Fiber Optic Sensing for Geomechanical Monitoring: (1)-Distributed Strain Measurements of Two Sandstones under Hydrostatic Confining and Pore Pressure Conditions

Abstract

:Featured Application

Abstract

1. Introduction

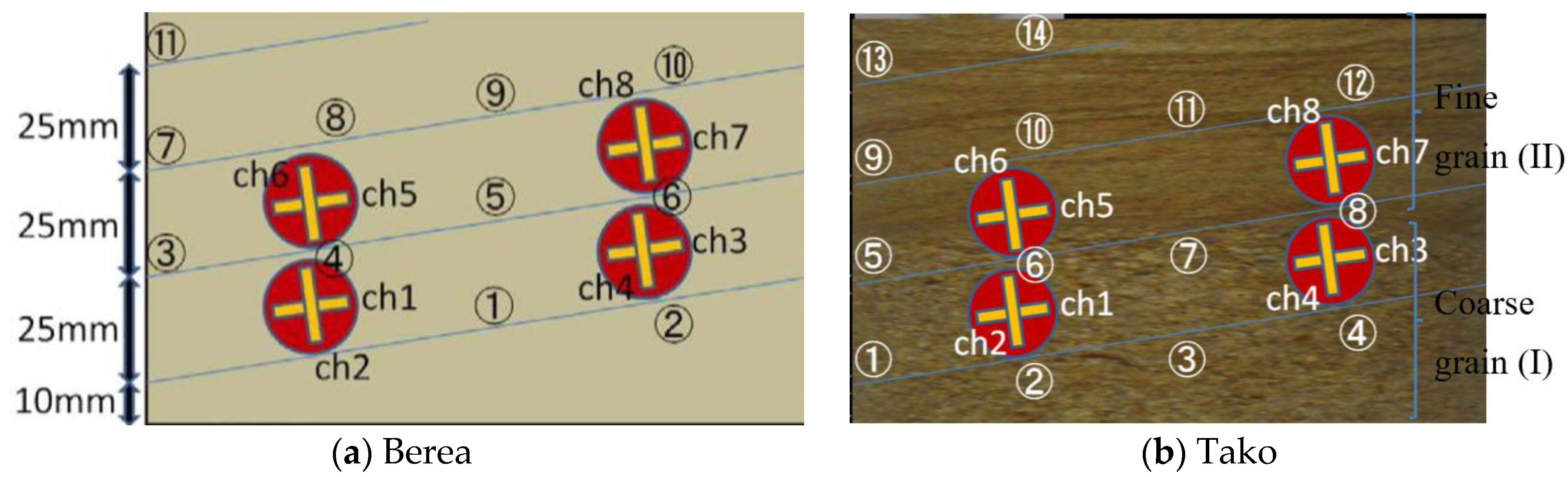

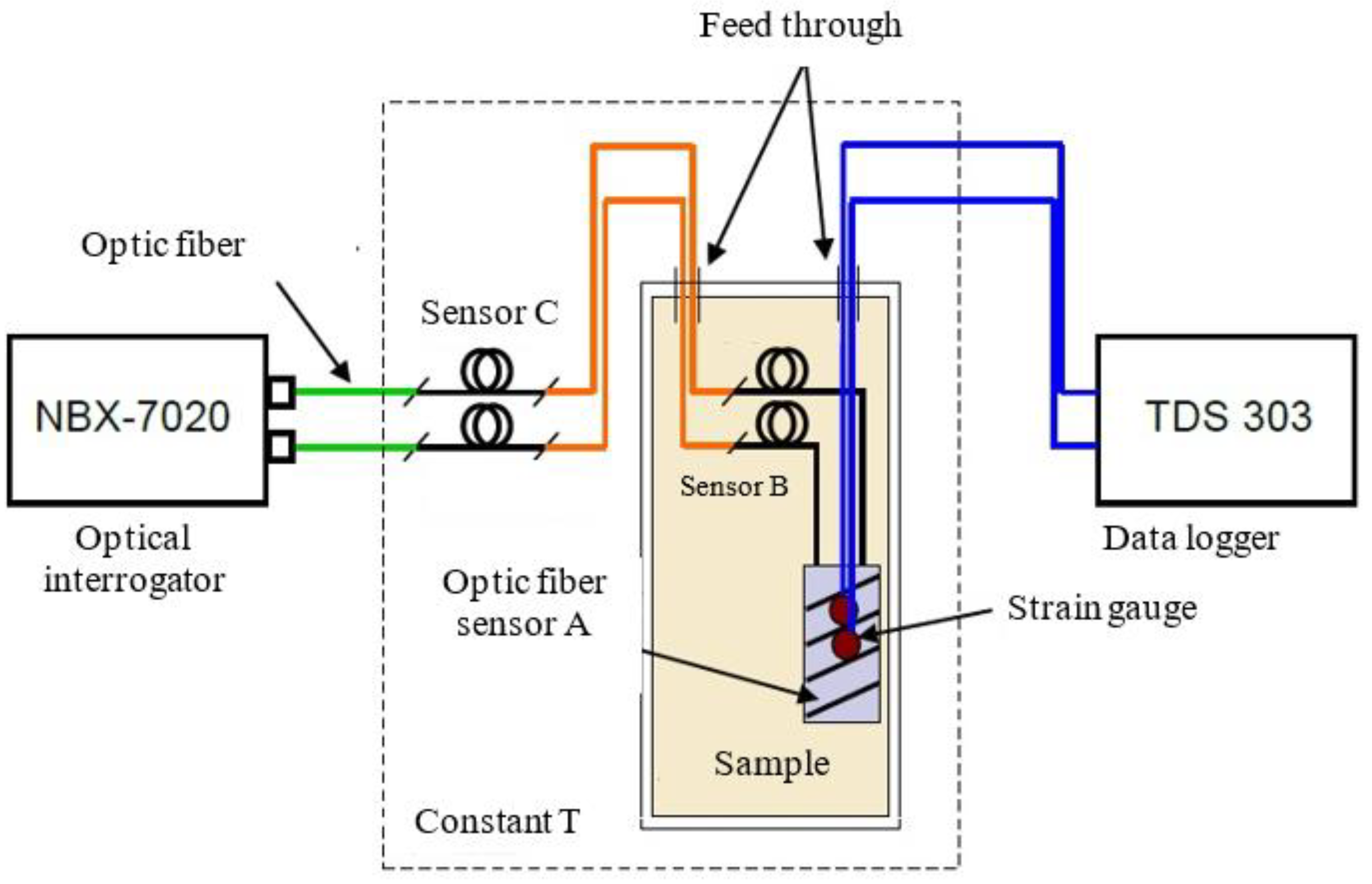

2. Experimental Set Up and Test Procedure

2.1. Experimental Setup

2.2. Experimental Procedure

- Measurements while increasing confining (oil) pressure

- After placing the sandstone sample into the high-pressure vessel, the system is vacuumed to remove residual air from the sample and the pure water injection line.

