A Novel Hybrid Actuator Driven Magnetically in the Bi-Cell PEM Fuel Cell Stack

Abstract

:1. Introduction

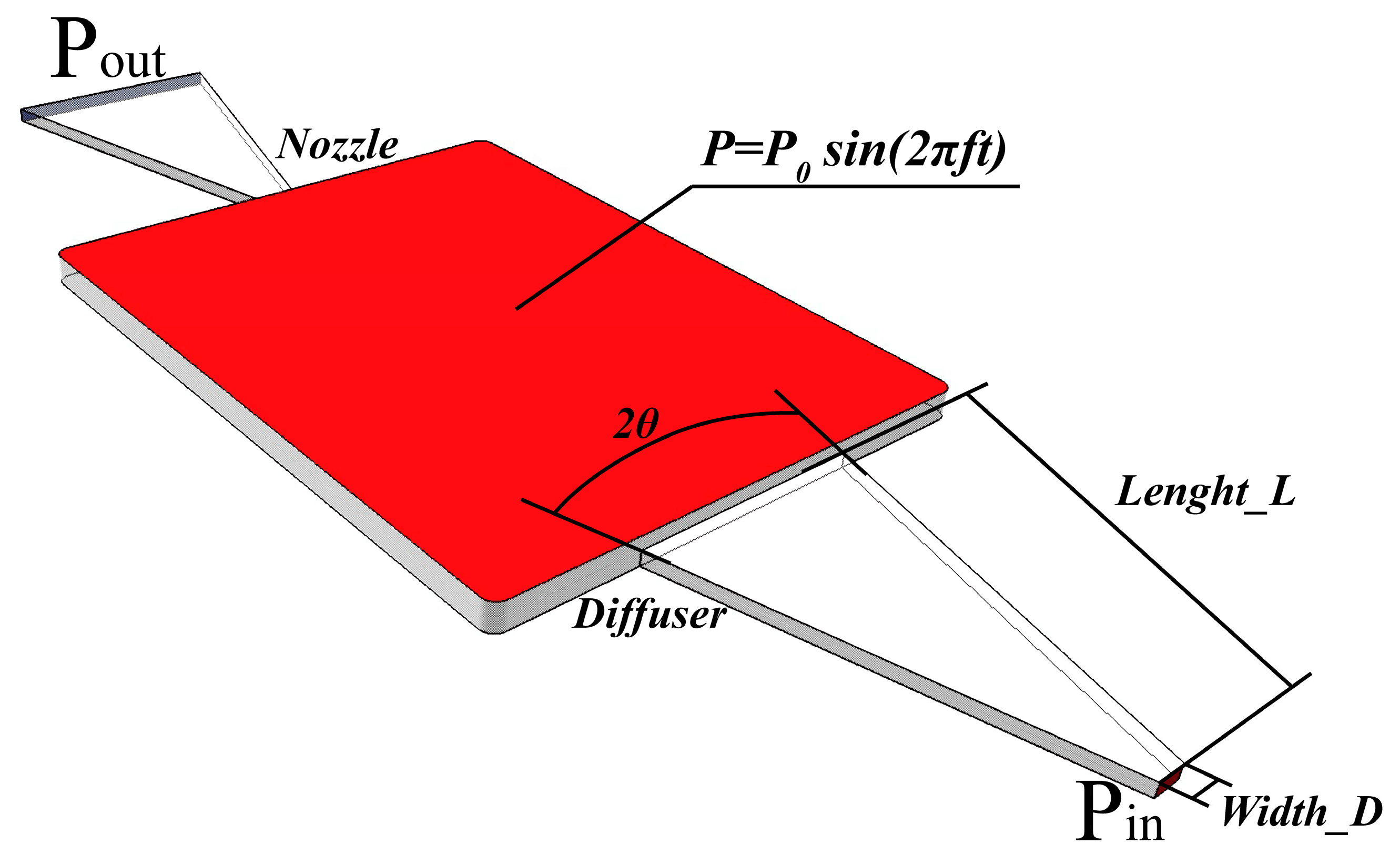

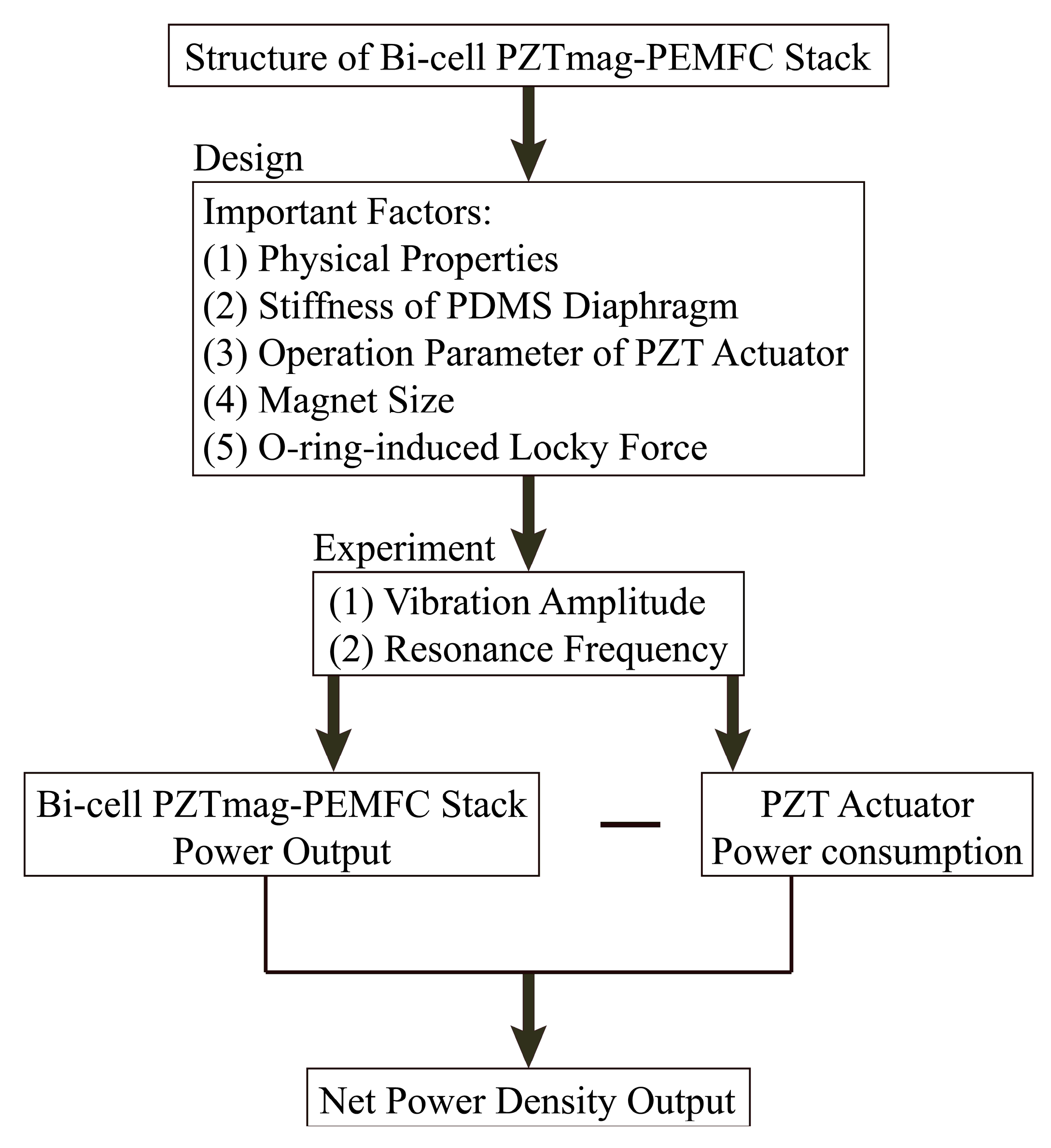

2. Working Principle of Bi-Cell PZTmag–PEMFC Stack

2.1. Analysis of Actuation Mechanism

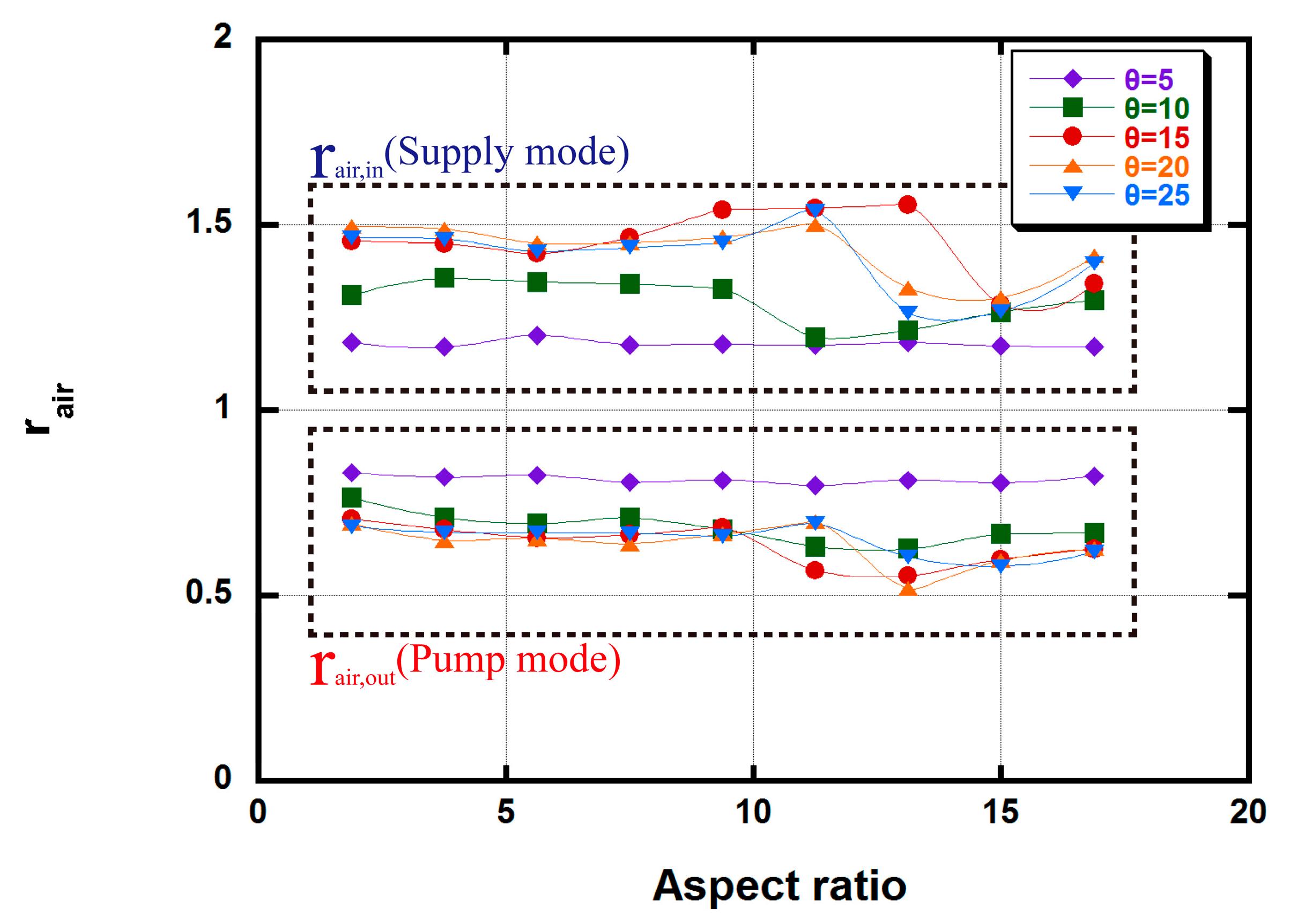

- In the supply mode (Pout > Pin > Pc), when the volume of the cathode chamber increases as the diaphragm moves outward, pressure in the chamber is lower than atmospheric pressure, which induces air flow into it. Moreover, the air pumped into the catalyst layer facilitates an electrochemical reaction in the fuel cell:

- In the pump mode (Pc > Pout > Pin), when the volume of the cathode chamber decreases as the diaphragm moves inward, the chamber pressure is higher than atmospheric pressure, which induces airflow out of the chamber. Water vapor is pumped out of the chamber before it condenses to water, which blocks the MEA, and the air pushed into the catalyst layer facilitates the electrochemical reaction in the fuel cell as well:

