Research Status and Prospect of Friction Stir Processing Technology

Abstract

:1. Introduction

2. Principle

2.1. Process Principle

2.2. Microstructure Transformation during Friction Stir Processing (FSP)

3. Process

3.1. Influence of Process Parameters

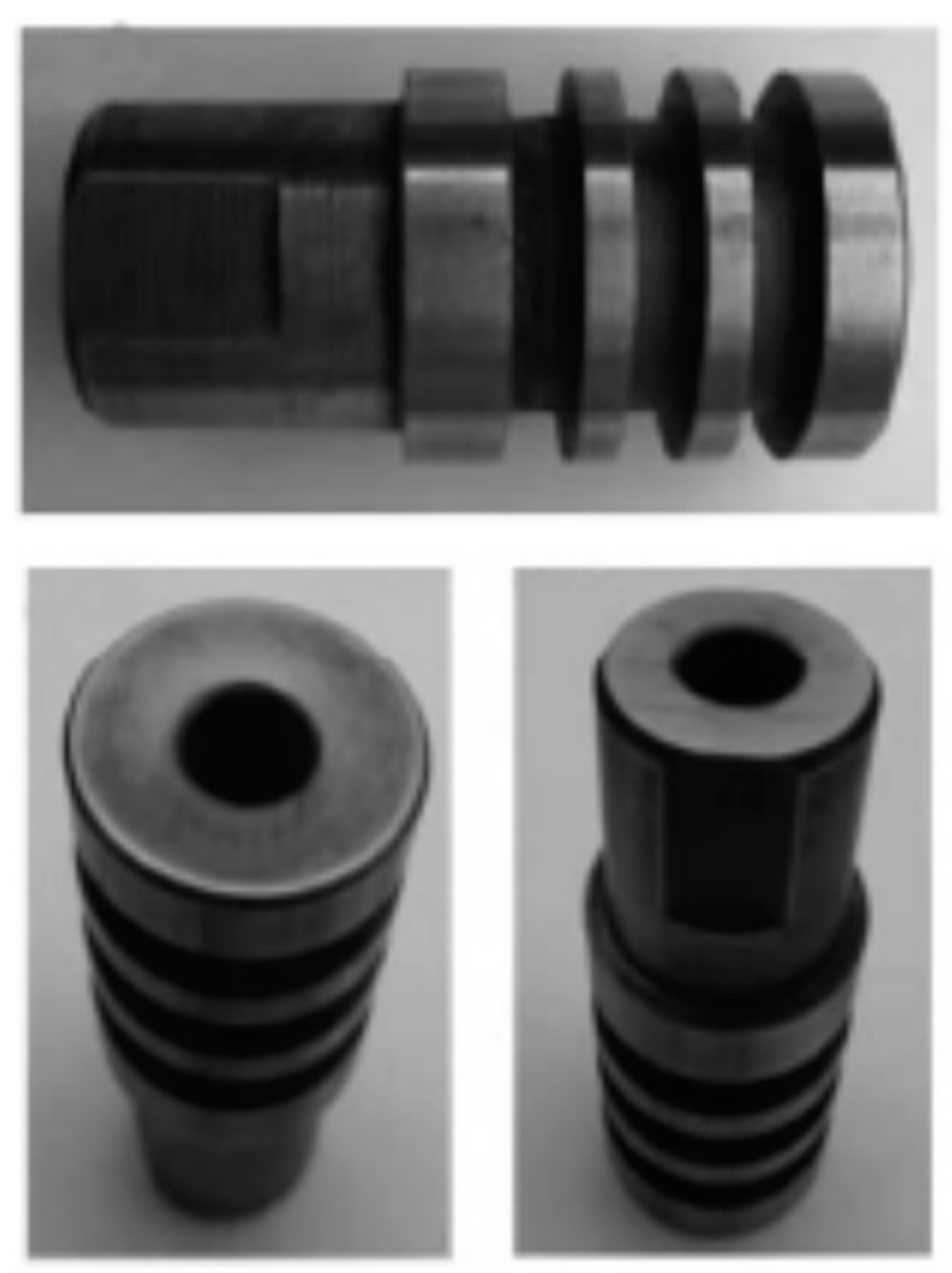

3.2. Influence of Tool Geometry

3.3. Method of Adding Reinforced Particles

4. Applications

4.1. Material Modification

4.1.1. Microstructure Improvement of Casting Materials

4.1.2. Preparation of Superplastic Materials

4.2. Fabrication of Metal Matrix Composites

4.2.1. Fabrication of Surface Composites via Reinforced Particles

4.2.2. Fabrication of In Situ Composites

5. Summary and Outlook

- More complete theoretical support and process standards are needed. Most fabrications are only in the feasibility stage. Practical applications require a stable and reliable process. Mathematical physics models can explain the mechanism of FSP, and the use of parameter optimization systems can help us formulate suitable processes.

- The process of composite fabrication should be improved. It is difficult to obtain complete and uniform composite materials through existing reinforcement phase addition methods—regardless of fabricating surface composites or bulk composites. These processes are too cumbersome to practically deploy.

- The wear of stir tools also limits industrial applications of FSP. Although the tools used in FSP are, in principle, non-consumable, they do experience severe wear during this process. Frequent tool replacement not only affects efficiency but also increases production costs. When processing materials have high melting points or high hardness, it is necessary to face high-temperature wear problems; conventional steel tools are difficult to meet the requirements of this application. How to improve the high-temperature wear resistance of the stir tools is a key issue.

Funding

Acknowledgments

Conflicts of Interest

References

