Evaluation of Deep Coalbed Methane Potential and Prediction of Favorable Areas within the Yulin Area, Ordos Basin, Based on a Multi-Level Fuzzy Comprehensive Evaluation Method

Abstract

:1. Introduction

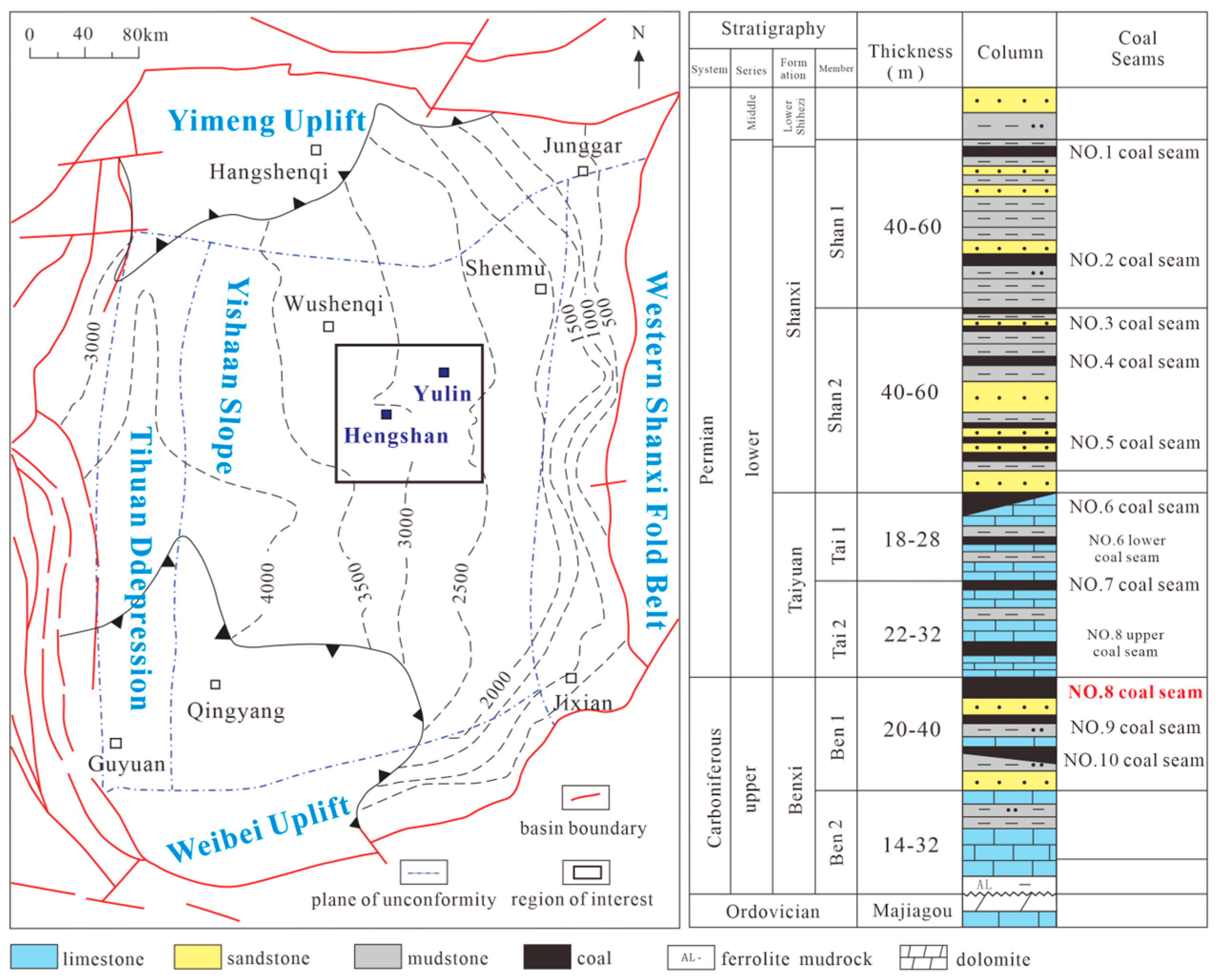

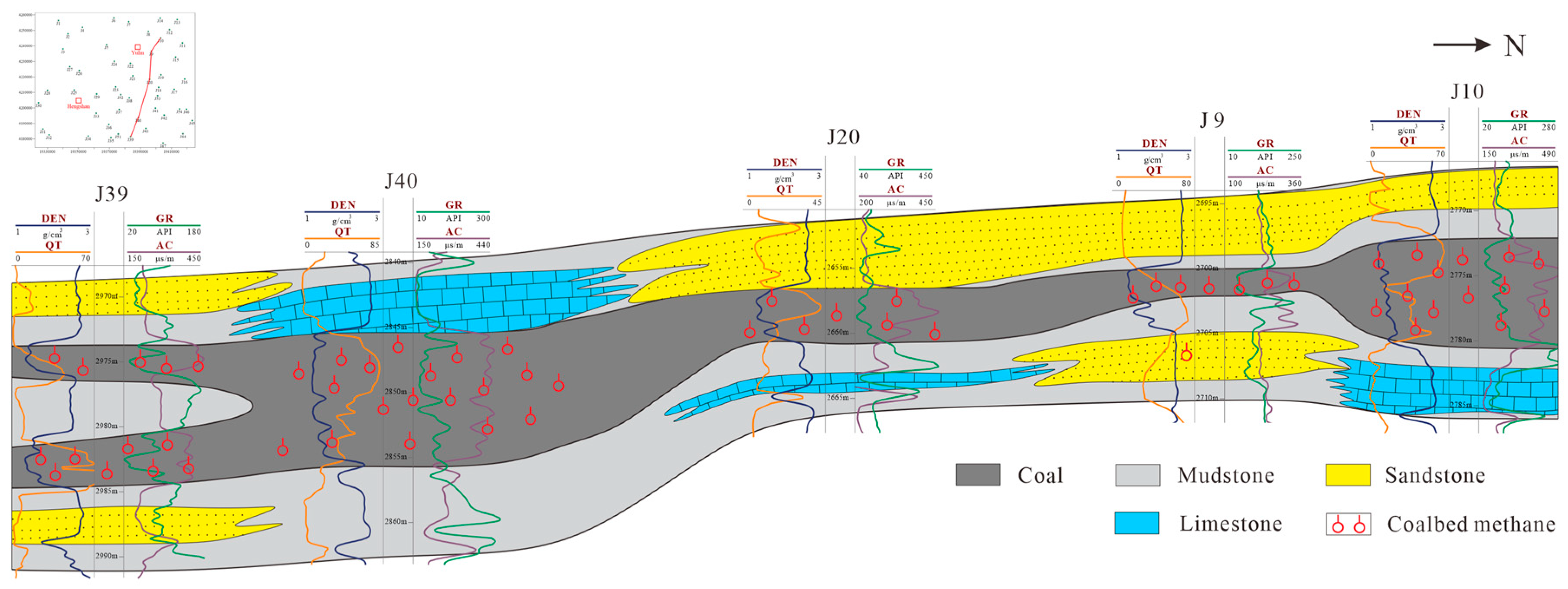

2. Geological Background

3. Databases and Methods

3.1. Data Collection

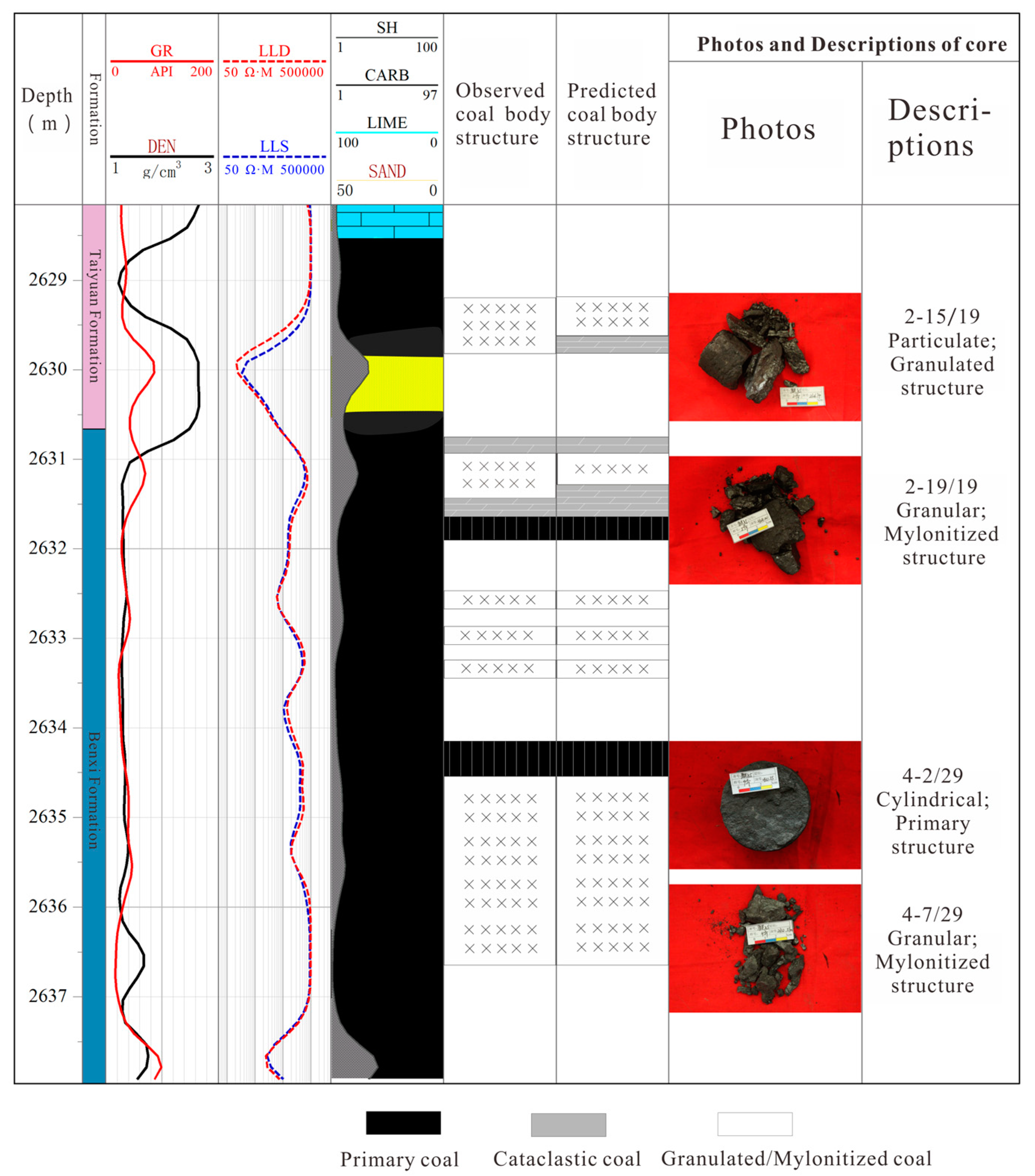

3.1.1. Logging Data

3.1.2. Gas Content Test Data

3.1.3. Vitrinite Reflectance Test Data

3.1.4. Core Observation Record

3.2. Multi-Level Fuzzy Comprehensive Evaluation Method

- (a)

- Determination of the influence factor set of the evaluation object

- (b)

- Determination of the weight of each evaluation index

- (c)

- Determination of the degree of affiliation of each influence index

- (d)

