Transparent Wood Fabrication and Applications: A Review

Abstract

:1. Introduction

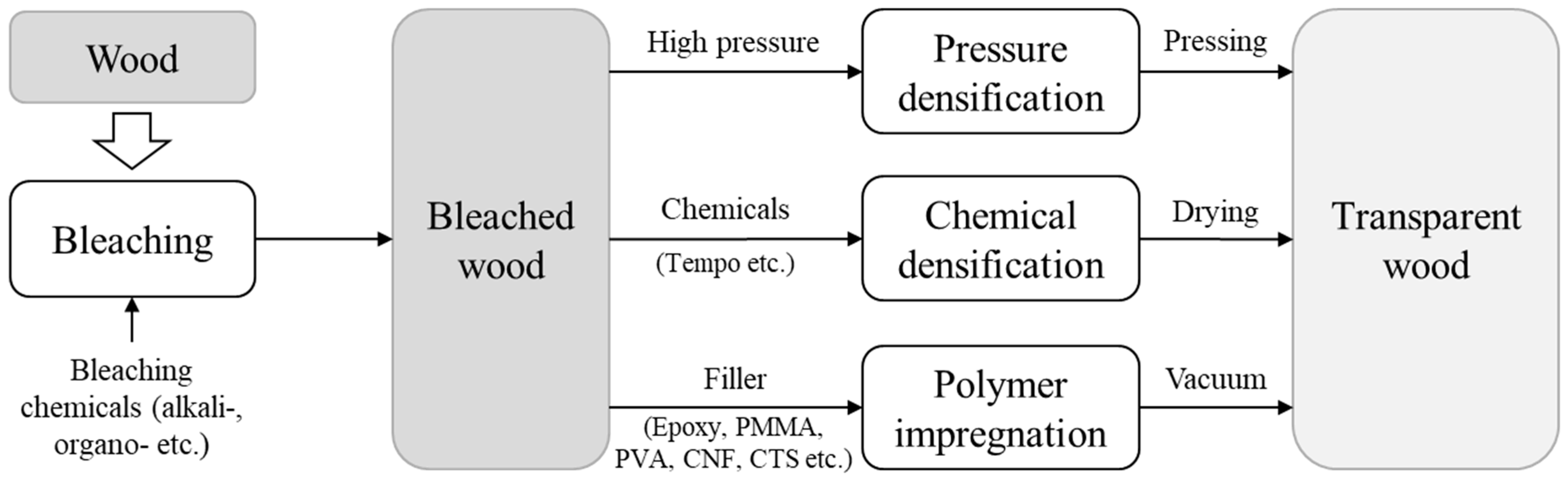

2. Review of the Fabrication Process of TW

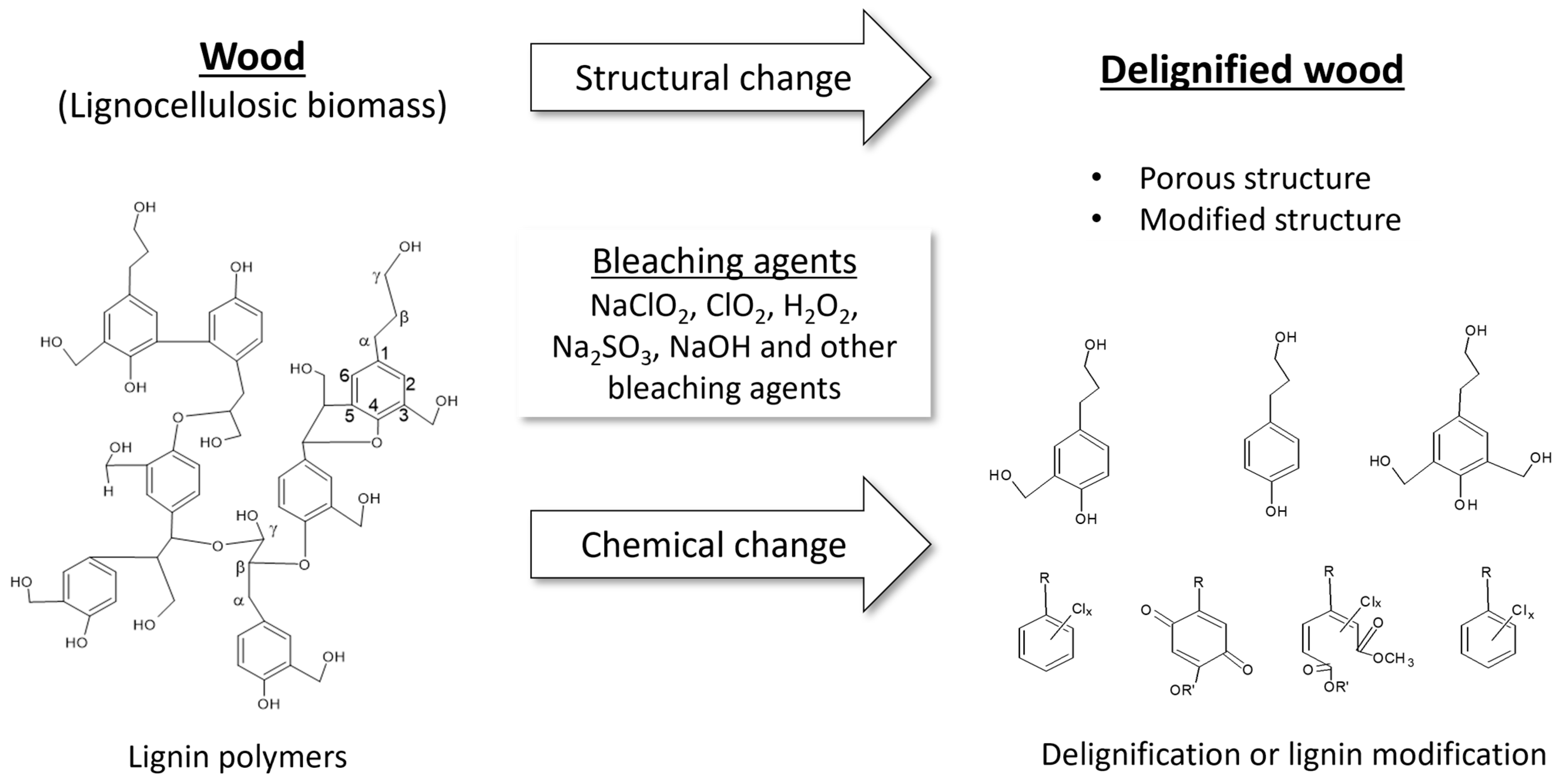

2.1. Bleaching and Delignification

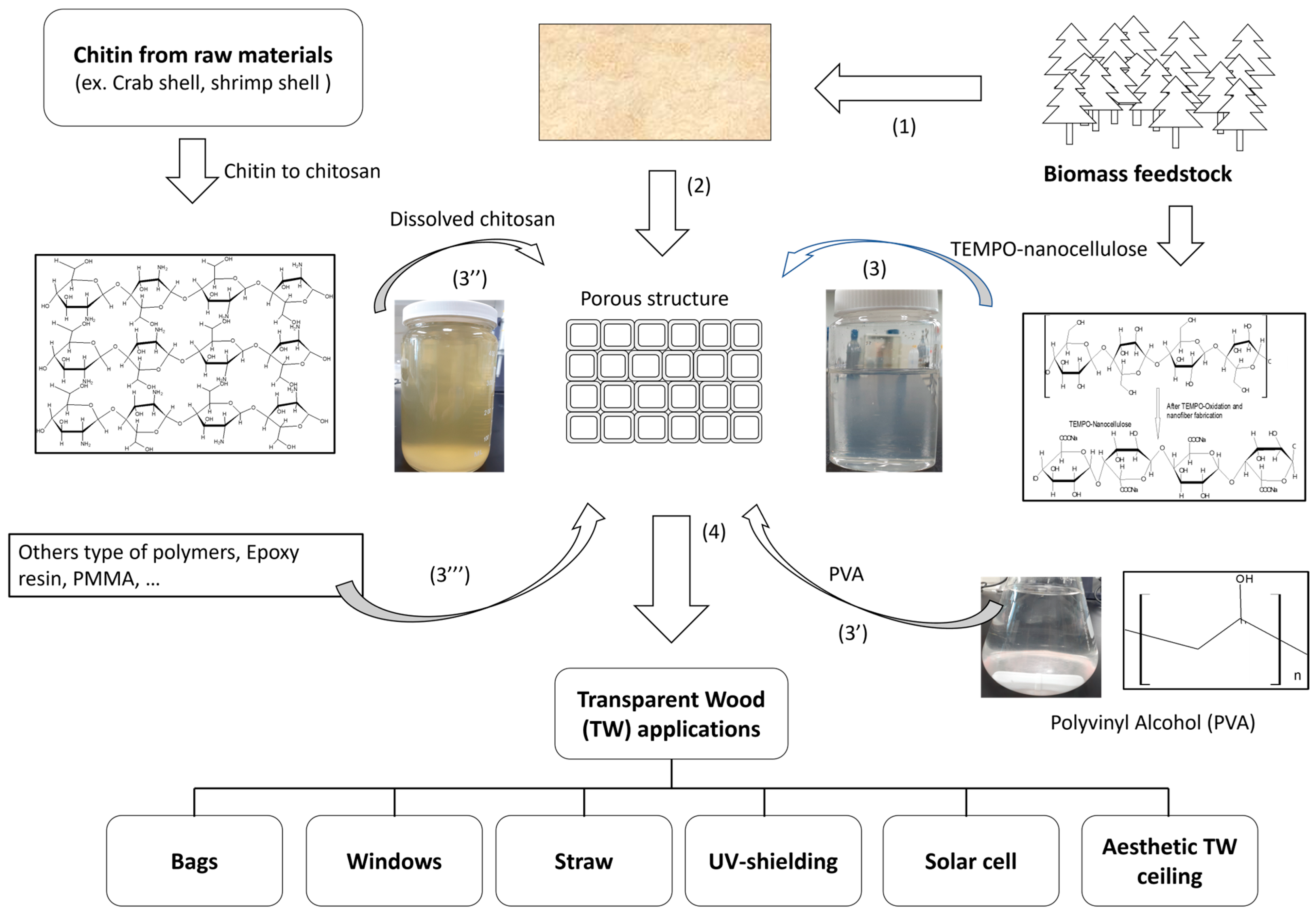

2.2. Impregnation of Bleached Wood with Various Polymers

2.2.1. Previous Approaches of Impregnation Process

2.2.2. Pressurization of Delignified Wood

2.2.3. Polymer Infiltration

2.2.4. Self-Densified TW

3. Physical Properties of TW

3.1. Optical Transmittance and Haziness

3.2. UV-Shielding Properties

3.3. Density, Modulus, Strength, and Toughness

3.4. Thermal Conductivity

4. Factors Affecting Optical and Mechanical Properties of TW

5. Potential Applications of TW

