Tissue Engineering Challenges for Cultivated Meat to Meet the Real Demand of a Global Market

Abstract

1. Introduction

2. The Cultivated Meat Market

2.1. The Global Market

2.2. Regulatory Aspects

3. Challenges to Overcome

3.1. Consumer Acceptance

3.2. Food Safety

3.3. Reproducibility

3.4. Scalability

3.5. Animal-Free Medium

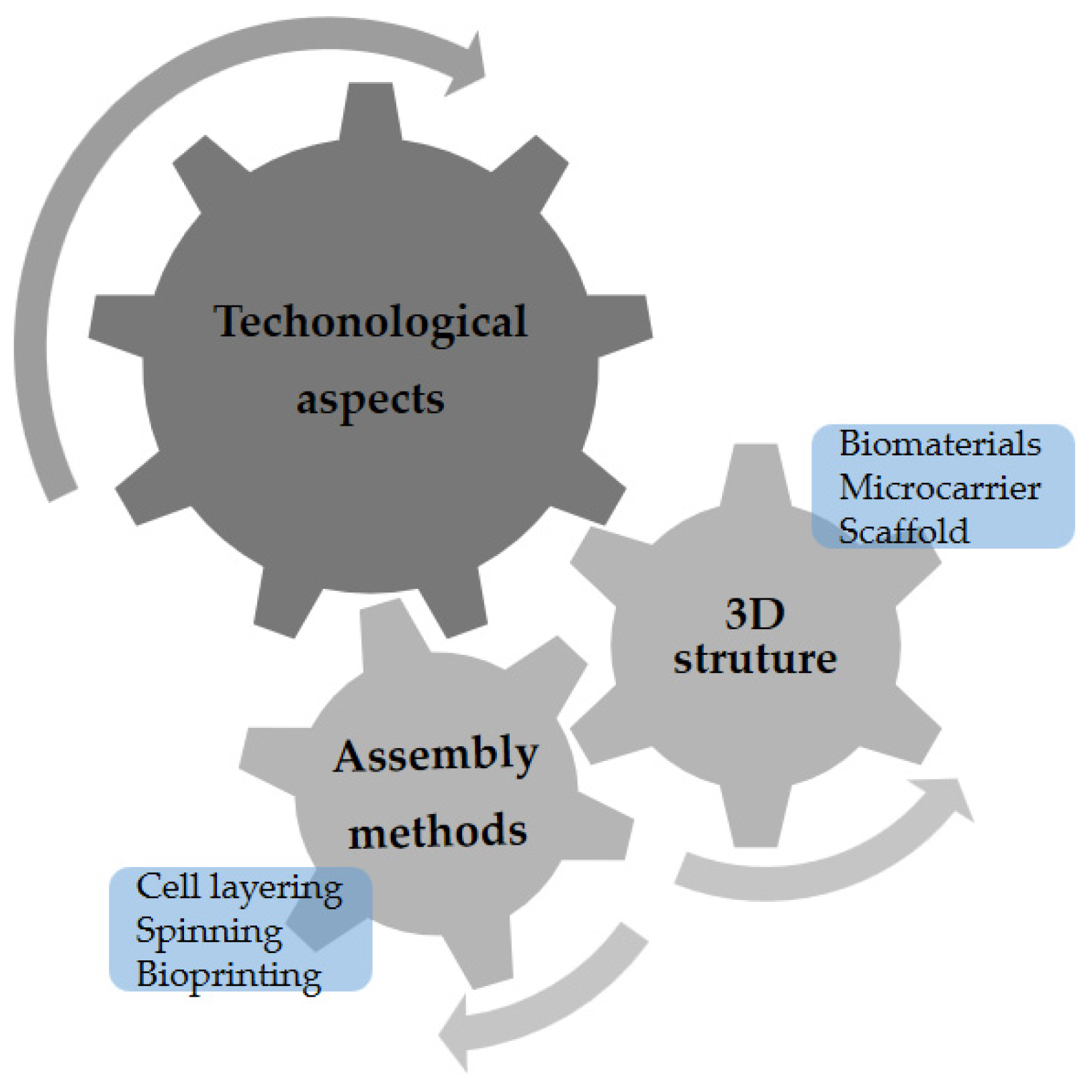

4. Three-Dimensional Models for Cultivated Meat Production: Technological Aspects

4.1. Biomaterials

4.2. Microcarriers

4.3. Scaffolds

5. Assembly Methods

5.1. Cell Layering or Self-Assembly

5.2. Spinning

5.3. Bioprinting

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ianovici, I.; Zagury, Y.; Redenski, I.; Lavon, N.; Levenberg, S. 3D-printable plant protein-enriched scaffolds for cultivated meat development. Biomaterials 2022, 284, 121487. [Google Scholar] [CrossRef]

- Stephens, N.; Ellis, M. Cellular agriculture in the UK: A review. Wellcome Open Res. 2020, 5, 12. [Google Scholar] [CrossRef] [PubMed]

- Seah, J.S.H.; Singh, S.; Tan, L.P.; Choudhury, D. Scaffolds for the manufacture of cultured meat. Crit. Rev. Biotechnol. 2022, 42, 311–323. [Google Scholar] [CrossRef] [PubMed]

- Reiss, J.; Robertson, S.; Suzuki, M. Cell Sources for Cultivated Meat: Applications and Considerations throughout the Production Workflow. Int. J. Mol. Sci. 2021, 22, 7513. [Google Scholar] [CrossRef] [PubMed]

- O’Neill, E.N.; Cosenza, Z.A.; Baar, K.; Block, D.E. Considerations for the development of cost-effective cell culture media for cultivated meat production. Compr. Rev. Food Sci. Food Saf. 2021, 20, 686–709. [Google Scholar] [CrossRef]

- Jo, B.; Nie, M.; Takeuchi, S. Manufacturing of animal products by the assembly of microfabricated tissues. Essays Biochem. 2021, 65, 611–623. [Google Scholar] [CrossRef]

- Schätzlein, E.; Blaeser, A. Recent trends in bioartificial muscle engineering and their applications in cultured meat, biorobotic systems and biohybrid implants. Commun. Biol. 2022, 5, 737. [Google Scholar] [CrossRef]

- Corsato, B.; Gallon, V. Setor de Proteínas Alternativas Recebeu Investimento Recorde de $5 Bilhões em 2021, 60% a Mais do que em 2020. Available online: https://gfi.org.br/2022/03/21/setor-de-proteinas-alternativas-recebeu-investimento-recorde-de-5-bilhoes-em-2021-60-a-mais-do-que-em-2020/ (accessed on 24 April 2022).

- Mosa Meat. Our Progress so Far; Mosa Meat: San Leandro, CA, USA, 2022. [Google Scholar]

- GFI. 2021 State of the Industry Report. Cultivated Meat and Seafood. 2022. Available online: https://gfi.org/resource/cultivated-meat-eggs-and-dairy-state-of-the-industry-report/ (accessed on 6 October 2022).

