Heat Transfer of Near Pseudocritical Nitrogen in Helically Coiled Tube for Cryogenic Energy Storage

Abstract

:1. Introduction

2. Experimental Methodology

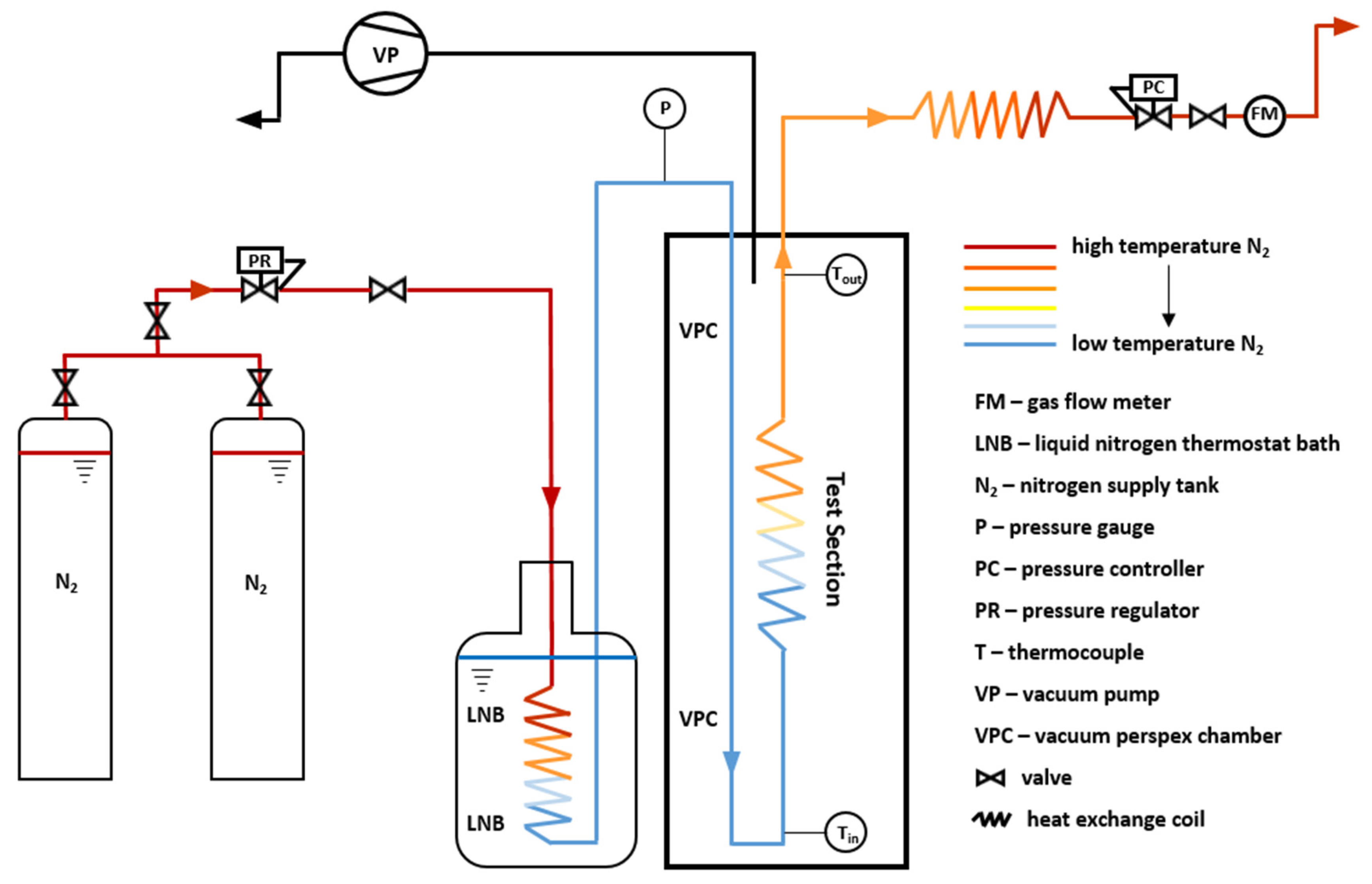

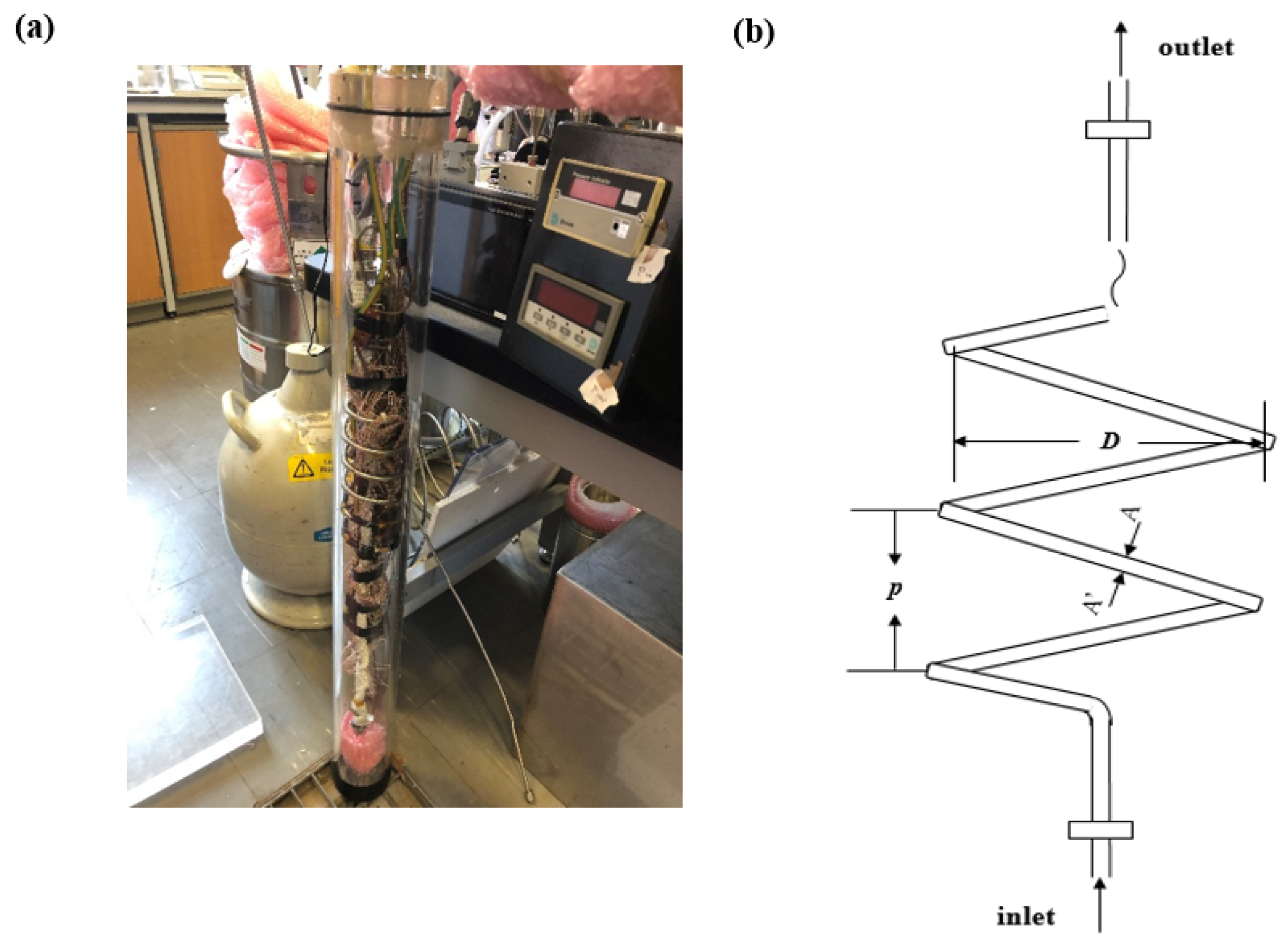

2.1. Experimental Apparatus

2.2. Experimental Apparatus

- U: given function of independent variables, U = U (X1, X2, ……, Xn);

- Xn: independent variable;

- σXn: uncertainty associated with corresponding independent variable, Xn;

- σU: uncertainty associated with dependent variable U.