- The comprehensive evaluation results

4. Results and Discussions

4.1. Evaluation Indexes

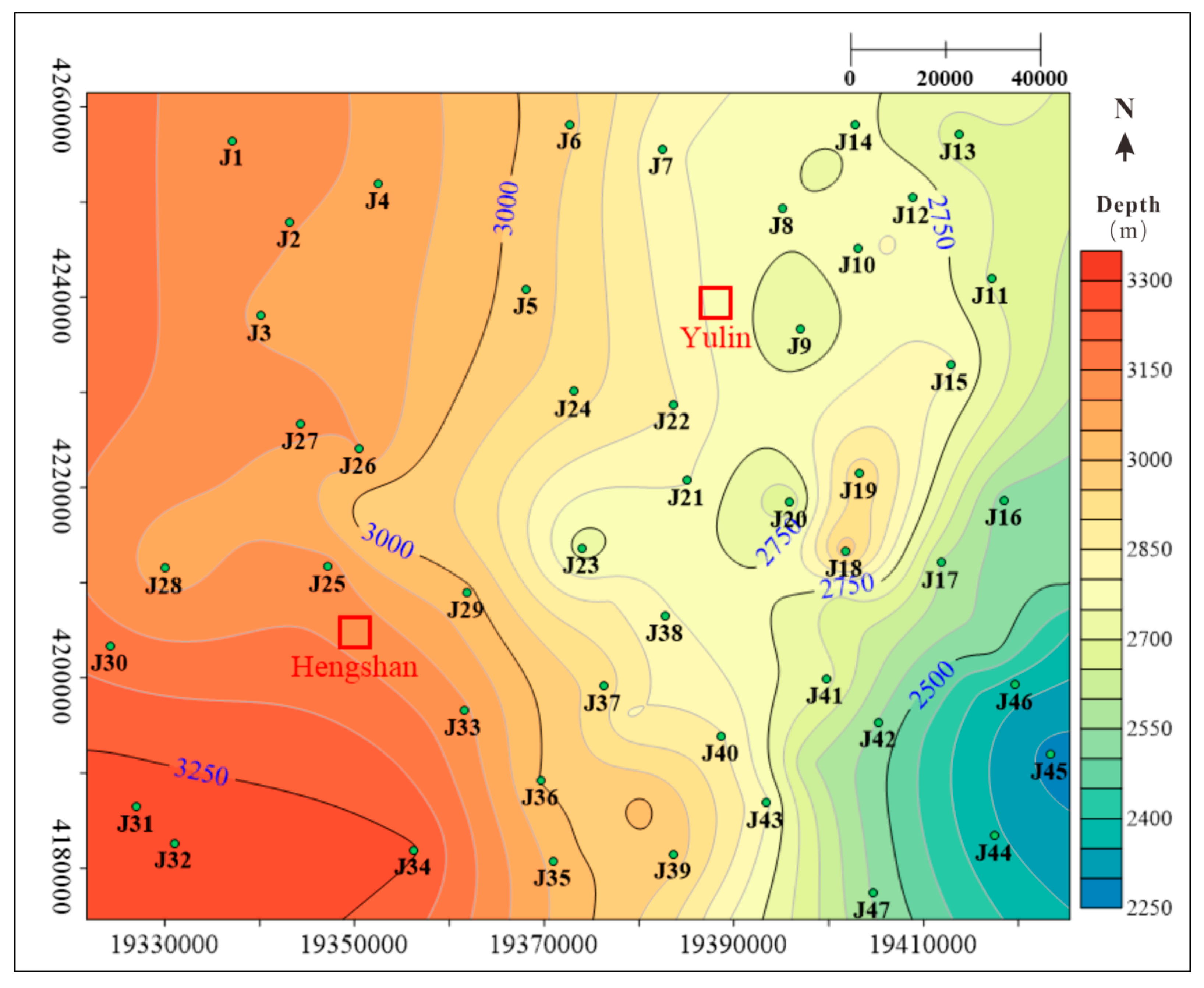

4.1.1. Burial Depth

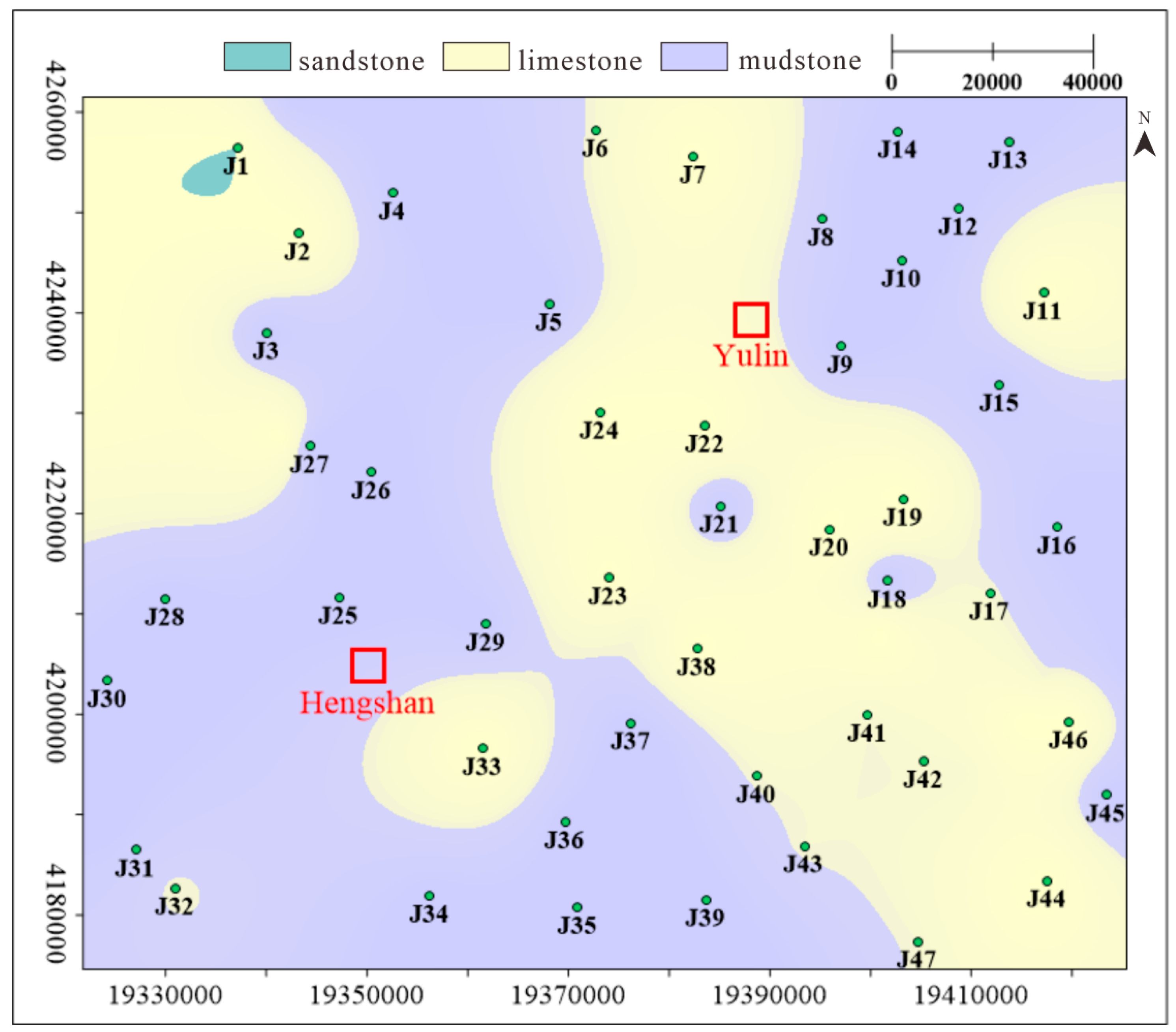

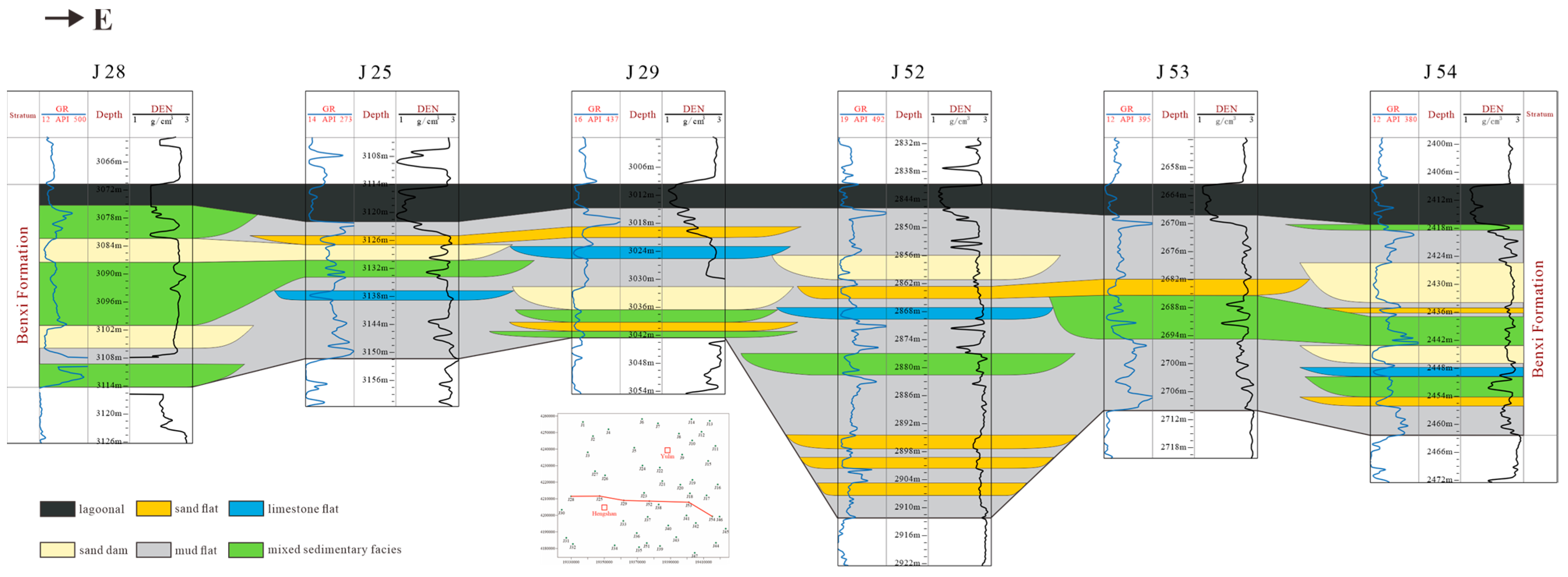

4.1.2. Coal Roof Lithology

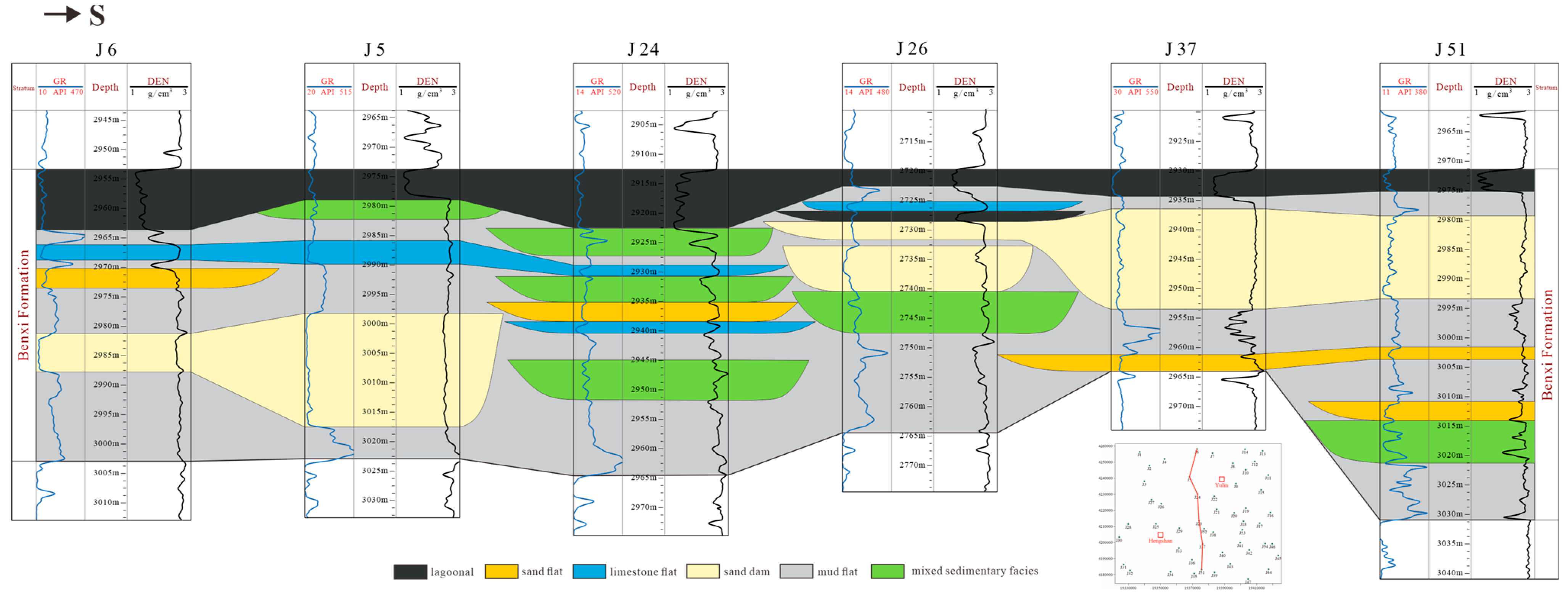

4.1.3. Coal Seam Thickness

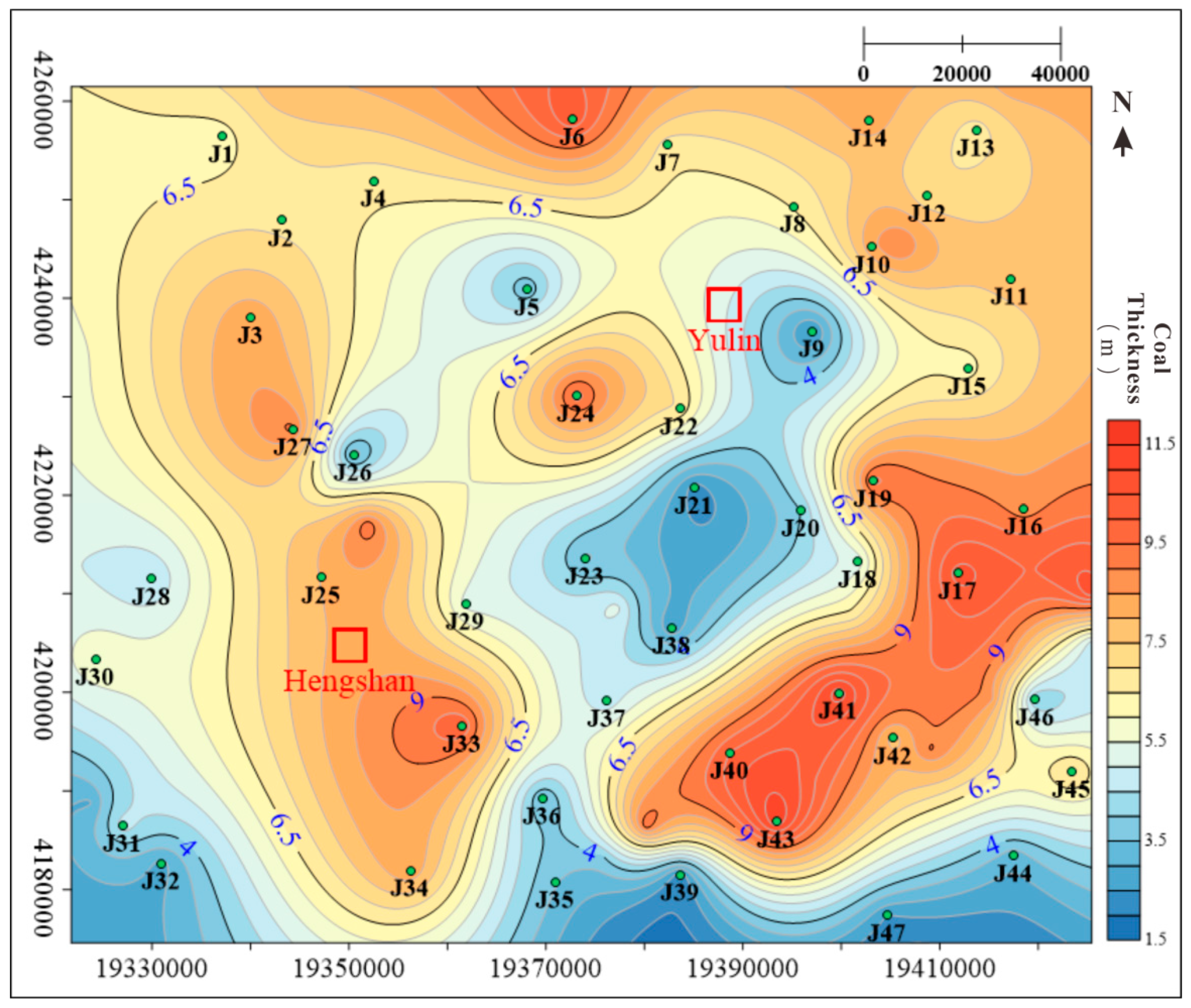

4.1.4. Gas Content

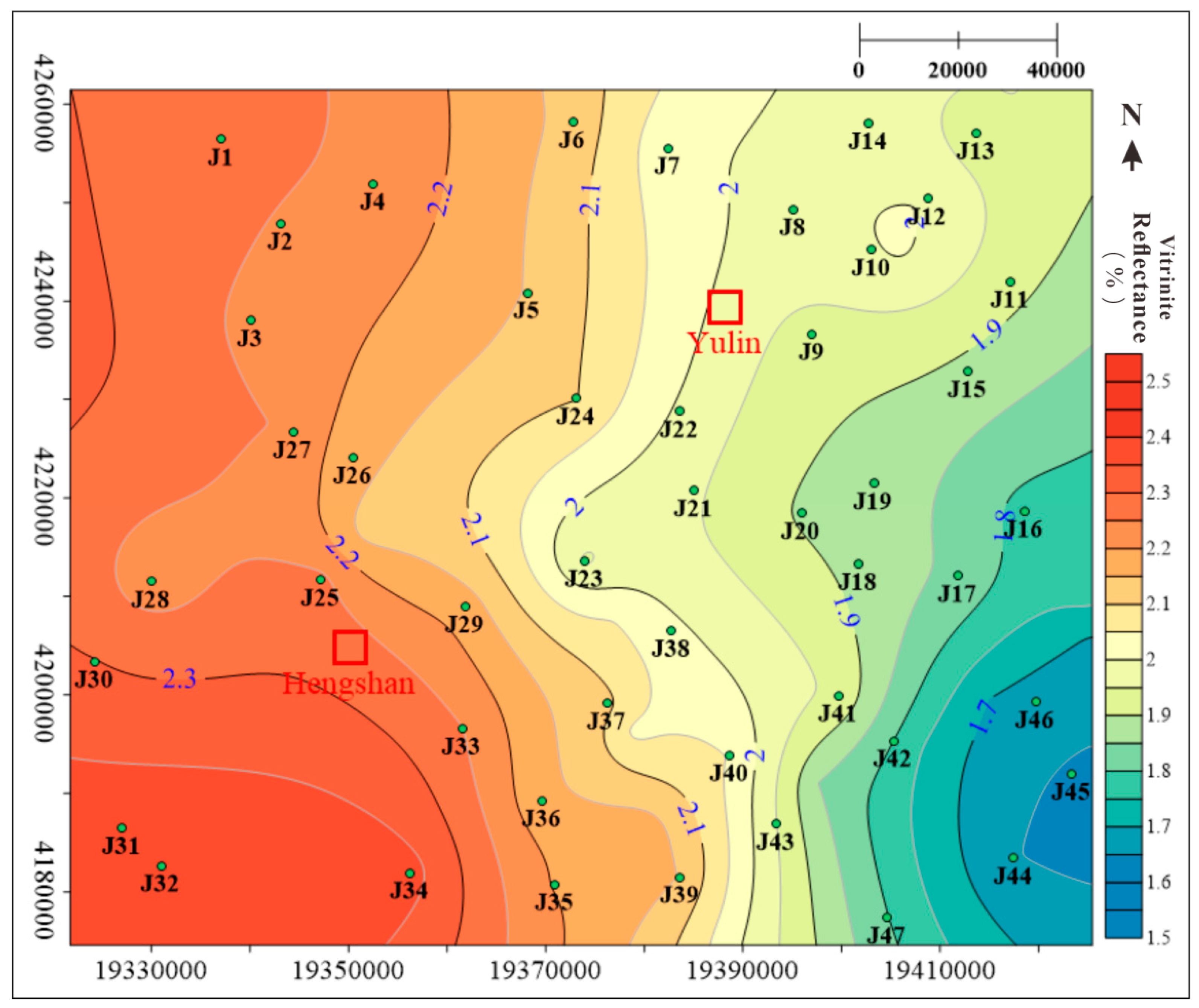

4.1.5. Vitrinite Reflectance

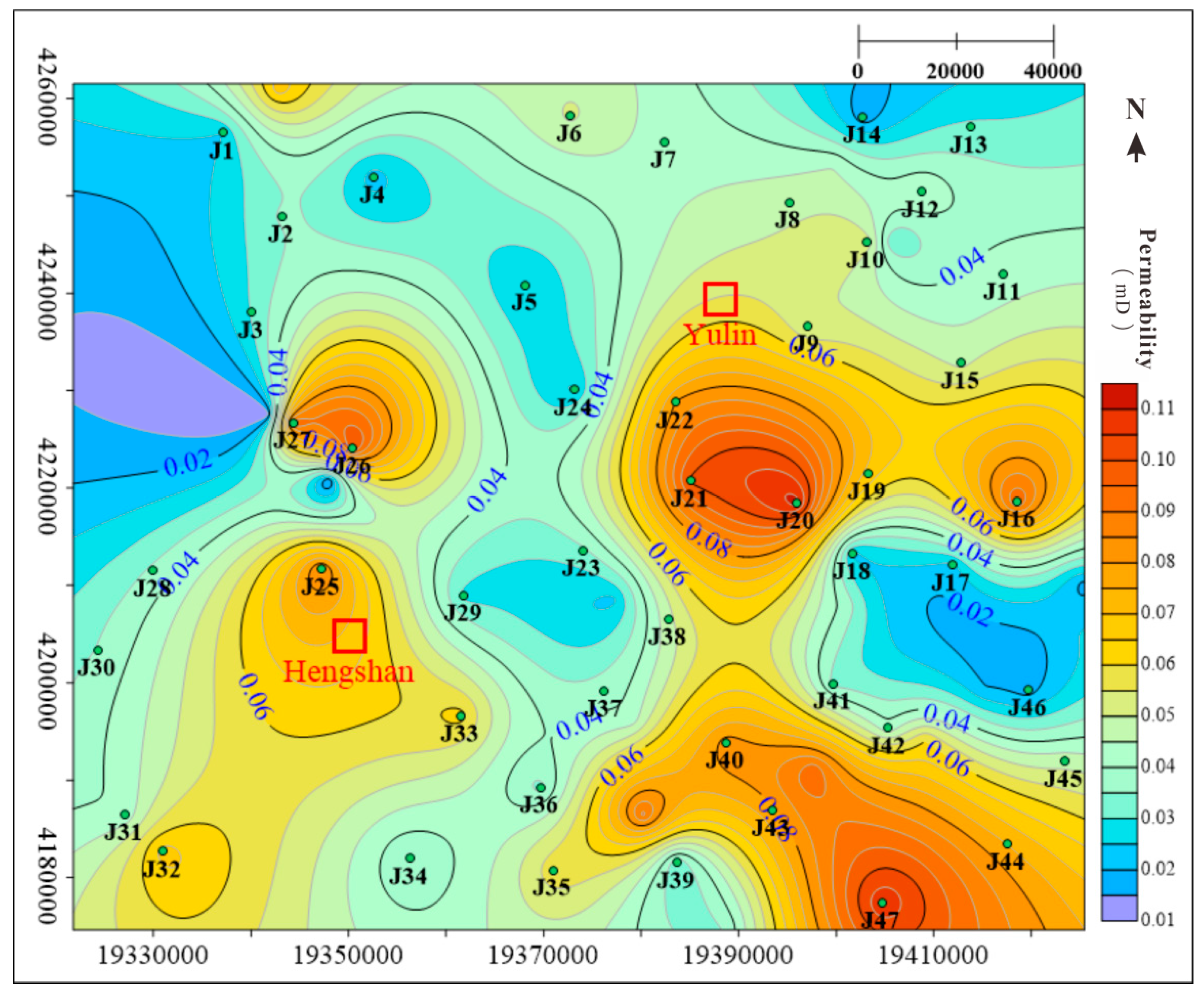

4.1.6. Coal Seam Permeability

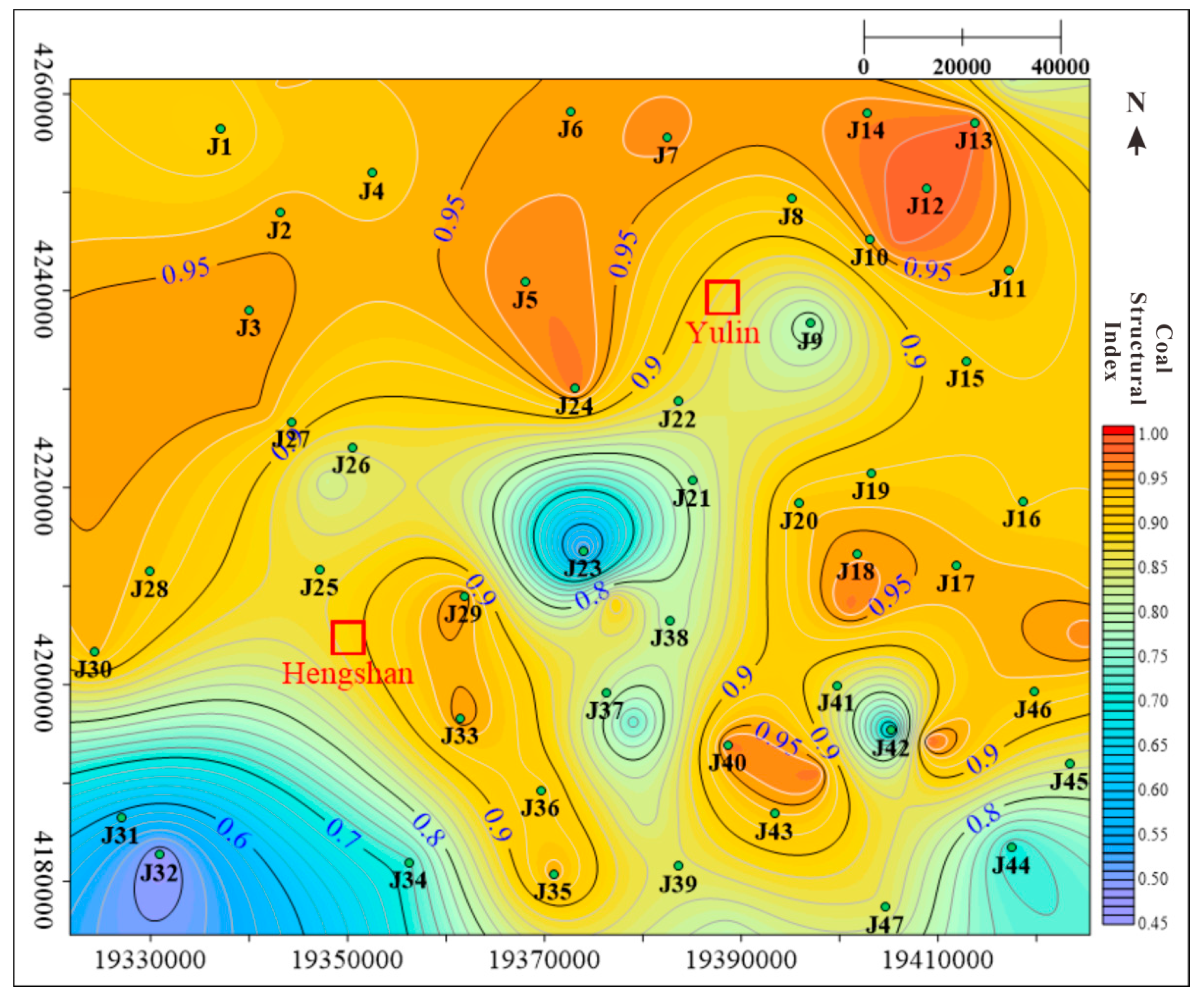

4.1.7. Coal Structural Index

4.2. Degree of Affiliation of Evaluation Indexes

4.2.1. Qualitative Index

4.2.2. Quantitative Indexes

- (1)

- Vitrinite reflectance

- (2)

- Gas Content

- (3)

- Coal seam thickness

- (4)

- Coal structure index

- (5)

- Permeability

- (6)

- Burial Depth

4.3. Comprehensive Evaluation Results

