Effect of Crack Orientation on Fatigue Life of Reinforced Concrete Bridge Decks

Abstract

:1. Introduction

2. Methodology and Studied Cases

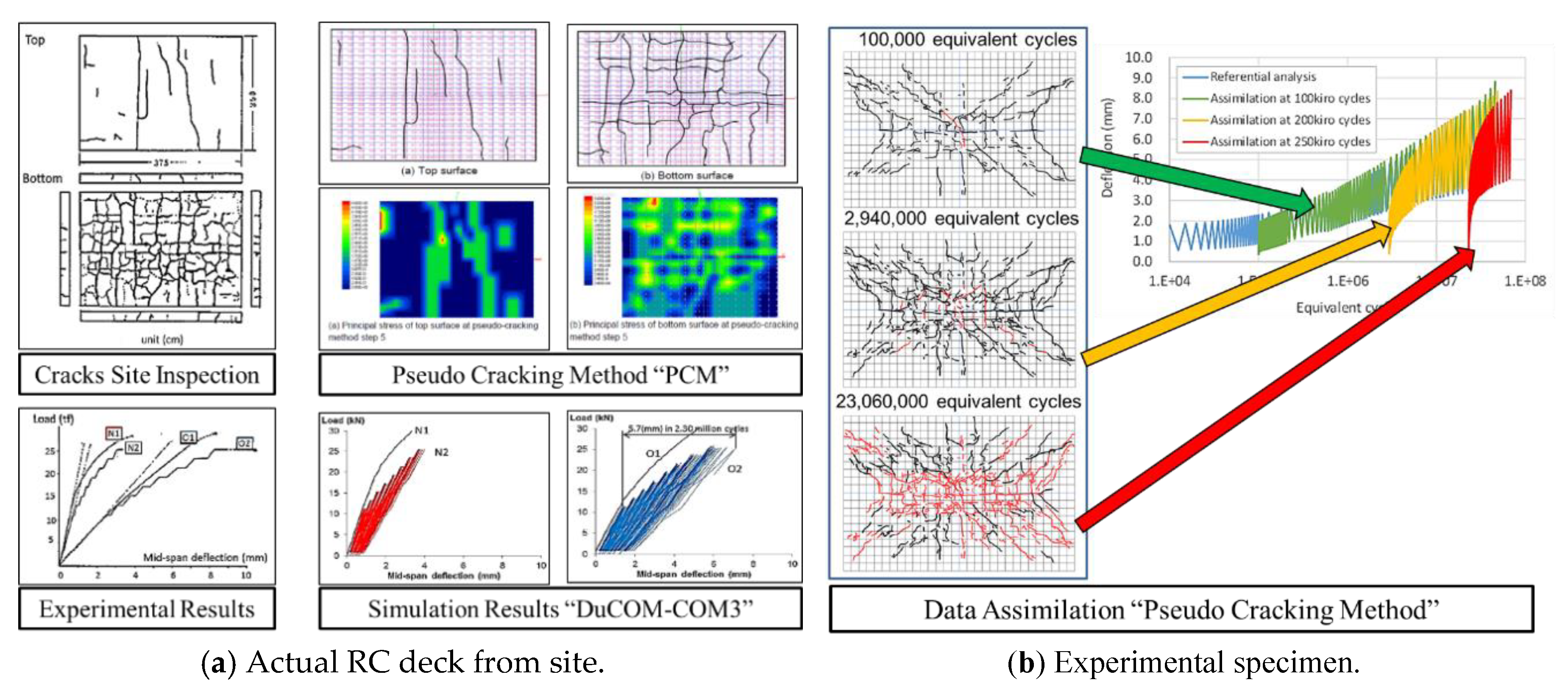

2.1. Data Assimilation Technology

2.2. Studied RC Deck