- Between the supply mode and the pump mode is the transition mode. In this mode (Pout > Pc > Pin), the chamber pressure is higher than the inlet pressure and lower than the outlet pressure (Pout > Pc > Pin):

- In the supply mode:

- In the transition mode:

- In the pump mode:

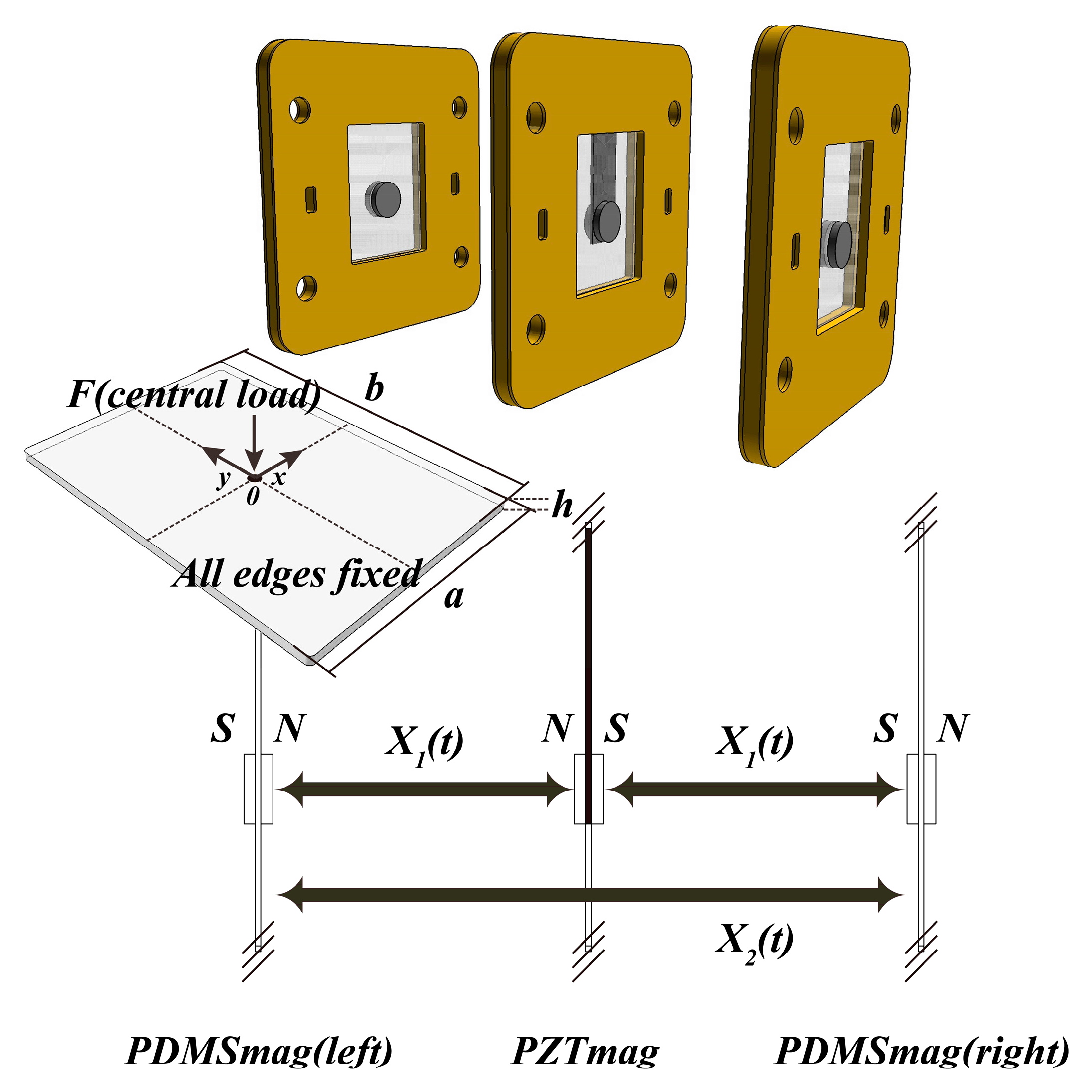

2.2. Influence of Magnetic Force on PDMSmag

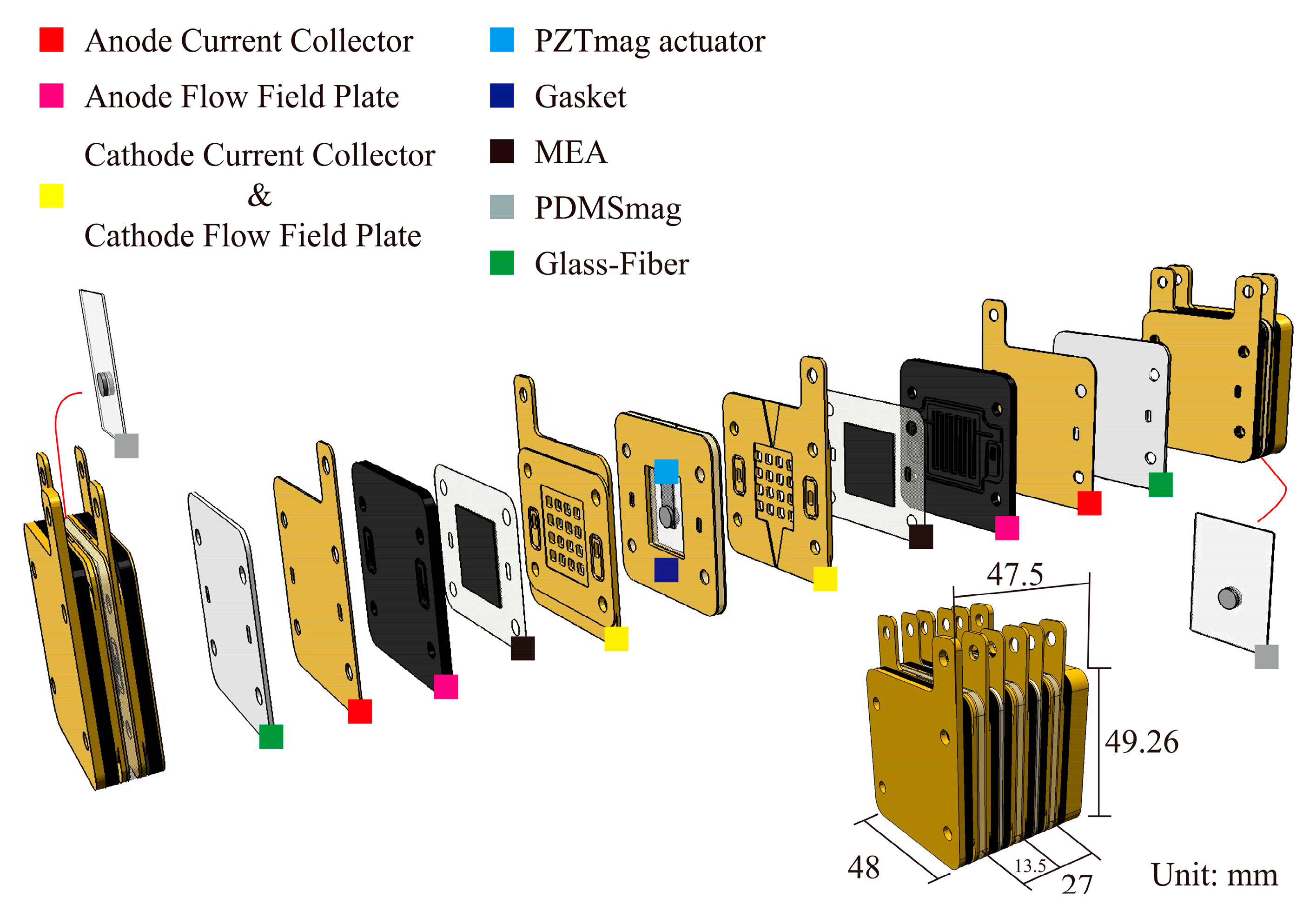

3. Development of Bi-Cell PZTmag–PEMFC Stack

3.1. Geometries

3.2. Manufacture

4. Experimental Set-Up

4.1. Analysis of PZT Actuation

4.2. Analysis of Bi-Cell PZTmag–PEMFC Stack

5. Results and Discussion

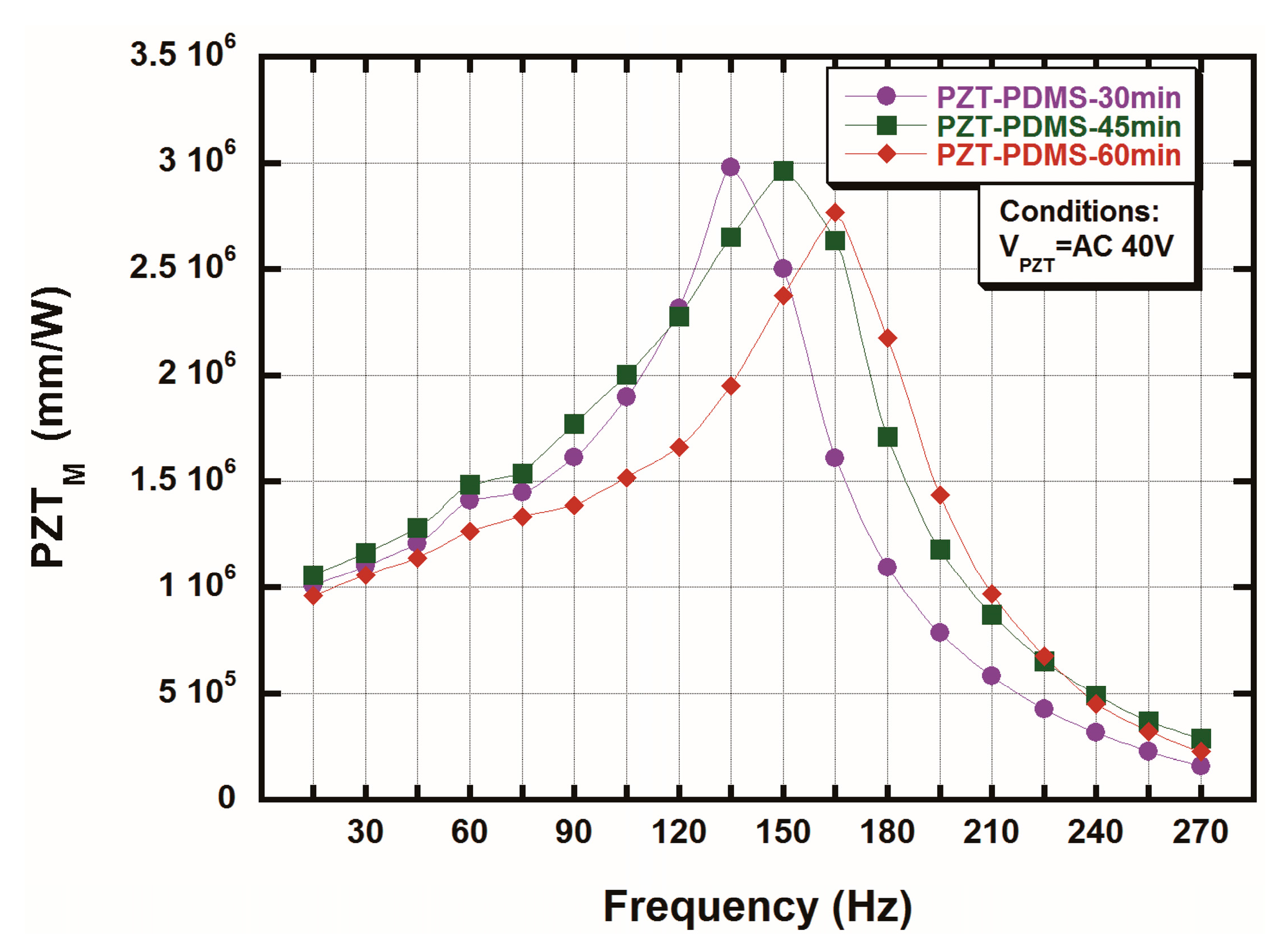

5.1. Influence of PDMS Curing Time on PZT Actuator

