Effect of Flaring Gate Piers on Discharge Coefficient for Finite Crest-Length Weirs

Abstract

:1. Introduction

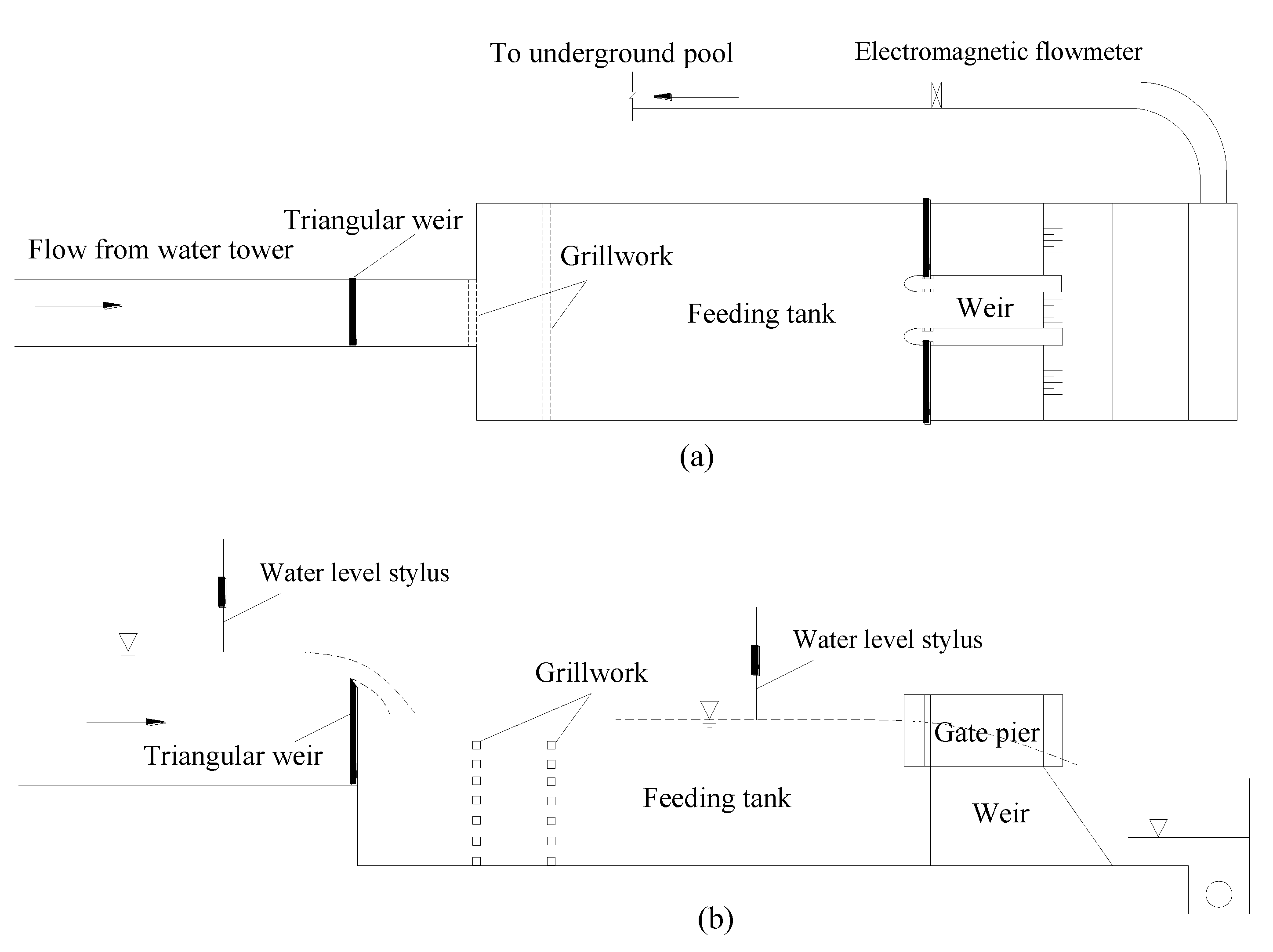

2. Experimental Setup and Methodology

3. Results and Discussions

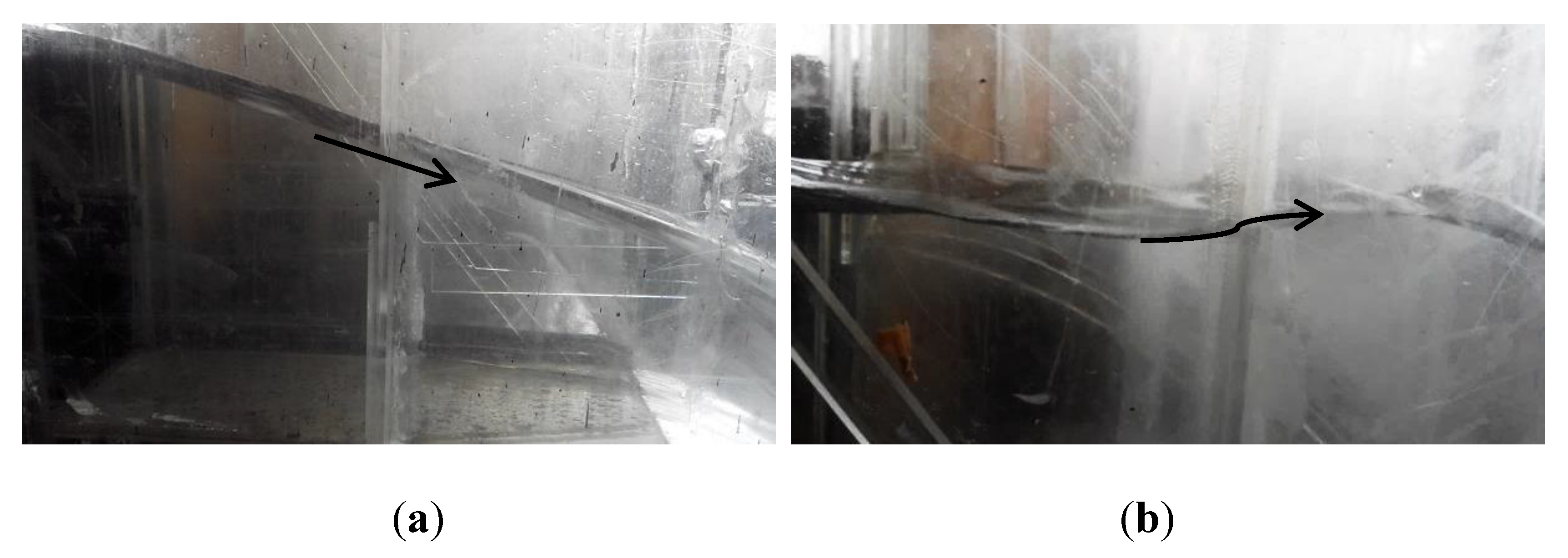

3.1. Flow Pattern Comparison with and without FGP

3.2. Discharge Capacity Comparison with and without FGP

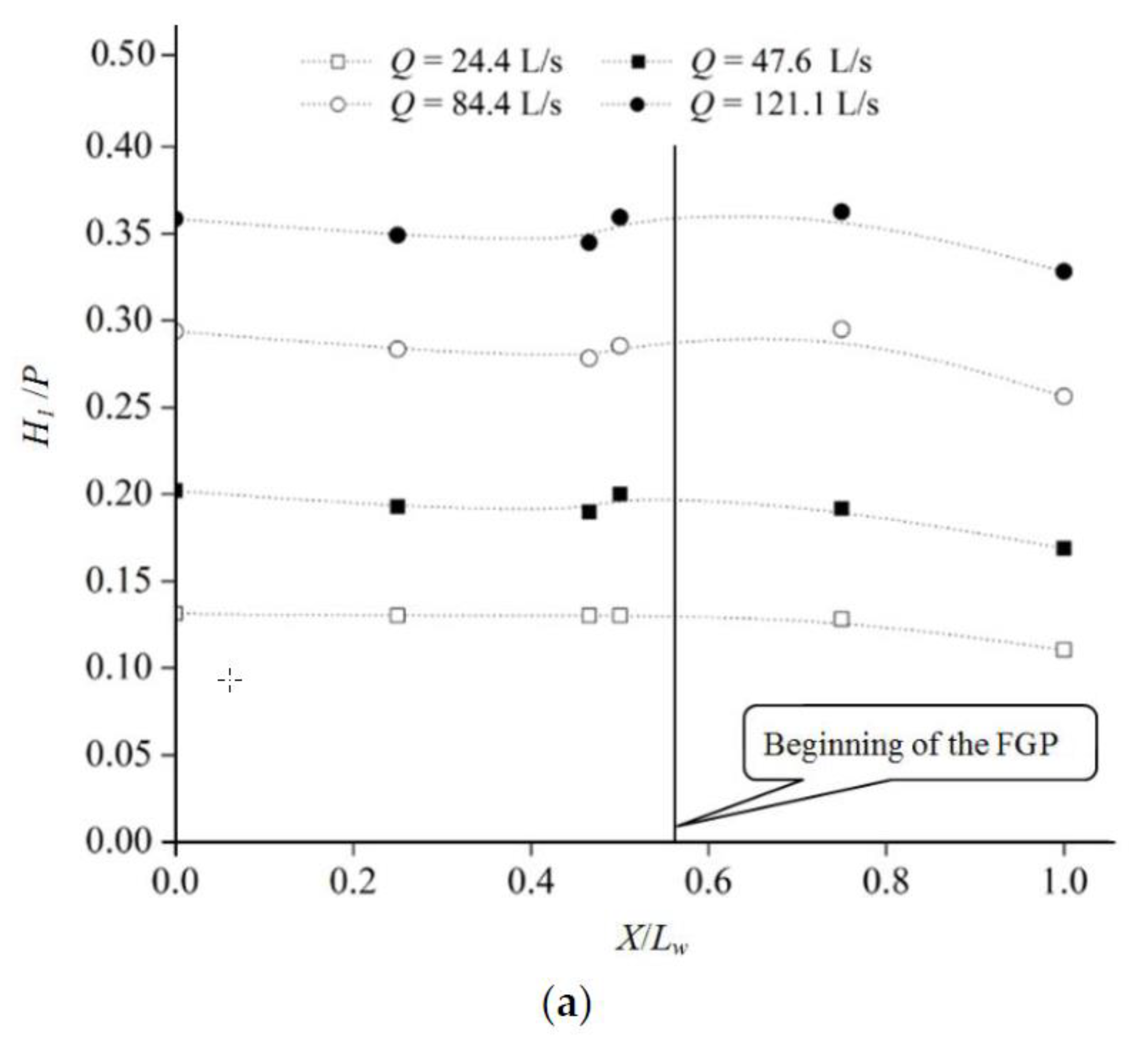

