Lossy Mode Resonance Sensors Fabricated by RF Magnetron Sputtering GZO Thin Film and D-Shaped Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Gallium-Doped Zinc Oxide Thin Film

2.2. Fabrication of LMR Fiber-Optic Sensors

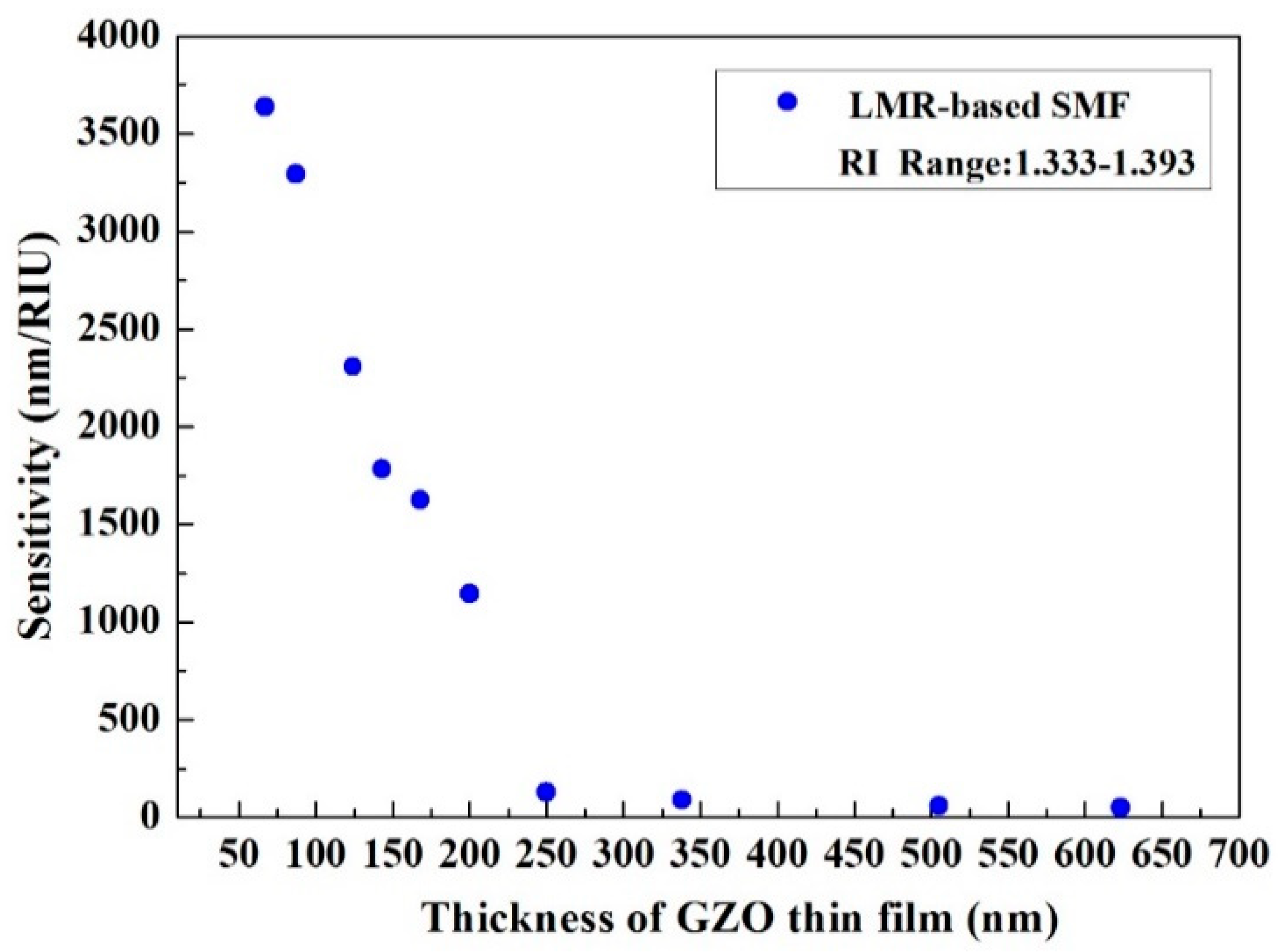

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ishaq, M.; Quintela, A.; James, S.W.; Ashwell, G.J.; Lopez-Higuera, J.M.; Tatam, R.P. Modification of the refractive index response of long period gratings using thin film overlays. Sens. Actuators B Chem. 2005, 107, 738–741. [Google Scholar] [CrossRef] [Green Version]

