Simulation of Damage Caused by Oil Fire in Cable Passage to Tunnel Cable

Abstract

:1. Introduction

2. Model Building

2.1. Cable Channel Prototype and Simplified Physical Model

2.1.1. Cable Tunnel Prototype

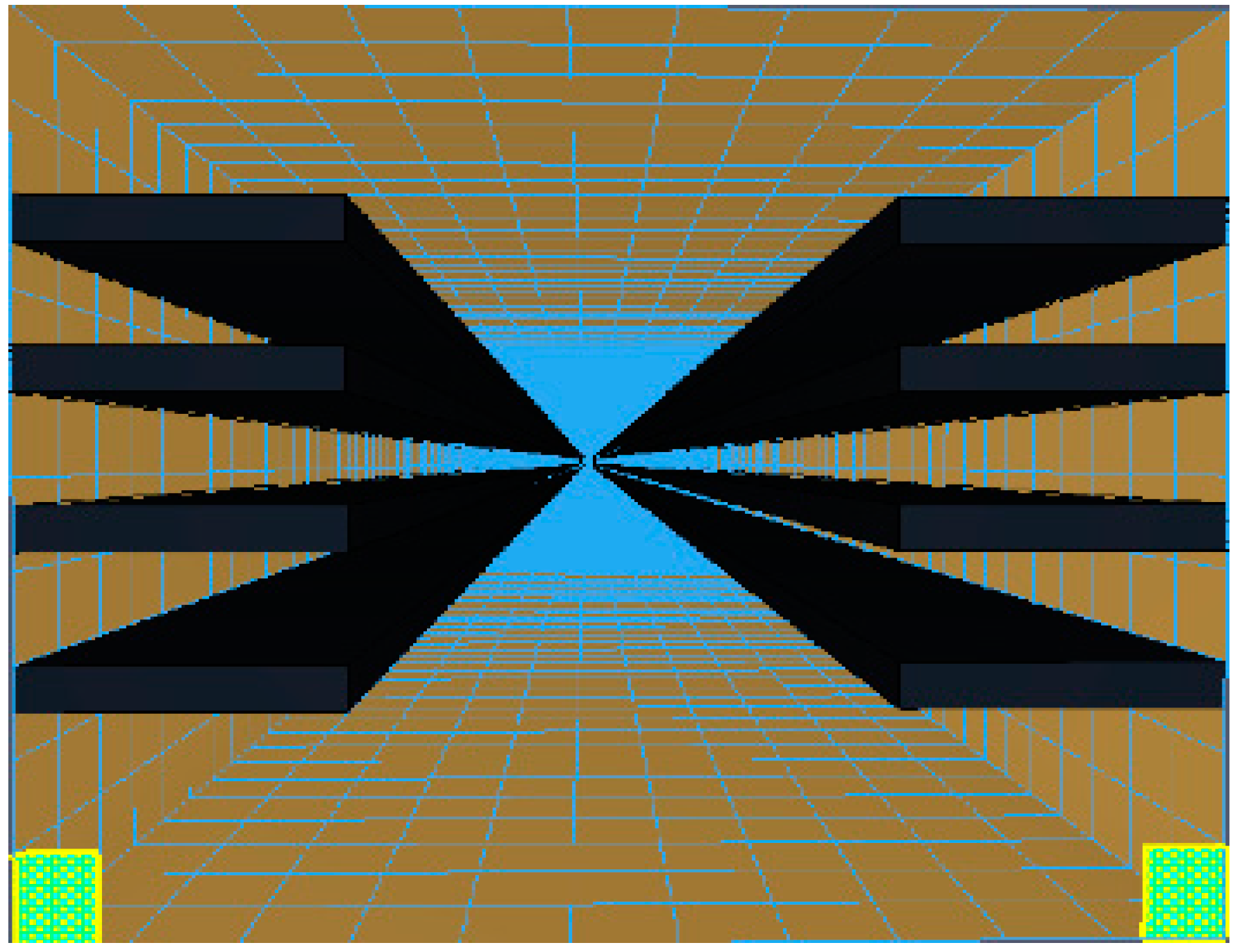

2.1.2. Physical Model

2.2. Cable Channel Prototype and Simplified Physical Model

2.3. Fire Scenario Analysis

2.4. Fire Source and Combustion Model

2.5. Grid Sensitivity Analysis

3. Results and Discussion

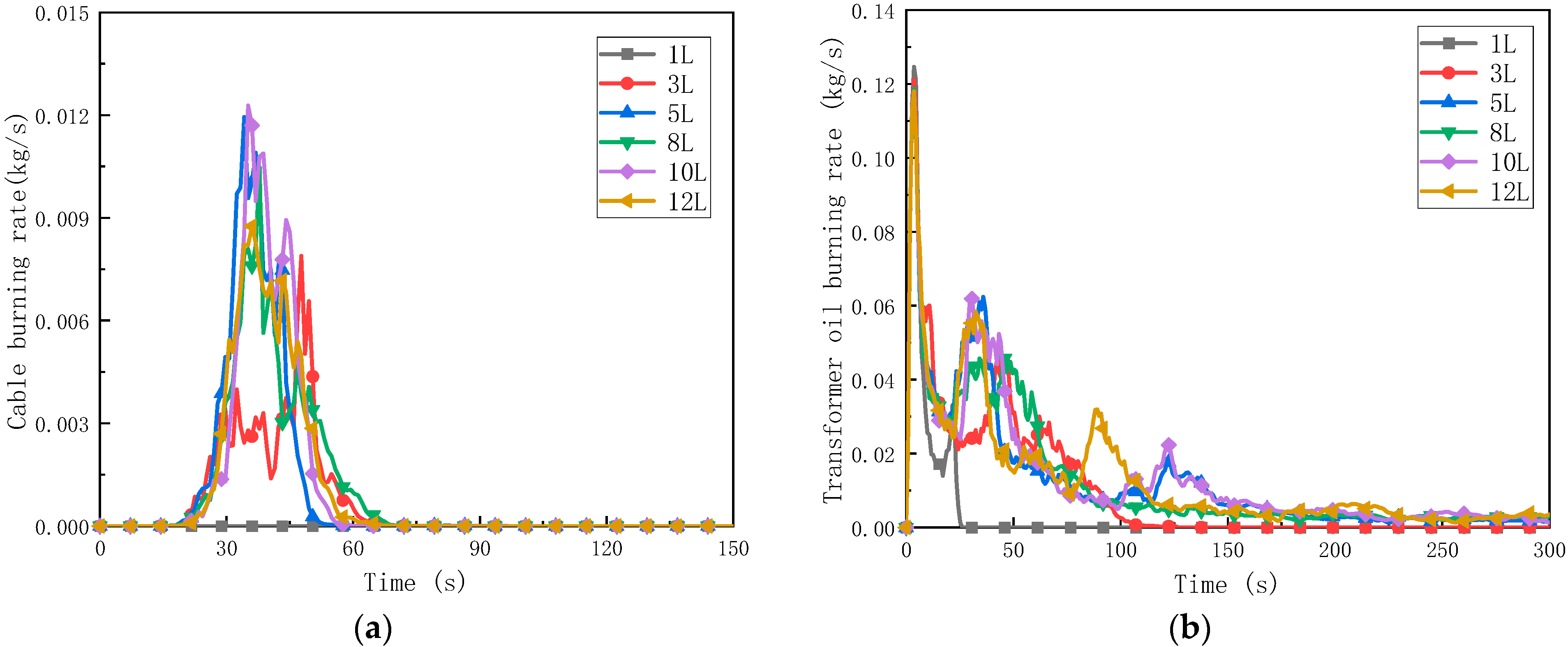

3.1. Influence of Leakage on the Fire Process of Cable Passage