5. Conclusions

- The planar distribution characteristics of the No. 8 coal reservoir in the Yulin area have been investigated. The thickness of the coal seam is significant, and the burial depth shows a trend of higher values in the west and lower values in the east. The roof is mostly mudstone, with good resource preservation conditions. The gas content is high, ranging from 9.74 m3/t to 23.38 m3/t. The vitrinite reflectance is high, with most being between 1.65% and 2.39%, showing a good positive correlation with the burial depth. The overall fracture permeability of the reservoir is low, with better coal structure integrity in the northern and eastern parts of the study area, indicating a strong potential for modification.

- An evaluation system for deep coalbed methane (CBM) reservoirs was established. Based on the characteristics of reservoirs in the Yulin Block, three types of geologically favorable areas have been reasonably classified. Overall, the Yulin Block shows the widespread development of Type I favorable areas, concentrated in the central-eastern, northern, and southwestern parts. Type II sub-favorable areas are closely distributed around the Type I favorable areas. Type III unfavorable areas are concentrated in a very small central part of the study area. Priority should be given to the exploration and development of the central-eastern part of the Yulin Block.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Xu, F.; Yan, X.; Li, S.; Xiong, X.; Wang, Y.; Zhang, L.; Liu, C.; Han, J.; Feng, Y.; Zhen, H.; et al. Theoretical and technological difficulties and countermeasures of deep CBM exploration and development in the eastern edge of Ordos Basin. Coal Geol. Explor. 2023, 51, 115–130. [Google Scholar]