- Kersey, D.; Davis, M.A.; Patrick, H.J.; LeBlan, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber Grating Sensors. J. Lightwave Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef] [Green Version]

- Espejo, R.J.; Dyer, S.D. Practical spatial resolution limits of high-resolution fibre Bragg grating sensors using layer peeling. Meas. Sci. Technol. 2007, 18, 1661–1666. [Google Scholar] [CrossRef]

- Matsubara, K.; Kawata, S.; Minami, S. Multilayer system for a high precision surface plasmon resonance sensor. Opt. Lett. 1990, 15, 75–77. [Google Scholar] [CrossRef] [PubMed]

- Suhadolnik, A. An optical fibre interferometric refractometer. Meas. Sci. Technol. 2007, 18, 1205–1208. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Chang, Y.J.; Chuang, Y.C.; Huang, B.Z.; Chen, C.C. A plasmonic refractive index sensor with an ultrabroad dynamic sensing range. Sci. Rep. 2019, 9, 5134. [Google Scholar] [CrossRef] [Green Version]

- Holm, E. Radioecology: Lectures in Environmental Radioactivity; World Scientific: Singapore, 1995; p. 153. [Google Scholar]

- Min, Z.J.; Li, J.P.; Jiang, S.H. Measurement of salt salinity in solar pond by supersonic method. Acta Eneglae Solaris Sinica 1995, 16, 224–228. [Google Scholar]

- Diniz, F.B.; de Freitas, K.C.S.; de Azevedo, W.M. Salinity measurements with polyaniline matrix coated wire electrodes. Electrochem. Commun. 1999, 1, 271–273. [Google Scholar] [CrossRef]

- Esteban, O.; Navarrete, M.C.; Cano, A.G.; Bernabeu, E. Measurement of the degree of salinity of water with a fiber-optic sensor. Appl. Opt. 1999, 38, 5267–5271. [Google Scholar] [CrossRef] [Green Version]

- Rahman, H.A.; Harun, S.W.; Yasin, M.; Ahmad, H. Fiber optic salinity sensor using beam-through technique. Optik 2013, 124, 679–681. [Google Scholar] [CrossRef]

- Cong, J.; Zhang, X.M.; Chen, K.S.; Xu, J. Fiber optic Bragg grating sensor based on hydrogels for measuring salinity. Sens. Actuators. B Chem. 2002, 87, 487–490. [Google Scholar] [CrossRef]

- Men, L.; Lu, P.; Chen, Q. A multiplexed fiber Bragg grating sensor for simultaneous salinity and temperature measurement. J. Appl. Phys. 2008, 103, 053107. [Google Scholar] [CrossRef]

- Yu, F.T.S.; Yin, S. Fiber Optic Sensors; Dekker: New York, NY, USA, 2002; Chaps. 2 and 4. [Google Scholar]

- Andreev, A.T.; Zafirova, B.S.; Karakoleva, E.I.; Dikovska, A.O.; Atanasov, P.A. Highly sensitive refractometers based on a side-polished single-mode fibre coupled with a metal oxide thin-film planar waveguide. J. Opt. A Pure Appl. Opt. 2008, 10, 035303. [Google Scholar] [CrossRef]

- Tien, C.L.; Chen, H.W.; Lin, S.W.; Liu, W.F.; Lin, Y.S. Hydrogen sensor based on side-polished fiber Bragg gratings coated with thin palladium film. Thin Solid Films 2008, 516, 5360–5363. [Google Scholar] [CrossRef]