- Food Ingridedients First. Upside Foods Raises US$400M to Commercialize Cell-Based Meat at Scale. 2022. Available online: https://www.foodingredientsfirst.com/news/upside-foods-raises-us400m-to-commercialize-cell-based-meat-at-scale.html (accessed on 19 September 2022).

- Vegconomist. Israeli Government Grants $18M to Cultivated Meat Consortium in ‘Unprecedented’ Move. 2022. Available online: https://vegconomist.com/cultivated-cell-cultured-biotechnology/cultivated-meat/cultivated-meat-consortium/ (accessed on 19 September 2022).

- Green Queen. Israel’s Cultivated Meat Consortium Gets Green Light and $18 Million From Government. 2022. Available online: https://www.greenqueen.com.hk/israels-cultivated-meat-consortium-given-green-light/ (accessed on 19 September 2022).

- Vegaconomist. Cultured Meat in Europe: Which Country Is Leading the Race? 2022. Available online: https://vegconomist.com/cultivated-cell-cultured-biotechnology/cultured-meat-in-europe-which-country-is-leading-the-race/ (accessed on 19 September 2022).

- Valdes, C. Brazil’s Momentum as a Global Agricultural Supplier Faces Headwinds. In Amber Waves: The Economics of Food, Farming, Natural Resources, and Rural America 2022; AgEcon: St. Paul, MN, USA, 2022. [Google Scholar] [CrossRef]

- Abras. JBS Investe Pesado Em Carne de Laboratório. 2022. Available online: https://www.abras.com.br/clipping/carnes-peixes/110871/jbs-investe-pesado-em-carne-de-laboratorio (accessed on 24 November 2022).

- Food Connection. Carne Cultivada Em Laboratório Deve Chegar Ao Mercado Brasileiro Em 2024. 2022. Available online: https://www.foodconnection.com.br/ingredientes/carne-cultivada-em-laboratorio-deve-chegar-ao-mercado-brasileiro-em-2024 (accessed on 24 November 2022).

- Ambi Real Food. Somos a Primeira Start up de Carne Cultivada Brasileira! 2022. Available online: https://ambirealfood.com/ (accessed on 25 April 2022).

- Sustineri PiscisSustineri Piscis Aquicultura Celular. 2022. Available online: https://sustineripiscis.com/#home (accessed on 24 November 2022).

- Green Queen. A Year After Historic Cultivated Meat Approval, Singapore Regulator Greenlights More Eat Just Products. 2021. Available online: https://www.greenqueen.com.hk/eat-just-cultivated-meat-regulatory-approval-singapore/ (accessed on 19 September 2022).

- Smart Brief Cultured Meat Could Come further out of the Lab in 2022. 2022. Available online: https://corp.smartbrief.com/original/2022/05/cultured-meat-could-come-further-out-of-the-lab-in-2022 (accessed on 19 September 2022).

- FDA. FDA Completes First Pre-Market Consultation for Human Food Made Using Animal Cell Culture Technology; FDA: Silver Spring, MD, USA, 2022.

- Vegaconomist. South Korea’s National Plan 2022 to Include Cultivated Meat Regulatory Approval Guidance. 2022. Available online: https://vegconomist.com/politics-law/south-koreas-national-plan-alt-protein/ (accessed on 19 September 2022).

- GFI Brasil. Estudo Regulatório Sobre Proteínas Alternativas No Brasil—Proteínas Vegetais. 2022. Available online: http://gfi.org.br/resources/estudo-regulatorio-sobre-proteinas-alternativas-no-brasil-proteinas-vegetais-2/ (accessed on 5 October 2022).

- Szejda, K.; Bryant, C.J.; Urbanovich, T. US and UK Consumer Adoption of Cultivated Meat: A Segmentation Study. Foods 2021, 10, 1050. [Google Scholar] [CrossRef] [PubMed]

- Bryant, C.; Barnett, J. Consumer Acceptance of Cultured Meat: An Updated Review (2018–2020). Appl. Sci. 2020, 10, 5201. [Google Scholar] [CrossRef]

- Valente, J.d.P.S.; Fiedler, R.A.; Sucha Heidemann, M.; Molento, C.F.M. First glimpse on attitudes of highly educated consumers towards cell-based meat and related issues in Brazil. PLoS ONE 2019, 14, e0221129. [Google Scholar] [CrossRef]

- Ng, S.; Kurisawa, M. Integrating biomaterials and food biopolymers for cultured meat production. Acta Biomater. 2021, 124, 108–129. [Google Scholar] [CrossRef]

- Soice, E.; Johnston, J. Immortalizing Cells for Human Consumption. Int. J. Mol. Sci. 2021, 22, 11660. [Google Scholar] [CrossRef] [PubMed]

- Treich, N. Cultured Meat: Promises and Challenges. Environ. Resour. Econ. 2021, 79, 33–61. [Google Scholar] [CrossRef] [PubMed]

- Pajčin, I.; Knežić, T.; Savic Azoulay, I.; Vlajkov, V.; Djisalov, M.; Janjušević, L.; Grahovac, J.; Gadjanski, I. Bioengineering Outlook on Cultivated Meat Production. Micromachines 2022, 13, 402. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, M.A.; Mesnage, R.; Tsatsakis, A.M.; Golokhvast, K.S.; Yang, S.H.; Antoniou, M.N.; Chung, G. Addressing concerns over the fate of DNA derived from genetically modified food in the human body: A review. Food Chem. Toxicol. 2019, 124, 423–430. [Google Scholar] [CrossRef]

- Knudtson, K.L.; Carnahan, R.H.; Hegstad-Davies, R.L.; Fisher, N.C.; Hicks, B.; Lopez, P.A.; Meyn, S.M.; Mische, S.M.; Weis-Garcia, F.; White, L.D.; et al. Survey on Scientific Shared Resource Rigor and Reproducibility. J. Biomol. Tech. 2019, 30, 36–44. [Google Scholar] [CrossRef]

- Baker, M. 1500 scientists lift the lid on reproducibility. Nature 2016, 533, 452–454. [Google Scholar] [CrossRef]

- Hildebrandt, T.; Prenoveau, J.M. Rigor and reproducibility for data analysis and design in the behavioral sciences. Behav. Res. Ther. 2020, 126, 103552. [Google Scholar] [CrossRef]

- Merz, K.M.; Amaro, R.; Cournia, Z.; Rarey, M.; Soares, T.; Tropsha, A.; Wahab, H.A.; Wang, R. Editorial: Method and Data Sharing and Reproducibility of Scientific Results. J. Chem. Inf. Model. 2020, 60, 5868–5869. [Google Scholar] [CrossRef]

- Ng, E.T.; Singh, S.; Yap, W.S.; Tay, S.H.; Choudhury, D. Cultured meat—A patentometric analysis. Crit. Rev. Food Sci. Nutr. 2021, 1–11. [Google Scholar] [CrossRef]

- Bellani, C.F.; Ajeian, J.; Duffy, L.; Miotto, M.; Groenewegen, L.; Connon, C.J. Scale-Up Technologies for the Manufacture of Adherent Cells. Front. Nutr. 2020, 7, 575146. [Google Scholar] [CrossRef] [PubMed]