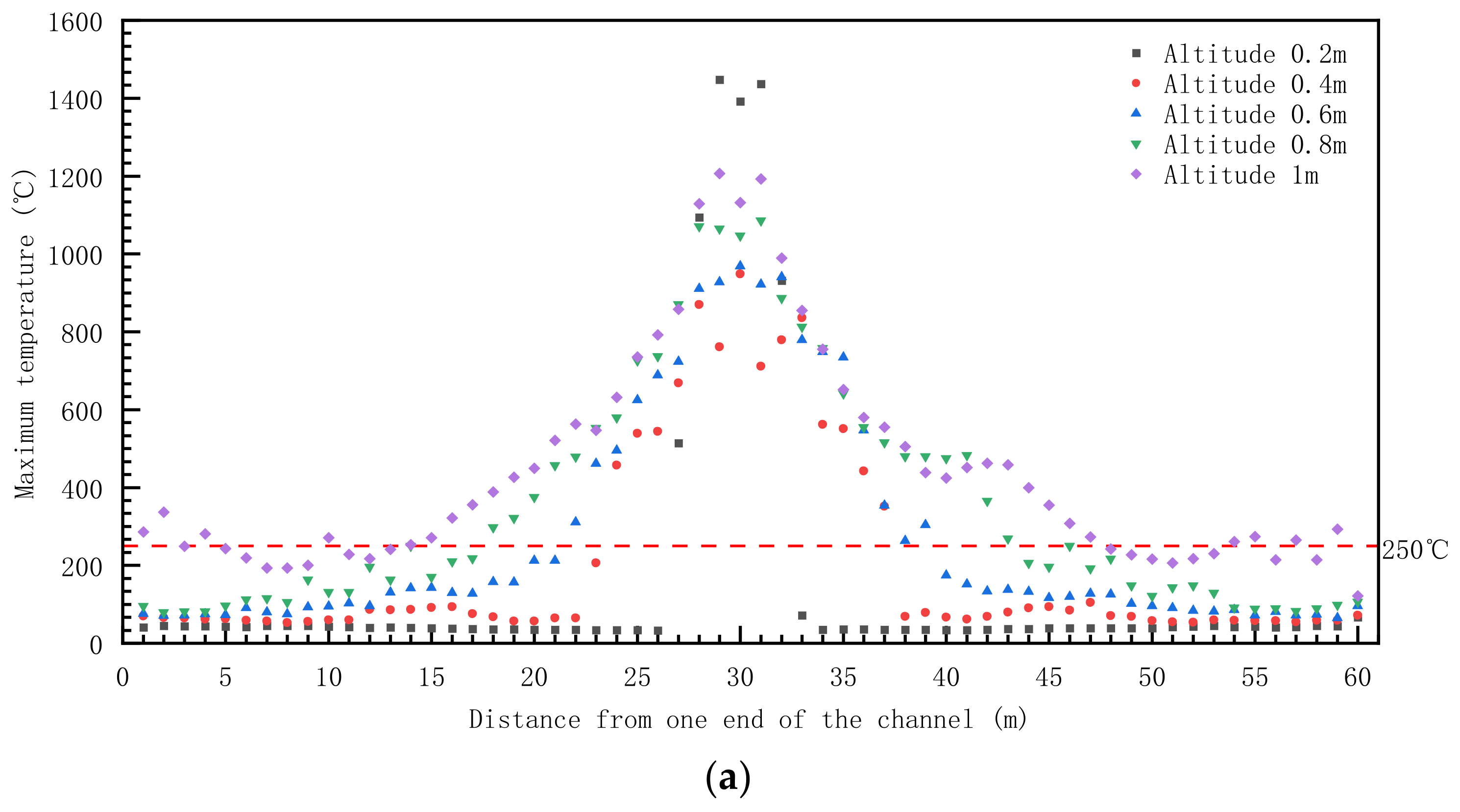

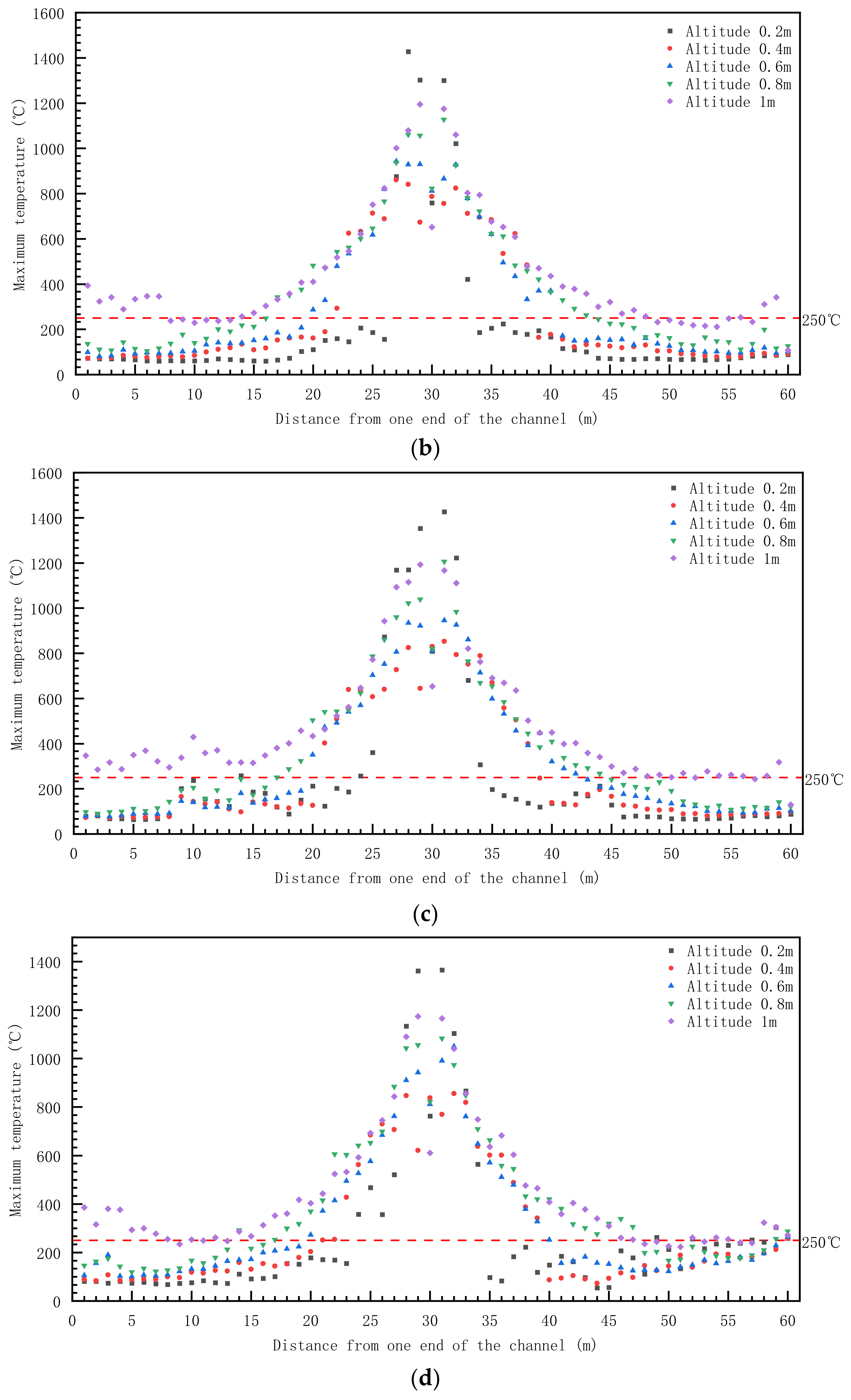

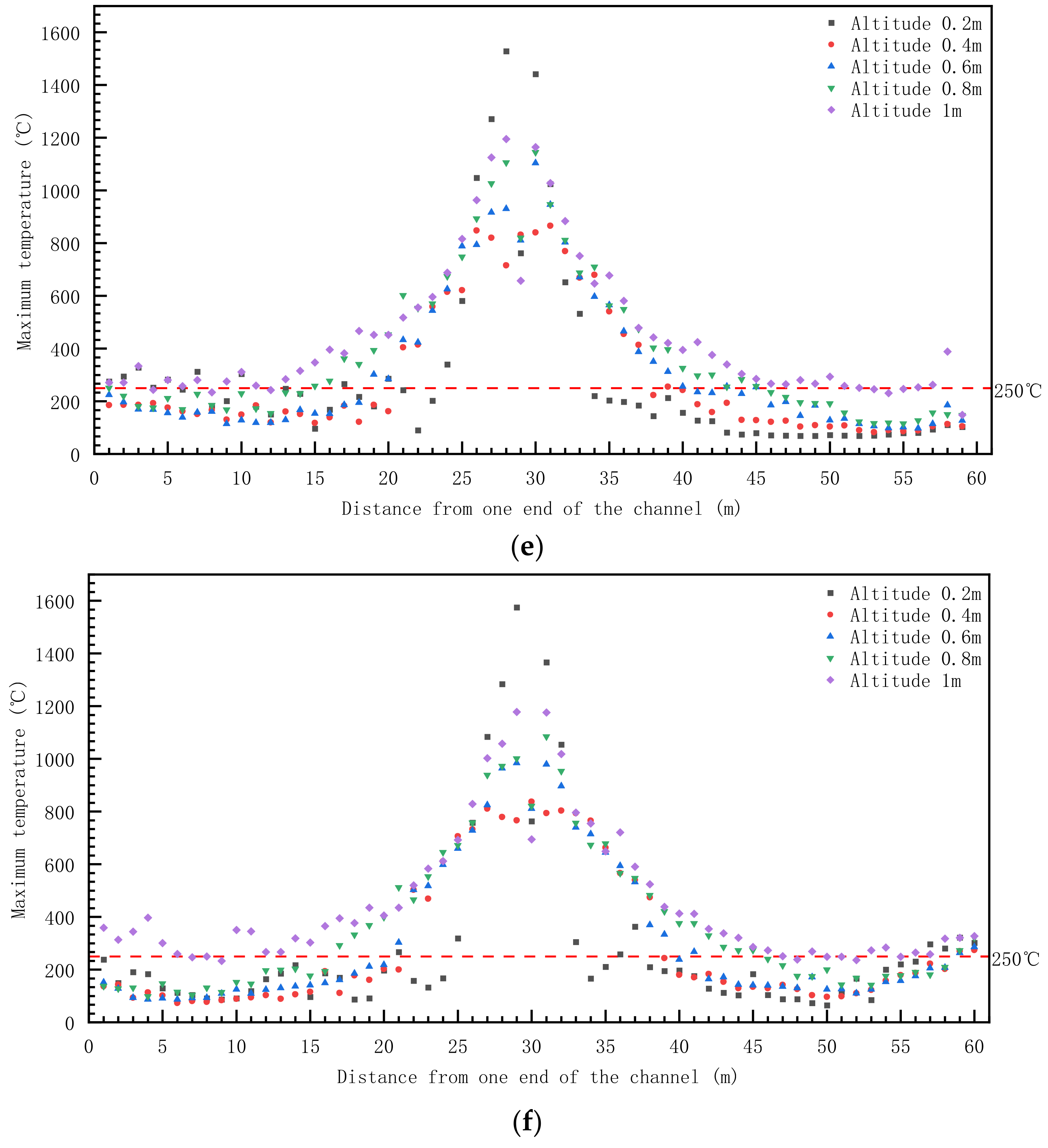

3.2. Assessment of Cable Damage Range Caused by Fire

4. Conclusions

- (1)

- Fire Duration and Transformer Oil Leakage

- (2)

- Cable Combustion Rates

- (3)

- Fire Development Process

- (4)

- Damage Distance Ranges

- (5)

- Layer-specific Damage Distances

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mao, Z. Study and Feasibility Analysis of Bulk Strong Oil Drainage Scheme in ULTRA-High Pressure Rheological Change Fire. