Greywater Reuse System Design and Economic Analysis for Residential Buildings in Taiwan

Abstract

:1. Introduction

2. Greywater System Review

3. Interior Customized Greywater System (ICGS) Design

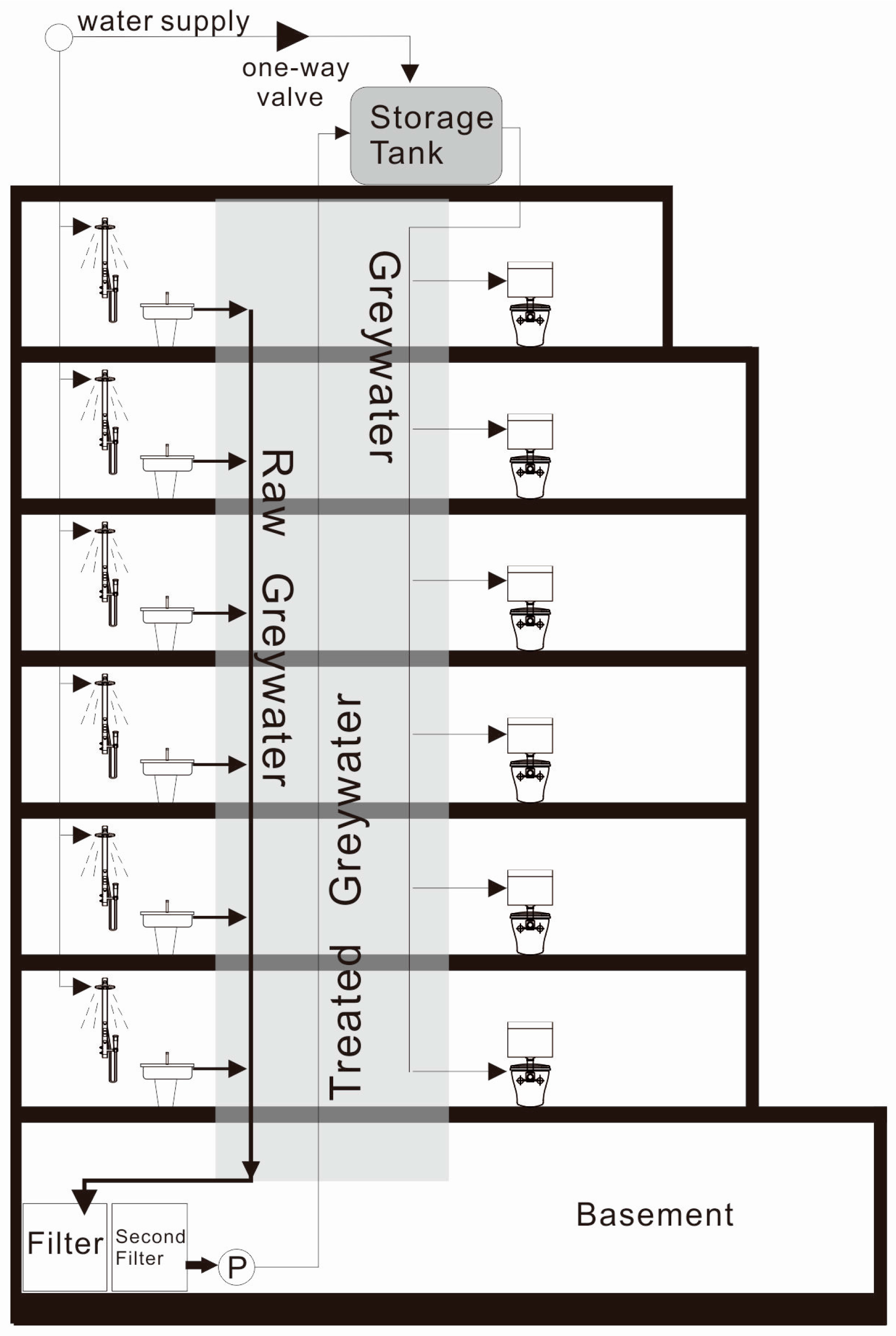

3.1. Conventional Greywater System

- Collection of raw greywater: lateral pipes are installed to collect greywater from bath, shower, and washbasin to central vertical pipes.

