Molecular Dynamics Simulation on Thickening and Solubility Properties of Novel Thickener in Supercritical Carbon Dioxide

Abstract

:1. Introduction

2. Results and Discussion

2.1. The Thickening Effect of PVAO

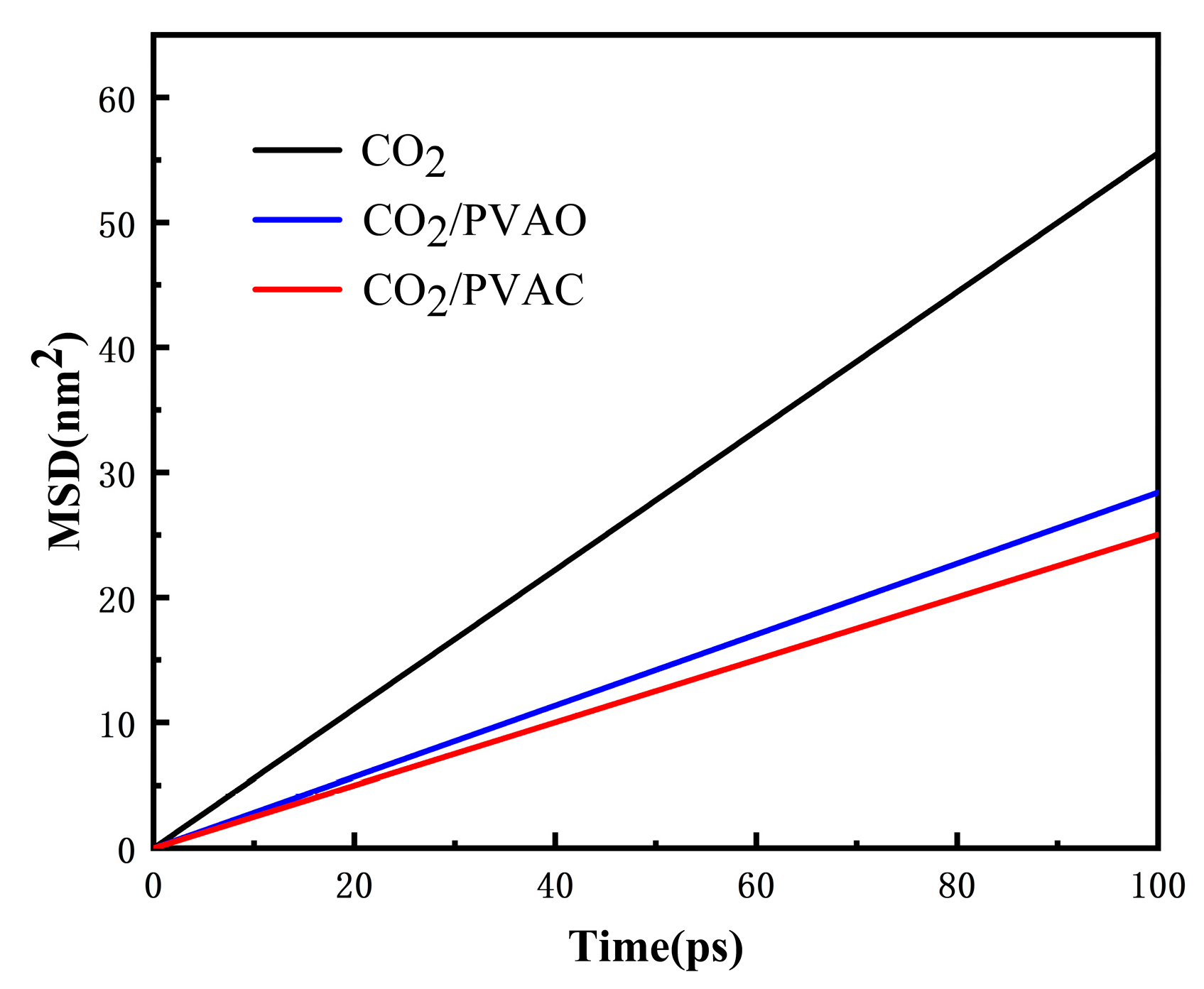

2.2. Diffusivity

2.3. Radial Distribution Function

2.4. Interaction Energy

2.5. Cohesive Energy Density and Solubility Parameters

3. Simulation Details and Methods

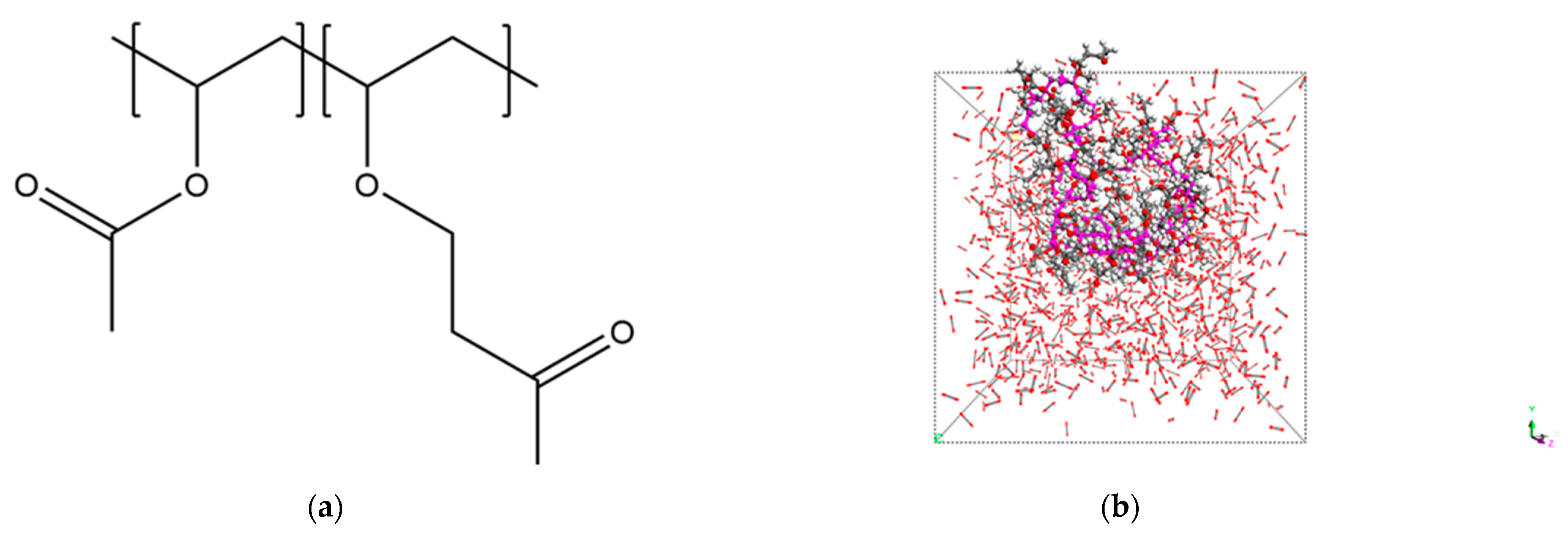

4. Design

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haizhu, W.; Gensheng, L.I.; Yong, Z.; Sepehrnoori, K.; Zhonghou, S.; Bing, Y.; Lujie, S. Research status and prospects of supercritical CO2 fracturing technology. Acta Pet. Sin. 2020, 41, 116–126. [Google Scholar]

- Joseph, M.D. Practical Approaches to Green Solvents. Science 2002, 297, 799–803. [Google Scholar] [CrossRef]

- Eric, J.B. A challenge for green chemistry: Designing molecules that readily dissolve in carbon dioxide. Chem. Commun. 2004, 17, 1885–1888. [Google Scholar] [CrossRef] [PubMed]

- Chatzis, G.; Samios, J. Binary mixtures of supercritical carbon dioxide with methanol. A molecular dynamics simulation study. Chem. Phys. Lett. 2003, 374, 187–193. [Google Scholar] [CrossRef]

- Stubbs, J.M.; Siepmann, J.I. Binary phase behavior and aggregation of dilute methanol in supercritical carbon dioxide: A Monte Carlo simulation study. J. Chem. Phys. 2004, 121, 1525–1534. [Google Scholar] [CrossRef] [PubMed]

- David, L.T.; Hongbo, L.; Dehua, L.; Xiangmin, H.; Maxwell, J.W.; Lee, L.J.; Kurt, W.K. A Review of CO2 Applications in the Processing of Polymers. Ind. Eng. Chem. Res. 2003, 42, 6431–6456. [Google Scholar] [CrossRef]

