Revisiting the Determination of the Degree of Deacetylation Using Potentiometric Titration: A New Equation for Modified Chitosan

Abstract

1. Introduction

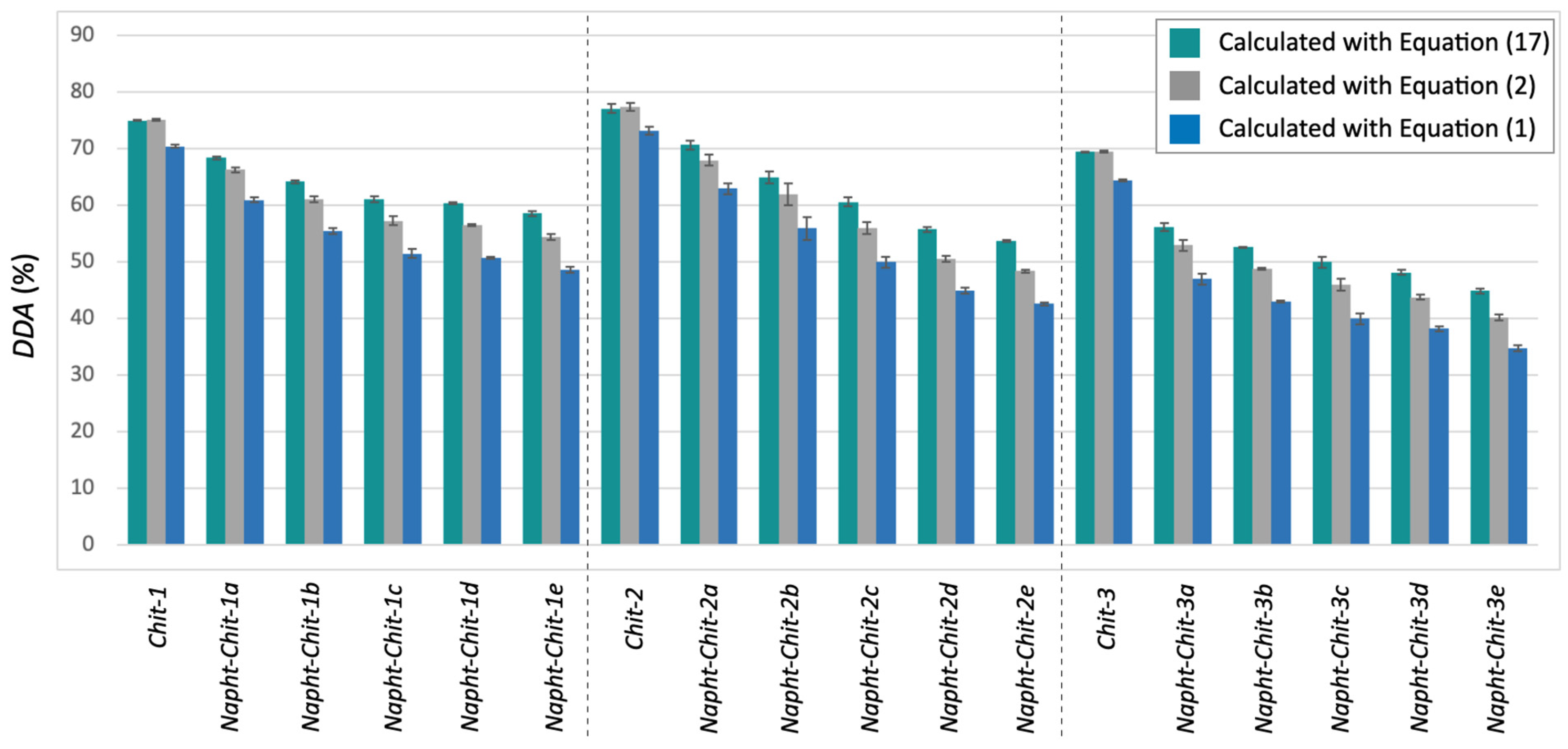

2. Results and Discussion

3. Materials and Methods

3.1. Materials

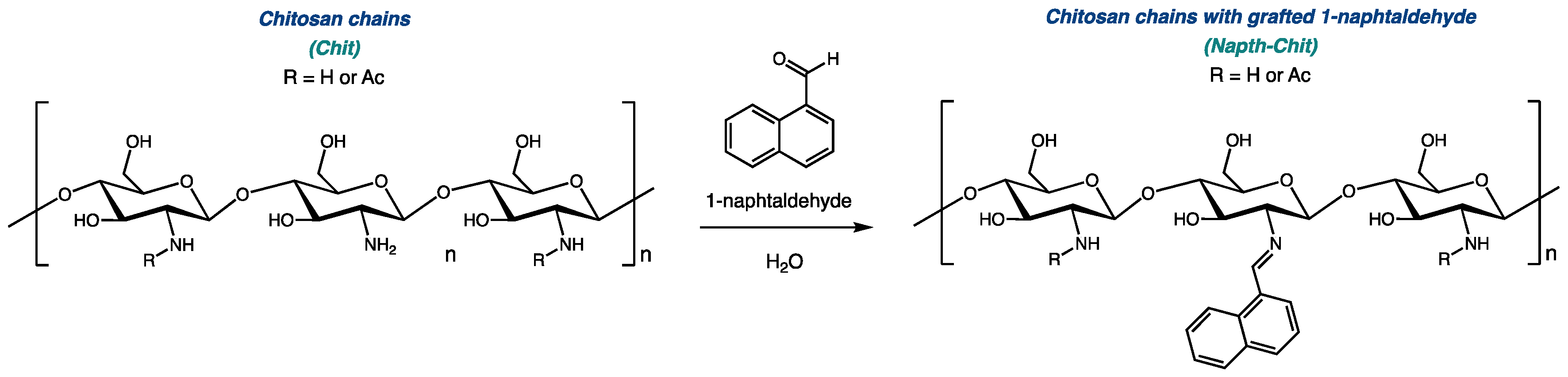

3.2. Preparation of Napth-Chit Resins

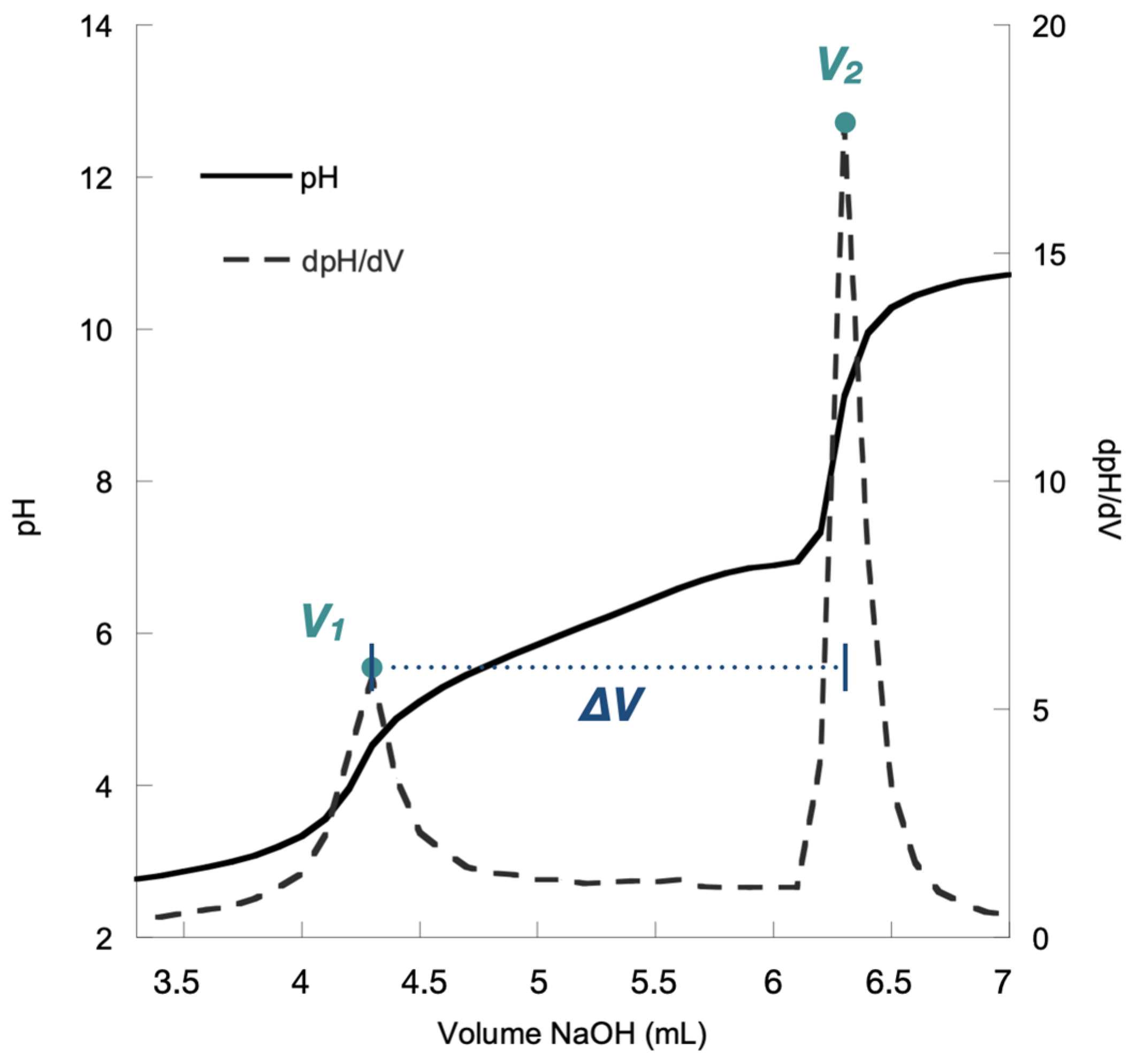

3.3. Potentiometric Titration of Chitosan Resins

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ehrlich, H.; Maldonado, M.; Spindler, K.-D.; Eckert, C.; Hanke, T.; Born, R.; Goebel, C.; Simon, P.; Heinemann, S.; Worch, H. First evidence of chitin as a component of the skeletal fibers of marine sponges. Part I. Verongidae (demospongia: Porifera). J. Exp. Zool. (Mol. Dev. Evol.) 2007, 308B, 347–356. [Google Scholar] [CrossRef]

