Simulations of Fine-Meshed Biaxial Tests with Barodesy

Abstract

:1. Introduction

2. Material and Methods

2.1. Constitutive Model—Barodesy

2.1.1. Critical State Soil Mechanics

- A critical stress state locus [11,12], which is a line, the Critical State Line (CSL), in the -q plot:with for axisymmetric triaxial compression, is the critical friction angle. In three dimensional stress space, the critical stress locus of barodesy practically coincides with the Matsuoka–Nakai failure criterion [11], see Figure 1.

- A stress dependent critical void ratio (CSL from [13]) in the -e plot, in order to distinguish between normally to slightly overconsolidated soil () and highly overconsolidated soil ():

- The isotropic normal compression line (NCL) from [14], in order to define the loosest possible packing:kPa is a reference stress, N and are soil parameters from Critical State Soil Mechanics.

2.1.2. Barotropy and Pyknotropy

2.2. Biaxial Tests

2.2.1. Initial Conditions

2.2.2. Evaluation of Stress Paths in the Deviatoric Plane

2.2.3. Evaluation of the Inclination of Final Shear Band

3. Results

3.1. Early Shear Band Development

3.2. Stress Paths in the Deviatoric Plane

3.3. Inclination of the Final Shear Band

4. Discussion and Conclusions

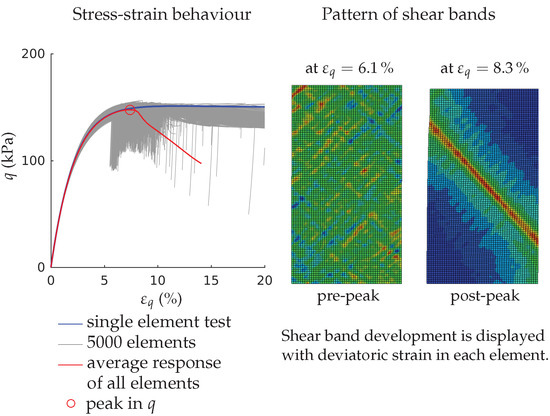

- Inhomogeneities in the samples density may be one cause for early shear bands development. Finite element simulations of fine-meshed biaxial test with the material model barodesy show this effect: In barodesy, the density is considered with the void ratio as state variable. A randomly distributed void ratio results in a scatter of dilatancy. Thus, pre-peak patterns of shear bands develop from the very beginning of the biaxial tests.

- The stress-strain behaviour of a biaxial test—in particular the post-peak behaviour—cannot be modelled with a single element test. In our simulations, the number of elements has been chosen in a way that the final shear band thickness is in the experimental confirmed range. A realistic estimation of the shear band thickness results in a realistic average response of the stress-strain behaviour, due to the pronounced localization.

- The stress paths in the deviatoric plane show reasonable results: The Lode angles of the stress paths for the OCRs 1.5, 3 and 6 are in the range of , which is experimentally confirmed for plane strain failure.

- The maximum deviatoric stress in the element test is higher than the maximum deviatoric stress of the average response of the fine-meshed test. The lower the initial overconsolidation ratio is, the larger is the deviation in peak strength.

- The inclination of the final shear band is dependent on the overconsolidation ratio: The higher the overconsolidation ratio is, the larger is the inclination of the final shear band.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CSL | Critical State Line |

| NCL | Normal Compression Line |

| OCR | OverConsolidation Ratio |

| Cauchy stress, stresses are considered as effective ones. | |

| stretching tensor; is the symmetric part of the velocity gradient. | |

| principal stresses, convention of mechanics, is defined negative for compression | |

| Tensors are written in bold capital letters, e.g., | |

| mean effective stress | |

| q | deviatoric stress |

| volumetric strain | |

| deviatoric strain with . | |

| For plane strain conditions with , | |

| mobilized friction angle |

Appendix A. Equations of Barodesy

References

- Herle, I. On basic features of constitutive models for geomaterials. J. Theor. Appl. Mech. 2008, 38, 61–80. [Google Scholar]

- Tejchman, J.; Herle, I.; Wehr, J. FE-studies on the influence of initial void ratio, pressure level and mean grain diameter on shear localization. Int. J. Numer. Anal. Methods Geomech. 1999, 23, 2045–2074. [Google Scholar] [CrossRef]