- Increase the oil pressure inside the high-pressure vessel to 0.5 MPa and monitor the strain readings until they stabilize (no change for 30 minutes). Then set the strain readings to zero (initialization).

- Perform Brillouin and Rayleigh frequency shift measurement respectively.

- Increase the oil pressure to 2 MPa, then incrementally up by 2 MPa to 12 MPa. After stabilization at each step, perform the frequency shift measurement respectively.

- Measurements while increasing pore pressure

- The oil pressure in the high-pressure vessel is maintained at 12 MPa.

- Set the flow rate of pure water syringe pump to 0.05 mL/min and a target pressure of 0.5 MPa, then put it in run state and open the water valve. When the water injection pressure is stabilized at 0.5 MPa, the strain readings are initialized (set to zero), and Brillouin and Rayleigh frequency shift measurements are performed respectively.

- Increase the water injection pressure to 2 MPa, then incrementally up by 2 MPa to 10 MPa at injection rate of is 0.05 mL/min. At each pore pressure step, take strain readings and perform Brillouin and Rayleigh frequency shift measurements when the injection pressure is stabilized.

3. Strain Gauges and Distributed Optic Fiber Strain Measurements

3.1. Berea Sandstone—Increasing Confining Pressure

3.1.1. Strain Gauge Readings

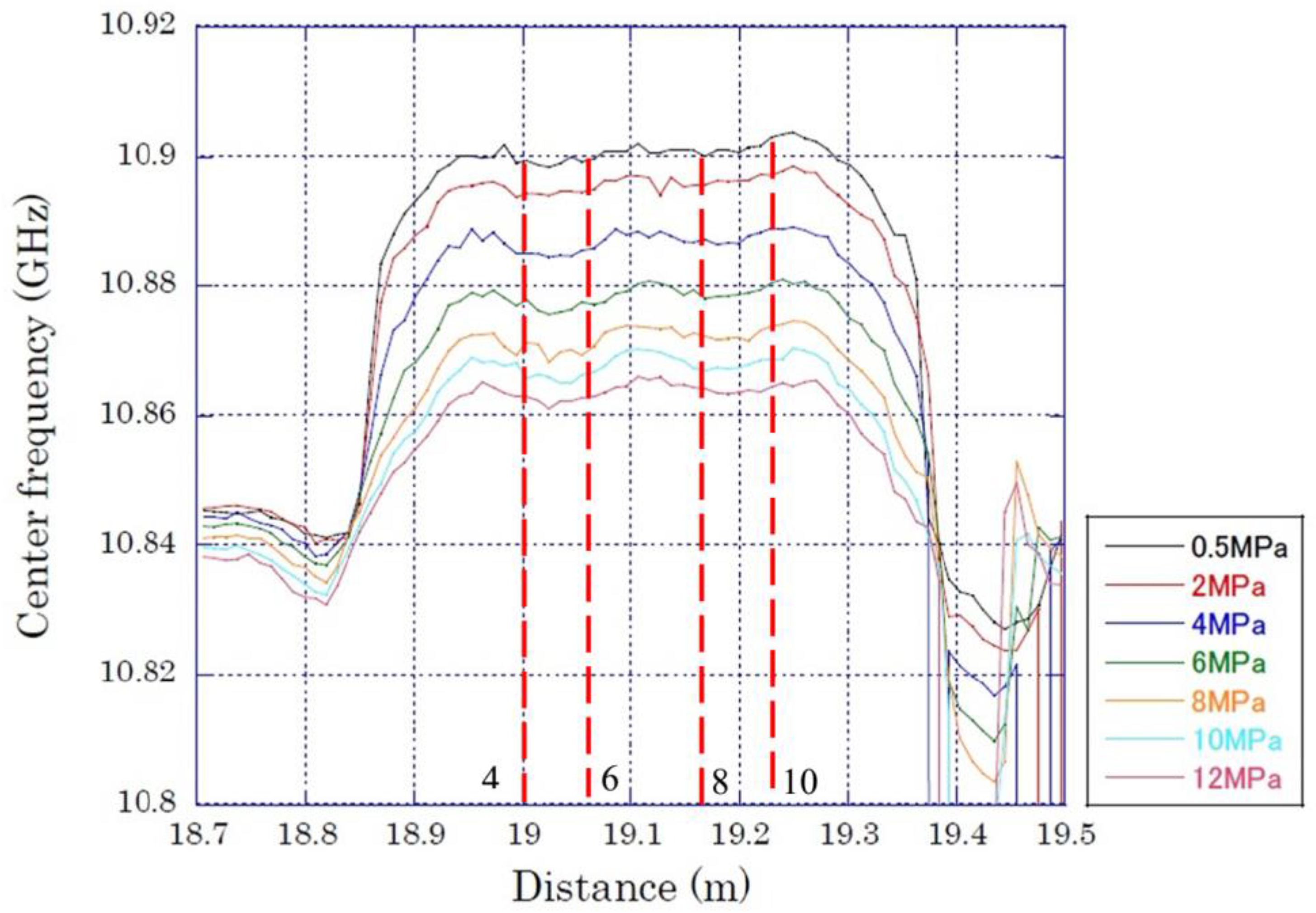

3.1.2. Optic Fiber Measurement—Rayleigh Frequency Shift

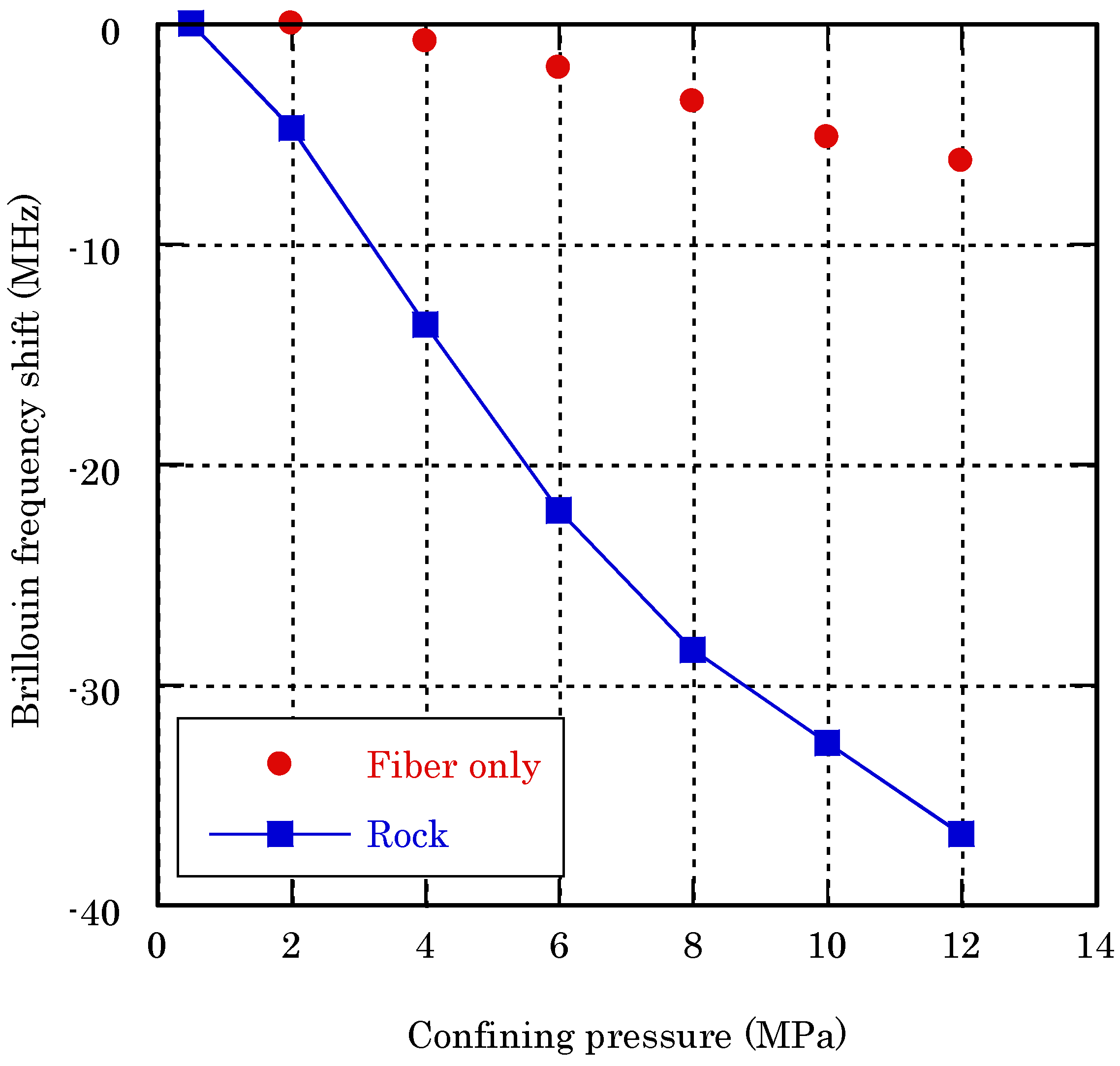

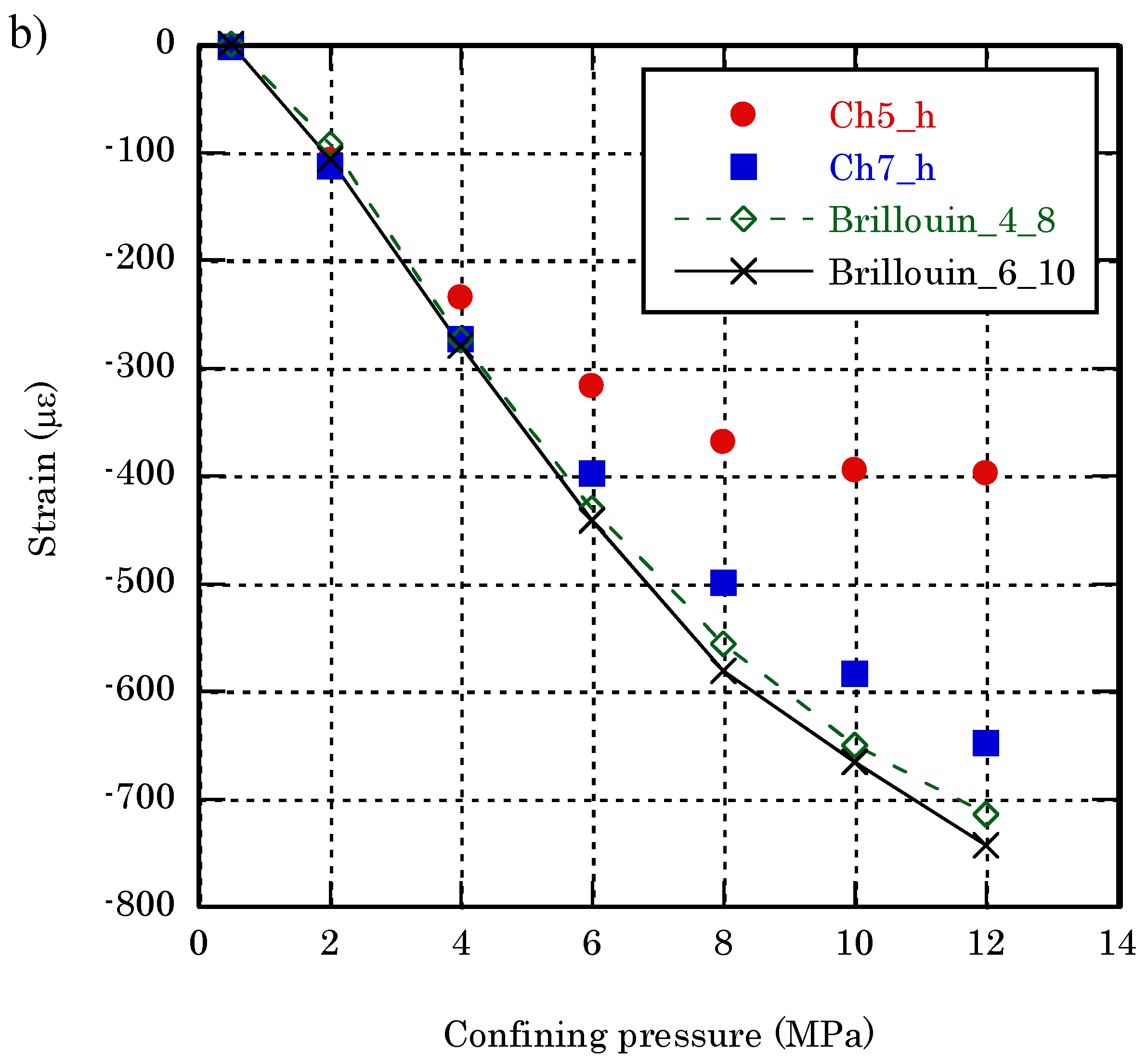

3.1.3. Optic Fiber Measurement—Brillouin Frequency Shift