- Aranaz, I.; Mengibar, M.; Harris, R.; Panos, I.; Miralles, B.; Acosta, N.; Galed, G.; Heras, A. Functional Characterization of Chitin and Chitosan. Curr. Chem. Biol. 2009, 3, 203–230. [Google Scholar] [CrossRef]

- Rinaudo, M. Chitin and Chitosan: Properties and Applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Díaz-Rojas, E.I.; Argüelles-Monal, W.M.; Higuera-Ciapara, I.; Hernández, J.; Lizardi-Mendoza, J.; Goycoolea, F.M. Determination of Chitin and Protein Contents During the Isolation of Chitin from Shrimp Waste. Macromol. Biosci. 2006, 6, 340–347. [Google Scholar] [CrossRef]

- Muzzarelli, R.A.A.; Muzzarelli, C. Chitosan Chemistry: Relevance to the Biomedical Sciences. Adv. Polym. Sci. 2005, 186, 151–209. [Google Scholar] [CrossRef]

- Dash, M.; Chiellini, F.; Ottenbrite, R.M.; Chiellini, E. Chitosan—A versatile semi-synthetic polymer in biomedical applications. Prog. Polym. Sci. 2011, 36, 981–1014. [Google Scholar] [CrossRef]

- Kumar, M.N.V.R. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Mohammadi, M.; Zamani, A.; Karimi, K. Determination of Glucosamine in Fungal Cell Walls by High-Performance Liquid Chromatography (HPLC). J. Agric. Food Chem. 2012, 60, 10511–10515. [Google Scholar] [CrossRef]

- Li, D.D.; Tao, Y.; Shi, Y.N.; Han, Y.B.; Yang, N.; Xu, X.M. Effect of re-acetylation on the acid hydrolysis of chitosan under an induced electric field. Food Chem. 2020, 309, 125767. [Google Scholar] [CrossRef]

- Chen, Q.; Qi, Y.; Jiang, Y.; Quan, W.; Luo, H.; Wu, K.; Li, S.; Ouyang, Q. Progress in Research of Chitosan Chemical Modification Technologies and Their Applications. Mar. Drugs 2022, 20, 536. [Google Scholar] [CrossRef]

