossRef]

- Qin, Z.; Ren, J.; Miao, M.; Li, Z.; Lin, J.; Xie, K. The catalytic methanation of coke oven gas over Ni-Ce/Al2O3 catalysts prepared by microwave heating: Effect of amorphous NiO formation. Appl. Catal. B Environ. 2015, 164, 18–30. [Google Scholar] [CrossRef]

- Konishcheva, M.V.; Potemkin, D.I.; Badmaev, S.D.; Snytnikov, P.V.; Paukshtis, E.A.; Sobyanin, V.A.; Parmon, V.N. On the Mechanism of CO and CO2 Methanation Over Ni/CeO2 Catalysts. Top. Catal. 2016, 59, 1424–1430. [Google Scholar] [CrossRef]

- Nematollahi, B.; Rezaei, M.; Lay, E.N. Selective methanation of carbon monoxide in hydrogen rich stream over Ni/CeO2 nanocatalysts. J. Rare Earths 2015, 33, 619–628. [Google Scholar] [CrossRef]

- Laosiripojana, N.; Assabumrungrat, S. Methane steam reforming over Ni/Ce-ZrO2 catalyst: Influences of Ce-ZrO2 support on reactivity, resistance toward carbon formation, and intrinsic reaction kinetics. Appl. Catal. A Gen. 2005, 290, 200–211. [Google Scholar] [CrossRef]

- Di Monte, R.; Fornasiero, P.; Kašpar, J.; Rumori, P.; Gubitosa, G.; Graziani, M. Pd/Ce0.6Zr0.4O2/Al2O3 as advanced materials for three-way catalysts. Part 1. Catalyst characterisation, thermal stability and catalytic activity in the reduction of NO by CO. Appl. Catal. B Environ. 2000, 24, 157–167. [Google Scholar] [CrossRef]

- Strobel, R.; Krumeich, F.; Pratsinis, S.E.; Baiker, A. Flame-derived Pt/Ba/CexZr1−xO2: Influence of support on thermal deterioration and behavior as NOx storage-reduction catalysts. J. Catal. 2006, 243, 229–238. [Google Scholar] [CrossRef]

- Le, T.A.; Kim, M.S.; Lee, S.H.; Park, E.D. CO and CO2 Methanation Over Supported Cobalt Catalysts. Top. Catal. 2017, 60, 714–720. [Google Scholar] [CrossRef]

- Youn, M.H.; Seo, J.G.; Cho, K.M.; Park, S.; Park, D.R.; Jung, J.C.; Song, I.K. Hydrogen production by auto-thermal reforming of ethanol over nickel catalysts supported on Ce-modified mesoporous zirconia: Effect of Ce/Zr molar ratio. Int. J. Hydrogen Energy 2008, 33, 5052–5059. [Google Scholar] [CrossRef]

- Silva, P.P.; Silva, F.A.; Portela, L.S.; Mattos, L.V.; Noronha, F.B.; Hori, C.E. Effect of Ce/Zr ratio on the performance of Pt/CeZrO2/Al2O3 catalysts for methane partial oxidation. Catal. Today 2005, 107–108, 734–740. [Google Scholar] [CrossRef]

- Koubaissy, B.; Pietraszek, A.; Roger, A.C.; Kiennemann, A. CO2 reforming of methane over Ce-Zr-Ni-Me mixed catalysts. Catal. Today 2010, 157, 436–439. [Google Scholar] [CrossRef]

- ten Have, I.C.; Kromwijk, J.J.G.; Monai, M.; Ferri, D.; Sterk, E.B.; Meirer, F.; Weckhuysen, B.M. Uncovering the reaction mechanism behind CoO as active phase for CO2 hydrogenation. Nat. Commun. 2022, 13. [Google Scholar] [CrossRef]

- Visconti, C.G.; Martinelli, M.; Falbo, L.; Fratalocchi, L.; Lietti, L. CO2 hydrogenation to hydrocarbons over Co and Fe-based Fischer-Tropsch catalysts. Catal. Today 2016, 277, 161–170. [Google Scholar] [CrossRef]

- Jimenez, J.D.; Wen, C.; Royko, M.M.; Kropf, A.J.; Segre, C.; Lauterbach, J. Influence of Coordination Environment of Anchored Single-Site Cobalt Catalyst on CO2 Hydrogenation. ChemCatChem 2020, 12, 846–854. [Google Scholar] [CrossRef]

- Zhang, Y.; Jacobs, G.; Sparks, D.E.; Dry, M.E.; Davis, B.H. CO and CO2 hydrogenation study on supported cobalt Fischer-Tropsch synthesis catalysts. Catal. Today 2002, 71, 411–418. [Google Scholar] [CrossRef]

- Ishchenko, O.V.; Dyachenko, A.G.; Yatsymyrskiy, A.V.; Zakharova, T.M.; Gaidai, S.V.; Lisnyak, V.V.; Mariychuk, R. CO2 methanation over Co-Ni catalysts. E3S Web Conf. 2020, 154, 02001. [Google Scholar] [CrossRef]

- Huynh, H.L.; Zhu, J.; Zhang, G.; Shen, Y.; Tucho, W.M.; Ding, Y.; Yu, Z. Promoting effect of Fe on supported Ni catalysts in CO2 methanation by in situ DRIFTS and DFT study. J. Catal. 2020, 392, 266–277. [Google Scholar] [CrossRef]

| Substance | Enthalpy (ΔH) | Entropy (ΔS) | Gibbs Free Energy (ΔG) |

|---|---|---|---|

| J/mol | J/mol.K | J/mol | |

| CO2 | −393,509 | 214 | −394,359 |

| H2 | 0 | 130.7 | 0 |

| CH4 | −74,520 | 186.4 | −50,460 |

| H2O | −241,818 | 188.3 | −228,572 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Memon, M.A.; Jiang, Y.; Hassan, M.A.; Ajmal, M.; Wang, H.; Liu, Y. Heterogeneous Catalysts for Carbon Dioxide Methanation: A View on Catalytic Performance. Catalysts 2023, 13, 1514. https://doi.org/10.3390/catal13121514

Memon MA, Jiang Y, Hassan MA, Ajmal M, Wang H, Liu Y. Heterogeneous Catalysts for Carbon Dioxide Methanation: A View on Catalytic Performance. Catalysts. 2023; 13(12):1514. https://doi.org/10.3390/catal13121514

Chicago/Turabian StyleMemon, Mazhar Ahmed, Yanan Jiang, Muhammad Azher Hassan, Muhammad Ajmal, Hong Wang, and Yuan Liu. 2023. "Heterogeneous Catalysts for Carbon Dioxide Methanation: A View on Catalytic Performance" Catalysts 13, no. 12: 1514. https://doi.org/10.3390/catal13121514

APA StyleMemon, M. A., Jiang, Y., Hassan, M. A., Ajmal, M., Wang, H., & Liu, Y. (2023). Heterogeneous Catalysts for Carbon Dioxide Methanation: A View on Catalytic Performance. Catalysts, 13(12), 1514. https://doi.org/10.3390/catal13121514