Effect of MAH-g-PLA on the Properties of Wood Fiber/Polylactic Acid Composites

Abstract

:1. Introduction

2. ExperimentalMaterials and Methods

2.1. Materials

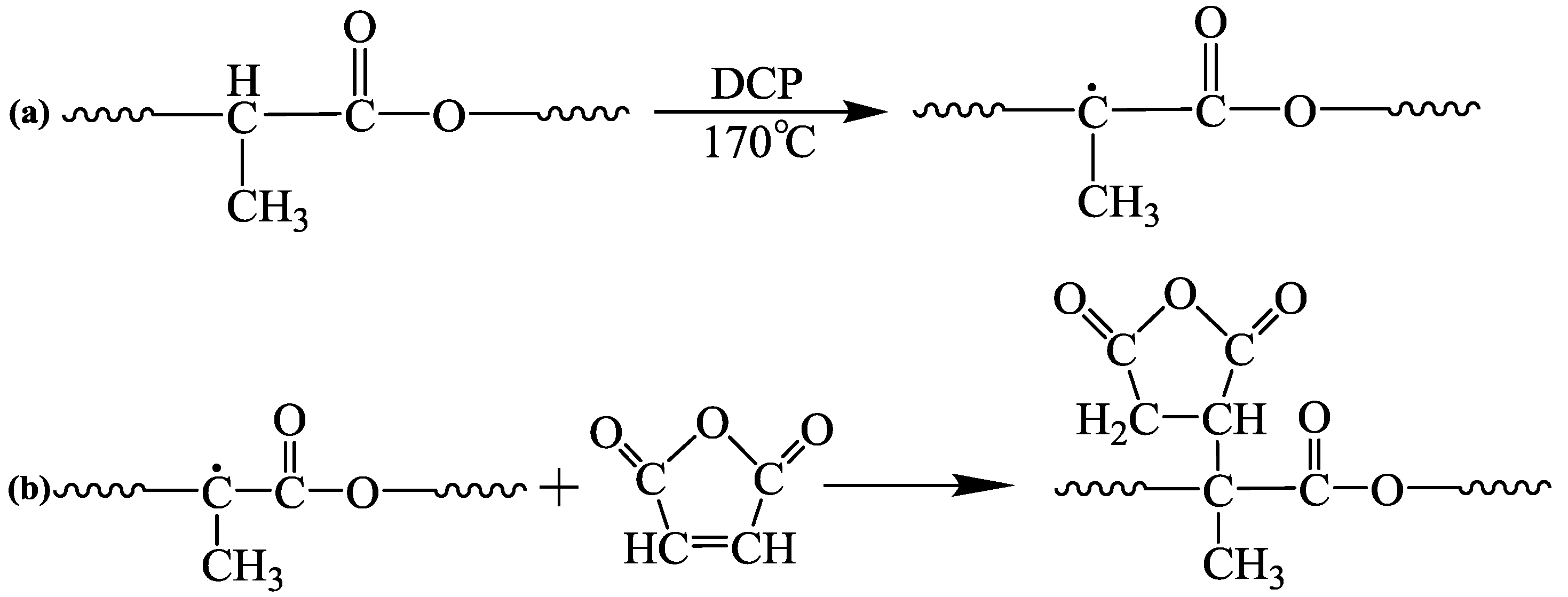

2.2. MAH-g-PLA Preparation

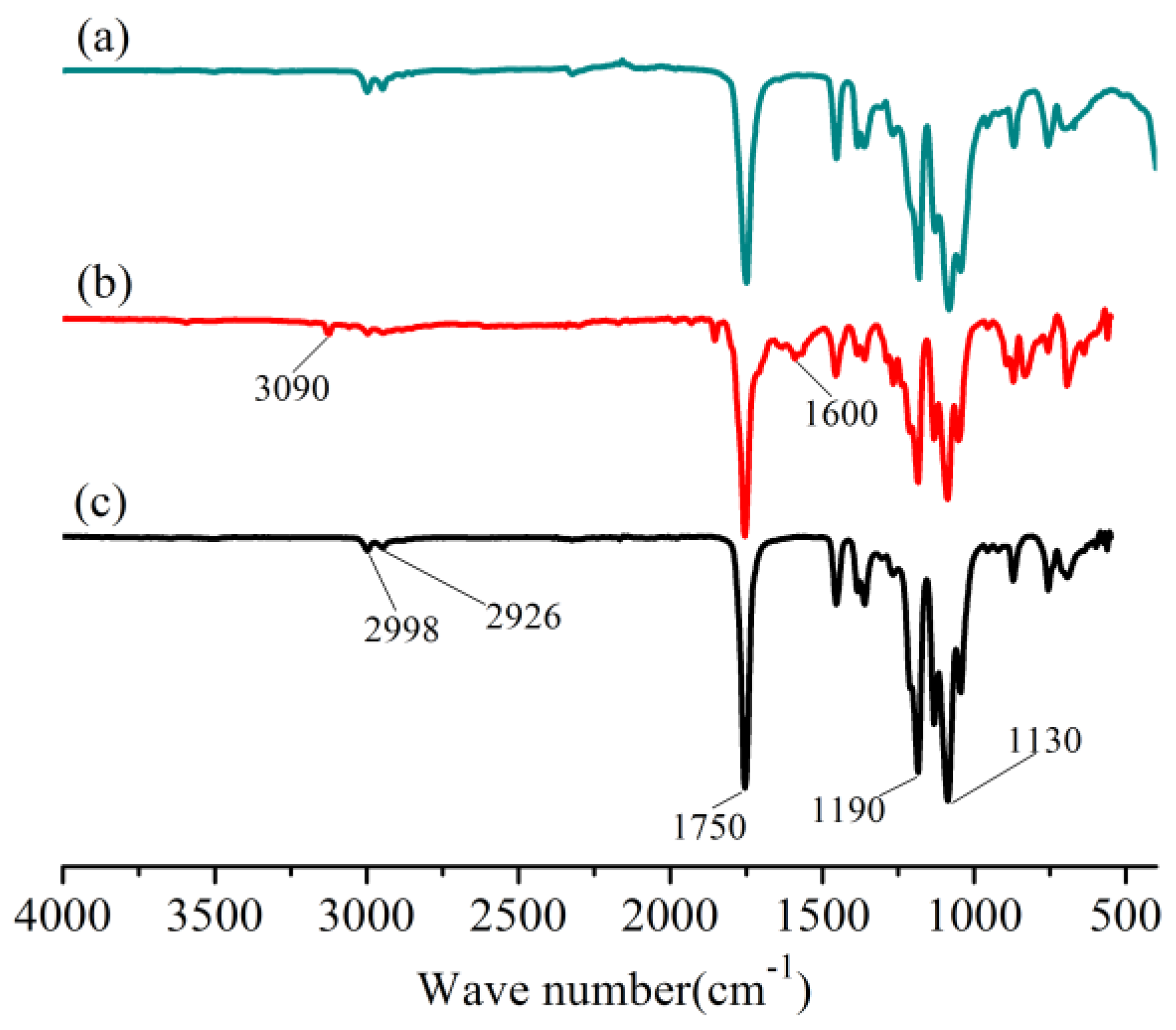

2.3. FT-IR of MAH-g-PLA

