1. Introduction

In a direct current (DC) rail system, the electrical power is transmitted from the alternating current (AC) grid substations to the AC/DC traction substations using overhead lines or cables. From the traction substations, the electrical power is distributed to the trains using the conductor rail or overhead contact system (OCS) and running rails. The DC traction main components are a high voltage (HV) supply cable/line, AC and DC switchgear, a transformer/rectifier, negative and positive feeders, a conductor rail or an overhead contact system, isolation facilities, and rails. The number of DC substations, the location, and the rating is determined by traction power modeling studies with input from the train operator and infrastructure engineer [

1,

2].

One of the significant challenges in designing a DC system is implementing a safe and reliable protection system. The main objectives of protection in the railway system are as follows:

to isolate/disconnect the faulted circuits from the electrical supplies;

to minimize the disruption to train services by disconnecting only the affected circuit;

to prevent damage to infrastructure and traction power equipment;

to prevent and reduce the risk of electric shock for the public and railway staff.

The short-circuit fault current in an AC railway system has lower values than in a DC railway system. Typical values of the fault currents for different AC and DC railway systems are presented below [

3]:

25 kV AC rail return or booster transformer systems—the short-circuit fault current has a maximum value of 6 kA;

25 kV AC rail return ‘booster-less’ systems—the short-circuit fault current has a maximum value of 8.5 kA;

2 × 25 kV autotransformer systems—the short-circuit fault current is limited to 12 kA using fault limiting reactors;