5.1. TW for Building and House Structure

5.2. Light Management, House Decoration, Solar Cells and Electric Devices

5.3. TW as Green Bio-Based Packaging Materials

5.4. Patents on TW

5.5. Future Trends and Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, T.; Zhu, M.W.; Yang, Z.; Song, J.W.; Dai, J.Q.; Yao, Y.G.; Luo, W.; Pastel, G.; Yang, B.; Hu, L.B. Wood Composite as an Energy Efficient Building Material: Guided Sunlight Transmittance and Effective Thermal Insulation. Adv. Energy Mater. 2016, 6, 1601122. [Google Scholar] [CrossRef]

- Yaddanapudi, H.S.; Hickerson, N.; Saini, S.; Tiwari, A. Fabrication and characterization of transparent wood for next generation smart building applications. Vacuum 2017, 146, 649–654. [Google Scholar] [CrossRef]

- Li, Y.; Vasileva, E.; Sychugov, I.; Popov, S.; Berglund, L. Optically transparent wood: Recent progress, opportunities, and challenges. Adv. Opt. Mater. 2019, 6, 1800059. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, M.; Jungstedt, E.; Xu, B.; Sun, L.; Berglund, L. Optically transparent wood substrate for perovskite solar cells. ACS Sustain. Chem. Eng. 2019, 7, 6061–6067. [Google Scholar] [CrossRef]

- Li, H.; Guo, X.; He, Y.; Zheng, R. House model with 2–5 cm thick translucent wood walls and its indoor light performance. Eur. J. Wood Wood Prod. 2019, 77, 843–851. [Google Scholar] [CrossRef]

- Fu, Q.L.; Yan, M.; Jungstedt, E.; Yang, X.; Li, Y.Y.; Berglund, L.A. Transparent plywood as a load-bearing and luminescent biocomposite. Compos. Sci. Technol. 2018, 164, 296–303. [Google Scholar] [CrossRef]