- Schroeder, K.; Ecke, W.; Mueller, R.; Willsch, R.; Andreev, A. A Fibre Bragg Grating Refractometer. Meas. Sci. Technol. 2001, 12, 757–764. [Google Scholar] [CrossRef]

- Cusano, A.; Iadicicco, A.; Pilla, P.; Contessa, L.; Campopiano, S.; Cutolo, A. Mode transition in high refractive index coated long period gratings. Opt. Express 2006, 14, 19–34. [Google Scholar] [CrossRef] [PubMed]

- Homola, J. Surface Plasmon Resonance Based Sensors; Springer: New York, NY, USA, 2006. [Google Scholar]

- Yang, F.; Sambles, J.R. Determination of the optical permittivity and thickness of absorbing films using long range modes. J. Mod. Opt. 1997, 44, 1155–1163. [Google Scholar] [CrossRef]

- Wang, T.; Zalkovskij, M.; Iwaszczuk, K.; Lavrinenko, A.V.; Naik, G.V.; Kim, J.; Boltasseva, A.; Jepsen, P.U. Ultrabroad band terahertz conductivity of highly doped ZnO and ITO. Opt. Mater. Express 2015, 5, 566–575. [Google Scholar] [CrossRef]

- Kim, J.; Naik, G.V.; Gavrilenko, A.V.; Dondapati, K.; Gavrilenko, V.I.; Prokes, S.M.; Glembocki, O.J.; Shalaev, V.M.; Boltasseva, A. Optical properties of gallium-doped zinc oxide—A low-loss plasmonic material: First-principles theory and experiment. Phys. Rev. X 2013, 3, 041037. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.S.; Jeong, J.H.; Park, J.K.; Baik, Y.J.; Kim, I.H.; Seong, T.Y.; Kim, W.M. Optical analysis of doped ZnO thin films using nonparabolic conduction-band parameters. J. Appl. Phys. 2012, 111, 123507. [Google Scholar] [CrossRef]

- Kim, Y.H.; Jeong, J.; Lee, K.S.; Cheong, B.; Seong, T.Y.; Kim, W.M. Effect of composition and deposition temperature on the characteristics of Ga doped ZnO thin films. Appl. Surf. Sci. 2010, 257, 109–115. [Google Scholar] [CrossRef]

- Rana, A.U.; Shahid, A.; Lee, J.Y.; Kim, H.S. High-Power Microwave-Assisted Ga Doping, an Effective Method to Tailor n-ZnO/p-Si Heterostructure Optoelectronic Characteristics. Phys. Status Solidi A 2018, 215, 1700763. [Google Scholar] [CrossRef]

- Rana, A.S.; Kim, H.S. NH4OH Treatment for an optimum morphological trade-off to hydrothermal Ga-doped n-ZnO/p-Si heterostructure characteristics. Materials 2018, 11, 37. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ko, H.J.; Chen, Y.F.; Hong, S.K.; Wenisch, H.; Yao, T.; Look, D.C. Ga-doped ZnO films grown on GaN templates by plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 2000, 77, 3761–3763. [Google Scholar] [CrossRef] [Green Version]

- Park, S.M.; Ikegami, T.; Ebihara, K. Effects of substrate temperature on the properties of Ga-doped ZnO by pulsed laser deposition. Thin Solid Films 2006, 513, 90–94. [Google Scholar] [CrossRef]

- Usha, S.P.; Mishra, S.K.; Gupta, B.D. Fiber optic hydrogen sulfide gas sensors utilizing ZnO thin film/ZnO nanoparticles: A comparison of surface plasmon resonance and lossy mode resonance. Sens. Actuators B Chem. 2015, 218, 196–204. [Google Scholar] [CrossRef]

- Gupta, B.D.; Verma, R.K. Surface Plasmon resonance-based fiber optic sensors: Principle, probe designs, and some applications. J. Sens. 2009, 2009, 979761–979772. [Google Scholar] [CrossRef]