- Li, S.; Wang, C.; Wang, H.; Wang, Y.; Xu, F.; Guo, Z.; Liu, X. Reservoir forming characteristics and favorable area evaluation of deep coalbed methane in Daning-Jixian Block. Coal Geol. Explor. 2022, 50, 59–67. [Google Scholar]

- Xu, H.; Tang, D.; Tao, S.; Li, S.; Tang, S.; Chen, S.; Zong, P.; Dong, Y. Formation mechanism of geological conditions differences between deep and shallow coalbed methane. Coal Geol. Explor. 2024, 52, 33–39, (In Chinese with English Abstract). [Google Scholar]

- Guo, G.; Xu, F.; Liu, L.; Cai, Y.; Qin, W.; Chen, Z.; Deng, J.; Li, Z. Enrichment and accumulation patterns and favorable area evaluation of deep coalbed methane in the Fugu area, Ordos Basin. Coal Geol. Explor. 2024, 52, 81–91, (In Chinese with English Abstract). [Google Scholar]

- Li, S.; Wang, H.; Xu, B.; Zhen, H.; Wang, C.; Yuan, P. Influencing factors on gas production effect of acid fractured CBM Wells in deep coal seam of Daning-Jixian Block. Coal Geol. Explor. 2022, 50, 165–172. [Google Scholar]