2.2.1. Dimensions and Reinforcement

2.2.2. Material Properties

2.2.3. Referential Loads & Boundary Conditions

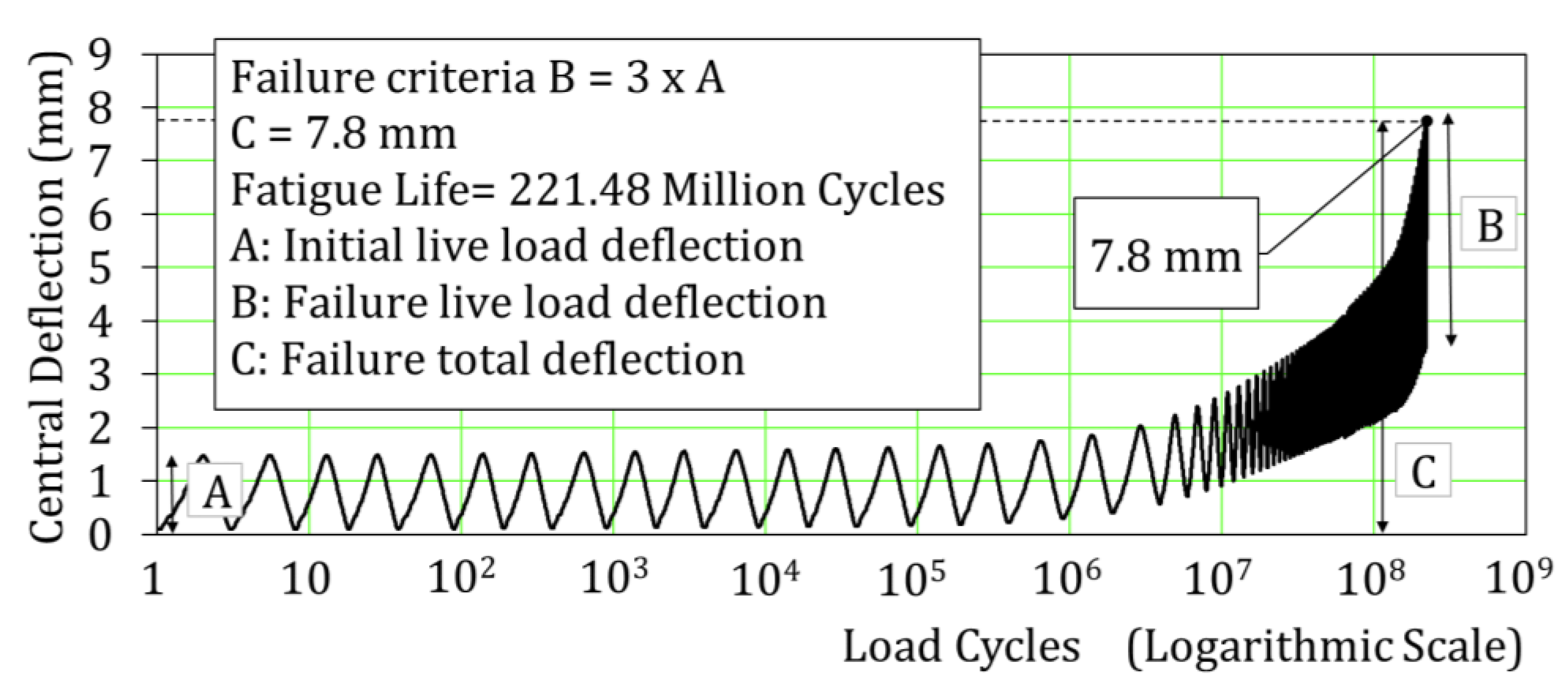

2.2.4. Failure Criteria

2.2.5. Fatigue Life of Non-Damaged Deck