2.4. Determination of Grafting Degree

2.5. Preparation of PLA/Wood Fiber/MAH-g-PLA Composites

2.6. Characterization of the PLA/Wood Fiber/MAH-g-PLA Composites

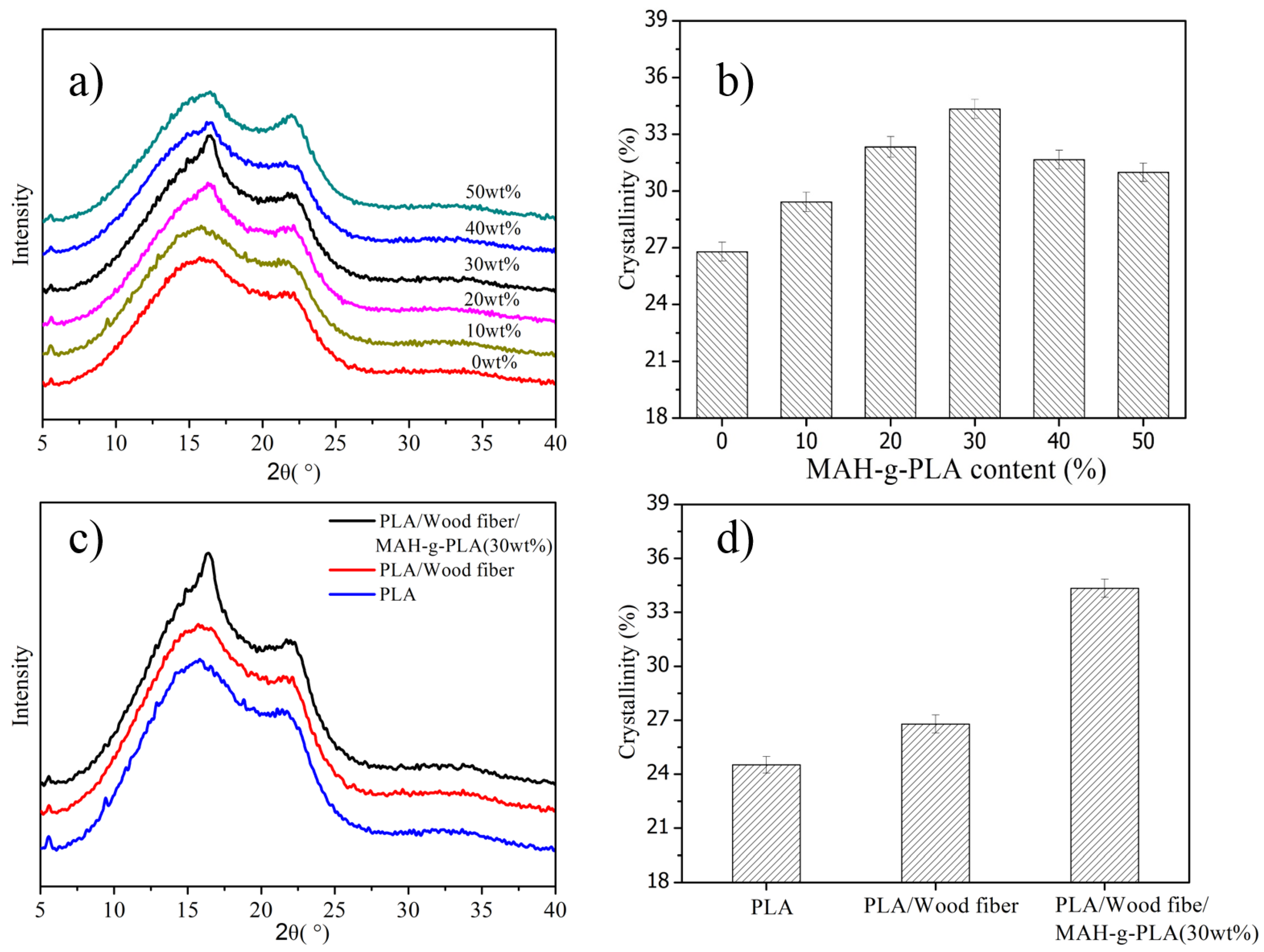

2.6.1. X-ray Diffraction and Crystallinity

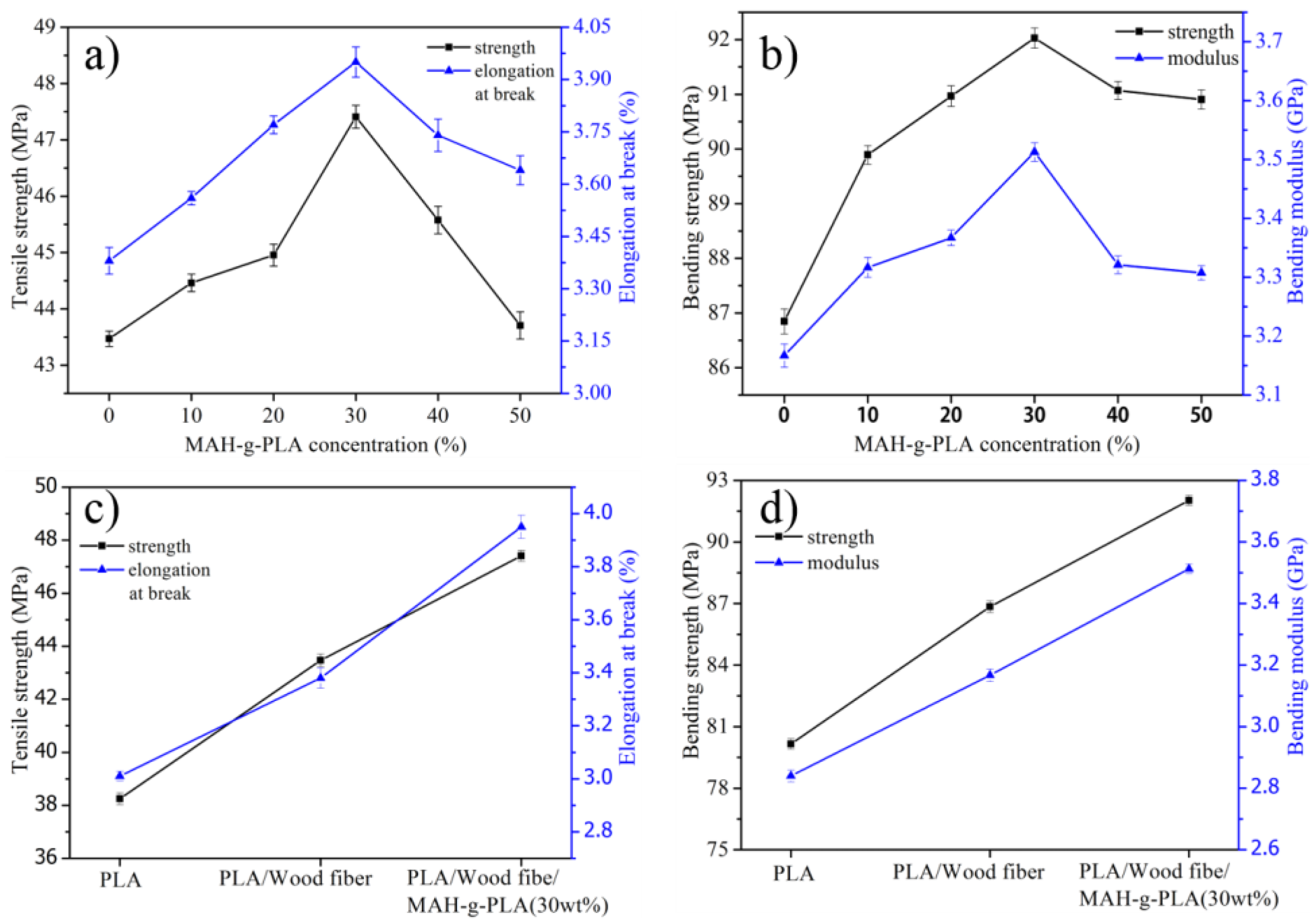

2.6.2. Mechanical Properties.