- Mishra, R.S.; Mahoney, M.W.; McFadden, S.X.; Mara, N.A.; Mukherjee, A.K. High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 1999, 42, 163–168. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Ma, Z.Y. Friction stir processing technology: A review. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies—Processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Development of metallographic etchants for the microstructure evolution of A6082-T6 BFSW welds. Metals 2017, 7, 423. [Google Scholar] [CrossRef]

- Xin, R.L.; Zheng, X.; Liu, Z.; Liu, D.; Qiu, R.S.; Li, Z.Y.; Liu, Q. Microstructure and texture evolution of an Mg-Gd-Y-Nd-Zr alloy during friction stir processing. J. Alloy. Compd. 2016, 659, 51–59. [Google Scholar] [CrossRef]

- Wang, L.Q.; Xie, L.C.; Lv, Y.T.; Zhang, L.C.; Chen, L.Y.; Meng, Q.; Qu, J.; Zhang, D.; Lu, W.J. Microstructure evolution and superelastic behavior in Ti-35Nb-2Ta-3Zr alloy processed by friction stir processing. Acta Mater. 2017, 131, 499–510. [Google Scholar] [CrossRef]

- Wang, Y.B.; Huang, Y.X.; Meng, X.C.; Wan, L.; Feng, J.C. Microstructural evolution and mechanical properties of Mg-Zn-Y-Zr alloy during friction stir processing. J. Alloy. Compd. 2017, 696, 875–883. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Thermomechanical grain refinement in AA6082-T6 thin plates under bobbin friction stir welding. Metals 2018, 8, 375. [Google Scholar] [CrossRef]

- Yang, Q.; Xiao, B.L.; Ma, Z.Y.; Chen, R.S. Achieving high strain rate superplasticity in Mg-Zn-Y-Zr alloy produced by friction stir processing. Scr. Mater. 2011, 65, 335–338. [Google Scholar] [CrossRef]

- Oh-Ishi, K.; McNelley, T.R. The influence of friction stir processing parameters on microstructure of as-cast NiAl bronze. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2005, 36A, 1575–1585. [Google Scholar] [CrossRef]

- Navaser, M.; Atapour, M. Effect of friction stir processing on pitting corrosion and intergranular attack of 7075 aluminum alloy. J. Mater. Sci. Technol. 2017, 33, 155–165. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.; Svec, P. Fabrication of a high strength ultra-fine grained Al-Mg-SiC nanocomposite by multi-step friction-stir processing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2017, 698, 313–325. [Google Scholar] [CrossRef]