- Schneider-Muntau, B.; Chen, C.H.; Bathaeian, S.M.I. Simulation of shear bands with Soft PARticle Code (SPARC) and FE. GEM Int. J. Geomath. 2017, 8, 135–151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Medicus, G.; Schneider-Muntau, B.; Kolymbas, D. Second-order work in barodesy. Acta Geotech. 2018. [Google Scholar] [CrossRef]

- Desrues, J.; Andò, E.; Bésuelle, P.; Viggiani, G.; Debove, L.; Charrier, P.; Toni, J.B. Localisation Precursors in Geomaterials? In Proceedings of the Bifurcation and Degradation of Geomaterials with Engineering Applications, IWBDG 2017, Limassol, Cyprus, 21–25 May 2017; Papamichos, E., Papanastasiou, P., Pasternak, E., Dyskin, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 3–10. [Google Scholar] [CrossRef]

- Medicus, G.; Fellin, W. An improved version of barodesy for clay. Acta Geotech. 2017, 12, 365–376. [Google Scholar] [CrossRef]

- Nübel, K. Experimental and Numerical Investigation of Shear Localization in Granular Material. Ph.D. Thesis, Veröffentlichungen des Institutes für Bodenmechanik und Felsmechanik der Universität Karlsruhe, Karlsruhe, Germany, 2002. [Google Scholar]

- Medicus, G.; Schneider-Muntau, B. Stress-dilatancy in barodesy. In Book of Extended Abstracts, 4th International Symposium on Computational Geomechanics, ComGeo IV, Assisi, Italy, 2–4 May 2018; International Centre for Computational Engineering: Rhodes, Greece; Swansea, UK, 2018; pp. 22–23. [Google Scholar]

- Von Wolffersdorff, P.A. A hypoplastic relation for granular materials with a predefined limit state surface. Mech. Cohesive-Frict. Mater. 1996, 1, 251–271. [Google Scholar] [CrossRef]

- Mašín, D. Clay hypoplasticity with explicitly defined asymptotic states. Acta Geotech. 2013, 8, 481–496. [Google Scholar] [CrossRef]

- Fellin, W.; Ostermann, A. The critical state behaviour of barodesy compared with the Matsuoka–Nakai failure criterion. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 299–308. [Google Scholar] [CrossRef]

- Medicus, G.; Kolymbas, D.; Fellin, W. Proportional stress and strain paths in barodesy. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 509–522. [Google Scholar] [CrossRef]

- Mašín, D. A hypoplastic constitutive model for clays. Int. J. Numer. Anal. Methods Geomech. 2005, 29, 311–336. [Google Scholar] [CrossRef]

- Butterfield, R. A natural compression law for soils (an advance on e-logp′). Géotechnique 1979, 29, 469–480. [Google Scholar] [CrossRef]

- Kolymbas, D. Sand as an archetypical natural solid. In Mechanics of Natural Solids; Kolymbas, D., Viggiani, G., Eds.; Springer: Berlin, Germany, 2009; pp. 1–26. [Google Scholar]

- Kolymbas, D. Introduction to barodesy. Géotechnique 2015, 65, 52–65. [Google Scholar] [CrossRef]

- Kolymbas, D.; Medicus, G. Genealogy of hypoplasticity and barodesy. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 2532–2550. [Google Scholar] [CrossRef]

- Medicus, G. Barodesy and Its Application for Clay. Ph.D. Thesis, University of Innsbruck, Innsbruck, Austria, 2014. [Google Scholar]

- Medicus, G.; Fellin, W.; Schranz, F. Konzepte der Barodesie. Bautechnik 2018, 95, 620–638. [Google Scholar] [CrossRef]

- D’Ignazio, M.; Länsivaara, T. Shear bands in soft clays: Strain-softening behaviour in finite element method. Rakenteiden Mekaniikka 2015, 48, 83–98. [Google Scholar]

- Jostad, H.; Andresen, L.; Thakur, V. Calculation of shear band thickness in sensitive clays. In Proceedings of the 6th European Conference on Numerical Methods in Geotechnical Engineering, Graz, Austria, 6–8 September 2006; pp. 27–32. [Google Scholar]