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2019. [Google Scholar]

- Chen, T.; Zhao, L.; Fu, X.; Zhang, J.; Wang, Q.; Hu, C.; Bao, Z.; Li, B.; Li, G. Fire accident characteristics and firefighting solutions of large converter transformer. Fire Sci. Technol. Fire Prot. 2020, 39, 1138–1141. [Google Scholar]

- Tao, L.; Zeng, Y.; Liu, Z.; Peng, J.; Zhou, X. Study on the influence of air curtain on fire temperature and flow field in subway tunnel. China Saf. Sci. J. 2021, 31, 157–163. [Google Scholar]

- Mi, H.; Zhang, X.; Yang, W.; Wang, W.; Liu, Y.; Jiao, Y. Fire probability analysis method of cable cabin in urban utility tunnel. China Saf. Sci. J. 2021, 31, 165–172. [Google Scholar]

- Liu, S.R.; Hu, Y.X.; Zheng, J.K.; Su, X.T.; Xu, Y. Dynamics simulation of 10 kV cable tunnel fire for single-phase arc grounding fault. High Volt. Eng. 2021, 47, 4341–4348. [Google Scholar] [CrossRef]

- Matala, A.; Hostikka, S. Probabilistic Simulation of Cable Performance and Water Based Protection in Cable Tunnel Fires. Nucl. Eng. Des. 2011, 241, 5263–5274. [Google Scholar] [CrossRef]

- Hao, G. Simulation Study on Fire Smoke in Cable Compartment of Integrated Pipe Gallery. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2017. [Google Scholar]

- Li, X. Numerical Simulation and Optimization Design of Ventilation System After Cable Cabin fire in Integrated Pipe Gallery. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2018. [Google Scholar]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Weinschenk, C.; Overholt, K. Fire Dynamics Simulator User’s Guide; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013.