- Sathiskumar, R.; Murugan, N.; Dinaharan, I.; Vijay, S.J. Role of friction stir processing parameters on microstructure and microhardness of boron carbide particulate reinforced copper surface composites. Sadhana Acad. Proc. Eng. Sci. 2013, 38, 1433–1450. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Formation mechanisms for entry and exit defects in bobbin friction stir welding. Metals 2018, 8, 33. [Google Scholar] [CrossRef]

- Sun, P.; Wang, K.; Wang, W.; Zhang, X. Influence of process parameter on microstructure of AZ31 magnesium alloy in friction stir processing. Hot Work. Technol. 2008, 37, 99. (In Chinese) [Google Scholar]

- Barmouz, M.; Givi, M.K.B.; Seyfi, J. On the role of processing parameters in producing Cu/SiC metal matrix composites via friction stir processing: Investigating microstructure, microhardness, wear and tensile behavior. Mater. Charact. 2011, 62, 108–117. [Google Scholar] [CrossRef]

- Han, J.Y.; Chen, J.; Peng, L.M.; Zheng, F.Y.; Rong, W.; Wu, Y.J.; Ding, W.J. Influence of processing parameters on thermal field in Mg-Nd-Zn-Zr alloy during friction stir processing. Mater. Des. 2016, 94, 186–194. [Google Scholar] [CrossRef]

- Jana, S.; Mishra, R.S.; Baumann, J.A.; Grant, G. Effect of process parameters on abnormal grain growth during friction stir processing of a cast Al alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2010, 528, 189–199. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Ruano, O.A.; Rauch, E.F.; Carreno, F. Severe friction stir processing of an Al-Zn-Mg-Cu alloy: Misorientation and its influence on superplasticity. Mater. Des. 2018, 137, 128–139. [Google Scholar] [CrossRef]

- Chen, C.F.; Kao, P.W.; Chang, L.W.; Ho, N.J. Effect of processing parameters on microstructure and mechanical properties of an Al-Al11Ce3-Al2O3 in-situ composite produced by friction stir processing. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41A, 513–522. [Google Scholar] [CrossRef]

- Zohoor, M.; Givi, M.K.B.; Salami, P. Effect of processing parameters on fabrication of Al-Mg/Cu composites via friction stir processing. Mater. Des. 2012, 39, 358–365. [Google Scholar] [CrossRef]

- Shahi, A.; Sohi, M.H.; Ahmadkhaniha, D.; Ghambari, M. In situ formation of Al-Al3Ni composites on commercially pure aluminium by friction stir processing. Int. J. Adv. Manuf. Technol. 2014, 75, 1331–1337. [Google Scholar] [CrossRef]

- Leal, R.M.; Galvao, I.; Loureiro, A.; Rodrigues, D.M. Effect of friction stir processing parameters on the microstructural and electrical properties of copper. Int. J. Adv. Manuf. Technol. 2015, 80, 1655–1663. [Google Scholar] [CrossRef]

- Mehta, K.P.; Badheka, V.J. Effects of tilt angle on the properties of dissimilar friction stir welding copper to aluminum. Mater. Manuf. Process. 2016, 31, 255–263. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Sohi, M.H.; Zarei-Hanzaki, A. Optimisation of friction stir processing parameters to produce sound and fine grain layers in pure magnesium. Sci. Technol. Weld. Join. 2014, 19, 235–241. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.; Simchi, A.; Kokabi, A.H. Cryogenic friction-stir processing of ultrafine-grained Al-Mg-TiO2 nanocomposites. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 620, 471–482. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, H.; Li, J.Z.; Cai, Z.H.; Zhao, J.W.; Yang, W.J. Influence of multi-pass friction stir processing on the microstructure and mechanical properties of Al-5083 alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 650, 281–289. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, Z.Y.; Zhao, Y.T.; Chen, G.; Guo, Y.H.; Liu, M.P.; Zhang, J. Effect of multi-pass friction stir processing on microstructure and mechanical properties of Al3Ti/A356 composites. Mater. Charact. 2015, 106, 62–69. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Arab, S.M.; Svec, P.; Gerlich, A.P. Fabrication of a new Al-Mg/graphene nanocomposite by multi-pass friction-stir processing: Dispersion, microstructure, stability, and strengthening. Mater. Charact. 2017, 132, 92–107. [Google Scholar] [CrossRef]