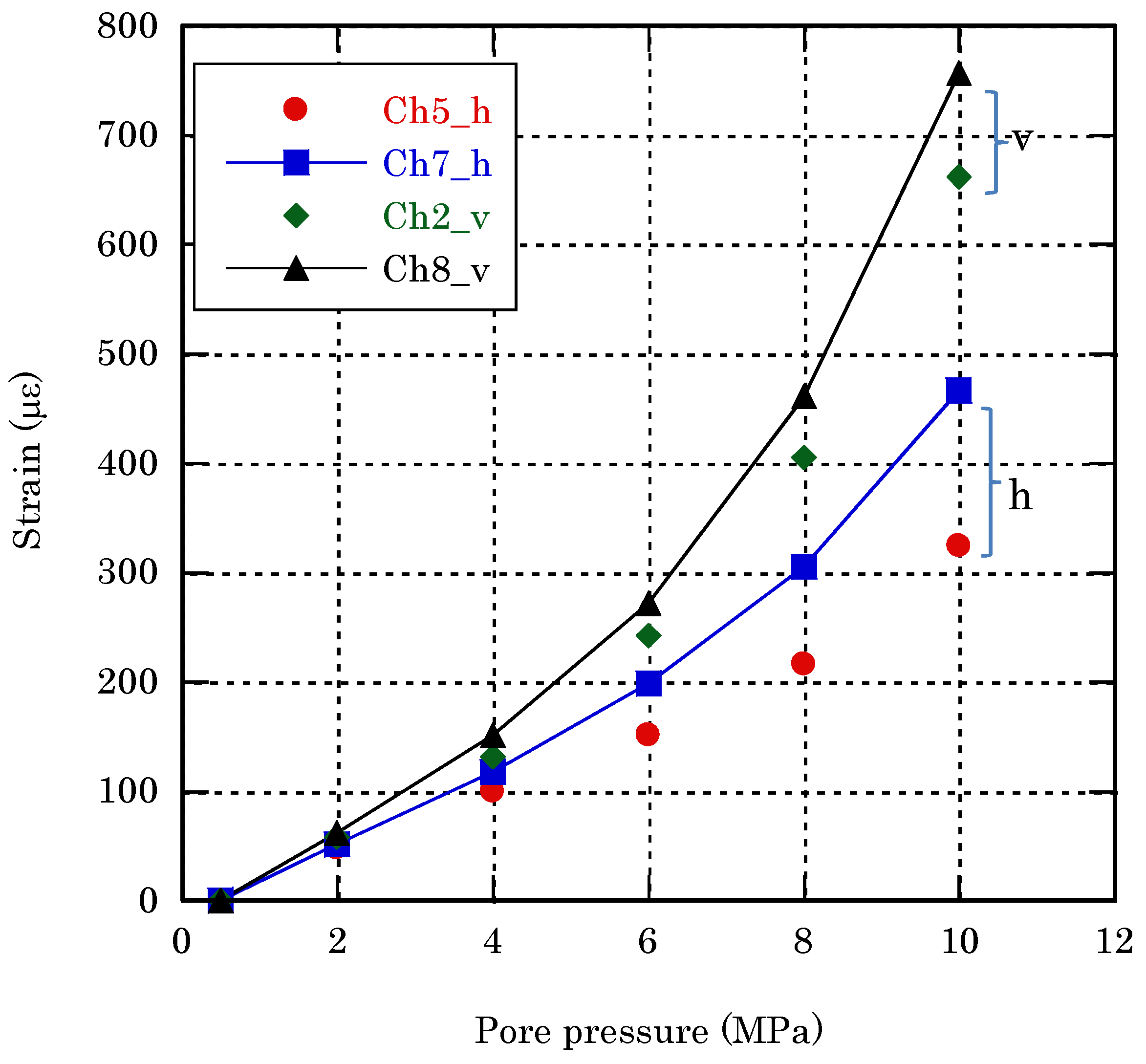

3.2. Berea—Increasing Pore Pressure

3.2.1. Strain Gauge Readings

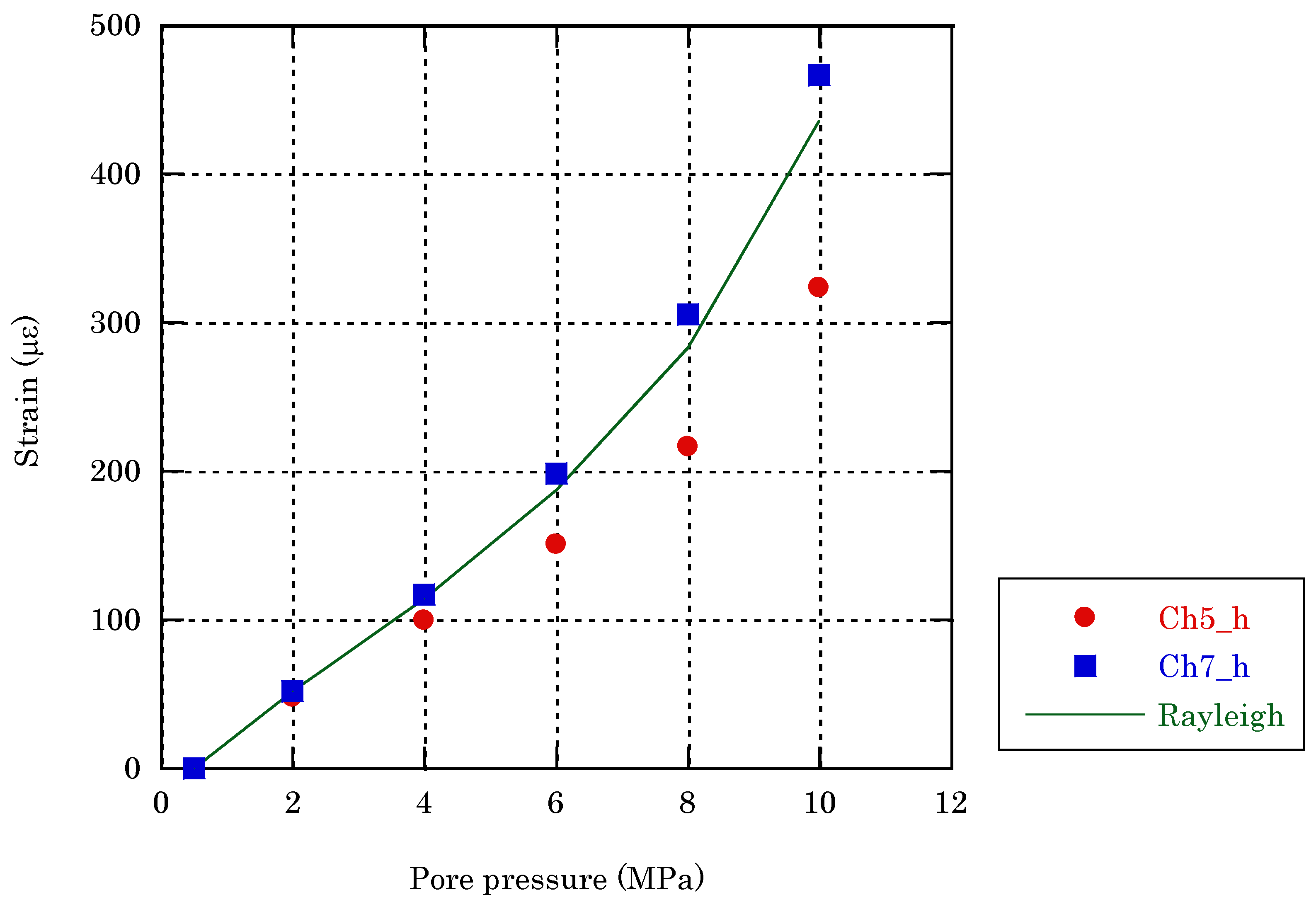

3.2.2. Optic Fiber Measurement

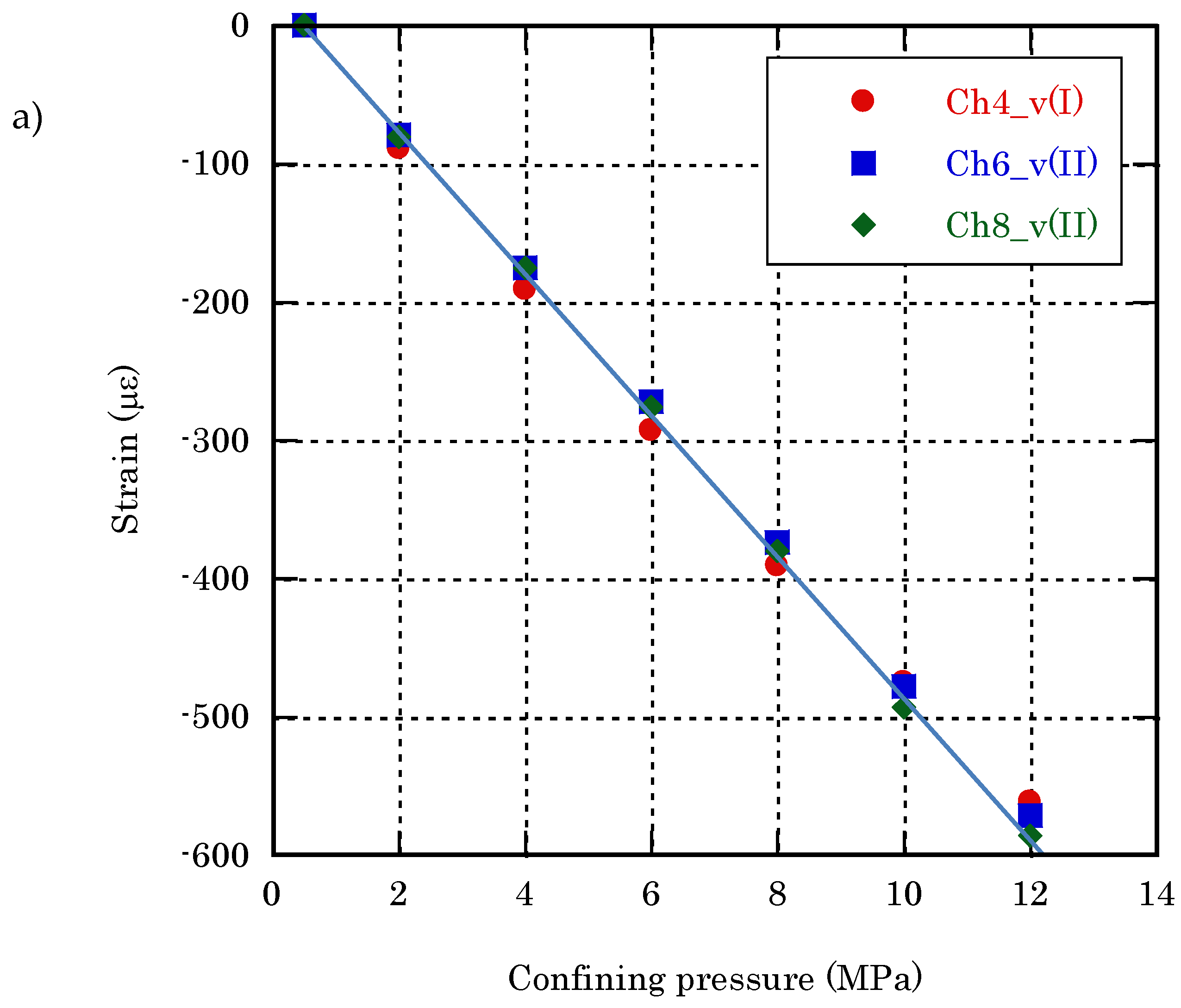

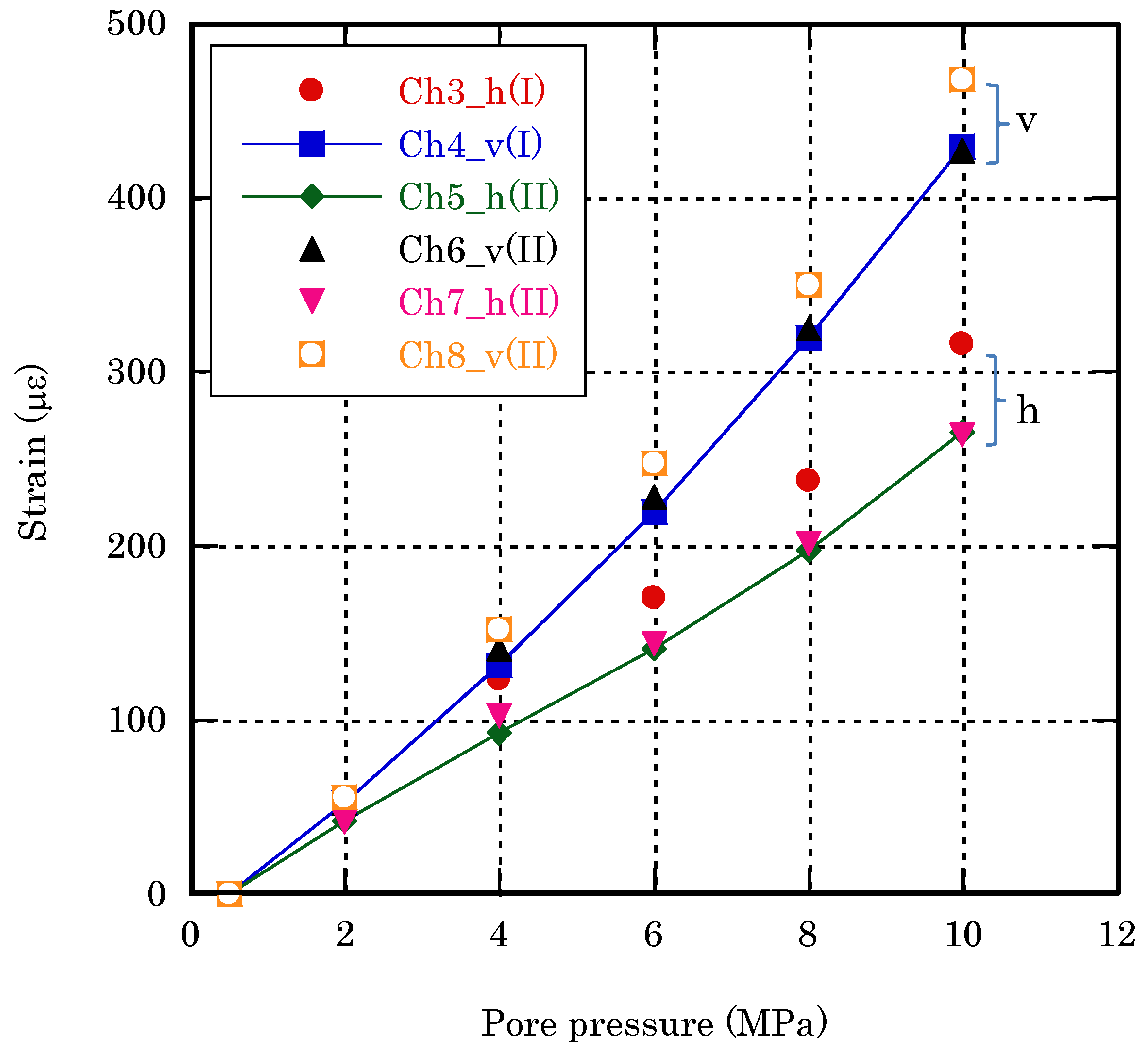

3.3. Tako Core

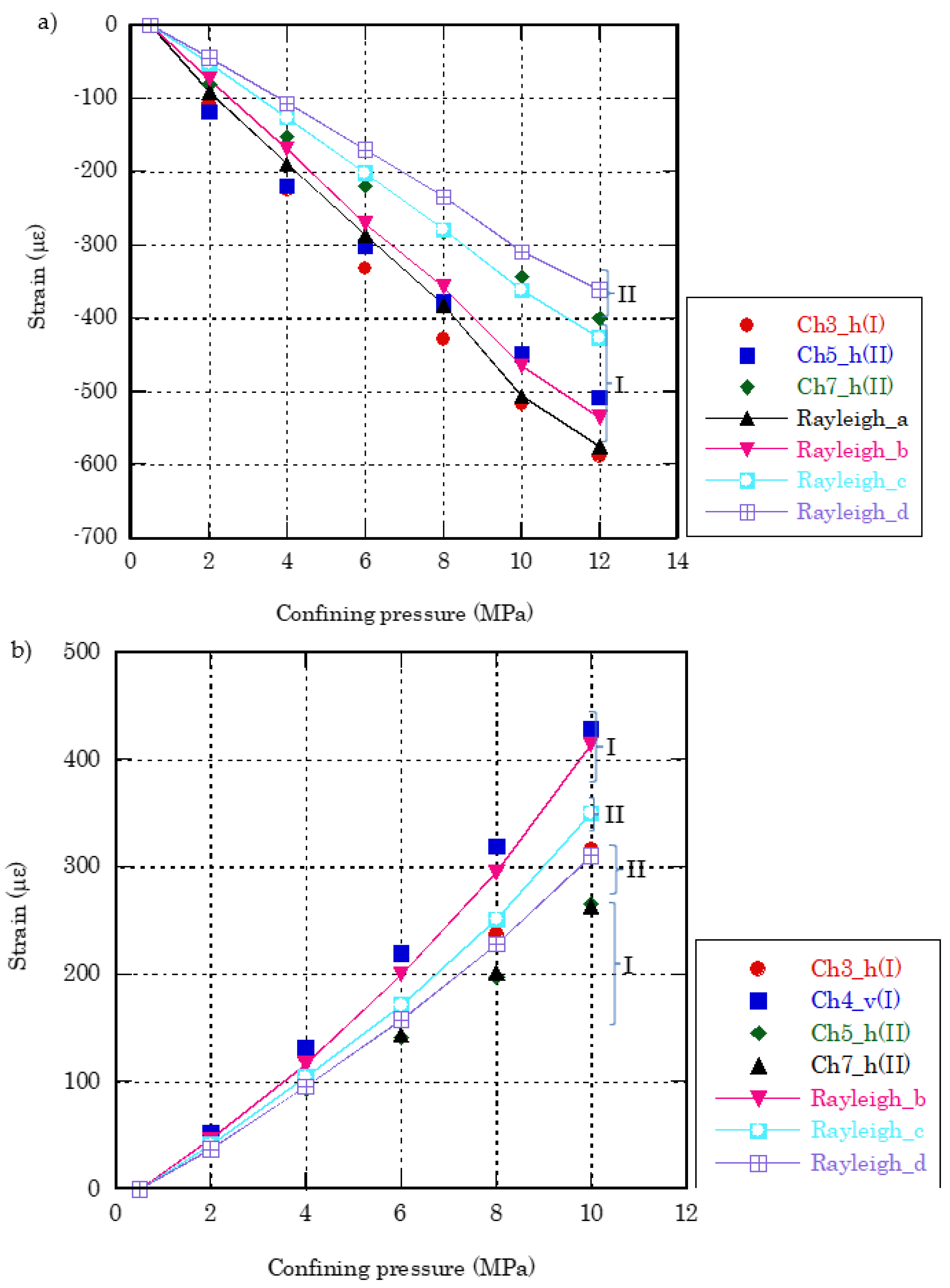

3.3.1. Strain Gauge Readings

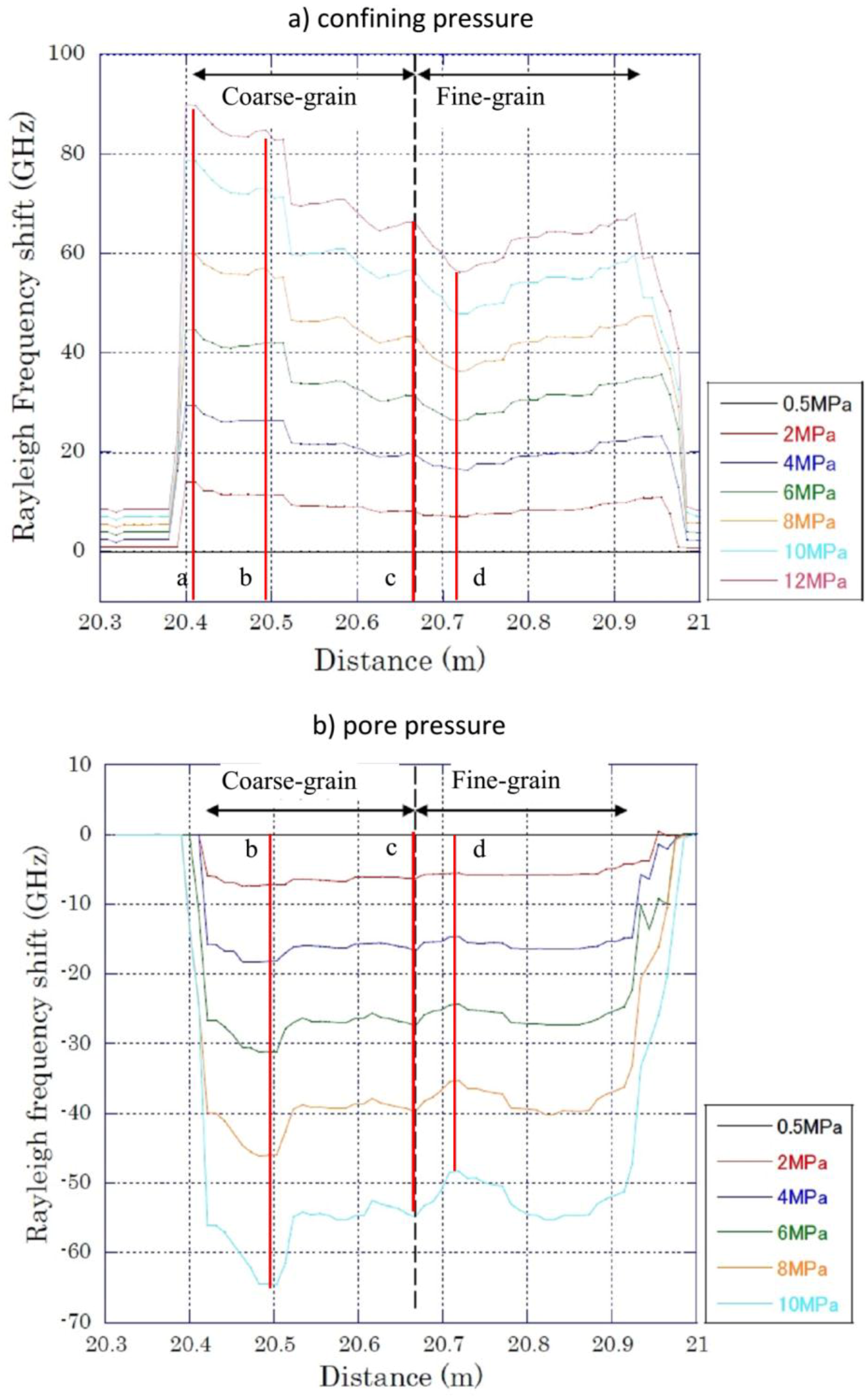

3.3.2. Optic Fiber—Rayleigh Frequency Shift

3.4. Distributed Fibre Optic Sensor vs. Strain Gauge

3.4.1. Berea Core

3.4.2. Tako Core

4. Concluding Remarks

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Onuma, T.; Ohkawa, S. Detection of surface deformation related with CO2 injection by DInSAR at In Salah, Algeria. Energy Procedia 2009, 1, 2177–2184. [Google Scholar] [CrossRef]