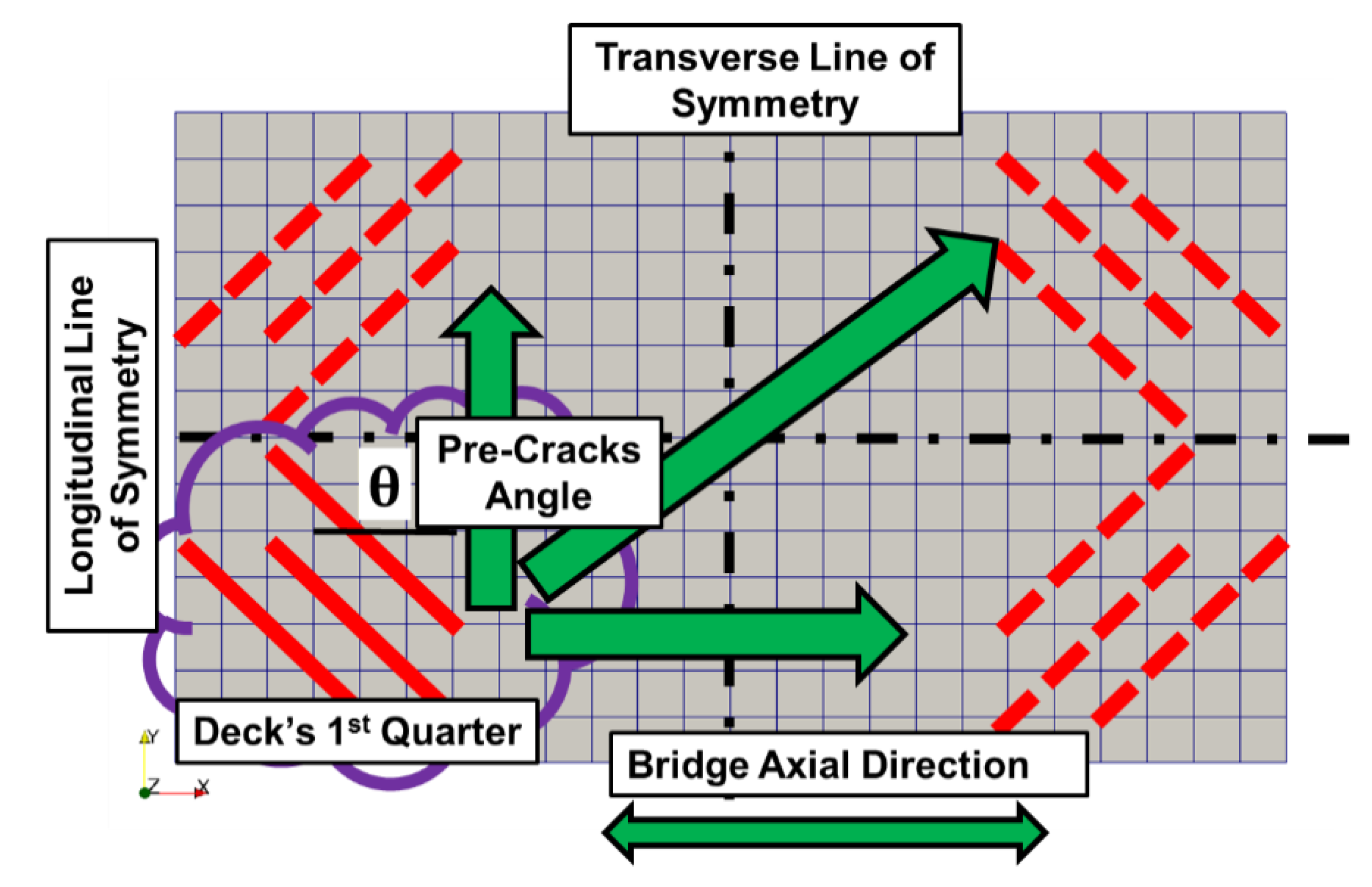

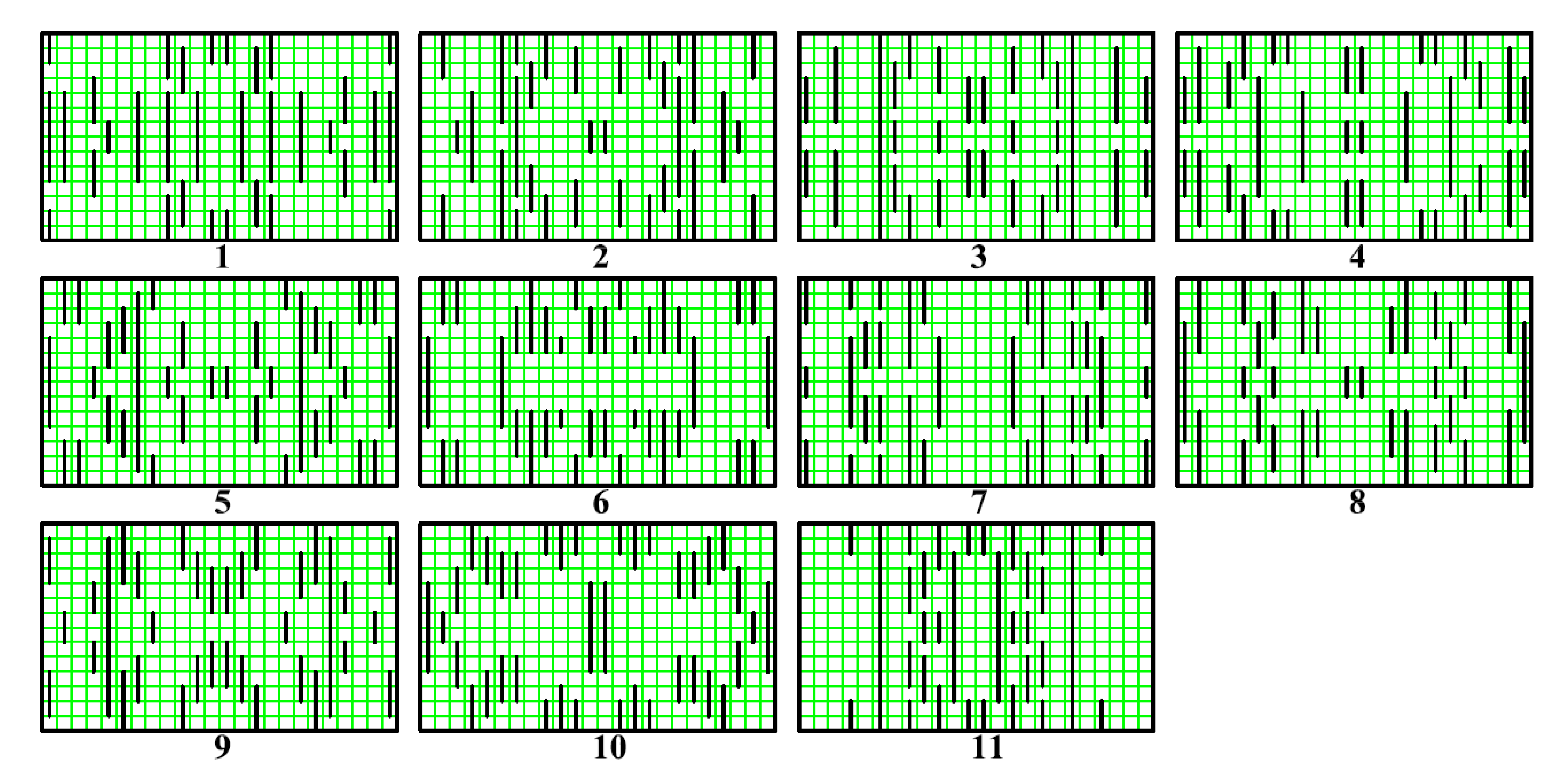

2.3. Randomized Artificial Crack Patterns (RACP)

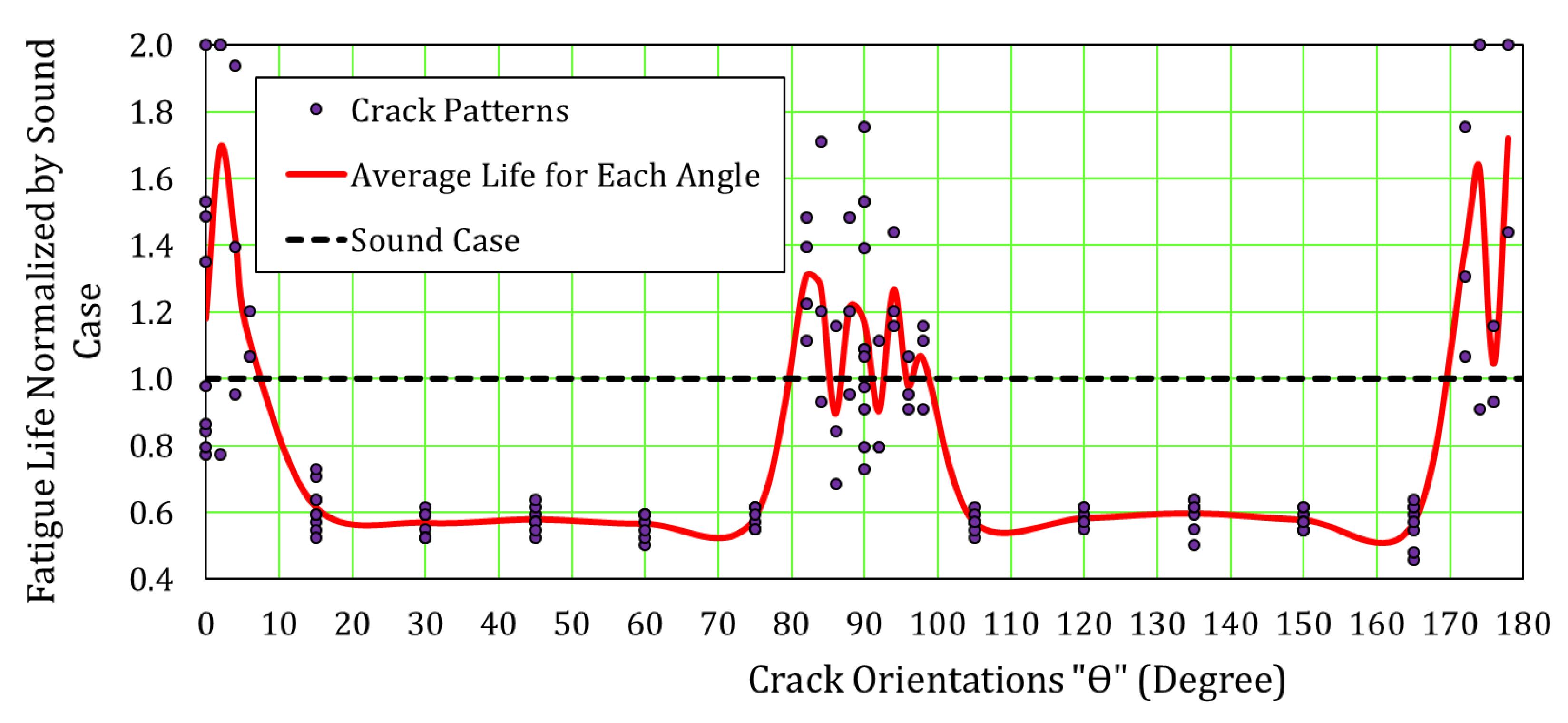

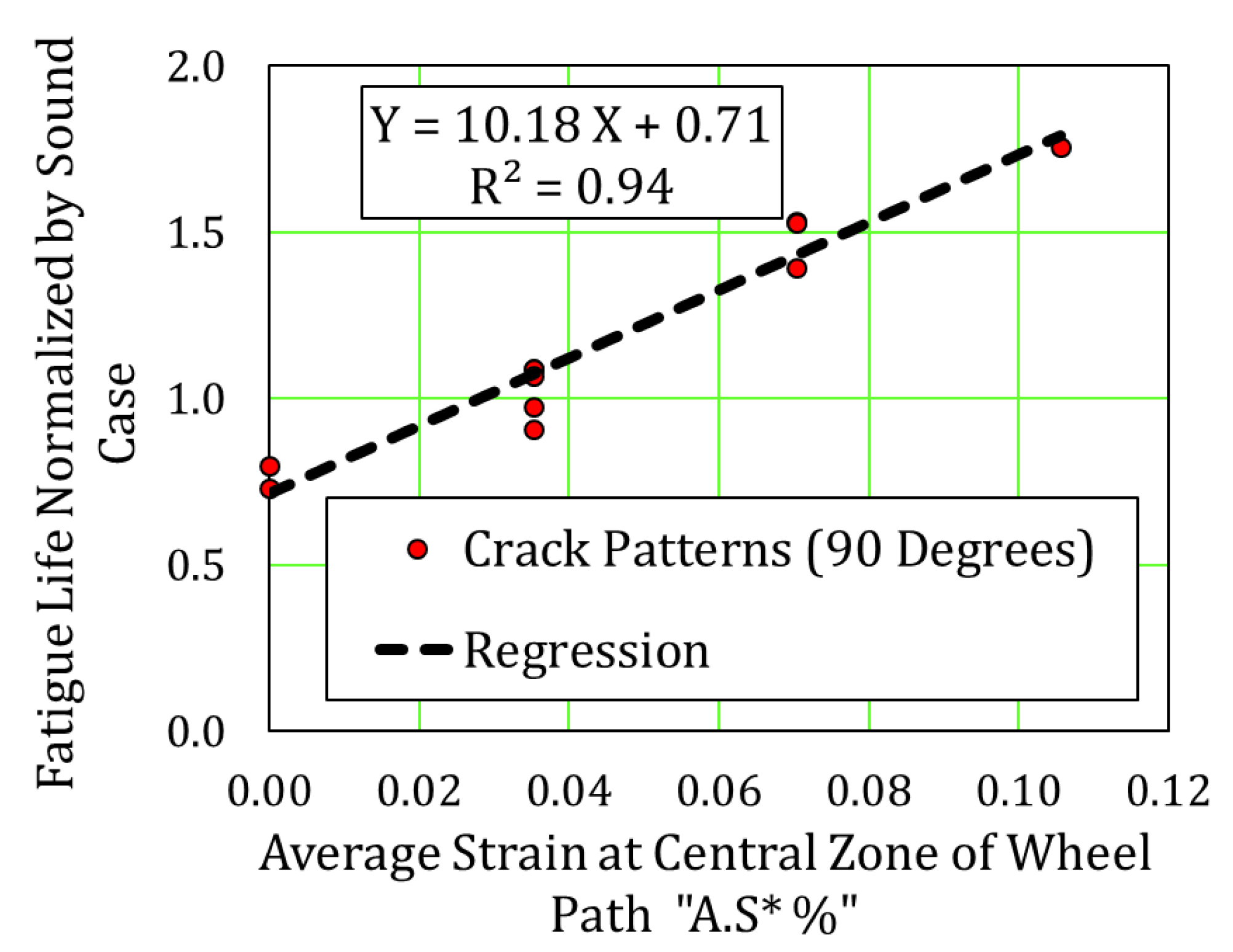

