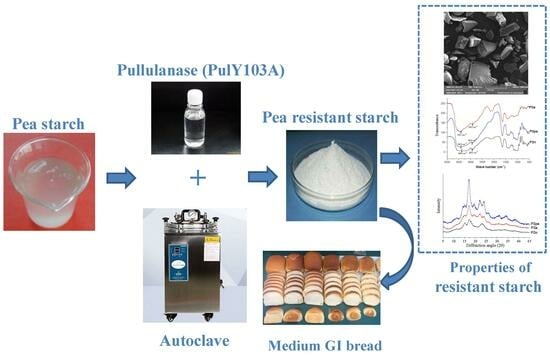

Preparation of Resistant Starch Types III + V with Moderate Amylopullulanase and Its Effects on Bread Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Determination of RS

2.3. Determination of Amylose Content

2.4. Swelling Power and Solubility

2.5. SEM Analysis

2.6. Thermal Analysis

2.7. Fourier Transform Infrared Spectra

2.8. X-ray Diffraction

2.9. Preparation of the Bread

2.10. Properties of the Bread

2.10.1. Sensory Analysis

2.10.2. Color of Crust

2.10.3. Hardness

2.10.4. Specific Volume

2.10.5. Total Dietary Fiber Content

2.10.6. In Vitro Bread Digestibility

2.10.7. In Vitro Mineral Bioavailability

2.11. Statistical Analysis

3. Results and Discussion

3.1. RS Preparation

3.2. RS Properties

3.3. FTIR and XRD Analysis

3.4. Bread Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tekin, T.; Dincer, E. Effect of resistant starch types as a prebiotic. Appl. Microbiol. Biotechnol. 2023, 107, 491–515. [Google Scholar] [CrossRef] [PubMed]

- Das, M.; Rajan, N.; Biswas, P.; Banerjee, R. A novel approach for resistant starch production from green banana flour using amylopullulanase. LWT-Food Sci. Technol. 2022, 153, 112391. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, L.; Han, P.; Liang, X. Pea resistant starch preparation with cold-active type I pullulanase from Bacillus megaterium and its potential application in rice noodles. LWT-Food Sci. Technol. 2023, 182, 114799. [Google Scholar] [CrossRef]

- Thakur, M.; Sharma, N.; Rai, A.K.; Singh, S.P. A novel cold-active type I pullulanase from a hot-spring metagenome for effective debranching and production of resistant starch. Bioresour. Technol. 2021, 320, 124288. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Lu, W.; Liang, Y.; Wang, L.; Jin, N.; Zhao, H.; Fan, B.; Wang, F. Research progress on hypoglycemic mechanisms of resistant starch: A Review. Molecules 2022, 27, 7111. [Google Scholar] [CrossRef] [PubMed]

- Niu, H.; Zhao, F.; Ji, W.; Ma, L.; Lu, B.; Yuan, Y.; Yue, T. Structural, physicochemical properties and noodle-making potential of quinoa starch and type 3, type 4, and type 5 quinoa resistant starch. Int. J. Biol. Macromol. 2024, 258, 128772. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, S.N.; Drawbridge, P.; Beta, T. Resistant starch in wheat-, barley-, rye-, and oat-based foods: A review. Starch-Stärke 2023, 75, 2100251. [Google Scholar] [CrossRef]

- Tian, S.; Sun, Y. Influencing factor of resistant starch formation and application in cereal products: A review. Int. J. Biol. Macromol. 2020, 149, 424–431. [Google Scholar] [CrossRef]

- Arp, C.G.; Correa, M.J.; Ferrero, C. Resistant starches: A smart alternative for the development of functional bread and other starch-based foods. Food Hydrocoll. 2021, 121, 106949. [Google Scholar] [CrossRef]

- Monsierra, L.; Mansilla, P.S.; Pérez, G.T. Whole flour of purple maize as a functional Ingredient of Gluten-Free bread: Effect of in vitro digestion on starch and bioaccessibility of bioactive compounds. Foods 2024, 13, 194. [Google Scholar] [CrossRef]

- Morales-Hernández, N.; Mondragón-Cortéz, P.; del Mercado, P.A.P.V. Pea starch: Functionality and potential applications. In Non-Conventional Starch Sources; Academic Press: Cambridge, MA, USA, 2024; pp. 495–521. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Tao, H.Y.; Chen, Z.; Liang, X.B.; Han, P.; Tao, J.H. Cloning and characterization of a novel amylopullulanase from Bacillus megaterium Y103 with transglycosylation activity. Biotechnol. Lett. 2020, 42, 1719–1726. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Siddiqui, S.; Ur Rahman, U.; Ali, H.; Saba, M.; Azhar, F.A.; Rehman, M.M.U.; Shah, A.A.; Badshah, M.; Hasan, F.; et al. Physicochemical properties of enzymatically prepared resistant starch from maize flour and its use in cookies formulation. Int. J. Food Prop. 2020, 23, 549–569. [Google Scholar] [CrossRef]