- Stout, A.J.; Mirliani, A.B.; Rittenberg, M.L.; Shub, M.; White, E.C.; Yuen, J.S.K.; Kaplan, D.L. Simple and effective serum-free medium for sustained expansion of bovine satellite cells for cell cultured meat. Commun. Biol. 2022, 5, 466. [Google Scholar] [CrossRef]

- Post, M.J.; Levenberg, S.; Kaplan, D.L.; Genovese, N.; Fu, J.; Bryant, C.J.; Negowetti, N.; Verzijden, K.; Moutsatsou, P. Scientific, sustainability and regulatory challenges of cultured meat. Nat. Food 2020, 1, 403–415. [Google Scholar] [CrossRef]

- Gaydhane, M.K.; Mahanta, U.; Sharma, C.S.; Khandelwal, M.; Ramakrishna, S. Cultured meat: State of the art and future. Biomanuf. Rev. 2018, 3, 1. [Google Scholar] [CrossRef]

- Park, Y.H.; Gong, S.P.; Kim, H.Y.; Kim, G.A.; Choi, J.H.; Ahn, J.Y.; Lim, J.M. Development of a serum-free defined system employing growth factors for preantral follicle culture. Mol. Reprod. Dev. 2013, 80, 725–733. [Google Scholar] [CrossRef]

- Freshney, R.I. Defined Media and Supplements. In Culture of Animal Cells; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Brunner, D.; Frank, J.; Appl, H.; Schöffl, H.; Pfaller, W.; Gstraunthaler, G. Serum-free Cell Culture: The Serum-free Media Interactive Online Database. ALTEX 2010, 27, 53–62. [Google Scholar] [CrossRef]

- Lee, D.Y.; Lee, S.Y.; Yun, S.H.; Jeong, J.W.; Kim, J.H.; Kim, H.W.; Choi, J.S.; Kim, G.-D.; Joo, S.T.; Choi, I.; et al. Review of the Current Research on Fetal Bovine Serum and the Development of Cultured Meat. Food Sci. Anim. Resour. 2022, 42, 775–799. [Google Scholar] [CrossRef]

- Kadim, I.T.; Mahgoub, O.; Baqir, S.; Faye, B.; Purchas, R. Cultured meat from muscle stem cells: A review of challenges and prospects. J. Integr. Agric. 2015, 14, 222–233. [Google Scholar] [CrossRef]

- Duque, P.; Gómez, E.; Díaz, E.; Facal, N.; Hidalgo, C.; Díez, C. Use of two replacements of serum during bovine embryo culture in vitro. Theriogenology 2003, 59, 889–899. [Google Scholar] [CrossRef] [PubMed]

- Messmer, T.; Klevernic, I.; Furquim, C.; Ovchinnikova, E.; Dogan, A.; Cruz, H.; Post, M.J.; Flack, J.E. A serum-free media formulation for cultured meat production supports bovine satellite cell differentiation in the absence of serum starvation. Nat. Food 2022, 3, 74–85. [Google Scholar] [CrossRef]

- Chen, G.; Gulbranson, D.R.; Hou, Z.; Bolin, J.M.; Ruotti, V.; Probasco, M.D.; Smuga-Otto, K.; Howden, S.E.; Diol, N.R.; Propson, N.E.; et al. Chemically defined conditions for human iPSC derivation and culture. Nat. Methods 2011, 8, 424–429. [Google Scholar] [CrossRef]

- Thermo Fisher Scientific Essential 8TM Medium; Thermo Fisher Scientific: Waltham, MA, USA, 2022.

- Kolkmann, A.M.; Post, M.J.; Rutjens, M.A.M.; van Essen, A.L.M.; Moutsatsou, P. Serum-free media for the growth of primary bovine myoblasts. Cytotechnology 2020, 72, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Kuo, H.-H.; Gao, X.; DeKeyser, J.-M.; Fetterman, K.A.; Pinheiro, E.A.; Weddle, C.J.; Fonoudi, H.; Orman, M.V.; Romero-Tejeda, M.; Jouni, M.; et al. Negligible-Cost and Weekend-Free Chemically Defined Human iPSC Culture. Stem Cell Rep. 2020, 14, 256–270. [Google Scholar] [CrossRef]

- McAleer, C.W.; Rumsey, J.W.; Stancescu, M.; Hickman, J.J. Functional myotube formation from adult rat satellite cells in a defined serum-free system. Biotechnol. Prog. 2015, 31, 997–1003. [Google Scholar] [CrossRef]

- Can, A.K.; Erikci, E.; Kiran, F. Microbiota-Derived Postbiotics: Alternative Supplement to Fetal Bovine Serum for Cultured Meat. U.S. Patent US20220098546A1, 28 September 2021. [Google Scholar]

- FiGlobal. New Growth Medium Supplement for ‘Clean Meat. 2021. Available online: https://insights.figlobal.com/startups/new-growth-medium-supplement-clean-meat (accessed on 21 August 2022).

- Gupta, S.; Lee, J.J.L.; Chen, W.N. Analysis of Improved Nutritional Composition of Potential Functional Food (Okara) after Probiotic Solid-State Fermentation. J. Agric. Food Chem. 2018, 66, 5373–5381. [Google Scholar] [CrossRef]

- Teng, T.S. Development of Serum Alternative with Fermented Soybean Residue (Okara): Towards Cultured Meat Production Application; Nanyang Technological University: Singapore, 2022. [Google Scholar]

- Straits Times. Saving Soya Pulp for Novel Foods and Aquaculture. 2021. Available online: https://www.straitstimes.com/singapore/environment/saving-soya-pulp-for-novel-foods-and-aquaculture (accessed on 18 October 2022).

- Benjaminson, M.A.; Gilchriest, J.A.; Lorenz, M. In vitro edible muscle protein production system (mpps): Stage 1, fish. Acta Astronaut. 2002, 51, 879–889. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.-Y.; Siu, K.-C.; Geng, P. Bioactive Ingredients and Medicinal Values of Grifola frondosa (Maitake). Foods 2021, 10, 95. [Google Scholar] [CrossRef]

- Andreassen, R.; Pedersen, M.; Kristoffersen, K.; Rønning, S. Screening of by-products from the food industry as growth promoting agents in serum-free media for skeletal muscle cell culture. Food Funct. 2020, 11, 2477–2488. [Google Scholar] [CrossRef]

- Posung, M.; Promkhatkaew, D.; Borg, J.; Tongta, A. Development of a modified serum-free medium for Vero cell cultures: Effects of protein hydrolysates, l-glutamine and SITE liquid media supplement on cell growth. Cytotechnology 2021, 73, 683–695. [Google Scholar] [CrossRef]

- Merten, O.-W. Safety issues of animal products used in serum-free media. Dev. Biol. Stand. 1999, 99, 167–180. [Google Scholar]