3. Results

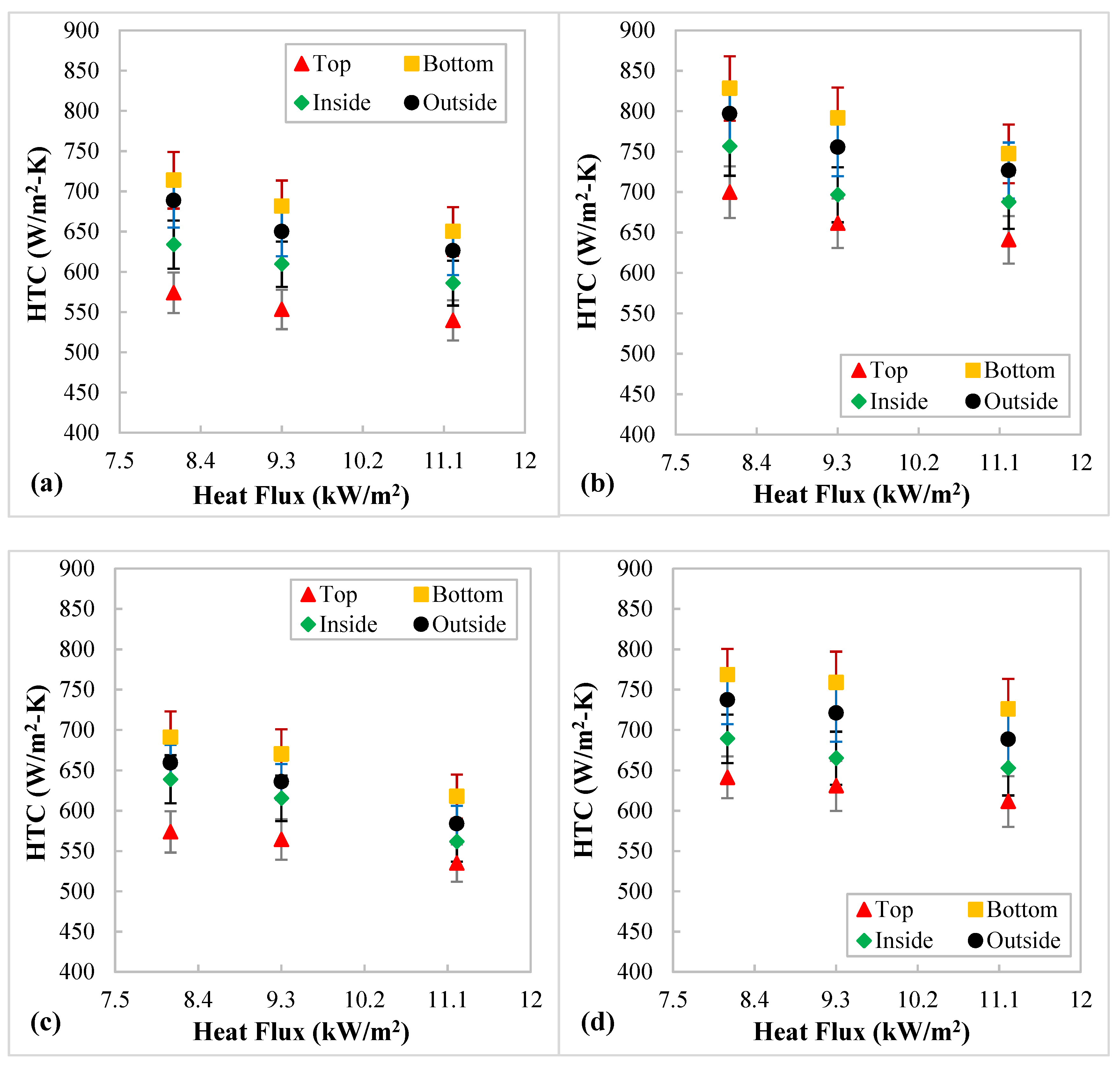

3.1. Effects of Heating