Effect of Substrate Temperature on the Optical and Electrical Properties of Nitrogen-Doped NiO Thin Films

Abstract

:1. Introduction

2. Materials and Methods

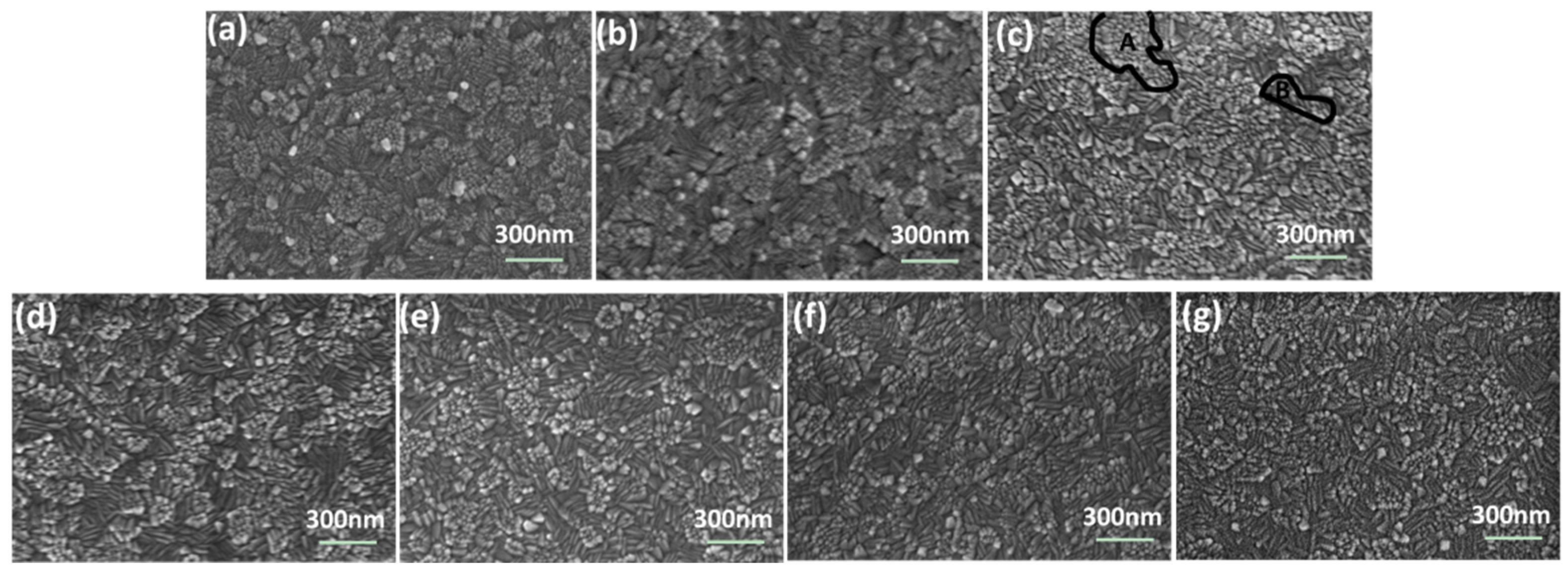

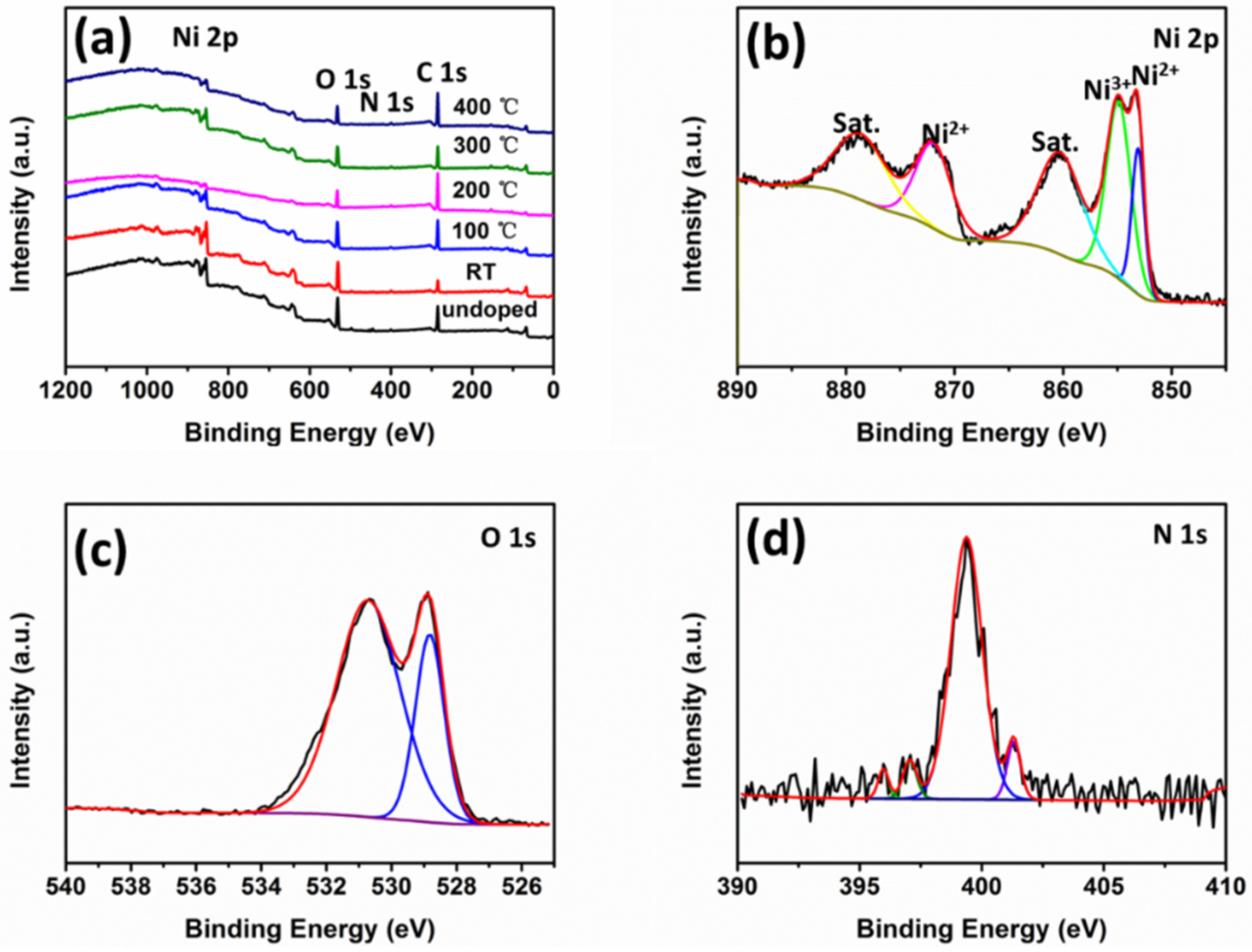

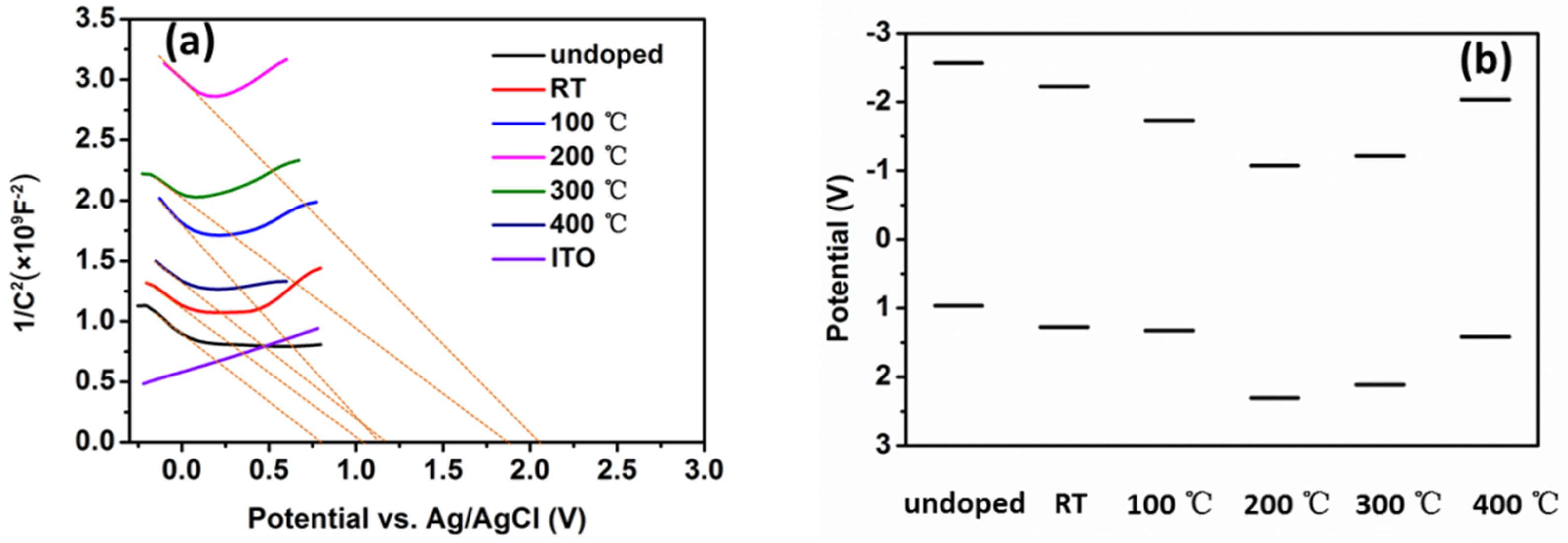

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sasi, B.; Gopchandran, K.G.; Manoj, P.K.; Koshy, P.; Rao, P.P.; Vaidyan, V.K. Preparation of transparent and semiconducting NiO films. Vacuum 2002, 68, 149–154. [Google Scholar] [CrossRef]

- Liu, H.; Zheng, W.; Yan, X.; Feng, B. Studies on electrochromic properties of nickel oxide thin films prepared by reactive sputtering. J. Alloy. Compd. 2008, 462, 356–361. [Google Scholar] [CrossRef]