3.3. Influence of Weir Length on Discharge Capacity with and without FGP

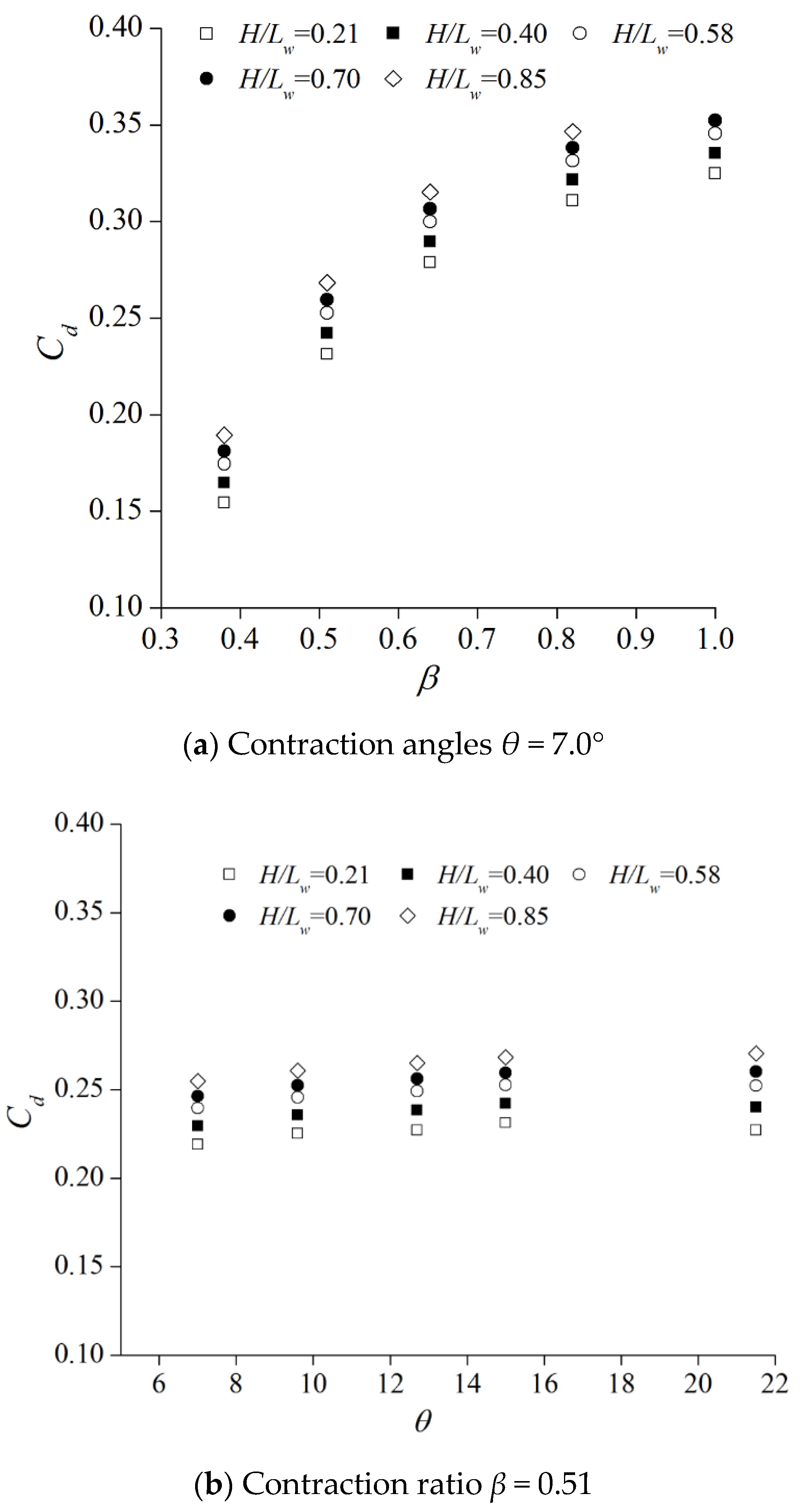

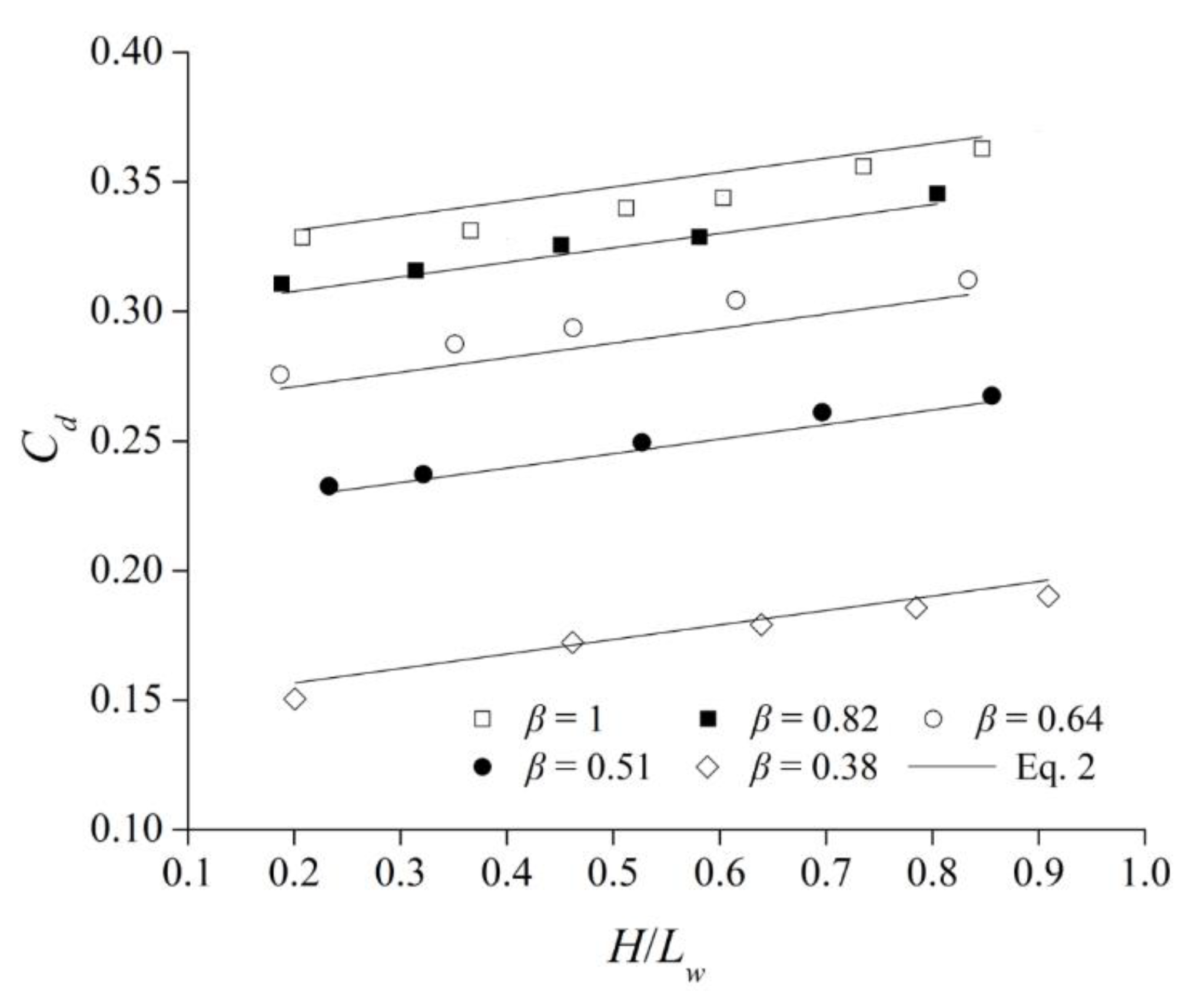

3.4. Discharge Coefficient of the Weir with FGP

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Horton, R.E. Weir Experiments, Coefficients, and Formulas; Proc. U.S. Geological Survey Water Supply; Government Printing Office: Washington, DC, USA, 1907.