2.6.3. Thermal Gravimetric Analysis

2.6.4. Dynamic Mechanical Thermal Analysis

2.6.5. Water Absorption

2.6.6. Scanning Electron Microscopy

3. Result

3.1. FTIR Spectra of MAH-g-PLA

3.2. Grafting Degree of MAH-g-PLA

3.3. Performance of PLA/Wood fiber/MAH-g-PLA

3.3.1. XRD and Crystallinity

3.3.2. Mechanical Properties

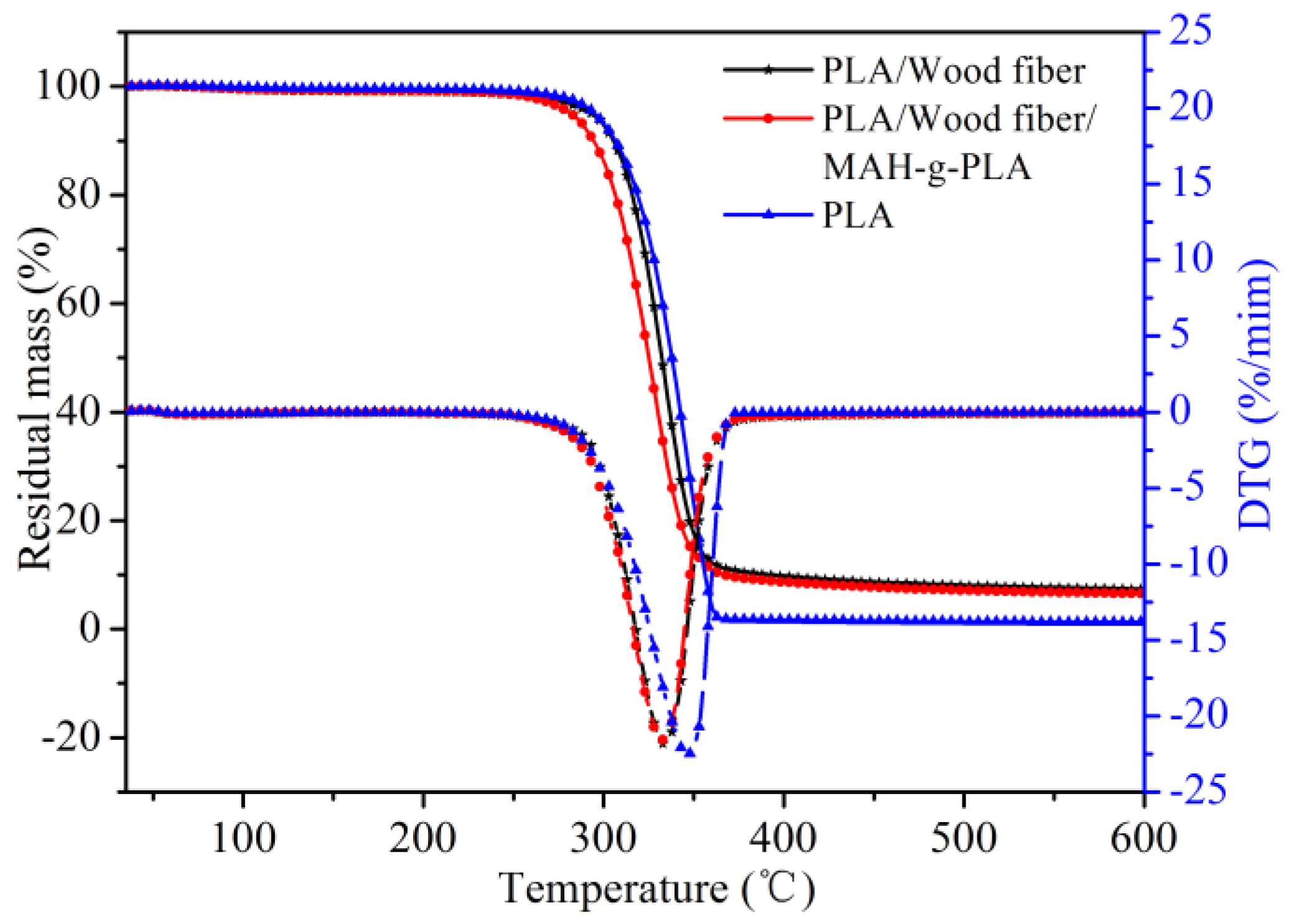

3.3.3. Thermal Stability

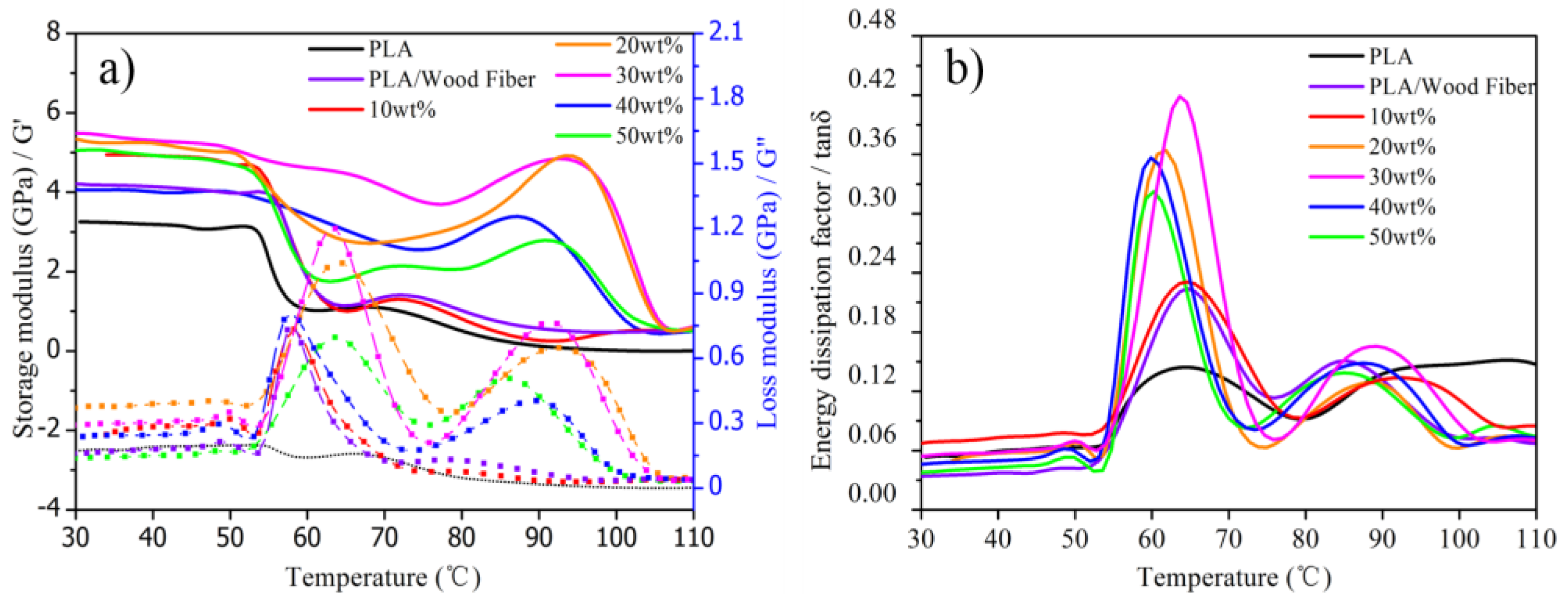

3.3.4. Dynamic Rhelogy

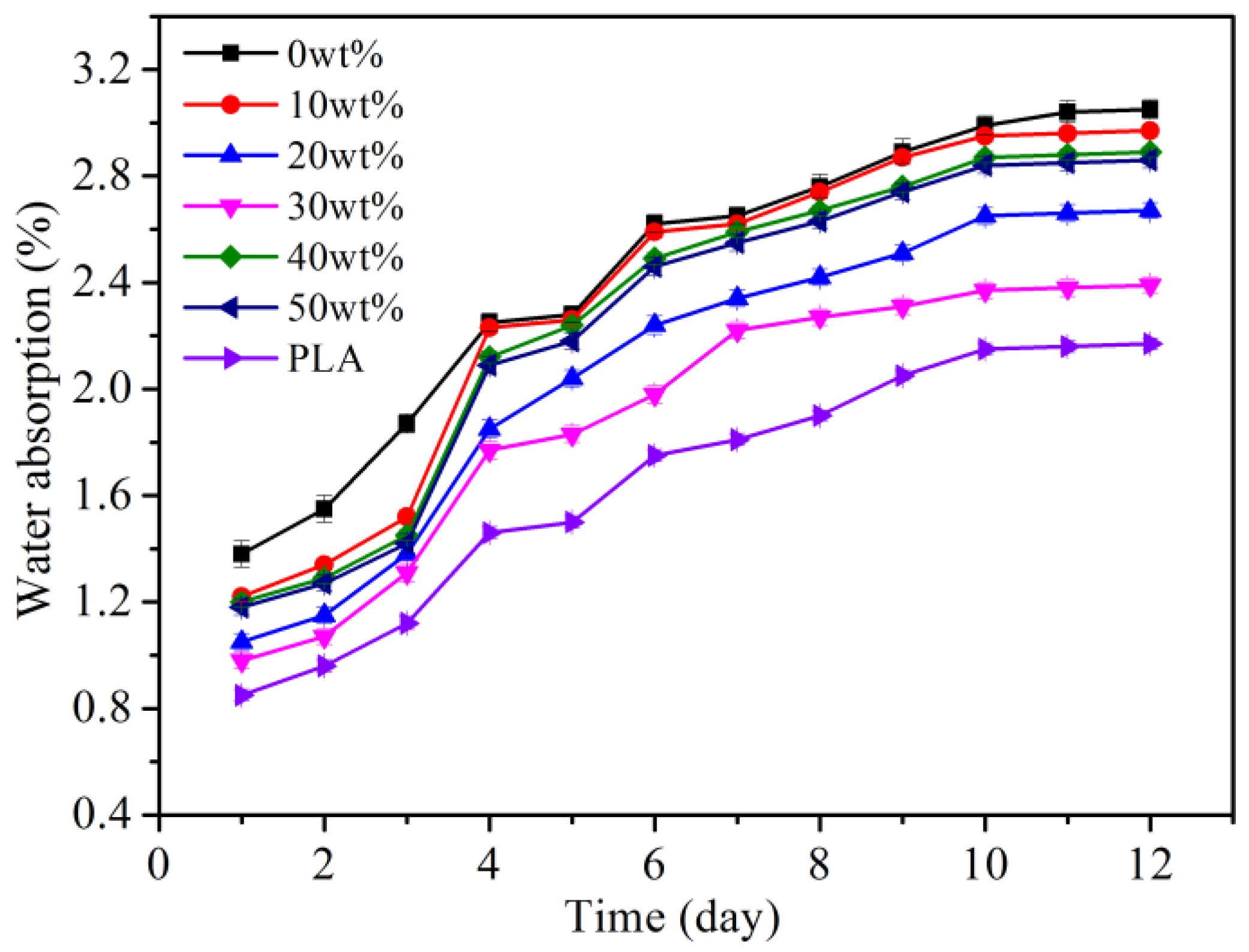

3.3.5. Water Absorption

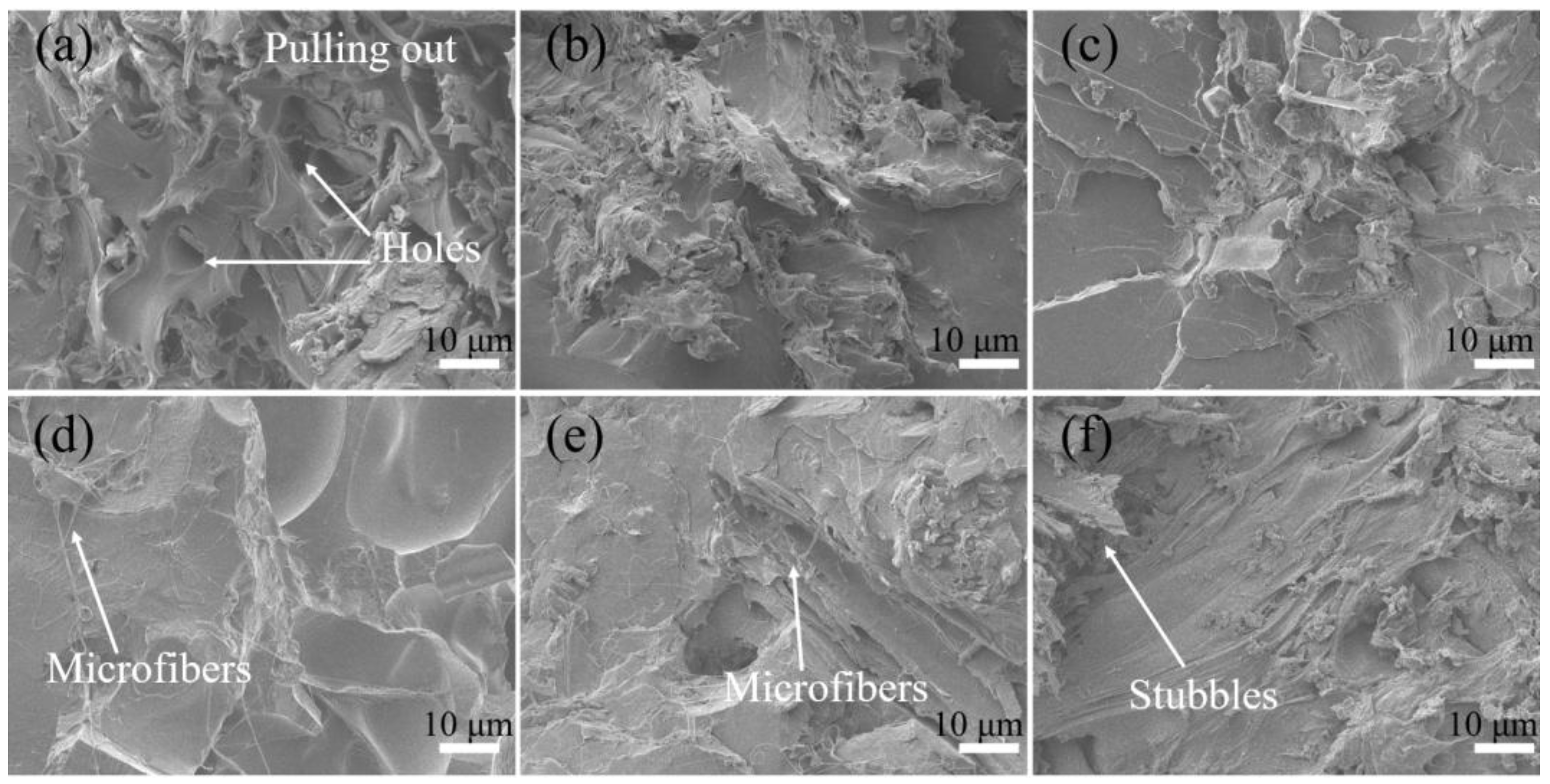

3.3.6. Morphology Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced polylactic acid (PLA) composites: An overview about mechanical characteristics and application areas. Compos. A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Kobayashi, S. Interfacial, mechanical and thermal properties of coir fiber-reinforced polylactic acid biodegradable composites. Adv. Compos. Mater. 2012, 21, 103–122. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Jandas, P.J.; Mohanty, S.; Nayak, S.K. Mechanical properties of surface-treated banana fiber/polylactic acid biocomposites: A comparative study of theoretical and experimental values. J. Appl. Polym. Sci. 2013, 127, 37–48. [Google Scholar] [CrossRef]