- Mahmoud, S.A.; Akl, A.A.; Kamal, H.; Abdel-Hady, K. Opto-structural, electrical and electrochromic properties of crystalline nickel oxide thin films prepared by spray pyrolysis. Physica B 2002, 311, 366–375. [Google Scholar] [CrossRef]

- Maruyama, T.; Arai, S. The electrochromic properties of nickel oxide thin films prepared by chemical vapor deposition. Sol. Energy Mater. Sol. Cells 1993, 30, 257–262. [Google Scholar] [CrossRef]

- Guo, W.; Hui, K.N.; Hui, K.S. High conductivity nickel oxide thin films by a facile sol-gel method. Mater. Lett. 2013, 92, 291–295. [Google Scholar] [CrossRef]

- Subramanian, B.; Ibrahim, M.M.; Senthilkumar, V.; Murali, K.R.; Vidhya, V.S.; Sanjeeviraja, C.; Jayachandran, M. Optoelectronic and electrochemical properties of nickel oxide (NiO) films deposited by DC reactive magnetron sputtering. Physica B 2008, 403, 4104–4110. [Google Scholar] [CrossRef]

- Ismail, R.A.; Ghafori, S.A.; Kadhim, G.A. Preparation and characterization of nanostructured nickel oxide thin films by spray pyrolysis. Appl. Nanosci. 2013, 3, 509–514. [Google Scholar] [CrossRef]

- Jahromi, S.P.; Huang, N.M.; Kamalianfar, A.; Lim, H.N.; Muhamad, M.R.; Yousefi, R. Facile synthesis of porous-structured nickel oxide thin film by pulsed laser deposition. J. Nanomater. 2012, 2012, 97. [Google Scholar] [CrossRef]

- Soo Kim, D.; Chul Lee, H. Nickel vacancy behavior in the electrical conductance of nonstoichiometric nickel oxide film. J. Appl. Phys. 2012, 112, 034504. [Google Scholar] [CrossRef]