- Jason, L. Small Molecule Associative CO₂ Thickeners for Improved Mobility Control. Doctoral Dissertation, University of Pittsburgh, Pittsburgh, PA, USA, 2017. [Google Scholar]

- Lee, J.J.; Stephen, C.; Aman, D.; Robert, M.E.; Eric, J.B.; Robert, J.P.; Michael, J.O.B.; Mark, D.D. Development of Small Molecule CO2 Thickeners for EOR and Fracturing. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 12–16 April 2014. [Google Scholar]

- Robert, M.E.; Olsen, D.K.; Ammer, J.R.; Schuller, W.A. Mobility and Conformance Control for CO2 EOR via Thickeners, Foams, and Gels—A Literature Review of 40 Years of Research and Pilot Tests. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Etienne, G.; Thierry, T.; Catherine, L.; Jean-Daniel, M.; Mathias, D. Distinctive Features of Solubility of RAFT/MADIX-Derived Partially Trifluoromethylated Poly(vinyl acetate) in Supercritical CO2. Macromolecules 2012, 45, 9674–9681. [Google Scholar] [CrossRef]

- Etienne, G.; Thierry, T.; Séverine, C.; Jean-Stéphane, C.; Jean-Daniel, M.; Mathias, D. Enhancement of Poly(vinyl ester) Solubility in Supercritical CO2 by Partial Fluorination: The Key Role of Polymer–Polymer Interactions. J. Am. Chem. Soc. 2012, 134, 11920–11923. [Google Scholar]

- Ruediger, M.; Bernhard, W. Solutions of Poly(dimethylsiloxane) in Supercritical CO2: Viscometric and Volumetric Behavior. Macromolecules 1994, 27, 3289–3294. [Google Scholar] [CrossRef]

- Jiarui, X. Carbon Dioxide Thickening Agents for Reduced CO2 Mobility. Doctoral Dissertation, University of Pittsburgh, Pittsburgh, PA, USA, 2003. [Google Scholar]

- Cui, S.T.; Cummings, P.T.; Cochran, H.D. The calculation of viscosity of liquid n-decane and n-hexadecane by the Green-Kubo method. Mol. Phys. 1998, 93, 117–122. [Google Scholar] [CrossRef]

- Yong, Z.; Akihito, O.; Edward, J.M. Reliable Viscosity Calculation from Equilibrium Molecular Dynamics Simulations: A Time Decomposition Method. J. Chem. Theory Comput. 2015, 11, 3537–3546. [Google Scholar] [CrossRef] [PubMed]

- Arno, L.; Chris, D.M. Reference Correlation for the Viscosity of Carbon Dioxide. J. Phys. Chem. Ref. Data 2017, 46, 013107. [Google Scholar] [CrossRef] [PubMed]

- Van der Vegt, N.F.A. Temperature Dependence of Gas Transport in Polymer Melts: Molecular Dynamics Simulations of CO2 in Polyethylene. Macromolecules 2000, 33, 3153–3160. [Google Scholar] [CrossRef]

- Christian, D.; Eric, J.B. Phase behavior of polymers containing ether groups in carbon dioxide. J. Supercrit. Fluids 2002, 22, 103–110. [Google Scholar] [CrossRef]

- Zhihao, S.; Mark, A.M.; Jiarui, X.; Belardi, J.; Sevgi, K.; Anita, J.M.; Bane, S.; Karnikas, C.; Eric, J.B.; Robert, M.E. CO2-solubility of oligomers and polymers that contain the carbonyl group. Polymer 2003, 44, 1491–1498. [Google Scholar] [CrossRef]

- Dongdong, H.; Shaojun, S.; Pei-Qing, Y.; Ling, Z.; Tao, L. Exploration of CO2-Philicity of Poly(vinyl acetate-co-alkyl vinyl ether) through Molecular Modeling and Dissolution Behavior Measurement. J. Phys. Chem. B 2015, 119, 12490–12501. [Google Scholar] [CrossRef] [PubMed]

- Dongdong, H.; Shaojun, S.; Pei-Qing, Y.; Ling, Z.; Tao, L. Evaluation of CO2-Philicity of Poly(vinyl acetate) and Poly(vinyl acetate-alt-maleate) Copolymers through Molecular Modeling and Dissolution Behavior Measurement. J. Phys. Chem. B 2015, 119, 3194–3204. [Google Scholar] [CrossRef]