Power, Flow Rate, and Pressure on Heat Transfer

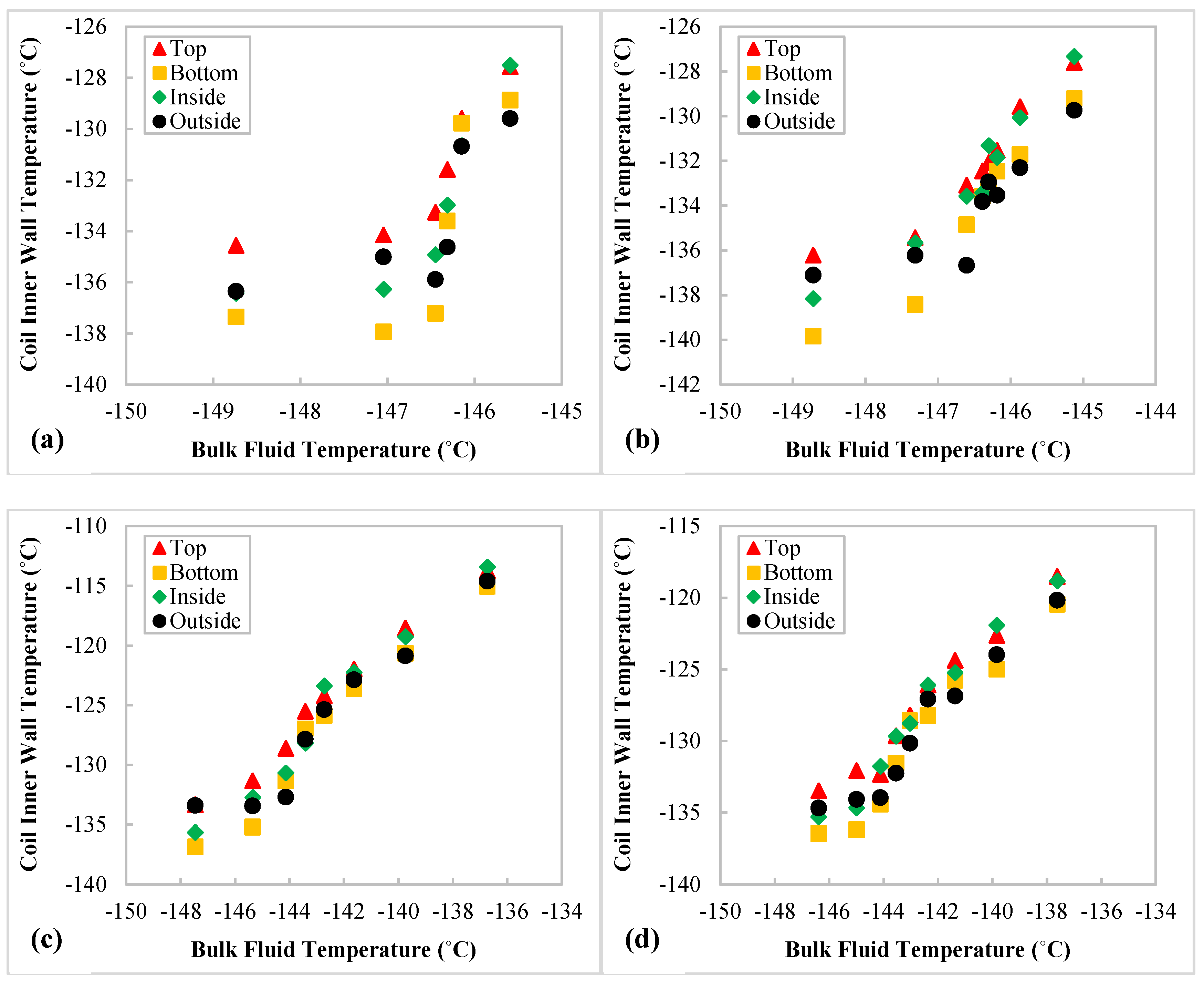

