A New Approach for the Synthesis of Powder Zinc Oxide and Zinc Borates with Desired Properties

Abstract

:1. Introduction

2. Results and Discussion

2.1. Synthesis of ZnO Powder with Desired Properties (Stage 1)

2.2. Synthesis of Finely Dispersed Zinc Borate Nanopowder (Stage 2)

3. Materials and Methods

3.1. Synthesis

3.2. Methods

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chizhikov, A.P.; Konstantinov, A.S.; Bazhin, P.M. Self-Propagating High-Temperature Synthesis of Ceramic Material Based on Aluminum-Magnesium Spinel and Titanium Diboride. Russ. J. Inorg. Chem. 2021, 66, 1002–1008. [Google Scholar] [CrossRef]

- Jiang, Y.; Lu, Y. Designing Transition-Metal-Boride-Based Electrocatalysts for Applications in Electrochemical Water Splitting. Nanoscale 2020, 12, 9327–9351. [Google Scholar] [CrossRef]

- Gunda, H.; Klebanoff, L.E.; Sharma, P.A.; Varma, A.K.; Dolia, V.; Jasuja, K.; Stavila, V. Progress, Challenges, and Opportunities in the Synthesis, Characterization, and Application of Metal-Boride-Derived Two-Dimensional Nanostructures. ACS Mater. Lett. 2021, 3, 535–556. [Google Scholar] [CrossRef]

- Malinina, E.A.; Goeva, L.V.; Buzanov, G.A.; Avdeeva, V.V.; Efimov, N.N.; Kozerozhets, I.V.; Kuznetsov, N.T. Synthesis and Physicochemical Properties of Binary Cobalt(II) Borides. Thermal Reduction of Precursor Complexes [CoLn][B10H10] (L = H2O, n = 6; N2H4, n = 3). Russ. J. Inorg. Chem. 2019, 64, 1325–1334. [Google Scholar] [CrossRef]

- Topnikova, A.P.; Belokoneva, E.L. The Structure and Classification of Complex Borates. Russ. Chem. Rev. 2019, 88, 204–228. [Google Scholar] [CrossRef]

- Zhou, Y.; Fang, C.; Fang, Y.; Zhu, F. Polyborates in Aqueous Borate Solution: A Raman and DFT Theory Investigation. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2011, 83, 82–87. [Google Scholar] [CrossRef]

- Avdeeva, V.V.; Malinina, E.A.; Vologzhanina, A.V.; Sivaev, I.B.; Kuznetsov, N.T. Formation of Oxidopolyborates in Destruction of the [B11H14]– Anion Promoted by Transition Metals. Inorganica Chim. Acta 2020, 509, 119693. [Google Scholar] [CrossRef]

- Avdeeva, V.V.; Malinina, E.A.; Kuznetsov, N.T. Boron Cluster Anions and Their Derivatives in Complexation Reactions. Coord. Chem. Rev. 2022, 469, 214636. [Google Scholar] [CrossRef]

- Sivaev, I.B. Functional Group Directed B–H Activation of Polyhedral Boron Hydrides by Transition Metal Complexes (Review). Russ. J. Inorg. Chem. 2021, 66, 1192–1246. [Google Scholar] [CrossRef]

- Korolenko, S.E.; Avdeeva, V.V.; Malinina, E.A.; Kuznetsov, N.T. Zinc(II) and Cadmium(II) Coordination Compounds with Boron Cluster Anions: Classification of Compounds Depending on Strength of Metal–Boron Cage Interaction and Analysis of Structures (Review). Russ. J. Inorg. Chem. 2021, 66, 1255–1279. [Google Scholar] [CrossRef]

- Çakal, G.; Baltacı, B.; Bayram, G.; Özkar, S.; Eroglu, I. Synthesis of Zinc Borate Using Water Soluble Additives: Kinetics and Product Characterization. J. Cryst. Growth 2020, 533, 125461. [Google Scholar] [CrossRef]

- Liang, P.; Li, S.Y. Synthesis, Characterization and Standard Molar Enthalpies of Formation of Two Zinc Borates: 2ZnO·2B2O3·3H2O and ZnB4O7. J. Chem. Thermodyn. 2019, 139, 105868. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, M.; Mutailipu, M.; Poeppelmeier, K.R.; Pan, S. Molecules Research and Development of Zincoborates: Crystal Growth, Structural Chemistry and Physicochemical Properties. Molecules 2019, 24, 2763. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Wu, W.; Wu, W.; Liu, C.; Wang, Y.; Wang, Z. Synthesis of a Triazine-Based Macromolecular Hybrid Charring Agent Containing Zinc Borate and Its Flame Retardancy and Thermal Properties in Polypropylene. Int. J. Polym. Anal. Charact. 2020, 25, 334–342. [Google Scholar] [CrossRef]