- Conveyance and treatment of greywater: collected raw greywater is conveyed through these separate vertical pipes to the basement for treatment. Treated greywater is then pumped to the top of the building to the storage tank.

- Distribution of treated greywater: treated greywater is then gravitationally conveyed from the storage tank to each family unit in each flat.

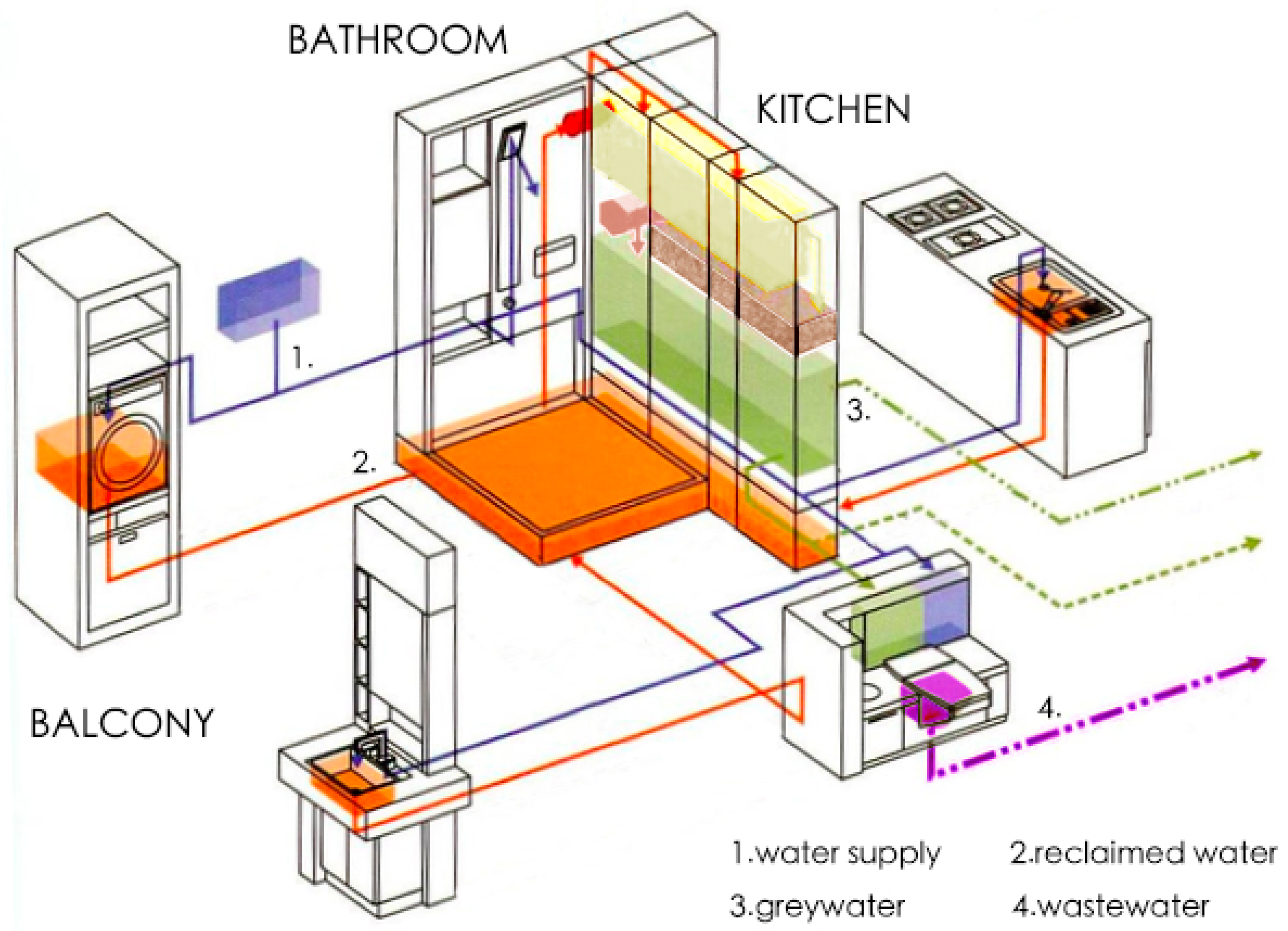

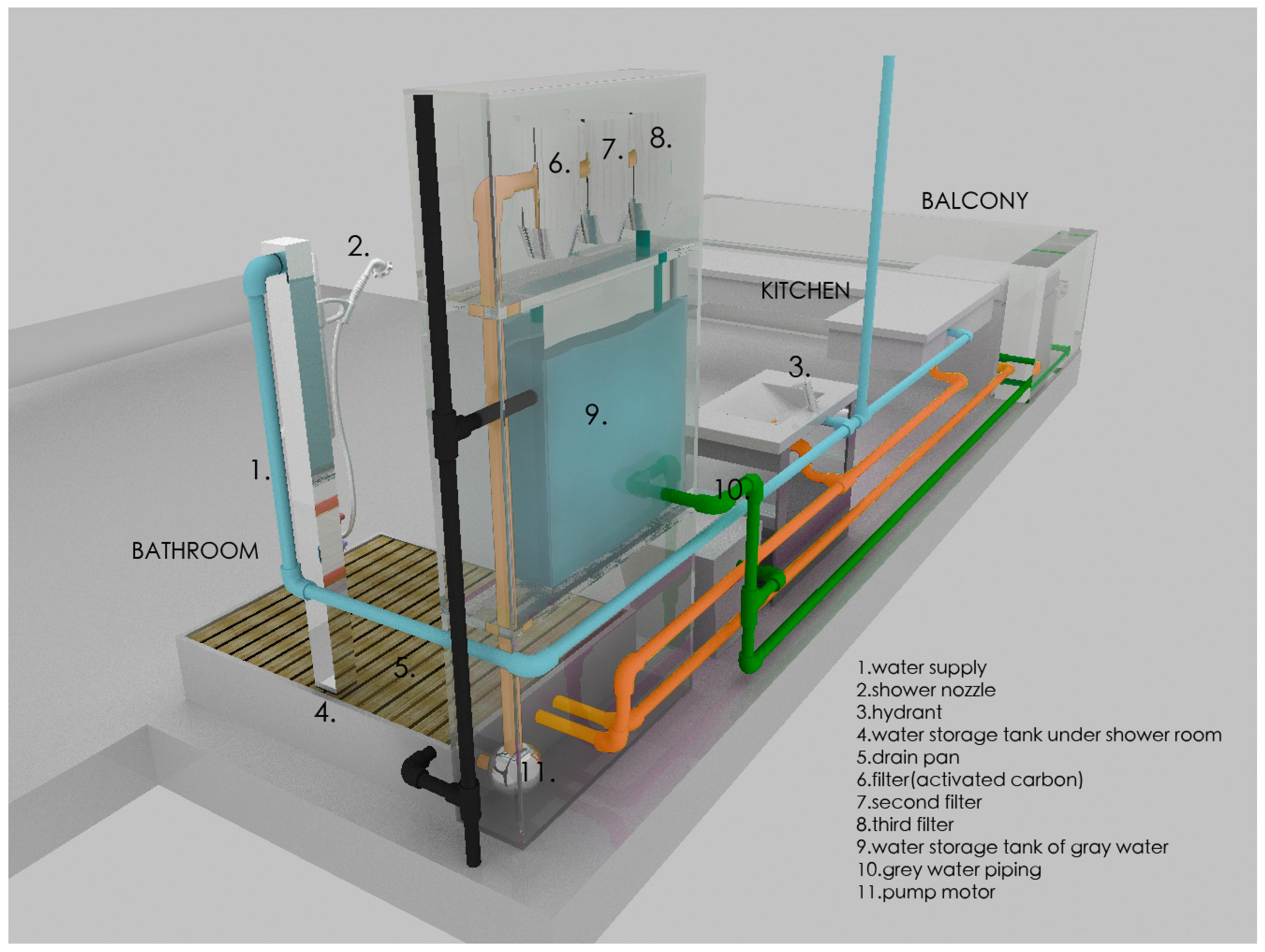

3.2. ICGS System

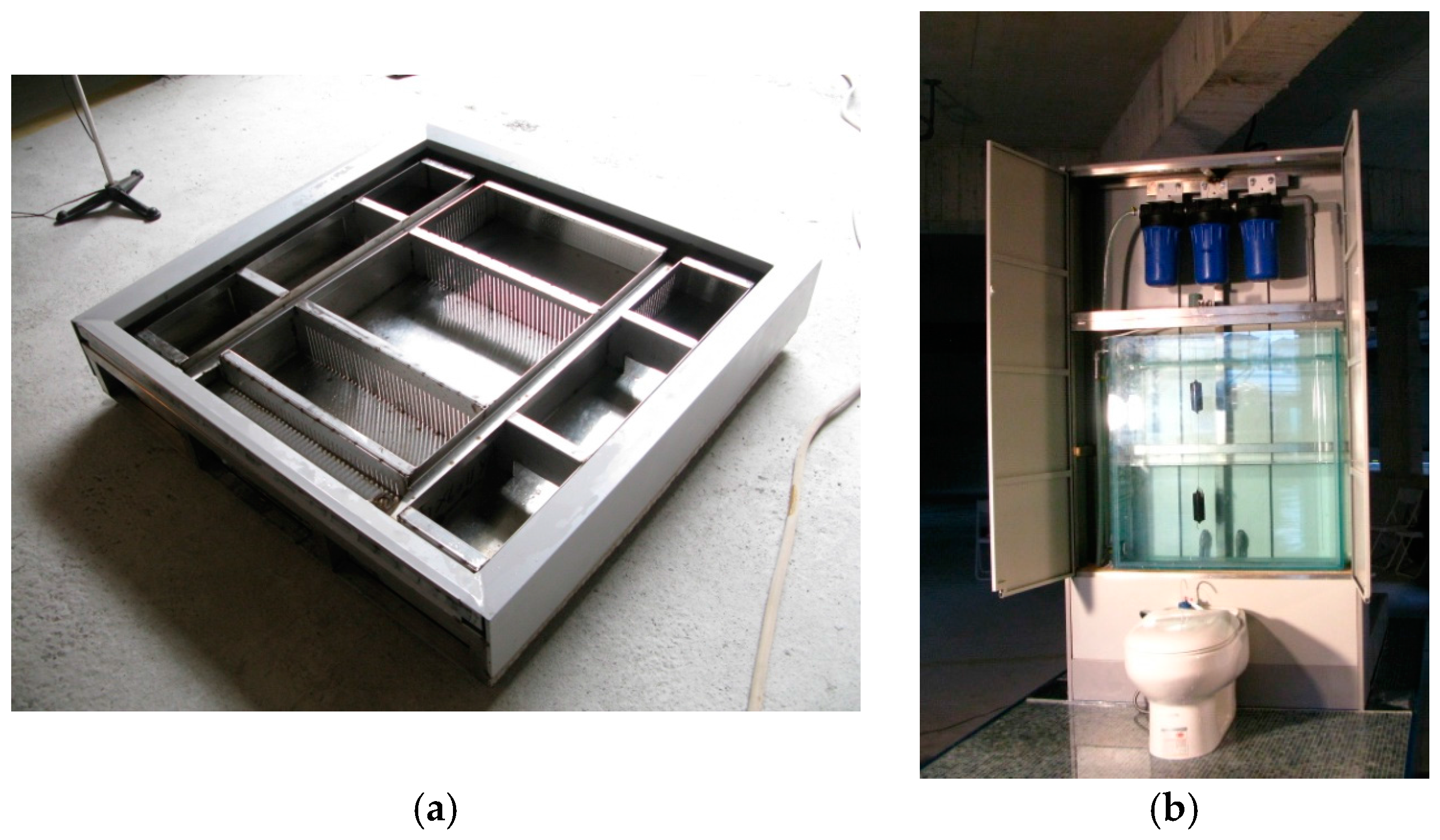

3.3. Greywater Processing Mechanism Design