- Qiu, Z.; Xiao, Z.; Gao, L.; Li, J.; Wang, H.; Wang, Y.; Xie, Y. Transparent wood bearing a shielding effect to infrared heat and ultraviolet via incorporation of modified antimony-doped tin oxide nanoparticles. Compos. Sci. Technol. 2019, 172, 43–48. [Google Scholar] [CrossRef]

- Hai, L.V.; Cho, S.W.; Kwon, G.J.; Lee, D.Y.; Ma, S.Y.; Bandi, R.; Kim, J.K.; Han, S.Y.; Dadigala, R.; Lee, S.H. Fabrication of eco-friendly transparent wood for UV-shielding functionality. Ind. Crop. Prod. 2023, 201, 116918. [Google Scholar] [CrossRef]

- Hai, L.V.; Hoa, P.D.; Kim, J.; Lee, S.H. All-biobased multilayer transparent wood infiltrated with cellulose and chitosan nanofibers: Improving anisotropic mechanical and ultraviolet shielding properties. Ind. Crop. Prod. 2024, 222, 119508. [Google Scholar] [CrossRef]

- Mi, R.Y.; Chen, C.J.; Keplinger, T.; Pei, Y.; He, S.M.; Liu, D.P.; Li, J.G.; Dai, J.Q.; Hitz, E.; Yang, B.; et al. Scalable aesthetic transparent wood for energy efficient buildings. Nat. Commun. 2020, 11, 3836. [Google Scholar] [CrossRef]

- Fink, S. Transparent wood—A new approach in the functional study of wood structure. Holzforschung 1992, 46, 403–408. [Google Scholar] [CrossRef]

- Katunský, D.; Kanócz, J.; Karľa, V. Structural elements with transparent wood in architecture. Int. Rev. Appl. Sci. Eng. 2018, 9, 101–106. [Google Scholar] [CrossRef]

- Mi, R.; Li, T.; Dalgo, D.; Chen, C.; Kuang, Y.; He, S.; Zhao, X.; Xie, W.; Gan, W.; Zhu, J. A clear, strong, and thermally insulated transparent wood for energy efficient windows. Adv. Funct. Mater. 2020, 30, 1907511. [Google Scholar] [CrossRef]

- Hai, L.V.; Muthoka, R.M.; Panicker, P.S.; Agumba, D.O.; Pham, H.D.; Kim, J. All-biobased transparent-wood: A new approach and its environmental-friendly packaging application. Carbohyd. Polym. 2021, 264, 118012. [Google Scholar] [CrossRef]

- Qin, J.; Li, X.; Shao, Y.; Shi, K.; Zhao, X.; Feng, T.; Hu, Y. Optimization of delignification process for efficient preparation of transparent wood with high strength and high transmittance. Vacuum 2018, 158, 158–165. [Google Scholar] [CrossRef]

- Li, Y.Y.; Fu, Q.L.; Rojas, R.; Yan, M.; Lawoko, M.; Berglund, L. Lignin-Retaining Transparent Wood. Chemsuschem 2017, 10, 3445–3451. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.M.; Wu, Y.; Yang, F.; Tang, C.Y.; Huang, Q.T.; Zhang, J.L. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A Appl. Sci. Manuf. 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.C.; Huang, Q.T.; Yang, F.; Wang, Y.J.; Wang, J. Study on the Properties of Partially Transparent Wood under Different Delignification Processes. Polym. Basel 2020, 12, 661. [Google Scholar] [CrossRef]

- Montanari, C.l.; Li, Y.; Chen, H.; Yan, M.; Berglund, L.A. Transparent wood for thermal energy storage and reversible optical transmittance. ACS Appl. Mater. Interfaces 2019, 11, 20465–20472. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Baitenov, A.; Li, Y.; Vasileva, E.; Popov, S.; Sychugov, I.; Yan, M.; Berglund, L. Thickness dependence of optical transmittance of transparent wood: Chemical modification effects. ACS Appl. Mater. Interfaces 2019, 11, 35451–35457. [Google Scholar] [CrossRef]