- Sadegh, Y.-N.; Jaber, S.; Javad, K.-S.; Ali, N.; Elham, A. Determination of momentum accommodation coefficients and velocity distribution function for Noble gas-polymeric surface interactions using molecular dynamics simulation. Appl. Surf. Sci. 2019, 493, 766–778. [Google Scholar] [CrossRef]

- Dai, X.; Chongtao, W.; Meng, W.; Ruying, M.; Yu, S.; Junjian, Z.; Xiaoqi, W.; Xuan, S.; Veerle, V. Interaction mechanism of supercritical CO2 with shales and a new quantitative storage capacity evaluation method. Energy 2023, 264, 126424. [Google Scholar] [CrossRef]

- Hojatollah, M.; Hedayat, A.; Parissa, K.P.; Nia, R. Supercritical Methanol and Ethanol Solubility Estimation by Using Molecular Dynamics Simulation. Chem. Eng. Technol. 2023, 46, 2167–2174. [Google Scholar] [CrossRef]

- Yan, Q.; Xiaoning, Y.; Yupeng, Z.; Ping, J.L. Molecular Dynamics Simulation of Interaction between Supercritical CO2 Fluid and Modified Silica Surfaces. J. Phys. Chem. C 2008, 112, 12815–12824. [Google Scholar] [CrossRef]

- Yalin, L.; Xiaoxiao, D.; Yuejin, Z.; Peng, H.; Bing, L.; Jianlin, L. Effect of the Water Film Rupture on the Oil Displacement by Supercritical CO2 in the Nanopore: Molecular Dynamics Simulations. Energy Fuels 2022, 36, 4348–4357. [Google Scholar] [CrossRef]

- Alberto, P.; Ivan, M.; Daniel, S.; Jiřί, Š.; Thomas, E.C.; Charles, A.L.; Modesto, O. Refinement of the AMBER Force Field for Nucleic Acids: Improving the Description of α/γ Conformers. Biophys. J. 2007, 92, 3817–3829. [Google Scholar] [CrossRef]

- MacKerell, A.D., Jr.; Bashford, D.; Bellott, M.L.D.R.; Dunbrack, R.L., Jr.; Evanseck, J.D.; Field, M.J.; Fischer, S.; Gao, J.; Guo, H.; Ha, S.; et al. All-Atom Empirical Potential for Molecular Modeling and Dynamics Studies of Proteins. J. Phys. Chem. B 1998, 102, 3586–3616. [Google Scholar] [CrossRef] [PubMed]

- David, L.R.; Huai, S.; Eichinger, B.E. Computer simulations of poly(ethylene oxide): Force field, pvt diagram and cyclization behaviour. Polym. Int. 1997, 44, 311–330. [Google Scholar] [CrossRef]

- Huai, S. COMPASS: An ab Initio Force-Field Optimized for Condensed-Phase Applications Overview with Details on Alkane and Benzene Compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Morteza, N.; Samane, M.; Yongan, G. Effects of Viscous and Capillary Forces on CO2 Enhanced Oil Recovery under Reservoir Conditions. Energy Fuels 2007, 21, 3469–3476. [Google Scholar] [CrossRef]

- Jie, Y.; Yi, R.; Anmin, T.; Huai, S. COMPASS Force Field for 14 Inorganic Molecules, He, Ne, Ar, Kr, Xe, H2, O2, N2, NO, CO, CO2, NO2, CS2, and SO2, in Liquid Phases. J. Phys. Chem. B 2000, 104, 4951–4957. [Google Scholar]

- Kaplun, A.B.; Meshalkin, A.B. Unified equation for calculating the viscosity coefficient of argon, nitrogen, and carbon dioxide. High Temp. 2016, 54, 808–814. [Google Scholar] [CrossRef]

- Xiaoqi, W.; Yongan, G. Oil Recovery and Permeability Reduction of a Tight Sandstone Reservoir in Immiscible and Miscible CO2 Flooding Processes. Ind. Eng. Chem. Res. 2011, 50, 2388–2399. [Google Scholar] [CrossRef]

