Manufacture of Microstructured Optical Fibers: Problem of Optimal Control of Silica Capillary Drawing Process

Abstract

:1. Introduction

- (1)

- radius deviations are measured in a certain area, i.e., at several points;

- (2)

- the measuring area and the radius control point are spaced along the length of the flow, with the measuring area as close as possible to the furnace outlet;

- (3)

- the control action (change in drawing speed) is determined from the solution of the optimal control problem of the distributed system.

2. Mathematical Modeling of the Capillary Drawing Process

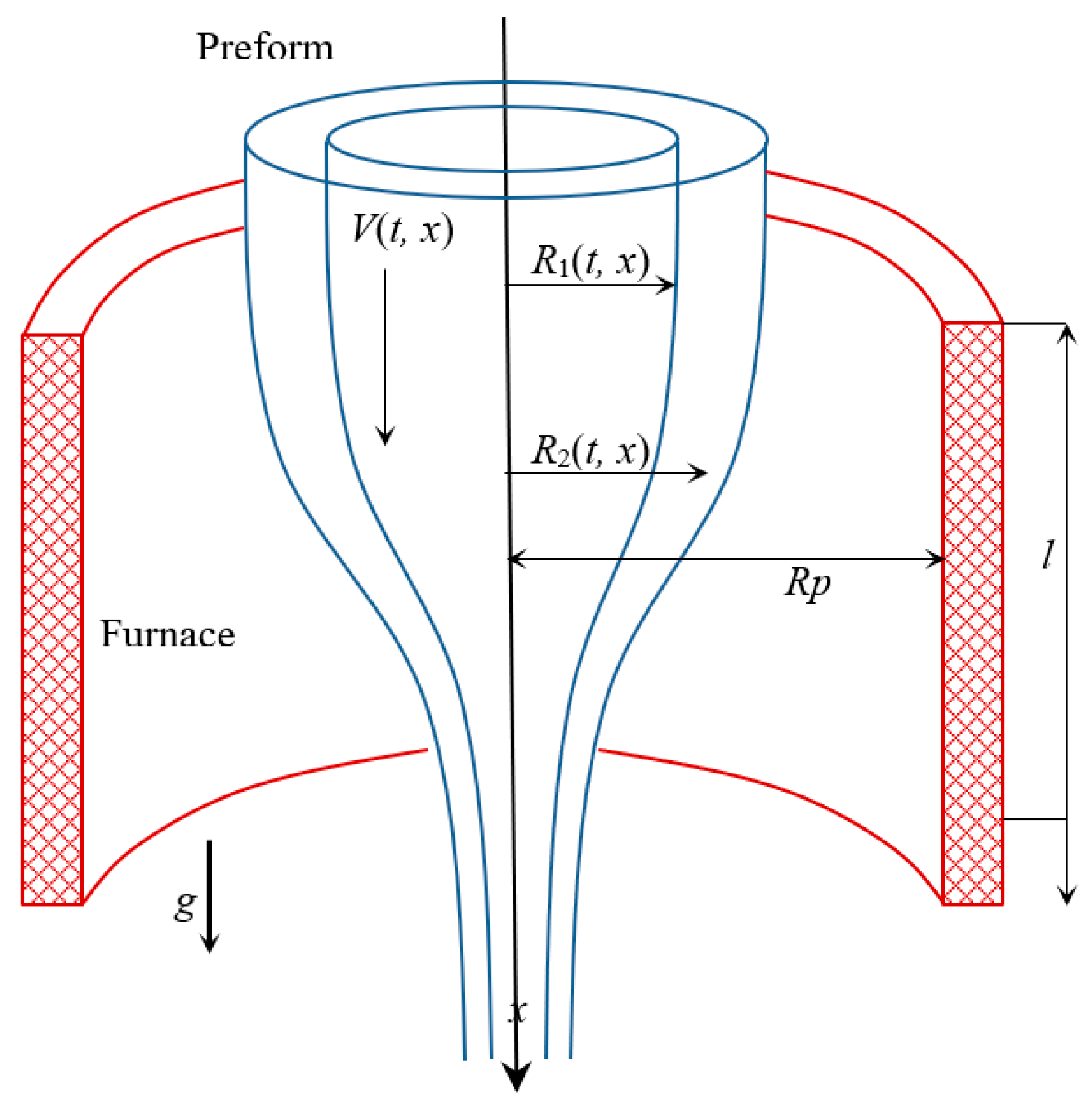

2.1. General Mathematical Model of Silica Capillary Drawing

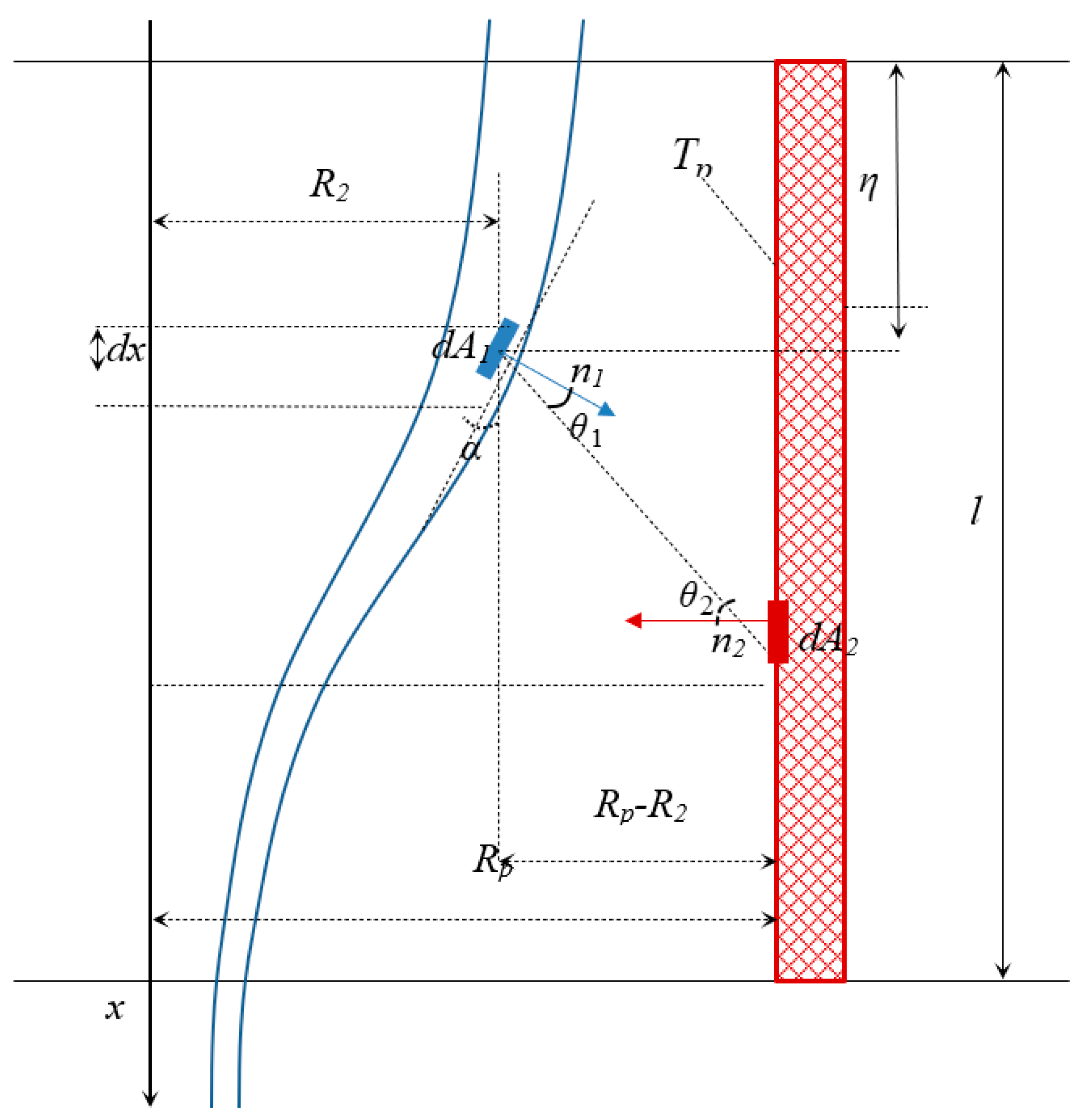

2.2. Mathematical Model of Stabilizing Optimal Control of Silica Capillary Drawing

3. Optimal Control of the Capillary Drawing Process

