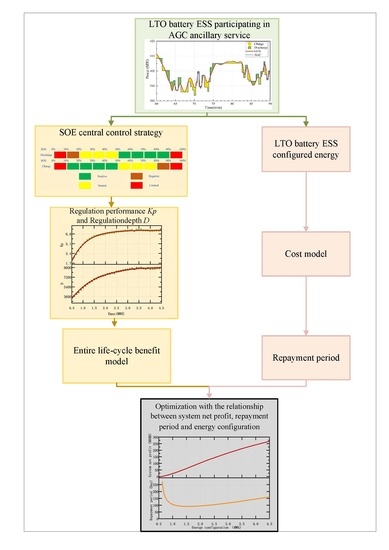

Control Strategies and Economic Analysis of an LTO Battery Energy Storage System for AGC Ancillary Service

Abstract

:1. Introduction

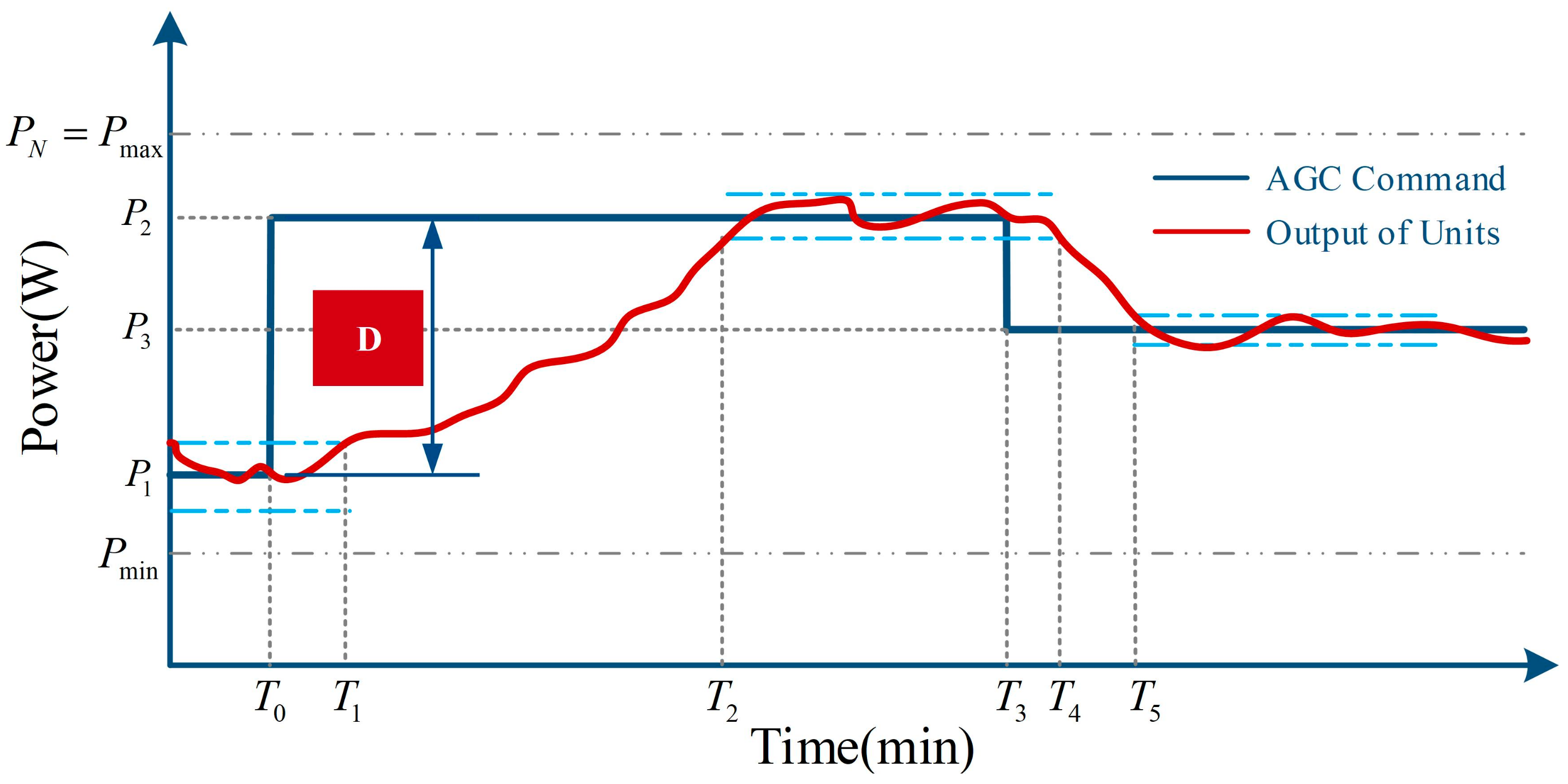

2. The Basic Principle of ESS Participating in AGC Ancillary Service

2.1. Compensation Standard for AGC Ancillary Service in the North China Power Grid

2.1.1. Normal Situation

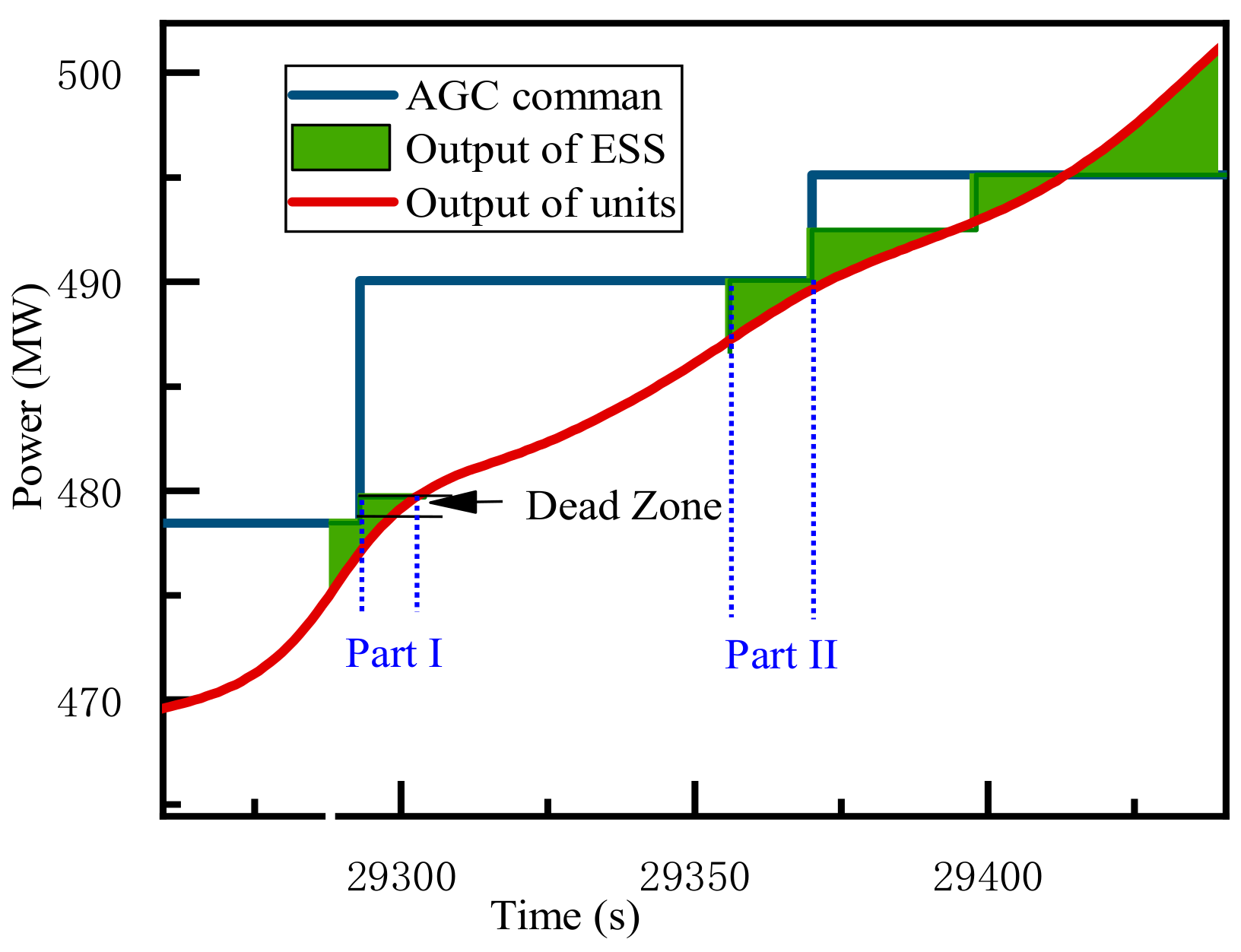

2.1.2. Delay Situation

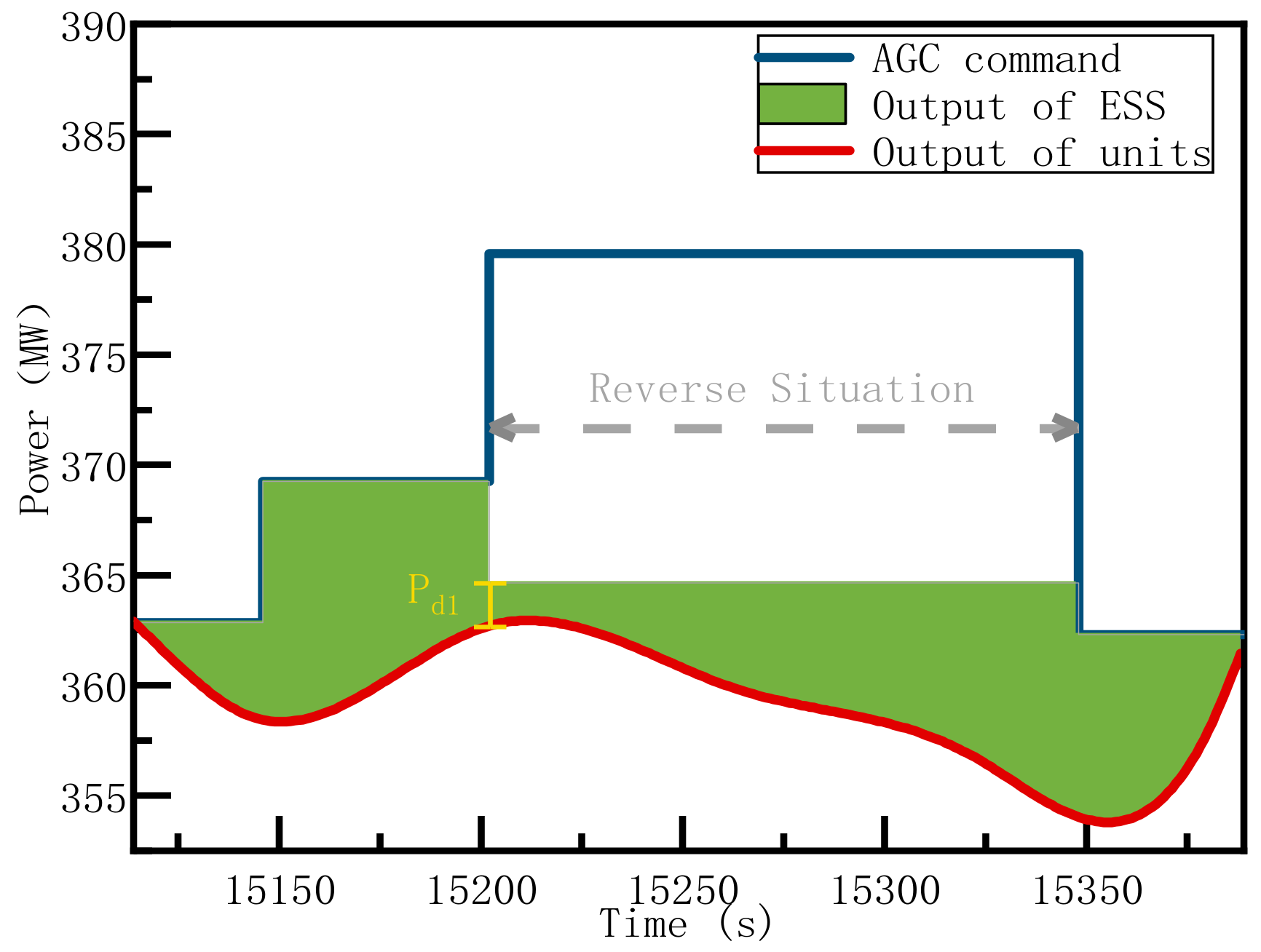

2.1.3. Reverse Situation

2.2. Compensation Fee for AGC Ancillary Services

2.3. The Principle of ESS Helps Thermal Power Units Provide AGC Ancillary Services