- Nandy, S.; Saha, B.; Mitra, M.K.; Chattopadhyay, K.K. Effect of oxygen partial pressure on the electrical and optical properties of highly (200) oriented p-type Ni1−xO films by DC sputtering. J. Mater. Sci. Lett. 2007, 42, 5766–5772. [Google Scholar] [CrossRef]

- Sato, H.; Minami, T.; Takata, S.; Yamada, T. Transparent conducting p-type NiO thin films prepared by magnetron sputtering. Thin Solid Films 1993, 236, 27–31. [Google Scholar] [CrossRef]

- Nandy, S.; Maiti, U.N.; Ghosh, C.K.; Chattopadhyay, K.K. Enhanced p-type conductivity and band gap narrowing in heavily Al doped NiO thin films deposited by RF magnetron sputtering. J. Phys. 2009, 21, 115804. [Google Scholar] [CrossRef] [PubMed]

- Keraudy, J.; Ferrec, A.; Richard-Plouet, M.; Hamon, J.; Goullet, A.; Jouan, P.Y. Nitrogen doping on NiO by reactive magnetron sputtering: A new pathway to dynamically tune the optical and electrical properties. Appl. Surf. Sci. 2017, 409, 77–84. [Google Scholar] [CrossRef]

- Slack, G.A. Crystallography and domain walls in antiferromagnetic NiO crystals. J. Appl. Phys. 1960, 31, 1571–1582. [Google Scholar] [CrossRef]

- Roth, W.L. Neutron and optical studies of domains in NiO. J. Appl. Phys. 1960, 31, 2000–2011. [Google Scholar] [CrossRef]

- Qiu, J.; Chen, Z.; Zhao, T.; Chen, Z.; Chu, W.; Yuan, N.; Ding, J. Electrochromic Properties of NiOx Films Deposited by DC Magnetron Sputtering. J. Nanosci. Nanotechnol. 2018, 18, 4222–4229. [Google Scholar] [CrossRef] [PubMed]

- Ramasami, A.K.; Reddy, M.V.; Balakrishna, G.R. Combustion synthesis and characterization of NiO nanoparticles. Mater. Sci. Semicond. Process. 2015, 40, 194–202. [Google Scholar] [CrossRef]

- Zhu, H.; Dong, H.; Laveille, P.; Saih, Y.; Caps, V.; Basset, J.M. Metal oxides modified NiO catalysts for oxidative dehydro genation of ethaneto ethylene. Catal. Today 2014, 228, 58–64. [Google Scholar] [CrossRef]

- Mironova-Ulmane, N.; Kuzmin, A.; Grabis, J.; Sildos, I.; Voronin, V.I.; Berger, I.F.; Kazantsev, V.A. Structural and magnetic properties of nickel oxide nanopowder. Solid State Phenom. 2011, 168, 341–344. [Google Scholar] [CrossRef]

- Lei, Y.; Li, J.; Wang, Y.; Gu, L.; Chang, Y.; Yuan, H.; Xiao, D. Rapid microwave-assisted green synthesis of 3D hierarchical flower-shaped NiCo2O4 microsphere for high-performance supercapacitor. ACS Appl. Mater. Interfaces 2014, 6, 1773–1780. [Google Scholar] [CrossRef]

- Sasi, B.; Gopchandran, K.G. Nanostructured mesoporous nickel oxide thin films. Nanotechnology 2007, 18, 115613. [Google Scholar] [CrossRef]

- Asahi, R.; Morikawa, T.; Ohwaki, T.; Aoki, K.; Taga, Y. Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 2001, 293, 269–271. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.R.; Hung, C.H. Characterization of N, C-codoped TiO2 films prepared by reactive DC magnetron sputtering. Appl. Surf. Sci. 2009, 256, 1595–1603. [Google Scholar] [CrossRef]

- Aduru, S.; Contarini, S.; Rabalais, J.W. Electron-, X-ray-, and ion-stimulated decomposition of nitrate salts. J. Phys. Chem. 1986, 90, 1683–1688. [Google Scholar] [CrossRef]

- Simon, P.; Pignon, B.; Miao, B.; Coste-Leconte, S.; Leconte, Y.; Marguet, S.; Herlin-Boime, N. N-doped titanium monoxide nanoparticles with TiO rock-salt structure, low energy band gap, and visible light activity. Chem. Mater. 2010, 22, 3704–3711. [Google Scholar] [CrossRef]