- Ben, G.; Kihara, Y.; Nakamori, K.; Aoki, Y. Examination of heat resistant tensile properties and molding conditions of green composites composed of kenaf fibers and PLA resin. Adv. Compos. Mater. 2007, 16, 361–376. [Google Scholar] [CrossRef]

- Bai, L.; Huan, S.; Gu, J.; McClements, D.J. Fabrication of oil-in-water nanoemulsions by dual-channel microfluidization using natural emulsifiers: Saponins, phospholipids, proteins, and polysaccharides. Food Hydrocoll. 2016, 61, 703–711. [Google Scholar] [CrossRef]

- Lee S, H.; Ohkita, T. Bamboo fiber (BF)-filled poly (butylenes succinate) bio-composite-effect of BF-e-MA on the properties and crystallization kinetics. Holzforschung 2004, 58, 537–543. [Google Scholar] [CrossRef]

- Bai, L.; Huan, S.; Li, Z.; McClements, D.J. Comparison of emulsifying properties of food-grade polysaccharides in oil-in-water emulsions: Gum arabic, beet pectin, and corn fiber gum. Food Hydrocoll. 2017, 66, 144–153. [Google Scholar] [CrossRef]

- Porras, A.; Maranon, A.; Ashcroft, I.A. Characterization of a novel natural cellulose fabric from Manicaria saccifera palm as possible reinforcement of composite materials. Compos. B Eng. 2015, 74, 66–73. [Google Scholar] [CrossRef]

- Gupta, A.; Simmons, W.; Schueneman, G.T.; Mintz, E.A. Lignin-coated cellulose nanocrystals as promising nucleating agent for polylactic acid. J. Therm. Anal. Calorim. 2016, 126, 1243–1251. [Google Scholar] [CrossRef]

- Wang, Y.; Weng, Y.; Wang, L. Characterization of interfacial compatibility of polylactic acid and bamboo flour (PLA/BF) in biocomposites. Polym. Test. 2014, 36, 119–125. [Google Scholar] [CrossRef]

- Zini, E.; Baiardo, M.; Armelao, L.; Scandola, M. Biodegradable polyesters reinforced with surface-modified vegetable fibers. Macromol. Biosci. 2004, 4, 286–295. [Google Scholar] [CrossRef] [PubMed]

- Tokoro, R.; Vu, D.M.; Okubo, K.; Tanaka, T.; Fujii, T.; Fujiura, T. How to improve mechanical properties of polylactic acid with bamboo fibers. J. Mater. Sci. 2007, 43, 775–787. [Google Scholar] [CrossRef]

- Yusoff, R.B.; Takagi, H.; Nakagaito, A.N. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind. Crop. Prod. 2016, 94, 562–573. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F.; El Kissi, N. Rheological and mechanical characterization of polypropylene-based wood plastic composites. Polym. Compos. 2015, 37, 3460–3473. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Wood-fiber-reinforced polylactic acid composites: Evaluation of the physicomechanical and morphological properties. J. Appl. Polym. Sci. 2006, 102, 4856–4869. [Google Scholar] [CrossRef]

- Talib, R.A.; Khalina, A.; Chin, N.L.; Ibrahim, M.N. Optimisation of processing variables of kenaf derived cellulose reinforced polylactic acid. Asian J. Chem. 2010, 22, 6652–6662. [Google Scholar]

- Jones, K.C.; Tinker, A. Blends of Natural Rubber: Novel Techniques for Blending with Specialty Polymers; Springer Science & Business Media: Berlin, Germany, 1997; Volume 49, pp. 472–478. [Google Scholar]

- Geissler, A.; Bonaccurso, E.; Heim, L.O.; Heinze, T.; Zhang, K. Temperature-responsive thin films from cellulose stearoyl triester. J. Phys. Chem. C 2014, 118, 2408–2417. [Google Scholar] [CrossRef]

- Perego, G.; Cella, G.D.; Bastioli, C. Effect of molecular weight and crystallinity on poly (lactic acid) mechanical properties. J. Appl. Polym. Sci. 1996, 59, 37–43. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Pan, Y.J.; Lou, C.W.; Huang, C.L.; Lin, Z.I.; Liao, J.M.; Lin, J.H. Polylactic acid/carbon fiber composites: Effects of functionalized elastomers on mechanical properties, thermal behavior, surface compatibility, and electrical characteristics. Fibers Polym. 2016, 17, 615–623. [Google Scholar] [CrossRef]

- Xu, S.; Xie, Y.; Meng, L. Application of biomass-based composites in food packaging. For. Eng. 2016, 32, 85–89. (In Chinese) [Google Scholar] [CrossRef]