- Zhu, M.W.; Song, J.W.; Li, T.; Gong, A.; Wang, Y.B.; Dai, J.Q.; Yao, Y.G.; Luo, W.; Henderson, D.; Hu, L.B. Highly Anisotropic, Highly Transparent Wood Composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.L.; Dong, Y.M.; Ling, Z.; Liu, X.R.; Shi, S.Q.; Li, J.Z. Transparent wood developed by introducing epoxy vitrimers into a delignified wood template. Compos. Sci. Technol. 2021, 207, 108690. [Google Scholar] [CrossRef]

- Montanari, C.; Ogawa, Y.; Olsén, P.; Berglund, L.A. High performance, fully bio-based, and optically transparent wood biocomposites. Adv. Sci. 2021, 8, 2100559. [Google Scholar] [CrossRef]

- Zhu, M.W.; Wang, Y.L.; Zhu, S.Z.; Xu, L.S.; Jia, C.; Dai, J.Q.; Song, J.W.; Yao, Y.G.; Wang, Y.B.; Li, Y.F.; et al. Anisotropic, Transparent Films with Aligned Cellulose Nanofibers. Adv. Mater. 2017, 29, 1606284. [Google Scholar] [CrossRef]

- Li, K.; Wang, S.N.; Chen, H.; Yang, X.; Berglund, L.A.; Zhou, Q. Self-Densification of Highly Mesoporous Wood Structure into a Strong and Transparent Film. Adv. Mater. 2020, 32, 2003653. [Google Scholar] [CrossRef]

- Zhou, J.C.; Wang, Y.J.; Wang, J.; Wu, Y. Multilayer Transparent Wood with Log Color Composed of Different Tree Species. ACS Omega 2022, 7, 46303–46310. [Google Scholar] [CrossRef]

- Bisht, P.; Pandey, K.K. Optical and mechanical properties of multilayered transparent wood. Mater. Today Commun. 2024, 38, 107871. [Google Scholar] [CrossRef]

- Rao, A.N.S.; Nagarajappa, G.B.; Nair, S.; Chathoth, A.M.; Pandey, K.K. Flexible transparent wood prepared from poplar veneer and polyvinyl alcohol. Compos. Sci. Technol. 2019, 182, 107719. [Google Scholar] [CrossRef]

- Jia, C.; Chen, C.J.; Mi, R.Y.; Li, T.; Dai, J.Q.; Yang, Z.; Pei, Y.; He, S.M.; Bian, H.Y.; Jang, S.H.; et al. Clear Wood toward High-Performance Building Materials. ACS Nano 2019, 13, 9993–10001. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.C.; Huang, Q.T.; Yang, F.; Wang, Y.J.; Liang, X.M.; Li, J.Z. Study on the Colorimetry Properties of Transparent Wood Prepared from Six Wood Species. ACS Omega 2020, 5, 1782–1788. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, J.M.; Yang, F.; Tang, C.Y.; Huang, Q.T. Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood. Polym. Basel 2019, 11, 776. [Google Scholar] [CrossRef]

- Brogdon, B.N.; Lucia, L.A. New insights into lignin modification during chlorine dioxide bleaching sequences (IV): The impact of modifications in the (EP) and (EOP) stages on the D stage. J. Wood Chem. Technol. 2007, 25, 149–170. [Google Scholar] [CrossRef]

- Tarvo, V.; Lehtimaa, T.; Kuitunen, S.; Alopaeus, V.; Vuorinen, T.; Aittamaa, J. A model for chlorine dioxide delignification of chemical pulp. J. Wood Chem. Technol. 2010, 30, 230–268. [Google Scholar] [CrossRef]

- Elhelece, W.A.; Abousekkina, M.M. Theoretical interpretation of the changes occur on cellulosic wastes as a result of different chemical treatments. Eur. Chem. Bull. 2013, 2, 328–334. [Google Scholar] [CrossRef]

- Xia, Q.Q.; Chen, C.J.; Li, T.; He, S.M.; Gao, J.L.; Wang, X.Z.; Hu, L.B. Solar-assisted fabrication of large-scale, patternable transparent wood. Sci. Adv. 2021, 7, eabd7342. [Google Scholar] [CrossRef]

- Zou, W.H.; Sun, D.L.; Wang, Z.H.; Li, R.Y.; Yu, W.X.; Zhang, P.F. Eco-friendly transparent poplar-based composites that are stable and flexible at high temperature. RSC Adv. 2019, 9, 21566–21571. [Google Scholar] [CrossRef]