- Fu, X.; Meng, Y.; Li, Z.; Kong, P.; Chang, S.; Yan, T.; Liu, Y. Coalbed Methane Potential Evaluation and Development Sweet Spot Prediction Based on the Analysis of Development Geological Conditions in Yangjiapo Block, Eastern Ordos Basin, China. Geofluids 2021, 2021, 8728005. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.; Shen, Y.; Wang, G. Resources and geology of coalbed methane in China: A review. Int. Geol. Rev. 2018, 60, 777–812. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Pan, Z.; Xu, H.; Tao, S.; Liu, Y.; Ren, P. Geological conditions of deep coalbed methane in the eastern margin of the Ordos Basin, China: Implications for coalbed methane development. J. Nat. Gas Sci. Eng. 2018, 53, 394–402. [Google Scholar] [CrossRef]

- Ju, W.; Shen, J.; Qin, Y.; Meng, S.; Wu, C.; Shen, Y.; Yang, Z.; Li, G.; Li, C. In-situ stress state in the Linxing region, eastern Ordos Basin, China: Implications for unconventional gas exploration and production. Mar. Pet. Geol. 2017, 86, 66–78. [Google Scholar] [CrossRef]

- Li, Y.; Tang, D.; Wu, P.; Niu, X.; Wang, K.; Qiao, P.; Wang, Z. Continuous unconventional natural gas accumulations of Carboniferous-Permian coal-bearing strata in the Linxing area, northeastern Ordos basin, China. J. Nat. Gas Sci. Eng. 2016, 36, 314–327. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, J.; Qu, Z.; Li, C.; Wang, L.; Li, M.; Liu, J. The stress characteristics of the DaningJixian Area and its influence on the permeability of the coal reservoir. Earth Sci. Front. 2016, 23, 17–23. [Google Scholar]

- Zhao, Z.; Xu, W.; Zhao, Z.; Yi, S.; Yang, W.; Zhang, Y.; Sun, Y.; Zhao, W.; Shi, Y.; Zhang, L.; et al. Geological characteristics and exploration breakthroughs of coal rock gas in Carboniferous Benxi Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2024, 51, 234–247+259, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Huang, W.; Tang, S.; Che, Y. A Comprehensive Model for Evaluating Coalbed Methane Reservoirs in China. Acta Geol. Sin. 2008, 82, 1253–1270. [Google Scholar]

- Zhang, Z.; Qin, Y.; Zhuang, X.; Li, G.; Liu, D. Geological Controls on the CBM Productivity of No.15 Coal Seam of Carboniferous-Permian Taiyuan Formation in Southern Qinshui Basin and Prediction for CBM High-yield Potential Regions. Acta Geol. Sin. 2018, 92, 2310–2332. [Google Scholar]

- Guo, G. Comprehensive evaluation study on favorable area of coalbed methane reservoir in southern Shizhuang Block. Coal Sci. Technol. 2019, 47, 200–206. [Google Scholar]

- Xiang, W.; Sang, S.; Wu, Z.; Tu, B.; Guo, Z.; Han, S.; Zhou, X.; Zhou, P. Characteristics of coal reservoirs and favorable areas classification and optimization of CBM planning blocks in Guizhou Province. Coal Geol. Explor. 2022, 50, 156–164. [Google Scholar]

- Shih, H.S.; Lai, Y.J.; Lee, E.S. Fuzzy approach for multi-level programming problems. Comput. Oper. Res. 1996, 23, 73–91. [Google Scholar] [CrossRef]

- Sinha, S. Fuzzy programming approach to multi-level programming problems. Fuzzy Sets Syst. 2003, 136, 189–202. [Google Scholar] [CrossRef]

- Abbaszadeh Shahri, A.; Chunling, S.; Larsson, S. A hybrid ensemble-based automated deep learning approach to generate 3D geo-models and uncertainty analysis. Eng. Comput. 2023, 1–16. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Xing, H. Main controlling factors and prediction methods of high yield and enrichment of coalbed methane. Well Test. 2000, 9, 62–65+91, (In Chinese with English Abstract). [Google Scholar]

- Li, G. Selection of the favorable coalbed methane (CBM) blocks in eastern Ordos basin. Coal Geol. Explor. 2015, 43, 28–32. [Google Scholar]

- Liu, D.; Yao, Y.; Tang, D.; Tang, S.; Che, Y.; Huang, W. Coal reservoir characteristics and coalbed methane resource assessment in Huainan and Huaibei coalfields, Southern North China. Int. J. Coal Geol. 2009, 79, 97–112. [Google Scholar] [CrossRef]

- Wang, G.; Qin, Y.; Xie, Y.; Shen, J.; Zhao, L.; Huang, B.; Zhao, W. Coalbed methane system potential evaluation and favourable area prediction of Gujiao blocks, Xishan coalfield, based on multi-level fuzzy mathematical analysis. J. Pet. Sci. Eng. 2018, 160, 136–151. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, L.; Li, G.; Zhang, L.; Yang, F.; Ma, Z.; Gao, Z. Prediction of favorable areas for low-rank coalbed methane based on Random Forest algorithm. Reserv. Eval. Dev. 2022, 12, 596–603, 616. [Google Scholar]

- Wei, X.; Chen, H.; Zhang, D.; Dai, R.; Guo, Y.; Chen, J.; Ren, J.; Liu, N.; Luo, S.; Zhao, J. Gas exploration potential of tight carbonate reservoirs: A case study of Ordovician Majiagou Formation in the eastern Yi-Shan slope, Ordos Basin, NW China. Pet. Explor. Dev. 2017, 44, 347–357. [Google Scholar] [CrossRef]

- GB/T 19559-2021; Method of Determining Coalbed Methane Content. China Coal Industry Association: Beijing, China, 2021.

- GB/T 6948-2008; Method of Determining Microscopically the Reflectance of Vitrinite in Coal. China Coal Industry Association: Beijing, China, 2008.

- Chatterjee, R.; Paul, S. Classification of coal seams for coal bed methane exploitation in central part of Jharia coalfield, India—A statistical approach. Fuel 2013, 111, 20–29. [Google Scholar] [CrossRef]

- Meng, Y.; Tang, D.; Xu, H.; Li, C.; Li, L.; Meng, S. Geological controls and coalbed methane production potential evaluation: A case study in Liulin area, eastern Ordos Basin, China. J. Nat. Gas Sci. Eng. 2014, 21, 95–111. [Google Scholar] [CrossRef]

- NB/T 10013-2014; The Procedure and Method of Coalbed Methane Play Evaluation and Selection. Coalbed Methane Standardization Technical Committee of Energy Industry: Beijing, China, 2014.

- Saaty, T.L. Axiomatic Fundation of the Analytic Hierarchy Process. Manag. Sci. 1986, 32, 841–855. [Google Scholar] [CrossRef]

- Heo, E.; Kim, J.; Boo, K.-J. Analysis of the assessment factors for renewable energy dissemination program evaluation using fuzzy AHP. Renew. Sustain. Energy Rev. 2010, 14, 2214–2220. [Google Scholar] [CrossRef]

- Ju, W.; Jiang, B.; Miao, Q.; Wang, J.; Qu, Z.; Li, M. Variation of in situ stress regime in coal reservoirs, eastern Yunnan region, South China: Implications for coalbed methane production. AAPG Bull. 2018, 102, 2283–2303. [Google Scholar] [CrossRef]

- Qin, Y.; Shen, J. On the fundamental issues of deep coalbed methane geology. Acta Petrolei Sinica 2016, 37, 125–136. [Google Scholar]

- Liu, D.; Yao, Y.; Cai, Y.; Zhang, B.; Zhang, K.; Li, J. Characteristics of Porosity and Permeability and Their Geological Control of Permo-Carboniferous Coals in North China. Geoscience 2010, 24, 1198–1203. [Google Scholar]

- Zhou, S.; Liu, D.; Sun, S.; Cai, Y. Factors Affecting Coalbed Methane Enrichment and CBM Favorable Area of Liuhuanggou Area in the Southern Jungger Basin. Geoscience 2015, 29, 179–189. [Google Scholar]

- Zou, Z.; Liu, D.; Cai, Y.; Wang, Y.; Li, J. Geological Factors and Reservoir Properties Affecting the Gas Content of Coal Seams in the Gujiao Area, Northwest Qinshui Basin, China. Energies 2018, 11, 1044. [Google Scholar] [CrossRef]

- Wang, H.; Shao, L.; Hao, L.; Zhang, P.; Glasspool, I.J.; Wheeley, J.R.; Wignall, P.B.; Yi, T.; Zhang, M.; Hilton, J. Sedimentology and sequence stratigraphy of the Lopingian (Late Permian) coal measures in southwestern China. Int. J. Coal Geol. 2011, 85, 168–183. [Google Scholar] [CrossRef]

- Diessel, C.F.K. Utility of coal petrology for sequence-stratigraphic analysis. Int. J. Coal Geol. 2007, 70, 3–34. [Google Scholar] [CrossRef]

- Wu, C.; Qin, Y.; Fu, X. Stratum energy of coal-bed gas reservoir and their control on the coal-bed gas reservoir formation. Sci. China Ser. D-Earth Sci. 2007, 50, 1319–1326. [Google Scholar] [CrossRef]