- Zeidabadi, S.R.H.; Daneshmanesh, H. Fabrication and characterization of in-situ Al/Nb metal/intermetallic surface composite by friction stir processing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2017, 702, 189–195. [Google Scholar] [CrossRef]

- Adetunla, A.; Akinlabi, E. Mechanical characterization of Al/Ti-6Al-4V surface composite fabricated via FSP: A comparison of tool geometry and number of passes. Mater. Res. Express 2018, 5, 13. [Google Scholar] [CrossRef]

- Costa, M.I.; Verdera, D.; Vieira, M.T.; Rodrigues, D.M. Surface enhancement of cold work tool steels by friction stir processing with a pinless tool. Appl. Surf. Sci. 2014, 296, 214–220. [Google Scholar] [CrossRef]

- Mahmoud, E.R.I.; Takahashi, M.; Shibayanagi, T.; Ikeuchi, K. Effect of friction stir processing tool probe on fabrication of SiC particle reinforced composite on aluminium surface. Sci. Technol. Weld. Join. 2009, 14, 413–425. [Google Scholar] [CrossRef]

- Qian, J.; Li, J.; Xiong, J.; Zhang, F.; Lin, X. In-situ synthesized Al3Ti-Al surface composites by friction stir processing. Trans. China Weld. Inst. 2010, 31, 61–64. [Google Scholar]

- Sathiskumar, R.; Murugan, N.; Dinaharan, I.; Vijay, S.J. Characterization of boron carbide particulate reinforced in situ copper surface composites synthesized using friction stir processing. Mater. Charact. 2013, 84, 16–27. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Ranjbar, K.; Dehmolaei, R.; Amirani, A.R. Fabrication of Al5083 surface composites reinforced by CNTs and cerium oxide nano particles via friction stir processing. J. Alloy. Compd. 2015, 622, 725–733. [Google Scholar] [CrossRef]

- Sahraeinejad, S.; Izadi, H.; Haghshenas, M.; Gerlich, A.P. Fabrication of metal matrix composites by friction stir processing with different Particles and processing parameters. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 626, 505–513. [Google Scholar] [CrossRef]

- Srinivasu, R.; Rao, A.S.; Reddy, G.M.; Rao, K.S. Friction stir surfacing of cast A356 aluminium-silicon alloy with boron carbide and molybdenum disulphide powders. Def. Technol. 2015, 11, 140–146. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Fedel, M.; Sohi, M.H.; Hanzaki, A.Z.; Deflorian, F. Corrosion behavior of magnesium and magnesium-hydroxyapatite composite fabricated by friction stir processing in Dulbecco’s phosphate buffered saline. Corros. Sci. 2016, 104, 319–329. [Google Scholar] [CrossRef]

- Garcia-Bernal, M.A.; Mishra, R.S.; Verma, R.; Hernandez-Silva, D. Influence of friction stir processing tool design on microstructure and superplastic behavior of Al-Mg alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 670, 9–16. [Google Scholar] [CrossRef]

- Patel, V.V.; Badheka, V.J.; Kumar, A. Influence of pin profile on the tool plunge stage in friction stir processing of Al-Zn-Mg-Cu alloy. Trans. Indian Inst. Met. 2017, 70, 1151–1158. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y.; Charit, I. Friction stir processing: A novel technique for fabrication of surface composite. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2003, 341, 307–310. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Marzbanrad, B.; Jahed, H.; Gerlich, A.P. Interfacial bonding mechanisms between aluminum and titanium during cold gas spraying followed by friction-stir modification. Appl. Surf. Sci. 2018, 462, 739–752. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.Y.; Niu, P.L.; Yang, X.W.; Xu, Y.X. Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: Microstructure characterization, mechanical performance and strengthening mechanisms. J. Alloy. Compd. 2018, 736, 115–123. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Veldhuis, S.C.; Elbestawi, M. Friction stir processing of AlSi10Mg parts produced by selective laser melting. J. Mater. Process. Technol. 2019, 263, 308–320. [Google Scholar] [CrossRef]

