Enhanced Wear Resistance of 316 L Stainless Steel with a Nanostructured Surface Layer Prepared by Ultrasonic Surface Rolling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Ultrasonic Surface Rolling Process

2.3. Wear Test, Microstructure Characterization and Hardness Test

3. Results and Discussion

3.1. Microstructures of the USR Surface Layer

3.2. Mechanical and Wear Behaviors

4. Conclusions

- A nanostructured surface layer, with a depth span of 15 μm, was fabricated on AISI 316 L stainless steel through USR processing.

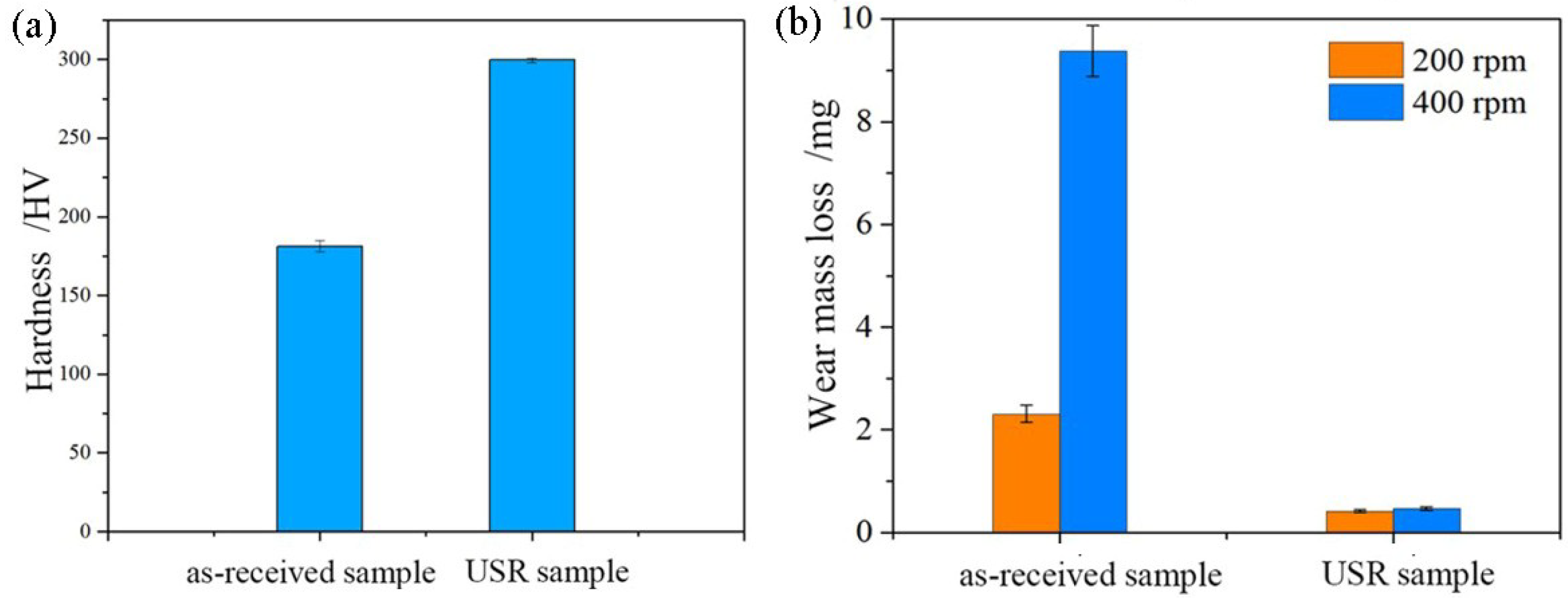

- USR 316 L stainless steel exhibited a significantly improved hardness and enhanced wear resistance, as well as a decreased surface roughness, compared with the as-received sample.

- Oxidation and abrasive wear, accompanied by mild adhesive wear, contorted the wear of USR 316 L stainless steel at both low and high wear speeds.