- Ipek, Y. Effect of Surfactant Types on Particle Size and Morphology of Flame-Retardant Zinc Borate Powder. Turkish J. Chem. 2020, 44, 214–223. [Google Scholar] [CrossRef]

- Kandirmaz, E.A. Flame Retardant Hybrid Paper Coatings with PVA—Melamine/Zinc Borat. J. Graph. Eng. Des. 2020, 11, 47–53. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, Y.; Yu, Y.; Zhang, Q.; Huang, B.; Chen, Z.; Chen, T.; Jiang, J. Flame Retardancy of Unsaturated Polyester Composites with Modified Ammonium Polyphosphate, Montmorillonite, and Zinc Borate. J. Appl. Polym. Sci. 2019, 136, 20–22. [Google Scholar] [CrossRef]

- Renger, S.; Alt, S.; Gocht, U.; Kästner, W.; Seeliger, A.; Kryk, H.; Harm, U. Multiscaled Experimental Investigations of Corrosion and Precipitation Processes After Loss-of-Coolant Accidents in Pressurized Water Reactors. Nucl. Technol. 2019, 205, 248–261. [Google Scholar] [CrossRef]

- Redkina, G.V.; Sergienko, A.S.; Kuznetsov, Y.I. On the Possibility of Inhibition of Zinc Corrosion by Phosphonates and Formulations on Their Basis 1. Int. J. Corros. Scale Inhib. 2019, 8, 689–701. [Google Scholar] [CrossRef]

- Sultigova, Z.K.; Borukaev, T.A.; Kitieva, L.I. Using Zinc Borate as Effective Flame Retardant. Key Eng. Mater. 2019, 816, 129–133. [Google Scholar] [CrossRef]

- Üreyen, M.E.; Kaynak, E. Effect of Zinc Borate on Flammability of PET Woven Fabrics. Adv. Polym. Technol. 2019, 2019, 7150736. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.; Day, T.; Boone, T.; Buziak, B.; Omar, A. Anti-Biofilm Activity of Two Novel, Borate Based, Bioactive Glass Wound Dressings. Biomed. Glasses 2019, 5, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Fu, L.; He, P.; Lin, T.; Wang, C. Crystallization and Wetting Behavior of Bismuth–Borate–Zinc Glass and Its Application in Low Temperature Joining Alumina Ceramics. J. Manuf. Process. 2019, 39, 128–137. [Google Scholar] [CrossRef]

- Januchta, K.; Youngman, R.E.; Jensen, L.R.; Smedskjaer, M.M. Mechanical Property Optimization of a Zinc Borate Glass by Lanthanum Doping. J. Non. Cryst. Solids 2019, 520, 119461. [Google Scholar] [CrossRef]

- Sudhakar, P.; Siva Sesha Reddy, A.; Zhydachevskyy, Y.; Brik, M.G.; Suchocki, A.; Ravi Kumar, V.; Piasecki, M.; Veeraiah, N. Influence of Some Thermally Resistant Transition Metal Oxides on Emission Features of Pr3+ Ions in Zinc Borate Glasses. J. Non. Cryst. Solids 2019, 503–504, 243–251. [Google Scholar] [CrossRef]

- Eraiah, R.B. Optical Properties of Zirconium Doped Sodium-Boro-Zinc Fluoride Glasses. AIP Conf. Proc. 2019, 2115, 030225. [Google Scholar] [CrossRef]

- Kozerozhets, I.V.; Panasyuk, G.P.; Semenov, E.A.; Voroshilov, I.L.; Avdeeva, V.V.; Buzanov, G.A.; Danchevskaya, M.N.; Kolmakova, A.A.; Malinina, E.A. A New Approach to the Synthesis of Nanosized Powder CaO and Its Application as Precursor for the Synthesis of Calcium Borates. Ceram. Int. 2022, 48, 7522–7532. [Google Scholar] [CrossRef]

- Schubert, D.M. Zinc Borate Hydrolysis. Molecules 2022, 27, 5768. [Google Scholar] [CrossRef]

- Kozerozhets, I.V.; Panasyuk, G.P.; Semenov, E.A.; Voroshilov, I.L.; Azarova, L.A.; Belan, V.N. Mechanism of the Conversion of γ-Al2O3 Nanopowder into Boehmite under Hydrothermal Conditions. Inorg. Mater. 2020, 56, 716–722. [Google Scholar] [CrossRef]