- Feng, Y.; Juliet, I.C.; Qin, W.; Duan, Y.; Gao, X.; Liu, Q.; Zhang, H.; Ma, H. Rheology, in vitro digestion and functional properties of Sagittaria sagittifolia L. resistant starch as affected by different preparation methods. Starch-Stärke 2022, 74, 2100181. [Google Scholar] [CrossRef]

- Sun, H.; Fan, J.; Tian, Z.; Ma, L.; Meng, Y.; Yang, Z.; Zeng, X.; Liu, X.; Kang, L.; Nan, X. Effects of treatment methods on the formation of resistant starch in purple sweet potato. Food Chem. 2022, 367, 130580. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Liu, G.; Li, J.; Wang, W.; Hu, A.; Zheng, J. Structural and physicochemical properties of resistant starch under combined treatments of ultrasound, microwave, and enzyme. Int. J. Biol. Macromol. 2023, 232, 123331. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Cao, W.; Wang, P.; Li, J.; Zhang, Q.; Yan, Y. Selectively hydrolyzed soy protein as an efficient quality improver for steamed bread and its influence on dough components. Food Chem. 2021, 359, 129926. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, H.; Brennan, M.; Brennan, C.; Qin, Y.; Cheng, G.; Liu, Y. Physical, chemical, sensorial properties and in vitro digestibility of wheat bread enriched with yunnan commercial and wild edible mushrooms. LWT-Food Sci. Technol. 2022, 169, 113923. [Google Scholar] [CrossRef]

- Zhang, T.; Tian, Z.; Sun, L.; Zhuang, Y. Effect of different cadmium levels in Boletus griseus on bioaccessibility, bioavailability, and intestinal flora by establishing a complete bionic digestion system in vitro. J. Food Sci. 2022, 87, 3677–3689. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Aribas, M.; Kahraman, K.; Koksel, H. Effects of resistant starch type 4 supplementation of bread on in vitro glycemic index value, bile acid-binding capacity, and mineral bioavailability. Cereal Chem. 2020, 97, 163–171. [Google Scholar] [CrossRef]

- Lu, Z.H.; Belanger, N.; Donner, E.; Liu, Q. Debranching of pea starch using pullulanase and ultrasonication synergistically to enhance slowly digestible and resistant starch. Food Chem. 2018, 268, 533–541. [Google Scholar] [CrossRef] [PubMed]

- Polesi, L.F.; Sarmento, S.B.; Franco, C.M. Production and physicochemical properties of resistant starch from hydrolysed wrinkled pea starch. Int. J. Food Sci. Technol. 2011, 46, 2257–2264. [Google Scholar] [CrossRef]

- Chang, D.; Hu, X.; Ma, Z. Pea-Resistant starch with different multi-scale structural features attenuates the obesity-related physiological changes in high-fat diet mice. J. Agric. Food Chem. 2022, 70, 11377–11390. [Google Scholar] [CrossRef]

- Tang, H.; Liu, X.; Li, Y.; Dong, S. Acetylated debranched rice starch: Structure, characterization, and functional properties. Int. J. Food Prop. 2017, 20, 2118–2126. [Google Scholar] [CrossRef]

- Zhou, D.; Ma, Z.; Xu, J.; Li, X.; Hu, X. Resistant starch isolated from enzymatic, physical, and acid treated pea starch: Preparation, structural characteristics, and in vitro bile acid capacity. LWT-Food Sci. Technol. 2019, 116, 108541. [Google Scholar] [CrossRef]

- Kang, X.; Gao, W.; Wang, B.; Yu, B.; Guo, L.; Cui, B.; Abd El-Aty, A.M. Effect of moist and dry-heat treatment processes on the structure, physicochemical properties, and in vitro digestibility of wheat starch-lauric acid complexes. Food Chem. 2021, 351, 129303. [Google Scholar] [CrossRef]

- Maache-Rezzoug, Z.; Zarguili, I.; Loisel, C.; Queveau, D.; Buleon, A. Structural modifications and thermal transitions of standard maize starch after DIC hydrothermal treatment. Carbohydr. Polym. 2008, 74, 802–812. [Google Scholar] [CrossRef]

- Arp, C.G.; Correa, M.J.; Ferrero, C. Kinetic study of staling in breads with high-amylose resistant starch. Food Hydrocoll. 2020, 106, 105879. [Google Scholar] [CrossRef]

- Tien, N.N.T.; Duyen, T.T.M.; Hung, P.V. Substitution of wheat flour with highly enzyme-resisted cassava starch and its effect on starch digestibility and quality of breads. J. Food Meas. Charact. 2019, 13, 1004–1010. [Google Scholar] [CrossRef]

- Lee, S.H.; Huang, W.Y.; Hwang, J.; Yoon, H.; Heo, W.; Hong, J.; Kim, M.J.; Kang, C.S.; Han, B.K.; Kim, Y.J. Characteristics of amylose–lipid complex prepared from pullulanase-treated rice and wheat flour. Food Sci. Biotechnol. 2023, 33, 1113–1122. [Google Scholar] [CrossRef]

- Kumar, A.; Panda, P.A.; Lal, M.K.; Ngangkham, U.; Sahu, C.; Soren, K.R.; Subudhi, H.N.; Samantaray, S.; Sharma, S. Addition of pulses, cooking oils, and vegetables enhances resistant starch and lowers the glycemic index of rice (Oryza sativa L.). Starch-Stärke 2020, 72, 1900081. [Google Scholar] [CrossRef]