- Gibeop, N.; Lee, D.W.; Prasad, C.V.; Toru, F.; Kim, B.S.; Song, J.I. Effect of plasma treatment on mechanical properties of jute fiber/polylactic acid biodegradable composites. Adv. Compos. Mater. 2013, 22, 389–399. [Google Scholar] [CrossRef]

- Bocz, K.; Tábi, T.; Vadas, D.; Sauceau, M.; Fages, J.; Marosi, G. Characterisation of natural fibre reinforced PLA foams prepared by supercritical CO2 assisted extrusion. Express Polym. Lett. 2016, 10, 771–779. [Google Scholar] [CrossRef]

- Torres, J.; Cotelo, J.; Karl, J.; Gordon, A.P. Mechanical property optimization of FDM PLA in shear with multiple objectives. JOM 2015, 67, 1183–1193. [Google Scholar] [CrossRef]

- Qin, J.; Jiang, Y.; Fu, J.; Wan, Y.; Yang, R.; Gao, W.; Wang, H. Evaluation of drug release property and blood compatibility of aspirin-loaded electrospun PLA/RSF composite nanofibers. Iran. Polym. J. 2013, 22, 729–737. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, G.; Dai, K.; Xie, M.; Liu, C.; Liu, B.; Zhang, X.; Wang, B.; Chen, J.; Shen, C.; et al. β-transcrystallinity developed from the novel ringed nuclei in the glass fiber/isotactic polypropylene composite. Mater. Lett. 2011, 65, 2274–2277. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, Y.; Zhang, L.; Zheng, G.; Dai, K.; Liu, C.; Yan, X.; Guo, J.; Guo, Z. Shear-induced interfacial sheath structure in isotactic polypropylene/glass fiber composites. Polymer 2015, 70, 326–335. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tabi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2011, 25, 927–948. [Google Scholar] [CrossRef]

- Lv, S.; Gu, J.; Tan, H.; Zhang, Y. The morphology, rheological, and mechanical properties of wood flour/starch/polylactic acid blends. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Way, C.; Wu, D.Y.; Cram, D.; Dean, K.; Palombo, E. Processing stability and biodegradation of polylactic acid (PLA) composites reinforced with cotton linters or maple hardwood fibres. J. Polym. Environ. 2012, 21, 5470–5479. [Google Scholar] [CrossRef]

- Yasuniwa, M.; Tsubakihara, S.; Sugimoto, Y.; Nakafuku, C. Thermal analysis of the double-melting behavior of poly (lactic acid). J. Polym. Sci. B Polym. Phys. 2004, 42, 25–32. [Google Scholar] [CrossRef]

- Lv, S.; Gu, J.; Tan, H.; Zhang, Y. Modification of wood flour/PLA composites by reactive extrusion with maleic anhydride. J. Appl. Polym. Sci. 2016, 133, 101–109. [Google Scholar] [CrossRef]

| MAH (g) | DCP (g) | PLA (g) | Acetone (mL) |

|---|---|---|---|

| 0.5 | 0.5 | 100 | 10 |

| 1.0 | 0.5 | 100 | 10 |

| 1.5 | 0.5 | 100 | 10 |

| 2.0 | 0.5 | 100 | 10 |

| 2.5 | 0.5 | 100 | 10 |

| Code | Wood Fiber (g) | PLA (g) | MAH-g-PLA (g) |

|---|---|---|---|

| 1 | 60 | 240 | 0 |

| 2 | 60 | 216 | 24 |

| 3 | 60 | 192 | 48 |

| 4 | 60 | 168 | 72 |

| 5 | 60 | 144 | 96 |

| 6 | 60 | 120 | 120 |

| MAH (g) | Grafting Degree (%) |

|---|---|

| 0.5 | 0.45 |

| 1.0 | 0.51 |

| 1.5 | 0.97 |

| 2.0 | 0.91 |

| 2.5 | 0.86 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Lv, S.; Sun, C.; Wan, L.; Tan, H.; Zhang, Y. Effect of MAH-g-PLA on the Properties of Wood Fiber/Polylactic Acid Composites. Polymers 2017, 9, 591. https://doi.org/10.3390/polym9110591

Zhang L, Lv S, Sun C, Wan L, Tan H, Zhang Y. Effect of MAH-g-PLA on the Properties of Wood Fiber/Polylactic Acid Composites. Polymers. 2017; 9(11):591. https://doi.org/10.3390/polym9110591

Chicago/Turabian StyleZhang, Lei, Shanshan Lv, Ce Sun, Lu Wan, Haiyan Tan, and Yanhua Zhang. 2017. "Effect of MAH-g-PLA on the Properties of Wood Fiber/Polylactic Acid Composites" Polymers 9, no. 11: 591. https://doi.org/10.3390/polym9110591

APA StyleZhang, L., Lv, S., Sun, C., Wan, L., Tan, H., & Zhang, Y. (2017). Effect of MAH-g-PLA on the Properties of Wood Fiber/Polylactic Acid Composites. Polymers, 9(11), 591. https://doi.org/10.3390/polym9110591