- Wang, Y.; Li, C.; Zhang, J.; Shang, F.; Lu, S.; Fan, M.; Cheng, D. Fire characteristic parameter analysis of KI50X UHV transformer oil. J. Saf. Environ. 2020, 20, 1361–1369. [Google Scholar]

- Anonymous. Material Safety Data Sheet of KI50X DC Transformer Oil. Available online: http://kunlunlube.cnpc.com.cn/klrhy/msdstzy/201606/fa791152f8794a6199c7ba19fa8cfd7f/files/1740388a6a3d42e69e033aa95a89db5e.pdf (accessed on 3 June 2020).

- Kai, L. Study on Fire Spreading Behavior and Smoke Flow Characteristics of Urban Underground Comprehensive Pipe Corridor. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Hamins, A.; Maranghides, A.; Johnsson, R.; Donnelly, M.; Yang, J.; Mulholland, G.; Anleitner, R.L. NIST Special Publication 1013-1. Report of Experimental Results for the International Fire Model Benchmarking and Validation Exercise #3; NIST: Gaithersburg, MD, USA, 2005.

- Tang, X. Study on Pyrolysis Kinetics And Radial One-Dimensional Thermal Expansion Model of Flame Retardant Cable. Ph.D. Thesis, University of Science and Technology of China, Langfang, China, 2018. [Google Scholar]

- Wang, Y.; Li, C.; Zhang, J.; Shang, F.; Lu, S.; Fan, M.; Wang, L. Research on characteristics and countermeasures of oil-immersed transformer fire accident. Saf. Environ. Eng. 2019, 26, 166–171. [Google Scholar]

- Wang, Y.; Li, C.; Zhang, J.; Shang, F.; Lu, S.; Fan, M.; Wang, L. Experimental Study on Combustion Characteristics of Insulating Oil of Typical Converter Transformer Based on Flame Spread Meter. Saf. Environ. Eng. 2020, 27, 190–196. [Google Scholar]

- Shen, T. Research on Fire Risk of Metro Tunnel Wire and Cable. Ph.D. Thesis, Capital University of Economics and Business, Beijing, China, 2018. [Google Scholar]

- Zhang, Z.; Wei, B. Preparation and Thermal degradation kinetics of palygorskite/silane crosslinked polyethylene composites. J. Northwest Norm. Univ. (Nat. Sci. Ed.) 2013, 49, 63–69. [Google Scholar]

| Leakage (L) | Cable Damage Distance (m) | |||

|---|---|---|---|---|

| Bottom Cable | Middle and Bottom Cable | Upper-Middle Cable | Top Cable | |

| 1 | 15 | 18 | 27 | 59 |

| 3 | 18 | 22 | 29 | 59 |

| 5 | 22 | 24 | 29 | 59 |

| 8 | 39 | 39 | 44 | 60 |

| 10 | 34 | 28 | 45 | 59 |

| 12 | 40 | 40 | 42 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Zhang, J.; Gu, M.; Liu, Y.; Sun, T.; Ye, L. Simulation of Damage Caused by Oil Fire in Cable Passage to Tunnel Cable. Fire 2024, 7, 147. https://doi.org/10.3390/fire7040147

Liu F, Zhang J, Gu M, Liu Y, Sun T, Ye L. Simulation of Damage Caused by Oil Fire in Cable Passage to Tunnel Cable. Fire. 2024; 7(4):147. https://doi.org/10.3390/fire7040147

Chicago/Turabian StyleLiu, Feng, Jiaqing Zhang, Mengfei Gu, Yushun Liu, Tao Sun, and Liangpeng Ye. 2024. "Simulation of Damage Caused by Oil Fire in Cable Passage to Tunnel Cable" Fire 7, no. 4: 147. https://doi.org/10.3390/fire7040147