4. System Application and Assessment

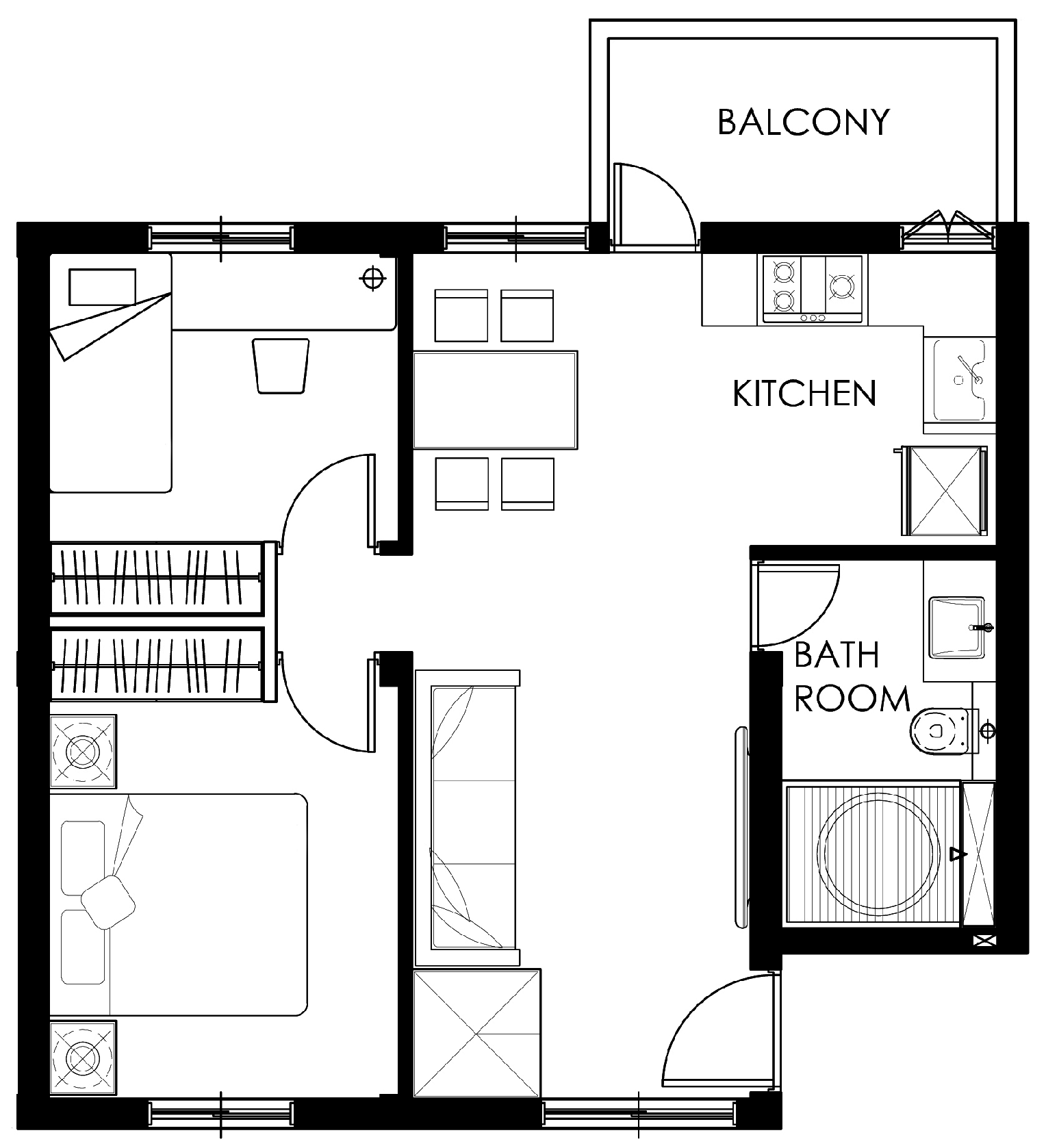

4.1. Case Study

4.2. Lifecycle Cost Analysis

- NPV =CFt: Sectional cash flow; i: discount rate; Cost: initial investment cost.

- SIR = Total savings/total investment

- Total savings: The difference between the water bills of the two systems (Sconventional-SICGS)Total investment: The difference between the total investment costs of the two systems (Iconventional-IICGS), including initial cost (A), Annual maintenance cost (B), Electricity bill (D), Replacement cost (E).