- Zhu, M.W.; Li, T.; Davis, C.S.; Yao, Y.G.; Dai, J.Q.; Wang, Y.B.; AlQatari, F.; Gilman, J.W.; Hu, L.B. Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 2016, 26, 332–339. [Google Scholar] [CrossRef]

- Wang, X.; Zhan, T.; Liu, Y.; Shi, J.; Pan, B.; Zhang, Y.; Cai, L.; Shi, S.Q. Large-size transparent wood for energy-saving building applications. Chemsuschem 2018, 11, 4086–4093. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Yao, Y.J.; Yao, J.N.; Zhang, L.M.; Chen, Z.; Gao, Y.F.; Luo, H.J. Transparent wood containing CsWO nanoparticles for heat-shielding window applications. J. Mater. Chem. A 2017, 5, 6019–6024. [Google Scholar] [CrossRef]

- Samanta, A.; Chen, H.; Samanta, P.; Popov, S.; Sychugov, I.; Berglund, L.A. Reversible dual-stimuli-responsive chromic transparent wood biocomposites for smart window applications. ACS Appl. Mater. Interfaces 2021, 13, 3270–3277. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, S.; Wang, Y.; Li, J.; Xiao, Z.; Wang, H.; Liang, D.; Xie, Y. Transparent wood with thermo-reversible optical properties based on phase-change material. Compos. Sci. Technol. 2020, 200, 108407. [Google Scholar] [CrossRef]

- Jungstedt, E.; Montanari, C.; Östlund, S.; Berglund, L. Mechanical properties of transparent high strength biocomposites from delignified wood veneer. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105853. [Google Scholar] [CrossRef]

- Lang, A.W.; Li, Y.Y.; De Keersmaecker, M.; Shen, D.E.; Österholm, A.M.; Berglund, L.; Reynolds, J.R. Transparent Wood Smart Windows: Polymer Electrochromic Devices Based on Poly(3,4-Ethylenedioxythiophene):Poly(Styrene Sulfonate) Electrodes. Chemsuschem 2018, 11, 854–863. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.Y.; Fu, Q.L.; Yu, S.; Yan, M.; Berglund, L. Optically Transparent Wood from a Nanoporous Cellulosic Template: Combining Functional and Structural Performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef]

- Zhang, K.; Sutton, I.; Smith, M.D.; Harper, D.P.; Wang, S.; Wu, T.; Li, M. Ambient-densified and polymer-free transparent wood film for smart food packaging window. IScience 2023, 26, 108455. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, M.; Li, T.; Gong, A.S.; Jianwei, S. Transparent Wood Composite, Systems and Method of Fabrication. WO2017136714A1, 3 February 2017. [Google Scholar]

- Li, Y.; Rojas, R.; Berglund, L. Transparent Wood and a Method for Its Preparation. AU2018245016B2, 29 March 2018. [Google Scholar]

| Wood Species; Size (W:L:T) | Bleaching Agents and Delignification | References |

|---|---|---|

| Poplar veneer; 80:80:3 mm3 | KOH (>98%) and DI water followed by NaClO (>98%) for 8 h at 120–130 °C. The amount of lignin content before and after bleaching is not indicated. | [36] |

| Basswood | Boiling with NaOH (2.5 mol L−1) and Na2SO3 (0.4 mol L−1) for 12 h. Second Step: H2O2, 2.5 mol L−1 for 12 h. In the first stage, lignin content = ~12–14%; second stage, the lignin content ≤ 3.0%. | [21] |

| Basswood | Soaking in NaOH (2.5 mol/L) and Na2SO3 (0.4 mol/L). Boiling for 12 h. Bleaching with H2O2, (2.5 mol/L). This resulted in 33%, 50%, and nearly 100% lignin removal. | [37] |

| Poplar (Populus sp.) and Balsa wood. Width (80–300 mm), Length from 25 to 300 mm and thickness from 1–10 mm | NaOH (10 wt%) and Na2SO3 (5 wt%) boiling for 2–4 h, followed by boiling in DI water. Further whitening using H2O2 (30 wt%) in boiling. The lignin content is ~2.8%. | [38] |