- Kozerozhets, I.V.; Panasyuk, G.P.; Semenov, E.A.; Simonenko, T.L.; Nikiforova, G.E.; Azarova, L.A. Water State in the Products of Hydrothermal Treatment of Hydrargillite and γ-Al2O3. Russ. J. Inorg. Chem. 2020, 65, 1384–1389. [Google Scholar] [CrossRef]

- Panasyuk, G.P.; Kozerozhets, I.V.; Semenov, E.A.; Danchevskaya, M.N.; Azarova, L.A.; Belan, V.N. Mechanism of Phase Transformations of γ-Al2O3 and Al(OH)3 into Boehmite (AlOOH) during Hydrothermal Treatment. Inorg. Mater. 2019, 55, 929–933. [Google Scholar] [CrossRef]

- Kozerozhets, I.V.; Panasyuk, G.P.; Semenov, E.A.; Danchevskaya, M.N.; Ivakin, Y.D.; Tsvetov, N.S. Combustion Synthesis of Highly Dispersed Zinc Oxide. Inorg. Mater. 2021, 57, 621–626. [Google Scholar] [CrossRef]

- Panasyuk, G.P.; Kozerozhets, I.V.; Voroshilov, I.L.; Ivakin, Y.D.; Privalov, V.I.; Danchevskaya, M.N. Water Forms on the Surface and in the Bulk of Silicon Dioxide. Russ. J. Inorg. Chem. 2021, 66, 623–630. [Google Scholar] [CrossRef]

- Choudhary, V.; Pinar, A.B.; Lobo, R.F.; Vlachos, D.G.; Sandler, S.I. Comparison of Homogeneous and Heterogeneous Catalysts for Glucose-to-Fructose Isomerization in Aqueous Media. ChemSusChem 2013, 6, 2369–2376. [Google Scholar] [CrossRef] [PubMed]

- Rasrendra, C.B.; Makertihartha, I.G.B.N.; Adisasmito, S.; Heeres, H.J. Green Chemicals from D-Glucose: Systematic Studies on Catalytic Effects of Inorganic Salts on the Chemo-Selectivity and Yield in Aqueous Solutions. Top. Catal. 2010, 53, 1241–1247. [Google Scholar] [CrossRef] [Green Version]

- Norton, A.M.; Nguyen, H.; Xiao, N.L.; Vlachos, D.G. Direct Speciation Methods to Quantify Catalytically Active Species of AlCl3 in Glucose Isomerization. RSC Adv. 2018, 8, 17101–17109. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Parauha, Y.R.; Sahu, V.; Dhoble, S.J. Prospective of Combustion Method for Preparation of Nanomaterials: A Challenge. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2021, 267, 115054. [Google Scholar] [CrossRef]

- Andrews, L.; Burkholder, T.R. Infrared Spectra of Molecular B(OH)3 and HOBO in Solid Argon. J. Chem. Phys. 1992, 97, 7203–7210. [Google Scholar] [CrossRef]

- Mondal, S.; Banthia, A.K. Low-Temperature Synthetic Route for Boron Carbide. J. Eur. Ceram. Soc. 2005, 25, 287–291. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, X.; Chen, J.; Qi, Y.; Zhang, Y.; Fu, H.; Zheng, J.; Li, X. Boric Acid-Destabilized Lithium Borohydride with a 5.6 Wt% Dehydrogenation Capacity at Moderate Temperatures. Dalt. Trans. 2017, 46, 4499–4503. [Google Scholar] [CrossRef]

- El-Batal, A.I.; El-Sayyad, G.S.; Al-Hazmi, N.E.; Gobara, M. Antibiofilm and Antimicrobial Activities of Silver Boron Nanoparticles Synthesized by PVP Polymer and Gamma Rays Against Urinary Tract Pathogens. J. Clust. Sci. 2019, 30, 947–964. [Google Scholar] [CrossRef]

- Kozetozhets, I.V.; Panasyuk, G.P.; Semenov, E.A.; Buzanov, G.A.; Avdeeva, V.V.; Danchevskaya, M.N.; Tsvetov, N.S.; Shapovalov, S.S.; Vasil’ev, M.G. Function of the Non-Crystalline X-ray Amorphous Phase of Highly Dispersed Powder of CaO in Adsorption of CO2 and H2O. Russ. J. Gen. Chem. 2021, 91 (Suppl. 1), S98–S105. [Google Scholar] [CrossRef]

- Nagaraju, G.; Udayabhanu; Shivaraj; Prashanth, S.A.; Shastri, M.; Yathish, K.V.; Anupama, C.; Rangappa, D. Electrochemical Heavy Metal Detection, Photocatalytic, Photoluminescence, Biodiesel Production and Antibacterial Activities of Ag–ZnO Nanomaterial. Mater. Res. Bull. 2017, 94, 54–63. [Google Scholar] [CrossRef]