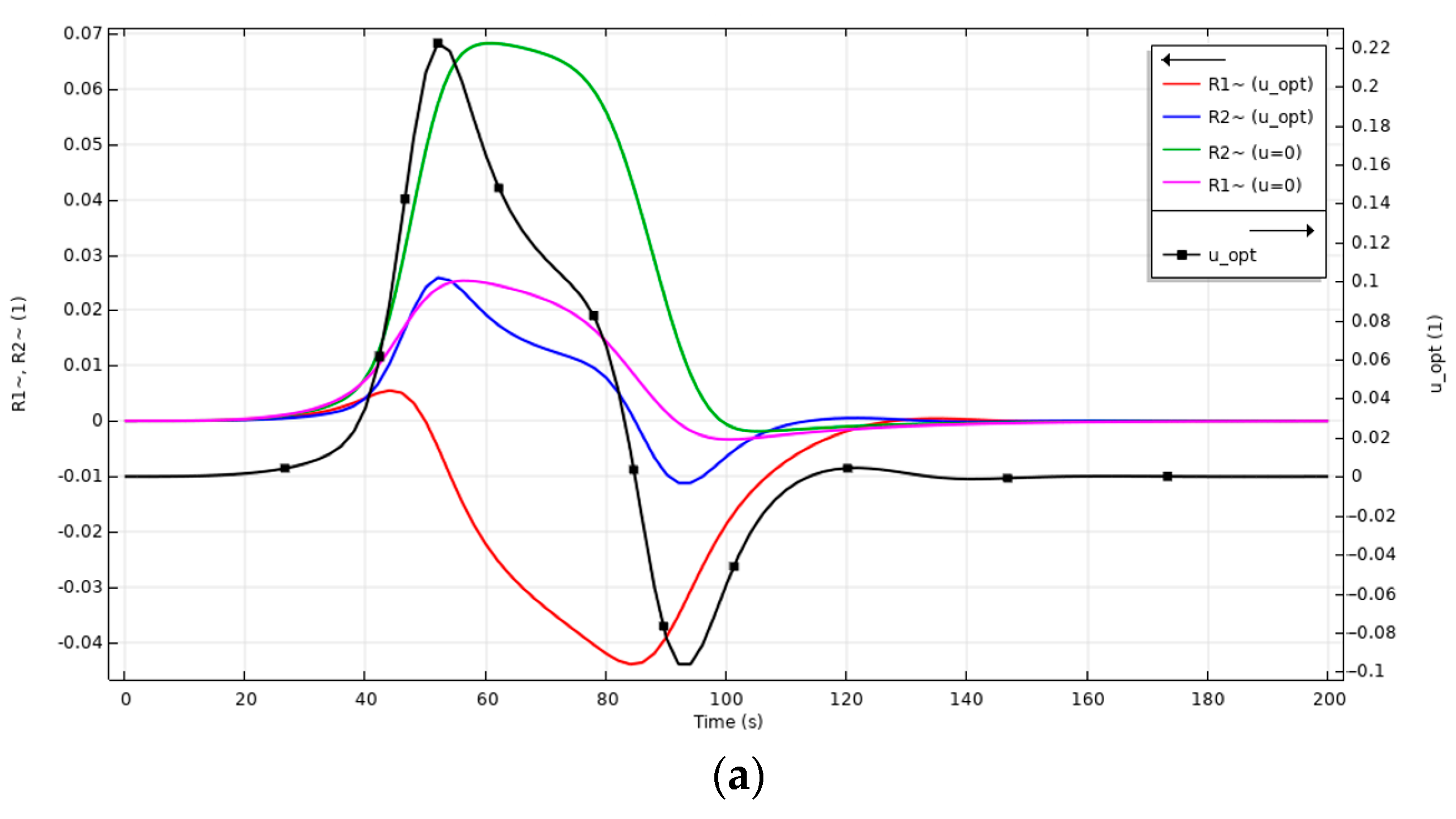

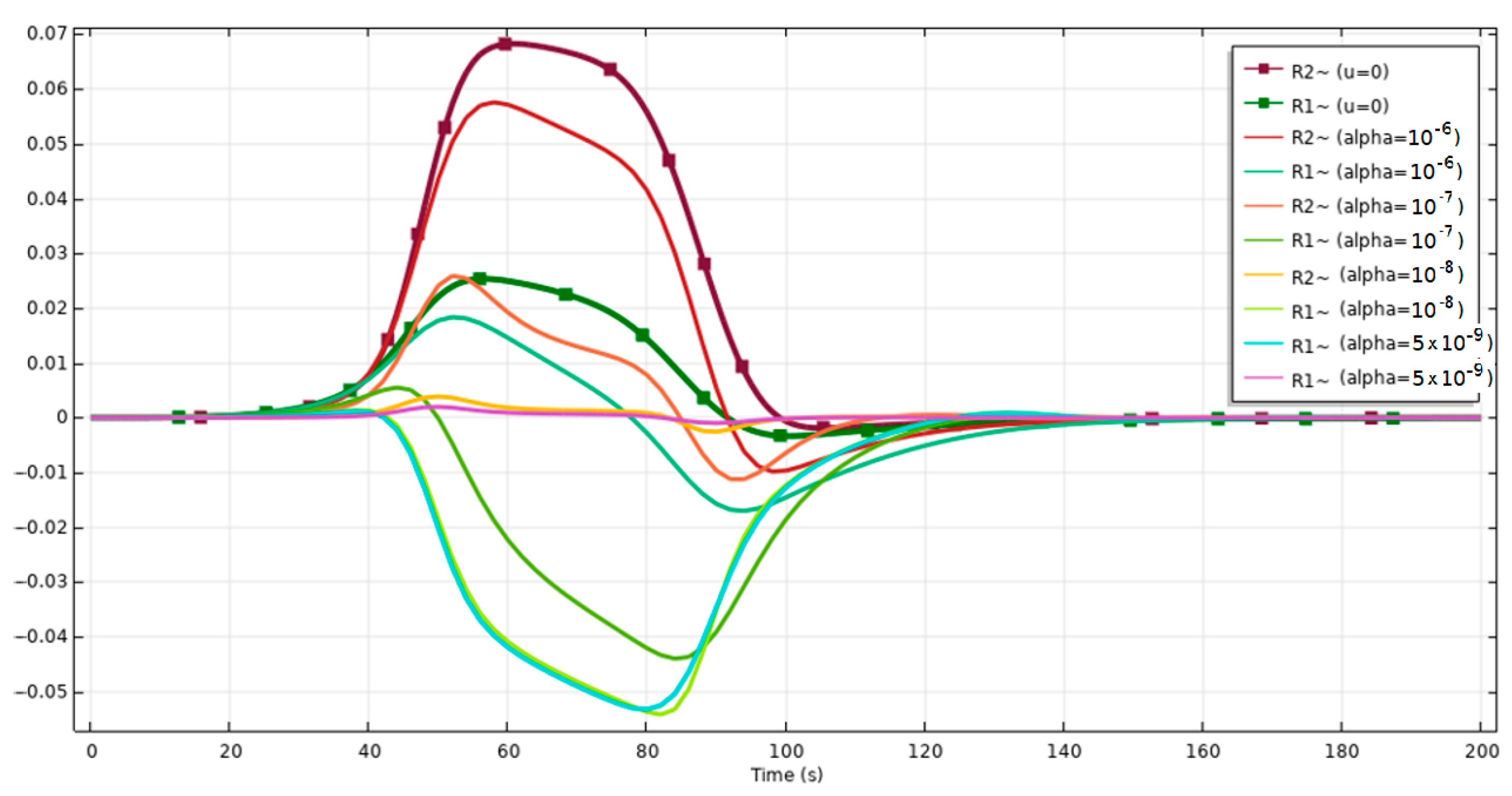

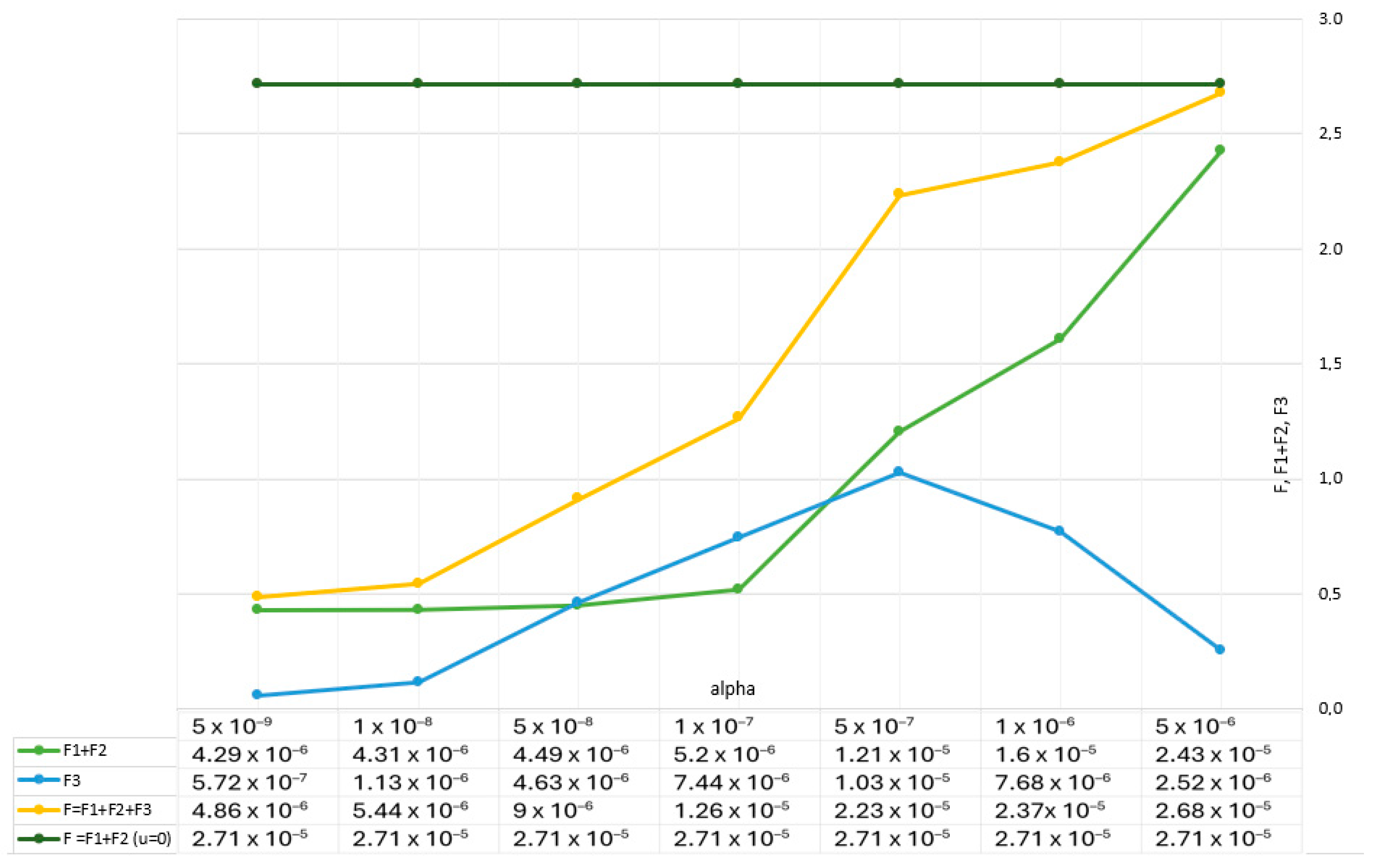

3.1. Isothermal Case

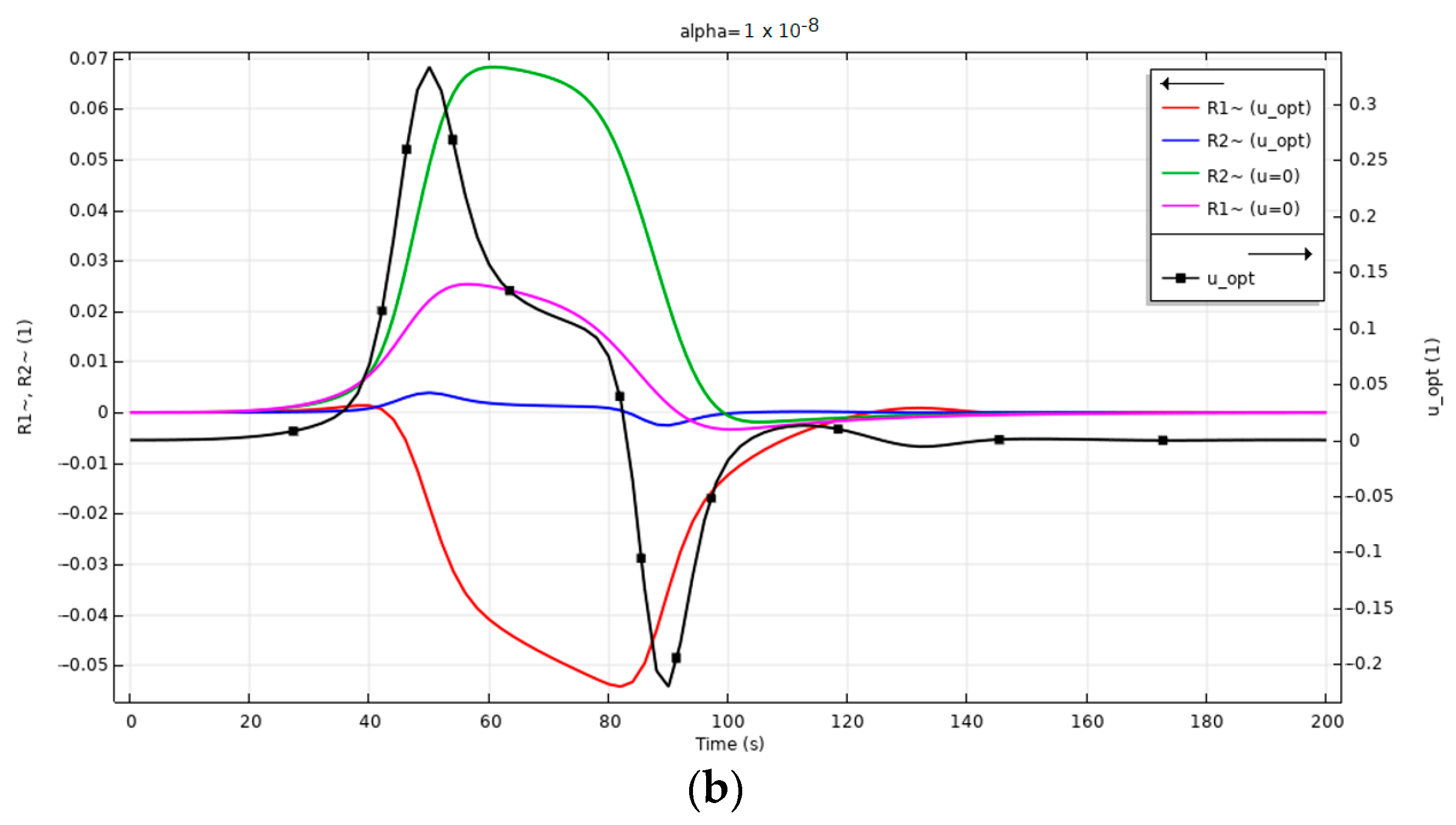

3.2. Non-Isothermal Case

4. Results and Discussion

5. Model Verification Proposal

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agrell, E.; Karlsson, M.; Chraplyvy, A.R.; Richardson, D.J.; Krummrich, P.M.; Winzer, P.; Roberts, K.; Fischer, J.K.; Savory, S.J.; Eggleton, B.J.; et al. Roadmap of optical communications. J. Opt. 2016, 18, 063002. [Google Scholar] [CrossRef]

- Liang, X.; Jiao, K.; Wang, X.; Wang, Y.; Wang, Y.; Bai, S.; Wang, R.; Zhao, Z.; Wang, X. Progresses of Mid-Infrared Glass Fiber for Laser Power Delivery. Photonics 2024, 11, 19. [Google Scholar] [CrossRef]