- Reddy, G.M.; Rao, A.S.; Rao, K.S. Friction stir surfacing route: effective strategy for the enhancement of wear resistance of titanium alloy. Trans. Indian Inst. Met. 2013, 66, 231–238. [Google Scholar] [CrossRef]

- Reddy, G.M.; Rao, A.S.; Rao, K.S. Friction stir processing for enhancement of wear resistance of ZM21 magnesium alloy. Trans. Indian Inst. Met. 2013, 66, 13–24. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, T.; Lu, S.; Liu, H.; Ao, F. A novel method of in-situ fabrication of Mg surface composites by friction stir process. Trans. China Weld. Inst. 2013, 34, 25–28. (In Chinese) [Google Scholar]

- Sekban, D.M.; Aktarer, S.M.; Yanar, H.; Alsaran, A.; Purcek, G. Improvement the wear behavior of low carbon steels by friction stir processing. IOP Conf. Ser. 2017, 174, 012058. [Google Scholar] [CrossRef] [Green Version]

- Tinubu, O.O.; Das, S.; Dutt, A.; Mogonye, J.E.; Ageha, V.; Xu, R.; Forsdike, J.; Mishra, R.S.; Scharf, T.W. Friction stir processing of A-286 stainless steel: Microstructural evolution during wear. Wear 2016, 356–357, 94–100. [Google Scholar] [CrossRef]

- Pang, J.J.; Liu, F.C.; Liu, J.; Tan, M.J.; Blackwood, D.J. Friction stir processing of aluminum alloy AA7075: Microstructure, surface chemistry and corrosion resistance. Corros. Sci. 2016, 106, 217–228. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. Principles of superplasticity in ultrafine-grained materials. J. Mater. Sci. 2007, 42, 1782–1796. [Google Scholar] [CrossRef] [Green Version]

- Ruano, O.A.; Sherby, O.D. On constitutive-equations for various diffusion-controlled creep mechanisms. Revue De Physique Appliquee 1988, 23, 625–637. [Google Scholar] [CrossRef]

- Carreño, F.; Orozco-Caballero, A. Superplastic GBS Constitutive equation incorporating average grain misorientation dependence. Mater. Sci. Forum 2018, 941, 1501–1506. [Google Scholar] [CrossRef]

- Zhang, W.J.; Ding, H.; Cai, M.H.; Yang, W.J.; Li, J.Z. Ultra-grain refinement and enhanced low-temperature superplasticity in a friction stir-processed Ti-6Al-4V alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 727, 90–96. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. High strain rate superplasticity in a commercial 2024 Al alloy via friction stir processing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2003, 359, 290–296. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Mishra, R.S.; Mahoney, M.W. Superplasticity in cast A356 induced via friction stir processing. Scr. Mater. 2004, 50, 931–935. [Google Scholar] [CrossRef]

- Johannes, L.B.; Mishra, R.S. Multiple passes of friction stir processing for the creation of superplastic 7075 aluminum. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2007, 464, 255–260. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Liu, F.C.; Mishra, R.S. Superplastic deformation mechanism of an ultrafine-grained aluminum alloy produced by friction stir processing. Acta Mater. 2010, 58, 4693–4704. [Google Scholar] [CrossRef]

- Xie, G.M.; Luo, Z.A.; Ma, Z.Y.; Xue, P.; Wang, G.D. Superplastic behavior of friction stir processed ZK60 magnesium alloy. Mater. Trans. 2011, 52, 2278–2281. [Google Scholar] [CrossRef]

- Chai, F.; Zhang, D.T.; Li, Y.Y.; Zhang, W.W. High strain rate superplasticity of a fine-grained AZ91 magnesium alloy prepared by submerged friction stir processing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 568, 40–48. [Google Scholar] [CrossRef]