- Pillai, C.K.S.; Paul, W.; Sharma, C.P. Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Mourya, V.K.; Inamdar, N. Chitosan-Modifications and applications: Opportunities galore. React. Funct. Polym. 2008, 68, 1013–1051. [Google Scholar] [CrossRef]

- Kritichenkov, A.S.; Skorik, Y.A. Click reactions in chitosan chemistry. Russ. Chem. Bull. Ed. 2017, 66, 769–781. [Google Scholar] [CrossRef]

- Amamou, O.; Denis, J.-P.; Heinen, E.; Boubaker, T.; Cardinal, S. A New and Rapid HPLC Method to Determine the Degree of Deacetylation of Glutaraldehyde-Cross-Linked Chitosan. Molecules 2023, 28, 7294. [Google Scholar] [CrossRef]

- Broussignac, P. Haut Polymère Naturel Connu dans l’industrie: Le chitosane. Chim. Ind. Génie Chim. 1968, 99, 1241–1247. [Google Scholar]

- Dos Santos, Z.M.; Caroni, A.L.P.F.; Pereira, M.R.; da Silva, D.R.; Fonseca, J.L.C. Determination of deacetylation degree of chitosan: A comparison between conductometric titration and CHN elemental analysis. Carbohydr. Res. 2009, 344, 2591–2595. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Ding, R.; Zhang, J.; Liu, J. Determination of the degree of deacetylation of chitosan by potentiometric titration preceded by enzymatic pretreatment. Carbohydr. Polym. 2011, 83, 813–817. [Google Scholar] [CrossRef]

- Tan, S.C.; Khor, E.; Tan, T.K.; Wong, S.M. The degree of deacetylation of chitosan: Advocating the first derivative UV-spectrophotometry method of determination. Talanta 1998, 45, 713–719. [Google Scholar] [CrossRef]

- Muñoz, G.; Valencia, C.; Valderruten, N.; Ruiz-Durántez, E.; Zuluaga, F. Extraction of chitosan from Aspergillus niger mycelium and synthesis of hydrogels for controlled release of betahistine. React. Funct. Polym. 2015, 91, 1–10. [Google Scholar] [CrossRef]

- Hiral, A.; Odani, H.; Nakajima, A. Determination of degree of deacetylation of chitosan by 1H NMR spectroscopy. Polym. Bull. 1991, 2, 87–94. [Google Scholar] [CrossRef]

- Sivashankari, P.R.; Prabaharan, M. Deacetylation modification techniques of chitin and chitosan. In Chitosan Based Biomaterials; Woodhead Publishing: Sawston, UK, 2017; Volume 1, pp. 117–133. [Google Scholar] [CrossRef]

- Czechowska-Biskup, R.; Jarosinska, D.; Rokita, B.; Ulanski, P.; Rosiak, J.M. Determination of degree of deacetylation of chitosan-Comparison of methods. Prog. Chem. Appl. Chitin. Deriv. 2012, XVII, 5–20. [Google Scholar]

- Vieira, R.S.; Beppu, M.M. Interaction of natural and crosslinked chitosan membranes with Hg(II) ions. Colloids Surf. A Physicochem. Eng. Asp. 2006, 279, 196–207. [Google Scholar] [CrossRef]

- Stroparo, E.C.; Mollinari, K.C.; Souza, K.V. Use of chitosan in the remediation of water from purification of biodiesel. Polimeros 2018, 28, 400–405. [Google Scholar] [CrossRef]

- Balazs, N.; Sipos, P. Limitations of pH-potentiometric titration for the determination of the degree of deacetylation of chitosan. Carbohydr. Res. 2007, 342, 124–130. [Google Scholar] [CrossRef]

- Tamer, T.M.; Hassan, M.A.; Omer, A.M.; Baset, W.M.A.; Hassan, M.E.; El-Shafeey, M.E.A.; Eldin, M.S.M. Synthesis, characterization and antimicrobial evaluation of two aromatic chitosan Schiff base derivatives. Pro. Biochem. 2016, 51, 1721–1730. [Google Scholar] [CrossRef]

- Hassan, M.A.; Omer, A.M.; Abbas, E.; Baset, W.M.A.; Tamer, T.M. Preparation, physicochemical characterization and antimicrobial activities of novel two phenolic chitosan Schiff base derivatives. Sci. Rep. 2018, 8, 11416. [Google Scholar] [CrossRef]