- Hongyu, G.; Hao, Z.; Long, X.; Yajun, L.; Mingzhe, D. Effects of cosolvent on dissolution behaviors of PVAc in supercritical CO2: A molecular dynamics study. Chem. Eng. Sci. 2019, 206, 22–30. [Google Scholar] [CrossRef]

- Denis, J.E.; Brad Lee, H. The Nose–Hoover thermostat. J. Chem. Phys. 1985, 83, 4069–4074. [Google Scholar] [CrossRef]

- Eichinger, B.E.; David, L.R.; Judith, A.S. Cohesive properties of Ultem and related molecules from simulations. Polymer 2002, 43, 599–607. [Google Scholar] [CrossRef]

- Huai, S.; David, L.R. Polysiloxanes: Ab initio force field and structural, conformational and thermophysical properties. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 1997, 53, 1301–1323. [Google Scholar] [CrossRef]

- Sergei, G.K.; Michael, V.; Frank, V.B.; Charles, L.L.; Charles, A.E. Specific Intermolecular Interaction of Carbon Dioxide with Polymers. J. Am. Chem. Soc. 1996, 118, 1729–1736. [Google Scholar] [CrossRef]

- Poovathinthodiyil, R.; Scott, L.W. Cooperative C−H···O Hydrogen Bonding in CO2−Lewis Base Complexes: Implications for Solvation in Supercritical CO2. J. Am. Chem. Soc. 2002, 124, 12590–12599. [Google Scholar] [CrossRef] [PubMed]

- Sevgi, K.; Michalik, S.; Yang, W.; Johnson, J.K.; Robert, M.E.; Eric, J.B. Phase Behavior of Oxygen-Containing Polymers in CO2. Macromolecules 2007, 40, 1332–1341. [Google Scholar]

- Peter, L.; Adel, A.; Lee, J.J.; Eric, J.B.; Robert, M.E. Thickening CO2 with Direct Thickeners, CO2-in-Oil Emulsions, or Nanoparticle Dispersions: Literature Review and Experimental Validation. Energy Fuels 2021, 35, 8510–8540. [Google Scholar] [CrossRef]

| Composition | ||||

|---|---|---|---|---|

| PVAc/CO2 | −3140.5 | −1162.8 | −1503.0 | −474.6 |

| PVAO/CO2 | −2273.9 | −1772.0 | −8.9 | −493.1 |

| Composition | (J/m3) | ((J/m3)1/2) |

|---|---|---|

| CO2 | 2.025 × 108 | 14.18 |

| PVAc | 2.561 × 108 | 15.98 |

| PVAO | 2.326 × 108 | 15.21 |

| System | Composition | No. of Chains | Mn of Chain | No. of VAc Units | No.of VO Units | No. of CO2 | No. of Atoms | |

|---|---|---|---|---|---|---|---|---|

| 1 | CO2 | 1000 | 3000 | 4 × 4 × 4 | ||||

| 2 | PVAc/CO2 | 1 | 6452 | 75 | 0 | 1000 | 3902 | 4.2 × 4.2 × 4.2 |

| 3 | PVAO/CO2 | 1 | 7002 | 35 | 35 | 1000 | 4052 | 4.2 × 4.2 × 4.2 |

| 4 | PVAc | 3 | 6452 | 75 | 0 | 0 | 2706 | 3 × 3 × 3 |

| 5 | PVAO | 3 | 7002 | 35 | 35 | 0 | 3156 | 3 × 3 × 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Liang, S.; Zhang, Q.; Wang, T.; Zhang, X. Molecular Dynamics Simulation on Thickening and Solubility Properties of Novel Thickener in Supercritical Carbon Dioxide. Molecules 2024, 29, 2529. https://doi.org/10.3390/molecules29112529

Wang X, Liang S, Zhang Q, Wang T, Zhang X. Molecular Dynamics Simulation on Thickening and Solubility Properties of Novel Thickener in Supercritical Carbon Dioxide. Molecules. 2024; 29(11):2529. https://doi.org/10.3390/molecules29112529

Chicago/Turabian StyleWang, Xiaohui, Shiwei Liang, Qihong Zhang, Tianjiao Wang, and Xiao Zhang. 2024. "Molecular Dynamics Simulation on Thickening and Solubility Properties of Novel Thickener in Supercritical Carbon Dioxide" Molecules 29, no. 11: 2529. https://doi.org/10.3390/molecules29112529