- Hartog, A.; Liokumovich, L.; Ushakov, N.; Kotov, O.; Dean, T.; Cuny, T.; Constantinou, A.; Englich, F. The use of multi-frequency acquisition to significantly improve the quality of fibre-optic-distributed vibration sensing. Geophys. Prospect. 2017, 66, 192–202. [Google Scholar] [CrossRef]

- Varshney, A.; Goya, V. Fiber Optics Communication: Evolution of Guided Media. Int. J. Res. Appl. Sci. Eng. Technol. (IJRASET) 2024, 12, 2321–9653. [Google Scholar] [CrossRef]

- Gorlov, N.I.; Bogachkov, I.V. The Principles of Information Safety for Physical Channels of Optical Access Networks. Instrum. Exp. Tech. 2020, 63, 591–594. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z.; Wang, G.; Yu, F.; Zhang, B.; Yang, F. Polarization Stability of Spun Fiber Resonator for Resonant Fiber Optic Gyro. IEEE Sens. J. 2023, 23, 15644–15651. [Google Scholar] [CrossRef]

- Mizeva, I.A.; Potapova, E.V.; Dremin, V.V.; Zherebtsov, E.A.; Mezentsev, M.A.; Shuleptsov, V.V.; Dunaev, A.V. Optical probe pressure effects on cutaneous blood flow. Clin. Hemorheol. Microcirc. 2019, 72, 259–267. [Google Scholar] [CrossRef]

- Chung, D.D.L. A Review of Self-Sensing in Carbon Fiber Structural Composite Materials. World Sci. Annu. Rev. Funct. Mater. 2023, 1, 2230004. [Google Scholar] [CrossRef]

- Matveenko, V.; Serovaev, G. Distributed Strain Measurements Based on Rayleigh Scattering in the Presence of Fiber Bragg Gratings in an Optical Fiber. Photonics 2023, 10, 868. [Google Scholar] [CrossRef]

- Chernutsky, A.O.; Khan, R.I.; Gritsenko, T.V.; Koshelev, K.I.; Zhirnov, A.A.; Pnev, A.B. Active Thermostatting of the Reference Optical Fiber Section Method in a Distributed Fiber-Optical Temperature Sensor. Instrum. Exp. Tech. 2023, 66, 824–831. [Google Scholar] [CrossRef]

- Bogachkov, I.V.; Gorlov, N.I.; Monastyrskaya, T.I. Types and Applications of Fiber-Optic Sensors Based on the Mandelstam—Brillouin Scattering Principle. In Proceedings of the 2022 International Conference on Information, Control, and Communication Technologies (ICCT), Astrakhan, Russia, 3–7 October 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Gritsenko, T.V.; Dyakova, N.V.; Zhirnov, A.A.; Stepanov, K.V.; Khan, R.I.; Koshelev, K.I.; Pnev, A.B.; Karasik, V.E. Study of Sensitivity Distribution Along the Contour of a Fiber-Optic Sensor Based on a Sagnac Interferometer. Instrum. Exp. Tech. 2023, 66, 788–794. [Google Scholar] [CrossRef]

- López-Mercado, C.; Itrin, P.; Korobko, D.A.; Zolotovskii, I.O.; Fotiadi, A.A. Brillouin optical time domain analysis with dual-frequency self-injection locked DFB laser. In Proceedings of the Proc. SPIE 12139, Optical Sensing and Detection VII, 121391D, Strasbourg, France, 17 May 2022. [Google Scholar] [CrossRef]