- Ou, C.; Li, C.; Zhi, D.; Xue, L.; Yang, S. Coupling accumulation model with gas-bearing features to evaluate low-rank coalbed methane resource potential in the southern Junggar Basin, China. AAPG Bull. 2018, 102, 153–174. [Google Scholar] [CrossRef]

- Hou, X.; Liu, S.; Zhu, Y.; Yang, Y. Evaluation of gas contents for a multi-seam deep coalbed methane reservoir and their geological controls: In situ direct method versus indirect method. Fuel 2020, 265, 116917. [Google Scholar] [CrossRef]

- Maehlmann, R.F.; Le Bayon, R. Vitrinite and vitrinite like solid bitumen reflectance in thermal maturity studies: Correlations from diagenesis to incipient metamorphism in different geodynamic settings. Int. J. Coal Geol. 2016, 157, 52–73. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, X.; Zhou, F.; Ju, P.; Chen, Y.; Cao, Z.; Xia, Y.; Zhang, X. Hydrocarbon yield evolution characteristics and geological significance in temperaturepressure controlled simulation experiment. Nat. Gas Geosci. 2022, 33, 1460–1475. [Google Scholar]

- Liu, A.; Fu, X.; Liang, W.; Lu, L.; Luo, P. Pore Distribution Features of Different Rank Coal and Influences to Coal Bed Methane Development. Coal Sci. Technol. 2013, 41, 104–108, (In Chinese with English Abstract). [Google Scholar]

- Bustin, R.M.; Clarkson, C.R. Geological controls on coalbed methane reservoir capacity and gas content (vol 38, pg 3, 1998). Int. J. Coal Geol. 1999, 40, 357–358. [Google Scholar]

- Yu, Q.; Ren, Z.; Li, R.; Wang, B.; Qin, X.; Tao, N. Paleogeotemperature and maturity evolutionary history of the source rocks in the Ordos Basin. Geol. J. 2017, 52, 97–118. [Google Scholar] [CrossRef]

- Li, P.; Zhang, X.; Li, J.; Zhao, J.; Huang, J.; Zhang, S.; Zhou, S. Analysis of the Key Factors Affecting the Productivity of Coalbed Methane Wells: A Case Study of a High-Rank Coal Reservoir in the Central and Southern Qinshui Basin, China. Acs Omega 2020, 5, 28012–28026. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Bustin, R.M. The effect of pore structure and gas pressure upon the transport properties of coal: A laboratory and modeling study. 1. Isotherms and pore volume distributions. Fuel 1999, 78, 1333–1344. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Che, Y.; Huang, W. Preliminary evaluation of the coalbed methane production potential and its geological controls in the Weibei Coalfield, Southeastern Ordos Basin, China. Int. J. Coal Geol. 2009, 78, 1–15. [Google Scholar] [CrossRef]

- Lu, W.; Huang, B.; Zhao, X. A review of recent research and development of the effect of hydraulic fracturing on gas adsorption and desorption in coal seams. Adsorpt. Sci. Technol. 2019, 37, 509–529. [Google Scholar] [CrossRef]

- Li, C. Study on Prediction Method of Coal Reservoir Permeability in Southern Qinshui Basin. Master’s Thesis, China University of Geosciences, Beijing, China, 2016. (In Chinese with English Abstract). [Google Scholar]

- Tao, S.; Pan, Z.; Tang, S.; Chen, S. Current status and geological conditions for the applicability of CBM drilling technologies in China: A review. Int. J. Coal Geol. 2019, 202, 95–108. [Google Scholar] [CrossRef]

- Zhang, X.; Du, Z.; Li, P. Physical characteristics of high-rank coal reservoirs in different coal-body structures and the mechanism of coalbed methane production. Sci. China-Earth Sci. 2017, 60, 246–255. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.; Cai, Y.; Yao, Y.; Pan, Z. Constraining coalbed methane reservoir petrophysical and mechanical properties through a new coal structure index in the southern Qinshui Basin, northern China: Implications for hydraulic fracturing. AAPG Bull. 2020, 104, 1817–1842. [Google Scholar] [CrossRef]

- Yang, S.; Fu, H.; Wang, G.; Yan, D.; Li, Y.; Yao, C.; Zhang, N. Evaluation System and Prediction of Coalbed Methane Exploration Targets in the Southern Junggar Basin. Xinjiang Geol. 2021, 39, 292–296. [Google Scholar]

- Meng, Y.; Li, Z.; Tang, S.; Lai, F. Laboratory investigation on methane sorption-induced strain and permeability in middle and high rank coal samples. J. China Coal Soc. 2021, 46, 1915–1924. [Google Scholar]

- Han, B. Porosity, Permeability and Favorable Production Region of Coal Reservoirs in Gujiao Block Xishan. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2015. (In Chinese with English Abstract). [Google Scholar]

| Sample ID | Depth (m) | Desorbed Gas Content (m3/t) | Residual Gas Content (m3/t) | Loss Gas Content (m3/t) | Total Gas Content (m3/t) |

|---|---|---|---|---|---|

| J27-3 | 3101.33–3101.61 | 17.02 | 0.02 | 4.09 | 21.13 |

| J27-4 | 3101.85–3102.23 | 18.26 | 0.02 | 6.65 | 24.93 |

| J27-7 | 3103.08–3103.36 | 15.77 | 0.07 | 4.06 | 19.91 |

| J27-12 | 3103.92–3104.12 | 15.33 | 0.07 | 2.96 | 18.36 |

| J27-15 | 3104.84–3105.04 | 11.61 | 0.02 | 4.93 | 16.56 |

| J42-1 | 2628.00–2628.35 | 18.11 | 0.15 | 1.40 | 26.04 |

| J42-3 | 2629.15–2629.53 | 16.74 | 0.20 | 1.49 | 24.80 |

| J42-5 | 2631.02–2631.40 | 15.32 | 0.17 | 1.38 | 23.24 |

| J42-8 | 2632.39–2632.72 | 20.40 | 0.14 | 1.79 | 23.65 |

| J42-13 | 2635.53–2635.88 | 16.61 | 0.15 | 1.05 | 19.13 |

| Well | Average Depth (m) | Ro,max (%) |

|---|---|---|

| J27 | 3102.91 | 2.06 |

| J31 | 3403.20 | 1.92 |

| J39 | 2975.5 | 1.85 |

| J42 | 2629.70 | 2.03 |

| J46 | 2374.91 | 1.52 |

| J48 | 3276.15 | 2.04 |

| J49 | 2883.33 | 1.90 |

| J50 | 3403.26 | 1.85 |

| J51 | 2736.15 | 1.99 |

| Primary Index | A Reservoir Comprehensive Evaluation Index | ||

|---|---|---|---|

| Secondary Indexes | A1 Resources Condition | A2 Storage Condition | A3 Mining Condition |

| Tertiary indexes | A11 Vitrinite reflectance | A21 Burial depth | A31 Coal structural index |

| A12 Gas content | A22 Coal roof lithology | A32 Coal seam permeability | |

| A13 Coal seam thickness | |||

| Importance Degree | Coefficient Value |

|---|---|

| extremely important | ≥3 |

| very important | 2–3 |

| somewhat important | 1–2 |

| equal important | 1 |

| somewhat unimportant | 1/2–1 |

| unimportant | 1/3–1/2 |

| extremely unimportant | ≤1/3 |

| Judging Matrix | Characteristic Vector | Maximum Characteristic Root (%) | |||

|---|---|---|---|---|---|

| A1 | A2 | A3 | |||

| A1 | 1 | 1/5 | 2/5 | 0.59 | 3 |

| A2 | 5 | 1 | 2 | 0.12 | |

| A3 | 5/2 | 1/2 | 1 | 0.29 | |

| A11 | A12 | A13 | |||

| A11 | 1 | 1/3.2 | 1/1.8 | 0.17 | 3 |

| A12 | 3.2 | 1 | 1.5 | 0.51 | |

| A13 | 1.8 | 1/1.5 | 1 | 0.32 | |

| A21 | A22 | ||||

| A21 | 1 | 4/5 | 0.56 | 2 | |

| A22 | 5/4 | 1 | 0.44 | ||

| A31 | A32 | ||||

| A31 | 1 | 4/5 | 0.56 | 2 | |

| A32 | 5/4 | 1 | 0.44 | ||

| Primary Index | Secondary Indexes | Weight | Tertiary Indexes | Weight | Total Weight | ||

|---|---|---|---|---|---|---|---|

| Reservoir comprehensive evaluation index | A1 | Resources condition | 0.59 | A11 | Vitrinite reflectance | 0.17 | 0.100 |