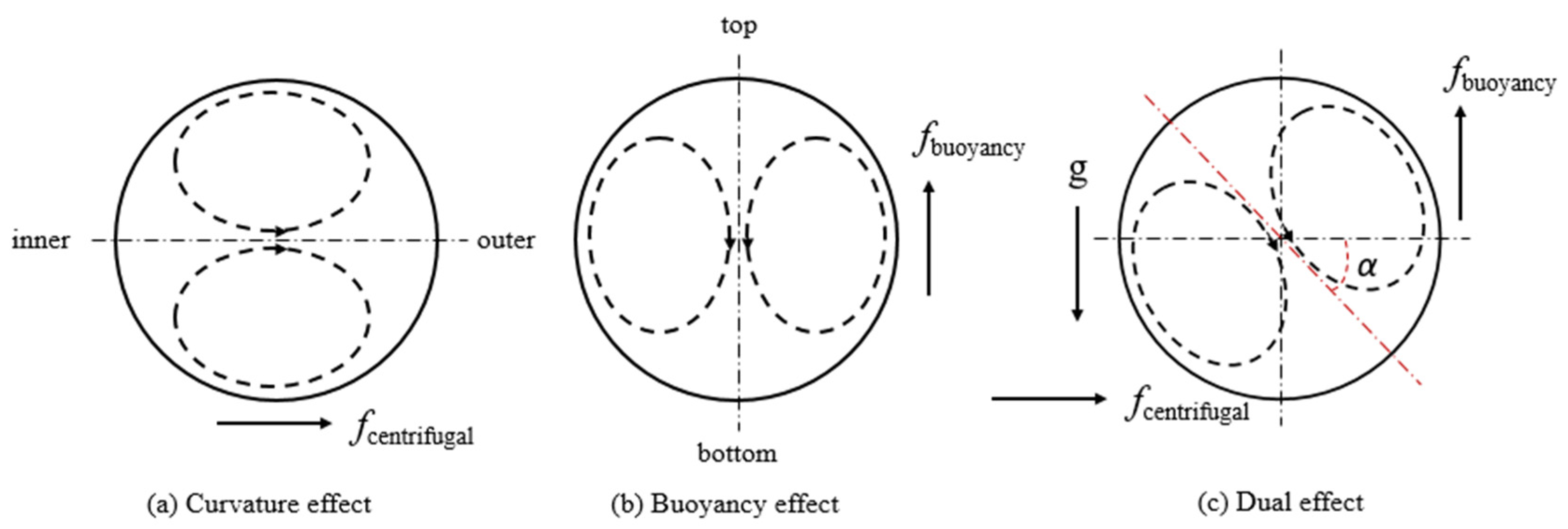

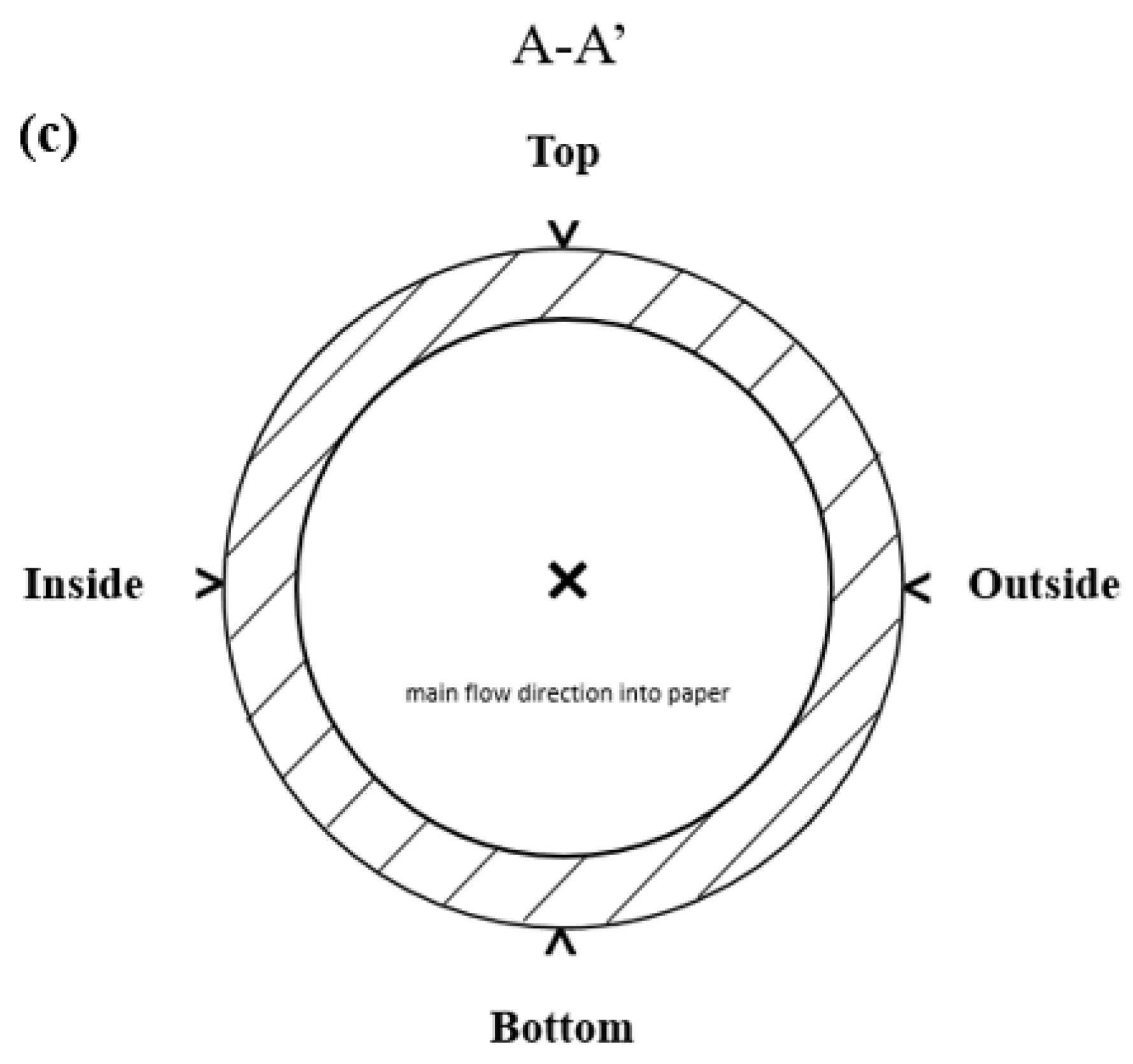

