The Effect of Ultrasound on the Rehydration Characteristics of Semi-Dried Salted Apostichopus japonicus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

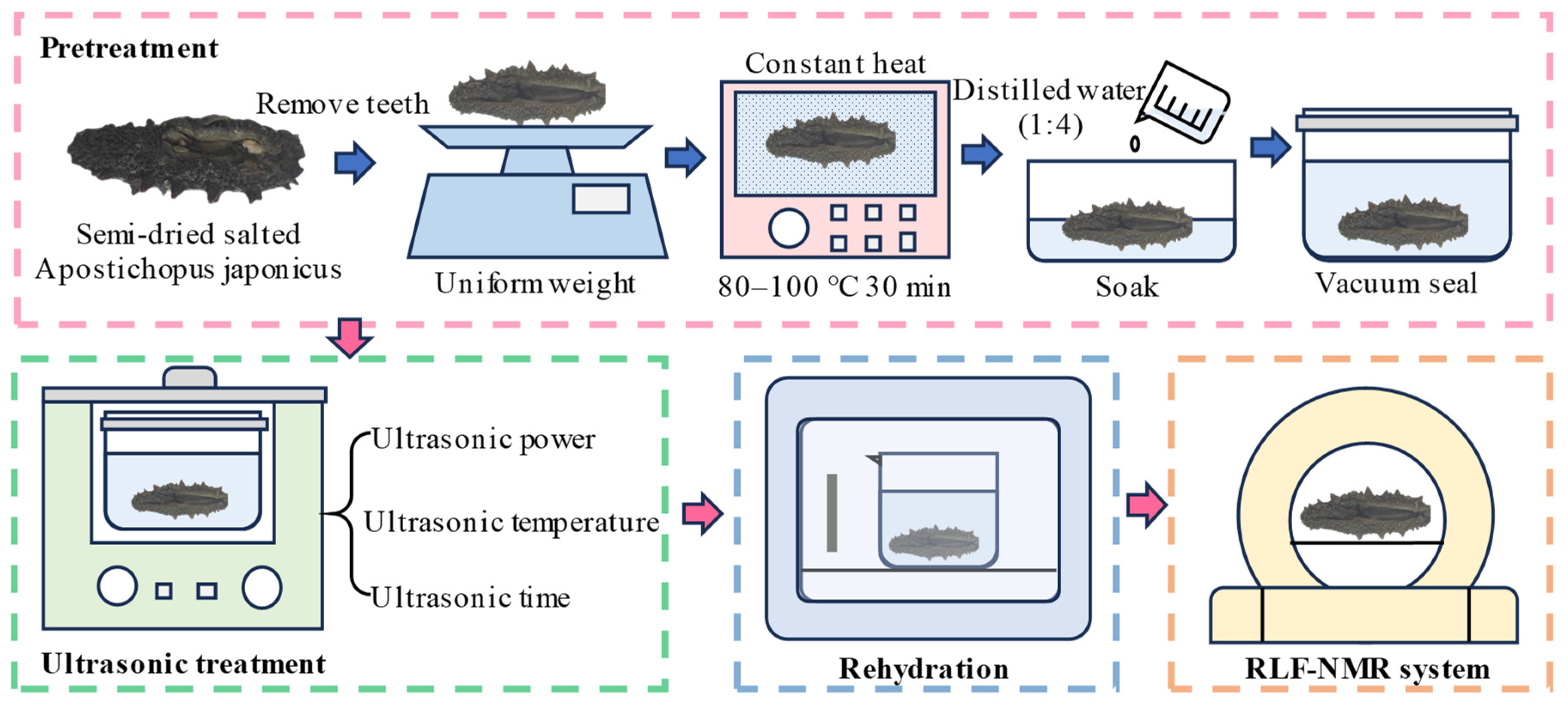

2.2. Pretreatment of Raw Materials

2.3. Traditional Rehydration Methods

2.4. Ultrasound-Assisted Rehydration

2.4.1. Ultrasound Power

2.4.2. Ultrasonic Temperature

2.4.3. Ultrasonic Time

2.5. Test of Response Surface Optimization Test

2.5.1. Measurement of the Rehydration Ratio

2.5.2. Measurement of Textural Properties

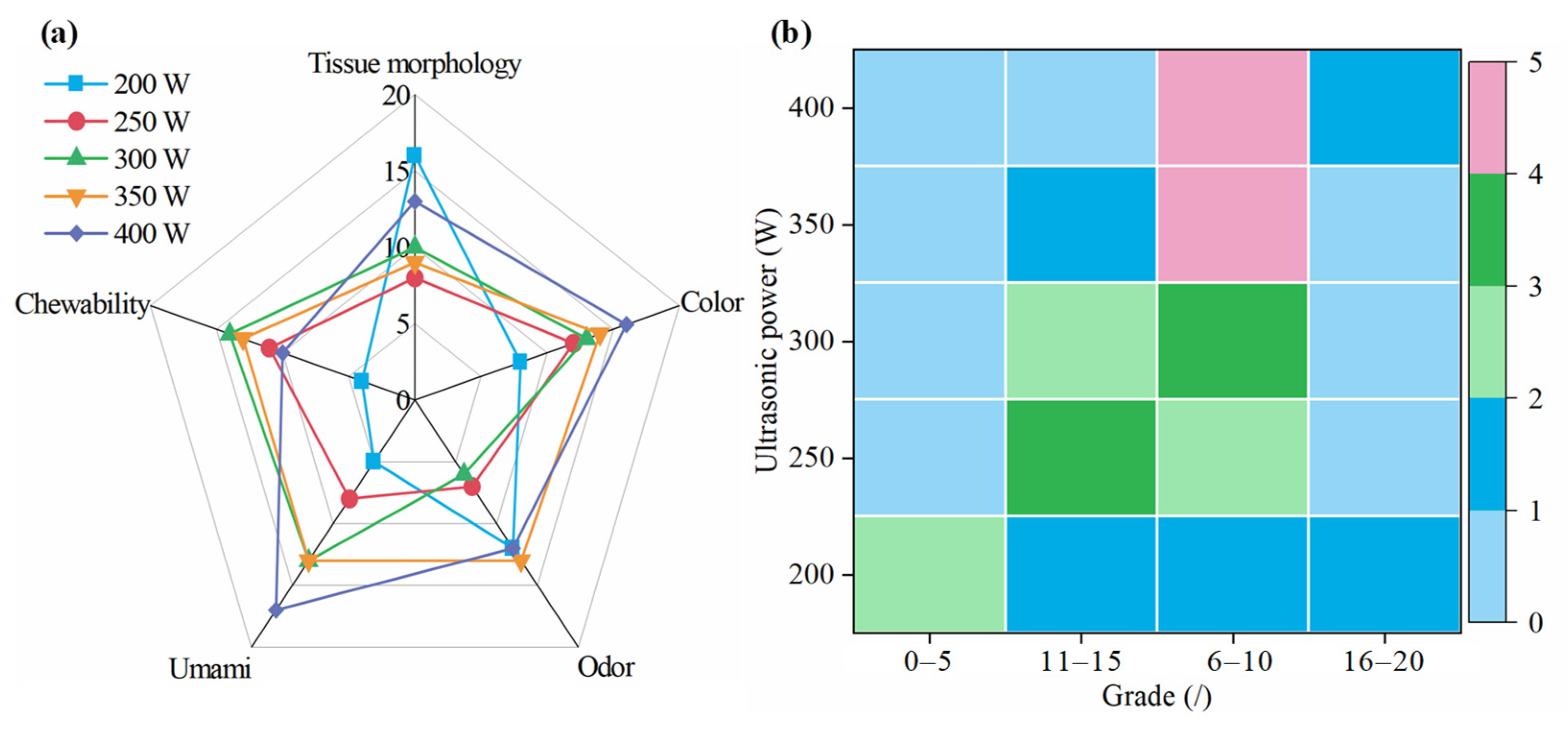

2.5.3. Sensory Evaluation

2.5.4. NMR Analysis Method

2.5.5. NRI Analysis Method

2.5.6. Scanning Electron Microscopy (SEM)

2.5.7. Data Processing

3. Results and Discussion

3.1. Analysis of Ultrasound-Assisted Rehydration Methods

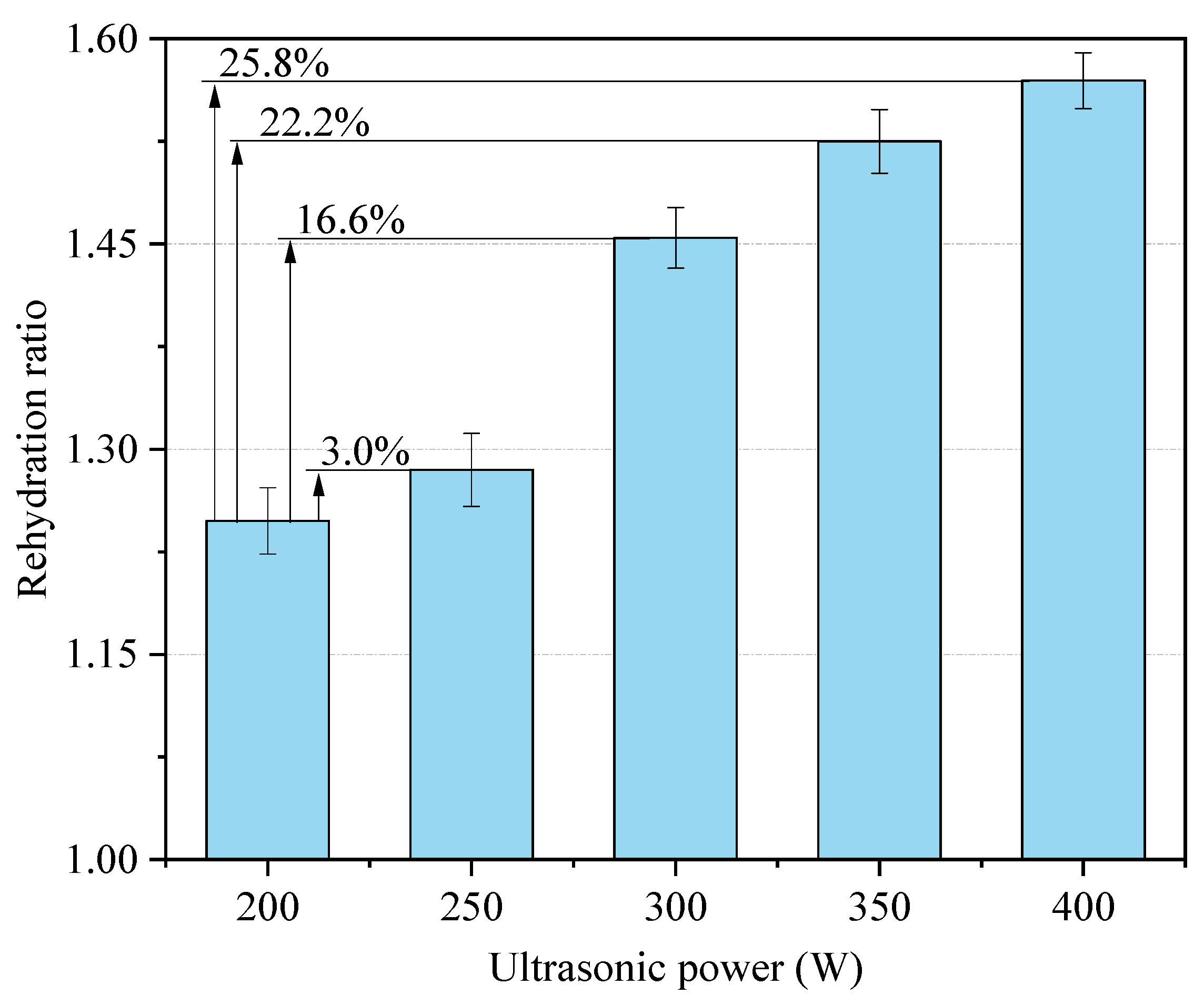

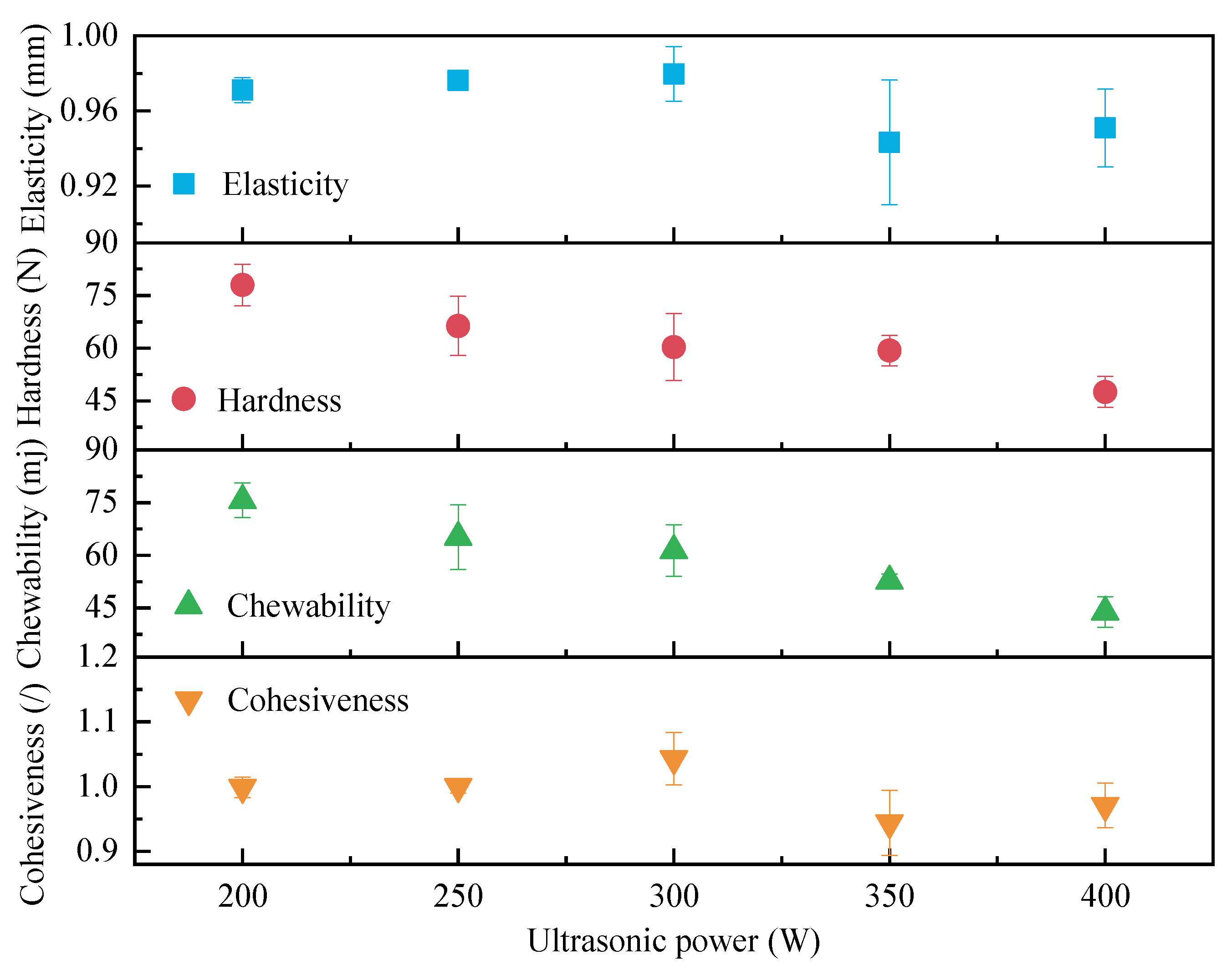

3.1.1. Effect of Ultrasonic Power on the Rehydration Characteristics