- Karthikeyan, L.; Kumar, V.S.S.; Padmanabhan, K.A. Investigations on superplastic forming of friction stir-processed AA6063-T6 aluminum alloy. Mater. Manuf. Process. 2013, 28, 294–298. [Google Scholar] [CrossRef]

- Cao, G.H.; Zhang, D.T.; Chai, F.; Zhang, W.W.; Qiu, C. Superplastic behavior and microstructure evolution of a fine-grained Mg-Y-Nd alloy processed by submerged friction stir processing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 642, 157–166. [Google Scholar] [CrossRef]

- Zhao, Y.T.; Kai, X.Z.; Chen, G.; Lin, W.L.; Wang, C.M. Effects of friction stir processing on the microstructure and superplasticity of in situ nano-ZrB2/2024Al composite. Prog. Nat. Sci. 2016, 26, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Orozco-Caballero, A.; Alvarez-Leal, M.; Hidalgo-Manrique, P.; Cepeda-Jimenez, C.M.; Ruano, O.A.; Carreno, F. Grain size versus microstructural stability in the high strain rate superplastic response of a severely friction stir processed Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2017, 680, 329–337. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.G.; Zhao, Y.T.; Kai, X.Z.; Tao, R. Superplasticity behavior and deformation mechanism of the in-situ Al3Zr/6063Al composites processed by friction stir processing. J. Alloy. Compd. 2017, 710, 225–233. [Google Scholar] [CrossRef]

- Jiao, L.; Yang, Y.G.; Li, H.; Zhao, Y.T.; Wang, X.L. Effects of plastic deformation on microstructure and superplasticity of the in situ AI(3)Ti/2024AI composites. Mater. Res. Express 2018, 5, 13. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Sohi, M.H.; Salehi, A.; Tahavvori, R. Formations of AZ91/Al2O3 nano-composite layer by friction stir processing. J. Magnes. Alloy. 2016, 4, 314–318. [Google Scholar] [CrossRef]

- Mahmoud, E.R.I.; Tash, M.M. Characterization of aluminum-based-surface matrix composites with iron and iron oxide fabricated by friction stir processing. Materials 2016, 9, 505. [Google Scholar] [CrossRef]

- Kim, J.Y.; Hwang, J.W.; Kim, H.Y.; Lee, S.M.; Jung, W.S.; Byeon, J.W. Fabrication of AZ31/CNT surface nano-composite by double-pass friction stir processing. Arch. Metall. Mater. 2017, 62, 1039–1042. [Google Scholar] [CrossRef]

- Moustafa, E. Effect of multi-pass friction stir processing on mechanical properties for AA2024/Al2O3 nanocomposites. Materials 2017, 10, 1053. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, J.B.; Macias, E.J.; Muro, J.; Caputi, L.S.; Miriello, D.; De Luca, R.; Roca, A.S.; Fals, H.D.C. Tribological behavior of AA1050H24-graphene nanocomposite obtained by friction stir processing. Metals 2018, 8, 113. [Google Scholar] [CrossRef]

- Parumandla, N.; Adepu, K. Effect of Al2O3 and SiC nano reinforcements on microstructure, mechanical and wear properties of surface nanocomposites fabricated by friction stir processing. Mater. Sci. Medzg. 2018, 24, 338–344. [Google Scholar] [CrossRef]

- Zhu, C.Y.; Lv, Y.T.; Qian, C.; Ding, Z.H.; Jiao, T.; Gu, X.Y.; Lu, E.Y.; Wang, L.Q.; Zhang, F.Q. Microstructures, mechanical, and biological properties of a novel Ti-6V-4V/zinc surface nanocomposite prepared by friction stir processing. Int. J. Nanomed. 2018, 13, 1881–1898. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tjong, S.C.; Ma, Z.Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Hsu, C.J.; Kao, P.W.; Ho, N.J. Ultrafine-grained Al-Al2Cu composite produced in situ by friction stir processing. Scr. Mater. 2005, 53, 341–345. [Google Scholar] [CrossRef]