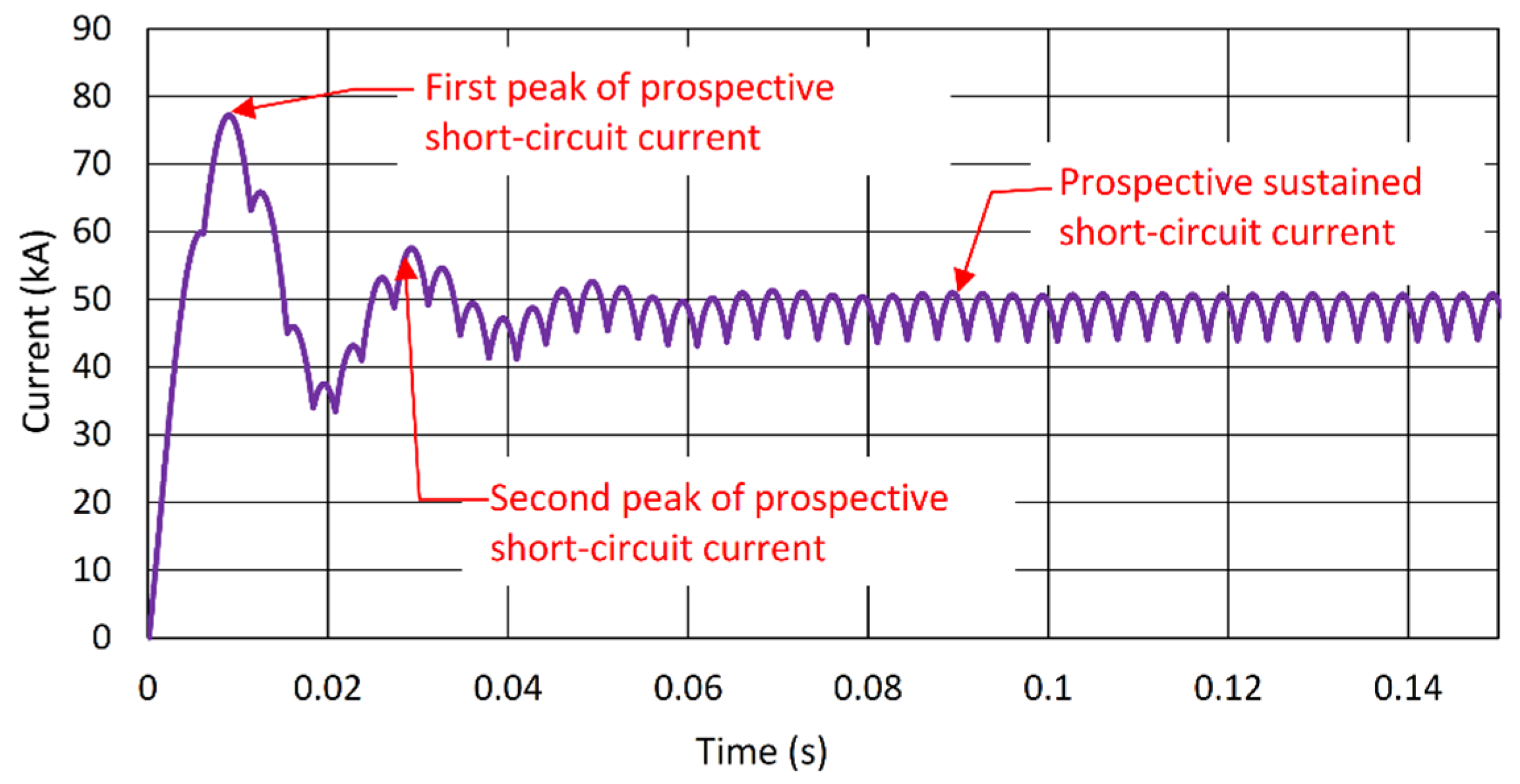

3.3 kV DC and 1.5 kV DC—the short-circuit fault current can have values of more than 50 kA.

Due to the high value of the DC short-circuit fault current, the circuit breaker (CB) disconnection time must be short to prevent damage to the infrastructure and traction equipment. Conventionally, self-acting circuit breakers are installed in DC substations where the minimum short-circuit current is used as the setting value for the overcurrent device. If the short-circuit fault current is above the setting value, the circuit breaker will fast trip. The main issue with setting the protection value of the direct acting overcurrent protection (DAOC) is that the maximum train load current may have close values to the minimum short-circuit current. Simple short-circuit calculations may not provide accurate and optimal results for protection settings. A solution to this problem may be to use simulation tools that model the entire DC railway system.

Currently, an increasing number of research studies are focused on modeling DC traction power systems for fault and protection analysis. Different methods and approaches are used to provide an electrical model that can accurately simulate the traction power system. Selected studies that present electrical models, input parameters, assumptions, and impacts on traction power supply when a short-circuit fault occurs are presented below.

In [

4], the authors propose a state space average model of a 750 V DC traction power system. The purpose of the model is to simulate short-circuit and open-circuit faults in the urban railway network. The proposed model consists of a third rail and running rails modeled as an equivalent resistance and inductance. A value of 15 Ωkm for the rail-to-earth resistance was used. The substation was modeled as a DC source with the output voltage constant. This is an oversimplification that will have a significant impact on the shape and magnitude of the fault current. The proposed model does not include HV source impedance, track feeder cables, or cross bonds. The open circuit fault (arc fault) was modeled by adding a serial resistance between the third rail and the running rail with a value of 1 MΩ. The short-circuit fault (bolted fault) was modeled by adding a serial resistance between the third rail and the running rail with a value of 1 μΩ. The values used for fault resistance are on the pessimistic side if we compare them with values used by other studies. The fault location was assumed at a distance of 4 km. The open-circuit fault had a value of 3 kA, and the short-circuit fault had a maximum value of 20 kA.

The paper [

5] is focused on the implication of the fault current on the public safety. The fault current and potentially dangerous touch voltages are discussed. The authors used a simplified 635 V DC model with a proposed characteristic for the transformer/rectifier. The transformer/rectifier was modeled as an equivalent voltage source in series with a resistance. The rails and OCS were modeled as longitudinal resistance with shunt conductance to the ground for the rails. HV source impedance and rail/OCS inductance were not considered in the proposed model. The ground fault in the substation provided a fault current of 11 kA. The simulation results show that the over-current protection is not sufficient to disconnect distant ground fault currents due to the low magnitude of the fault current.

In [

6] the model of transformer rectifier for urban railway transit is analyzed in detail to simulate close fault currents. The proposed model considers of three-winding transformer connected to two bridges to form 12-pulse rectifier. Tensor analysis was used to reformulate circuit equations and linear interpolation was used to determine the switching time. It was shown that the inductance of AC side and inductance on DC side has a significant effect on short circuit transient current. For a fault located 50 m from the substation (2 MVA transformer rectifier) the peak of the short-circuit current has a value of 33 kA.