| Balsa (Ochroma pyramidale), alder (Alnus glutinosa), birch (Betula pendula), and beech (Fagus sylvestris); 0.7–3 mm thickness | Peracetic acid (PAA) and CH3COOOH. Treated at 80 °C using aqueous PAA solution (4 wt%) at a pH of 4. 8 (adjusted with NaOH), followed by washing with DI water and acetone. Lignin removal from 18.2% to 27.9% of untreated to 0.9 to 2.0% of treated biomass. | [23] |

| Basswood (Tilia); 20:20:0.42 mm3 | 2.0 wt% NaClO2 and 0.1 wt% acetic acid glacial, bleaching time for 30, 60, 90, 120, and 150 min. This resulted in lignin removal of 33, 38, 47, 51, and 64%, with treatment time of 30, 60, 90, 120, and 150 min, respectively. | [17] |

| Basswood (Tilia); 20:20:0.42 mm3 | 6.0 wt% H2O2, 1.0 wt% trisodium citrate 95% dihydrate, 1.0 wt% of NaOH, and 92 wt%. Bleaching time of 30, 60, 90, 120, and 150 min, and lignin content varied from 24.3, 19.5, 18.4, 16.6, 15.2 and 14.9 wt%. | [30] |

| Beechwood | NaClO2 (5.0 wt%) in acetate buffer solution at 95 °C for 12 h. The lignin content was not indicated. | [2] |

| Birch (Betula alnoides, Betula) and New Zealand pine (Pinups radiata D. Don); 20:20:0.5 mm3 | NaClO2 (0.4–1.0%) at 70–90 °C for 45–135 min. The pH 4.6 was adjusted by adding CH3COOH. | [18] |

| Wood Species | Fabrication Method and Filler (Polymer) | Applications | Ref. |

|---|---|---|---|

| Basswood | 15 wt% Polyvinylpyrrolidone (PVP) ethanol. Degassed under 200 Pa for ~10 min | Highly efficient broadband light management in solar cells | [37] |

| Poplar (Populus sp.) and Balsa wood | Impregnation using vacuum infiltration process with prepolymerized MMA solution (PMMA) | TW for Energy-saving building | [38] |

| Silver birch wood (Betula pendula) | Impregnation using vacuum infiltration with PEG/MMA (70/30 wt%) solution | Thermal energy storage and reversible optical transmittance | [19] |

| Balsa wood | Impregnation using vacuum infiltration with polyvinyl alcohol (PVA) solution | Thermally insulated TW for energy-efficient windows | [13] |

| Douglas fir, Bass, Balsa, and Pinewood | Infiltration into the delignified wood scaffold using epoxy resin, followed by solidification for 24 h | Aesthetic TW for energy-efficient buildings | [10] |

| Basswood | Impregnation with 2 epoxy resins (E-128 resin and D-630) at a mass ratio of 3:1 | Thick translucent wood walls and indoor light performance | [5] |

| Balsa wood | Infiltration using poly-methyl methacrylate (PMMA) and laser deposition for conductive film layer using indium tin oxide (ITO). | TW substrate for perovskite solar cells | [4] |

| Beechwood | Impregnation using vacuum infiltration with poly methyl methacrylate (PMMA) for 1 h with three repetitions, followed by heat treatment in a box furnace at 85 °C for 12 h | Next-generation smart building materials | [2] |

| Beechwood | Impregnation using vacuum infiltration with CsxWO3/prepolymerized methyl methacrylate (MMA) mixed solution, followed by infiltration for 30 min with three repetitions | TW containing CsxWO3 nanoparticles for heat-shielding-window | [39] |

| Fir wood | Impregnation using vacuum infiltration with TEMPO-treated nanocellulose and chitosan solution | Food packaging materials, medical packaging materials, and straw | [14] |

| Balsa wood | Impregnation using vacuum infiltration with PVA, PVA-lignin nanoparticle | UV-shielding windows application | [8] |

| Name of Wood | Wood Sizes (mm) | Bleaching Agents | Polymer | Tensile Strength (MPa) | Young’s Modulus (GPa) | Transmittance (%) | Ref. |

|---|---|---|---|---|---|---|---|

| Beechwood | T: 0.1–0.7 | NaClO2 | PMMA | NW: 220 DL: 75 TW: 150 | NW: 1.52 DL: 2.5 TW: 2.1 | >10–70 | [2] |

| Douglas fir (Pseudotsuga menziesii) | 320 × 170 T: 0.6–2 | NaClO2 | Epoxy resin | NW⊥: 6.24 NW//: N/A TW⊥: 21.6 TW//: 92 | N/A | >80 | [10] |