- Qian, J.W.; Li, J.L.; Xiong, J.T.; Zhang, F.S.; Lin, X. In situ synthesizing Al3Ni for fabrication of intermetallic-reinforced aluminum alloy composites by friction stir processing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2012, 550, 279–285. [Google Scholar] [CrossRef]

- You, G.L.; Ho, N.J.; Kao, P.W. The microstructure and mechanical properties of an Al-CuO in-situ composite produced using friction stir processing. Mater. Lett. 2013, 90, 26–29. [Google Scholar] [CrossRef]

- You, G.L.; Ho, N.J.; Kao, P.W. Aluminum based in situ nanocomposite produced from Al-Mg-CuO powder mixture by using friction stir processing. Mater. Lett. 2013, 100, 219–222. [Google Scholar] [CrossRef]

- Hsu, C.J.; Kao, P.W.; Ho, N.J. Intermetallic-reinforced aluminum matrix composites produced in situ by friction stir processing. Mater. Lett. 2007, 61, 1315–1318. [Google Scholar] [CrossRef]

- Madhu, H.C.; Kailas, S.V. In-situ aluminothermal reduction synthesis of Ti3AlC2 aluminium composite by friction stir processing. Procedia Manuf. 2016, 7, 157–162. [Google Scholar] [CrossRef]

- Rajan, H.B.M.; Dinaharan, I.; Ramabalan, S.; Akinlabi, E.T. Influence of friction stir processing on microstructure and properties of AA7075/TiB2 in situ composite. J. Alloy. Compd. 2016, 657, 250–260. [Google Scholar] [CrossRef]

| Materials | Maximum Elongation | Temperature | Strain Rate | Reference |

|---|---|---|---|---|

| AA7075 | 1000% | 490 °C | 1 × 10−2 s−1 | Mishra et al. [1] |

| AA2024 | 525% | 430 °C | 1 × 10−2 s−1 | Charit et al. [57] |

| Cast A356 | 650% | 530 °C | 1 × 10−3 s−1 | Ma et al. [58] |

| AA7075 | 1255% | 470 °C | 1 × 10−2 s−1 | Johannes et al. [59] |

| Al–4Mg–1Zr | 1400% | 425 °C | 1 s−1 | Ma et al. [60] |

| ZK60 | 1800% | 325 °C | 1 × 10−3 s−1 | Xie et al. [61] |

| Mg–Zn–Y–Zr | 1110% | 450 °C | 1 × 10−2 s−1 | Yang et al. [10] |

| AZ91 | 990% | 350 °C | 2 × 10−2 s−1 | Chai et al. [62] |

| AA6063-T6 | 225% | 344 °C | 1 × 10−2 s−1 | Karthikeyan et al. [63] |

| Mg–Y–Nd | 967% | 500 °C | 3 × 10−3 s−1 | Cao et al. [64] |

| ZrB2/2024Al composites | 292.5% | 477 °C | 5 × 10−3 s−1 | Zhao et al. [65] |

| AA7075 | 550% | 220–380 °C | 1 × 10−2 s−1 | Orozco-Caballero et al. [66] |

| Al3Zr/6063Al composites | 330% | 500 °C | 1 × 10−2 s−1 | Yang et al. [67] |

| Al3Ti/2024Al composites | 642% | 510 °C | 0.15 s−1 | Jiao et al. [68] |

| Ti-6Al-4V | 1130% | 600 °C | 3 × 10−4 s−1 | Zhang et al. [56] |

| Base Metal | Reinforcement | Method of Adding Reinforcement | Remarks | Reference |

|---|---|---|---|---|

| AA5083 | SiC | smearing | Microhardness was double of AA5083 | Mishra et al. [43] |

| Ti-6Al-4V | B4C | holes | Wear resistance was better than that of mild steel and stainless steel. | Reddy et al. [47] |

| Cu | B4C | groove | The microhardness and wear resistance increased with increasing volume fraction of B4C. | Sathiskumar et al. [36] |