- Hager, W.H.; Schwalt, M. Broad-crested weir. J. Irrig. Drain. Eng. 1994, 120, 13–26. [Google Scholar] [CrossRef]

- Fritz, H.M.; Hager, W.H. Hydraulics of embankment weirs. J. Hydraul. Eng. 1998, 124, 963–971. [Google Scholar] [CrossRef]

- Bai, R.; Zhang, F.; Liu, S.; Wang, W. Air concentration and bubble characteristics sownstream of a chute aerator. Int. J. Multiphase Flow 2016, 87, 156–166. [Google Scholar] [CrossRef]

- Bai, R.; Liu, S.; Tian, Z.; Wang, W.; Zhang, F. Experimental investigations on air–water flow properties of offset–aerator. J. Hydraul. Eng. 2018, 144, 04017059. [Google Scholar] [CrossRef]

- Govinda Rao, N.S.; Muralidhar, D. Discharge characteristics of weirs of finite crest width. Houille Blanche 1963, 18, 537–545. [Google Scholar] [CrossRef]

- Ramamurty, A.S.; Udoyara, S.T.; Rao, M.V.J. Characteristic of square-edged and round-nosed broad-crested weirs. J. Irrig. Drain. Eng. 1988, 114, 61–73. [Google Scholar] [CrossRef]

- Sarker, M.A.; Rhodes, D.G. Calculation of free-surface profile over a rectangular broad-crested weir. Flow Meas. Instrum. 2004, 15, 215–219. [Google Scholar] [CrossRef]

- Andersson, A.G.; Andreasson, P.; Staffan Lundström, T. CFD-modelling and validation of free surface flow during spilling of reservoir in down-scale model. Eng. Appl. Comput. Fluid Mech. 2013, 7, 159–167. [Google Scholar] [CrossRef]

