Extended Kalman Filter Based Sliding Mode Control of Parallel-Connected Two Five-Phase PMSM Drive System

Abstract

:1. Introduction

2. Modeling of Multiphase AC Drive System

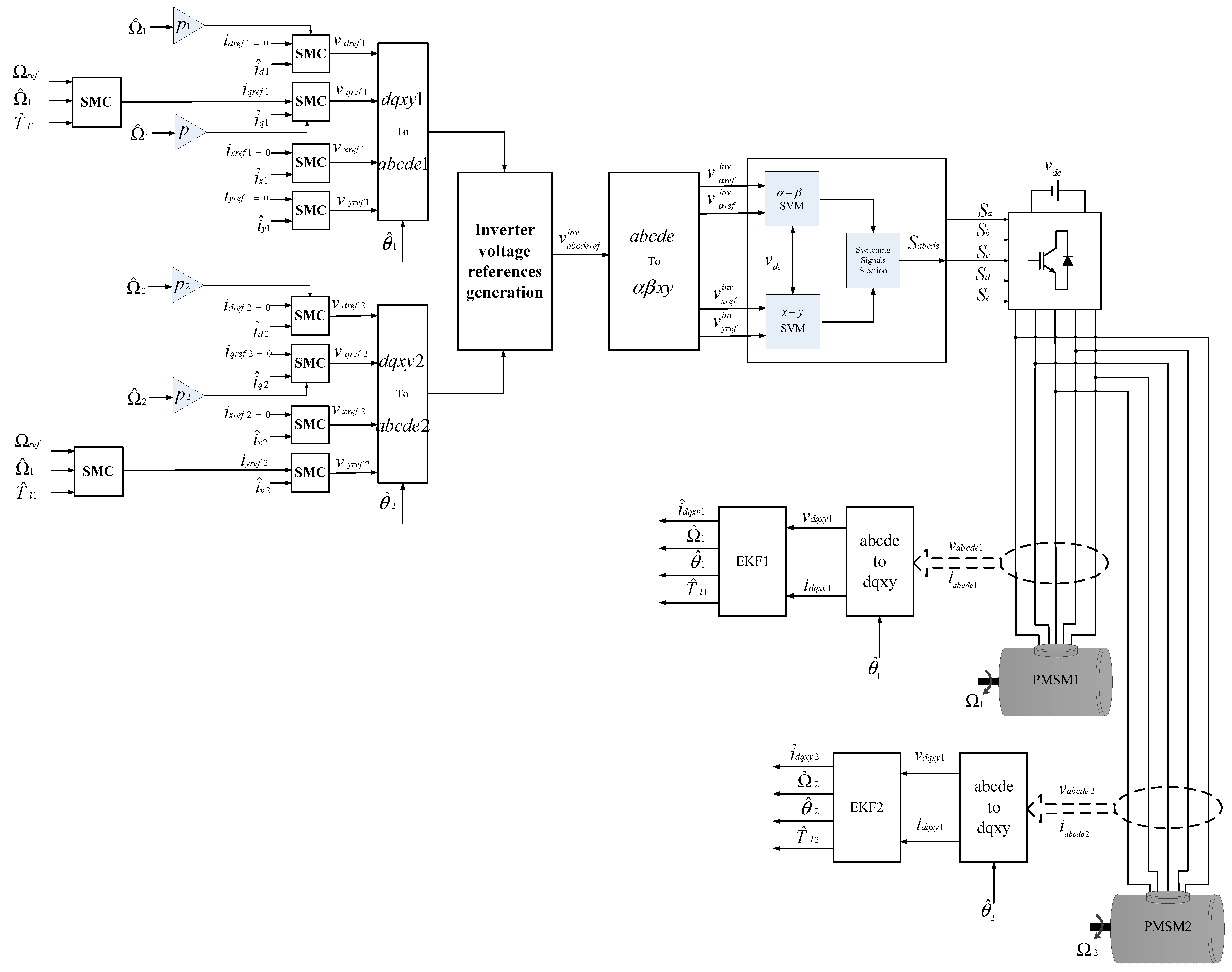

3. Sliding Mode Controller (SMC)

3.1. Sliding Surfaces Choice

3.2. Controller Design

- The Lyapunov function V is positive definite.

- The derivative of the sliding function should be negative .