3. Performance of the LTO Battery

3.1. LTO Battery

3.2. Estimation of State of Energy

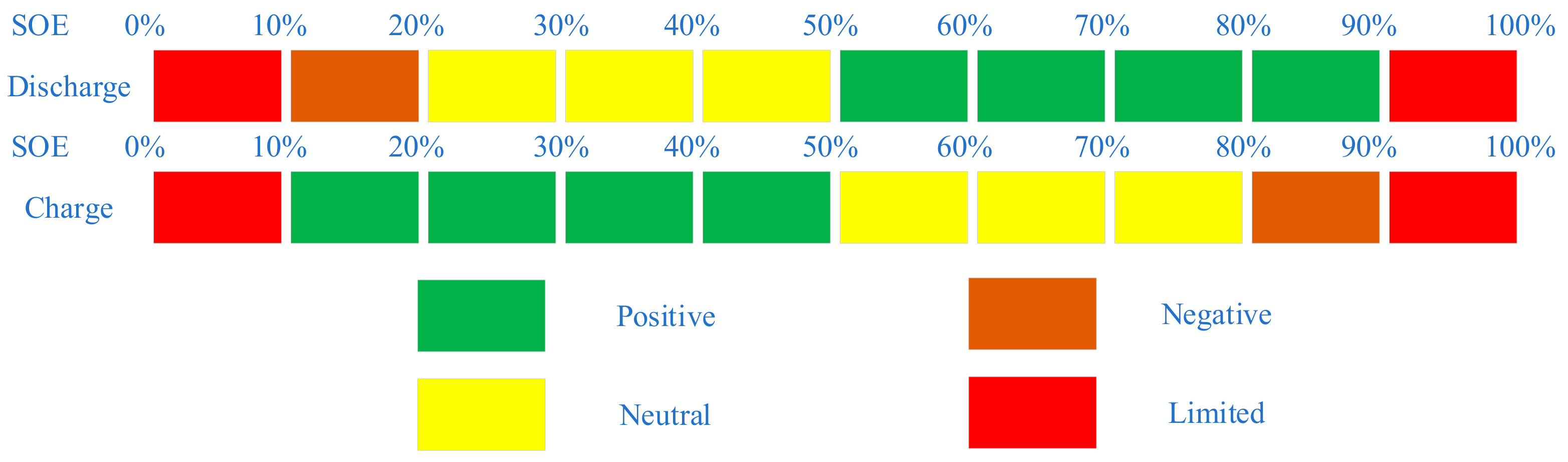

4. Control Strategy for ESS

4.1. Design of Control Strategy

4.1.1. Positive Strategy

4.1.2. Neutral Strategy

4.1.3. Negative Strategy

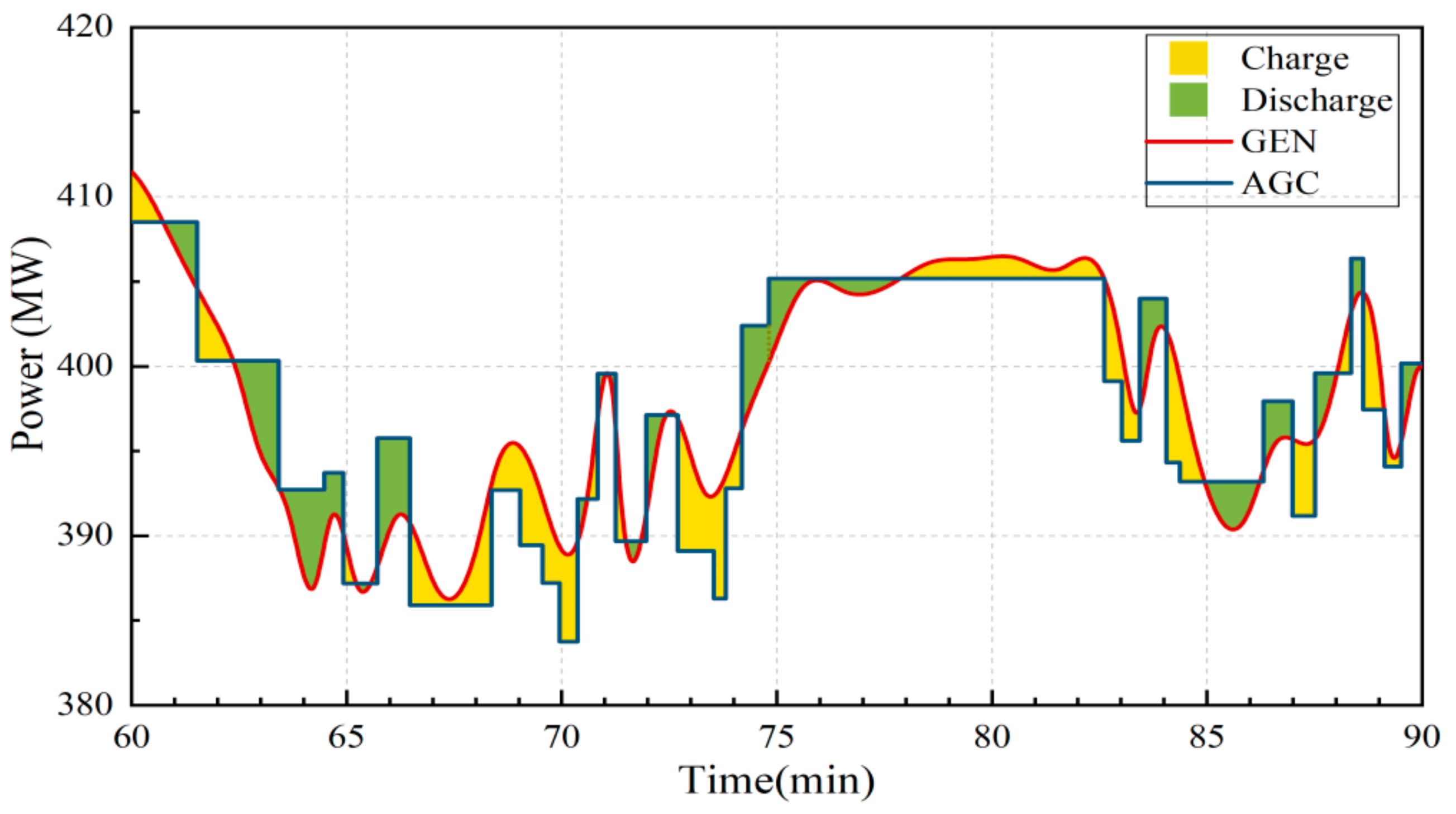

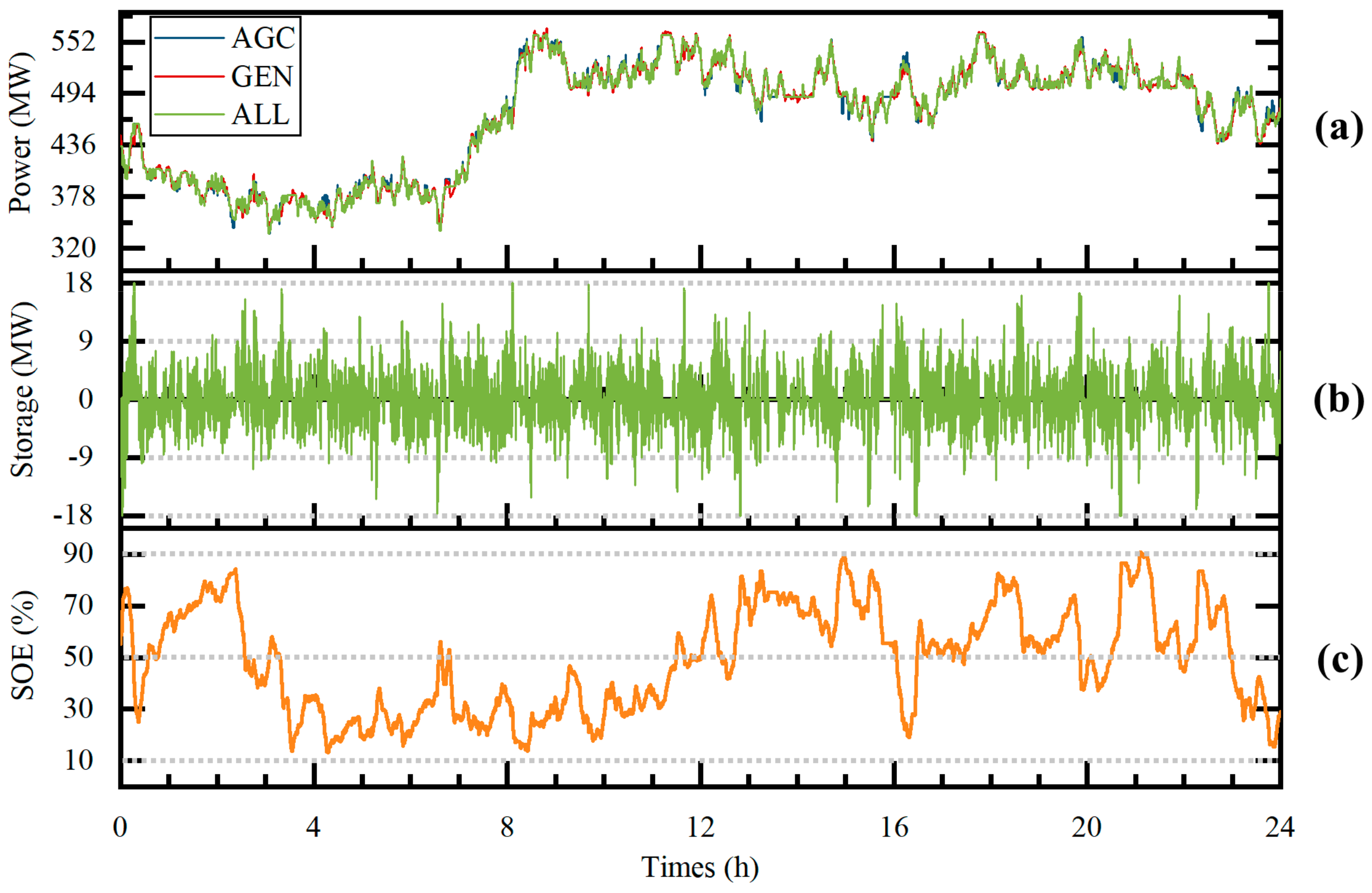

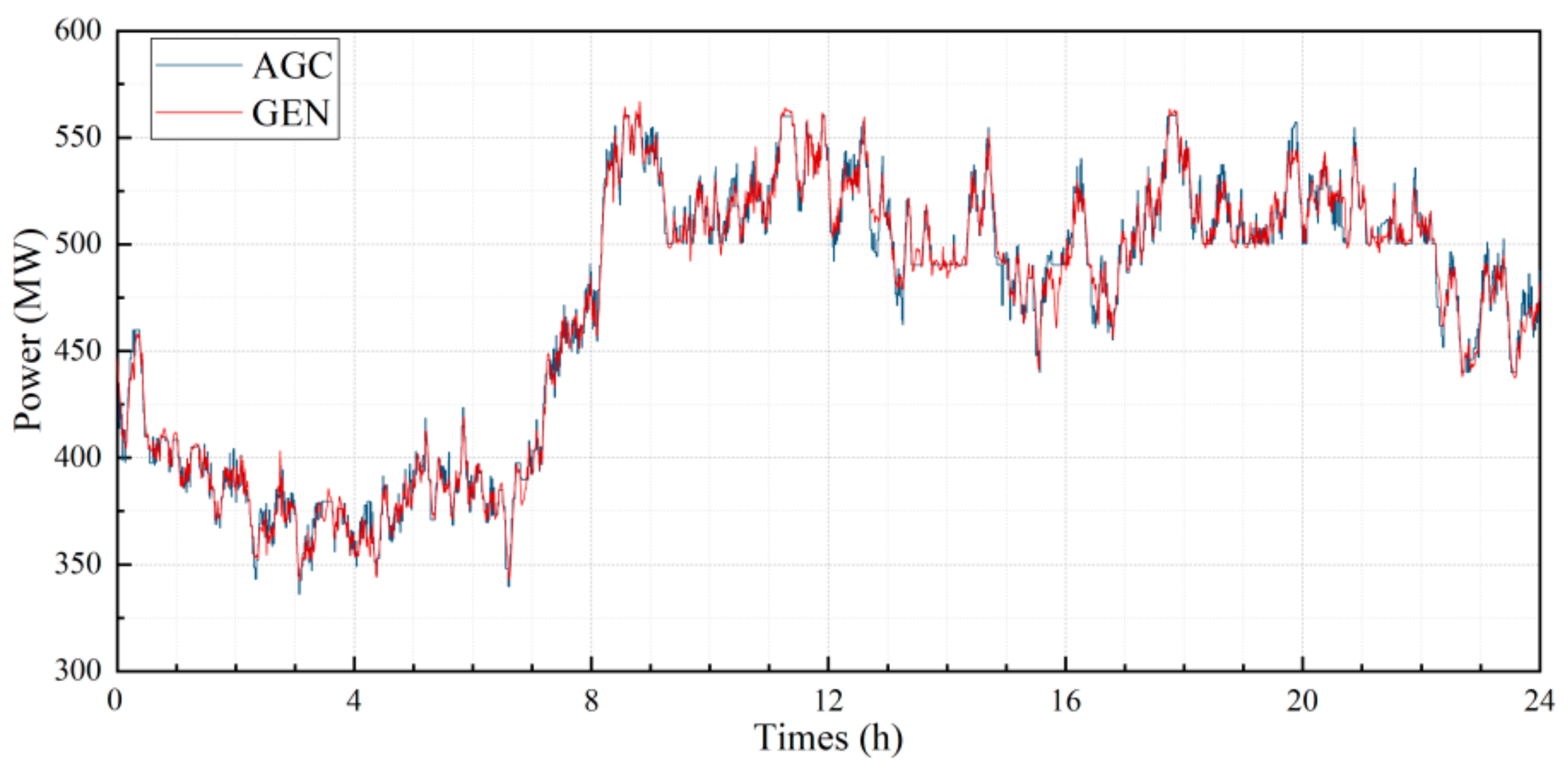

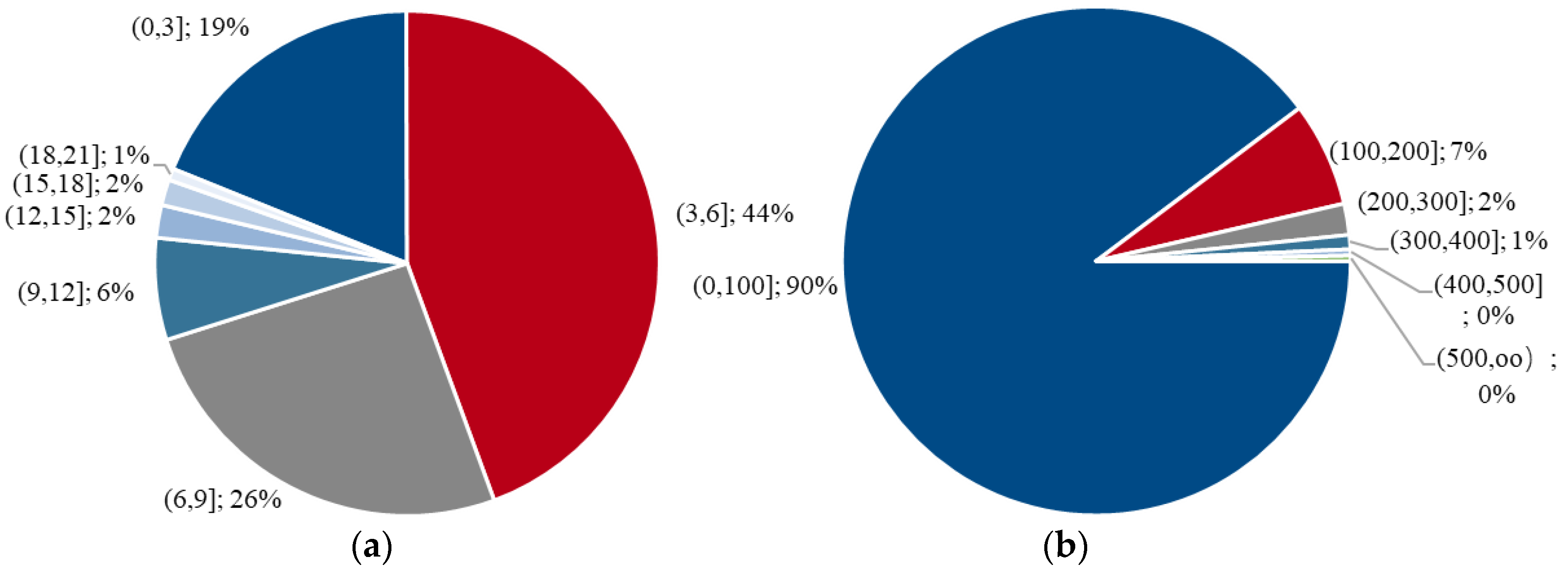

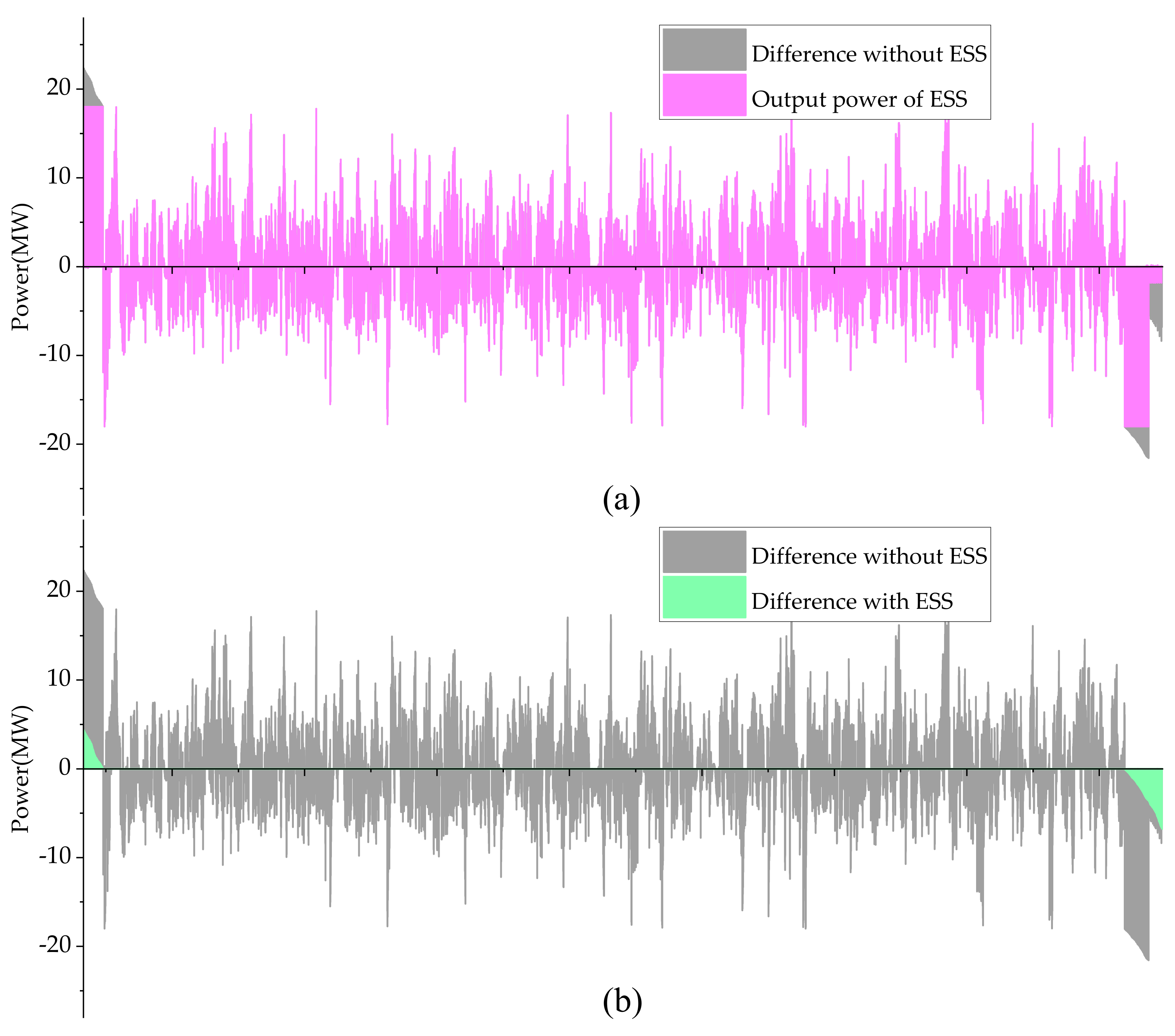

4.2. Results of the Strategy

5. The Economic Model and Case Analysis

5.1. The Cost-Benefit Model

5.1.1. The Cost Model

5.1.2. The Benefit Model