- Ferreira, M.F.S. Optical Fibers: Technology, Communications and Recent Advances; Nova Science Publishers: Hauppauge, NY, USA, 2017; ISBN 9781536109917. [Google Scholar]

- Kharakhordin, A.; Rybaltovsky, A.; Popov, S.; Ryakhovskiy, D.; Afanasiev, F.; Alyshev, S.; Khegai, A.; Melkumov, M.; Firstova, E.; Chamorovsky, Y.; et al. Random Laser Operating at Near 1.67 µM Based on Bismuth-Doped Artificial Rayleigh Fiber. J. Light. Technol. 2023, 41, 6362–6368. [Google Scholar] [CrossRef]

- Fotiadi, A.A.; Korobko, D.A.; Zolotovskii, I.O. Brillouin Lasers and Sensors: Trends and Possibilities. Optoelectron. Instrum. Proc. 2023, 59, 66–76. [Google Scholar] [CrossRef]

- Gangwar, R.K.; Kumari, S.; Pathak, A.K.; Gutlapalli, S.D.; Meena, M.C. Optical Fiber Based Temperature Sensors: A Review. Optics 2023, 4, 171–197. [Google Scholar] [CrossRef]

- Pioz, M.J.; Espinosa, R.L.; Laguna, M.F.; Santamaria, B.; Murillo, A.M.M.; Hueros, Á.L.; Quintero, S.; Tramarin, L.; Valle, L.G.; Herreros, P.; et al. A review of Optical Point-of-Care devices to Estimate the Technology Transfer of These Cutting-Edge Technologies. Biosensors 2022, 12, 1091. [Google Scholar] [CrossRef]

- Guzmán-Sepúlveda, J.R.; Guzmán-Cabrera, R.; Castillo-Guzmán, A.A. Optical Sensing Using Fiber-Optic Multimode Interference Devices: A Review of Nonconventional Sensing Schemes. Sensors 2021, 21, 1862. [Google Scholar] [CrossRef]

- Pallarés-Aldeiturriaga, D.; Roldán-Varona, P.; Rodríguez-Cobo, L.; López-Higuera, J.M. Optical Fiber Sensors by Direct Laser Processing: A Review. Sensors 2020, 20, 6971. [Google Scholar] [CrossRef] [PubMed]

- Bourdine, A.V.; Demidov, V.V.; Kuznetsov, A.A.; Vasilets, A.A.; Ter-Nersesyants, E.V.; Khokhlov, A.V.; Matrosova, A.S.; Pchelkin, G.A.; Dashkov, M.V.; Zaitseva, E.S.; et al. Twisted Few-Mode Optical Fiber with Improved Height of Quasi-Step Refractive Index Profile. Sensors 2022, 22, 3124. [Google Scholar] [CrossRef] [PubMed]

- Portosi, V.; Laneve, D.; Falconi, M.C.; Prudenzano, F. Advances on Photonic Crystal Fiber Sensors and Applications. Sensors 2019, 19, 1892. [Google Scholar] [CrossRef]

- Mittal, S.; Saharia, A.; Ismail, Y.; Petruccione, F.; Bourdine, A.V.; Morozov, O.G.; Demidov, V.V.; Yin, J.; Singh, G.; Tiwari, M. Spiral Shaped Photonic Crystal Fiber-Based Surface Plasmon Resonance Biosensor for Cancer Cell Detection. Photonics 2023, 10, 230. [Google Scholar] [CrossRef]

- Bourdine, A.V.; Barashkin, A.Y.; Burdin, V.A.; Dashkov, M.V.; Demidov, V.V.; Dukelskii, K.V.; Evtushenko, A.S.; Ismail, Y.; Khokhlov, A.V.; Kuznetsov, A.A.; et al. Twisted Silica Microstructured Optical Fiber with Equiangular Spiral Six-Ray Geometry. Fibers 2021, 9, 27. [Google Scholar] [CrossRef]

- Li, J.; Wang, R.; Wang, J.; Xu, Z.; Su, Y. Novel large negative dispersion photonic crystal fiber for dispersion compensation. In Proceedings of the 2011 Second International Conference on Mechanic Automation and Control Engineering, Inner Mongolia, China, 15–17 July 2011; pp. 1443–1446. [Google Scholar] [CrossRef]

- Cui, M.; Wang, Z.; Yu, C. Refractive Index Sensing Using Helical Broken-Circular-Symmetry Core Microstructured Optical Fiber. Sensors 2022, 22, 9523. [Google Scholar] [CrossRef] [PubMed]

- Wei, L. Advanced Fiber Sensing Technologies; Springer: Berlin, Germany, 2020; Volume 9, ISBN 978-981-15-5506-0. [Google Scholar] [CrossRef]

- Pysz, D.; Kujawa, I.; Stępień, R.; Klimczak, M.; Filipkowski, A.; Franczyk, M.; Kociszewski, L.; Buźniak, J.; Haraśny, K.; Buczyński, R. Stack and draw fabrication of soft glass microstructured fiber optics. Bull. Pol. Acad. Sci. Tech. Sci. 2014, 62, 667–682. [Google Scholar] [CrossRef]

- Yajima, T.; Yamamoto, J.; Ishii, F.; Hirooka, T.; Yoshida, M.; Nakazawa, M. Low-loss photonic crystal fiber fabricated by a slurry casting method. Opt. Express 2013, 21, 30500. [Google Scholar] [CrossRef] [PubMed]

- Bernard, T.; Blanco, I.H.; Peters, M. Model predictive control of a complex rheological forming process based in a finite element model. In Proceedings of the Comsol Multiphysics Conference, Frankfurt, Germany, 19 January 2005; Proceedings and User Presentations CD. 2006. [Google Scholar]