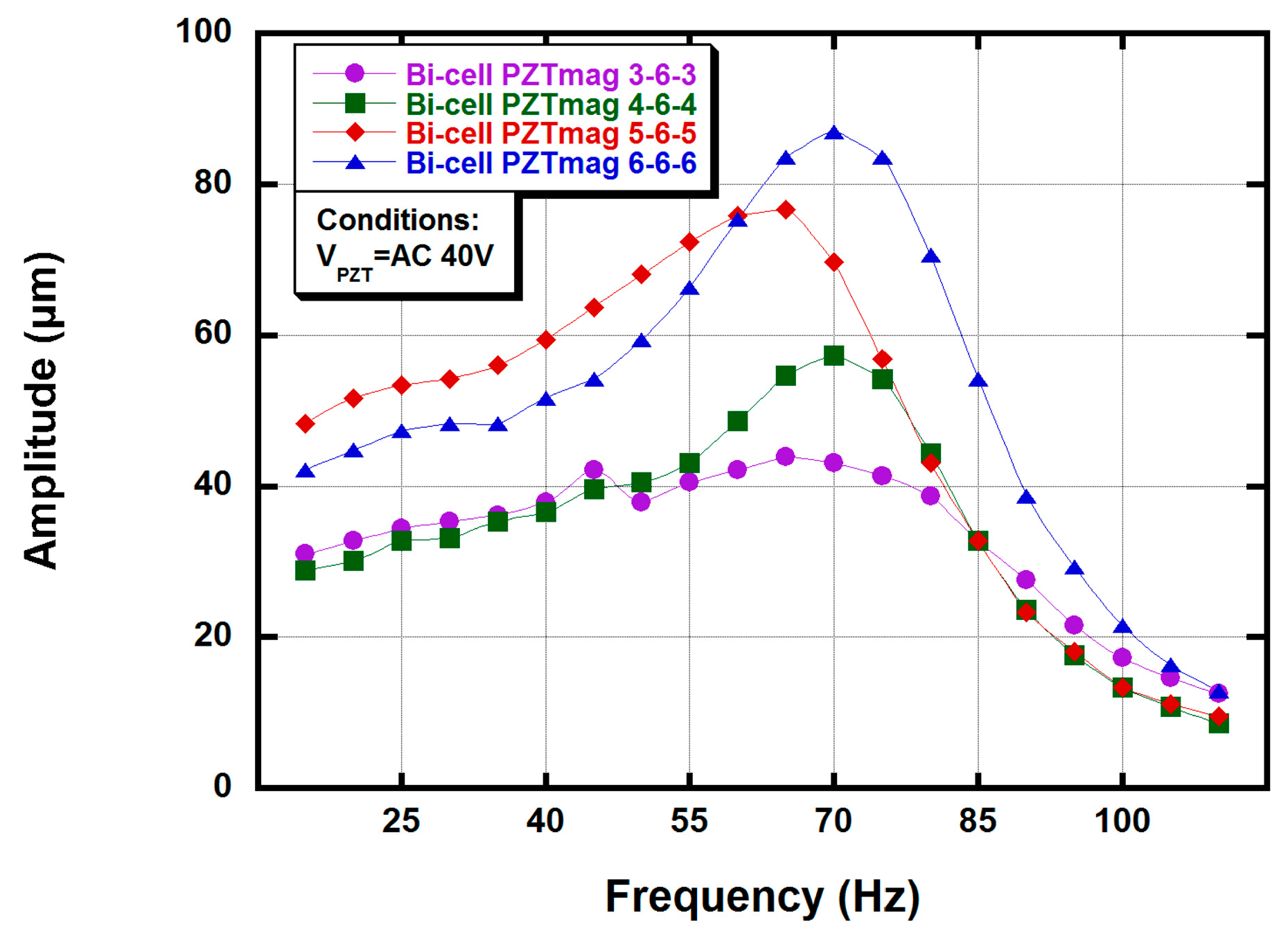

5.2. Influence of Magnet Size on PZTmag Actuator

5.3. Influence of O-Rings within a PZTmag–PEMFC Stack

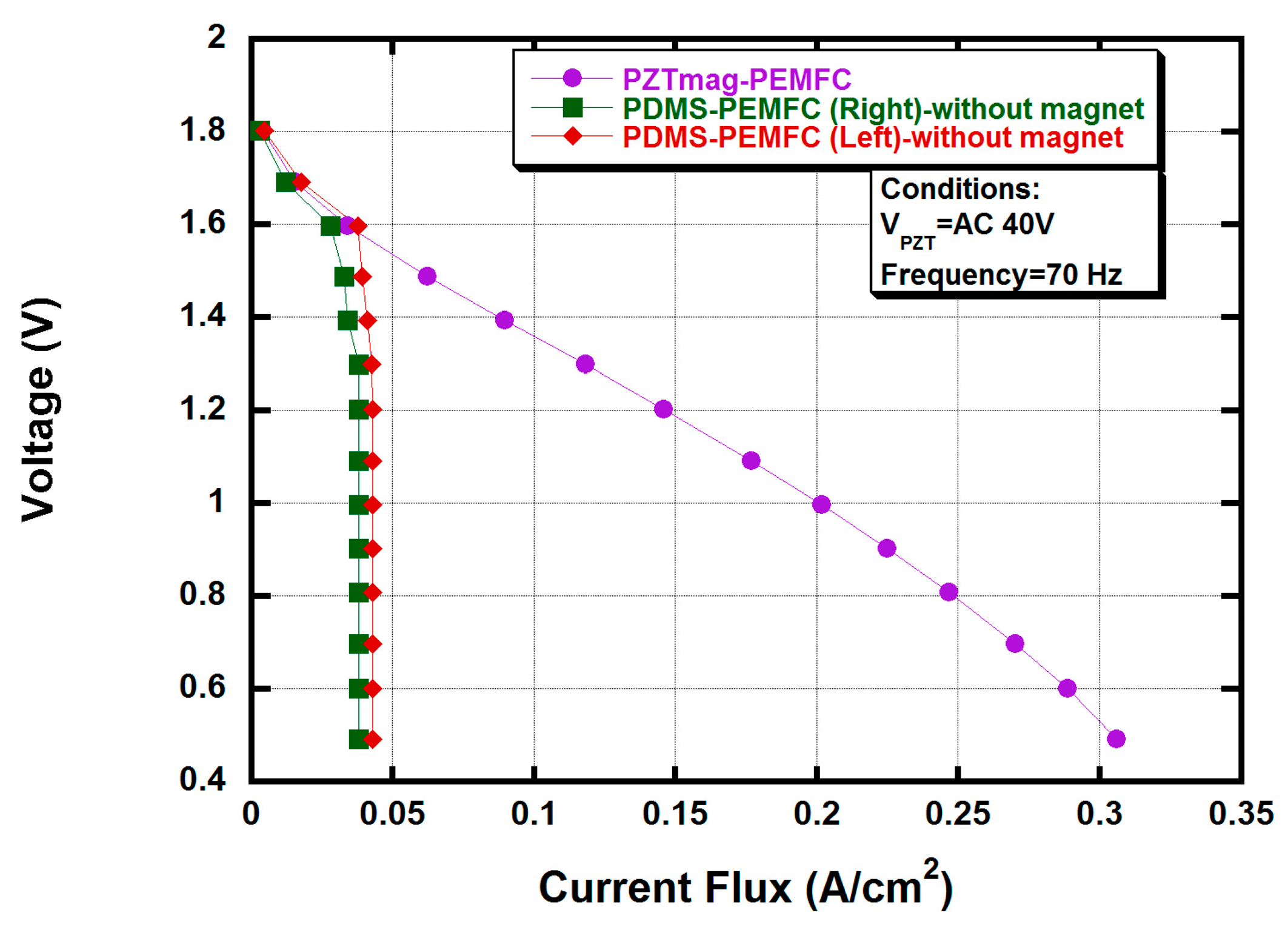

5.4. Performance of Bi-Cell PZTmag–PEMFC Stack

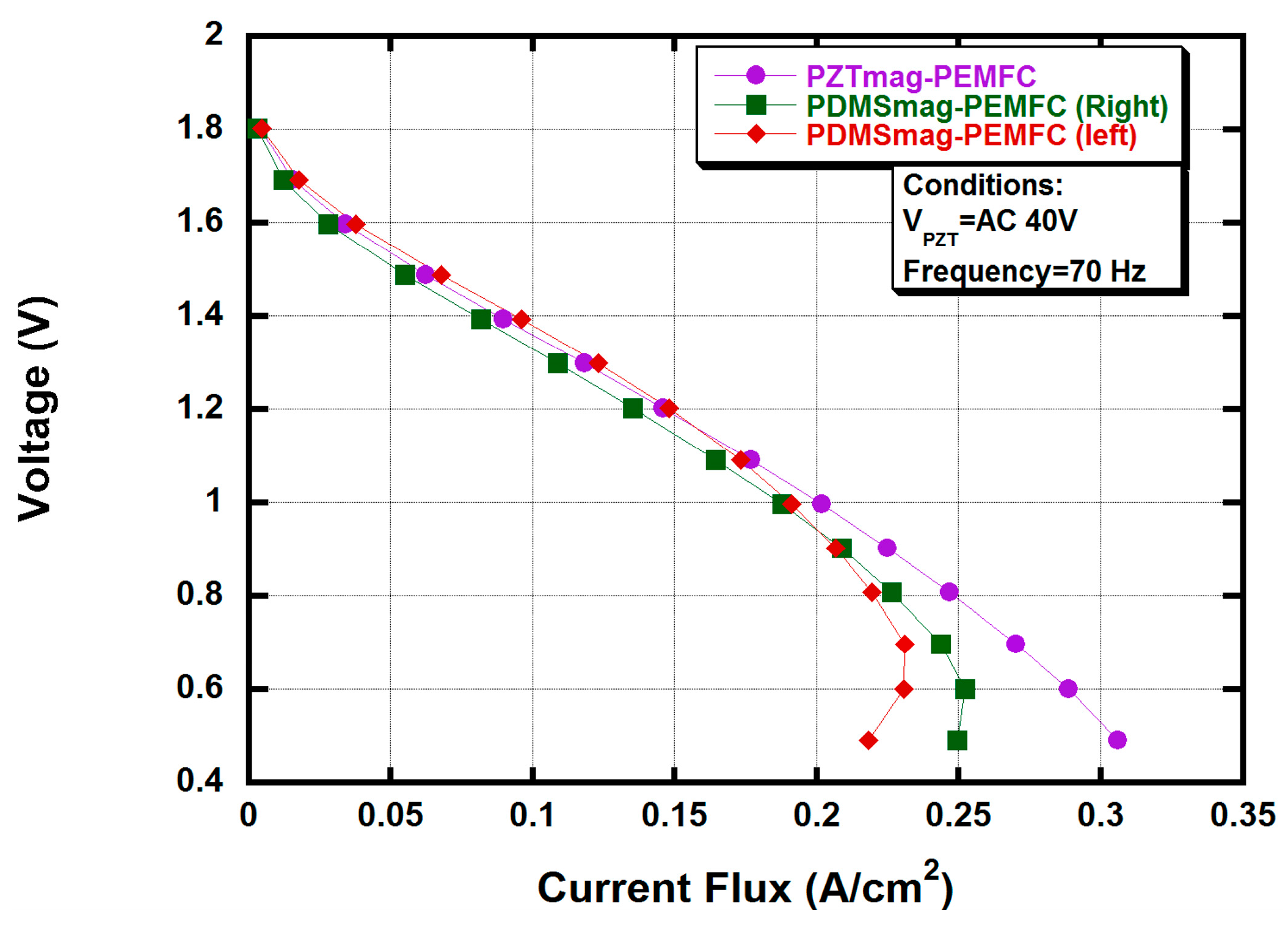

5.4.1. Effect of Each Bi-Cell on PDMS and PZTmag Actuator

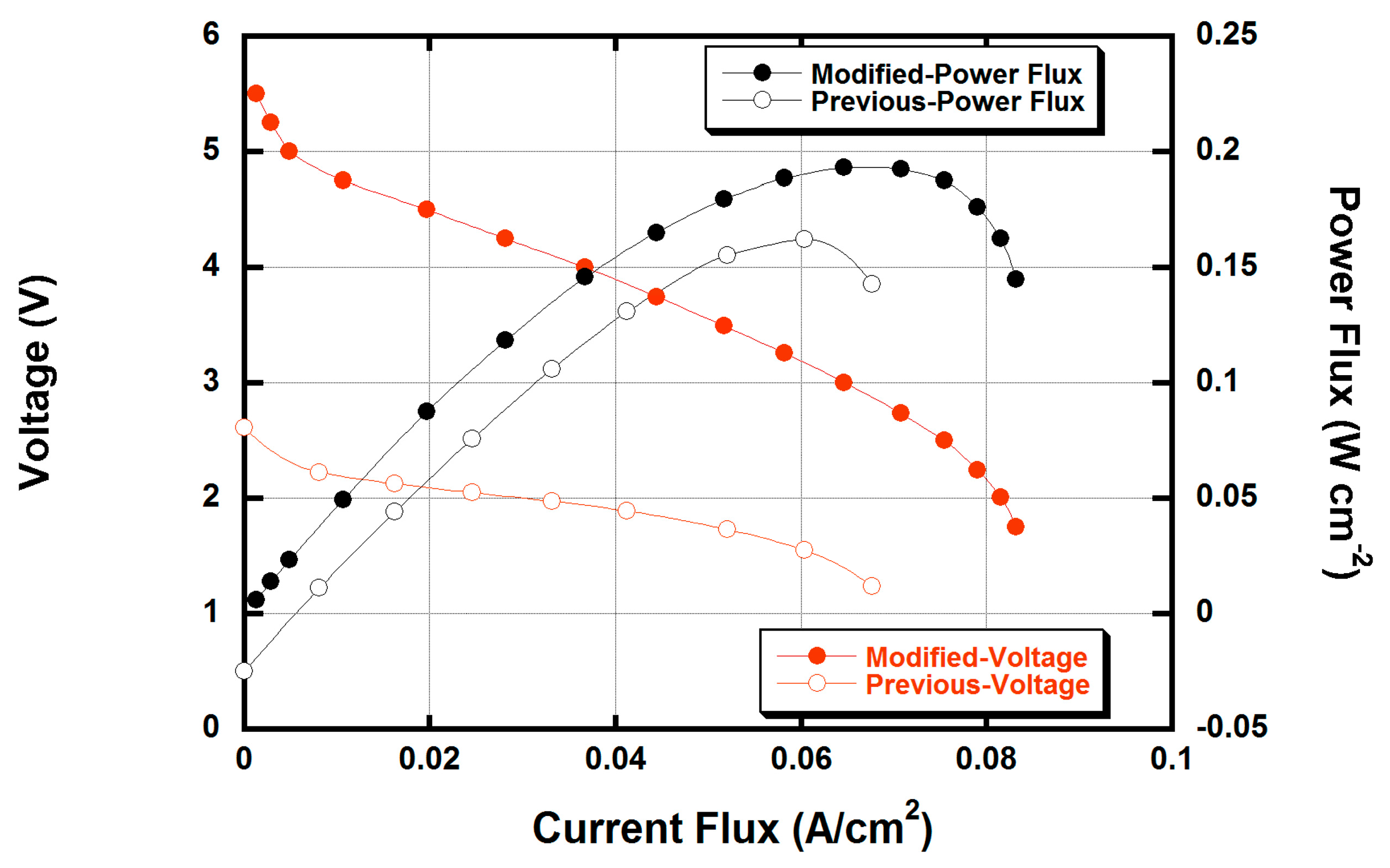

5.4.2. Net Power Output of the Bi-Cell PZTmag–PEMFC Stack

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| APZT | Piezoelectric area (m2) |

| AR | Aspect ratio |

| a | The width of rectangular PDMS (mm) |

| B0 | Magnetic flux density |

| b | The length of rectangular PDMS (mm) |

| C | Conductivity coefficient |

| Cn | Nozzle conductivity coefficient |