- Villar, I.D.; Hernaez, M.; Zamarreño, C.R.; Sánchez, P.; Fernández-Valdivielso, C.; Arregui, F.J.; Matias, I.R. Design rules for lossy mode resonance based sensors. Appl. Opt. 2012, 51, 4298–4307. [Google Scholar] [CrossRef]

- Batchman, T.E.; McWright, G.M. Mode coupling between dielectric and semiconductor planar waveguides. IEEE J. Quant. Electron. 1982, 18, 782–788. [Google Scholar] [CrossRef]

- Marciniak, M.; Grzegorzewski, J.; Szustakowski, M. Analysis of lossy mode cut-off conditions in planar waveguides with semiconductor guiding layer. IEE Proc. Part. J. Optoelectron. 1993, 140, 247–252. [Google Scholar] [CrossRef]

- Zamarreño, C.R.; Hernáez, M.; del Villar, I.; Matias, I.R.; Arregui, F.J. Tunable humidity sensor based on ITO coated optical fiber. Sens. Actuators B Chem. 2010, 146, 414–417. [Google Scholar] [CrossRef]

- Hernaez, M.; del Villar, I.; Zamarreño, C.M.; Arregui, F.J.; Matias, I.R. Optical fiber refractometers based on lossy mode resonances supported by TiO2 coatings. Appl. Opt. 2010, 49, 3980–3985. [Google Scholar] [CrossRef] [PubMed]

- Villar, I.D.; Zamarreño, C.R.; Hernáez, M.; Sánchez, P.; Carlos; Valdivielso, F.; Arregui, F.J.; Matías, I.R. Generation of lossy mode resonances by deposition of high-refractive-index coatings on uncladded multimode optical fibers. J. Opt. 2010, 12, 095503. [Google Scholar] [CrossRef] [Green Version]

- Sehmi, H.S.; Langbein, W.; Muljarov, E.A. Optimizing the Drude-Lorentz model for material permittivity: Method, program, and examples for gold, silver, and copper. Phys. Rev. B 2017, 95, 115444. [Google Scholar] [CrossRef] [Green Version]

- Ziman, M. Principles of the Theory of Solids; Cambridge University Press: London, UK, 1979. [Google Scholar]

- Look, D.C.; Leedy, K.D.; Grzybowski, G.J.; Claflin, B.B. Near-infrared (1 to 4 μm) control of plasmonic resonance wavelength in Ga-doped ZnO. Opt. Eng. 2017, 56, 057109. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, V.K.; Kapoor, A. Integrated optic TE/TM pass polarizers using resonant coupling between ITO thin film lossy modes and dielectric waveguides modes. Opt. Commun. 2012, 291, 247–252. [Google Scholar] [CrossRef]

- Tien, C.L.; Lin, T.W.; Hsu, H.Y.; Chen, L.C.; Chen, Y.C.; Liu, W.F. Double-sided polishing long period fiber grating sensors for measuring liquid refractive index. Proc. SPIE 2009, 7634, 76341A. [Google Scholar]

- Usha, S.P.; Gupta, B.D. Performance analysis of zinc oxide-implemented lossy mode resonance-based optical fiber refractive index sensor utilizing thin film/nanostructure. Appl. Opt. 2017, 56, 5716–5725. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tien, C.-L.; Mao, T.-C.; Li, C.-Y. Lossy Mode Resonance Sensors Fabricated by RF Magnetron Sputtering GZO Thin Film and D-Shaped Fibers. Coatings 2020, 10, 29. https://doi.org/10.3390/coatings10010029

Tien C-L, Mao T-C, Li C-Y. Lossy Mode Resonance Sensors Fabricated by RF Magnetron Sputtering GZO Thin Film and D-Shaped Fibers. Coatings. 2020; 10(1):29. https://doi.org/10.3390/coatings10010029

Chicago/Turabian StyleTien, Chuen-Lin, Tzu-Chi Mao, and Chi-Yuan Li. 2020. "Lossy Mode Resonance Sensors Fabricated by RF Magnetron Sputtering GZO Thin Film and D-Shaped Fibers" Coatings 10, no. 1: 29. https://doi.org/10.3390/coatings10010029