- Fitt, A.D.; Furusawa, K.; Monro, T.M.; Please, C.P.; Richardson, D.J. The mathematical modelling of capillary drawing for holey fiber manufacture. J. Eng. Math. 2002, 43, 201–227. [Google Scholar] [CrossRef]

- Griffiths, I.M.; Howell, P.D. Mathematical modelling of non-axisymmetric capillary tube drawing. J. Fluid Mech. 2008, 605, 181–206. [Google Scholar] [CrossRef]

- Vasil’ev, V.N.; Dul’nev, G.N.; Naumchik, V.D. Nestatsionarnye protsessy pri formirovanii opticheskogo volokna. Ustoichivost’ protsessa vytiazhki. In Non-Stationary Processes in the Formation of the Optical Fiber. Stability of Drawing Process; Energoperenos v Konvektivnykh Potokakh: Minsk, Belarus, 1985; pp. 64–76. [Google Scholar]

- Vladimirova, D.B. Optimal Control of the Silica Capillaries Drawing Process. In Proceedings of the 2020 2nd International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency (SUMMA): Lipetsk State Techn. Univ., Lipetsk, Russia, 10–13 November 2020; pp. 517–520. [Google Scholar]

- Butt, A.I.K.; Pinnau, R. Pinnau Optimal control of a non-isothermal tube drawing process. J. Eng. Math. 2012, 76, 1–17. [Google Scholar] [CrossRef]

- Vladimirova, D.B. Control of the Silica Photonic Crystal Fiber Production. IOP Conf. Ser. Earth Environ. Sci. 2021, 720, 012137. [Google Scholar] [CrossRef]

- Pervadchuk, V.; Vladimirova, D.; Derevyankina, A. Mathematical Modeling of Capillary Drawing Stability for Hollow Optical Fibers. Algorithms 2023, 16, 83. [Google Scholar] [CrossRef]

- Pervadchuk, V.; Vladimirova, D.; Gordeeva, I.; Kuchumov, A.G.; Dektyarev, D. Fabrication of Silica Optical Fibers: Optimal Control Problem Solution. Fibers 2021, 9, 77. [Google Scholar] [CrossRef]

- Butt, A.; Abbas, M.; Ahmad, W. A mathematical analysis of an isothermal tube drawing process. Alex. Eng. J. 2020, 59, 3419–3429. [Google Scholar] [CrossRef]

- Choudhury, S.R.; Jaluria, Y. Practical aspects in the drawing of an optical fiber. J. Mater. Res. 1998, 13, 483–493. [Google Scholar] [CrossRef]

- Pervadchuk, V.P.; Vladimirova, D.B.; Gordeeva, I.V. Optimal control of distributed systems in problems of quartz optical fiber production. In Proceedings of the 6th International Eurasian Conference on Mathematical Sciences and Applications (IECMSA 2017), Budapest, Hungary, 15–18 August 2017. [Google Scholar]

- Pervadchuk, V.P.; Vladimirova, D.B.; Gordeeva, I.V. The boundary control problem of optical fiber drawing. J. Phys. Conf. Ser. 2019, 1172, 012047. [Google Scholar] [CrossRef]

- Talataisong, W.; Ismaeel, R.; Beresna, M.; Brambilla, G. Suspended-Core Microstructured Polymer Optical Fibers and Potential Applications in Sensing. Sensors 2019, 19, 3449. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.; Park, K.S.; Cho, J. Modelling of chemical vapour deposition for optical fibre manufacture. Opt. Quantum Electron. 1995, 27, 327–335. [Google Scholar] [CrossRef]

- Lienard, I.V.; John, H. A Heat Transfer Textbook; Phlogiston Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Fitt, A.D.; Furusawa, K.; Monro, T.M.; Please, C.P. Modeling the fabrication of hollow fibers: Capillary drawing. J. Light. Technol. 2001, 19, 1924–1931. [Google Scholar] [CrossRef]

- Pervadchuk, V.P.; Vladimirova, D.B.; Gordeeva, I.V. Granichnoe upravlenie raspredelennoj sistemoj v zadachah vytyazhki kvarcevyh opticheskih volokon. Comput. Contin. Mech. 2018, 11, 388–396. [Google Scholar] [CrossRef]

- Fursikov, A.V. Optimal Control of Distributed Systems. In Theory and Applications; Moscow State University: Moscow, Russia; p. 320.

- Rizwan, M.; Ahmad, S.; Shah, S.N.; Ali, M.; Shah, M.U.H.; Zaman, M.; Suleman, H.; Habib, M.; Tariq, R.; Krzywanski, J. Optimizing the Air Conditioning Layouts of an Indoor Built Environment: Towards the Energy and Environmental Benefits of a Clean Room. Buildings 2022, 12, 2158. [Google Scholar] [CrossRef]

- Dong, Y.; Teng, L.; Zhang, H.; Jiang, T.; Zhou, D. Characterization of Distributed Birefringence in Optical Fibers. In Handbook of Optical Fibers; Peng, G.D., Ed.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Lee, H.; Noda, K.; Nakamura, K.; Mizuno, Y. Fiber-optic distributed measurement of polarization beat length using slope-assisted Brillouin optical correlation-domain reflectometry. Opt. Rev. 2020, 27, 542–547. [Google Scholar] [CrossRef]

- Bogachkov, I.V.; Gorlov, N.I. Experimental investigations into characteristics of Mandelshtam–Brillouin scattering in single-mode optical fiber of various types. Instrum. Exp. Tech. 2023, 66, 775–781. [Google Scholar] [CrossRef]