- Duarte, D.A.; Sagás, J.C.; da Silva Sobrinho, A.S.; Massi, M. Modeling the reactive sputter deposition of N-doped TiO2 for application in dye-sensitized solar cells: Effect of the O2 flow rate on the substitutional N concentration. Appl. Surf. Sci. 2013, 269, 55–59. [Google Scholar] [CrossRef]

- Jang, W.L.; Lu, Y.M.; Hwang, W.S.; Chen, W.C. Electrical properties of Li-doped NiO thin films. J. Eur. Ceram. Soc. 2010, 30, 503–508. [Google Scholar] [CrossRef]

- Zhang, S.; Ali, N. (Eds.) Nanocomposite Thin Films and Coatings: Processing, Properties and Performances; Imperial College Press: London, UK, 2007; p. 299. [Google Scholar]

- Nguyen, D.T.; Ferrec, A.; Keraudy, J.; Richard-Plouet, M.; Goullet, A.; Cattin, L.; Jouan, P.Y. Ellipsometric and XPS characterization of transparent nickel oxide thin films deposited by reactive HiPIMS. Surf. Coat. Technol. 2014, 250, 21. [Google Scholar] [CrossRef]

- Ahn, K.S.; Deutsch, T.; Yan, Y.; Jiang, C.S.; Perkins, C.L.; Turner, J.; Al-Jassim, M. Synthesis of band-gap-reduced p-type ZnO films by Cu incorporation. J. Appl. Phys. 2007, 102, 023517. [Google Scholar] [CrossRef]

- Baumanis, C.; Bahnemann, D.W. TiO2 thin film electrodes: Correlation between photocatalytic activity and electrochemical properties. J. Phys. Chem. C 2008, 112, 19097–19101. [Google Scholar] [CrossRef]

- Fogler, H.S. Elements of Chemical Reaction Engineering, 2nd ed.; Prentice-Hall: New York, NY, USA, 1992; p. 254. [Google Scholar]

- Liu, J.; Huang, X.; Li, Y.; Zhong, Q.; Ren, L. Preparation and photoluminescence of ZnO complex structures with controlled morphology. Mater. Lett. 2006, 60, 1354–1359. [Google Scholar] [CrossRef]

- Kumari, L.; Li, W.Z.; Vannoy, C.H.; Leblanc, R.M.; Wang, D.Z. Vertically aligned and interconnected nickel oxide nanowalls fabricated by hydrothermal route. Cryst. Res. Technol. 2009, 44, 495–499. [Google Scholar] [CrossRef]

- Musevi, S.J.; Aslani, A.; Motahari, H.; Salimi, H. Offer a novel method for size appraise of NiO nanoparticles by PL analysis: Synthesis by sonochemical method. J. Saudi Chem. Soc. 2016, 20, 245–252. [Google Scholar] [CrossRef] [Green Version]

| Substrate Temperature (°C) | Deposition Rate (nm/min) |

|---|---|

| RT | 82 |

| 100 °C | 83 |

| 200 °C | 85 |

| 300 °C | 88 |

| 400 °C | 94 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Gong, L.; Qi, X.; Yang, Y.; Zhao, X. Effect of Substrate Temperature on the Optical and Electrical Properties of Nitrogen-Doped NiO Thin Films. Coatings 2019, 9, 634. https://doi.org/10.3390/coatings9100634

Tian Y, Gong L, Qi X, Yang Y, Zhao X. Effect of Substrate Temperature on the Optical and Electrical Properties of Nitrogen-Doped NiO Thin Films. Coatings. 2019; 9(10):634. https://doi.org/10.3390/coatings9100634

Chicago/Turabian StyleTian, Yuan, Lianguo Gong, Xueqian Qi, Yibiao Yang, and Xiaodan Zhao. 2019. "Effect of Substrate Temperature on the Optical and Electrical Properties of Nitrogen-Doped NiO Thin Films" Coatings 9, no. 10: 634. https://doi.org/10.3390/coatings9100634