- El Hamdaoui, L.; El Marouani, M.; El Bouchti, M.; Kifani-Sahban, F.; El Moussaouiti, M. Thermal Stability, Kinetic Degradation and Lifetime Prediction of Chitosan Schiff Bases Derived from Aromatic Aldehydes. ChemistrySelect 2021, 6, 306–317. [Google Scholar] [CrossRef]

- Omer, A.M.; Eweida, B.Y.; Tamer, T.M.; Soliman, H.M.A.; Mohamed, A.S.; Zaatot, A.A.; Mohy-Eldin, M.S. Removal of oil spills by novel developed amphiphilic chitosan-g-citronellal schif base polymer. Sci. Rep. 2021, 11, 19879. [Google Scholar] [CrossRef]

- De Aragão Tavares, E.; de Medeiros, W.M.T.Q.; de Assis Pontes, T.P.; Barbosa, M.M.; de Araújo, A.A.; de Araújo, R.F.; Araújo, R.F.; Figueiredo, J.G.; Leitão, R.C.; Martins, C.d.S.; et al. Chitosan Membrane Modified With a New Zinc(II)-Vanillin Complex Improves Skin Wound Healing in Diabetic Rats. Front. Pharmacol. 2019, 9, 1511. [Google Scholar] [CrossRef]

- Tiew, S.X.; Misran, M. Thermal Properties of Acylated Low Molecular Weight Chitosans. J. Chem. Soc. Pak. 2019, 41, 207–217. [Google Scholar]

- Gavalyan, V.B. Synthesis and characterization of new chitosan-based Schiff base compounds. Carbohydr. Polym. 2016, 145, 37–47. [Google Scholar] [CrossRef]

| Starting Material I | Napht:NH2 | Product Name |

|---|---|---|

| ChitoClear® HQG 10 | 0 II | Chit-1 |

| 1:4 | Napht-Chit-1a | |

| 1:2 | Napht-Chit-1b | |

| 1:1 | Napht-Chit-1c | |

| 2:1 | Napht-Chit-1d | |

| 4:1 | Napht-Chit-1e | |

| ChitoClear® HQG 400 | 0 II | Chit-2 |

| 1:4 | Napht-Chit-2a | |

| 1:2 | Napht-Chit-2b | |

| 1:1 | Napht-Chit-2c | |

| 2:1 | Napht-Chit-2d | |

| 4:1 | Napht-Chit-2e | |

| ChitoClear® HQG 1600 | 0 II | Chit-3 |

| 1:4 | Napht-Chit-3a | |

| 1:2 | Napht-Chit-3b | |

| 1:1 | Napht-Chit-3c | |

| 2:1 | Napht-Chit-3d | |

| 4:1 | Napht-Chit-3e |

| Chitosan Resin | DDA Values Determined through Potentiometric Titration (%) I | ΔDDA (%) III | |