- Chen, Y.; Fu, Z.; Chen, Q.; Cui, Z. Discharge Coefficient of Rectangular Short-CrestedWeir with Varying Slope Coefficients. Water 2018, 10, 204. [Google Scholar] [CrossRef]

- Azimi, A.H.; Rajaratnam, N.; Zhu, D.Z. Submerged Flows over Rectangular Weirs of Finite Crest Length. J. Irrig. Drain. Eng. 2014, 140, 06014001. [Google Scholar] [CrossRef]

- Jan, C.D.; Chang, C.J.; Kuo, F.H. Experiments on discharge equations of compound broad-crested weirs. J. Irrig. Drain. Eng. 2009, 135, 511–515. [Google Scholar] [CrossRef]

- Xie, S.Z.; Li, S.Q.; Li, G.F. Development of flaring gate piers in China. Hongshui River 1995, 14, 3–11. (In Chinese) [Google Scholar]

- Guo, J.; Liu, Z.P. Field observations on the RCC stepped spillways with the flaring pier gate on the Dachaoshan Project. In Proceedings of the IAHR XXX International Congress, Theme D, Thessaloniki, Greece, August 2003; pp. 473–478. [Google Scholar]

- Zhang, T.; Wu, C.; Liao, H.S. 3D numerical simulation on water and air two-phase flows of the steps and flaring gate pier. J. Hydrodyn. 2005, 17, 338–343. [Google Scholar]

- Wang, B.; Wu, C.; Mo, Z.Y. Relationship of first step height, step slope and cavity in X-shaped flaring gate piers. J. Hydrodyn. 2007, 19, 349–355. [Google Scholar] [CrossRef]

- Futian, L.; Peiqing, L.; Weilin, X.; Zhong, T. Experimental study on effect of flaring piers on weir discharge capacity in high arch dam. J. Hydraul. Eng. 2003, 11, 43–47. (In Chinese) [Google Scholar]

- Li, N.W.; Liu, C.; Deng, J.; Zhang, X.Z. Theoretical and experimental studies of the flaring piers on the surface spillway in a high-arch dam. J. Hydrodyn. 2012, 24, 496–505. [Google Scholar] [CrossRef]

- Ramamurthy, A.S.; Vo, N.D. Characteristics of circular-crested weir. J. Hydraul. Eng. 1963, 119, 1055–1062. [Google Scholar] [CrossRef]

| Weir Type | Weir Height | Weir Length | Channel Width | Contraction Ratio | Contraction Angle | Case Name |

|---|---|---|---|---|---|---|

| P (m) | Lw (m) | B (m) | β = B’/B | θ | ||

| Type 1 | 1.493 | 0.422 | 0.30 | 0.51 | 15 | N1 |

| 1 | 0 | N2 | ||||

| Type 2 | 1.379 | 0.519 | 0.30 | 0.51 | 15 | N3 |

| 1 | 0 | N4 | ||||

| Type 3 | 1.28 | 0.601 | 0.30 | 0.51 | 15 | N5 |

| 1 | 0 | N6 | ||||

| 0.38 | 15 | N7 | ||||

| 0.64 | 15 | N8 | ||||

| 0.82 | 15 | N9 | ||||

| 0.51 | 7 | N10 | ||||

| 0.51 | 9.6 | N11 | ||||

| 0.51 | 12.7 | N12 | ||||

| 0.51 | 21.5 | N13 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; Wang, W.; Bai, R.; Li, N. Effect of Flaring Gate Piers on Discharge Coefficient for Finite Crest-Length Weirs. Water 2018, 10, 1349. https://doi.org/10.3390/w10101349

Tian Z, Wang W, Bai R, Li N. Effect of Flaring Gate Piers on Discharge Coefficient for Finite Crest-Length Weirs. Water. 2018; 10(10):1349. https://doi.org/10.3390/w10101349

Chicago/Turabian StyleTian, Zhong, Wei Wang, Ruidi Bai, and Nan Li. 2018. "Effect of Flaring Gate Piers on Discharge Coefficient for Finite Crest-Length Weirs" Water 10, no. 10: 1349. https://doi.org/10.3390/w10101349