4. Sliding Mode Control of the Five-Phase Two-Machine AC Drive System

4.1. Speeds SMC Design

4.2. Currents SMC Design

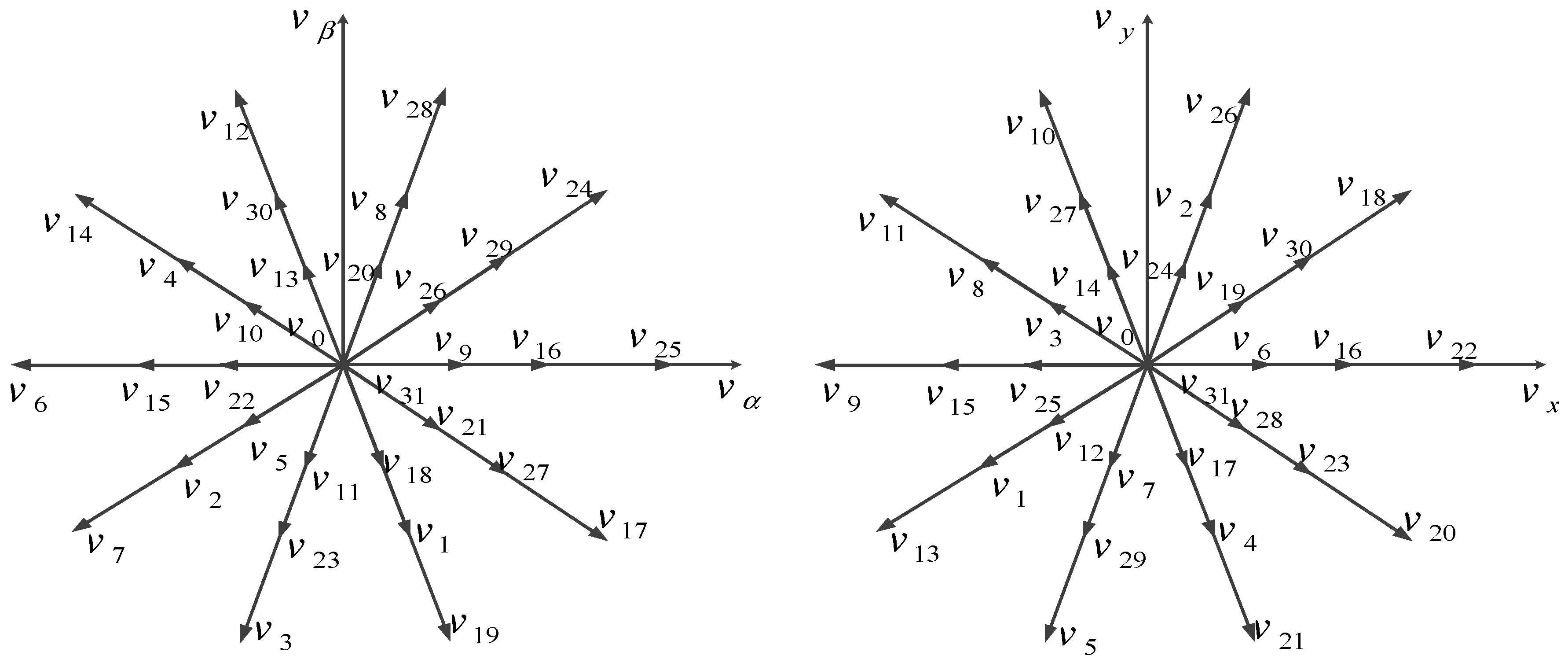

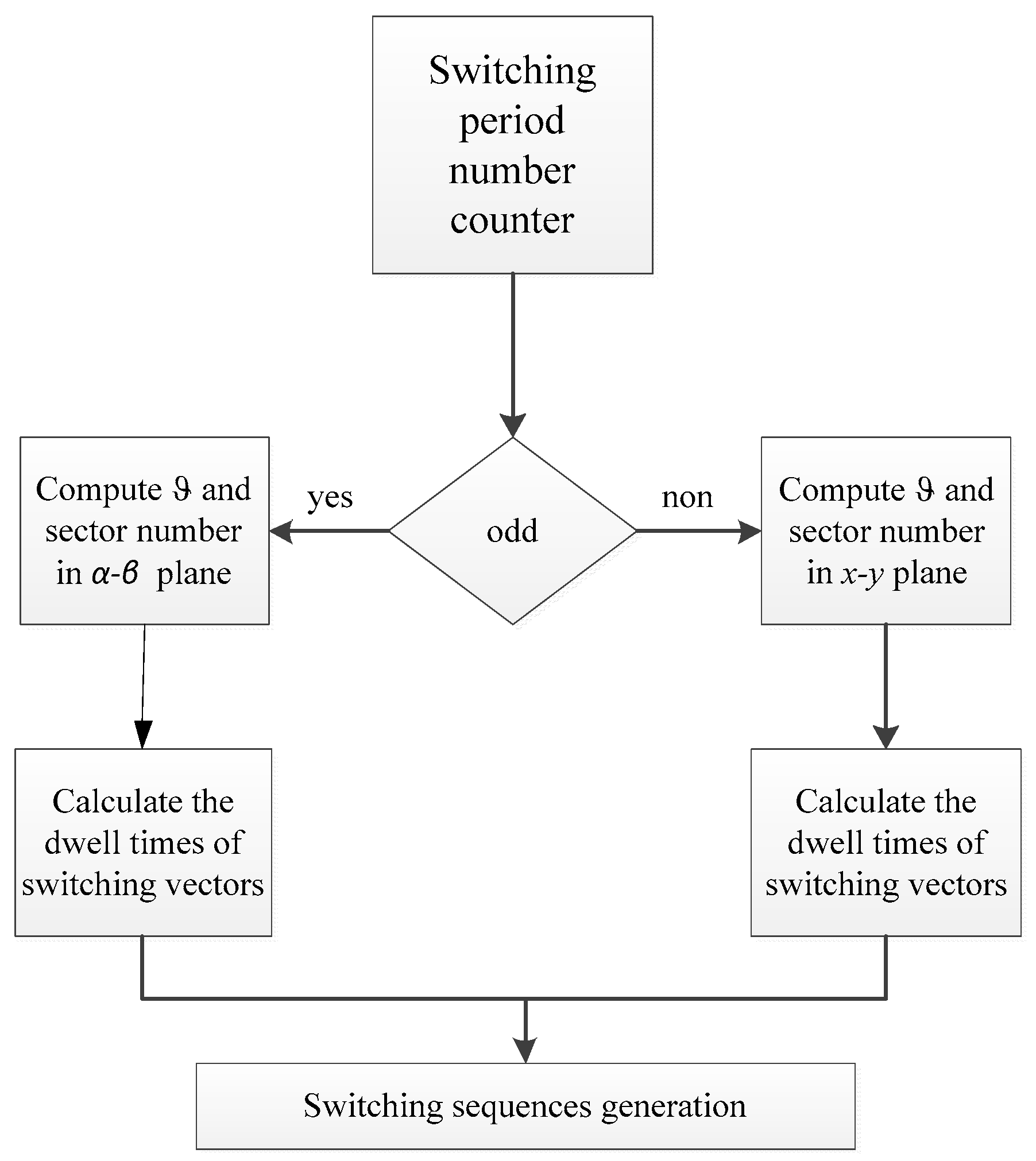

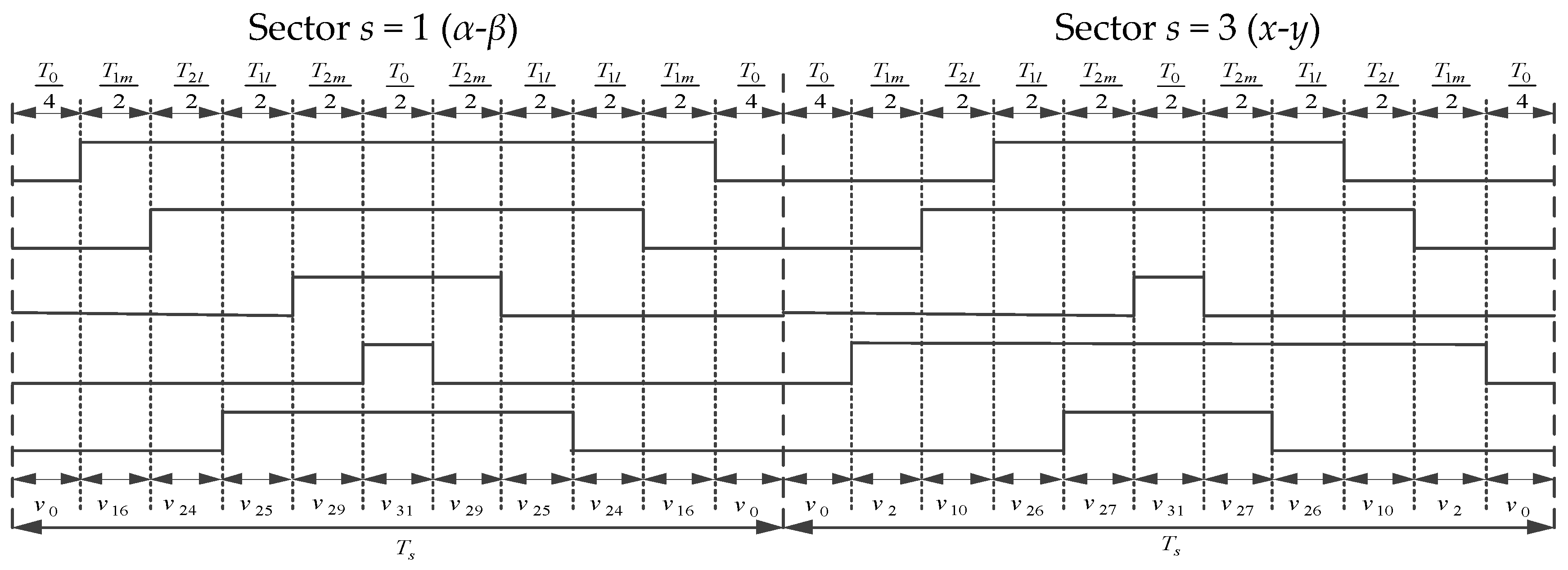