| Balsa wood (Ochroma pyramidale) | 20 × 20 T: 0.7–3.7 | NaClO2 | PMMA | NW: N/A DL: 10 TW: 95 | NW: N/A DL: 0.22 T: 2.05 | 40–90 | [1] |

| Pine, birch, and ash wood veneer | 100 × 100 T: 1.5 | H2O2, NaClO2 | PMMA | 100.7 | N/A | 80 | [16] |

| Basswood | 50 × 50 T: 3 | NaOH; Na2SiO3, H2O2 | Epoxy resin | NW⊥: <5 NW//: <45 TW⊥: <23.4 TW//: 45.4 | NW⊥: N/A NW//: N/A T⊥: 1.22 T//: 2.37 | 80–90 | [21] |

| Balsa wood | 20 × 40 T: 0.8 | NaClO | Polyvinyl alcohol (PVA) | NW⊥: 1.15 NW//: 18.8 TW⊥: 67 TW//: 143 | N/A | 90 | [10] |

| Poplar wood (Populus deltoides) | 20 × 20 T: 1 | NaOH, Na2EDTA, MgSO4, and H2O2 | PVA and PG | NW: 61.5 LMW: 33.3 T-PG0: 39.9 T-PG50: 22.6 T-PG100: 13.3 | NW: 1.98 LMW: 1.49 T-PG0: 1.51 T-PG50: 0.80 T-PG100: 0.26 | 65–80 | [28] |

| Basswood | T: ∼0.7 | NaClO, NaClO2 | Epoxy resin | NW⊥: 8.5 NW//: 55 TW⊥: 33.3 TW//: 44.4 | N/A | 90 | [29] |

| Poplar wood (P. adenopoda Maxim) | 25 × 25 and 50 × 50 T: 1 | NaClO2 | ATO/PMMA | NW: 78.3 DL: 21.9: T: 93.0 ATO0.3–0.7T: 96.4–113.1 | NW: 3.74 DL: 1.71 T: 3.38 ATO0.3–0.7 T: 4.27–4.46 | 45–80 | [7] |

| Silver birch wood (Betula pendula) | 20 × 20; 20 × 20 T: 0.5–1.5 | NaClO2 | PEG/PMMA | NW: 129.6 TW-TES: 70.5 | NW:14.5 T: 14.9 | 60–80 | [19] |

| Balsa wood (Ochroma pyramidale) | 20 × 20 T: 1, 1.5, 2, and 5 | NaClO2 | Epoxy resin | NW⊥: 1.02 NW//: 12.01 TW⊥: 4.12–63.05 TW//: 45.12–75.12 | N/A | 10–80 | [15] |

| Basswood (Tilia) | 20 × 20 T: 0.42 | NaClO2 | PMMA | NW: 121.9 DL: 84–8-114.3 TW: 152.4–171.4 | N/A | 10–60 | [17] |

| Fir | 100 × 100 100 × 200 T: 0.1 | NaClO2 | Cellulose nanofiber, Chitosan | NW⊥: 1 NW//: 75 TW⊥: 26 TW//: 258 TW⊥: 26 TW//: 171 | 15 13 | 75–80 | [14] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hai, L.V.; Srikanth, N.; Le, T.D.T.; Park, S.H.; Kim, T.H. Transparent Wood Fabrication and Applications: A Review. Molecules 2025, 30, 1506. https://doi.org/10.3390/molecules30071506

Hai LV, Srikanth N, Le TDT, Park SH, Kim TH. Transparent Wood Fabrication and Applications: A Review. Molecules. 2025; 30(7):1506. https://doi.org/10.3390/molecules30071506

Chicago/Turabian StyleHai, Le Van, Narayanan Srikanth, Tin Diep Trung Le, Seung Hyeon Park, and Tae Hyun Kim. 2025. "Transparent Wood Fabrication and Applications: A Review" Molecules 30, no. 7: 1506. https://doi.org/10.3390/molecules30071506

APA StyleHai, L. V., Srikanth, N., Le, T. D. T., Park, S. H., & Kim, T. H. (2025). Transparent Wood Fabrication and Applications: A Review. Molecules, 30(7), 1506. https://doi.org/10.3390/molecules30071506