The authors propose a mathematical method to simulate DC railway traction system for load analysis and substation fault modes [

7]. Contact line and running rails are modeled as a resistance. A voltage regulation characteristic is proposed for the rectifier but it is not clear how this was implemented in the model. The equivalent circuit of the railway power network shows the substation as a constant voltage source. In the paper, no value was provided for rail-to-earth resistance. The short-circuit fault was modeled between the contact line and earth with a resistance of 0.1 Ω. In a short-circuit fault study the contact line and running rail inductance has a significant impact on the fault current. The use of a constant voltage source to model the DC substation is an over simplification which may yield inaccurate results. The paper does not provide fault current results or any specific analysis on the fault subject.

The paper [

8] presents an analysis of the DC short-circuit current, protection settings, guidance for design and selection of the DC circuit breakers. A simulation model of the AC supply, rectifier and subway traction network is proposed. The DC circuit breaker topology is present with emphasis on selection and design of DC circuit breaker taking into consideration DC protection.

In [

9], the authors propose a DC railway model based on MATLAB/Simulink (MathWorks) to model distant fault short circuits. The substation was modeled using MATLAB/Simulink blocks for a three-phase source, a three-phase transformer, and a rectifier. An S-function is proposed to build the impedance model for the third rail system. Simulation results are presented for a distant fault (2.88 km) with and without the skin effect of the short-circuit current. The skin effect impedance was derived using Maxwell’s equations. With the skin effect, the short circuit current had a value of 1.1 kA, and without the skin effect, it had a value of 1.9 kA. The authors do not provide a full list of parameters used for simulation, and it is not possible to determine why the fault currents had such low values.

In [

10], the authors conducted field tests on a Portland 825 V DC light rail system. Two types of field tests were conducted: the frame fault and the ground fault. For a diode grounded system, the frame fault peak current was 10 kA. In a floating ground configuration (grounding diode disconnected), the frame fault current magnitude was 300 A. Equations are proposed for the ground fault to determine the step and touch potential. Based on the test conducted, the grounding diodes were disconnected at all substations locations, as they would be damaged in the event of a ground fault. A rail-to-earth voltage relay is recommended for ground fault detection.

A MATLAB/Simulink model was proposed for a DC traction power supply system in [

11]. The model uses predefined Simulink blocks: a three-phase source, a zigzag phase-shifting transformer, a three-phase transformer, and a universal bridge for the rectifier. At the output of the system, an RL filter (MATLAB/Simulink block) was used at the output of the 24-pulse rectifier unit. The simulated and measured external characteristics of the 24-pulse rectifier unit were compared and showed good convergence. The “PI line section” block from MATLAB/Simulink was used to model the traction power network. The peak of the short-circuit current had a value of 14.9 kA for close faults and 4 kA for distant faults. It was shown that close short-circuit faults can cause large transient peak fault currents and a high rate of increase in fault currents.

In [

12], real data on short-circuit fault and load current values, measured on the tram network of Turin, Italy, are presented. The peak of the short-circuit current for distant bolted faults had a value of 3.6 kA with a current rate of increase of 60 A/ms. Trams equipped with a variable speed drive (rheostatic control) had a peak load current of 450 A and a current rate of increase of 4 A/ms. Trams equipped with a variable frequency drive had a peak load current of 1.1 kA and a current rate of increase of 1.5 A/ms. The maximum current threshold to protect the cable overload was set in the range of 3600 A to 4100 A. The current rate of increase recognition threshold was set to 30 A/ms, and the maximum rate of increase threshold was set to 120 A/ms.

The paper [

13] focuses on grounding faults and rail potential in a DC traction power supply system. The grounding fault was a short circuit between contact line and OCS structures with a resistance of a few ohms to tens of ohms. The main issue in detecting grounding faults is that the load current of the train has higher values than the grounding fault current. The grounding fault is detected by measuring the potential between the rail and the substation grounding mesh. Train load current and rail potential measurements were conducted for seven substations in the East Japan Railway area. For the Tokyo substation (1.5 kV DC), it was shown that the 10 min rectifier load current had peak values of 10 kA with a maximum rail potential of 40 V. A simplified simulation model with constant voltage sources was proposed to calculate the rail potential. The rail-to-earth resistance was assumed to be 10 Ω·km. It was shown that the rail potential at the substation can become positive, which contradicts the general belief that it is negative.

In conclusion, many improvements could be made when simulating a DC traction power railway system for fault current and protection analysis. The simulation model needs to include the following parameters for an accurate representation of the DC railway system:

the contact system, running rail resistance, and inductance;

HV source impedance;

the transformer and rectifier, modeled separately as different components;

the positive and negative track feeders’ resistance and inductance;

rail-to-earth resistance;

cross bonds;

short-circuit resistance;

temperature, which is an important factor that needs to be considered when calculating the resistance and inductance.