5. Space Vector Modulation Technique for Parallel Connected Multiphase AC Drive System

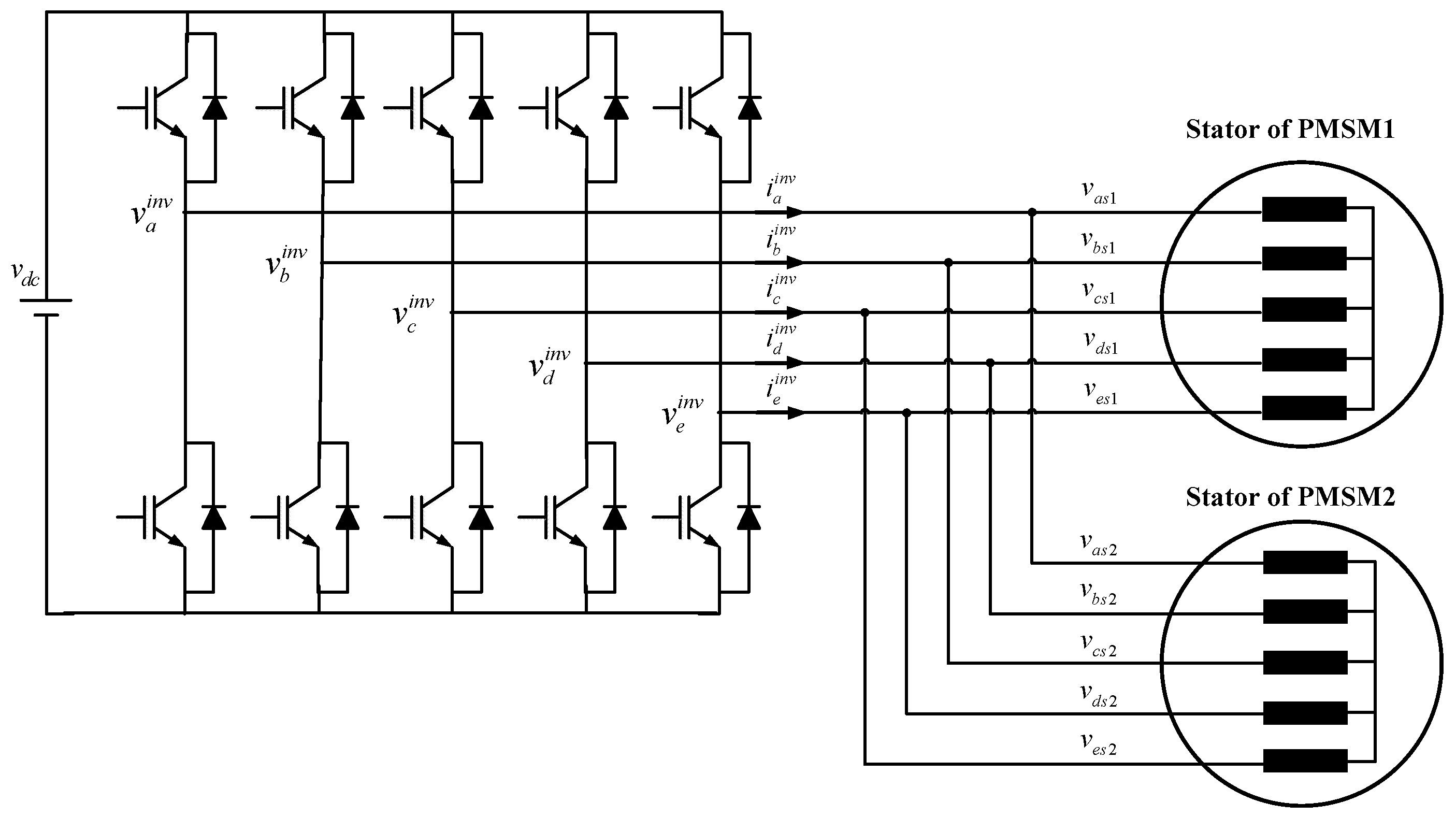

5.1. Five-Leg VSI Modeling

5.2. SVM Method for Five-Leg VSI

6. Extended Kalman Filter Based Speed Estimator for Parallel Connected Two Motor Drivel

- Sate prediction:

- Estimation of the matrix of the covariance error:

- Kalman coefficient update:

- State estimation:

- Covariance error matrix update:where is the system state, ujk is the system input vector, y is the system output vector, P, Q and R are the covariance matrices, C is the transformation matrix.