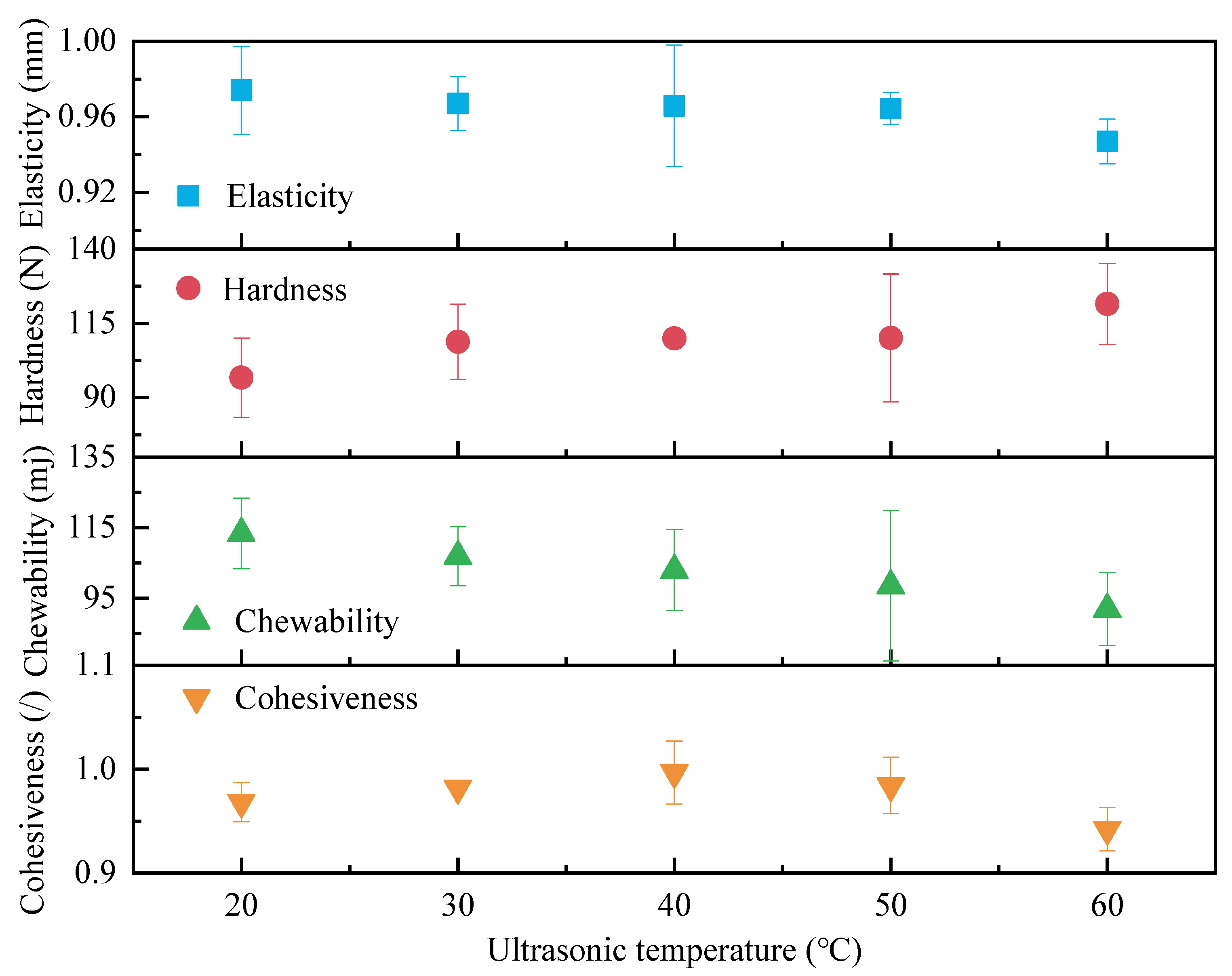

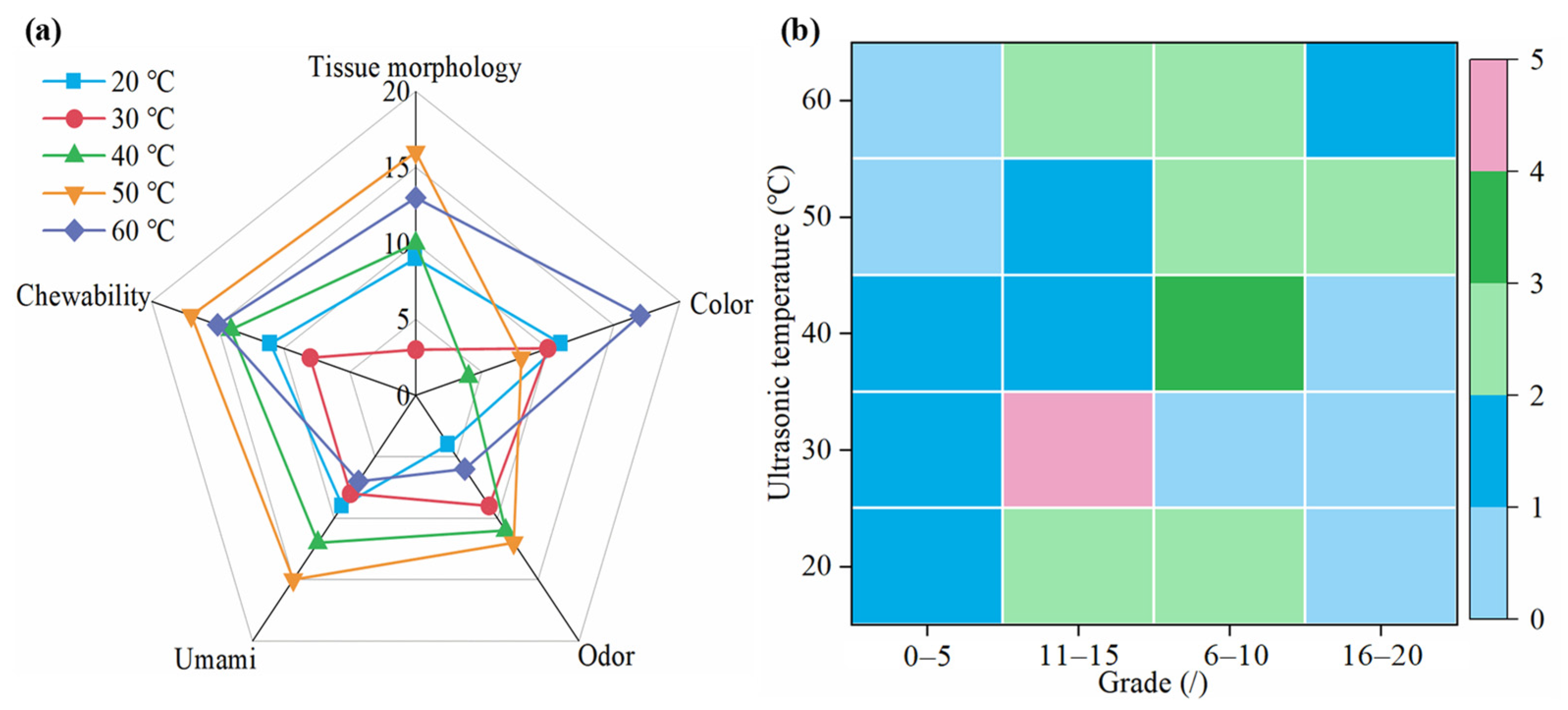

3.1.2. Effect of Ultrasonic Temperature on the Rehydration Characteristics

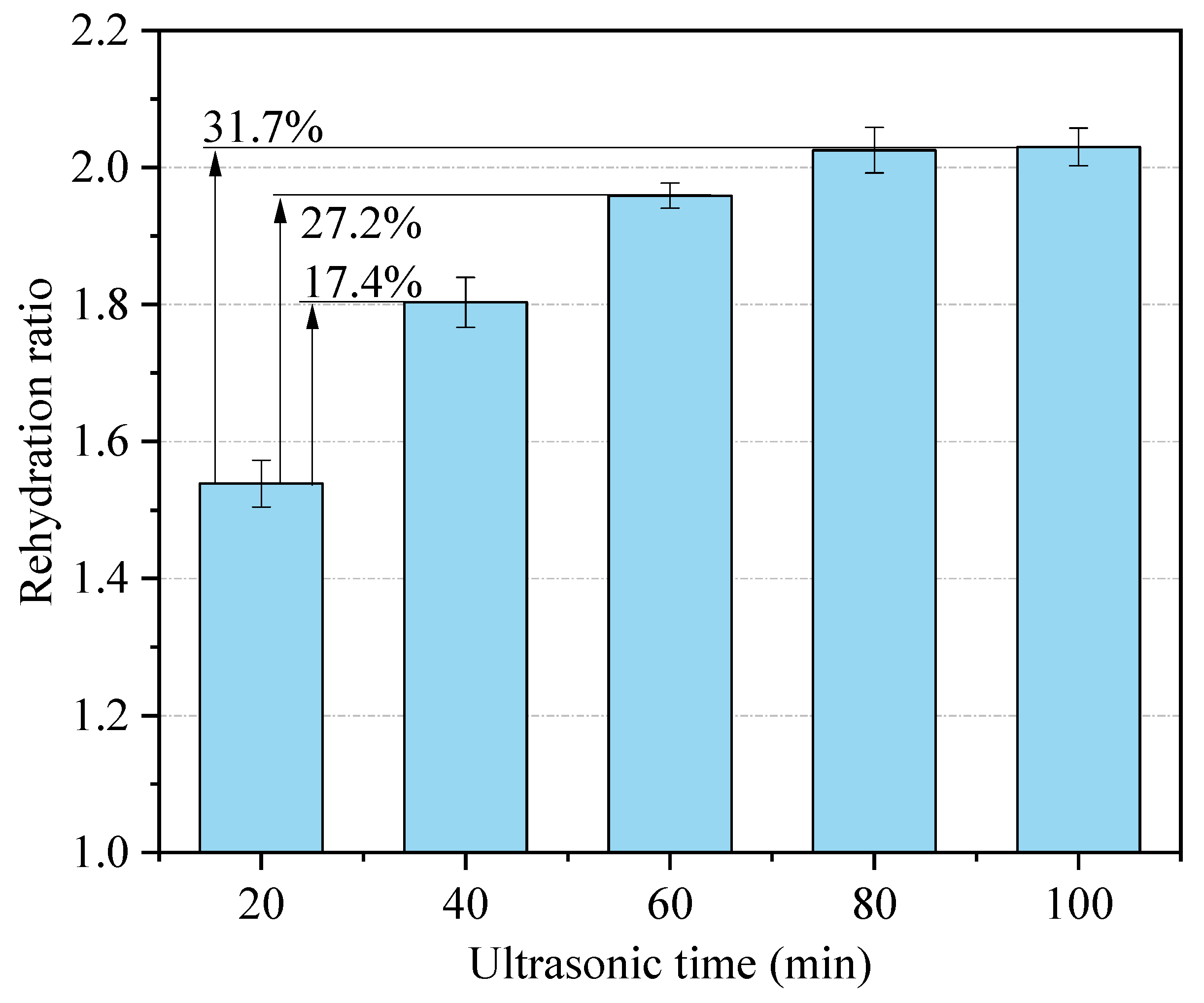

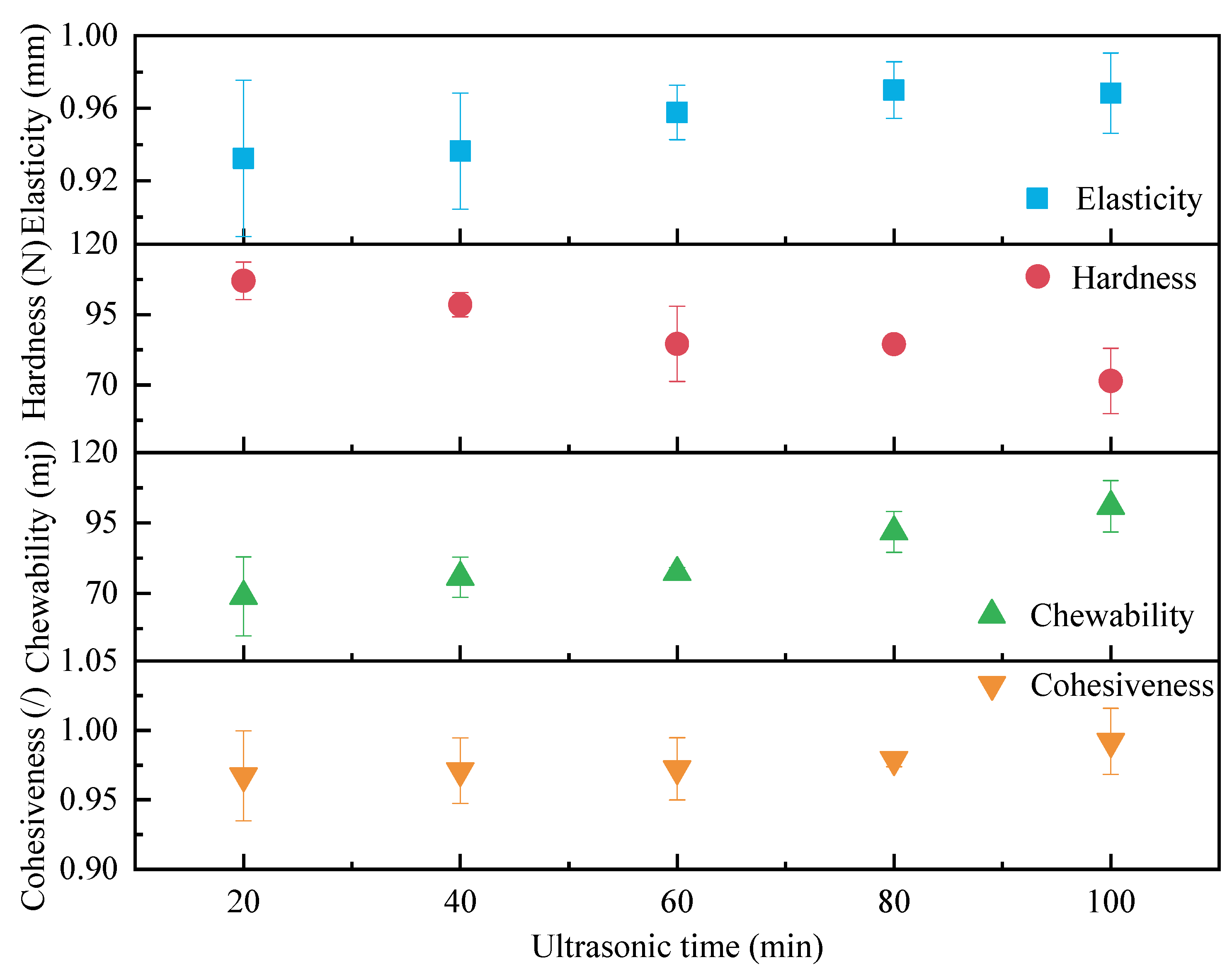

3.1.3. Effect of Ultrasonic Treatment Time on Rehydration Characteristics

3.2. Design and Results of the Response Surface

3.2.1. Establishment and Analysis of Rehydration Ratio Model

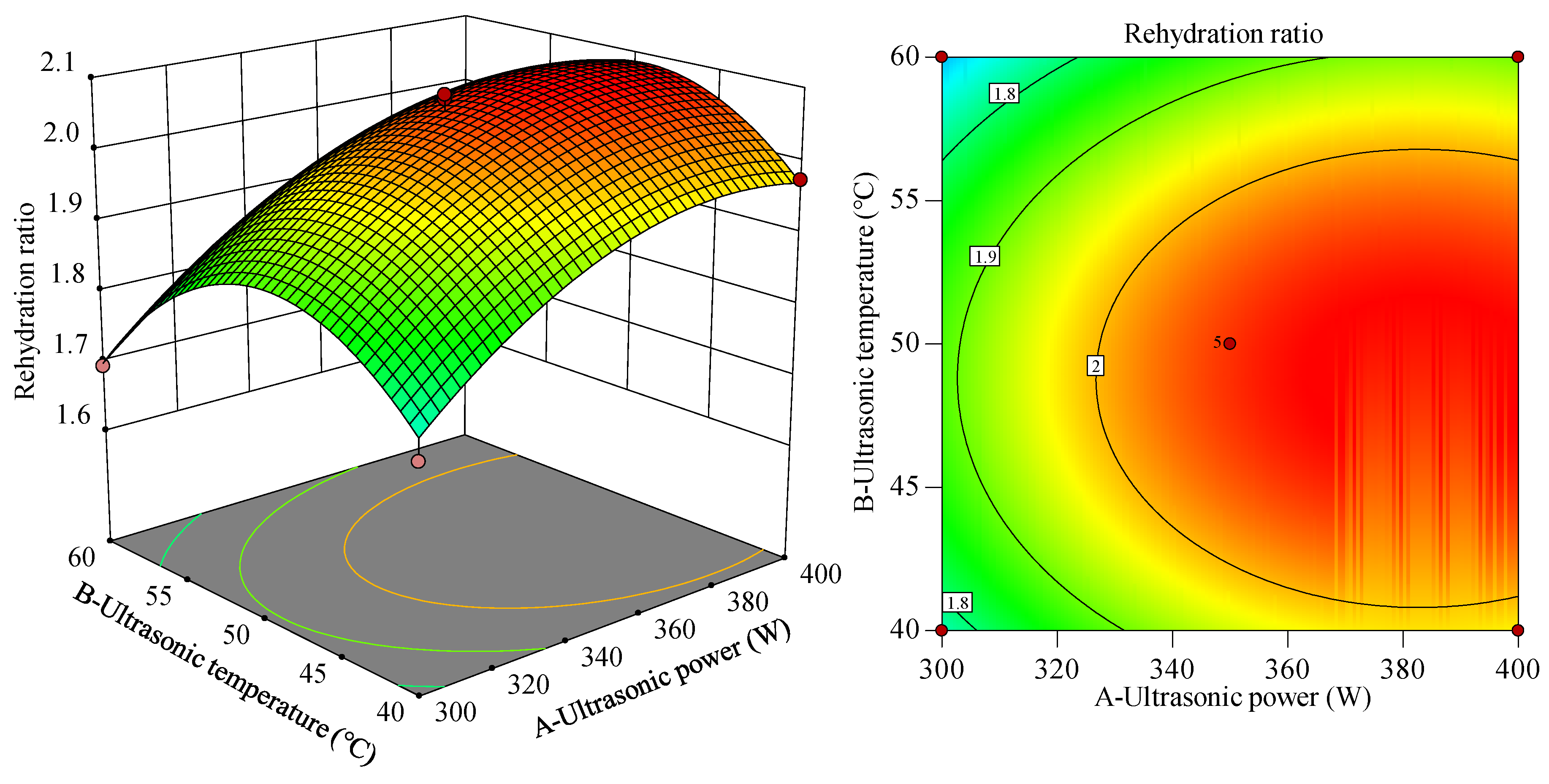

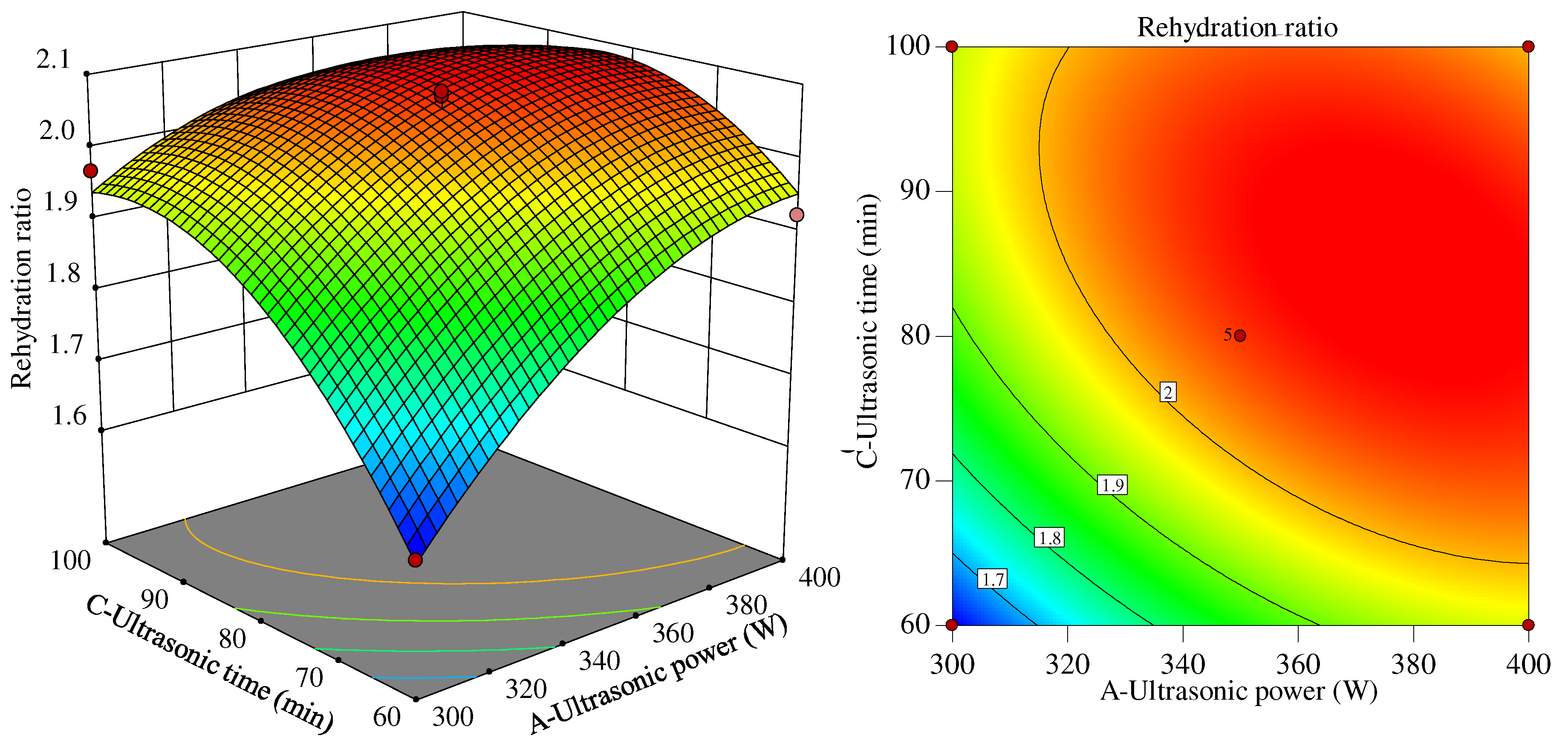

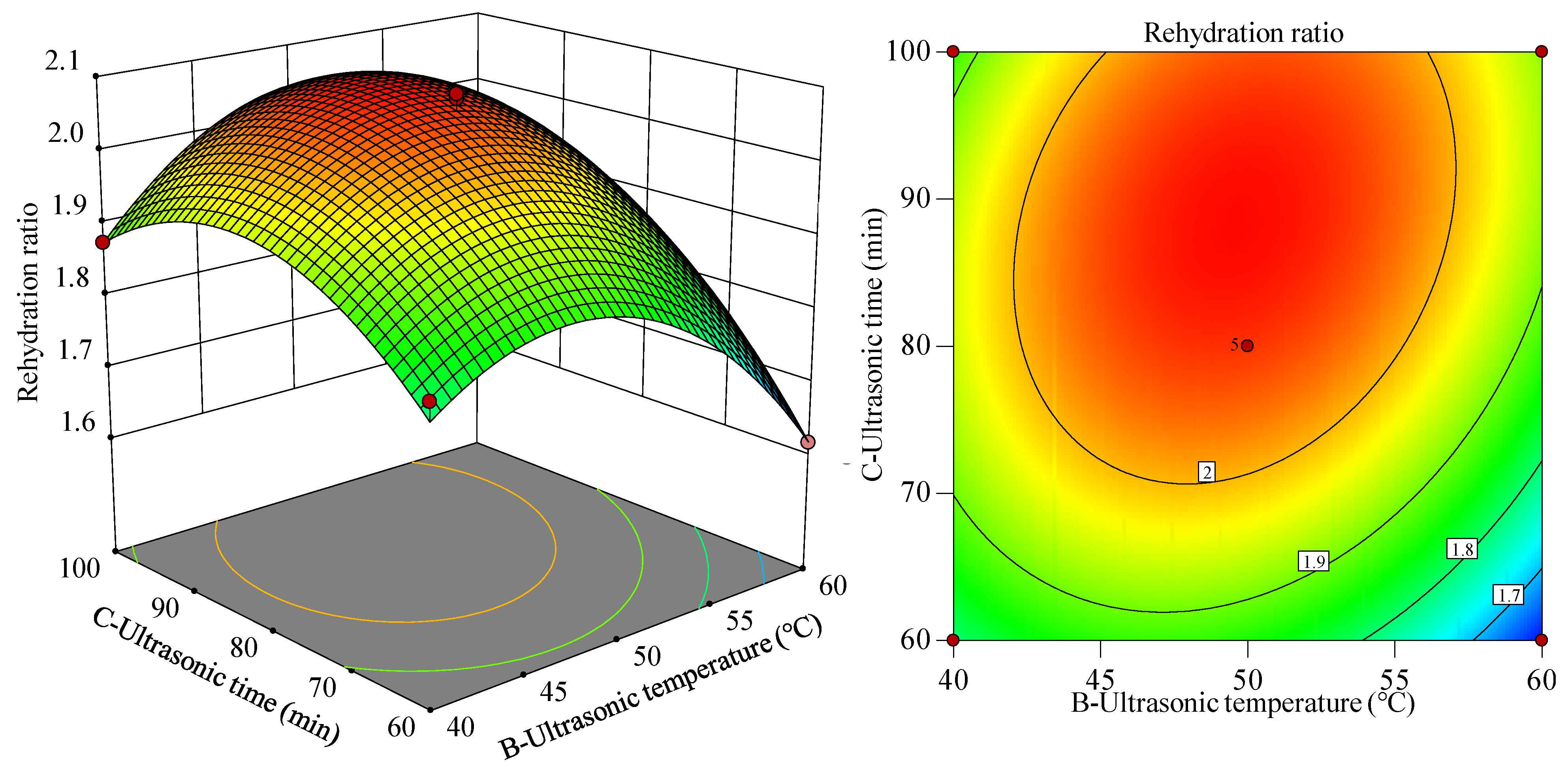

3.2.2. Interaction among Various Factors

3.2.3. Verification of Test Results

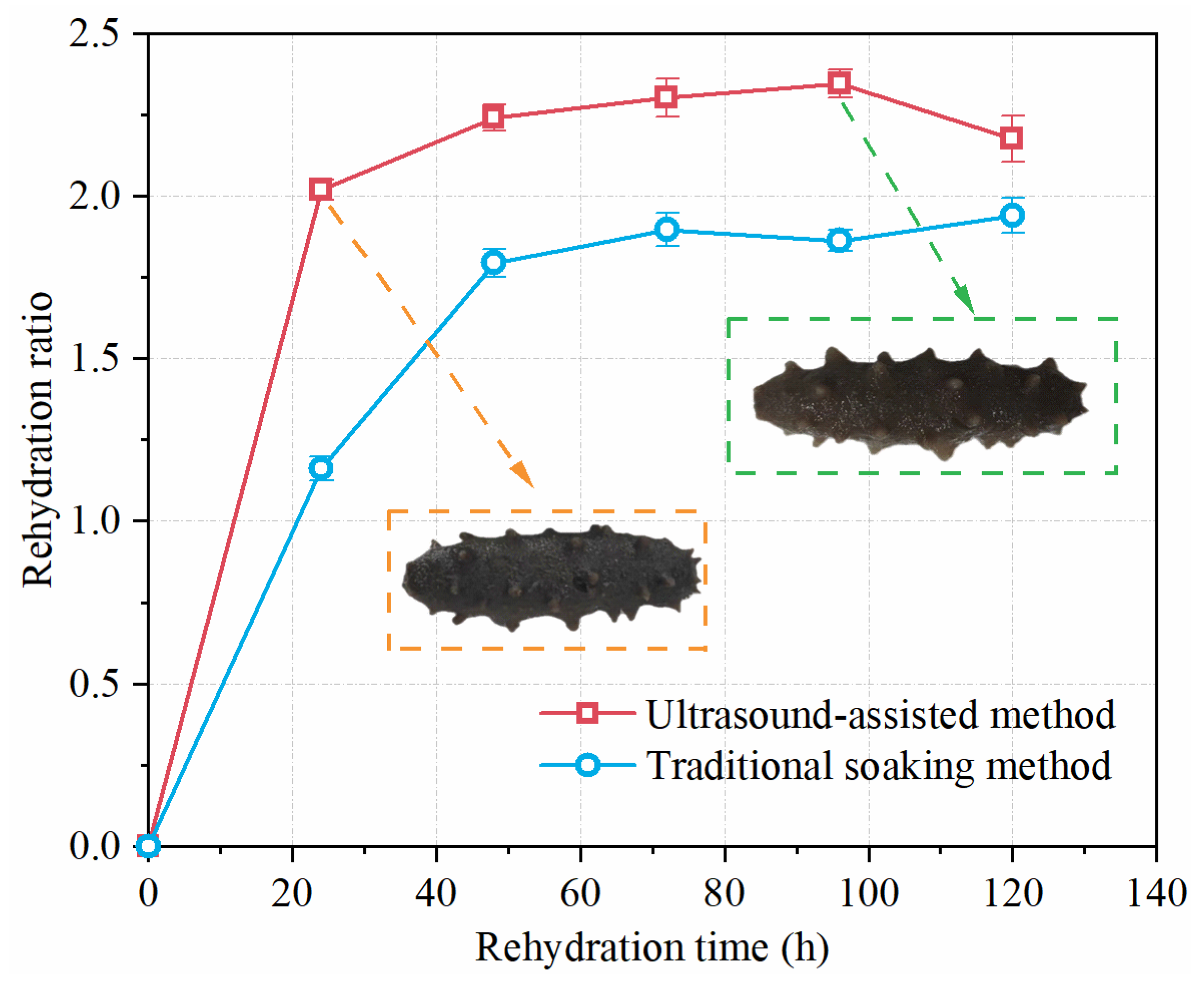

3.3. Comparison of Ultrasound-Assisted and Traditional Soaking Methods

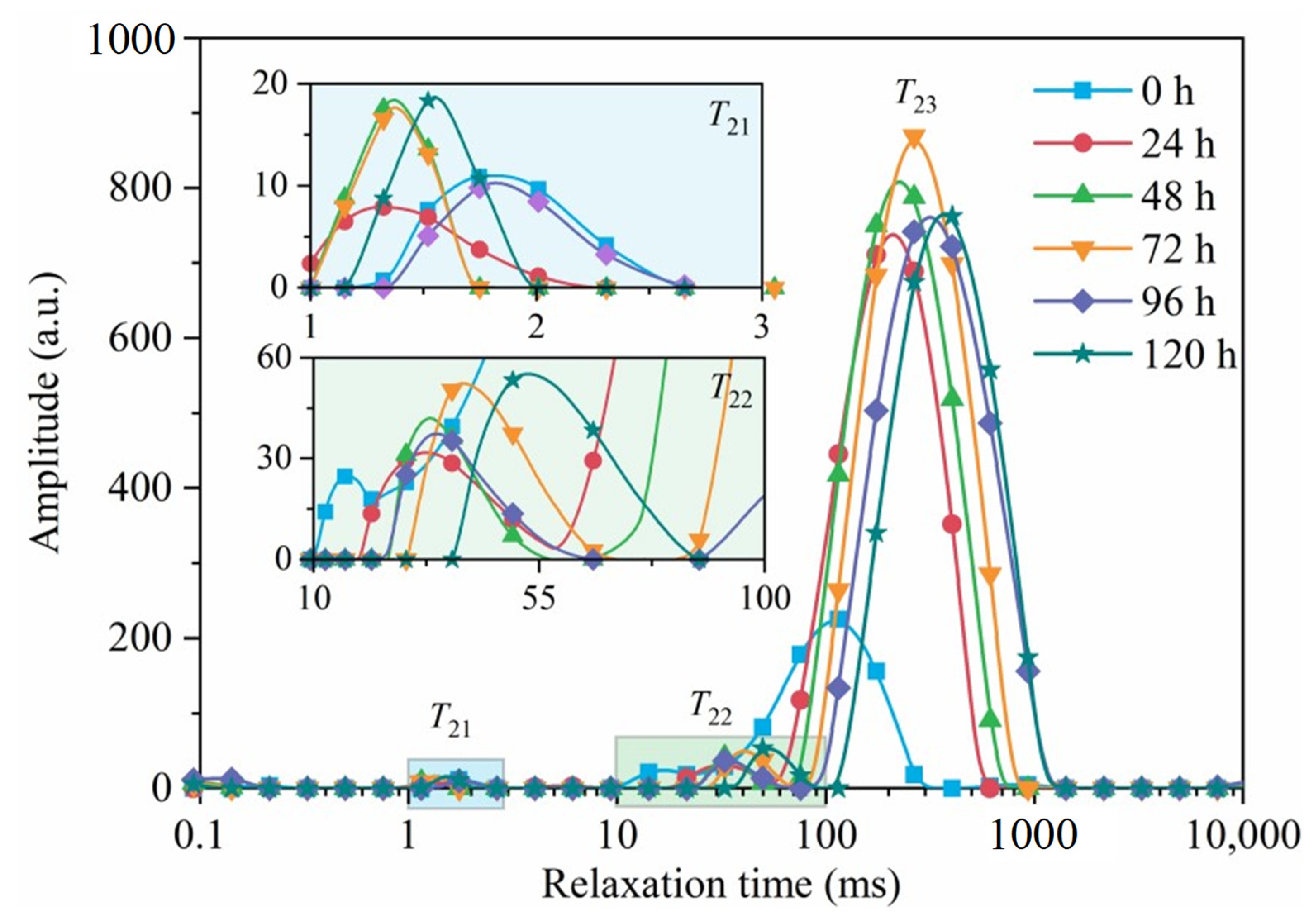

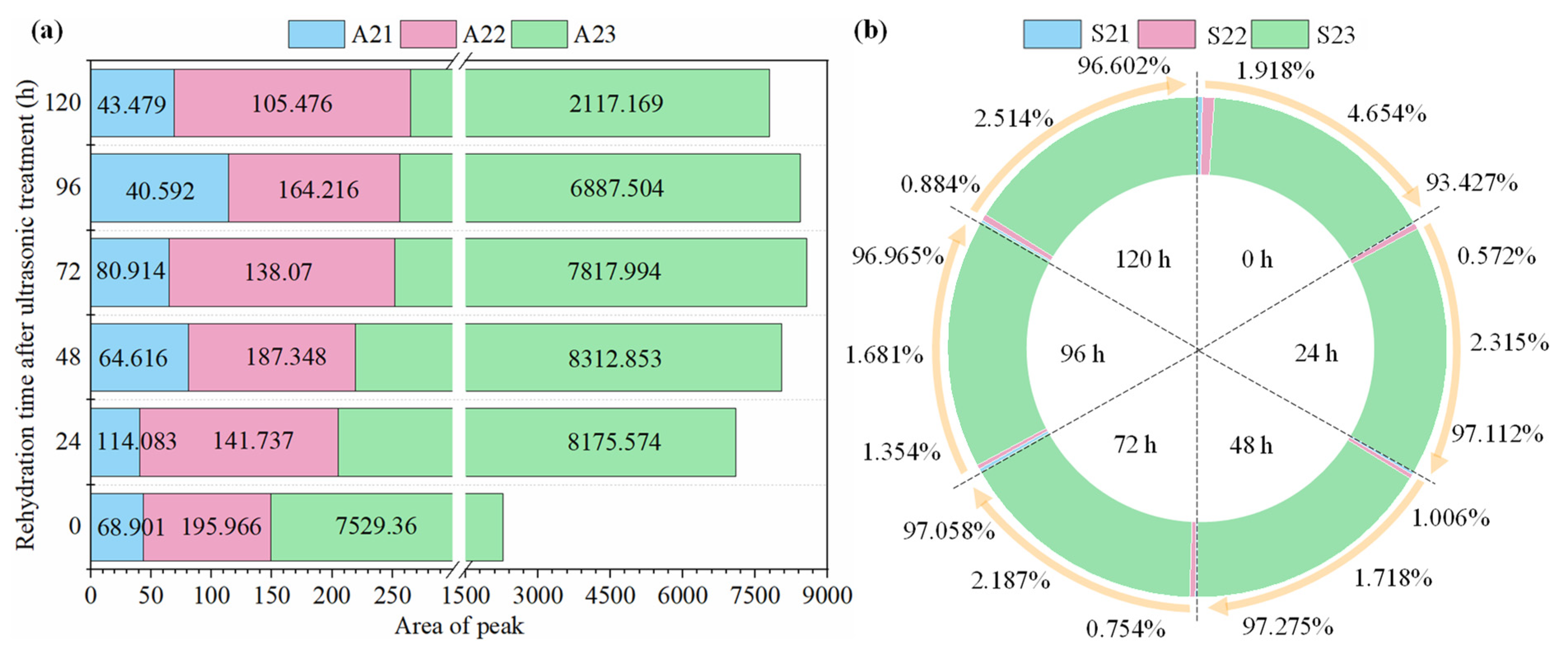

3.4. NMR Analysis

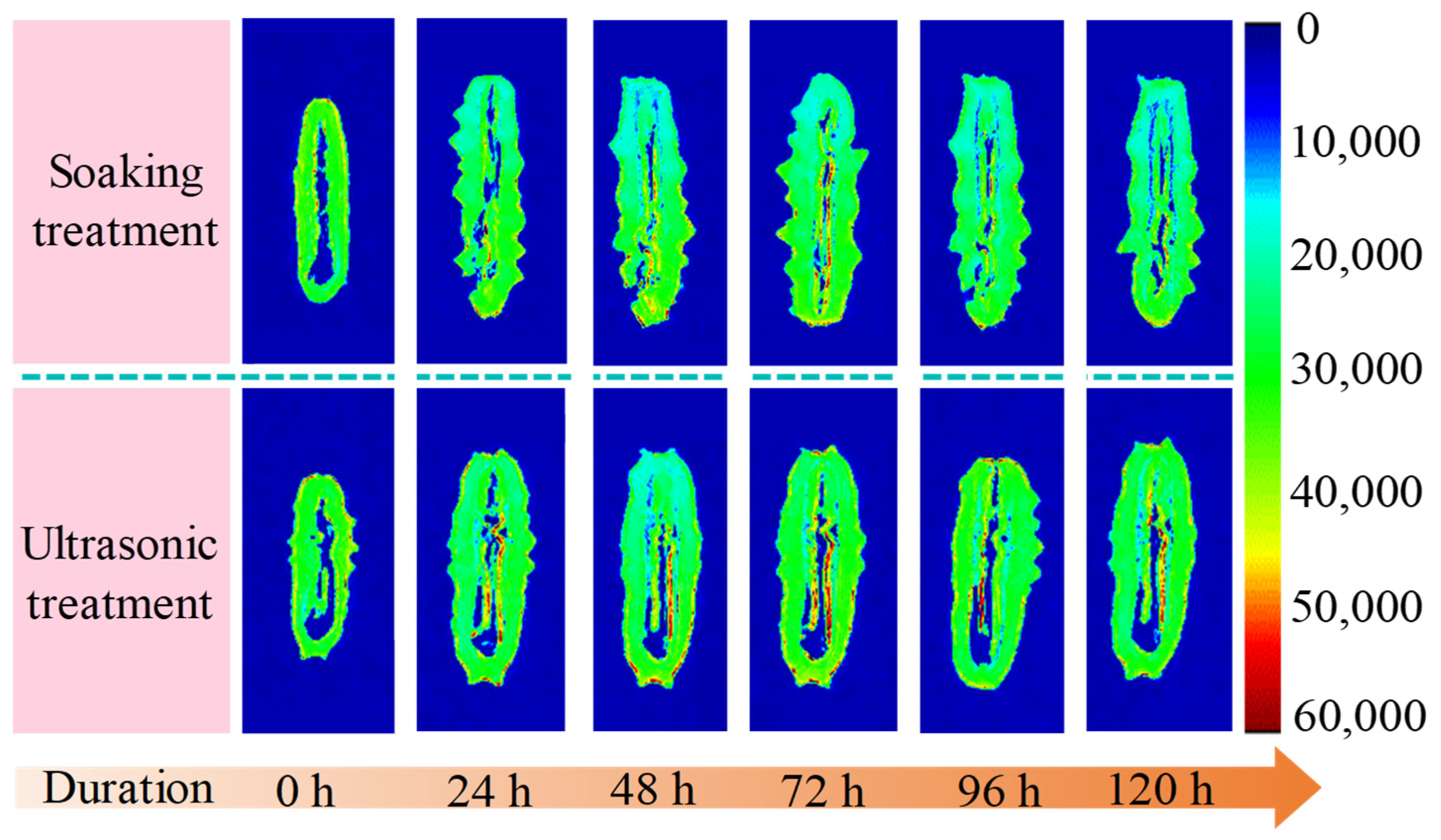

3.5. MRI Analysis