3. Crack Patterns & Simulation Results

4. Discussions

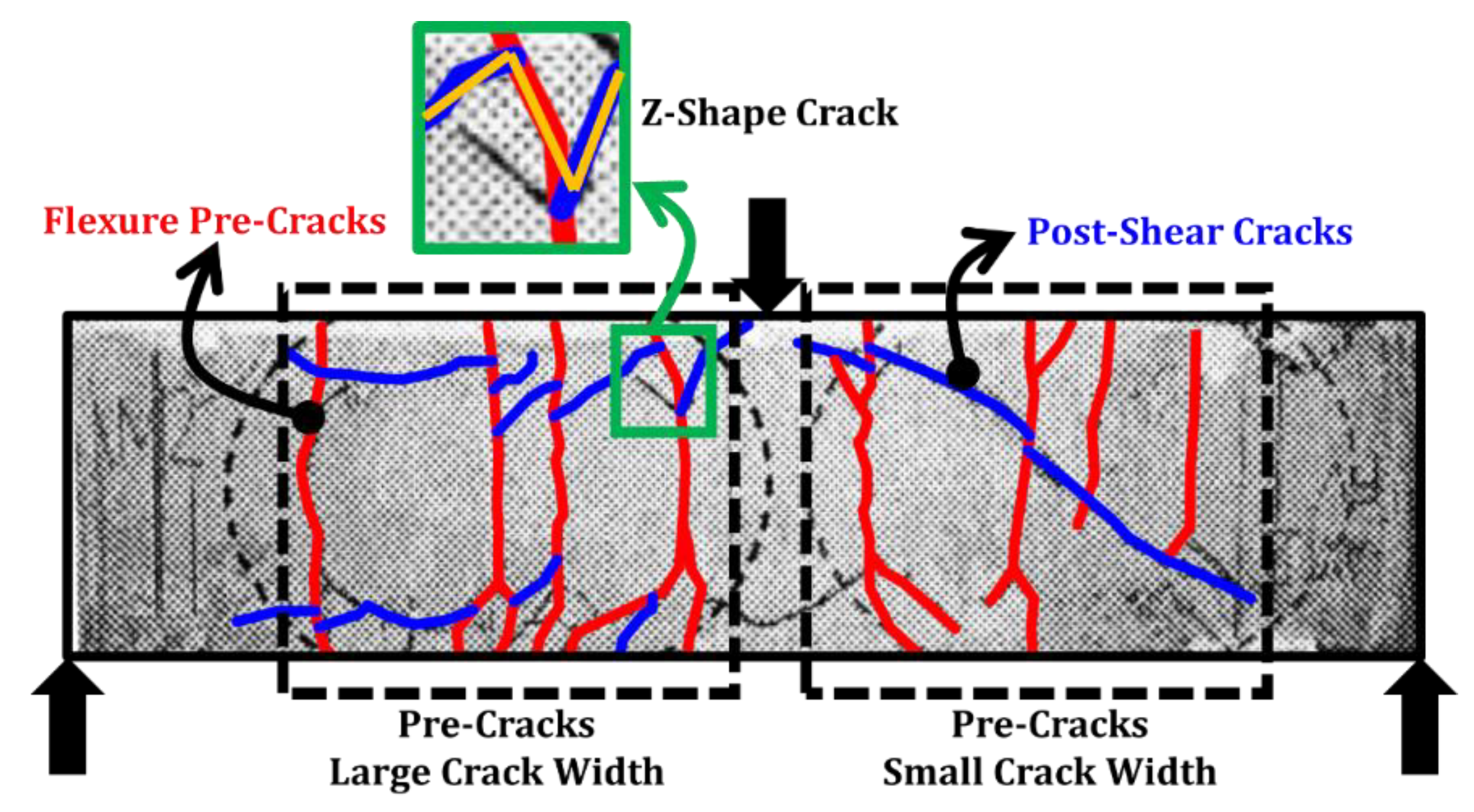

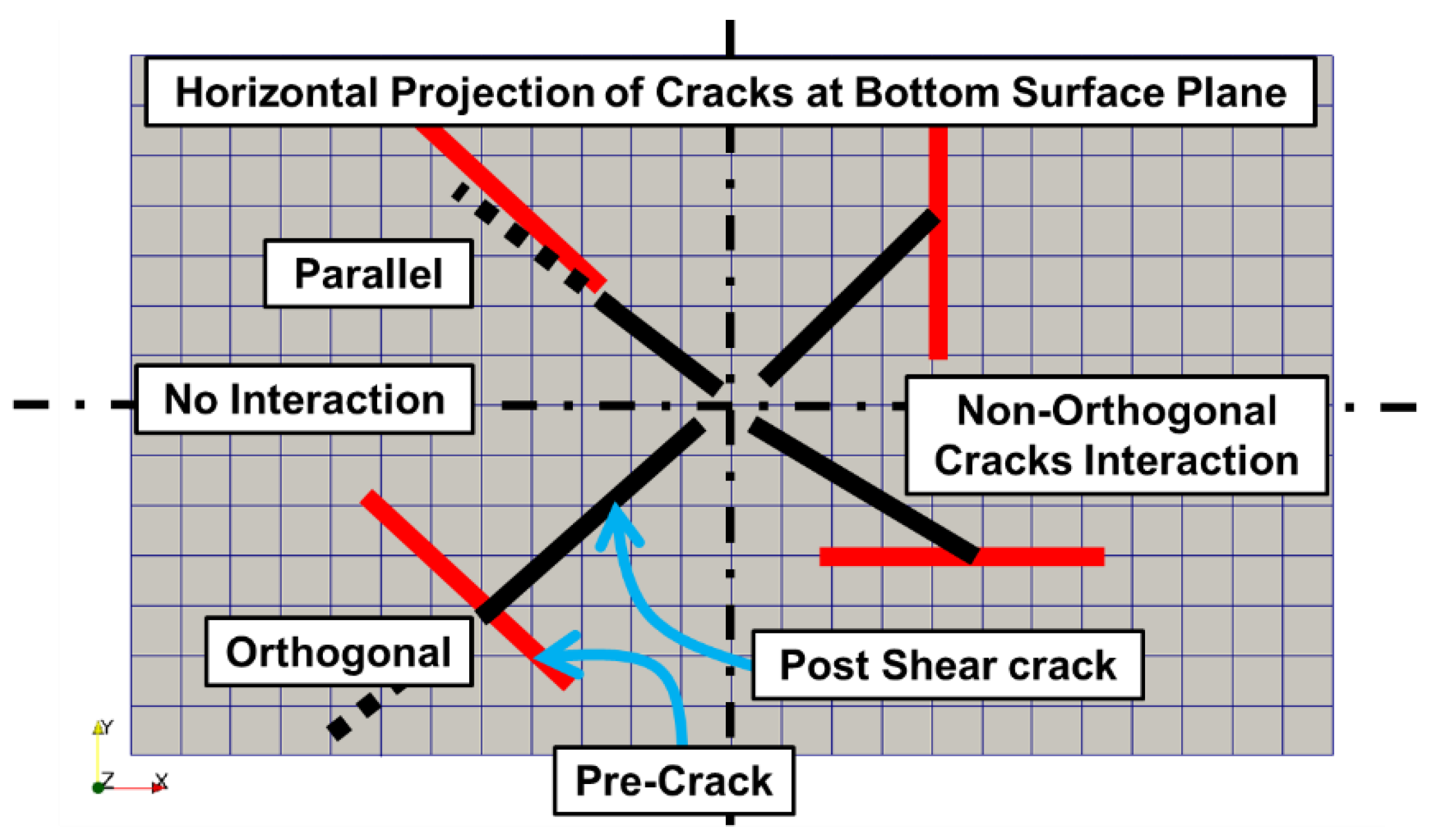

4.1. Coupled Flexure-Shear Mode–Crack Arrest Mechanism

4.2. Effect of Cracks Location on Coupled Flexure-Shear Mode

4.3. High Risk Location of Cracking

5. Conclusions

- The crack orientation is highly associated with the coupled flexure-shear mode of failure, where pre-cracks tend to arrest the ensuing propagation of post-shear cracks. As a result, enhanced fatigue life is obtained.

- The pre-crack arrest mechanism enables bridge maintenance managers to conduct a fair assessment of RC decks that present a rough appearance but have mechanically enhanced fatigue life.