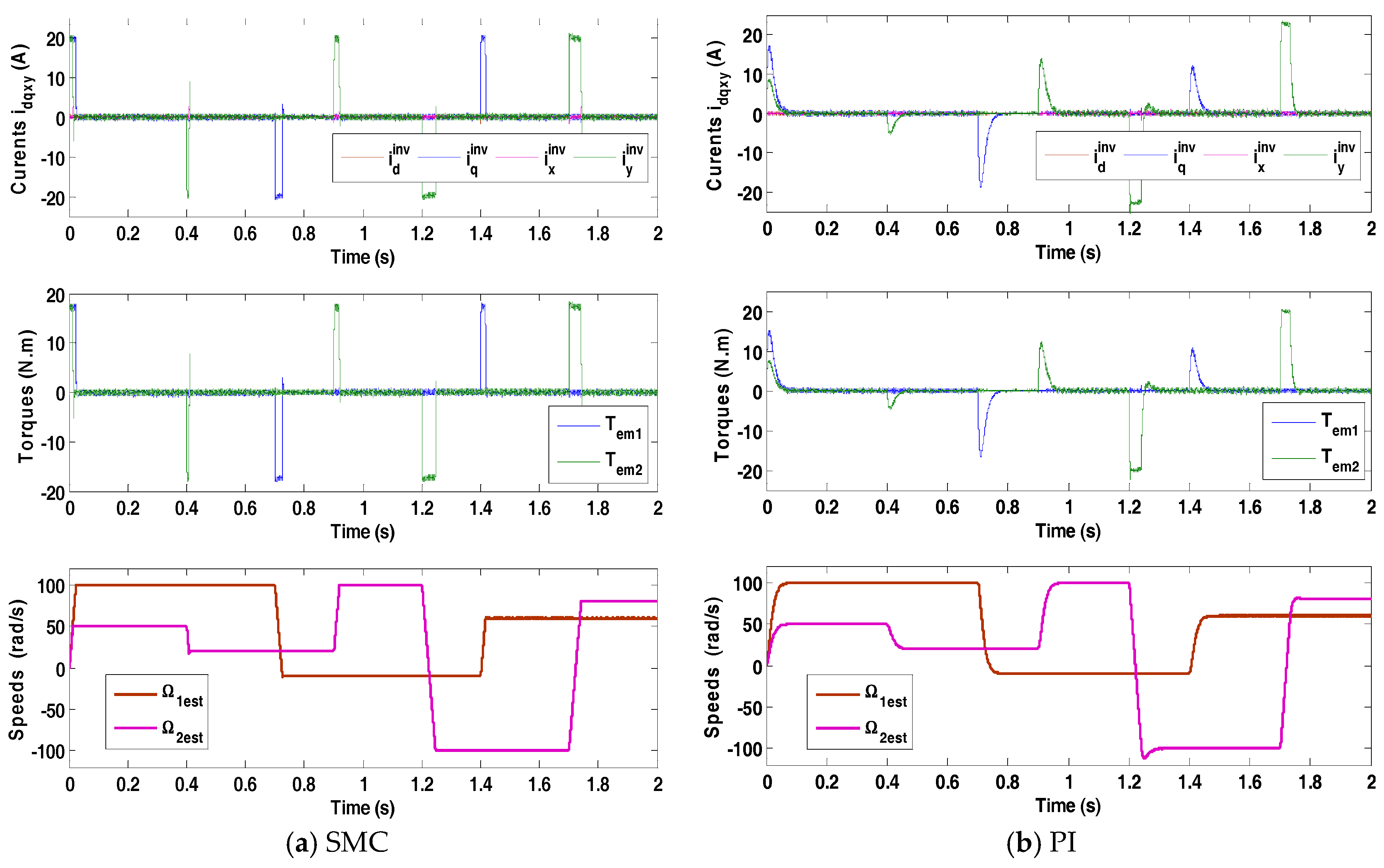

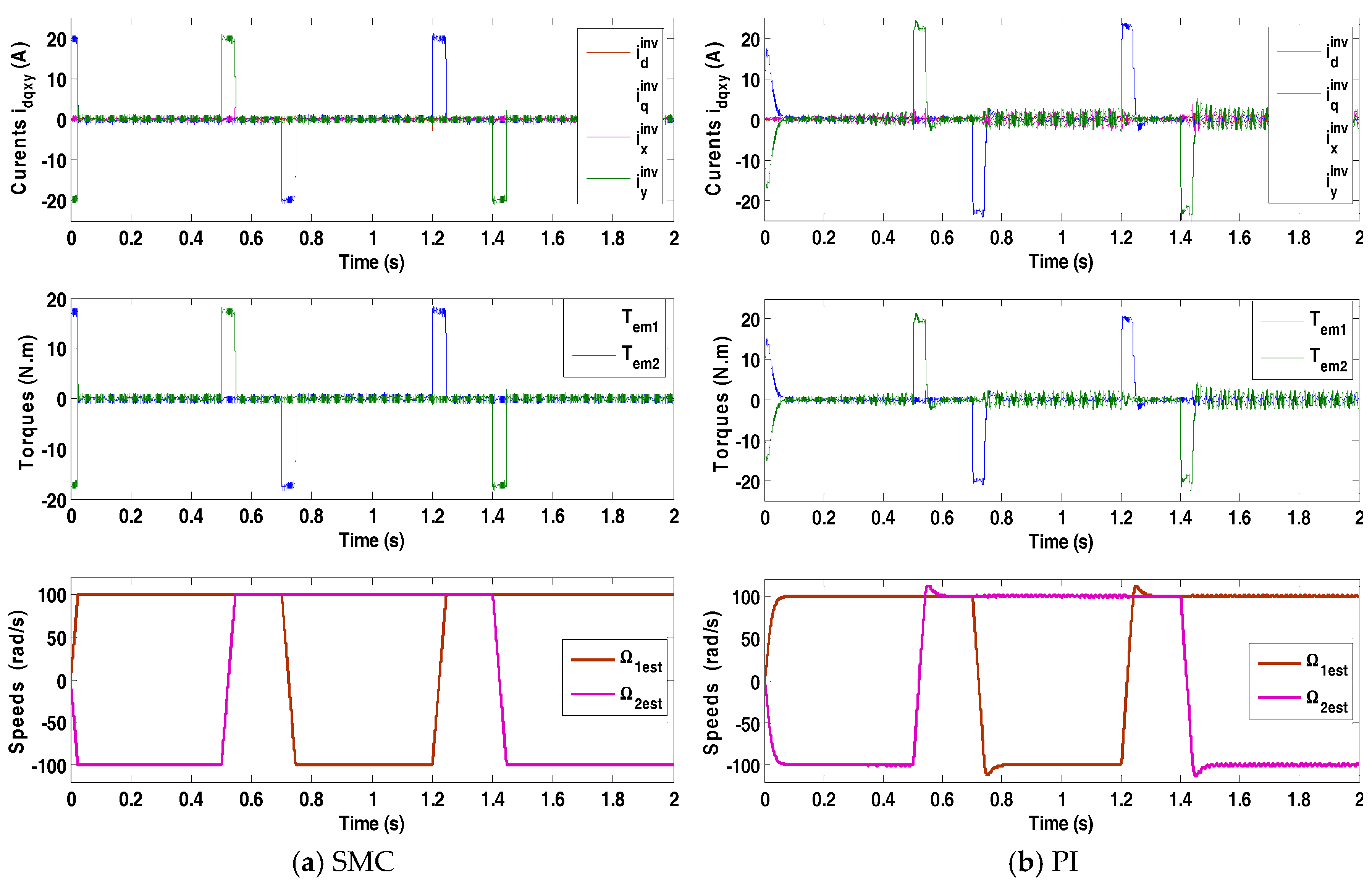

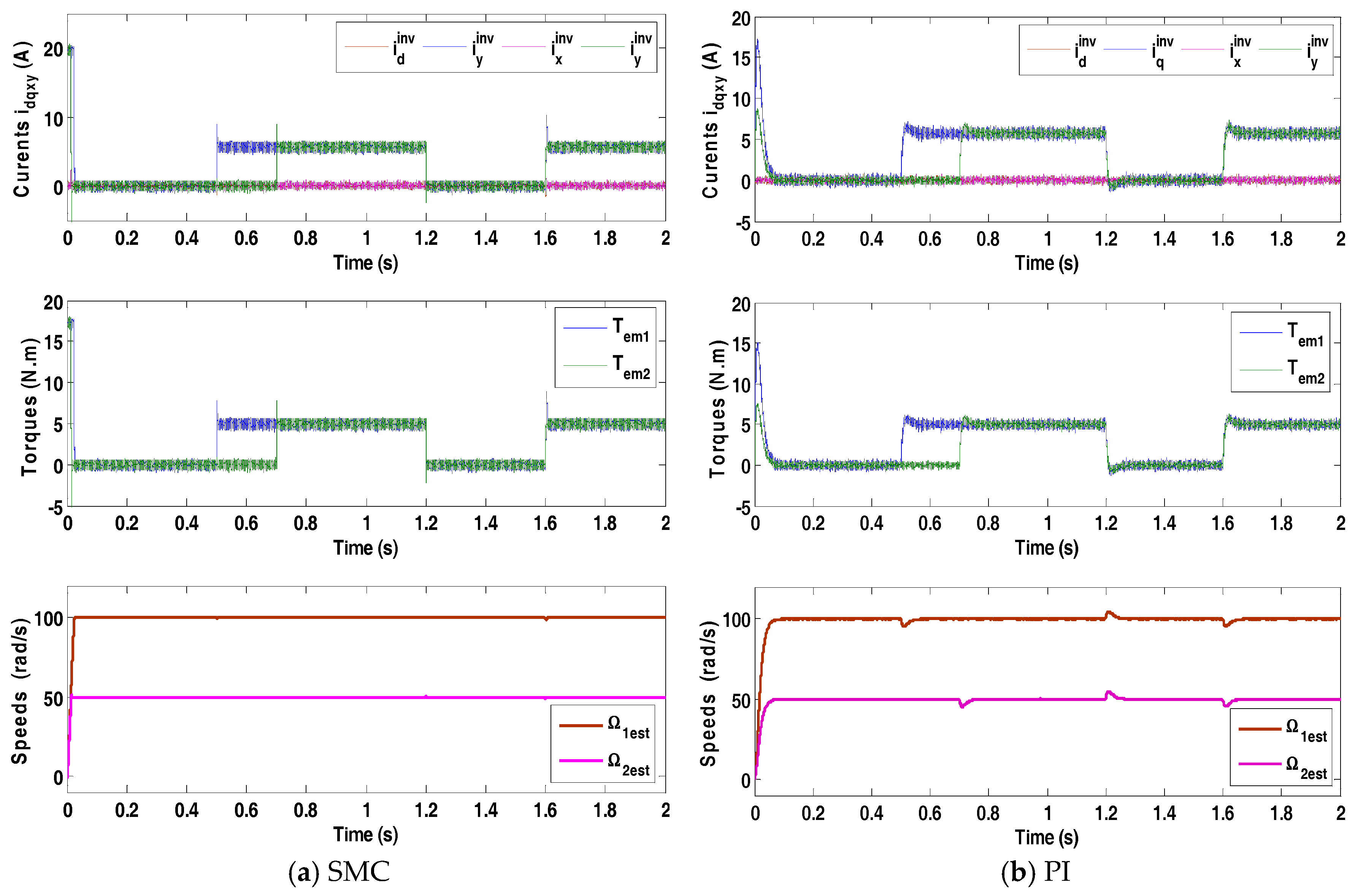

7. Numerical Simulation Results

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Navid, R.A. Sliding-mode control of a six-phase series/parallel connected two induction motors drive. ISA Trans. 2014, 53, 1847–1856. [Google Scholar]

- Chen, H.H.; Chong, X.S. Current control for single-inverter-fed series-connected five-phase PMSMS. In Proceedings of the IEEE International Symposium on Industrial Electronics, Taipei, Taiwan, 28–31 May 2013; pp. 1–6. [Google Scholar]

- Liliang, G.; John, E.F. A space vector switching strategy for three-level five-phase inverter drives. IEEE Trans. Ind. Electron. 2010, 57, 2332–2343. [Google Scholar] [CrossRef]

- Sneessens, C.; Labbe, T.; Baudart, F.; Matagne, E. Position sensorless control for five-phase permanent-magnet synchronous motors. In Proceedings of the International Conference on Advanced Intelligent Mechatronics, Besançon, France, 8–11 July 2014; pp. 794–799. [Google Scholar]

- Wang, Z.; Wang, X.J.C.; Cheng, M.; Hu, Y. Direct torque control of T-NPC inverters fed double-stator-winding PMSM drives with SVM. IEEE Trans. Power Electron. 2018, 33, 1541–1553. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Cheng, M.; Hu, Y. Remedial strategies of T-NPC three-level asymmetric six-phase PMSM drives based on SVM-DTC. IEEE Trans. Ind. Electron. 2017, 64, 6841–6853. [Google Scholar] [CrossRef]

- Lei, Y.; Ming-liang, C.; Jian-qing, S.; Fei, X. Current Harmonics Elimination Control Method for Six-Phase PM Synchronous Motor Drives. ISA Trans. 2015, 59, 443–449. [Google Scholar]