- Arp, C.G.; Correa, M.J.; Ferrero, C. High-amylose resistant starch as a functional ingredient in breads: A technological and microstructural approach. Food Bioprocess Technol. 2018, 11, 2182–2193. [Google Scholar] [CrossRef]

- Sciarini, L.S.; Bustos, M.C.; Vignola, M.B.; Paesani, C.; Salinas, C.N.; Perez, G.T. A study on fibre addition to gluten free bread: Its effects on bread quality and in vitro digestibility. J. Food Sci. Technol. 2017, 54, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Mu, T.; Sun, H.; Zhou, L. Evaluation of texture, retrogradation enthalpy, water mobility, and anti-staling effects of enzymes and hydrocolloids in potato steamed bread. Food Chem. 2022, 368, 130686. [Google Scholar] [CrossRef] [PubMed]

| Parameters | PSn | PSa | PSpa |

|---|---|---|---|

| Amylose content (%) | 14.3 ± 0.2 c | 20.7 ± 0.1 b | 30.5 ± 0.1 a |

| Solubility (%) | 43.5 ± 1.4 a | 31.0 ± 1.2 b | 12.5 ± 0.1 c |

| Swelling power (%) | 21.5 ± 2.7 a | 11.0 ± 0.7 b | 7.9 ± 0.8 c |

| Relatively crystallinity (%) | 13.3 | 20.5 | 26.6 |

| To (°C) | 74.1 | 86.8 | 96.1 |

| Tp (°C) | 99.6 | 113.7 | 121.3 |

| Tc (°C) | 110.0 | 120.6 | 133.3 |

| ΔH (J/g) | 2.5 | 4.5 | 10.5 |

| Samples | Appearance | Aroma | Taste | Texture | Colour |

|---|---|---|---|---|---|

| Control | 13.3 ±1.2 a | 21.8 ± 1.9 a | 20.7 ± 1.4 a | 13.4 ± 1.0 a | 17.4 ± 0.8 a |

| 5% PSpa | 13.1 ± 0.9 a | 22.1 ± 1.3 a | 21.1 ± 1.3 a | 13.0 ± 0.9 a | 17.0 ± 1.0 a |

| 10% PSpa | 12.9 ± 1.4 a | 21.0 ± 3.0 a | 20.8 ± 1.9 a | 13.1 ± 1.2 a | 16.9 ± 1.0 a |

| 15% PSpa | 10.4 ± 1.6 b | 18.8 ± 3.5 b | 14.5 ± 1.7 b | 10.6 ± 1.2 b | 16.6 ± 1.5 b |

| Samples | Specific Volume (mL/g) | Color of Crust | Hardness (g) | ||

|---|---|---|---|---|---|

| L* | a* | b* | |||

| Control | 3.43 ± 0.02 a | 12.26 ± 0.04 a | −0.09 ± 0.01 b | −0.64 ± 0.01 a | 234.1 ± 14.8 b |

| 5% PSpa | 3.47 ± 0.03 a | 12.21 ± 0.09 a | −0.10 ± 0.01 b | −0.67 ± 0.04 a | 240.9 ± 31.7 b |

| 10% PSpa | 3.48 ± 0.01 a | 12.17 ± 0.04 a | −0.11 ± 0.03 b | −0.67 ± 0.02 a | 261.7 ± 24.4 b |

| 15% PSpa | 2.78 ± 0.03 b | 12.19 ± 0.10 a | −0.06 ± 0.01 a | −0.73 ± 0.02 b | 439.0 ± 39.0 a |

| Samples | TDF (%) | In Vitro Mineral Bioavailability (%) | In Vitro GI | ||

|---|---|---|---|---|---|

| Ca | Fe | Zn | |||

| Control | 3.1 ± 0.1 b | 40.3 ± 0.7 a | 18.9 ± 2.4 a | 23.6 ± 0.1 a | 100.0 ± 0.0 a |

| 10% PSpa | 11.6 ± 0.1 a | 32.7 ± 0.8 b | 17.3 ± 1.5 a | 22.6 ± 0.6 a | 69.9 ± 0.5 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Deng, F.; Han, P.; Ding, Y.; Cao, J. Preparation of Resistant Starch Types III + V with Moderate Amylopullulanase and Its Effects on Bread Properties. Foods 2024, 13, 1251. https://doi.org/10.3390/foods13081251

Li J, Deng F, Han P, Ding Y, Cao J. Preparation of Resistant Starch Types III + V with Moderate Amylopullulanase and Its Effects on Bread Properties. Foods. 2024; 13(8):1251. https://doi.org/10.3390/foods13081251

Chicago/Turabian StyleLi, Jianglong, Faxiang Deng, Peng Han, Yangyue Ding, and Jianxin Cao. 2024. "Preparation of Resistant Starch Types III + V with Moderate Amylopullulanase and Its Effects on Bread Properties" Foods 13, no. 8: 1251. https://doi.org/10.3390/foods13081251