1. Introduction

Epoxy resins (EPs) are important thermoset materials that are extensively used in chemical, electrical, transport, and defense industries [

1,

2,

3,

4]. These materials can be used in various applications, such as coatings, adhesives, electrical and electronic parts, fiber reinforced, optical fiber, and flame retardant material, because of their excellent chemical resistance, adhesive strength, mechanical strength, electrical insulation, thermal stability, dimensional stability, and cost-effectiveness [

5,

6,

7,

8,

9,

10,

11]. However, EPs are highly flammable materials with a limiting oxygen index (LOI) for combustion of ≤19.8 [

12,

13]. Moreover, application is limited by the production of large amounts of smoke and toxic gases during combustion [

14,

15]. Therefore, for most applications, EPs need to be modified by adding flame retardants [

16]. Flame retardants include inorganic materials like metal hydrates [

17], halogen-based materials containing bromine or chlorine [

18], phosphorus-based materials centered on phosphoric acid esters [

19], and nitrogen-based materials, like melamine cyanurate [

20]. Recent developments include biomaterial wood composites that exhibit flame retardancy and biomimetic properties [

21].

Two primary methods exist for enhancing the flame retardancy of EPs. The first involves the incorporation of brominated bisphenol A. The second entails blending flame retardant additives into the residual matrix, which is the most common process. However, halogenated flame retardants can produce toxic volatile dioxins from the polymer matrix during thermal decomposition in the event of an actual fire. Additionally, additive flame retardants are susceptible to migration [

22,

23].

Among various additive flame retardants, phosphorus-based compounds are the most effective alternatives to halogenated flame retardants. Because their presence provides excellent flame retardancy, and they do not promote the generation of toxic gases during combustion [

24,

25]. Furthermore, in contrast to other additive flame retardants prone to migration from the polymer matrix, phosphorus compounds typically exhibit good compatibility with polymers, preventing delamination [

26].

Notably, the acidic thermal decomposition products in phosphorus compounds exert a strong dehydration effect, promoting cationic crosslinking and the formation of a char layer at the polymer surface [

27,

28].

This char layer acts as a physical barrier, insulating the polymer materials from further heat and flame exposure, slowing down its thermal decomposition, and suppressing the release of flammable gases that could feed the fire [

29]. Currently, Diethyl (hydroxymethyl) phosphonate (DEHMP), a phosphorus compound with excellent compatibility with various polymers, is attracting interest as a potential flame retardant for polymer-based materials, such as epoxy resins [

30]. However, adding flame retardants may reduce the thermal or mechanical properties of resins. Therefore, in addition to providing sufficient flame retardancy, minimizing resin property degradation is essential for tuning a flame-retardant additive [

31].

Functionalized polysilsesquioxanes are widely regarded as a new generation of high-performance materials and hybrid organic–inorganic structures [

32]. Methods for the synthesis of silsesquioxanes include sol-gel [

33], hydrosilylation [

34], ring-opening polymerization [

35], and step-growth polymerization [

36]. The sol-gel method is the most popular synthesis method because it provides a uniform environment for hydrolysis and condensation reactions and relatively mild reaction conditions, making it compatible with various organosilane precursors and functional groups, and allowing the synthesis of organic-inorganic hybrids [

37].

Siloxanes are widely used as silicon-based flame retardants because they provide polymer blends with excellent mechanical properties, high thermal stability, and superior flame retardancy, even in small amounts [

38]. Recently, much attention has been paid to flame retardants containing silicon, phosphorus, and sulfur [

39]. Because of the cooperative effects of phosphorus–silicon and sulfur, compounds containing all these elements have been found to have excellent flame-retardant performance [

40]. They work together to form a thermally stable carbon-residue surface, blocking heat and mass transfer during polymer decomposition.

Additive manufacturing, mainly 3D printing, represents a significant application area for epoxy resins. Recent studies have explored DGEBA epoxy blends containing various functional additives, including mixtures with photo-curable acrylic resin for 3D printing carbon fiber composites [

41,

42,

43].

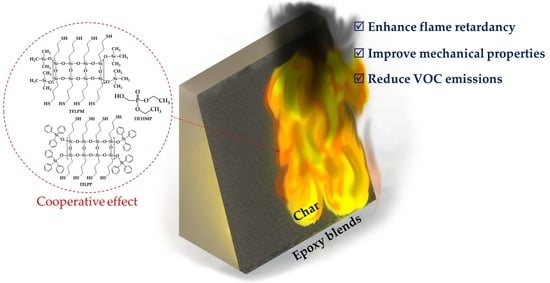

However, the issue of VOC emissions during 3D printing remains a concern. Minimizing VOC emissions from the epoxy resins used in the thermal curing process of 3D printing is a viable solution [

44,

45]. The thermal, mechanical, and flame retardant properties of epoxy systems containing phosphorus, silicon, and sulfur have been investigated [

46,

47]. However, the impact of these additives on VOC emissions during combustion has not been examined. This study aims to manufacture an epoxy blend that increases mechanical properties and flame resistance while minimizing VOC emissions. It also proposes a high-functionality epoxy blend that alleviates the issue of VOC emissions during the thermosetting of epoxy used in additive-manufacturing 3D printing.