- The superior wear-resistant performance of USR 316 L stainless steel was attributed to the nanostructured surface layer, which had a high hardness and thereby withstood the severe abrasive wear.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, X.H.; Lu, J.; Lu, L.; Lu, K. Tensile properties of a nanocrystalline 316 L austenitic stainless steel. Scr. Mater. 2005, 52, 1039–1044. [Google Scholar] [CrossRef]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R Rep. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Wang, P.F.; Han, Z. Friction and wear behaviors of a gradient nano-grained AISI 316 L stainless steel under dry and oil-lubricated conditions. J. Mater. Sci. Technol. 2018, 34, 1835–1842. [Google Scholar] [CrossRef]

- Wang, B.; Yao, B.; Han, Z. Annealing Effect on wear resistance of nanostructured 316 L stainless steel subjected to dynamic plastic deformation. J. Mater. Sci. Technol. 2012, 28, 871–877. [Google Scholar] [CrossRef]

- Zhou, L.; Long, C.; He, W.; Tian, L.; Jia, W. Improvement of high-temperature fatigue performance in the nickel-based alloy by LSP-induced surface nanocrystallization. J. Alloy. Compd. 2018, 744, 156–164. [Google Scholar] [CrossRef]

- Liu, C.; Zheng, H.; Gu, X.; Jiang, B.; Liang, J. Effect of severe shot peening on corrosion behavior of AZ31 and AZ91 magnesium alloys. J. Alloy. Compd. 2019, 770, 500–506. [Google Scholar] [CrossRef]

- Lu, K.; Lu, J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2004, 375–377, 38–45. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Enhanced mechanical behavior of a nanocrystallised stainless steel and its thermal stability. Mater. Sci. Eng. A 2007, 445, 281–288. [Google Scholar] [CrossRef]

- Sun, Y. Sliding wear behaviour of surface mechanical attrition treated AISI 304 stainless steel. Tribol. Int. 2013, 57, 67–75. [Google Scholar] [CrossRef]

- Zhang, H.; Hei, Z.K.; Liu, G.; Lu, J.; Lu, K. Formation of nanostructured surface layer on AISI 304 stainless steel by means of surface mechanical attrition treatment. Acta Mater. 2003, 51, 1871–1881. [Google Scholar] [CrossRef]

- Li, W.L.; Tao, N.R.; Lu, K. Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment. Scr. Mater. 2008, 59, 546–549. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, H.; Lu, K. Formation of nano-laminated structure in nickel by means of surface mechanical grinding treatment. Acta Mater. 2015, 96, 24–36. [Google Scholar] [CrossRef]

- Xin, C.; Sun, Q.; Xiao, L.; Sun, J. Biaxial fatigue property enhancement of gradient ultra-fine-grained Zircaloy-4 prepared by surface mechanical rolling treatment. J. Mater. Sci. 2018, 53, 12492–12503. [Google Scholar] [CrossRef]

- Liu, G.; Lu, K.; Lu, J. Surface nanocrystallization of 316 L stainless steel induced by ultrasonic shot peening. Mater. Sci. Eng. A 2000, 286, 91–95. [Google Scholar] [CrossRef]

- Zhu, L.; Guan, Y.; Lin, J.; Zhai, J.; Xie, Z. A nanocrystalline-amorphous mixed layer obtained by ultrasonic shot peening on pure titanium at room temperature. Ultrason. Sonochem. 2018, 47, 68–74. [Google Scholar] [CrossRef] [PubMed]

- Ba, D. Surface nanostructure formation mechanism of 45 steel induced by supersonic fine particles pombarding. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 2008, 15, 561–567. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Z.; Lu, B.J.; Lu, K. Fatigue behaviors of AISI 316 L stainless steel with a gradient nanostructured surface layer. Acta Mater. 2015, 87, 150–160. [Google Scholar] [CrossRef]

- Bagherifard, S.; Slawik, S.; Fernández-Pariente, I.; Pauly, C.; Mücklich, F.; Guagliano, M. Nanoscale surface modification of AISI 316 L stainless steel by severe shot peening. Mater. Des. 2016, 102, 68–77. [Google Scholar] [CrossRef]

- Benafia, S.; Retraint, D.; Yapi Brou, S.; Panicaud, B.; Grosseau Poussard, J.L. Influence of surface mechanical attrition treatment on the oxidation behaviour of 316 L stainless steel. Corros. Sci. 2018, 136, 188–200. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, Z.; Su, W.; Zhou, H.; Liu, C.; Yang, Y.; Qi, X. Microstructure and surface properties of 17-4PH stainless steel by ultrasonic surface rolling technology. Surf. Coat. Tech. 2017, 321, 64–73. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.G.; Pan, Y.X.; Li, X.Q. Effects of the different frequencies and loads of ultrasonic surface rolling on surface mechanical properties and fretting wear resistance of HIP Ti6Al4V alloy. Appl Surf. Sci. 2016, 389, 324–334. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.; Xie, M.; Li, X. Effect of ultrasonic surface rolling at low temperatures on surface layer microstructure and properties of HIP Ti-6Al-4V alloy. Surf. Coat. Tech. 2017, 316, 75–84. [Google Scholar] [CrossRef]