5.2. Case Analysis

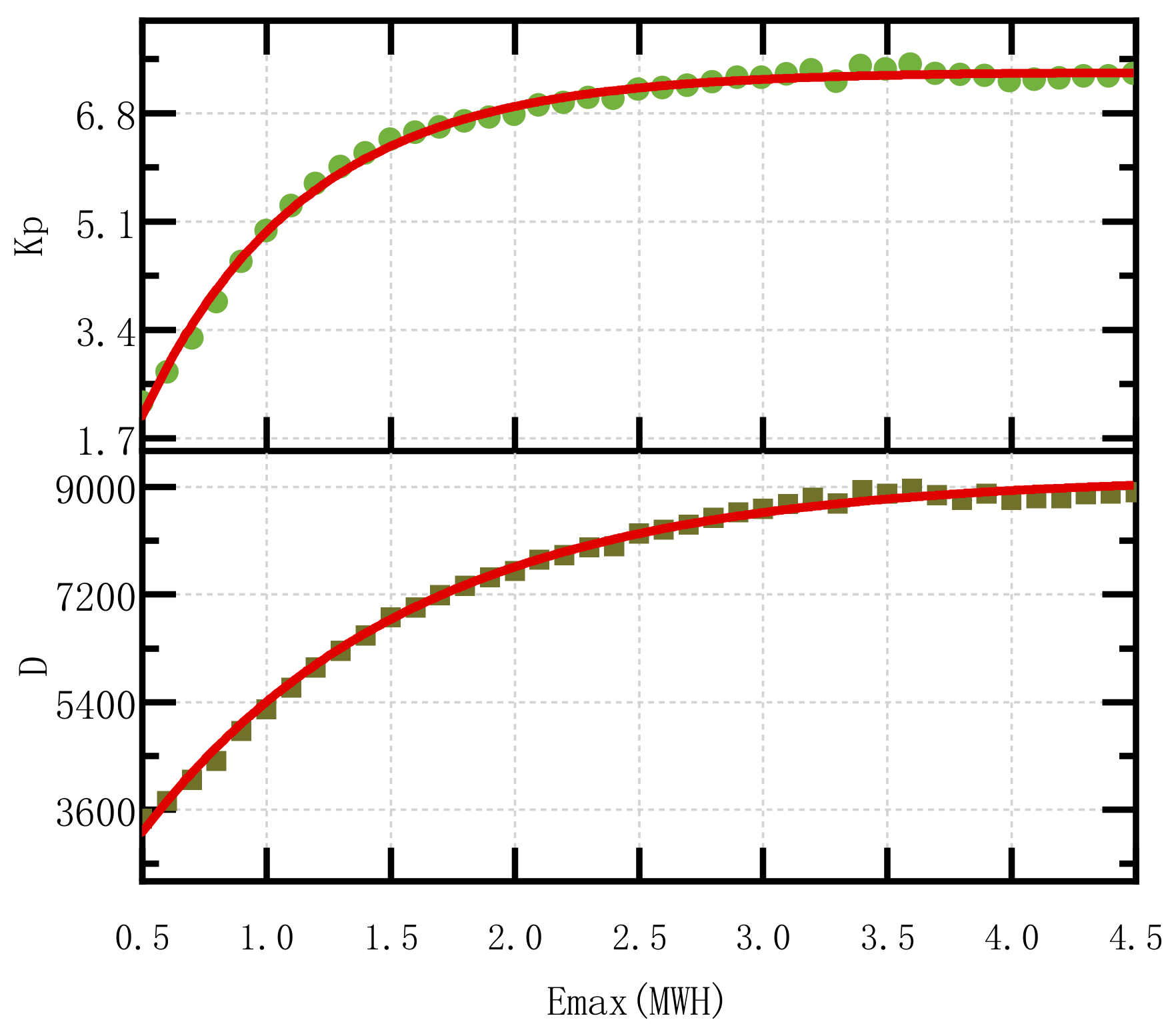

5.2.1. Energy of the ESS

5.2.2. Simulation Parameter

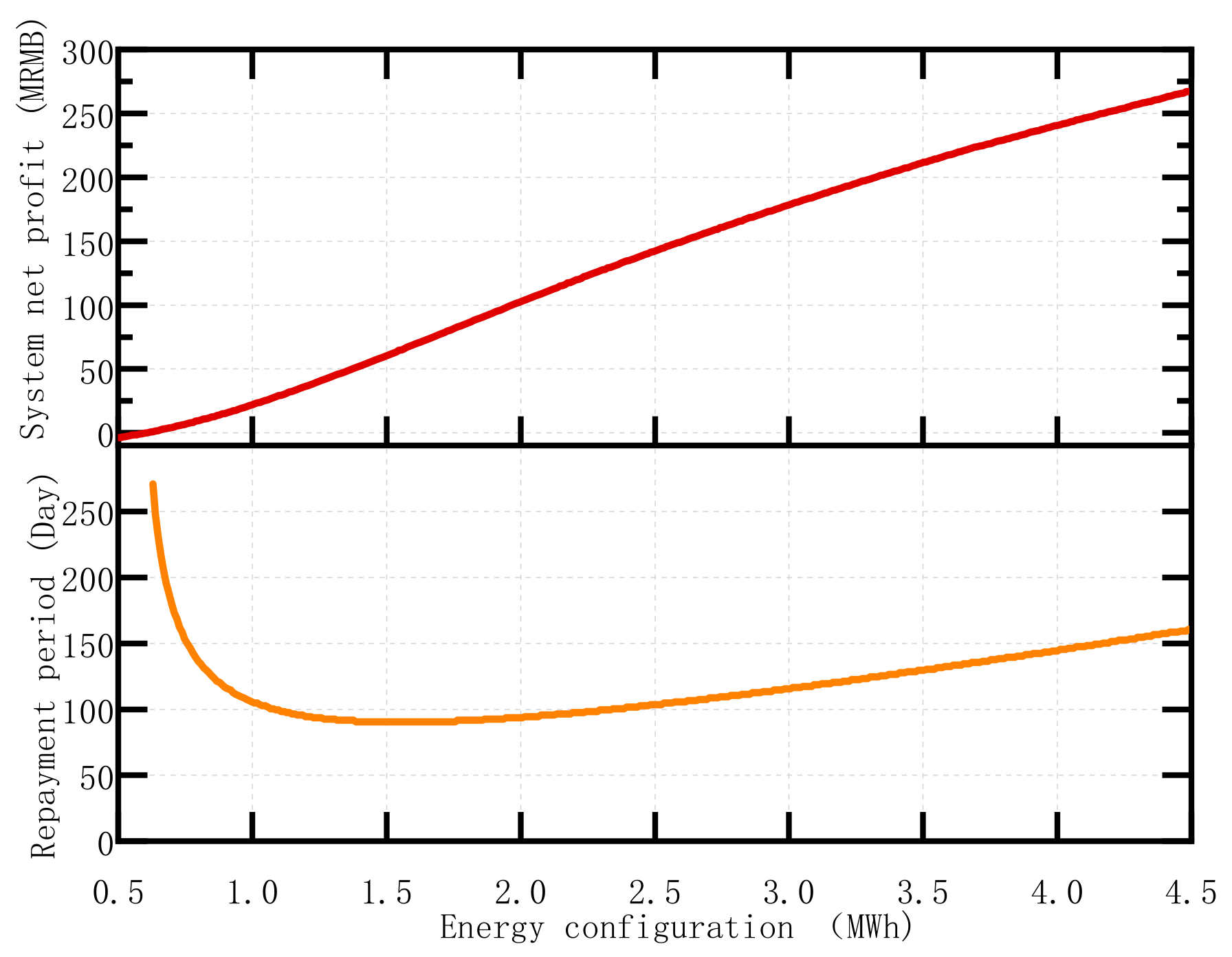

5.2.3. Result of the Simulation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Meaning |

| Iday | Daily income of the unit in AGC ancillary services |

| YAGC | Service price of AGC market |

| Dday | Daily regulation depth |

| Kp | Index of regulation performance |

| Pdis | Output power of ESS |

| ηPCS | Conversion efficiency of PCS and isolation transformer |

| Pa | AGC command |

| Pg | Output power of the unit |

| ti | i-th AGC regulation |