- The cracks that approximate the deck’s longitudinal or transverse direction are understood to most extend the remaining fatigue life of RC decks.

- The central zone of the loading path is found to be the location where the crack arrest mechanism is effective, and the remaining fatigue life is elevated.

- During inspections, careful attention shall be paid to cracks at the corners of RC decks since the stopping mechanism that arrests diagonal cracking does not effectively function there.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Val, D.V.; Stewart, M.G.; Melchers, R.E. Effect of reinforcement corrosion on reliability of highway bridges. Eng. Struct. 1998, 20, 1010–1019. [Google Scholar] [CrossRef]

- Vassie, P. Reinforcement corrosion and the durability of concrete bridges. In Proceedings of Institution of Civil Engineers; Institution of Civil Engineers: London, UK, 1984; Volume 76, pp. 713–723. [Google Scholar]

- Cady, P.D.; Weyers, R.E. Chloride penetration and the deterioration of concrete bridge decks. Cem. Concr. Aggreg. 1983, 5, 81–87. [Google Scholar]

- Freyermuth, C.L.; Klieger, P.; Stark, D.C.; Wenke, H.N. Durability of concrete bridge decks—A review of cooperative studies. Highw. Res. Rec. 1970, 328, 50–60. [Google Scholar]

- Lindquist, W.D.; Darwin, D.; Browning, J.; Miller, G.G. Effect of Cracking on Chloride Content in Concrete Bridge Decks. Aci Mater. J. 2006, 103, 467–473. [Google Scholar]

- Shah, S.P.; Weiss, W.J.; Yang, W. Shrinkage Cracking—Can It Be Prevented? Concr. Int. 1998, 20, 51–55. [Google Scholar]

- Sakulich, A.R.; Bentz, D.P. Increasing the service life of bridge decks by incorporating phase-change materials to reduce freeze-thaw cycles. J. Mater. Civ. Eng. 2011, 24, 1034–1042. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Kojundic, T.; Fidjestol, P. Evaluation of bridge deck overlays. Concr. Int. Detroit 1997, 19, 43–46. [Google Scholar]

- Ulm, F.J.; Coussy, O.; Kefei, L.; Larive, C. Thermo-chemo-mechanics of ASR expansion in concrete structures. J. Eng. Mech. 2000, 126, 233–242. [Google Scholar] [CrossRef]

- Schläfli, M.; Brühwiler, E. Fatigue of existing reinforced concrete bridge deck slabs. Eng. Struct. 1998, 20, 991–998. [Google Scholar] [CrossRef]

- Lee, M.K.; Barr, B.I.G. An overview of the fatigue behaviour of plain and fibre reinforced concrete. Cem. Concr. Compos. 2004, 26, 299–305. [Google Scholar] [CrossRef]

- Sparks, P.R.; Menzies, J.B. The effect of rate of loading upon the static and fatigue strengths of plain concrete in compression. Mag. Concr. Res. 1973, 25, 73–80. [Google Scholar] [CrossRef]

- Cornelissen, H.A.W.; Reinhardt, H.W. Uniaxial tensile fatigue failure of concrete under constant-amplitude and program loading. Mag. Concr. Res. 1984, 36, 216–226. [Google Scholar] [CrossRef]

- Tepfers, R.; Kutti, T. Fatigue Strength of Plain, Ordinary, and Lightweight Concrete. ACI J. 1979, 76, 635–652. [Google Scholar]

- Kolluru, S.V.; O’Neil, E.F.; Popovics, J.S.; Shah, S.P. Crack propagation in flexural fatigue of concrete. J. Eng. Mech. 2000, 126, 891–898. [Google Scholar] [CrossRef]

- Slowik, V.; Plizzari, G.A.; Saouma, V.E. Fracture of concrete under variable amplitude fatigue loading. ACI Mater. J. 1996, 93, 272–283. [Google Scholar]

- NEXCO-Japan. Regarding Large-Scale Renewal and Large-Scale Repair on the Expressway Managed by Eastern. Central and West Japan Expressway Co., Ltd. 2014. Available online: https://www.c-nexco.co.jp/koushin/pdf/about.pdf (accessed on 17 May 2018).

- Pimanmas, A.; Maekawa, K. Shear failure of RC members subjected to pre-cracks and combined axial tension and shear. J. Mater. Concr. Struct. Pavements JSCE 2001, 53, 159–174. [Google Scholar] [CrossRef]

- Tanaka, Y.; Kishi, T.; Maekawa, K. Experimental research on the structural mechanism of RC members containing artificial crack in shear. JSCE 2005, 802, 109–121. [Google Scholar]

- Fathalla, E.; Tanaka, Y.; Maekawa, K. Remaining fatigue life assessment of in-service road bridge decks based upon artificial neural networks. Eng. Struct. 2018, 171, 602–616. [Google Scholar] [CrossRef]

- Fathalla, E.; Tanaka, Y.; Maekawa, K.; Sakurai, A. Quantitative deterioration assessment of road bridge decks based on site inspected cracks. Appl. Sci. 2018, 8, 1197. [Google Scholar] [CrossRef]

- Fathalla, E.; Tanaka, Y.; Maekawa, K.; Sakurai, A. Quantitative deterioration assessment of road bridge decks based on site inspected cracks under stagnant water. J. Adv. Concr. Technol. 2019, 17, 16–33. [Google Scholar] [CrossRef]