- Leila, P.; Hamid, A.T. Sensorless Direct Torque Control of Five-Phase Interior Permanent-Magnet Motor Drives. IEEE Trans. Ind. Appl. 2007, 43, 952–959. [Google Scholar]

- Siavash, S.; Lusu, G.; Hamid, A.T.; Leila, P. Wide Operational Speed Range of Five-Phase Permanent Magnet Machines by Using Different Stator Winding Configurations. IEEE Trans. Ind. Electron. 2012, 59, 2621–2631. [Google Scholar]

- Hosseyni, A.; Ramzi, T.; Faouzi, M.M.; Atif, I.; Rashid, A. Sensorless Sliding Mode Observer for a Five-Phase Permanent Magnet Synchronous Motor Drive. ISA Trans. 2015, 58, 462–473. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.A.; Dahaman, I.; Pais, S.; Shahid, I. Speed-Sensorless Control of Parallel-Connected PMSM Fed By A Single Inverter Using MRAS. In Proceedings of the IEEE International Power Engineering and Optimization Conference, Melaka, Malaysia, 6–7 June 2012; pp. 35–39. [Google Scholar]

- Zhang, H.; Luo, S.; Yu, Y.; Liu, L. Study On Series Control Method For Dual Three-Phase PMSM Based On Space Vector Pulse Width Modulation. Int. J. Control Autom. 2015, 8, 197–210. [Google Scholar] [CrossRef]

- Martin, J.; Emil, L.; Slobodan, N.V. Independent Control of Two Five-Phase Induction Machines Connected In Parallel To A Single Inverter Supply. In Proceedings of the IEEE Industrial Electronics Conference, Paris, France, 6–10 November 2006; pp. 1257–1262. [Google Scholar]

- Levi, E.; Jones, M.; Vukosavic, S.N.; Iqbal, A.; Toliyat, H.A. Modeling, control, and experimental investigation of a five-phase series-connected two-motor drive with single inverter supply. IEEE Trans. Ind. Electron. 2007, 54, 1504–1516. [Google Scholar] [CrossRef]

- Levi, E.; Jones, M.; Slobodan, N.V.; Hamid, A.T. Steady-State Modeling of Series-Connected Five-Phase And Six-Phase Two-Motor Drives. IEEE Trans. Ind. Appl. 2008, 44, 1559–1568. [Google Scholar] [CrossRef]

- Mekri, F.; Charpentier, J.F.; Semail, E. An Efficient Control of A Series Connected Two-Synchronous Motor 5-Phase with Non-Sinusoidal EMF Supplied By A Single 5-Leg VSI: Experimental And Theoretical Investigations. Electr. Power Syst. Res. 2012, 92, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Jones, M.; Vukosavic, S.N.; Levi, E. Parallel-Connected Multiphase Multidrive Systems with Single Inverter Supply. IEEE Trans. Ind. Electron. 2019, 56, 2047–2057. [Google Scholar] [CrossRef]

- Zhang, X.; Lizhi, S.; Zhao, K.; Sun, L. Nonlinear Speed Control for PMSM System Using Sliding-Mode Control and Disturbance Compensation Techniques. IEEE Trans. Power Electron. 2013, 28, 1358–1365. [Google Scholar] [CrossRef]

- Fatemi, F.S.M.J.R.; Navid, R.A.; Jafar, S.; Saeed, A. Speed Sensorless Control of a Six-Phase Induction Motor Drive Using Backstepping Control. IET Power Electron. 2014, 7, 114–123. [Google Scholar] [CrossRef]

- Anissa, H.; Ramzi, T.; Atif, I.; Med, F.M. Backstepping Control for a Five-Phase Permanent Magnet Synchronous Motor Drive. Int. J. Power Electron. Drive Syst. 2015, 6, 842–852. [Google Scholar]

- Ahmed, M.; Karim, F.M.; Abdelkader, M.; Abdelber, B. Input Output Linearization And Sliding Mode Control of a Permanent Magnet Synchronous Machine Fed by a Three Levels Inverter. J. Electr. Eng. 2006, 57, 205–210. [Google Scholar]

- Le-Bao, L.; Ling-Ling, S.; Sheng-Zhou, Z.; Qing-Quan, Y. PMSM Speed Tracking And Synchronization of Multiple Motors Using Ring Coupling Control and Adaptive Sliding Mode Control. ISA Trans. 2015, 58, 635–649. [Google Scholar]

- Lin, S.F.J.; Hung, Y.C.; Tsai, M.T. Fault-Tolerant Control for Six-Phase PMSM Drive System via Intelligent Complementary Sliding Mode Control Using TSKFNN-AMF. IEEE Trans. Ind. Electron. 2013, 60, 5747–5762. [Google Scholar] [CrossRef]

- Chen, S.; Luo, Y.; Pi, Y.G. PMSM Sensorless Control with Separate Control Strategies and Smooth Switch from Low Speed to High Speed. ISA Trans. 2015, 58, 650–658. [Google Scholar] [CrossRef] [PubMed]

- Dujic, D.; Jones, M.; Levi, E.; Prieto, J.; Barrero, F. Switching Ripple Characteristics of Space Vector PWM Schemes for Five-Phase Two-Level Voltage Source Inverters—Part 1: Flux Harmonic Distortion Factors. IEEE Trans. Ind. Electron. 2011, 58, 2789–2798. [Google Scholar] [CrossRef]