- Payback = Total investment expense/net annual income.

4.3. Scenario Simulation for Three Types of Economies

- Scenario 1: Future water cost remains unchanged.

- Scenario 2: Cost remains unchanged from the first to fifth year and surges by 30% from the sixth year until twentieth year.

- Scenario 3: Cost surges by 50% from the first to fifth year, 100% from the sixth to tenth year and 500% from the eleventh to twentieth year.

5. Conclusions

Author Contributions

Conflicts of Interest

References

- World Water Development Report (WWDR). Water for People, Water for Life; The United Nations Educational, Scientific and Cultural Organization: Paris, France, 2003. [Google Scholar]

- Coalition for Environmentally Responsible Economies (CERES). Water Scarcity & Climate Change: Growing Risks for Businesses & Investors; CERES: Boston, MA, USA, 2009. [Google Scholar]

- Gross, A.; Wiel-Shafran, A.; Bondarenko, N.; Ronen, Z. Reliability of small scale greywater treatment systems and the impact of its effluent on soil properties. Int. J. Environ. Stud. 2008, 65, 41–50. [Google Scholar] [CrossRef]

- Water Resources Agency Ministry of Economic Affairs. 2014. Available online: http://www.wra.gov.tw/ct.asp?xItem=30421&ctNode=1967 (accessed on 16 April 2016). (In Chinese)

- Wang, C.; Wang, J. Analysis and Evaluation of Taiwan Water Shortage Factors and Solution Strategies. Asian Soc. Sci. 2010, 6. [Google Scholar] [CrossRef]

- Water Resources Agency, Ministry of Economic Affairs. The Domestic Water Consumption in Taiwan for 2012; Water Resources Agency: Taichung, Taiwan, 2012.

- World Water Development Report (WWDR). The United Nations World Water Development Report 4. Managing Water under Uncertainty and Risk; The United Nations Educational, Scientific and Cultural Organization: Paris, France, 2012. [Google Scholar]

- Marlow, D.R.; Moglia, M.; Cook, S.; Beale, D.J. Towards sustainable urban water management: A critical reassessment. Water Res. 2013, 47, 7150–7161. [Google Scholar] [CrossRef] [PubMed]

- Jefferson, B.; Laine, A.; Parsons, S.; Stephenson, T.; Judd, S. Technologies for domestic wastewater recycling. Urban Water 1999, 1, 285–292. [Google Scholar] [CrossRef]

- Ottoson, J.; Stenström, T.A. Faecal contamination of greywater and associated microbial risks. Water Res. 2003, 37, 645–655. [Google Scholar] [CrossRef]

- International Water Association (IWA). IWA-World Water Congress and Exhibition; International Water Association (IWA): Paris, France, 2012; Volume 1. [Google Scholar]

- Nolde, E. Greywater reuse systems for toilet flushing in multi-storey buildings—Over ten years experience in Berlin. Urban Water 2000, 32, 43–53. [Google Scholar] [CrossRef]

- Liu, S.; Butler, D.; Memon, F.A.; Makropoulos, C.; Avery, L.; Jefferso, B. Impacts of residence time during storage on potential of water saving for grey water recycling system. Sci. Direct Water Res. 2010, 44, 267–277. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mourad, K.A.; Berndtsson, J.C.; Berndtsson, R. Potential fresh water saving using greywater in toilet flushing in Syria. J. Environ. Manag. 2011, 92, 2447–2453. [Google Scholar] [CrossRef] [PubMed]

- Vakil, K.A.; Sharma, M.K.; Bhatia, A.; Kazmi, A.A.; Sarkar, S. Characterization of greywater in an Indian middle-class household and investigation of physicochemical treatment using electrocoagulation. Sep. Purif. Technol. 2014, 130, 160–166. [Google Scholar] [CrossRef]

- Jabornig, S.; Favero, E. Single household greywater treatment with a moving bed biofilm membrane reactor (MBBMR). J. Membr. Sci. 2013, 446, 277–285. [Google Scholar] [CrossRef]