- Fathalla, E.; Tanaka, Y.; Maekawa, K. Fatigue life of RC bridge decks affected by non-uniformly dispersed stagnant water. Appl. Sci. 2019, 9, 607. [Google Scholar] [CrossRef]

- Maekawa, K.; Ishida, T.; Chijiwa, N.; Fujiyama, C. Multiscale coupled-hygromechanistic approach to the life-cycle performance assessment of structural concrete. J. Mater. Civ. Eng. Am. Soc. Civ. Eng. 2015, 27, A4014003. [Google Scholar] [CrossRef]

- Maekawa, K.; Toongoenthong, K.; Gebreyouhannes, E.; Kishi, T. Direct path-integral scheme for fatigue simulation of reinforced concrete in shear. J. Adv. Concr. Technol. 2006, 4, 159–177. [Google Scholar] [CrossRef]

- Tanaka, Y.; Maekawa, K.; Maeshima, T.; Iwaki, I.; Nishida, T.; Shiotani, T. Data assimilation for fatigue life assessment of RC bridge decks coupled with hygro-mechanistic model and nondestructive inspection. J. Disaster Res. 2017, 12, 422–431. [Google Scholar] [CrossRef]

- Fujiyama, C.; Tang, X.J.; Maekawa, K.; An, X. Pseudo-cracking approach to fatigue life assessment of RC bridge decks in service. J. Adv. Concr. Technol. 2013, 11, 7–21. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Razavi, S.M.J.; Chamani, H.R. Fatigue Life Extension by Crack Repair Using Stop-hole Technique under Pure Mode-I and Pure mode-II Loading Conditions. Procedia Eng. 2014, 74, 18–21. [Google Scholar] [CrossRef] [Green Version]

- Song, P.S.; Shieh, Y.L. Stop drilling procedure for fatigue life improvement. Int. J. Fatigue 2004, 26, 1333–1339. [Google Scholar] [CrossRef]

- Mikkelsen, O.; Rege, K.; Hemmingsen, T.; Pavlou, D.G. Numerical estimation of the stop holes-induced fatigue crack growth retardation in offshore structures taking into account the corrosion effect. In Proceedings of the 27th International Ocean and Polar Engineering Conference, International Society of Offshore and Polar Engineers, San Francisco, CA, USA, 25–30 June 2017. [Google Scholar]

- Razavi, S.M.J.; Ayatollahi, M.R.; Sommitsch, C.; Moser, C. Retardation of fatigue crack growth in high strength steel S690 using a modified stop-hole technique. Eng. Fract. Mech. 2017, 169, 226–237. [Google Scholar] [CrossRef]

- Pavlou, D.G.; Labeas, G.N.; Vlachakis, N.V.; Pavlou, F.G. Fatigue crack propagation trajectories under mixed-mode cyclic loading. Eng. Struct. 2003, 25, 869–875. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Estenssoro, L.F. Surface singularity and crack propagation. Int. J. Solids Struct. 1979, 15, 405–426. [Google Scholar] [CrossRef] [Green Version]

- Irwin, G.R. Fracture Mechanics, in the Book of Structural Mechanics; Pergamon Press: New York, NY, USA, 1958; pp. 557–594. [Google Scholar]

- Japan Road Association. Specifications for Highway Bridges—Part III Concrete Bridges; Japan Road Association: Tokyo, Japan, 2012. [Google Scholar]

- Matsui, S. Lifetime prediction of bridge. J. Jpn. Soc. Civ. Eng. 1996, 30, 432–440. [Google Scholar]

- Maeshima, T.; Koda, Y.; Tsuchiya, S.; Iwaki, I. Influence of corrosion of rebars caused by chloride induced deterioration on fatigue resistance in RC road deck. J. Jpn. Soc. Civ. Eng. 2014, 70, 208–225. [Google Scholar]

- Matsui, S.; Maeda, Y. A rational valuation method for deterioration of highway bridge decks. J. Jpn. Soc. Civ. Eng. 1986, 374, 419–426. [Google Scholar]

| Material Type | Concrete | Steel Reinforcement | |

|---|---|---|---|

| Young’s Modulus | N/mm2 | 24,750 | 205,000 |

| Compressive Strength | N/mm2 | 30 | 295 |

| Tensile Strength | N/mm2 | 2.2 | 295 |

| Specific Weight | kN/m3 | 24 | 78 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fathalla, E.; Tanaka, Y.; Maekawa, K. Effect of Crack Orientation on Fatigue Life of Reinforced Concrete Bridge Decks. Appl. Sci. 2019, 9, 1644. https://doi.org/10.3390/app9081644

Fathalla E, Tanaka Y, Maekawa K. Effect of Crack Orientation on Fatigue Life of Reinforced Concrete Bridge Decks. Applied Sciences. 2019; 9(8):1644. https://doi.org/10.3390/app9081644

Chicago/Turabian StyleFathalla, Eissa, Yasushi Tanaka, and Koichi Maekawa. 2019. "Effect of Crack Orientation on Fatigue Life of Reinforced Concrete Bridge Decks" Applied Sciences 9, no. 8: 1644. https://doi.org/10.3390/app9081644