The scope of this paper is to present a simulation tool that incorporates all of the requirements needed to model fault currents in a DC railway system to assist in the protection and fault assessment of traction power equipment. The accuracy of the model is affected by the accuracy of the input data used for the simulation. The main contributions of the paper are as follows:

a technical description of short-circuit fault current and protection concepts;

a proposal for a simulation tool and its application in the design of DC railway systems;

a presentation of the main equations used to calculate the input data for the simulation tool;

a discussion of the results from the case study conducted—an application of the developed tool to assess the withstand/breaking capacity of the circuit breakers and to conduct protection analysis.

This paper is structured as follows: In

Section 2, the technical aspects of the short-circuit fault current and protection is discussed with respect to a DC light rail system.

Section 3 describes the implementation of the DC light rail system in MATLAB/Simulink together with mathematical equations and typical input data used in the proposed model. The MATLAB/Simulink model was validated following European Standard (EN) 50123-1 guidance. In

Section 4, a case study is considered to assess the withstand and breaking capacity of the Alstom DC circuit breaker for maximum currents and distant faults. A protection analysis was conducted, considering the protection of the direct acting overcurrent and the current rate of increase. To assist with the protection assessment, traction power modeling was conducted in Modeltrack software [

14,

15]. Findings and conclusions are presented in

Section 5.

3. MATLAB/Simulink Modeling of the DC System with a Wayside Energy Storage Device

A light rail 1500 V DC traction power system was assumed for modeling purposes in MATLAB/Simulink (MathWorks). The power was distributed to trains from 1500 V DC substations using the overhead contact system. The current returns from trains to substations use train wheels and running rails. Because the rails are not perfectly insulated from the ground, some of the current will return to substations using ground and buried metalwork. This current is referred to earth leakage current or “stray current”.

Figure 2 presents a typical 1500 V DC substation feeding arrangement. The substation is connected to the 22 kV AC distribution network operator (DNO) via HV lines. The OCS is fed from the substation transformer rectifier unit via DC circuit breakers and positive feeder cables (PF). In a normal feeding arrangement, the DC substation is equipped with two or more TRUs that feed in parallel with the OCS. The substation negative busbar is connected to the running rail via return negative feeders (NF). As there is no connection between the substation negative busbar and the ground, the system return is “floating”. The main reason that the negative return system is isolated from the ground is to minimize the earth leakage current and protect the buried metalwork. This may create touch potential issues along the route, as the rail-to-earth potential may rise. To provide a fault clearance path and to reduce rail-to-earth voltage, voltage limiting devices (VLDs) are installed along the route and at stations. EN 50122-1 provides guidance regarding touch potential limits [

19]. British Standard (BS) 7671 provides guidance related to the touch potential clearance area [

20].

In a DC traction power system, a trackside paralleling hut (TPH) is used to improve line voltage and to provide switching points between electrical sections. The TPH runs parallel with multiple tracks, and this reduces the longitudinal system impedance.

Figure 3 presents a TPH with a wayside energy storage device (WESD). The WESD with supercapacitors charges from the regenerative braking trains and boosts the line voltage when the line voltage is below a threshold value.

The 1500V DC traction power system was divided in the following blocks to be modeled in MATLAB/Simulink:

The substation block was divided into an HV source, a transformer, a rectifier, a positive feeder, and a negative feeder.

A trackside paralleling hut block was equipped with a wayside energy storage device.

OCS, running rails, and the earth block were also modeled.

3.1. Modeling of the Substation

The HV source was modeled in MATLAB/Simulink using a sinusoidal ideal voltage source. The AC voltage [

21] is calculated as in Equation (1):

where ∅ is the phase angle in radians,

f is the frequency in Hz and

ω is calculated as in Equation (2):

A three-phase system with an internal resistance and inductance can be modeled using three ideal voltage sources connected in Y with the neutral connection grounded. The source internal resistance and inductance were calculated from the internal impedance using the X/R ratio and short-circuit current. The short-circuit current and X/R ratio value were provided by the DNO. The ANSI standard IEEE C37.010 provided typical values for the transformer X/R ratios [

22]. It is known that the higher the X/R ratio is, the longer the time constant is.