| Pd1 | Threshold of effective regulation rate |

| CALL | ESS costs |

| CINT | Initial investment cost |

| COM | Maintenance cost |

| CBAT | Battery module cost |

| CCE | Energy conversion equipment cost |

| CAE | Ancillary equipment cost |

| CCC | Construction cost |

| UBAT | Unit price of battery module cost |

| EN | Rated energy of ESS |

| UCE | Unit price of energy conversion equipment |

| PN | Rated power of ESS |

| UAE | Unit price of ancillary equipment |

| UCC | Unit price of construction |

| UOM | Unit price of maintenance |

| EMAX | Maximum available energy of ESS |

| IAGC | Income of ESS |

| IALL | Income of AGC system (ESS and units) |

| IGEN | Income of units |

| Kp,GEN | Index of regulation performance without ESS |

| DGEN | Regulation depth without ESS |

| IAGC, year | Annual income of ESS |

| Ccycle | Effective days of ESS in the year |

| Elife | Energy throughput in Total Life Cycle of ESS |

| Ncycle | Cycles in Total Life Cycle of ESS |

| Rcut-off | The ratio of the maximum available capacity to the rated capacity at the end of the cycle life |

| Eiadd | Energy throughput of ESS at day i |

| tcut-off | Battery cycle life |

| EtMAX | Maximum available energy at day t of ESS |

| Pnet | life cycle net profit of ESS |

References