- Zhang, Z.; He, Q.; Deng, W.; Chen, Q.; Hu, X.; Gong, A.; Cao, X.; Yu, J.; Xu, X. Nasal ectomesenchymal stem cells: Multi-lineage differentiation and transformation effects on fibrin gels. Biomaterials 2015, 49, 57–67. [Google Scholar] [CrossRef] [PubMed]

- Baker, B.M.; Chen, C.S. Deconstructing the third dimension—How 3D culture microenvironments alter cellular cues. J. Cell Sci. 2012, 125, 3015–3024. [Google Scholar] [CrossRef]

- Burla, F.; Mulla, Y.; Vos, B.E.; Aufderhorst-Roberts, A.; Koenderink, G.H. From mechanical resilience to active material properties in biopolymer networks. Nat. Rev. Phys. 2019, 1, 249–263. [Google Scholar] [CrossRef]

- Yu, D.; Cai, Z.; Li, D.; Zhang, Y.; He, M.; Yang, Y.; Liu, D.; Xie, W.; Li, Y.; Xiao, W. Myogenic Differentiation of Stem Cells for Skeletal Muscle Regeneration. Stem Cells Int. 2021, 2021, 8884283. [Google Scholar] [CrossRef]

- Abbasi, N.; Hamlet, S.; Love, R.M.; Nguyen, N.-T. Porous scaffolds for bone regeneration. J. Sci. Adv. Mater. Devices 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Gyawali, D.; Nair, P.; Kim, H.K.W.; Yang, J. Citrate-based biodegradable injectable hydrogel composites for orthopedic applications. Biomater. Sci. 2013, 1, 52–64. [Google Scholar] [CrossRef]

- Jorgensen, A.M.; Varkey, M.; Gorkun, A.; Clouse, C.; Xu, L.; Chou, Z.; Murphy, S.V.; Molnar, J.; Lee, S.J.; Yoo, J.J.; et al. Bioprinted Skin Recapitulates Normal Collagen Remodeling in Full-Thickness Wounds. Tissue Eng. Part A 2020, 26, 512–526. [Google Scholar] [CrossRef]

- Biswal, T. Biopolymers for tissue engineering applications: A review. Mater. Today Proc. 2021, 41, 397–402. [Google Scholar] [CrossRef]

- Sombatmankhong, K.; Sanchavanakit, N.; Pavasant, P.; Supaphol, P. Bone Scaffolds from Electrospun Fiber Mats of Poly(3-Hydroxybutyrate), Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) and Their Blend. Polymer 2007, 48, 1419–1427. [Google Scholar] [CrossRef]

- Depan, D.; Surya, P.V.; Girase, B.; Misra, R. Organic/Inorganic Hybrid Network Structure Nanocomposite Scaffolds Based on Grafted Chitosan for Tissue Engineering. Acta Biomater. 2011, 7, 2163–2175. [Google Scholar] [CrossRef]

- Page, R.L.; Malcuit, C.; Vilner, L.; Vojtic, I.; Shaw, S.; Hedblom, E.; Hu, J.; Pins, G.D.; Rolle, M.W.; Dominko, T. Restoration of Skeletal Muscle Defects with Adult Human Cells Delivered on Fibrin Microthreads. Tissue Eng. Part A 2011, 17, 2629–2640. [Google Scholar] [CrossRef]

- Dugan, J.M.; Collins, R.F.; Gough, J.E.; Eichhorn, S.J. Oriented Surfaces of Adsorbed Cellulose Nanowhiskers Promote Skeletal Muscle Myogenesis. Acta Biomater. 2013, 9, 4707–4715. [Google Scholar] [CrossRef]

- Lu, H.; Lv, L.; Dai, Y.; Wu, G.; Zhao, H.; Zhang, F. Porous Chitosan Scaffolds with Embedded Hyaluronic Acid/Chitosan/Plasmid-DNA Nanoparticles Encoding TGF-Β1 Induce DNA Controlled Release, Transfected Chondrocytes, and Promoted Cell Proliferation. PLoS ONE 2013, 8, e69950. [Google Scholar] [CrossRef]

- Wang, L.; Cao, L.; Shansky, J.; Wang, Z.; Mooney, D.; Vandenburgh, H. Minimally Invasive Approach to the Repair of Injured Skeletal Muscle With a Shape-Memory Scaffold. Mol. Ther. 2014, 22, 1441–1449. [Google Scholar] [CrossRef] [PubMed]

- Sensini, A.; Gualandi, C.; Zucchelli, A.; Boyle, L.A.; Kao, A.P.; Reilly, G.C.; Tozzi, G.; Cristofolini, L.; Focarete, M.L. Tendon Fascicle-Inspired Nanofibrous Scaffold of Polylactic Acid/Collagen with Enhanced 3D-Structure and Biomechanical Properties. Sci. Rep. 2018, 8, 17167. [Google Scholar] [CrossRef]

- Barros, D.; Conde-Sousa, E.; Gonçalves, A.M.; Han, W.M.; García, A.J.; Amaral, I.F.; Pêgo, A.P. Engineering Hydrogels with Affinity-Bound Laminin as 3D Neural Stem Cell Culture Systems. Biomater. Sci. 2019, 7, 5338–5349. [Google Scholar] [CrossRef]

- Wei, Q.; Young, J.; Holle, A.; Li, J.; Bieback, K.; Inman, G.; Spatz, J.P.; Cavalcanti-Adam, E.A. Soft Hydrogels for Balancing Cell Proliferation and Differentiation. ACS Biomater. Sci. Eng. 2020, 6, 4687–4701. [Google Scholar] [CrossRef]

- Sheikholeslam, M.; Wright, M.E.E.; Cheng, N.; Oh, H.H.; Wang, Y.; Datu, A.K.; Santerre, J.P.; Amini-Nik, S.; Jeschke, M.G. Electrospun Polyurethane–Gelatin Composite: A New Tissue-Engineered Scaffold for Application in Skin Regeneration and Repair of Complex Wounds. ACS Biomater. Sci. Eng. 2020, 6, 505–516. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.; Stadler, F.J.; Fu, M. Biomimetic Electrospun Tubular PLLA/Gelatin Nanofiber Scaffold Promoting Regeneration of Sciatic Nerve Transection in SD Rat. Mater. Sci. Eng. C 2021, 121, 111858. [Google Scholar] [CrossRef]

- Post, M.J.; Hocquette, J.-F. New Sources of Animal Proteins: Cultured Meat. In New Aspects of Meat Quality; Elsevier: Amsterdam, The Netherlands, 2017; pp. 425–441. [Google Scholar]

- Bilirgen, A.C.; Toker, M.; Odabas, S.; Yetisen, A.K.; Garipcan, B.; Tasoglu, S. Plant-Based Scaffolds in Tissue Engineering. ACS Biomater. Sci. Eng. 2021, 7, 926–938. [Google Scholar] [CrossRef]

- Badylak, S.F.; Taylor, D.; Uygun, K. Whole-Organ Tissue Engineering: Decellularization and Recellularization of Three-Dimensional Matrix Scaffolds. Annu. Rev. Biomed. Eng. 2011, 13, 27–53. [Google Scholar] [CrossRef]

- Wollschlaeger, J.O.; Maatz, R.; Albrecht, F.B.; Klatt, A.; Heine, S.; Blaeser, A.; Kluger, P.J. Scaffolds for Cultured Meat on the Basis of Polysaccharide Hydrogels Enriched with Plant-Based Proteins. Gels 2022, 8, 94. [Google Scholar] [CrossRef]

- U.S. Food & Drug Administration. Substances Added to Food (Formerly EAFUS); FDA: Silver Spring, MD, USA, 2018.