- Iqbal, A.; Levi, E. Space Vector Modulation Schemes for a Five-Phase Voltage Source Inverter. In Proceedings of the European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005; pp. 1–12. [Google Scholar]

- Dujic, D.; Grandi, G.; Jones, M.; Levi, E. A Space Vector PWM Scheme for Multi Frequency Output Voltage Generation with Multiphase Voltage-Source Inverters. IEEE Trans. Ind. Electron. 2008, 55, 1943–1955. [Google Scholar] [CrossRef]

- Quang, N.K.; Hieu, N.T.; Ha, Q.P. FPGA-Based Sensorless PMSM Speed Control Using Reduced-Order Extended Kalman Filters. IEEE Trans. Ind. Electron. 2014, 12, 6574–6582. [Google Scholar] [CrossRef]

- Zhuang, X.; Rahman, M.F. Comparison of a Sliding Observer and a Kalman Filter for Direct-Torque-Controlled IPM Synchronous Motor Drives. IEEE Trans. Ind. Electron. 2012, 59, 4179–4188. [Google Scholar]

- Dong, X.; Zhang, S.; Liu, J. Very-Low Speed Control of PMSM Based on EKF Estimation with Closed Loop Optimized Parameters. ISA Trans. 2013, 52, 835–843. [Google Scholar]

- Abbas, N.K.; Jafar, S. MTPA Control of Mechanical Sensorless IPMSM Based on Adaptive Nonlinear Control. ISA Trans. 2016, 61, 348–356. [Google Scholar]

- Khan, M.R.; Iqbal, A. MRAS Based Sensorless Control of a Series-Connected Five-Phase Two-Motor Drive System. J. Electr. Eng. Technol. 2008, 3, 224–234. [Google Scholar] [CrossRef]

- Khan, M.R.; Iqbal, A. Extended Kalman Filter Based Speeds Estimation of Series-Connected Five-Phase Two-Motor Drive System. Simul. Model. Pract. Theory 2009, 17, 1346–1360. [Google Scholar] [CrossRef]

- Ali, W.H.; Gowda, M.; Cofie, P.; Fuller, J. Design of a Speed Controller Using Extended Kalman Filter for PMSM. In Proceedings of the IEEE 57th International Midwest Symposium on Circuits and Systems, College Station, TX, USA, 8–11 July 2014; pp. 1101–1104. [Google Scholar]

- Slotine, J.J. Applied Nonlinear Control; Tice Hall: Englewood Cliffs, NJ, USA, 1991. [Google Scholar]

- Iqbal, A.; Levi, E. Space Vector PWM for a Five-Phase VSI Supplying Two Five-Phase Series-Connected Machines. In Proceedings of the 12th International Power Electronics and Motion Control Conference, Portoroz, Slovenia, 30 August–1 September 2006; pp. 222–227. [Google Scholar]

- Dujic, D.; Jones, M.; Levi, E. Generalised Space Vector PWM for Sinusoidal Output Voltage Generation with Multiphase Voltage Source Inverters. Int. J. Ind. Electron. Drives 2009, 1, 1–13. [Google Scholar] [CrossRef]

- Jones, M.; Dordevic, O.; Bodo, N.; Levi, E. PWM Algorithms for Multilevel Inverter Supplied Multiphase Variable-Speed Drives. Electronics 2012, 16, 22–31. [Google Scholar] [CrossRef]

| pj | Ldj | Lqj | Llsj | Jj | rsj | fj | |

|---|---|---|---|---|---|---|---|

| 2 | 8.5 mH | 8 mH | 0.2 mH | 0.175 Wb | 0.004 kg m2 | 1 Ω | 0 |

| Speed Controller | isd Controller | isq Controller | isx Controller | isy Controller | |

|---|---|---|---|---|---|

| PI | kp = 0.8 | kp = 33 | kp = 33 | kp = 33 | kp = 33 |

| ki = 40 | ki = 32,000 | ki = 32,000 | ki = 32,000 | ki = 32,000 | |

| SMC | GΩj = 5 | Gidj = 4000 | Giqj = 7000 | Gixj = 4000 | Giyj = 7000 |

| Comparison Criterion | SMC | PI |

|---|---|---|

| Settling time (s) | 0.028 | 0.075 |

| Recovery time (at abrupt load) (s) | 0.0045 | 0.05 |

| Overshoot in reversal mode (%) | 0 | 18% |

| Starting current (A) | 20 | 17 |

| Starting torque (Nm) | 18 | 15 |

| Speeds drops (%) | 0 | 5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamel, T.; Abdelkader, D.; Said, B.; Padmanaban, S.; Iqbal, A. Extended Kalman Filter Based Sliding Mode Control of Parallel-Connected Two Five-Phase PMSM Drive System. Electronics 2018, 7, 14. https://doi.org/10.3390/electronics7020014

Kamel T, Abdelkader D, Said B, Padmanaban S, Iqbal A. Extended Kalman Filter Based Sliding Mode Control of Parallel-Connected Two Five-Phase PMSM Drive System. Electronics. 2018; 7(2):14. https://doi.org/10.3390/electronics7020014

Chicago/Turabian StyleKamel, Tounsi, Djahbar Abdelkader, Barkat Said, Sanjeevikumar Padmanaban, and Atif Iqbal. 2018. "Extended Kalman Filter Based Sliding Mode Control of Parallel-Connected Two Five-Phase PMSM Drive System" Electronics 7, no. 2: 14. https://doi.org/10.3390/electronics7020014