- Sher, F.; Kawai, A.; Güleç, F.; Sadiq, H. Sustainable energy saving alternatives in small buildings. Sustain. Energy Technol. Assess. 2019, 32, 92–99. [Google Scholar] [CrossRef]

- Cuce, E.; Nachan, Z.; Cuce, P.M.; Sher, F.; Neighbour, G.B. Strategies for ideal indoor environments towards low/zero carbon buildings through a biomimetic approach. Int. J. Ambient Energy 2019, 40, 86–95. [Google Scholar] [CrossRef]

- Cuce, E.; Sher, F.; Sadiq, H.; Cuce, P.M.; Guclu, T.; Besir, A.B. Sustainable ventilation strategies in buildings: CFD research. Sustain. Energy Technol. Assess. 2019, 36, 100540. [Google Scholar] [CrossRef]

- Daneshazarian, R.; Cuce, E.; Cuce, P.M.; Sher, F. Concentrating photovoltaic thermal (CPVT) collectors and systems: Theory, performance assessment and applications. Renew. Sustain. Energy Rev. 2018, 81, 473–492. [Google Scholar] [CrossRef]

- Miao, F.; Tang, X.; Qi, Z. Fluctuation feature extraction of wind power. In Proceedings of the 2012 IEEE Innovative Smart Grid Technologies, Tianjin, China, 21–24 May 2012; pp. 1–5. [Google Scholar]

- Datta, M.; Senjyu, T. Fuzzy control of distributed PV inverters/energy storage systems/electric vehicles for frequency regulation in a large power system. IEEE Trans. Smart Grid 2013, 4, 479–488. [Google Scholar] [CrossRef]