- FAO. Dietary Carbohydrate Composition. 2022. Available online: https://www.fao.org/3/W8079E/w8079e0h.htm (accessed on 21 October 2022).

- ODEX STAN 247. General Standard for Fruit Juices and Nectars (CODEX STAN 247-2005). 2005. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/es/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B247-2005%252FCXS_247e.pdf (accessed on 21 October 2022).

- Nwe, N.; Furuike, T.; Tamura, H. The Mechanical and BiologicalProperties of Chitosan Scaffolds for Tissue Regeneration Templates Are SignificantlyEnhanced by Chitosan from Gongronella Butleri. Materials 2009, 2, 374–398. [Google Scholar] [CrossRef]

- Basha, R.Y.; Kumar, T.S.S.; Doble, M. Electrospun Nanofibers of Curdlan (β-1,3 Glucan) Blend as a Potential Skin Scaffold Material. Macromol. Mater. Eng. 2017, 302, 1600417. [Google Scholar] [CrossRef]

- Prasopdee, T.; Sinthuvanich, C.; Chollakup, R.; Uttayarat, P.; Smitthipong, W. The Albumin/Starch Scaffold and Its Biocompatibility with Living Cells. Mater. Today Commun. 2021, 27, 102164. [Google Scholar] [CrossRef]

- Poddar, S.; Agarwal, P.S.; Sahi, A.K.; Vajanthri, K.Y.; Pallawi; Singh, K.N.; Mahto, S.K. Fabrication and Cytocompatibility Evaluation of Psyllium Husk (Isabgol)/Gelatin Composite Scaffolds. Appl. Biochem. Biotechnol. 2019, 188, 750–768. [Google Scholar] [CrossRef]

- Bar-Shai, N.; Sharabani-Yosef, O.; Zollmann, M.; Lesman, A.; Golberg, A. Seaweed Cellulose Scaffolds Derived from Green Macroalgae for Tissue Engineering. Sci. Rep. 2021, 11, 11843. [Google Scholar] [CrossRef] [PubMed]

- Indurkar, A.; Bangde, P.; Gore, M.; Agrawal, A.K.; Jain, R.; Dandekar, P. Fabrication of Guar Gum-Gelatin Scaffold for Soft Tissue Engineering. Carbohydr. Polym. Technol. Appl. 2020, 1, 100006. [Google Scholar] [CrossRef]

- Li, N.; Xue, F.; Zhang, H.; Sanyour, H.J.; Rickel, A.P.; Uttecht, A.; Fanta, B.; Hu, J.; Hong, Z. Fabrication and Characterization of Pectin Hydrogel Nanofiber Scaffolds for Differentiation of Mesenchymal Stem Cells into Vascular Cells. ACS Biomater. Sci. Amp; Eng. 2019, 5, 6511–6519. [Google Scholar] [CrossRef]

- Bektas, E.I.; Pekozer, G.G.; Kök, F.N.; Kose, G.T. Evaluation of Natural Gum-Based Cryogels for Soft Tissue Engineering. Carbohydr. Polym. 2021, 271, 118407. [Google Scholar] [CrossRef]

- Feroz, S.; Dias, G. Hydroxypropylmethyl Cellulose (HPMC) Crosslinked Keratin/Hydroxyapatite (HA) Scaffold Fabrication, Characterization and in Vitro Biocompatibility Assessment as a Bone Graft for Alveolar Bone Regeneration. Heliyon 2021, 7, e08294. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.U.A.; Razak, S.I.A.; Ansari, M.N.M.; Zulkifli, R.M.; Zawawi, N.A.; Arshad, M. Development of Biodegradable Bio-Based Composite for Bone Tissue Engineering: Synthesis, Characterization and In Vitro Biocompatible Evaluation. Polymers 2021, 13, 3611. [Google Scholar] [CrossRef]

- Aparicio-Collado, J.L.; García-San-Martín, N.; Molina-Mateo, J.; Cabanilles, C.T.; Quiles, V.D.; Serrano-Aroca, A.; Serra, R.S. Electroactive Calcium- Alginate/Polycaprolactone/Reduced Graphene Oxide Nanohybrid Hydrogels for Skeletal Muscle Tissue Engineering. Colloids Surf. B Biointerfaces 2022, 214, 112455. [Google Scholar] [CrossRef] [PubMed]

- Rekulapally, R.; Udayachandrika, K.; Hamlipur, S.; Nair, A.S.; Pal, B.; Singh, S. Tissue Engineering of Collagen Scaffolds Crosslinked with Plant Based Polysaccharides. Prog. Biomater. 2021, 10, 29–41. [Google Scholar] [CrossRef]

- Sun, M.; Wang, Y.; Yao, L.; Li, Y.; Weng, Y.; Qiu, D. Fabrication and Characterization of Gelatin/Polyvinyl Alcohol Composite Scaffold. Polymers 2022, 14, 400. [Google Scholar] [CrossRef]

- U.S. Food & Drug Administration. Questions and Answers on Dietary Fiber; FDA: Silver Spring, MD, USA, 2021.

- Food Standards Australia & New Zealand. Application A1077—Fungal Hitosan as a Processing Aid; Food Standards Australia & New Zealand: Barton, Australia, 2013.

- CODEX STAN 192-1995; General Standard for Food Additives. CODEX Alimentarius International Food Standards: Rome, Italy, 1995.

- FDA. Food Additive Status List; FDA: Silver Spring, MD, USA, 2022.

- AgriFiber Solutions, LLC. Safety Evaluation Dossier Supporting a Generally Recognized as Safe (Gras) Conclusion for the Use of Corn Bran Arabinoxylan in Conventional Foods—GRAS Notice (GRN) No. 998; AgriFiber Solutions, LLC.: Mundelein, IL, USA, 2021. [Google Scholar]

- Zhang, G.; Zhao, X.; Li, X.; Du, G.; Zhou, J.; Chen, J. Challenges and possibilities for bio-manufacturing cultured meat. Trends Food Sci. Technol. 2020, 97, 443–450. [Google Scholar] [CrossRef]

- Moritz, M.S.M.; Verbruggen, S.E.L.; Post, M.J. Alternatives for large-scale production of cultured beef: A review. J. Integr. Agric. 2015, 14, 208–216. [Google Scholar] [CrossRef]

- Andreassen, R.C.; Rønning, S.B.; Solberg, N.T.; Grønlien, K.G.; Kristoffersen, K.A.; Høst, V.; Kolset, S.O.; Pedersen, M.E. Production of food-grade microcarriers based on by-products from the food industry to facilitate the expansion of bovine skeletal muscle satellite cells for cultured meat production. Biomaterials 2022, 286, 121602. [Google Scholar] [CrossRef] [PubMed]

