Microfluidic Synthesis and Properties of Thermoresponsive Hydrogel Core–Shell Particles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Photopolymerization

2.3. Particle Separation Post Treatment

2.4. Measuring Swellability

2.5. Measuring Thermosensitivity via Microscopy

3. Results and Discussion

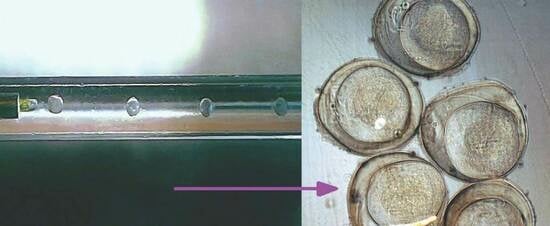

3.1. Microfluidic Arrangement

3.2. Core and Shell Materials

3.3. Generation and Properties of Particles

4. Conclusions

- Liquid solutions for core and shell materials must have poor or no miscibility with each other and with the carrier fluid;

- The carrier should be chosen for best particle geometry; i.e., viscosity, density, and interfacial tension have to be selected or adjusted;

- Core and shell materials must allow for fast solidification (during temperature change, irradiation, etc.);

- Solvents should be easily removable, if required (by diffusion, evaporation, etc.).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, T.; Ma, J.; Li, C.; Lin, K.; Lou, F.; Jiang, H.; Gao, Y.; Yang, Y.; Ming, C.; Ruan, B. Core-shell lipid polymer nanoparticles for combined chemo and gene therapy of childhood head and neck cancers. Oncol. Rep. 2017, 37, 1653–1661. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.; Kim, S.-Y.; Lim, Y.T.; Lee, T.S. Synthesis of Conjugated Polymer Nanoparticles with Core-Shell Structure for Cell Imaging and Photodynamic Cancer Therapy. Macromol. Res. 2017, 25, 572–577. [Google Scholar] [CrossRef]

- Wang, Q.; Alshaker, H.; Böhler, T.; Srivats, S.; Chao, Y.; Cooper, C.; Pchejetski, D. Core shell lipid-polymer hybrid nanoparticles with combined docetaxel and molecular targeted therapy for the treatment of metastatic prostate cancer. Sci. Rep. 2017, 7, 5901. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, C.; Li, Z.; Tang, C.-Y.; Law, W.-C.; Gong, X.; Liu, Z.; Liao, Y.; Zhang, G.; Long, S.; et al. Thermal and Photo Dual-Responsive Core-Shell Polymeric Nanocarriers with Encapsulation of Upconversion Nanoparticles for Controlled Anticancer Drug Release. J. Phys. Chem. C 2019, 123, 10658–10665. [Google Scholar] [CrossRef]

- Bravo-Osuna, I.; Vauthier, C.; Chacun, H.; Ponchel, G. Specific permeability modulation of intestinal paracellular pathway by chitosan-poly(isobutylcyanoacrylate) core-shell nanoparticles. Eur. J. Pharm. Biopharm. 2008, 69, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Chaw, C.-S.; Chooi, K.-W.; Liu, X.-M.; Tan, C.; Wang, L.; Yang, Y.-Y. Thermally responsive core-shell nanoparticles self-assembled from cholesteryl end-capped and grafted polyacrylamides: Drug incorporation and in vitro release. Biomaterials 2004, 25, 4297–4308. [Google Scholar] [CrossRef] [PubMed]

- Xing, L.; Cao, Y.; Che, S. Synthesis of core–shell coordination polymer nanoparticles (CPNs) for pH-responsive controlled drug release. Chem. Commun. 2012, 48, 5995–5997. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Wang, B.; Wang, Y.; Lou, D. Polymer-controlled core-shell nanoparticles: A novel strategy for sequential drug release. RSC Adv. 2014, 4, 30430. [Google Scholar] [CrossRef]

- Kim, H.-C.; Kim, H.-I. Preparation of PVDF Microfiltration Membranes with Thermo-responsive PNIPAM Hydrogel Composite Particles. Compos. Interfaces 2009, 16, 329–336. [Google Scholar] [CrossRef]

- Hu, Y.; Barbier, L.; Li, Z.; Ji, X.; Le Blay, H.; Hourdet, D.; Sanson, N.; Lam, J.W.Y.; Marcellan, A.; Tang, B.Z. Hydrophilicity-Hydrophobicity Transformation, Thermoresponsive Morphomechanics, and Crack Multifurcation Revealed by AIEgens in Mechanically Strong Hydrogels. Adv. Mater. 2021, 33, 2101500. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, D.; Singh, N.; Afreen, S.; Talreja, N.; Ashfaq, M.; Sankararamakrishnan, N.; Chaudhary, G.R. A thermoresponsive CA-PNIPAM-based electrospun nanofibrous membrane for oil/water separation. New J. Chem. 2022, 46, 18984. [Google Scholar] [CrossRef]

- Wan, T.; Xiong, J.; Zhao, Q.; Wu, D.; Tang, L.; Liao, L.; Chen, Q. Crosslinker effects on swelling and gel properties of pH- and temperature-responsive poly (NIPAM/IA/AM) hydrogels. Polym. Bull. 2016, 73, 1447–1458. [Google Scholar] [CrossRef]