- Junwei, D.; Yu, S.; Yonghao, H.; Yuanjing, M.; Jincheng, S.; Qing, X.; Chongqing, K. Competition models for automatic generation control in deregulated power systems. J. Tsinghua Univ. Sci. Technol. 2003, 9, 1191–1194. [Google Scholar]

- Xinran, L.; Jiyuan, H.; Yuanyang, C.; Weijian, L. Review on large-scale involvement of energy storage in power grid fast frequency regulation. Power Syst. Prot. Control 2016, 44, 145–153. [Google Scholar]

- Yangtian, N. Research on Energy Storage System Dispatch Model Based on Peak Load Shift. Master’s Thesis, North China Electric Power University, Beijing, China, 2015. [Google Scholar]

- Zechun, H.; Rui, X.; Linlin, W.; Hui, L. Joint Operation Optimization of Wind-Storage Union with Energy Storage Participating Frequency Regulation. Power Syst. Technol. 2016, 40, 2251–2257. [Google Scholar]

- Leitermann, O. Energy Storage for Frequency Regulation on the Electric Grid. Ph. D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2012. [Google Scholar]

- Xie, X.; Guo, Y.; Wang, B.; Dong, Y.; Mou, L.; Xue, F. Improving AGC performance of coal-fueled thermal generators using multi-MW scale BESS: A practical application. IEEE Trans. Smart Grid 2018, 9, 1769–1777. [Google Scholar] [CrossRef]

- Zhongwei, S.; Guoliang, L.; Wenwei, L. Research and Application of BESS-aided Thermal Power Frequency-regulation Technology. Shanxi Electr. Power 2017, 6, 62–66. [Google Scholar]

- Cheng, Y.; Tabrizi, M.; Sahni, M.; Povedano, A.; Nichols, D. Dynamic available AGC based approach for enhancing utility scale energy storage performance. IEEE Trans. Smart Grid 2014, 5, 1070–1078. [Google Scholar] [CrossRef]

- Stroe, D.I.; Knap, V.; Swierczynski, M.; Stroe, A.I.; Teodorescu, R. Operation of a grid-connected lithium-ion battery energy storage system for primary frequency regulation: A battery lifetime perspective. IEEE Trans. Ind. Appl. 2017, 53, 430–438. [Google Scholar] [CrossRef]

- Zechun, H.; Xu, X.; Fang, Z.; Jing, Z.; Yonghua, S. Research on Automatic Generation Control Strategy Incorporating Energy Storage Resources. Proc. CSEE 2014, 34, 5080–5087. [Google Scholar]

- Lijuan, C.; Yuxuan, J.; Chun, W. Strategy and capacity of energy storage for improving AGC performance of power plant. Electr. Power Autom. Equip. 2017, 37, 52–59. [Google Scholar]

- Yang, N.; Feng, Z.; Hui, Z.; Jun, L.; Libin, Y.; Guanghui, S. Optimal Control Strategy and Capacity Pianning of Hybrid Energy Storage System for Improving AGC Performance of Thermal Power Units. Autom. Electr. Power Syst. 2016, 40, 38–45. [Google Scholar]

- Swierczynski, M.; Stroe, D.I.; Stan, A.I.; Teodorescu, R.; Sauer, D.U. Selection and performance-degradation modeling of limo2/li 4ti5o12 and lifepo4/c battery cells as suitable energy storage systems for grid integration with wind power plants: An example for the primary frequency regulation service. IEEE Trans. Sustain. Energy 2014, 5, 90–101. [Google Scholar] [CrossRef]

- Krishnan, V.; Das, T.; McCalley, J.D. Impact of short-term storage on frequency response under increasing wind penetration. J. Power Sources 2014, 257, 111–119. [Google Scholar] [CrossRef]

- Hu, J.; He, Y.; Xu, L.; Williams, B.W. Improved control of DFIG systems during network unbalance using PI-R current regulators. IEEE Trans. Ind. Electron. 2009, 56, 439–451. [Google Scholar] [CrossRef]

- Sun, J. Impedance-based stability criterion for grid-connected inverters. IEEE Trans. Power Electron. 2011, 26, 3075–3078. [Google Scholar] [CrossRef]

- Jie, D.; Seuss, J.; Suneja, L.; Harley, R.G. SoC feedback control for wind and ess hybrid power system frequency regulation. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 79–86. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Battery module cost | RMB/Wh | 7 |

| Energy conversion equipment cost | MRMB/MW | 0.5 |

| Ancillary equipment cost | MRMB/MWh | 1 |

| Construction cost | MRMB/MWh | 0.5 |

| Operating cost | MRMB/MWh | 0.1 |

| Ancillary service income | RMB/MW | 5 |

| Discount rate | - | 6% |

| Efficiency of battery | - | 96% |

| Efficiency of energy conversion equipment | - | 93% |

| Life cycle number | Cycle | 15,000 |

| Capacity ratio of retirement battery | - | 80% |

| Depth of discharge | - | 80% |

| Running days per year | Day | 330 |

| Indicators | Unit | Value |

|---|---|---|

| Rated power | MW | 10.50 |

| Rated energy | MWh | 1.75 |

| Initial investment | MRMB | 20.13 |

| Average daily income | RMB | 199,900 |

| Net profit for the whole life cycle | MRMB | 79.79 |

| Payback period | Day | 93 |

| Life expectancy | Day | 541 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, B.; He, X.; Zhang, W.; Li, Y.; Gong, M.; Yang, Y.; Su, X.; Zhu, Z.; Gao, W. Control Strategies and Economic Analysis of an LTO Battery Energy Storage System for AGC Ancillary Service. Energies 2020, 13, 505. https://doi.org/10.3390/en13020505

Sun B, He X, Zhang W, Li Y, Gong M, Yang Y, Su X, Zhu Z, Gao W. Control Strategies and Economic Analysis of an LTO Battery Energy Storage System for AGC Ancillary Service. Energies. 2020; 13(2):505. https://doi.org/10.3390/en13020505

Chicago/Turabian StyleSun, Bingxiang, Xitian He, Weige Zhang, Yangxi Li, Minming Gong, Yang Yang, Xiaojia Su, Zhenlin Zhu, and Wenzhong Gao. 2020. "Control Strategies and Economic Analysis of an LTO Battery Energy Storage System for AGC Ancillary Service" Energies 13, no. 2: 505. https://doi.org/10.3390/en13020505