- Wen, G.; Zhang, H.; Li, T.; Qu, J.; Jia, D.; Liu, T. A 10-km Polarization Maintaining Fiber Distributed Polarization Coupling Measurement Method with Dispersion Compensation Function Based on White Light Interferometer. IEEE Sens. J. 2023, 23, 21293–21300. [Google Scholar] [CrossRef]

- Tkachenko, A.Y.; Lobach, I.A.; Kablukov, S.I. Coherent Optical Frequency Reflectometry Based on a Fiber Self-Scanning Laser: Current Status and Development Prospects (Review). Instrum. Exp. Tech. 2023, 66, 730–736. [Google Scholar] [CrossRef]

- Poddubrovskii, N.R.; Lobach, I.A.; Kablukov, S.I. Signal Processing in Optical Frequency Domain Reflectometry Systems Based on Self-Sweeping Fiber Laser with Continuous-Wave Intensity Dynamics. Algorithms 2023, 16, 260. [Google Scholar] [CrossRef]

- Yang, Q.; Xie, W.; Yang, J.; Yan, R.; Wang, C.; Zheng, X.; Wei, W.; Dong, Y. Interval-locked dual-frequency φ-OFDR with an enhanced strain dynamic range and a long-term stability. Opt. Lett. 2023, 48, 5523–5526. [Google Scholar] [CrossRef]

- Han, G.; Guo, Z.; Wang, S.; Du, H.; Marco, J.; Greenwood, D.; Yu, Y.; Yan, J. Integrated Silicon Photonics OFDR System for High-Resolution Distributed Measurements Based on Rayleigh Backscattering. J. Light. Technol. 2024, 42, 3482–3493. [Google Scholar] [CrossRef]

- Dhar, A.; Dutta, D.; Choudhury, N.; Ghosh, D. A Novel Approach to Reduce Attenuation Loss in Silica-based Microstructured Optical Fibers. In Conference on Lasers and Electro-Optics; Kang, J., Tomasulo, S., Ilev, I., Müller, D., Litchinitser, N., Polyakov, S., Podolskiy, V., Nunn, J., Dorrer, C., Fortier, T., et al., Eds.; OSA Technical Digest; Optica Publishing Group: San Jose, CA, USA, 2021. [Google Scholar] [CrossRef]

- Gerosa, R.M.; Osório, J.H.; Lopez-Cortes, D.; Cordeiro, C.M.B.; De Matos, C.J.S. Distributed Pressure Sensing Using an Embedded-Core Capillary Fiber and Optical Frequency Domain Reflectometry. IEEE Sens. J. 2021, 21, 360–365. [Google Scholar] [CrossRef]

- Rizzolo, S.; Boukenter, A.; Perisse, J.; Bouwmans, G.; El Hamzaoui, H.; Bigot, L.; Ouerdane, Y.; Cannas, M.; Bouazaoui, M.; Mace, J.-R.; et al. Radiation Response of OFDR Distributed Sensors Based on Microstructured Pure Silica Optical Fibers. In Proceedings of the 2015 15th European Conference on Radiation and Its Effects on Components and Systems (RADECS), Moscow, Russia, 14–18 September 2015; pp. 1–3. [Google Scholar] [CrossRef]

- Belokrylov, M.E.; Claude, D.; Konstantinov, Y.A.; Karnaushkin, P.V.; Ovchinnikov, K.A.; Krishtop, V.V.; Gilev, D.G.; Barkov, F.L.; Ponomarev, R.S. Method for Increasing the Signal-to-Noise Ratio of Rayleigh Back-Scattered Radiation Registered by a Frequency Domain Optical Reflectometer Using Two-Stage Erbium Amplification. Instrum. Exp. Tech. 2023, 66, 761–768. [Google Scholar] [CrossRef]

- Pedraza, A.; del Río, D.; Bautista-Juzgado, V.; Fernández-López, A.; Sanz-Andrés, Á. Study of the Feasibility of Decoupling Temperature and Strain from a ϕ-PA-OFDR over an SMF Using Neural Networks. Sensors 2023, 23, 5515. [Google Scholar] [CrossRef]

- Meng, X.; Luo, M.; Liu, J.; Zhao, S.; Zhou, R. Birefringence characterization in a dual-hole microstructured optical fiber using an OFDR method. Appl. Opt. 2024, 63, 772–776. [Google Scholar] [CrossRef]

- Konstantinov, Y.A.; Kryukov, I.I.; Pervadchuk, V.P.; Toroshin, A.Y. Polarisation reflectometry of anisotropic optical fibres. Quantum Electron. 2009, 39, 11. [Google Scholar] [CrossRef]

- Turov, A.T.; Barkov, F.L.; Konstantinov, Y.A.; Korobko, D.A.; Lopez-Mercado, C.A.; Fotiadi, A.A. Activation Function Dynamic Averaging as a Technique for Nonlinear 2D Data Denoising in Distributed Acoustic Sensors. Algorithms 2023, 16, 440. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vladimirova, D.; Pervadchuk, V.; Konstantinov, Y. Manufacture of Microstructured Optical Fibers: Problem of Optimal Control of Silica Capillary Drawing Process. Computation 2024, 12, 86. https://doi.org/10.3390/computation12050086

Vladimirova D, Pervadchuk V, Konstantinov Y. Manufacture of Microstructured Optical Fibers: Problem of Optimal Control of Silica Capillary Drawing Process. Computation. 2024; 12(5):86. https://doi.org/10.3390/computation12050086

Chicago/Turabian StyleVladimirova, Daria, Vladimir Pervadchuk, and Yuri Konstantinov. 2024. "Manufacture of Microstructured Optical Fibers: Problem of Optimal Control of Silica Capillary Drawing Process" Computation 12, no. 5: 86. https://doi.org/10.3390/computation12050086