Table 1 presents the typical model input values calculated for the HV source block. The short-circuit current was assumed to be 13 kA, and the X/R ratio was assumed to be 7.

The rectifier transformer was modeled using a predefined MATLAB/Simulink three-phase transformer block. The primary transformer winding is connected in Δ, the first secondary winding is connected in Δ, and the second secondary winding is connected in Y. Values for the transformer rated power, voltage, current, and impedance can be sourced from the manufacturer data sheet. The simulation model requires values for the transformer magnetization resistance and inductance [

18].

Equations (3) and (4) can be used to calculate per unit resistance and inductance for each winding [

23].

The base resistance and inductance can be calculated as in Equations (5) and (6) [

23]:

An assumed magnetization current of 0.2% provides a magnetization resistance of 500 pu for the resistance and inductance.

Table 2 presents the transformer input parameters used for simulation purposes. The magnetization resistance and inductance were calculated with Equations (3)–(6).

A 12-pulse diode rectifier was modeled using diode blocks with internal resistance and diode forward voltage parameters. Each diode was equipped with a capacitor connected in parallel. At the output of the rectifier, a capacitor was connected in parallel to provide a steady voltage. The rectifier parameters were sourced from manufacturer data sheets.

Figure 4 presents the HV source and the transformer rectifier blocks that were modeled in MATLAB/Simulink.

The diode internal resistance and forward voltage was sourced from [

24]. The diode parallel capacitor and rectifier output capacitor were sized with a trial-and-error method (

Table 3). These values can be sourced from the rectifier manufacturer data sheet.

Figure 5 presents the positive and negative feeder blocks that were modeled in MATLAB/Simulink. The positive feeder was modeled using a resistance (

RPF) connected in parallel with an inductance (

LPF). The negative feeder was modeled similarly using a resistance (

RNF) connected in parallel with an inductance (

LNF).

The resistance and inductance for the positive feeder and the negative feeder were sourced at a temperature of 20 °C, based on the manufacturer data sheet. Depending on the geographic area where the traction power system was located, the resistance and inductance were calculated for a temperature between 45 and 60 °C, taking into consideration the traction current.

Table 4 presents the resistance and inductance value calculated for the substation positive feeder cable and the negative feeder cable according to BS IEC 60287-2-1:2015 [

25].

3.2. Trackside Paralleling Hut with Wayside Energy Storage Device

The trackside paralleling hut was modeled similar to the substation block described in

Section 3.1. The trackside paralleling hut was equipped with a positive and negative busbar to provide a paralleling point and supply continuity from the WESD to the tracks. The WESD was modeled with the MATLAB/Simulink supercapacitor block and Cuk converter arrangement standards described in [

27].

To protect the WESD from a high fault current, the maximum load/fault current was limited to 3000 A. Resistance and inductance ‘RL’ MATLAB/Simulink blocks were connected in series with the WESD. The resistance was calculated as 0.523 Ω, and the inductance was assumed to be 6 mH.

3.3. Modeling of the OCS, Running Rail, and Earth

The OCS was modeled using a resistance connected in parallel with an inductance. Typical OCS resistance (ROCS) and inductance (LOCS) values (Ω/km and H/km) were sourced at a temperature of 20 °C, based on the manufacturer data sheet. Depending on the geographic area where the traction power system was located, the resistance and inductance were calculated for a temperature between 45 and 60 °C, taking into consideration the traction current. The contact wire wear was normally assumed to be 30% of the new contact wire.

The track feeders, the OCS, and the rail inductance

L (mH/km) can be calculated as in Equation (7):

where

R is the radius of the conductor, measured in meters:

The running rail resistance (

RRR) and inductance (

LRR) were modeled like the OCS. The wear for the rail is normally assumed to be 20% from the top of the rail. A common assumption in traction power modeling projects is that the top of the rail is 1/3 of the rail. The rail-to-earth resistance (

RRE) is approximative 100 Ω·km for a new railway system and drops to 10 Ω·km after a period of usage [

13]. For the signaling system to work, the rail-to-earth resistance is normally required to be above 2–3 Ω·km.

Figure 6 presents the OCS and running rails blocks that were modeled in MATLAB/Simulink.

Table 5 summarizes the OCS and running rail input parameters. The OCS/rail resistance and inductance at a final temperature of 45 °C were calculated as in [

15]. The input parameters for the temperature calculations were similar to the one used in [

15].