- Sheikh, B. The city of Los Angeles grey water pilot project shows safe use of grey water is possible. In Water Management in the 90s: A Time for Innovation; American Society of Civil Engineers: New York, NY, USA, 1993; p. 681. [Google Scholar]

- Ghisi, E.; Ferreira, D.F. Potential for potable water savings by using rainwater and greywater in a multi-storey residential building in southern Brazil. Build. Environ. 2007, 42, 2512–2522. [Google Scholar] [CrossRef]

- Ismail, Z.; Ellias, S.; Tajuddin, R.M.; Atan, I.; Ashaari, Y.; Endut, I.R.; Baki, A. Alternative Water Resources for Sustainable Buildings. In Proceedings of the 3rd AUN/SEED-Net Regional Conference on Global Environment, AUN/SEED-Net, Mid Valley, MY, USA, 21–22 February 2011.

- United Nations Economic and Social Commission for Asia and the Pacific. Water Resource Management: Policy Recommendations for the Development of Eco-Efficient Infrastructure, 2012. Available online: http://www.unescap.org/sites/default/files/8.%20Water-Resource-Management.pdf (accessed on 16 April 2016).

- Mandala, D.; Labhasetwarb, P.; Dhonea, S.; Dubeya, A.S.; Shindec, G.; Watea, S. Water conservation due to greywater treatment and reuse in urban setting with specific context to developing countries. Resour. Conserv. Recycl. 2011, 55, 356–361. [Google Scholar] [CrossRef]

- Kordana, S.; Słyś, D.; Dziopak, J. Rationalization of water and energy consumption in shower systems of single-family dwelling houses. J. Clean. Prod. 2014, 82, 58–69. [Google Scholar] [CrossRef]

- Ghisi, E. Potential for potable water savings by using rainwater in the residential sector of Brazil. Build. Environ. 2006, 41, 1544–1550. [Google Scholar] [CrossRef]

- García-Montoyaa, M.; Bocanegra-Martíneza, A.; Nápoles-Riveraa, F.; Serna-Gonzáleza, M.; Ponce-Ortegaa, J.M. Simultaneous design of water reusing and rainwater harvesting systems in a residential complex. Comput. Chem. Eng. 2014, 76, 104–116. [Google Scholar] [CrossRef]

- Friedler, E.; Hadari, M. Economic feasibility of on-site greywater reuse in multi-storey buildings. Desalination 2006, 190, 221–234. [Google Scholar] [CrossRef]

- Widiastuti, N.; Wu, H.; Ming, A.; Zhang, D.K. The potential application of natural zeolite for greywater treatment. Desalination 2008, 218, 271–280. [Google Scholar] [CrossRef]

- Taiwan Water Corporation. Available online: http://www3.water.gov.tw/ch/03service/ser_02detail.asp?bull_id=242 (accessed on 20 April 2016). (In Chinese)

| Attributes | Conventional System | ICGS | Year of Occurrence |

|---|---|---|---|

| Initial cost (A) | 10,000 | 15,000 | 0 |

| Maintenance cost (B) | 500 | 4,600 | annual |

| Operation cost: water bill (C) | 7,800 | 3,510 | annual |

| Operation cost: electricity bill (D) | 400 | 1,200 | annual |

| Replacement cost (E) | 0 | 3,500 | 10 |

| Cost Items | Base Date Cost (NT$) | Year of Occurrence | Present Value (NT$) | Difference | |

|---|---|---|---|---|---|

| Initial invest cost | Greywater | 15,000 | Base Date | 15,000 | 5,000 |

| Traditional | 10,000 | Base Date | 10,000 | ||

| Maintenance and Repair cost | Greywater | 4,600 | annual | 68,436 | 60,998 |

| Traditional | 500 | annual | 7,439 | ||

| Residual value | Greywater | 0 | 20 | 0 | 0 |

| Traditional | 0 | 20 | 0 | ||

| Operation cost | Greywater | 1,200 | annual | 17,853 | 11,902 |

| Traditional | 400 | annual | 5,951 | ||

| Water bill | Greywater | 3,510 | annual | 52,220 | 63,824 |

| Traditional | 7,800 | annual | 116,044 | ||

| Pump cost | Greywater | 3,500 | 10 | 2,604 | 0 |

| Traditional | 3,500 | 10 | 2,604 | ||

| Present value of greywater system | Total | 156,114 | |||

| Present value of traditional system | Total | 142,038 | |||

| NPV result | NPV < 0 | −14,075 | |||

| SIR result | SIR < 1 | 0.82 | |||

| Payback result | Payback period | unrecoverable | |||

| Cost Items | Base Date Cost (NT$) | Year of Occurrence | Present Value (NT$) | Difference | |