- Zhao, X.; Xue, G.; Liu, Y. Gradient crystalline structure induced by ultrasonic impacting and rolling and its effect on fatigue behavior of TC11 titanium alloy. Results Phys. 2017, 7, 1845–1851. [Google Scholar] [CrossRef]

- Ting, W.; Dongpo, W.; Gang, L.; Baoming, G.; Ningxia, S. Investigations on the nanocrystallization of 40cr using ultrasonic surface rolling processing. Appl. Surf. Sci. 2008, 255, 1824–1829. [Google Scholar] [CrossRef]

- Wang, H.; Yang, X.; Li, H.; Song, G.; Tang, G. Enhanced fatigue performance and surface mechanical properties of AISI 304 stainless steel induced by electropulsing-assisted ultrasonic surface rolling process. J. Mater. Res. 2018, 33, 3827–3840. [Google Scholar] [CrossRef]

- Wang, H.; Song, G.; Tang, G. Enhanced surface properties of austenitic stainless steel by electropulsing-assisted ultrasonic surface rolling process. Surf. Coat. Tech. 2015, 282, 149–154. [Google Scholar] [CrossRef]

- Lu, K.; Hansen, N. Structural refinement and deformation mechanisms in nanostructured metals. Scr. Mater. 2009, 60, 1033–1038. [Google Scholar] [CrossRef]

- Lin, Y.; Lu, J.; Wang, L.; Xu, T.; Xue, Q. Surface nanocrystallization by surface mechanical attrition treatment and its effect on structure and properties of plasma nitrided AISI 321 stainless steel. Acta Mater. 2006, 54, 5599–5605. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Fatigue life improvement through surface nanostructuring of stainless steel by means of surface mechanical attrition treatment. Scr. Mater. 2006, 54, 1949–1954. [Google Scholar] [CrossRef]

- Lu, J.; Luo, K.; Zhang, Y.; Sun, G.; Gu, Y.; Zhou, J.; Ren, X.D.; Zhang, X.C.; Zhang, L.F.; Chen, K.M.; et al. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel. Acta Mater. 2010, 58, 5354–5362. [Google Scholar] [CrossRef]

- Ye, C.; Telang, A.; Gill, A.S.; Suslov, S.; Idell, Y.; Zweiacker, K.; Wiezorek, J.M.K.; Zhou, Z.; Qian, D.; Mannava, S.R. Gradient nanostructure and residual stresses induced by Ultrasonic Nano-crystal Surface Modification in 304 austenitic stainless steel for high strength and high ductility. Mater. Sci. Eng. A 2014, 613, 274–288. [Google Scholar] [CrossRef]

- Liu, J.; Suslov, S.; Vellore, A.; Ren, Z.; Amanov, A.; Pyun, Y.; Martini, A.; Dong, Y.; Ye, C. Surface nanocrystallization by ultrasonic nano-crystal surface modification and its effect on gas nitriding of Ti6Al4V alloy. Mater. Sci. Eng. A 2018, 736, 335–343. [Google Scholar] [CrossRef]

- Lim, S.C.; Ashby, M.F.; Brunton, J.H. Wear-rate transitions and their relationship to wear mechanisms. Acta Metall. 1987, 35, 1343–1348. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Han, J.; Zhao, J.; Song, Y.; Man, J.; Zhu, H.; Sun, J.; Fang, L. Enhanced Wear Resistance of 316 L Stainless Steel with a Nanostructured Surface Layer Prepared by Ultrasonic Surface Rolling. Coatings 2019, 9, 276. https://doi.org/10.3390/coatings9040276

Wang C, Han J, Zhao J, Song Y, Man J, Zhu H, Sun J, Fang L. Enhanced Wear Resistance of 316 L Stainless Steel with a Nanostructured Surface Layer Prepared by Ultrasonic Surface Rolling. Coatings. 2019; 9(4):276. https://doi.org/10.3390/coatings9040276

Chicago/Turabian StyleWang, Cong, Jing Han, Jiyun Zhao, Yuanming Song, Jiaxiang Man, Hua Zhu, Jiapeng Sun, and Liang Fang. 2019. "Enhanced Wear Resistance of 316 L Stainless Steel with a Nanostructured Surface Layer Prepared by Ultrasonic Surface Rolling" Coatings 9, no. 4: 276. https://doi.org/10.3390/coatings9040276