| Cd | Diffuser conductivity coefficient |

| D | Channel opening width (mm) |

| E | The Young’s modulus of PDMS |

| F | Force between two cylindrical magnets applied at the center of rectangular PDMS (N) |

| f | Frequency of PZT (Hz) |

| hPDMS | The thickness of PDMS (mm) |

| hmag | The height of magnet (mm) |

| L | Channel path (mm) |

| P | Pressure (N·m−2) |

| Pc | Channel pressure (N·m−2) |

| Pin | Inlet pressure (N·m−2) |

| Pout | Outlet pressure (N·m−2) |

| PZTM | Vibrating amplitude per power consumption for the PZT (mm/W) |

| Q | Airflow rate (m3·s−1) |

| Qin,total | Total flow rate (m3·s−1) |

| Qin,n | Inlet flow rate from the nozzle (m3·s−1) |

| Qout,n | Outlet flow rate from the nozzle (m3·s−1) |

| Qin,d | Inlet flow rate from the diffuser (m3·s−1) |

| Qout,d | Outlet flow rate from the diffuser (m3·s−1) |

| R | Gas constant (J·mol−1·K−1) |

| rair,in | In supply mode, the ratio of air inflow |

| rair,out | In pump mode, the ratio of air outflow |

| r | The radius of magnet |

| t | Time (s) |

| T | Temperature (K) |

| VPZT | Motion equation of the piezoelectric device (m3·s−1) |

| ν | The Poisson’s ratio of PDMS |

| wcenter | Deflection at the center of rectangular PDMS |

| x | Distance between two magnets |

| α | The coefficient decided by b/a |

| Loss coefficient | |

| Λ | Amplitude (μm) |

| θ | Diffuser angle |

| ρ | Density (kg·m−3) |

| μ0 | The permeability of free space |

| ∀ | Volume displacement (m3) |

References

- Li, X.; Sabir, I. Review of bipolar plates in pem fuel cells: Flow-field designs. Int. J. Hydrog. Energy 2005, 30, 359–371. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H. Flow-field designs of bipolar plates in pem fuel cells: Theory and applications. Fuel Cells 2012, 12, 989–1003. [Google Scholar] [CrossRef]

- Böhm, S.; Olthuis, W.; Bergveld, P. A plastic micropump constructed with conventional techniques and materials. Sens. Actuators A Phys. 1999, 77, 223–228. [Google Scholar] [CrossRef]

- Yamahata, C.; Lotto, C.; Al-Assaf, E.; Gijs, M.A.M. A pmma valveless micropump using electromagnetic actuation. Microfluid. Nanofluid. 2005, 1, 197–207. [Google Scholar] [CrossRef]