- Pouragha, M.; Wan, R. Micromechanical study of instability in granular materials using μ-GM constitutive model. In Book of Extended Abstracts, 4th International Symposium on Computational Geomechanics, ComGeo IV, Assisi, Italy, 2–4 May 2018; International Centre for Computational Engineering: Rhodes, Greece; Swansea, UK, 2018; pp. 51–52. [Google Scholar]

- Gylland, A.S.; Jostad, H.P.; Nordal, S. Experimental study of strain localization in sensitive clays. Acta Geotech. 2014, 9, 227–240. [Google Scholar] [CrossRef]

- abaqus FEA 6.14, Simulia, Dassault Systèmes. 78140 Vélizy-Villacoublay, France, 2018. Available online: https://www.3ds.com/de/produkte-und-services/simulia/produkte/abaqus/ (accessed on 28 November 2018).

- Gudehus, G.; Amorosi, A.; Gens, A.; Herle, I.; Kolymbas, D.; Mašín, D.; Muir Wood, D.; Nova, R.; Niemunis, A.; Pastor, M.; et al. The soilmodels.info project. Int. J. Numer. Anal. Methods Geomech. 2008, 32, 1571–1572. [Google Scholar] [CrossRef]

- Bode, M.; Schranz, F.; Medicus, G.; Fellin, W. Vergleich unterschiedlicher Materialmodelle an einer Aushubsimulation. Geotechnik 2018, in press. [Google Scholar]

- Schneider-Muntau, B.; Medicus, G.; Fellin, W. Strength reduction method in Barodesy. Comput. Geotech. 2018, 95, 57–67. [Google Scholar] [CrossRef]

- Nakai, T. Modeling of soil behaviour based on tij concept. In Proceedings of the 13th ARCSMGE, Kolkata, India, 10 December 2007; Volume 2, pp. 69–89. [Google Scholar]

- Muir Wood, D. Soil Behaviour and Critical State Soil Mechanics; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Alshibli, K.A.; Akbas, I.S. Strain localization in clay: Plane strain versus triaxial loading conditions. Geotech. Geol. Eng. 2006, 25, 45. [Google Scholar] [CrossRef]

- Roscoe, K.H. The Influence of Strains in Soil Mechanics. Géotechnique 1970, 20, 129–170. [Google Scholar] [CrossRef]

- Arthur, J.R.F.; Dunstan, T.; Al-Ani, Q.A.J.L.; Assadi, A. Plastic deformation and failure in granular media. Géotechnique 1977, 27, 53–74. [Google Scholar] [CrossRef]

- Desrues, J.; Zweschper, B.; Vermeer, P. Database for Tests on Hostun RF Sand; Technical Report; Institute for Geotechnical Engineering, University of Stuttgart: Stuttgart, Germany, 2000. [Google Scholar]

| Material | N | Source | |||

|---|---|---|---|---|---|

| Weald clay | 24 | 0.8 | 0.059 | 0.018 | Mašín [10] |

| OCR | Mean Value | Standard Deviation | ||

|---|---|---|---|---|

| 1.5 | 0.656 | 0.005 | 100 kPa | |

| 3 | 0.590 | 0.005 | 100 kPa | |

| 6 | 0.526 | 0.005 | 100 kPa | |

| 54 | 0.340 | 0.005 | 100 kPa |

| OCR | Difference in q | Difference in | ||||

|---|---|---|---|---|---|---|

| Element Test | FE | Element Test | FE | |||

| 1.5 | kPa | kPa | ||||

| 3 | kPa | kPa | ||||

| 6 | kPa | kPa | ||||

| 54 | kPa | kPa | ||||

| OCR | ||||||

|---|---|---|---|---|---|---|

| 6 | ||||||

| 54 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medicus, G.; Schneider-Muntau, B. Simulations of Fine-Meshed Biaxial Tests with Barodesy. Geosciences 2019, 9, 20. https://doi.org/10.3390/geosciences9010020

Medicus G, Schneider-Muntau B. Simulations of Fine-Meshed Biaxial Tests with Barodesy. Geosciences. 2019; 9(1):20. https://doi.org/10.3390/geosciences9010020

Chicago/Turabian StyleMedicus, Gertraud, and Barbara Schneider-Muntau. 2019. "Simulations of Fine-Meshed Biaxial Tests with Barodesy" Geosciences 9, no. 1: 20. https://doi.org/10.3390/geosciences9010020