- Zhao, C.; He, P.; Xiao, C.; Gao, X.; Zhuang, X.; Chen, X. Photo-Cross-Linked Biodegradable Thermo- and pH-Responsive Hydrogels for Controlled Drug Release. J. Appl. Polym. Sci. 2012, 123, 2923–2932. [Google Scholar] [CrossRef]

- Rahman, M.A.; Karim, M.R.; Miah, M.A.J.; Ahmad, H. Encapsulation of Submicron-sized Silica Particles by Stimuli-responsive Copolymer Shell Layer. Macromol. Res. 2010, 18, 247–253. [Google Scholar] [CrossRef]

- Cai, J.; Guo, J.; Ji, M.; Yang, W.; Wang, C.; Fu, S. Preparation and characterization of multiresponsive polymer composite microspheres with core–shell structure. Colloid Polym. Sci. 2007, 285, 1607–1615. [Google Scholar] [CrossRef]

- Serra, C.A.; Chang, Z. Microfluidic-Assisted Synthesis of Polymer Particles. Chem. Eng. Technol. 2008, 31, 1099–1115. [Google Scholar] [CrossRef]

- Zadražil, A.; Štěpánek, F. Investigation of thermo-responsive optical properties of a composite hydrogel. Colloids Surf. A Physicochem. Eng. Asp. 2010, 372, 115–119. [Google Scholar] [CrossRef]

- Kronfeld, K.-P.; Ellinger, T.; Köhler, J.M. Microfluidically prepared sensor particles for determination of chloride by fluorescence quenching of matrix-embedded lucigenin. SN Appl. Sci. 2020, 2, 366–373. [Google Scholar] [CrossRef]

- Fairbanks, B.D.; Schwartz, M.P.; Bowman, C.N.; Anseth, K.S. Photoinitiated polymerization of PEG-diacrylate with lithium phenyl-2,4,6-trimethylbenzoylphosphinate: Polymerization rate and cytocompatibility. Biomaterials 2009, 30, 6702–6707. [Google Scholar] [CrossRef] [PubMed]

- Halperin, A.; Kröger, M.; Winnik, F.M. Poly(N-isopropylacrylamid)-Phasendiagramme: 50 Jahre Forschung. Angew. Chem. 2015, 127, 15558–15586. [Google Scholar] [CrossRef]

- GESTIS Stoffdatenbank. Available online: https://gestis.dguv.de/ (accessed on 21 March 2023).

| Solvent | Solubility in Water (g/L) 1 | Result of Polymerization |

|---|---|---|

| n-butanol | 77 | sticky gel |

| tert-amyl alcohol | 118 | firm gel |

| n-hexanol | 5.9 | soft gel |

| cyclohexanol | 40 | viscous solution |

| cyclohexanone | 103 | liquid unchanged |

| Monomer Composition | Polymer Properties | ||||||

|---|---|---|---|---|---|---|---|

| ID | NIPAM (mol/L) | Cross- Linker | mol/L | Molar Ratio | Mass Increase after Swelling | Water/Polymer Ratio in Swollen State | Thermo-Responsive y/n (VPTT) |

| 1 | 1.96 | MBBA | 0.050 | 0.025 | 3.36 | 11.9 | y (33 °C) |

| 2 | 1.71 | MBBA | 0.076 | 0.045 | 1.79 | 12.2 | y (34 °C) |

| 3 | 1.72 | MBBA | 0.038 | 0.022 | 6.17 | 42.7 | y (33 °C) |

| 4 | 1.96 | MBBA | 0.149 | 0.076 | 1.72 | 5.6 | y |

| 5 | 1.73 | TPGDA | 0.040 | 0.023 | 3.17 | 22.4 | y |

| 6 | 1.74 | TPGDA | 0.059 | 0.034 | 1.57 | 10.6 | y |

| 7 | 1.73 | EGDM | 0.061 | 0.035 | 8.91 | 64.6 | y |

| 8 | 1.73 | BDDA | 0.061 | 0.035 | 1.29 | 8.5 | y (<26 °C) |

| 9 | 1.72 | BDDA | 0.046 | 0.027 | 0.95 | 6.0 | y |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kronfeld, K.-P.; Köhler, J.M.; Ellinger, T. Microfluidic Synthesis and Properties of Thermoresponsive Hydrogel Core–Shell Particles. J. Compos. Sci. 2024, 8, 162. https://doi.org/10.3390/jcs8050162

Kronfeld K-P, Köhler JM, Ellinger T. Microfluidic Synthesis and Properties of Thermoresponsive Hydrogel Core–Shell Particles. Journal of Composites Science. 2024; 8(5):162. https://doi.org/10.3390/jcs8050162

Chicago/Turabian StyleKronfeld, Klaus-Peter, Johann Michael Köhler, and Thomas Ellinger. 2024. "Microfluidic Synthesis and Properties of Thermoresponsive Hydrogel Core–Shell Particles" Journal of Composites Science 8, no. 5: 162. https://doi.org/10.3390/jcs8050162