- Panasyuk, G.P.; Kozerozhets, I.V.; Semenov, E.A.; Azarova, L.A.; Belan, V.N.; Danchevskaya, M.N. A New Method for Producing a Nanosized γ-Al2O3 Powder. Russ. J. Inorg. Chem. 2018, 63, 1303–1308. [Google Scholar] [CrossRef]

- Kozerozhets, I.V.; Panasyuk, G.P.; Semenov, E.A.; Avdeeva, V.V.; Ivakin, Y.D.; Danchevskaya, M.N. New Approach to Prepare the Highly Pure Ceramic Precursor for the Sapphire Synthesis. Ceram. Int. 2020, 46, 28961–28968. [Google Scholar] [CrossRef]

| Processing Temperature, °C | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 150 | 250 | 350 | 450 | 550 | 650 | 750 | 800 | 850 | |

| C | 22.85 | 37.69 | 34.71 | 8.87 | 5.64 | 1.1 | 0.25 | - | - |

| H | 5.1 | 2.68 | 2.71 | 2.43 | 2.31 | 0.43 | 0.21 | 0.14 | - |

| N | 5.63 | 2.36 | 2.25 | 0.82 | - | - | - | - | - |

| Sample 2 | Sample 5 | |

|---|---|---|

| Particle size range | 0.1–7.2 µm | 10–90 nm |

| Average particle size | 2.3 µm | 43 nm |

| Thermal conductivity coefficient W/(m K) | 0.07 | 0.15 |

| Specific surface area (m2/g) | 7 | 30 |

| Bulk density (g/cm3) | 0.4 | 1.2 |

| Method for Preparation | Phase Composition | |

|---|---|---|

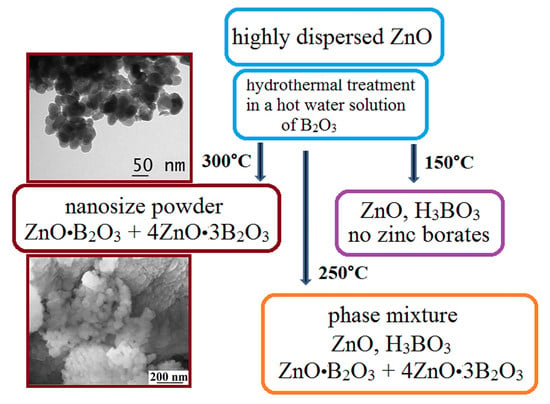

| sample 1 | heating of aqueous Zn(NO3)2 and D-glucose at 350 °C (τ = 1 h) | X-ray amorphous |

| sample 2 | heating of sample 1 at 800 °C (τ = 1 h) | ZnO |

| sample 3 | hydrothermal treatment of the suspension obtained when sample 1 reacted with aqueous H3BO3 at 150 °C (τ = 72 h) | ZnO, H3BO3 |

| sample 4 | hydrothermal treatment of the suspension obtained when sample 1 reacted with aqueous H3BO3 at 250 °C (τ = 72 h) | ZnO, H3BO3, ZnO•B2O3, 4ZnO•3B2O3 |

| sample 5 | hydrothermal treatment of the suspension obtained when sample 1 reacted with aqueous H3BO3 at 300 °C (τ = 72 h) | ZnO•B2O3, 4ZnO•3B2O3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozerozhets, I.V.; Avdeeva, V.V.; Buzanov, G.A.; Semenov, E.A.; Ioni, Y.V.; Gubin, S.P. A New Approach for the Synthesis of Powder Zinc Oxide and Zinc Borates with Desired Properties. Inorganics 2022, 10, 212. https://doi.org/10.3390/inorganics10110212

Kozerozhets IV, Avdeeva VV, Buzanov GA, Semenov EA, Ioni YV, Gubin SP. A New Approach for the Synthesis of Powder Zinc Oxide and Zinc Borates with Desired Properties. Inorganics. 2022; 10(11):212. https://doi.org/10.3390/inorganics10110212

Chicago/Turabian StyleKozerozhets, Irina V., Varvara V. Avdeeva, Grigorii A. Buzanov, Evgeniy A. Semenov, Yulia V. Ioni, and Sergey P. Gubin. 2022. "A New Approach for the Synthesis of Powder Zinc Oxide and Zinc Borates with Desired Properties" Inorganics 10, no. 11: 212. https://doi.org/10.3390/inorganics10110212