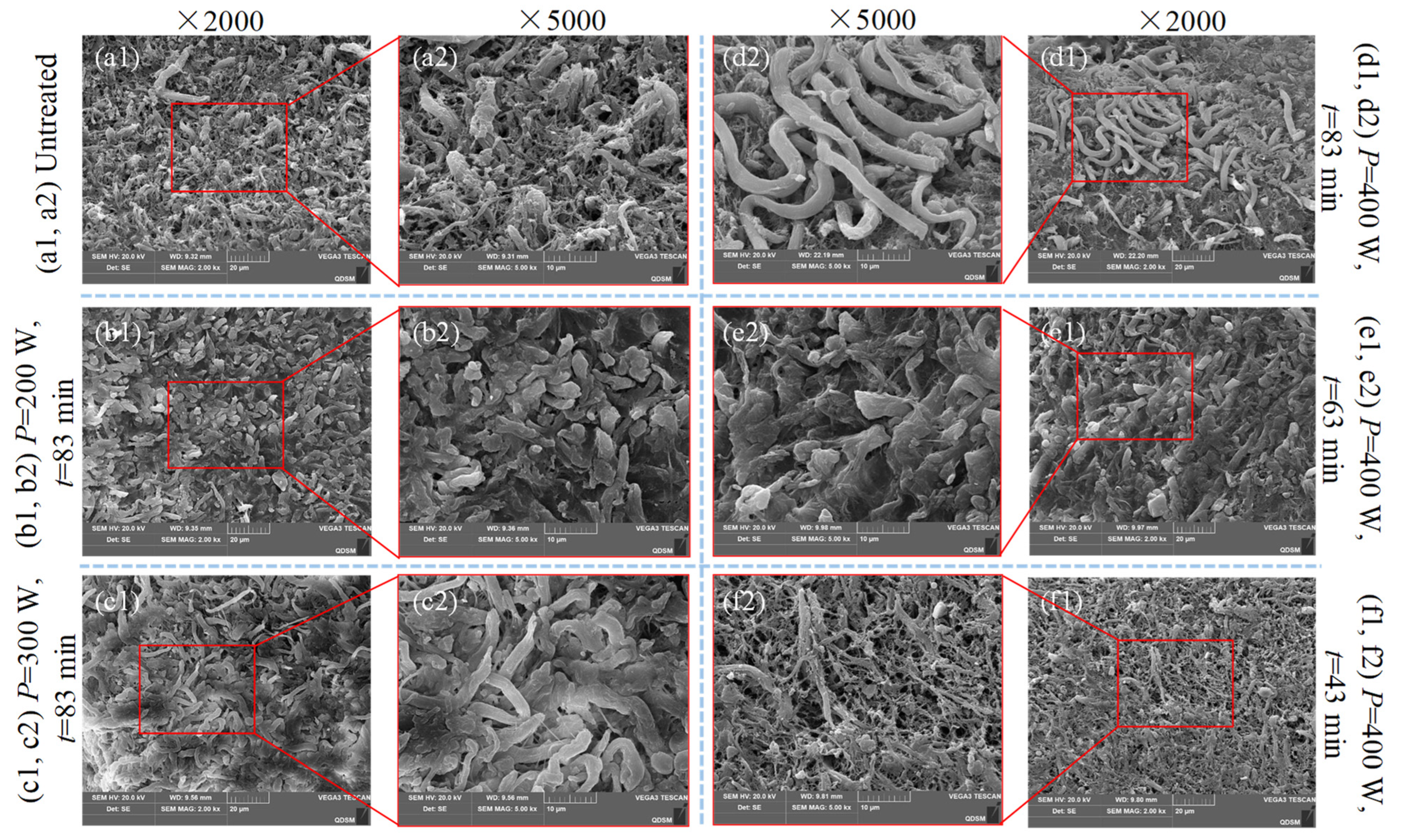

3.6. SEM Image Analysis

4. Conclusions

- (a)

- Compared with the traditional soaking method, the rehydration time of semi-dry salted A. japonicus can be shortened to 72 h using the ultrasound-assisted method, and the rehydration rate can be improved.

- (b)

- The cavitation effect produced by ultrasound causes a spatial network structure to form in the body of the semi-dry salted A. japonicus, which promotes water absorption and increases the free water content in its body. The water absorption of semi-dry salted A. japonicus was enhanced using an ultrasonic-assisted method.

- (c)

- The optimal rehydration effect could be obtained when the ultrasonic power was 400 W, the ultrasonic temperature was 50 °C, and the ultrasonic time was 83 min. Ultrasonic power, ultrasonic time, and ultrasonic temperature influenced the rehydration ratio of semi-dry salted A. japonicus.

- (d)