3.4. Model Validation

A validation was conducted to compare the short-circuit fault current calculated from the proposed MATLAB/Simulink model with the values obtained from hand calculations according to EN 50123-1 [

16].

For the validation exercise, the following input data was used:

a single track 1500 V DC system with a single 4 MW TRU substation (for substation parameters, see

Table 2 and

Table 3);

DC substation negative and positive feeders with a length of 50 m (for cable parameters, see

Table 4);

a track length of 1 km (the OCS and running rail resistance are presented in

Table 5);

a bolted fault between the OCS and the running rail that was assumed to be 1 km away from the substation (

Figure 7).

Table 6 presents the calculated equivalent source resistance and loop resistance. The loop resistance includes the positive feeder, negative feeder, OCS, and single running rail resistance.

The bolted short-circuit fault current contribution (

IF) from the substation can be calculated with Equation (9):

Figure 8 presents the MATLAB/Simulink calculation result of the 9.467 kA short-circuit bolted fault current. The fault current is a distant short-circuit fault current simulated to be 1 km from the analyzed substation.

Table 7 presents the simulation and hand calculation results. The approximation error between the two set of the results was calculated. The results below show that the relative error was 1.02% for the modeled short-circuit current, which provides a good validation of the proposed MATLAB/Simulink model.

5. Conclusions

The MATLAB/Simulink model developed for fault modeling in DC systems is a useful tool to model different types of DC short-circuit faults: distant, close, bolted, and arc short-circuit faults. The paper presents a method to model substations, trackside paralleling huts, wayside energy storage devices, track feeders (positive and negative), overhead contact systems, running rails, and rail-to-earth resistance in MATLAB/Simulink. The proposed model eliminates the over-simplification of existing short-circuit models by taking the parameters that have a direct impact on the magnitude and shape of the fault current into consideration. A validation of the software according to EN 50123-1 [

11] was conducted with good results, showing a 1.02% relative error.

Results of the case study using the MATLAB/Simulink model for a 1500 V DC light rail system show that the maximum short-circuit current for a bolted fault at the DC positive busbar is 88.27 kA (F3). The analyzed Alstom circuit breaker can withstand 97 kA at a time constant of 4.3 ms. The distant fault (F1) shows a maximum short-circuit fault current of 9.2 kA. At a track time constant of 87.9 ms, the Alstom circuit breaker can withstand 28.5 kA. The simulation results demonstrate that the circuit breaker is correct rated for the analyzed system (

Table 17).

In [

6], a fault modeled 50 m from a DC substation (2 MVA TRU) had a short-circuit current peak of 33 kA. In this paper, the substations were equipped with a 2 × 4 MW TRU, and the close fault was modeled at the substation DC busbar, which provided a higher fault current. In another study, the peak of the short-circuit current for the distant bolted fault was 3.6 kA [

12], comparable to the value modeled in this paper, i.e., 3.9 kA (F1,

Table 14).

The WESD maximum load and fault current was limited to 3000 A to protect the equipment. The WESD fault contribution was marginal compared with the substation fault contribution located adjacent to the fault location.

Protection analysis was conducted to determine if direct acting overcurrent protection can distinguish between the maximum load current and the minimum short-circuit fault current. The Modeltrack simulation results showed that the maximum 1 s RMS load current in the Substation 2 track feeders (F4) was 3624 A. The fault current was 8247 A (MATLAB/Simulink), which proves that discrimination between load and fault current can be achieved. The short-circuit current rate of increase was 72 A/ms which is above the 20 A/ms assumed current rate of increase limit for load current. The simulation results demonstrate that the circuit direct acting overcurrent and current rate of increase can be protected by this system (

Table 17). In [

12], the current rate of increase recognition threshold was set to 30 A/ms, which aligns with the approach used in this paper.

The proposed MATLAB/Simulink model together with the Modeltrack tool [

9,

10] and the methods presented in this paper can be used for DC protection settings calculations and DC circuit breaker rating analysis. The added benefit of the simulation tool is that it can model different fault types (bolted or arc faults) and fault scenarios (close or distant faults) in a short period of time. The simulations results may be used to assess the withstand capacity of traction equipment against short-circuit fault currents. For example, if a new substation is added to an existing electrified rail section, the fault current in that section may significantly increase. This can be a high risk to the public and the existing infrastructure (i.e., the existing switchgear in the substations may not withstand the new short-circuit fault currents).