- Worth, K.; White, D.; Chalaturnyk, R.; Sorensen, J.; Hawkes, C.; Rostron, B.; Johnson, J.; Young, A. Aquistore project measurement, monitoring, and verification: from concept to CO2 injection. Energy Procedia 2014, 63, 3202–3208. [Google Scholar] [CrossRef]

- Yang, Q.; Zhao, W.; Dixon, T.; Amelung, F.; Han, W.; Li, P. InSAR monitoring of ground deformation due to CO2 injection at an enhanced oil recovery site, West Texas. Int. J. Greenh. Gas Control 2015, 41, 20–28. [Google Scholar] [CrossRef]

- Johnston, W.D.; Kaminow, I.P. Temperature dependence of Raman and Rayleigh scattering in LiNbO3 and LiTaO3. Phys. Rev. 1968, 168, 1045–1054. [Google Scholar] [CrossRef]

- Parker, T.R.; Farhadiroushan, M.; Handerek, V.A.; Rogers, A.J. Temperature and strain dependence of the power level and frequency of spontaneous Brillouin scattering in optical fibers. Opt. Lett. 1997, 22, 787–789. [Google Scholar] [CrossRef] [PubMed]

- Froggatt, M.; Moore, J. High-spatial resolution distributed strain measurements in optical fiber with Rayleigh scatter. Appl. Opt. 1998, 37, 1735–1740. [Google Scholar] [CrossRef] [PubMed]

- Barrias, A.; Casas, J.R.; Villalba, S. A review of distributed optical fiber sensors for civil engineering applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.M.; Kim, C.M.; Choi, S.Y.; Lee, B.Y. Enhanced strain measurement range of an FBG sensor embedded in seven-wire steel strands. Sensors 2017, 17, 1654. [Google Scholar] [CrossRef] [PubMed]

- Drake, D.A.; Sullivan, R.W.; Wilson, J.C. Distributed strain sensing from different optical fiber configurations. Inventions 2018, 3, 67. [Google Scholar] [CrossRef]

- Becker, T.; Ziemann, O.; Engelbrecht, R.; Schmauss, B. Optical strain measurement with step-index polymer optical fiber based on the phase measurement of an intensity-modulated signal. Sensors 2018, 18, 2319. [Google Scholar] [CrossRef] [PubMed]

- Kishida, K.; Li, C.H.; Nishiguchi, K. Pulsed pre-pump method to achieve cm-order spatial resolution in Brillouin distributed measuring technique, Tech. Rep. IEICE 2004, 104, 15–20. [Google Scholar]

- Nishiguchi, K.; Kishida, K.; Li, C.H. Synthetic Approach for Brillouin Optical Time-Domain Reflectometry. In Proceedings of the 42nd ISCIE International Symposium on Stochastic Systems Theory and Applications, Okayama, Japan, 26–27 November 2010. [Google Scholar]

- Koyamada, Y. New technique for distributed strain measurement in optical fibers with very high sensitivity by making use of Rayleigh backscattering. Tech. Rep. IEICE OFT98-23, 21–25.

- Kogure, T.; Horiuchi, Y.; Kiyama, T.; Nishizawa, O.; Xue, Z.; Matsuoka, T. Fiber optic strain measurements using distributed sensor system under static pressure conditions. BUTSURI-TANSA 2015, 68, 23–38. [Google Scholar] [CrossRef]

- Yamauchi, Y. A Measurement Method to Determine Strain and Temperature Coefficients in Fiber Optic Sensors. In Proceedings of the Asia Pacific Workshop on Structural Health Monitoring (APWSHM), Tokyo, Japan, 30 November–2 December 2010. [Google Scholar]

- Kishida, K.; Li, C.H.; Nishiguchi, K.; Yamauchi, Y.; Guzik, A.; Tsuda, T. Hybrid Brillouin-Rayleigh distributed sensing system. SPIE 2012, 8421, G1–G4. [Google Scholar]

| Brillouin-Based Sensing | Rayleigh-Based Sensing | ||

|---|---|---|---|

| BOTDA PPP-BOTDA | BOTDR S-BOTDR | TW-COTDR | |

| Double end | Single | Single | |

| Minimum spatial resolution | 2 cm | 10 cm | 2 cm |

| Resolution | 5 με/0.5 °C | 5 με/0.5 °C | 0.5 με/0.05 °C |

| Measurement time | 5 s@2000 με | 40 s@10,000 με | 60 s/2000 με |

| Maximum measurement distance | 20 km@1 m | 20 km@1 m | 20 km@20 cm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, Z.; Shi, J.-Q.; Yamauchi, Y.; Durucan, S. Fiber Optic Sensing for Geomechanical Monitoring: (1)-Distributed Strain Measurements of Two Sandstones under Hydrostatic Confining and Pore Pressure Conditions. Appl. Sci. 2018, 8, 2103. https://doi.org/10.3390/app8112103

Xue Z, Shi J-Q, Yamauchi Y, Durucan S. Fiber Optic Sensing for Geomechanical Monitoring: (1)-Distributed Strain Measurements of Two Sandstones under Hydrostatic Confining and Pore Pressure Conditions. Applied Sciences. 2018; 8(11):2103. https://doi.org/10.3390/app8112103

Chicago/Turabian StyleXue, Ziqiu, Ji-Quan Shi, Yoshiaki Yamauchi, and Sevket Durucan. 2018. "Fiber Optic Sensing for Geomechanical Monitoring: (1)-Distributed Strain Measurements of Two Sandstones under Hydrostatic Confining and Pore Pressure Conditions" Applied Sciences 8, no. 11: 2103. https://doi.org/10.3390/app8112103