- Under the optimal rehydration conditions in this study, the rehydration ratio of semi-dry salted A. japonicus obtained by the tests was 2.103, which was within 5% of the predicted rehydration ratio of 2.10. The quadratic polynomial regression model established in this study for predicting the optimal rehydration ratio is reasonable and effective.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, Y.; Ding, P.; Qiao, Y.; Liu, Y.; Wang, X.; Zhang, T.; Ding, J.; Chang, Y.; Zhao, C. The feces of sea urchins as food improves survival, growth, and resistance of small sea cucumbers Apostichopus japonicus in summer. Sci. Rep. 2023, 13, 5361. [Google Scholar] [CrossRef]

- Hossain, A.; Dave, D.; Shahidi, F. Antioxidant potential of sea cucumbers and their beneficial effects on human health. Mar. Drugs 2022, 20, 521. [Google Scholar] [CrossRef]

- Liang, Q.; Ahmed, F.; Zhang, M.; Sperou, N.; Franco, C.M.M.; Feng, Q.; Zhang, W. In vivo and clinical studies of sea cucumber-derived bioactives for human health and nutrition from 2012–2021. Front. Mar. Sci. 2022, 9, 917857. [Google Scholar] [CrossRef]

- Senadheera, T.R.L.; Hossain, A.; Dave, D.; Shahidi, F. Functional and physiochemical properties of protein isolates from different body parts of North Atlantic sea cucumber (Cucumaria frondosa). Food Biosci. 2023, 52, 102511. [Google Scholar] [CrossRef]

- Puspitasari, Y.E.; Tuenter, E.; Foubert, K.; Herawati, H.; Hariati, A.M.; Aulanni’am, A.; Pieters, L.; De Bruyne, T.; Hermans, N. Saponin and fatty acid profiling of the sea cucumber Holothuria atra, α-glucosidase inhibitory activity and the identification of a novel triterpene glycoside. Nutrients 2023, 15, 1033. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Liu, Y.-X.; Zhao, G.-H.; Song, L.; Wu, Z.-X.; Jiang, P.-F.; Zhou, D.-Y.; Zhu, B.