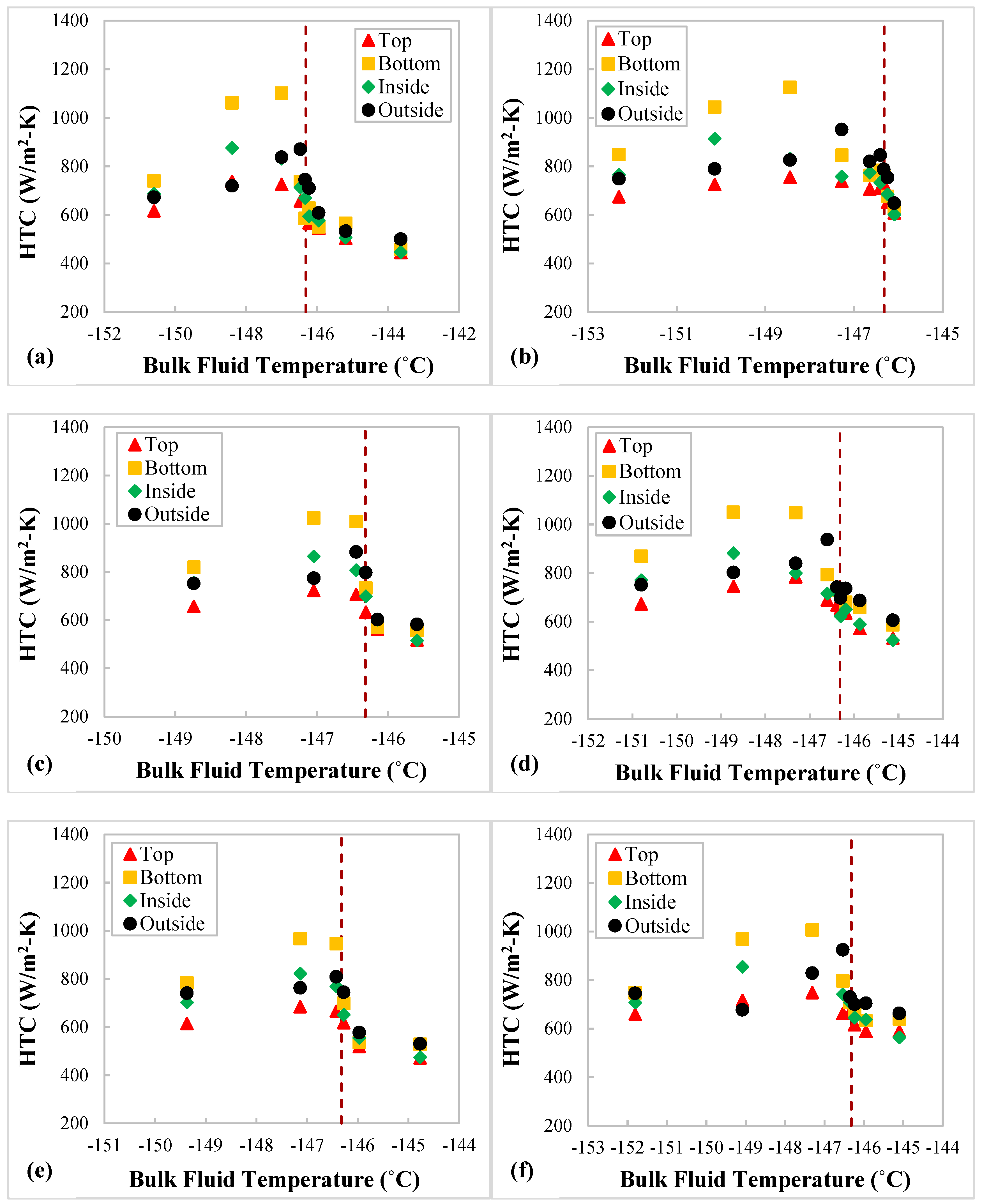