Polysilsesquioxanes with a ladder structure, end-capped with CH3 and phenyl groups, respectively, have been synthesized for potential flame-retardant applications. They were characterized using gel permeation chromatography (GPC), Fourier transform infrared spectroscopy (FTIR), nuclear magnetic resonance (NMR), and TGA. Additionally, epoxy blends with different formulations were prepared for comparison with the properties of blends containing phosphorus-only flame retardants. The structure, flame retardancy, thermal, mechanical, and VOC emission properties of the cured epoxy blends were assessed using differential scanning calorimetry (DSC), a universal testing machine (UTM), dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA), cone calorimetry, scanning electron microscopy (SEM), LOI determination, and a VOC analyzer.

2. Experimental

2.1. Materials

For thermal curing, the diglycidyl ether of bisphenol A (DGBEA, YD-128) with an epoxy equivalent weight of 172–176 g/eq was purchased from Kukdo Chemical (Seoul, Republic of Korea). It was vacuum-dried at 80 °C for 3 h and then stored in a dryer for use. m-Xylylenediamine (m-XDA, 99%), supplied by Sigma-Aldrich (Saint Louis, MO, USA), is an aromatic amine in the liquid state, chosen for its excellent compatibility with DGEBA at room temperature. It facilitates the formation of an efficient curing system with epoxy resin. Diethyl (hydroxymethyl) phosphonate (DEHMP, 97%), supplied by TCI (Tokyo, Japan), is a liquid at room temperature, making it easily mixable with various additives, including epoxy resins. It was chosen for its ability to enhance flame retardancy without adversely affecting the material’s processing characteristics. TCI Chemicals supplied materials such as (3-Mercaptopropyl)trimethoxysilane(95%), Methoxytrimethylsilane (MTMS, 98%), and Methoxytriphenylsilane (MTPS, 98%) that are suitable for forming polysilsesquioxanes through the sol-gel process. All materials were used as received, without any additional purification.

2.2. Synthesis of Thiol-Functionalized Ladder-like Polysilsesquioxane End-Capped with Methyl Groups (TFLPM)

First, 30 g of solvent (tetrahydrofuran [THF]) and 5 g of (3-mercaptopropyl) trimethoxysilane monomer (25.46 mmol) were added to a 250-mL two-necked flask and stirred using a magnetic stirrer. Second, a 0.05N sodium hydroxide aqueous solution (1.5 g) was added to the mixture. Then, the solution was heated at 50 °C for 16 h under a nitrogen atmosphere. After the reaction, MTMS (0.58 g, 5.57 mmol) and 0.91 g of hydrochloric acid (36.5% aqueous solution, 25 mmol) were added and stirred at 50 °C for 8 h. After removing the solvent from the reaction mixture, it was washed several times with dichloromethane and distilled water. Then, dichloromethane and impurities were removed using a rotary evaporator and dried in a vacuum oven at 100 °C overnight.

TFLPM: 1H NMR (300 MHz, CDCl3, ppm): δ = 0.07–0.20 (m, Si–CH3), 0.71–0.84 (s, Si–CH2), 1.25–1.48 (m, Si–CH2–CH2–CH2–SH), 1.63–1.79 (d, Si–CH2–CH2), 2.49–2.66 (d, Si–CH2–CH2–CH2), 13C NMR (100.62 MHz, CDCl3, ppm): δ = 1.34 (Si–CH3), 11.18 (Si–CH2), 27.77 (Si–CH2–CH2–CH2–SH). Yield: 78%.

2.3. Synthesis of Thiol-Functionalized Ladder-like Polysilsesquioxane End-Capped with Phenyl Groups (TFLPP)

First, 30 g of solvent (THF) and 5 g of (3-mercaptopropyl) trimethoxysilane monomer (25.46 mmol) were added to a 250 mL two-necked flask and stirred using a magnetic stirrer. Second, a 0.05 N sodium hydroxide aqueous solution (1.5 g) was added to the mixture. Then, the solution was heated at 50 °C for 16 h under a nitrogen atmosphere. After the reaction, MTPS (0.52 g, 1.79 mmol) and 1.56 g of hydrochloric acid (36.5% aqueous solution, 43 mmol) were added and stirred at 50 °C for 8 h. After removing the solvent from the reaction mixture, it was washed several times with dichloromethane and distilled water. Then, dichloromethane and impurities were removed using a rotary evaporator and dried in a vacuum oven at 100 °C overnight. The synthesis of TLPM and TFLPP is shown in

Scheme 1.