- Bomkamp, C.; Skaalure, S.C.; Fernando, G.F.; Ben-Arye, T.; Swartz, E.W.; Specht, E.A. Scaffolding Biomaterials for 3D Cultivated Meat: Prospects and Challenges. Adv. Sci. 2022, 9, 2102908. [Google Scholar] [CrossRef]

- Shahin-Shamsabadi, A.; Selvaganapathy, P.R. A rapid biofabrication technique for self-assembled collagen-based multicellular and heterogeneous 3D tissue constructs. Acta Biomater. 2019, 92, 172–183. [Google Scholar] [CrossRef]

- Koudan, E.V.; Gryadunova, A.A.; Karalkin, P.A.; Korneva, J.V.; Meteleva, N.Y.; Babichenko, I.I.; Volkov, A.V.; Rodionov, S.A.; Parfenov, V.A.; Pereira, F.D.A.S.; et al. Multiparametric Analysis of Tissue Spheroids Fabricated from Different Types of Cells. Biotechnol. J. 2020, 15, 1900217. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.L.; Todhunter, M.E.; LaBarge, M.A.; Gartner, Z.J. Opportunities for organoids as new models of aging. J. Cell Biol. 2018, 217, 39–50. [Google Scholar] [CrossRef]

- Milián, E.; Julien, T.; Biaggio, R.; Venereo-Sanchez, A.; Montes, J.; Manceur, A.P.; Ansorge, S.; Petiot, E.; Rosa-Calatrava, M.; Kamen, A. Accelerated mass production of influenza virus seed stocks in HEK-293 suspension cell cultures by reverse genetics. Vaccine 2017, 35, 3423–3430. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Guttieres, D.; Koenigsberg, A.; Barone, P.W.; Sinskey, A.J.; Springs, S.L. Large-scale cultured meat production: Trends, challenges and promising biomanufacturing technologies. Biomaterials 2022, 280, 121274. [Google Scholar] [CrossRef]

- Ben-Arye, T.; Shandalov, Y.; Ben-Shaul, S.; Landau, S.; Zagury, Y.; Ianovici, I.; Lavon, N.; Levenberg, S. Textured soy protein scaffolds enable the generation of three-dimensional bovine skeletal muscle tissue for cell-based meat. Nat. Food 2020, 1, 210–220. [Google Scholar] [CrossRef]

- Park, S.; Jung, S.; Choi, M.; Lee, M.; Choi, B.; Koh, W.-G.; Lee, S.; Hong, J. Gelatin MAGIC powder as nutrient-delivering 3D spacer for growing cell sheets into cost-effective cultured meat. Biomaterials 2021, 278, 121155. [Google Scholar] [CrossRef] [PubMed]

- Shahin-Shamsabadi, A.; Selvaganapathy, P.R. Engineering Murine Adipocytes and Skeletal Muscle Cells in Meat-like Constructs Using Self-Assembled Layer-by-Layer Biofabrication: A Platform for Development of Cultivated Meat. Cells Tissues Organs 2022, 211, 304–312. [Google Scholar] [CrossRef]

- Zhang, S.; Xing, M.; Li, B. Biomimetic Layer-by-Layer Self-Assembly of Nanofilms, Nanocoatings, and 3D Scaffolds for Tissue Engineering. Int. J. Mol. Sci. 2018, 19, 1641. [Google Scholar] [CrossRef] [PubMed]

- Tonndorf, R.; Aibibu, D.; Cherif, C. Isotropic and Anisotropic Scaffolds for Tissue Engineering: Collagen, Conventional, and Textile Fabrication Technologies and Properties. Int. J. Mol. Sci. 2021, 22, 9561. [Google Scholar] [CrossRef]

- Jin, S.; Chen, Z.; Xin, B.; Xi, T.; Meng, N. An investigation on the comparison of wet spinning and electrospinning: Experimentation and simulation. Fibers Polym. 2017, 18, 1160–1170. [Google Scholar] [CrossRef]

- Hong, J.; Yeo, M.; Yang, G.H.; Kim, G. Cell-Electrospinning and Its Application for Tissue Engineering. Int. J. Mol. Sci. 2019, 20, 6208. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Gilbert-Honick, J.; Somers, S.M.; Mao, H.-Q.; Grayson, W.L. Modified cell-electrospinning for 3D myogenesis of C2C12s in aligned fibrin microfiber bundles. Biochem. Biophys. Res. Commun. 2019, 516, 558–564. [Google Scholar] [CrossRef] [PubMed]

- Ramachandraiah, K. Potential development of sustainable 3d-printed meat analogues: A review. Sustainability 2021, 13, 938. [Google Scholar] [CrossRef]

- Balasubramanian, B.; Liu, W.; Pushparaj, K.; Park, S. The Epic of In Vitro Meat Production—A Fiction into Reality. Foods 2021, 10, 1395. [Google Scholar] [CrossRef]

- Hospodiuk, M.; Dey, M.; Sosnoski, D.; Ozbolat, I.T. The bioink: A comprehensive review on bioprintable materials. Biotechnol. Adv. 2017, 35, 217–239. [Google Scholar] [CrossRef] [PubMed]

- Costantini, M.; Testa, S.; Mozetic, P.; Barbetta, A.; Fuoco, C.; Fornetti, E.; Tamiro, F.; Bernardini, S.; Jaroszewicz, J.; Święszkowski, W.; et al. Microfluidic-enhanced 3D bioprinting of aligned myoblast-laden hydrogels leads to functionally organized myofibers in vitro and in vivo. Biomaterials 2017, 131, 98–110. [Google Scholar] [CrossRef]

- Kim, J.H.; Seol, Y.-J.; Ko, I.K.; Kang, H.-W.; Lee, Y.K.; Yoo, J.J.; Atala, A.; Lee, S.J. 3D Bioprinted Human Skeletal Muscle Constructs for Muscle Function Restoration. Sci. Rep. 2018, 8, 12307. [Google Scholar] [CrossRef]

- Yeo, M.; Lee, H.; Kim, G.H. Combining a micro/nano-hierarchical scaffold with cell-printing of myoblasts induces cell alignment and differentiation favorable to skeletal muscle tissue regeneration. Biofabrication 2016, 8, 035021. [Google Scholar] [CrossRef]

- Kang, D.-H.; Louis, F.; Liu, H.; Shimoda, H.; Nishiyama, Y.; Nozawa, H.; Kakitani, M.; Takagi, D.; Kasa, D.; Nagamori, E.; et al. Engineered whole cut meat-like tissue by the assembly of cell fibers using tendon-gel integrated bioprinting. Nat. Commun. 2021, 12, 5059. [Google Scholar] [CrossRef]

- Gillies, A.R.; Lieber, R.L. Structure and function of the skeletal muscle extracellular matrix. Muscle Nerve 2011, 44, 318–331. [Google Scholar] [CrossRef]