|---|---|---|---|---|---|

| Initial invest cost | Greywater | 15,000 | Base Date | 15,000 | 5,000 |

| Traditional | 10,000 | Base Date | 10,000 | ||

| Maintenance and Repair cost | Greywater | 4,600 | annual | 68,436 | 60,998 |

| Traditional | 500 | annual | 7,439 | ||

| Residual value | Greywater | 0 | 20 | 0 | 0 |

| Traditional | 0 | 20 | 0 | ||

| Operation cost | Greywater | 1,200 | annual | 17,853 | 11,902 |

| Traditional | 400 | annual | 5,951 | ||

| Water bill | Greywater | 3,510 | annual (1st–5th year) | 16,075 | 96,468 |

| 5,265 | annual (6th–20th year) | 62,853 | |||

| Traditional | 7,800 | annual (1st–5th year) | 35,722 | ||

| 11,700 | annual (6th–20th year) | 139,674 | |||

| Pump cost | Greywater | 3,500 | 10 | 2,604 | 0 |

| Traditional | 3,500 | 10 | 2,604 | ||

| Present value of greywater system | Total | 182,822 | |||

| Present value of traditional system | Total | 201,390 | |||

| NPV result | NPV > 0 | 18,568 | |||

| SIR result | SIR > 1 | 1.12 | |||

| Payback result | Payback period | Approximately 20 years | |||

| Cost Items | Base Date Cost (NT$) | Year of Occurrence | Present Value (NT$) | Difference | |

|---|---|---|---|---|---|

| Initial invest cost | Greywater | 15,000 | Base Date | 15,000 | 5,000 |

| Traditional | 10,000 | Base Date | 10,000 | ||

| Maintenance and Repair cost | Greywater | 4,600 | annual | 68,436 | 60,998 |

| Traditional | 500 | annual | 7,439 | ||

| Residual value | Greywater | 0 | 20 | 0 | 0 |

| Traditional | 0 | 20 | 0 | ||

| Operation cost | Greywater | 1,200 | annual | 17,853 | 11,902 |

| Traditional | 400 | annual | 5,951 | ||

| Water bill | Greywater | 5,265 | annual (1st–5th year) | 24,112 | 251,737 |

| 7,020 | annual (6th–10th year) | 32,150 | |||

| 17,550 | annual (11th–20th year) | 149,705 | |||

| Traditional | 11,700 | annual (1st–5th year) | 53,583 | ||

| 15,600 | annual (6th–10th year) | 71,443 | |||

| 39,000 | annual (11th–20th year) | 332,678 | |||

| Pump cost | Greywater | 3,500 | 10 | 2,604 | 0 |

| Traditional | 3,500 | 10 | 2,604 | ||

| Present value of greywater system | Total | 309,860 | |||

| Present value of traditional system | Total | 483,698 | |||

| NPV result | NPV > 0 | 173,838 | |||

| SIR result | SIR > 1 | 3.23 | |||

| Payback result | Payback period | Approximately 4 years | |||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juan, Y.-K.; Chen, Y.; Lin, J.-M. Greywater Reuse System Design and Economic Analysis for Residential Buildings in Taiwan. Water 2016, 8, 546. https://doi.org/10.3390/w8110546

Juan Y-K, Chen Y, Lin J-M. Greywater Reuse System Design and Economic Analysis for Residential Buildings in Taiwan. Water. 2016; 8(11):546. https://doi.org/10.3390/w8110546

Chicago/Turabian StyleJuan, Yi-Kai, Yi Chen, and Jing-Ming Lin. 2016. "Greywater Reuse System Design and Economic Analysis for Residential Buildings in Taiwan" Water 8, no. 11: 546. https://doi.org/10.3390/w8110546