-W. Studying on effects of boiling on texture, microstructure and physiochemical properties of sea cucumber body wall and its mechanism using second harmonic generation (SHG) microscopy. Food Chem. 2022, 400, 134055. [Google Scholar] [CrossRef]

- Thimmappa, R.; Wang, S.; Zheng, M.; Misra, R.C.; Huang, A.C.; Saalbach, G.; Chang, Y.; Zhou, Z.; Hinman, V.; Bao, Z.; et al. Biosynthesis of saponin defensive compounds in sea cucumbers. Nat. Chem. Biol. 2022, 18, 774–781. [Google Scholar] [CrossRef] [PubMed]

- Roggatz, C.C.; González-Wangüemert, M.; Pereira, H.; Vizetto-Duarte, C.; Rodrigues, M.J.; Barreira, L.; da Silva, M.M.; Varela, J.; Custódio, L. A first glance into the nutritional properties of the sea cucumber Parastichopus regalis from the Mediterranean Sea (SE Spain). Nat. Prod. Res. 2018, 32, 116–120. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.; Hu, C.; Fan, S. Chemical composition and nutritional quality of sea cucumbers. J. Sci. Ff Food Agric. 2010, 90, 2469–2474. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.L.; Wang, H.; Tu, Z.C. A comprehensive review of the control and utilization of aquatic animal products by autolysis-based processes: Mechanism, process, factors, and application. Food Res. Int. 2023, 164, 112325. [Google Scholar] [CrossRef]

- Bai, Y.X.; Qu, M.; Luan, Z.Q.; Li, X.J.; Yang, Y.X. Electrohydrodynamic drying of sea cucumber (Stichopus japonicus). LWT-Food Sci. Technol. 2013, 54, 570–576. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, J.; Li, P.; Zeng, F.; Wang, H. Hyperspectral detection of salted sea cucumber adulteration using different spectral preprocessing techniques and SVM method. LWT 2021, 152, 112295. [Google Scholar] [CrossRef]

- Geng, S.T.; Wang, H.H.; Wang, X.L.; Ma, X.J.; Xiao, S.; Wang, J.H.; Tan, M.Q. A non-invasive NMR and MRI method to analyze the rehydration of dried sea cucumber. Anal. Methods 2015, 7, 2413–2419. [Google Scholar] [CrossRef]