|---|---|---|---|

| Calculated with Equation (1) | Calculated with Equation (2) | ||

| Chit-1 | 70.5 ± 0.2 | 75.1 ± 0.2 | 4.6 ± 0.4 |

| Napht-Chit-1a | 61.0 ± 0.5 | 66.3 ± 0.5 | 5 ± 1 |

| Napht-Chit-1b | 55.5 ± 0.5 | 61.1 ± 0.5 | 6 ± 1 |

| Napht-Chit-1c | 51.5 ± 0.8 | 57.3 ± 0.8 | 6 ± 2 |

| Napht-Chit-1d | 50.8 ± 0.2 | 56.5 ± 0.2 | 5.7 ± 0.4 |

| Napht-Chit-1e | 48.6 ± 0.5 | 54.4 ± 0.5 | 6 ± 1 |

| Chit-2 | 73.2 ± 0.7 | 77.5 ± 0.7 | 4 ± 1 |

| Napht-Chit-2a | 63 ± 1 | 68 ± 1 | 5 ± 2 |

| Napht-Chit-2b | 56 ± 2 | 62 ± 2 | 6 ± 4 |

| Napht-Chit-2c | 50 ± 1 | 56 ± 1 | 6 ± 2 |

| Napht-Chit-2d | 44.9 ± 0.5 II | 50.6 ± 0.5 II | 6 ± 1 |

| Napht-Chit-2e | 42.6 ± 0.2 II | 48.4 ± 0.2 II | 5.8 ± 0.4 |

| Chit-3 | 64.4± 0.2 | 69.5 ± 0.2 | 5.1 ± 0.4 |

| Napht-Chit-3a | 47 ± 1 | 53 ± 1 | 6 ± 2 |

| Napht-Chit-3b | 43.0 ± 0.2 | 48.8 ± 0.2 | 5.8 ± 0.4 |

| Napht-Chit-3c | 40 ± 1 | 46 ± 1 | 6 ± 2 |

| Napht-Chit-3d | 38.2 ± 0.5 | 43.8 ± 0.5 | 6 ± 1 |

| Napht-Chit-3e | 34.8 ± 0.5 | 40.2 ± 0.5 | 5 ± 1 |

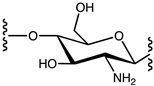

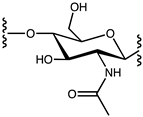

| Monomer | Structure | Molecular Weight (g/mol) |

|---|---|---|

| D-glucosamine |  | 161.16 |

| N-acetyl-glucosamine |  | 203.19 |

| Modified monomer (N-Napht-glucosamine) |  | 299.33 |

| Chitosan Resin | DDA Values Calculated with the New Equation (17) (%) I | ΔDDA (%) Equations (17)–(2) |

|---|---|---|

| Napht-Chit-1a | 68.4 ± 0.3 | 2.1 ± 0.8 |

| Napht-Chit-1b | 64.2 ± 0.3 | 3.1 ± 0.8 |

| Napht-Chit-1c | 61.1 ± 0.6 | 4 ± 1 |

| Napht-Chit-1d | 60.4 ± 0.2 | 3.9 ± 0.4 |

| Napht-Chit-1e | 58.6 ± 0.4 | 4.2 ± 0.9 |

| Napht-Chit-2a | 70.7 ± 0.8 | 3 ± 2 |

| Napht-Chit-2b | 65 ± 1 | 3 ± 3 |

| Napht-Chit-2c | 60.6 ± 0.8 | 5 ± 2 |

| Napht-Chit-2d | 55.8 ± 0.4 II | 5.2 ± 0.9 |

| Napht-Chit-2e | 53.8 ± 0.2 II | 5.4 ± 0.4 |

| Napht-Chit-3a | 56.2 ± 0.7 | 3 ± 2 |

| Napht-Chit-3b | 52.6 ± 0.1 | 3.8 ± 0.3 |

| Napht-Chit-3c | 50 ± 1 | 4 ± 2 |

| Napht-Chit-3d | 48.2 ± 0.4 | 4.4 ± 0.9 |

| Napht-Chit-3e | 44.9 ± 0.4 | 4.7 ± 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amamou, O.; Kefil, S.; Denis, J.-P.; Boubaker, T.; Cardinal, S. Revisiting the Determination of the Degree of Deacetylation Using Potentiometric Titration: A New Equation for Modified Chitosan. Molecules 2024, 29, 2962. https://doi.org/10.3390/molecules29132962

Amamou O, Kefil S, Denis J-P, Boubaker T, Cardinal S. Revisiting the Determination of the Degree of Deacetylation Using Potentiometric Titration: A New Equation for Modified Chitosan. Molecules. 2024; 29(13):2962. https://doi.org/10.3390/molecules29132962

Chicago/Turabian StyleAmamou, Ons, Sarah Kefil, Jean-Philippe Denis, Taoufik Boubaker, and Sébastien Cardinal. 2024. "Revisiting the Determination of the Degree of Deacetylation Using Potentiometric Titration: A New Equation for Modified Chitosan" Molecules 29, no. 13: 2962. https://doi.org/10.3390/molecules29132962

APA StyleAmamou, O., Kefil, S., Denis, J.-P., Boubaker, T., & Cardinal, S. (2024). Revisiting the Determination of the Degree of Deacetylation Using Potentiometric Titration: A New Equation for Modified Chitosan. Molecules, 29(13), 2962. https://doi.org/10.3390/molecules29132962