- Olsson, A.; Stemme, G.; Stemme, E. Diffuser-element design investigation for valve-less pumps. Sens. Actuators A Phys. 1996, 57, 137–143. [Google Scholar] [CrossRef]

- Stemme, E.; Stemme, G. A valveless diffuser/nozzle-based fluid pump. Sens. Actuators A Phys. 1993, 39, 159–167. [Google Scholar] [CrossRef]

- Wang, B.; Chu, X.; Li, E.; Li, L. Simulations and analysis of a piezoelectric micropump. Ultrasonics 2006, 44, e643–e646. [Google Scholar] [CrossRef] [PubMed]

- Benard, W.L.; Kahn, H.; Heuer, A.H.; Huff, M.A. Thin-film shape-memory alloy actuated micropumps. J. Microelectromech. Syst. 1998, 7, 245–251. [Google Scholar] [CrossRef]

- Olivier, F.; Isabelle, D.; Emmanuel, S. Analytical static modelling and optimization of electrostatic micropumps. J. Micromech. Microeng. 1997, 7, 183. [Google Scholar]

- Wego, A.; Glock, H.W.; Pagel, L.; Richter, S. Investigations on thermo-pneumatic volume actuators based on pcb technology. Sens. Actuators A Phys. 2001, 93, 95–102. [Google Scholar] [CrossRef]

- Kim, E.G.; Oh, J.G.; Choi, B. A Study on the development of a continuous peristaltic micropump using magnetic fluids. Sens. Actuators A Phys. 2006, 128, 43–51. [Google Scholar] [CrossRef]

- Lemoff, A.V.; Lee, A.P. An ac magnetohydrodynamic micropump. Sens. Actuators B Chem. 2000, 63, 178–185. [Google Scholar] [CrossRef]

- Zhong, J.; Yi, M.; Bau, H.H. Magneto hydrodynamic (mhd) pump fabricated with ceramic tapes. Sens. Actuators A Phys. 2002, 96, 59–66. [Google Scholar] [CrossRef]

- Ma, H.K.; Huang, S.H.; Chen, B.R.; Cheng, L.W. Numerical study of a novel micro-diaphragm flow channel with piezoelectric device for proton exchange membrane fuel cells. J. Power Sources 2008, 180, 402–409. [Google Scholar] [CrossRef]

- Ma, H.K.; Huang, S.H.; Wang, J.S.; Hou, C.G.; Yu, C.C.; Chen, B.R. Experimental study of a novel piezoelectric proton exchange membrane fuel cell with nozzle and diffuser. J. Power Sources 2010, 195, 1393–1400. [Google Scholar] [CrossRef]

- Ma, H.K.; Cheng, H.M.; Cheng, W.Y.; Fang, F.M.; Luo, W.F. Development of a piezoelectric proton exchange membrane fuel cell stack (pzt-stack). J. Power Sources 2013, 240, 314–322. [Google Scholar] [CrossRef]

- Fuard, D.; Tzvetkova-Chevolleau, T.; Decossas, S.; Tracqui, P.; Schiavone, P. Optimization of Poly-di-Methyl-Siloxane (pdms) substrates for studying cellular adhesion and motility. Microelectron. Eng. 2008, 85, 1289–1293. [Google Scholar] [CrossRef]

- Ma, H.K.; Su, H.C.; Luo, W.F. Investigation of a piezoelectric fan cooling system with multiple magnetic fans. Sens. Actuators A Phys. 2013, 189, 356–363. [Google Scholar] [CrossRef]

- Ullmann, A. The piezoelectric valve-less pump—Performance enhancement analysis. Sens. Actuators A Phys. 1998, 69, 97–105. [Google Scholar] [CrossRef]

- Tsui, Y.Y.; Lu, S.L. Evaluation of the performance of a valveless micropump by cfd and lumped-system analyses. Sens. Actuators A Phys. 2008, 148, 138–148. [Google Scholar] [CrossRef]

- Timoshenko, S.; Woinowsky-Krieger, S. Theory of Plates and Shells; McGraw-Hill: New York, NY, USA, 1959. [Google Scholar]

- Furlani, E.P. Chapter 3—Field Analysis. In Permanent Magnet and Electromechanical Devices; Academic Press: San Diego, CA, USA, 2001; pp. 97–205. [Google Scholar]

- Mark, J.E. Polymer Data Handbook; Oxford University Press: Oxford, UK, 1999. [Google Scholar]

| Serial Number | PDMSmag (Left) | PZTmag Actuator | PDMSmag (Right) |

|---|---|---|---|

| Arrangement-A | 6.0 mm | 6.0 mm | 6.0 mm |

| Arrangement-B | 5.0 mm | 6.0 mm | 5.0 mm |

| Arrangement-C | 4.0 mm | 6.0 mm | 4.0 mm |

| Arrangement-D | 3.0 mm | 6.0 mm | 3.0 mm |

| Serial Number | Curing Time at 100 °C | Young’s Modulus | Poisson’s Ratio [23] |

|---|---|---|---|

| PDMS-A | 30 min | 1250 kPa | 0.5 |

| PDMS-B | 45 min | 1375 kPa | 0.5 |

| PDMS-C | 60 min | 1625 kPa | 0.5 |

| Serial Number | Amplitude/μm | Power Consumption/W | Frequency/Hz |

|---|---|---|---|

| PZT–PDMS-30 | 1602 | 0.073 | 135 |

| PZT–PDMS-45 | 1581 | 0.080 | 150 |

| PZT–PDMS-60 | 1559 | 0.093 | 165 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Hsu, Y.; Hsu, P. A Novel Hybrid Actuator Driven Magnetically in the Bi-Cell PEM Fuel Cell Stack. Metals 2017, 7, 453. https://doi.org/10.3390/met7110453

Ma H, Hsu Y, Hsu P. A Novel Hybrid Actuator Driven Magnetically in the Bi-Cell PEM Fuel Cell Stack. Metals. 2017; 7(11):453. https://doi.org/10.3390/met7110453

Chicago/Turabian StyleMa, Hsiaokang, Yuanlung Hsu, and Poching Hsu. 2017. "A Novel Hybrid Actuator Driven Magnetically in the Bi-Cell PEM Fuel Cell Stack" Metals 7, no. 11: 453. https://doi.org/10.3390/met7110453