- Jiang, P.F.; Jin, W.G.; Liu, Y.; Sun, N.; Zhu, K.Y.; Bao, Z.J.; Dong, X.P. Hot-air drying characteristics of sea cucumber (Apostichopus japonicus) and its rehydration properties. J. Food Qual. 2022, 2022, 5147373. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, X.; Miao, S.; Zeng, S.; Zhang, Y.; Zheng, B. Ultrasound-Assisted Rehydration of Dried Sea Cucumber (Stichopus japonicus)-Kinetics. Int. J. Food Eng. 2016, 12, 753–761. [Google Scholar] [CrossRef]

- Fukunaga, T.; Matsumoto, M.; Murakami, T.; Hatae, K. Effects of soaking conditions on the texture of dried sea cucumber. Fish. Sci. 2004, 70, 319–325. [Google Scholar] [CrossRef]

- Zhi-bin, X.; Qing, C.; Jian-rong, L. Effect of water immersion conditions on textural properties and microstructure of dried sea cucumber. Food Sci. 2010, 31, 37–41. [Google Scholar]

- Lu, C.; Pan, Z.L.; Yue, T.L.; Atungulu, G.G.; Berrios, J. Effect of ultrasonic treatment of brown rice at different temperatures on cooking properties and quality. Cereal Chem. 2010, 87, 403–408. [Google Scholar]

- Wambura, P.; Yang, W.; Wang, Y. Power ultrasound enhanced one-step soaking and gelatinization for rough rice parboiling. Int. J. Food Eng. 2008, 4, 99–107. [Google Scholar] [CrossRef]

- Yildirim, A.; Öner, M.D.; Bayram, M. Fitting Fick’s Model to Analyze Water Diffusion into Chickpeas During Soaking with Ultrasound Treatment. J. Food Eng. 2011, 104, 134–142. [Google Scholar] [CrossRef]

- Yildirim, A.; Öner, M.D.; Bayram, M. Effect of Soaking and Ultrasound Treatments on Texture of Chickpea. J. Food Sci. Technol. 2013, 50, 455–465. [Google Scholar] [CrossRef] [PubMed]

- Huang, X. The Effect of Ultrasound on Rehydration Quality of Sea Cucumber and Mechanism Research. Ph.D. Thesis, Fujian Agriculture and Forestry University, Fuzhou, China, 2016. [Google Scholar]

- Xiang, Y.-H.; Su, X.-R.; Dong, M.-M.; Chen, C.-L. Study on water immersion technology of salted sea cucumber. Food Sci. 2007, 28, 153–156. [Google Scholar]

- Rongrong, L.I.; Carpenter, J.A.; Cheney, R. Sensory and Instrumental Properties of Smoked Sausage Made with Mechanically Separated Poultry (Msp) Meat and Wheat Protein. J. Food Sci. 1998, 63, 923–929. [Google Scholar]

- Cheng, S.S.; Zhang, T.; Yao, L.; Wang, X.H.; Song, Y.K.; Wang, H.H.; Tan, M.Q. Use oflow-field-NMR andMRI to characterize water mobility and distribution in pacific oyster (Crassostrea gigas) during drying process. Dry. Technol. 2017, 36, 630–636. [Google Scholar] [CrossRef]

- Collewet, G.; Moussaoui, S.; Quellec, S.; Hajjar, G.; Leport, L.; Musse, M. Characterization of Potato Tuber Tissues Using Spatialized MRI T2 Relaxometry. Biomolecules 2023, 13, 286. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, T.; Sekiyama, Y.; Kawamura, T.; Fukuda, Y.; Nagata, M. Tissue structural analysis for internal browning sweet potatoes using magnetic resonance imaging and bio-electrochemical impedance spectroscopy. J. Food Eng. 2023, 349, 111451. [Google Scholar] [CrossRef]

- Kerr, J.D.; Gruber, D.M.; Augustine, M.P. Using MRI to Study High Pressure Assisted Nutrient Infusion. Molecules 2022, 27, 7972. [Google Scholar] [CrossRef] [PubMed]

- Coleen, R.; Adèle, L.; Maxime, G.; Anne, D.; Bénédicte, G.; Jean-Philippe, R. The Role of the Human Hypothalamus in Food Intake Networks: An MRI Perspective. Front. Nutr. 2022, 8, 760914. [Google Scholar]

- De Richter, S.K.; Gaudel, N.; Gaiani, C.; Pascot, A.; Ferrari, M.; Jenny, M. Swelling of couscous grains under saturated conditions. J. Food Eng. 2022, 319, 110910. [Google Scholar] [CrossRef]

- Fundo, J.F.; Galvis-Sanchez, A.; Madureira, A.R.; Carvalho, A.; Feio, G.; Silva, C.L.M.; Quintas, M.A.C. NMR water transverse relaxation time approach to understand storage stability of fresh-cut ‘Rocha’ pear. LWT-Food Sci. Technol. 2016, 74, 280–285. [Google Scholar] [CrossRef]

| Factor | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A—Ultrasonic power (W) | 300 | 350 | 400 |

| B—Ultrasonic temperature (°C) | 40 | 50 | 60 |

| C—Ultrasonic time (min) | 60 | 80 | 100 |

| Item | Grade | |||

|---|---|---|---|---|

| 1–5 | 6–10 | 11–15 | 16–20 | |

| Color | White, Nonuniform color | Light brown or light yellow, Nonuniform color | Light brown or tan, Slightly uniform color | Black brown or black gray, Uniform color |

| Chewability | Soft, Nonelastic | Slightly soft, Poor elasticity | Hard, Elastic | Good elasticity, Moderate hardness |

| Umami | No umami, Funny flavor | Slightly umami, Odorless | Strong umami | Rich umami |

| Odor | Scentless, Fishy | Faint scent, Slightly fishy | Obviously fragrant, Tasteless | Excellent fragrance, Tasteless |

| Morphology | Incompleteness, Soft thorn | Slightly complete, Slightly soft thorn | Complete, Slightly straight thorn | Complete, Straight thorn |

| Case | A—Ultrasonic Power (W) | B—Ultrasonic Temperature (°C) | C—Ultrasonic Time (min) | Rehydration Ratio |

|---|---|---|---|---|

| 1 | 300 | 40 | 80 | 1.7404 |

| 2 | 400 | 40 | 80 | 1.9747 |

| 3 | 300 | 60 | 80 | 1.6935 |

| 4 | 400 | 60 | 80 | 1.9284 |

| 5 | 400 | 50 | 100 | 1.9919 |

| 6 | 300 | 50 | 60 | 1.6162 |

| 7 | 350 | 60 | 100 | 1.8884 |

| 8 | 300 | 50 | 100 | 1.968 |

| 9 | 350 | 40 | 100 | 1.8751 |

| 10 | 400 | 50 | 60 | 1.9241 |

| 11 | 350 | 40 | 60 | 1.825 |

| 12 | 350 | 50 | 80 | 2.0835 |

| 13 | 350 | 60 | 60 | 1.6155 |

| 14 | 350 | 50 | 80 | 2.0239 |

| 15 | 350 | 50 | 80 | 2.0835 |

| 16 | 350 | 50 | 80 | 2.0769 |

| 17 | 350 | 50 | 80 | 2.0372 |

| Item | Sum of Squares of Deviations | Degree of Freedom | Mean Square | F-Value | p-Value | Significance Level |

|---|---|---|---|---|---|---|

| Model | 0.38 | 9 | 0.042 | 36.73 | <0.0001 | ** |

| A—Ultrasonic power | 0.08 | 1 | 0.08 | 69.65 | <0.0001 | ** |

| B—Ultrasonic temperature | 0.01 | 1 | 0.01 | 9.09 | 0.0195 | * |

| C—Ultrasonic time | 0.069 | 1 | 0.069 | 59.86 | 0.0001 | ** |

| AB | 9.00 × 10−8 | 1 | 9.00 × 10−8 | 7.82 × 10−5 | 0.9932 | |

| AC | 0.02 | 1 | 0.02 | 17.51 | 0.0041 | ** |

| BC | 0.012 | 1 | 0.012 | 10.78 | 0.0134 | * |

| A2 | 0.025 | 1 | 0.025 | 21.32 | 0.0024 | ** |

| B2 | 0.095 | 1 | 0.095 | 82.71 | <0.0001 | ** |

| C2 | 0.051 | 1 | 0.051 | 43.92 | 0.0003 | ** |

| Residual | 8.06 × 10−3 | 7 | 1.15 × 10−3 | |||

| Lack of fit | 4.85 × 10−3 | 3 | 1.62 × 10−3 | 2.02 | 0.2541 | ns |

| Pure error | 3.21 × 10−3 | 4 | 8.02 × 10−4 | |||

| Total | 0.39 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Su, Y.; Wang, Y.; Chen, X.; Chen, X.; Liu, Z. The Effect of Ultrasound on the Rehydration Characteristics of Semi-Dried Salted Apostichopus japonicus. Foods 2023, 12, 4382. https://doi.org/10.3390/foods12244382

Wang X, Su Y, Wang Y, Chen X, Chen X, Liu Z. The Effect of Ultrasound on the Rehydration Characteristics of Semi-Dried Salted Apostichopus japonicus. Foods. 2023; 12(24):4382. https://doi.org/10.3390/foods12244382

Chicago/Turabian StyleWang, Xiaoyan, Yongchang Su, Yangduo Wang, Xiaoting Chen, Xiaoe Chen, and Zhiyu Liu. 2023. "The Effect of Ultrasound on the Rehydration Characteristics of Semi-Dried Salted Apostichopus japonicus" Foods 12, no. 24: 4382. https://doi.org/10.3390/foods12244382