| AA5083 | CeO2 + CNTs | groove | The tensile strength increased with increasing volume fraction of carbon nanotubes (CNTs). | Hosseini et al. [37] |

| Al–Mg | TiO2 | groove | Grains significantly refined under cryogenic condition. | Khodabakhshi et al. [27] |

| A356 | B4C + MoS2 | holes | Hardness and wear resistance increased. | Srinivasu et al. [39] |

| A356 | Al3Ti | casting | Both the strength and ductility enhanced after multi-pass FSP. | Yang et al. [29] |

| Mg | HA | groove | Corrosion resistance decreased with hydroxyapatite particles. | Ahmadkhaniha et al. [40] |

| AZ91 | Al2O3 | groove | Nano Al2O3 reduced the grain sizes and increased the hardness and wear resistance. | Ahmadkhaniha et al. [69] |

| Al1050-H24 | Fe/Fe3O4 | groove | The saturation magnetization of the AA1050/Fe was higher than that of the AA1050/Fe3O4. | Mahmoud et al. [70] |

| Al–Mg | GNPs | groove | The main strengthening mechanism was the coefficient of thermal expansion (CTE) mismatch strengthening. | Khodabakhshi et al. [30] |

| Al–Mg | SiC | groove | The main strengthening mechanism was the grain boundary strengthening. | Khodabakhshi et al. [13] |

| AZ31 | CNTs | groove | The distribution of CNTs was more homogeneous after double-pass FSP. | Kim et al. [71] |

| AA2024 | Al2O3 | groove | The quality of surface composites depended on the number of FSP passes. | Moustafa [72] |

| Al1050-H24 | GNSs | groove | Graphene particles worked as lubricant and reduced the friction coefficient. | Fernandez et al. [73] |

| AA 6061-T6 | Al2O3/SiC | groove | Wear resistance of surface nanocomposites was increased with increasing volume percentage of reinforcement. | Parumandla et al. [74] |

| AA2024 | Al2O3 | cold spraying | The main strengthening mechanisms was the improved interparticle bonding and the dispersion strengthening of the refined Al2O3 particles. | Yang et al. [45] |

| Ti-6Al-4V | Zn | holes | The surface nanocomposite has great mechanical properties and biocompatibility. | Zhu et al. [75] |

| Al | AlSi10Mg | selective laser melting | FSP could be used to improve the microstructure and reduce porosity. | Maamoun et al. [46] |

| Matrix | Additives | Method of Adding Additives | Intermetallic Phases | Reference |

|---|---|---|---|---|

| Al | Cu | sintering | Al2Cu | Hsu et al. [77] |

| Al | Ti | sintering | Al3Ti | Hsu et al. [81] |

| Al1100-H14 | Ni | groove | Al3Ni | Qian et al. [78] |

| Al | Mg + CuO | cold compacting | MgO + Al2Cu | You et al. [80] |

| Al | CuO | sintering | Al2O3 + Al2Cu | You et al. [79] |

| Al | TiO2 + graphite | groove | Ti3AlC2 + TiC | Madhu et al. [82] |

| AA7075 | K2TiF6 + KBF4 | casting | TiB2 | Rajan et al. [83] |

| AA2024 | K2ZrF6 + KBF4 | casting | ZrB2 | Zhao et al. [65] |

| Al1050 | Nb | groove | Al3Nb | Zeidabadi et al. [31] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Liu, X.; Zhao, Y. Research Status and Prospect of Friction Stir Processing Technology. Coatings 2019, 9, 129. https://doi.org/10.3390/coatings9020129

Li K, Liu X, Zhao Y. Research Status and Prospect of Friction Stir Processing Technology. Coatings. 2019; 9(2):129. https://doi.org/10.3390/coatings9020129

Chicago/Turabian StyleLi, Kan, Xuemei Liu, and Yi Zhao. 2019. "Research Status and Prospect of Friction Stir Processing Technology" Coatings 9, no. 2: 129. https://doi.org/10.3390/coatings9020129