TFLPP: 1H NMR (300 MHz, CDCl3, ppm): δ = 0.71–0.88 (s, Si–CH2), 1.25–1.51 (m, Si–CH2–CH2–CH2–SH), 1.61–1.82 (d, Si–CH2–CH2), 2.45–2.68 (d, Si–CH2–CH2–CH2), 7.28–7.67 (m, Si–PH). 13C NMR (100.62 MHz, CDCl3, ppm): δ = 11.75 (Si–CH2), 27.31 (Si–CH2–CH2–CH2–SH), 127.82 (Ortho-C), 130.28 (Para-C), 134.06 (Meta-C). Yield: 72%.

2.4. Preparation of Epoxy Blends (EP, EP-DP5, EP-TM5-DP5, and EP-TP5-DP5)

Flame retardants (TFLPM, TFLPP, and DEHMP in a total weight ratio of 10 wt%) were added into DGBEA, with the weight of the curing agent m-XDA fixed at 10 wt%. The mixture was stirred magnetically at 400 rpm for 30 min, followed by curing at 130 °C for 1 h and at 150 °C for an additional 1 h. The formulations for the flame-retardant EP specimens are detailed in

Table 1.

2.5. Characterization of TFLPM, TFLPP, and Epoxy Blends

TFLPM and TFLPP were structurally analyzed using a Spectrum-400 FTIR spectrometer (Perkin Elmer, Waltham, MA, USA) that conducted 100 scans in the wavenumber range of 650–4000 cm−1. The ATR crystals at room temperature received the samples (10 μm) through dropping. All spectra were adjusted through CO2 reduction, noise removal, and baseline fitting. 1H, 13C, and 29Si NMR spectra were performed with CDCl3 as the solvent and using 300-MHz NMR equipment (Bruker, Billerica, MA, USA, Avance 300) at room temperature.

The molecular weights of TFLPM and TFLPP were determined through size exclusion chromatography using an EcoSEC HLC-8320 GPC from TOSOH Corporation (Tokyo, Japan). A 0.15% solution (wt/vol) of TFLPM or TFLPP in THF was injected into the GPC system. Separation utilized a combination of Guard Super MP (HZ)-M+2 and TSK Gel Super-multipore HZ-M columns (150 mm × 4.6 mm, 3 μm). The mobile phase comprised high-performance liquid chromatography-grade THF, flowing at a rate of 0.45 mL/min. The column temperature was set at 40 °C. The GPC system was calibrated with a range of thin polystyrene molecular weight standards: 580, 2980, 9960, 30,230, 69,650, 128,600, 325,600, and 660,500 Da.

The thermal stability of the samples was determined using a TGA-4000 thermal analyzer (Perkin Elmer, Waltham, MA, USA). Here, 5–10 mg samples were heated in a nitrogen environment at a rate of 10 °C/min from 50 °C to 800 °C.

A DSC (Perkin-Elmer DSC-8500, Waltham, MA, USA) was used to investigate the thermal behavior of EP, EP-DP5, EP-TM5-DP5, and EP-TP5-DP5. A 5 to 10 g sample was placed in an aluminum pan for the DSC, and the experiment was conducted under a nitrogen atmosphere of 5 °C/min in the 30–200 °C range. The thermal stability and decomposition temperatures of the fully cured epoxy compound were measured by TGA using a Perkin Elmer Pyris 1 thermal analyzer. Samples weighing 5–10 mg were placed on a ceramic pan and heated in a nitrogen atmosphere to prevent oxidation. The heating process was performed at a constant rate of 10 °C/min from 50 °C to 800 °C. The thermogravimetric analysis (TGA) was carried out on TGA Q5000 IR thermal gravimetric analyzer (TA Instruments, New Castle, DE, USA). About 4–10 mg of epoxy resins was heated from room temperature to 800 °C under air or nitrogen purges. Cone calorimetry tests were conducted using the cone calorimeter (Fire Testing Technology, East Grinstead, UK) following ISO 5660 standard [

48] procedures. Each specimen, with dimensions of 130 × 130 × 3 mm

3, was prepared, mounted on aluminum foil, and irradiated horizontally at a heat flux of 35 kW m⁻

2.