- Jairath, G.; Mal, G.; Gopinath, D.; Singh, B. A holistic approach to access the viability of cultured meat: A review. Trends Food Sci. Technol. 2021, 110, 700–710. [Google Scholar] [CrossRef]

- Chriki, S.; Payet, V.; Pflanzer, S.B.; Ellies-Oury, M.-P.; Liu, J.; Hocquette, É.; Rezende-de-Souza, J.H.; Hocquette, J.-F. Brazilian Consumers’ Attitudes towards So-Called ‘Cell-Based Meat’. Foods 2021, 10, 2588. [Google Scholar] [CrossRef] [PubMed]

- Churchill, W. Fifty Years Hence. 1931. Available online: https://www.nationalchurchillmuseum.org/fifty-years-hence.html (accessed on 6 October 2022).

| Component Category | Components | Quantity (When Specified) |

|---|---|---|

| Proteins | Albumin Fibronectin Globulins Protease inhibitors Transferrin | 40–80 g/L overall |

| Hormones | Insulin Glucagon Corticosteroids Vasopressin Thyroid hormones Parathyroid hormone Growth hormone Pituitary glandotropic factors Prostaglandin | ------ |

| Growth factors | EGF PDGF IGF-1 and 2 FGF IL-1 IL-6 TGF-β1 NGF | 1–100 μg/L overall |

| Lipids | CholesterolLinoleic acid Phospholipids | 2–10 g/L overall |

| Carbohydrates | Fructose Galactose Glucose Glycolytic metabolites Mannose Ribose | 1–2 g/L overall |

| Vitamins | Vitamins A, C and E, and the B group | 10 μg/L to 10 mg/L overall |

| Minerals | Ca, Cl, Cr, Cu, F, Fe, I, K, Mn, Mo, Na, Ni, Se, Sn and Zn | 0.79 μg/L to 3.57 g/L overall |

| Medium | Composition | Use | Reference |

|---|---|---|---|

| E8 | DMEM/F12 in a 1:1 ratio, L-ascorbic acid-2-magnesium phosphate (64 mg/L) with sodium selenium (14 µg/L), FGF-2 (100 µg/L), insulin (19.4 mg/L), NaHCO3 (543 mg/L) and transferrin (10.7 mg/L), TGFβ1 (2 µg/L) or NODAL (100 µg/L) | Growth of primary bovine myoblasts | Kolkmann et al. (2020) [51] |

| Beefy-9 | DMEM/F12 in a 1:1 ratio with HEPES, insulin (20 µg/mL), L-ascorbic acid-2-phosphate (200 µg/mL), transferrin (20 µg/mL), sodium selenite (20 ng/mL), FGF-2 (40 ng/mL), TGF-β3 (0.1 ng/mL), NRG1 (0.1 ng/mL) and human albumin (800 µg/mL) | Bovine satellite cell growth | Stout et al. (2022) [39] |

| McAleer differentiation medium | Neurobasal/L15 1:1 with addition of EGF (0.1 µg/mL) and IGF (0.01 µg/mL) | Differentiation of bovine satellite cells | McAleer et al. (2015) [53]; Stout et al. (2022) [39] |

| Messmer differentiation medium | DMEM/F12 1:1 with EGF-1 (10 ng/mL), human albumin (0.5 mg/mL), L-ascorbic acid-2-phosphate (40 µM), sodium selenite (80 nM), NaHCO3 (6.5 mM), MEM amino acids (0.5%), insulin (1.8 µM), transferrin (135 nM), lysophosphatidic acid (1 µM) and acetylcholine (10 µM) | Differentiation of bovine satellite cells | Messmer et al. (2022) [48] |

| Benjaminson Maitake medium | MEM-Hanks’ with maitake extract in a ratio of 1:9 | Growth of fish muscle cell explants | Benjaminson, Gilchriest and Lorenz (2002) [59] |

| Andreassen yeast medium | DMEM with 10 mg/mL of yeast extract | Maintenance of primary skeletal bovine cells | Andreassen et al. (2020) [61] |

| Composition | Technique/ Feature | Application | Reference |

|---|---|---|---|

| Poly(3-hydroxybutyrate), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) | Electrospinning | Bone scaffolds | Sombatmankhong et al. (2007) [72] |

| Chitosan/hydroxypropylated oxide/ethylene glycol functionalised nanohydroxyapatite | Nanocomposite | Bone tissue | Depan et al. (2011) [73] |

| Fibrin | Microthread extrusion | Skeletal muscle regeneration | Page et al. (2011) [74] |

| Cellulose/fibronectin | Spin coating | Skeletal muscle myogenesis | Dugan et al. (2013) [75] |

| Hydroxyapatite/polyethylene glycol maleate citrate/polyethylene glycol diacrylate | Hydrogel | Orthopaedics | Gyawali et al. (2013) [69] |

| Hyaluronic acid/chitosan/plasmid-DNA nanoparticles | Nanoparticle incorporation | Cartilage tissue | Lu et al. (2013) [76] |

| Alginate | Oligopeptide modification for lyophilised hydrogel generation | Skeletal muscle injures | Wang et al. (2014) [77] |

| Polylactic acid/collagen | Electrospinning | Tendon reconstruction | Sensini et al. (2018) [78] |

| Polyethylene glycol macromere/laminin | Hydrogel | Neural stem cell culture systems | Barros et al. (2019) [79] |

| Polyethylene glycol | Hydrogel | Bone marrow | Wei et al. (2020) [80] |

| Skeletal muscle–derived decellularised extracellular matrix (dECM)/IGF-1 | dECM hydrogel and poly L- lactic acid | Skeletal muscle regeneration | Lee et al. (2020) [45] |

| Polyurethane/gelatine | Electrospinning | Skin regeneration and repair | Sheikholeslam et al. (2020) [81] |

| Poly L-lactic acid/gelatine | Electrospinning | Schwann cells | Niu, Stadler and Fu (2021) [82] |

| Biomaterial | Food Industry Use | Tissue Engineering | |||

|---|---|---|---|---|---|

| Technique | Cell Culture | Application | Reference | ||

| Chitosan | A1077 4 | Freeze- drying | Fibroblasts (NIH3T3) | Potential for tissue regeneration | Nwe, Furuike and Tamura (2009) [90] |

| Beta-glucan soluble fibre 1 | Component of cell wall material in barley and oats 5 | Electrospinning | L6 myoblasts (NCCS, Pune) | Potential skin scaffold material | Basha, Sampath Kumar and Doble (2017) [91] |

| Starches | EM, St, Tck 6 | Suspension, free- drying | Cancer cell line (HepG2) | Matrix for culturing living cells | Prasopdee et al. (2021) [92] |

| Psyllium husk 1 | St, FS, 0.5% by weight in frozen desserts 7 | Freeze- drying | L929 fibroblast | Potential macroporous scaffold in TE | Poddar et al. (2019) [93] |