| A12 | Gas content | 0.51 | 0.301 | ||||

| A13 | Coal seam thickness | 0.32 | 0.189 | ||||

| A2 | Storage condition | 0.12 | A21 | Burial depth | 0.56 | 0.067 | |

| A22 | Coal roof lithology | 0.44 | 0.053 | ||||

| A3 | Mining condition | 0.29 | A31 | Coal structural index | 0.56 | 0.162 | |

| A32 | Coal seam permeability | 0.44 | 0.128 | ||||

| Evaluation Indexes | Class Interval | Degree of Affiliation | |

|---|---|---|---|

| Resources condition | Gas content | ≥15 | 1 |

| 12–15 | 4/15 × V − 3 | ||

| <12 | 0.2 | ||

| Coal seam thickness | ≥8 | 1 | |

| 4–8 | 0.2 × H − 0.6 | ||

| <4 | 0.2 | ||

| Vitrinite reflectance | ≥2.1 | 1 | |

| 1.8–2.1 | 8/3 × Ro,max − 23/5 | ||

| <1.8 | 0.2 | ||

| Storage condition | Burial depth | <2800 | 1 |

| 2800–3200 | −0.0002 × D + 6.6 | ||

| ≥3200 | 0.2 | ||

| Coal roof lithologic character | mudstone | 1 | |

| limestone | 0.8 | ||

| sandstone | 0.6 | ||

| Mining condition | Coal structural index | ≥0.95 | 1 |

| 0.8–0.95 | 16/3 × F − 61/15 | ||

| <0.8 | 0.2 | ||

| Coal seam permeability | ≥0.04 | 1 | |

| 0.02–0.04 | 40 × K − 0.6 | ||

| <0.02 | 0.2 | ||

| Coal Roof Lithology | Membership Degree |

|---|---|

| Mudstone | 1 |

| Limestone | 0.8 |

| Sandstone | 0.6 |

| Well | Ro,max (%) | M11 | A11 | V (m3/t) | M12 | A12 | H (m) | M13 | A13 | A1 |

|---|---|---|---|---|---|---|---|---|---|---|

| J1 | 2.264 | 1.000 | 0.100 | 11.015 | 0.200 | 0.060 | 6.260 | 0.652 | 0.123 | 0.283 |

| J3 | 2.237 | 1.000 | 0.100 | 13.741 | 0.664 | 0.200 | 8.352 | 1.000 | 0.189 | 0.489 |

| J6 | 2.134 | 1.000 | 0.100 | 13.921 | 0.712 | 0.214 | 10.372 | 1.000 | 0.189 | 0.503 |

| J14 | 1.971 | 0.655 | 0.066 | 18.252 | 1.000 | 0.301 | 8.280 | 1.000 | 0.189 | 0.556 |

| J15 | 2.012 | 0.764 | 0.076 | 17.147 | 1.000 | 0.301 | 6.272 | 0.654 | 0.124 | 0.501 |

| J20 | 1.894 | 0.450 | 0.045 | 17.165 | 1.000 | 0.301 | 4.020 | 0.204 | 0.039 | 0.385 |

| J23 | 1.943 | 0.582 | 0.058 | 9.739 | 0.200 | 0.060 | 3.426 | 0.200 | 0.038 | 0.156 |

| J35 | 2.196 | 1.000 | 0.100 | 17.818 | 1.000 | 0.301 | 3.552 | 0.200 | 0.038 | 0.439 |

| J37 | 2.113 | 1.000 | 0.100 | 17.382 | 1.000 | 0.301 | 4.692 | 0.338 | 0.064 | 0.465 |

| J40 | 2.047 | 0.859 | 0.086 | 20.077 | 1.000 | 0.301 | 10.020 | 1.000 | 0.189 | 0.576 |

| Well | D (m) | M21 | A21 | R | M22 | A22 | A2 |

|---|---|---|---|---|---|---|---|

| J1 | 3124.760 | 0.350 | 0.023 | sandstone | 0.600 | 0.032 | 0.055 |

| J3 | 3091.304 | 0.417 | 0.028 | mudstone | 1.000 | 0.053 | 0.081 |

| J6 | 2963.498 | 0.673 | 0.045 | limestone | 0.800 | 0.042 | 0.087 |

| J14 | 2758.880 | 1.000 | 0.067 | mudstone | 1.000 | 0.053 | 0.120 |

| J15 | 2808.842 | 0.982 | 0.066 | mudstone | 1.000 | 0.053 | 0.119 |

| J20 | 2660.520 | 1.000 | 0.067 | sandstone | 0.600 | 0.032 | 0.099 |

| J23 | 2721.598 | 1.000 | 0.067 | sandstone | 0.600 | 0.032 | 0.099 |

| J35 | 3038.352 | 0.523 | 0.035 | mudstone | 1.000 | 0.053 | 0.088 |

| J37 | 2934.416 | 0.731 | 0.049 | mudstone | 1.000 | 0.053 | 0.102 |

| J40 | 2855.220 | 0.890 | 0.060 | limestone | 0.800 | 0.042 | 0.102 |

| Well | F | M31 | A31 | K (mD) | M32 | A32 | A3 |

|---|---|---|---|---|---|---|---|

| J1 | 0.899 | 0.726 | 0.118 | 0.025 | 0.401 | 0.051 | 0.169 |

| J3 | 0.958 | 1.000 | 0.162 | 0.030 | 0.618 | 0.079 | 0.241 |

| J6 | 0.952 | 1.000 | 0.162 | 0.051 | 1.000 | 0.128 | 0.290 |

| J14 | 0.966 | 1.000 | 0.162 | 0.017 | 0.200 | 0.026 | 0.188 |

| J15 | 0.917 | 0.823 | 0.133 | 0.049 | 1.000 | 0.128 | 0.261 |

| J20 | 0.933 | 0.908 | 0.147 | 0.112 | 1.000 | 0.128 | 0.275 |

| J23 | 0.511 | 0.200 | 0.032 | 0.034 | 0.762 | 0.098 | 0.130 |

| J35 | 0.950 | 1.000 | 0.162 | 0.058 | 1.000 | 0.128 | 0.290 |

| J37 | 0.826 | 0.338 | 0.055 | 0.038 | 0.910 | 0.116 | 0.171 |

| J40 | 0.973 | 1.000 | 0.162 | 0.082 | 1.000 | 0.128 | 0.290 |

| Well | A | Well | A |

|---|---|---|---|

| J1 | 0.508 | J36 | 0.770 |

| J2 | 0.694 | J37 | 0.738 |

| J3 | 0.811 | J38 | 0.678 |

| J4 | 0.738 | J40 | 0.968 |

| J5 | 0.750 | J44 | 0.618 |

| J6 | 0.881 | J47 | 0.676 |

| J7 | 0.758 | J52 | 0.841 |

| J9 | 0.673 | J53 | 0.942 |

| J13 | 0.859 | J54 | 0.721 |

| J14 | 0.863 | J56 | 0.523 |

| J15 | 0.881 | J57 | 0.731 |

| J16 | 0.893 | J58 | 0.786 |

| J17 | 0.831 | J59 | 0.870 |

| J20 | 0.758 | J60 | 0.909 |

| J23 | 0.385 | J61 | 0.885 |

| J24 | 0.752 | J62 | 0.788 |

| J25 | 0.829 | J63 | 0.726 |

| J29 | 0.814 | J64 | 0.807 |

| J30 | 0.686 | J65 | 0.864 |

| J32 | 0.643 | J67 | 0.882 |

| J33 | 0.937 | J68 | 0.774 |

| J34 | 0.789 | J69 | 0.676 |

| J35 | 0.817 |

| Types | Type I Favorable Area | Type II Sub-Favorable Area | Type III Unfavorable Area |

|---|---|---|---|

| Interval | (0.4, 0.65] | (0.65, 0.75] | (0.75, 1] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, K.; Sun, F.; Yang, C.; Qiu, F.; Wang, Z.; Xu, S.; Chen, J. Evaluation of Deep Coalbed Methane Potential and Prediction of Favorable Areas within the Yulin Area, Ordos Basin, Based on a Multi-Level Fuzzy Comprehensive Evaluation Method. Processes 2024, 12, 820. https://doi.org/10.3390/pr12040820

Zhou K, Sun F, Yang C, Qiu F, Wang Z, Xu S, Chen J. Evaluation of Deep Coalbed Methane Potential and Prediction of Favorable Areas within the Yulin Area, Ordos Basin, Based on a Multi-Level Fuzzy Comprehensive Evaluation Method. Processes. 2024; 12(4):820. https://doi.org/10.3390/pr12040820

Chicago/Turabian StyleZhou, Keyu, Fengrui Sun, Chao Yang, Feng Qiu, Zihao Wang, Shaobo Xu, and Jiaming Chen. 2024. "Evaluation of Deep Coalbed Methane Potential and Prediction of Favorable Areas within the Yulin Area, Ordos Basin, Based on a Multi-Level Fuzzy Comprehensive Evaluation Method" Processes 12, no. 4: 820. https://doi.org/10.3390/pr12040820