Thermomechanical properties were measured using DMA under the nitrogen atmosphere in tensile mode. The constant frequency was 1 Hz, and the heating temperature was from −50 °C to 200 °C. The dimension of the specimens was 25 mm × 25 mm. The total VOC (TVOC) emission from the samples was quantified using a thermal extractor (TE, Gerstel, Linthicum, MD, USA) with flow regulation (10–300 mL/min). The VOCs were released from the samples by carrier gas at a 134 mL/min flow rate and collected in an adsorption tube. A separate glass extraction tube was used for each 25 mg sample. The TE consisted of a controllable (room temperature) furnace that heated the glass tube (178 mm, diameter 13.6 mm) containing the sample. VOC analysis was performed according to ES 02603.1: “Methods for measurement of VOC emissions from interior and construction materials—Solid absorber tubes and GC-MS/FID method”. VOCs were extracted using a Tenax TA adsorption tube (Supelco, Bellefonte, PA, USA) and a micro-pump (MP-30, SIBATA, Saitama, Japan) under a steady flow of pure nitrogen gas. A total of 1 L of gas was sampled during the thermal extraction procedure at 25 °C ± 5 °C for 30 min. Individual calibration lines for the following compounds were used for the qualitative analysis: TVOC, benzene, toluene, ethylbenzene,

o-,

m-,

p-xylene, and styrene. The TVOC concentration (µg/m

3) was calculated using the toluene calibration curve for the total area of the chromatogram between

n-hexane and

n-hexadecane. The epoxy cure blends of LOI were determined using an LOI tester (FTT, Derby, UK) by making specimen dimensions 130 × 6.5 × 3.0 mm

3 according to the ASTM 2863 standard [

49]. After placing the specimen vertically in the LOI tester, a constant flow of high-purity nitrogen and oxygen was introduced from the bottom, and the combustion behavior was checked by igniting the leading edge of the specimen. SEM analysis was performed using Nova Nano FE-SEM 450 (FEI Company, Hillsboro, OR, USA).

The LOI value was calculated using the following Equation (1).

where [O

2] is the oxygen flow rate (L/min

−1) and [N

2] is the nitrogen flow rate (L/min

−1). The flammability of epoxy-cured blends materials was measured following the ASTM 3801 standard [

50] with a specimen size of 130 × 130 × 3 mm

3, pretreatment at 23 °C ± 2 °C, and 50% ± 5% relative humidity for 48 h. A universal material testing machine model 5567 (universal testing machine, UTM, Instron, Norwood, MA, USA) was used to measure the tensile strength of the epoxy blends following ASTM D638 [

51]. Tensile tests were performed at a 10 mm/min test speed, 10 tests were performed for each specimen, and the mean value was used. A lap shear test was performed to measure the mechanical properties of the specimen. The test specimen consisted of an aluminum plate with an area of 25.4 × 10 mm

2 coated with a 0.2 mm thick epoxy adhesive layer. Tests were performed according to ASTM D1002 [

52], using a model 5567 universal testing machine (Instron, Norwood, MA, USA) at a speed of 1.3 mm (0.05 in)/min. Before testing, specimens were cured for 3 h at 130 °C in an oven. Lap shear strength was calculated as an average of five samples for each configuration, with error bars representing one standard deviation.

4. Conclusions

This study successfully developed novel ladder-structured polysilsesquioxane flame retardants, end-capped with methyl (CH3) and phenyl groups, respectively, via the sol-gel method. Epoxy blends incorporating TFLPM and TFLPP demonstrated superior flame retardancy compared to phosphorus-only flame retardants, which is attributed to the cooperative effects of silicon, phosphorus, and sulfur. The enhancement is ascribed to the cooperative effect of silicon–phosphorus–sulfur. Epoxy blends incorporating silicon–sulfur–phosphorus achieved a UL 94 V-0 rating. The non-flammable gas produced by sulfur decomposition played a crucial role in gas-phase flame retardation by diluting the combustible gas and reducing oxygen concentrations. Among the epoxy blends, those containing TFLPP exhibited the highest LOI value (33.7%) and residual char content according to the LOI Test and TGA analysis. SEM results further indicated that blends containing TFLPP generated a dense, uniform char layer. Epoxy blends enriched with phenyl groups, particularly those containing TFLPP, showed increased stiffness and glass transition temperature (Tg), resulting in a higher storage modulus and a 25% improvement in lap shear strength compared to pure epoxy (EP). Importantly, these blends also demonstrated the lowest volatile organic compound (VOC) emissions.

The developed epoxy blend also provides significant advantages for using 3D printing in additive manufacturing. It improves mechanical strength and flame retardancy while reducing the emission of volatile organic compounds (VOCs). This reduction mitigates potential environmental and health issues that could arise during the thermal curing process of 3D printing.