| Powdered cellulose 1 | Aa, Ba, EM, Ga, H, St, Tck 6 | Decellularisation | NIH-3T3 stably expressing GFP-actin | Potential macroporous and fibrous scaffold in TE | Bar-Shai et al. (2021) [94] |

| Guar gum 1 | EM, St, Tck 6 | Hydrogels/freeze-drying | Human keratinocytes (HaCaT) | Scaffolds desirable for soft TE | Indurkar et al. (2020) [95] |

| Pectin 1 | EM, Gg, Ga, St 6 | Hydrogel/crosslinking/electrospinning | Human bone marrow–derived MSCs | Potential scaffold for vascular TE | Li et al. (2019) [96] |

| Locust bean gum 1 | EM, St, Tc 6 | Cryogels/freeze- drying | NIH-3T3 cells | Macroporous scaffold for cartilage and other soft tissue | Bektas et al. (2021) [97] |

| Hydroxypropyl methyl cellulose 1 | Ba, EM, Ga, St, Tc 6 | Crosslinking/freeze-drying | Human Saos-2 osteoblast-like cells | Potential scaffold for bone graft for alveolar bone regeneration | Feroz and Dias (2021) [98] |

| Arabinoxylan 2 | Binder, Gg, Txz, St, Tck, EM 8 | Freeze- drying | MC3T3-E1 cell lines | Regenerate fractured bone | Khan et al. (2021) [99] |

| Alginate 2 | EM, FAg, FE, FAd, PAd, St, Tck, Sag, Txz 3 | Hydrogel/crosslinking | C2C12 murine myoblasts | Potential to regenerate skeletal muscle | Aparicio-Collado et al. (2022) [100] |

| Acacia (gum arabic) 2 | Ba, carrier, EM, Ga, St, Tck 6 | Crosslinking/gel | MSCs from human placenta and IVD | Potential candidate in applications in TE | Rekulapally et al. (2021) [101] |

| Agarose | In agar (Ba, carrier, EM, Ga, Gg, H, St, Tck) 6 | Hydrogels | Murine myoblast C2C12 cell line | Polysaccharide–protein scaffolds as potential candidates for cultured meat | Wollschlaeger et al. (2022) [86] |

| 75Gellan | EM, FoAg, St, Tck 6 | ||||

| Xanthan gum | EM, FoAg, ST, Tck 6 | ||||

| Locust bean gum | |||||

| Pea protein | |||||

| Soy Protein | |||||

| Polyvinyl alcohol | Ga, Tc 6 | Freeze- drying | Not used | Potential to be applied in the field of TE that demands high strength | Sun et al. (2022) [102] |

| Title | Conclusions | Authors |

|---|---|---|

| Cell sources for cultivated meat: applications and considerations throughout the production workflow | The development of highly proliferative, multipotent livestock cell sources is a crucial technical challenge in the effort to scale up CM production for commercial sale. Further advancements to develop immortalised off-the-shelf cell lines will be needed to reach the necessary scale and cost for commercial production and sale of CM products. | Reiss et al. (2021) [4] |

| Bioengineering outlook on cultivated meat production | On a global scale, the CM industry is still at the proof-of-concept stage. The CM industry will need to overcome its cost of production, primarily associated with metabolic inefficiency, shear-induced cell damage and low growth rates. It is also necessary to improve the proliferative capacity of the cells and to create immortalised cell lines of different livestock species. | Pajčin et al. (2022) [31] |

| Considerations for the development of cost-effective cell culture media for cultivated meat production | Clearly, the design of culture media to achieve scalable, low-cost and high-quality CM products remains a complex challenge. Continuing research should be focused on developing an understanding of how the molecular mechanisms controlling muscle cell growth and differentiation can be simulated via more affordable and ethical means. | O’Neill et al. (2021) [5] |

| Scaffolding biomaterials for 3D cultivated meat: prospects and challenges | Although the development of appropriate scaffolds for CM is challenging, it is also tractable and provides novel opportunities to customise meat properties. Future research will provide scaffolds capable of supporting the growth of high-quality meat while minimising production costs. | Bomkamp et al. (2022) [111] |

| Scaffolds for the manufacture of cultured meat | So far, the scaffolds used in CM research are predominantly collagen and gelatine, which are derived from animals. While many materials and processing techniques have great potential, the major challenge faced by this field is the development of a vascularised, perfusable scaffold that can be employed to provide some form of structure to CM such that meat products can mimic steak and strips. | Seah et al. (2021) [3] |

| Integrating biomaterials and food biopolymers for cultured meat production | CM faces significant impediments to market feasibility. This is due to fundamental knowledge gaps in producing realistic meat tissues via conventional tissue engineering approaches, as well as translational challenges in scaling up these approaches in an efficient, sustainable and high-volume manner. | Ng and Kurisawa (2021) [28] |

| Consumer acceptance of cultured meat: an updated review (2018–2020) | Consumers are particularly open to the concept of CM; they mostly identified animal- and environment-related benefits as drivers of this. In the long-term, objections based on neophobia and norm violation will decrease, and widespread acceptance will depend in large part on the price and flavour of CM. | Bryant and Barnett (2020) [26] |

| Brazilian consumers’ attitudes towards so-called “cell-based meat” | Although they would not be willing to pay more for CM than for conventional meat, younger respondents have the highest willingness to consume it. The answers of 4471 respondents revealed that 46.6% of them thought CM was promising and acceptable and more than 66% were willing to try it. | Chriki et al. (2021) [134] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, A.C.A.; Camarena, D.E.M.; Roncoli Reigado, G.; Chambergo, F.S.; Nunes, V.A.; Trindade, M.A.; Stuchi Maria-Engler, S. Tissue Engineering Challenges for Cultivated Meat to Meet the Real Demand of a Global Market. Int. J. Mol. Sci. 2023, 24, 6033. https://doi.org/10.3390/ijms24076033

Santos ACA, Camarena DEM, Roncoli Reigado G, Chambergo FS, Nunes VA, Trindade MA, Stuchi Maria-Engler S. Tissue Engineering Challenges for Cultivated Meat to Meet the Real Demand of a Global Market. International Journal of Molecular Sciences. 2023; 24(7):6033. https://doi.org/10.3390/ijms24076033

Chicago/Turabian StyleSantos, Andressa Cristina Antunes, Denisse Esther Mallaupoma Camarena, Gustavo Roncoli Reigado, Felipe S. Chambergo, Viviane Abreu Nunes, Marco Antonio Trindade, and Silvya Stuchi Maria-Engler. 2023. "Tissue Engineering Challenges for Cultivated Meat to Meet the Real Demand of a Global Market" International Journal of Molecular Sciences 24, no. 7: 6033. https://doi.org/10.3390/ijms24076033

APA StyleSantos, A. C. A., Camarena, D. E. M., Roncoli Reigado, G., Chambergo, F. S., Nunes, V. A., Trindade, M. A., & Stuchi Maria-Engler, S. (2023). Tissue Engineering Challenges for Cultivated Meat to Meet the Real Demand of a Global Market. International Journal of Molecular Sciences, 24(7), 6033. https://doi.org/10.3390/ijms24076033