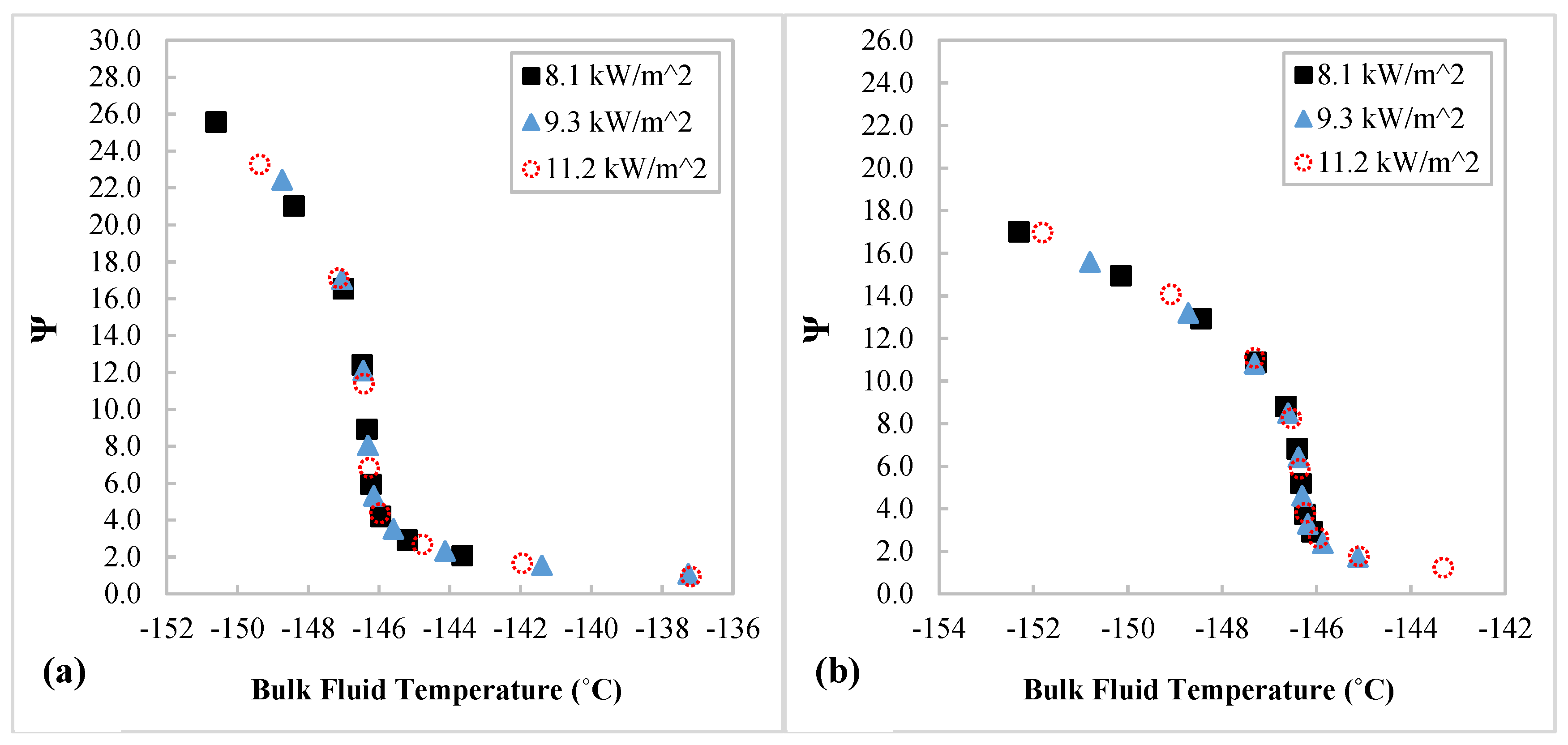

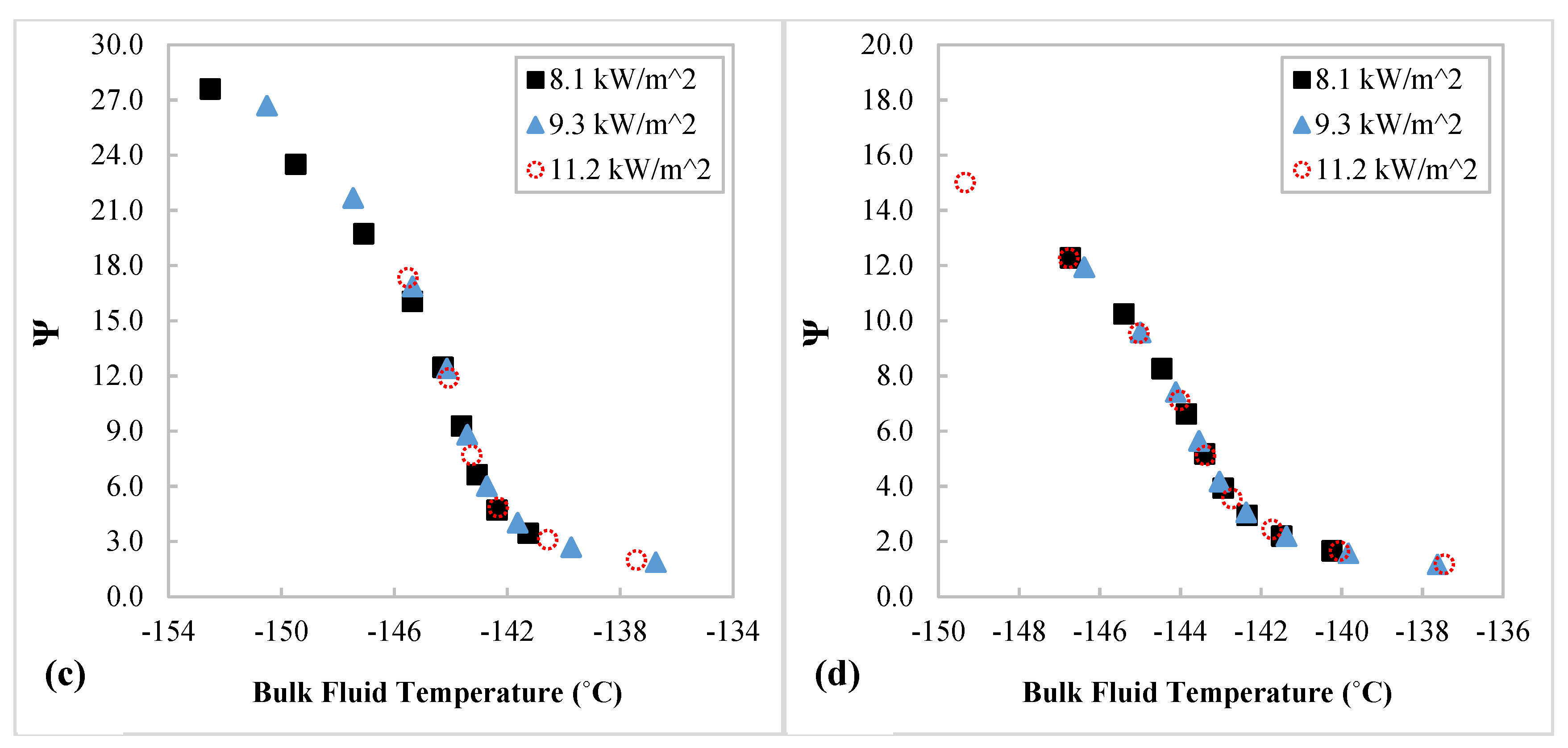

3.2. Effects of Buoyancy and Coil Curvature-Induced Centrifugal Force on Heat Transfer

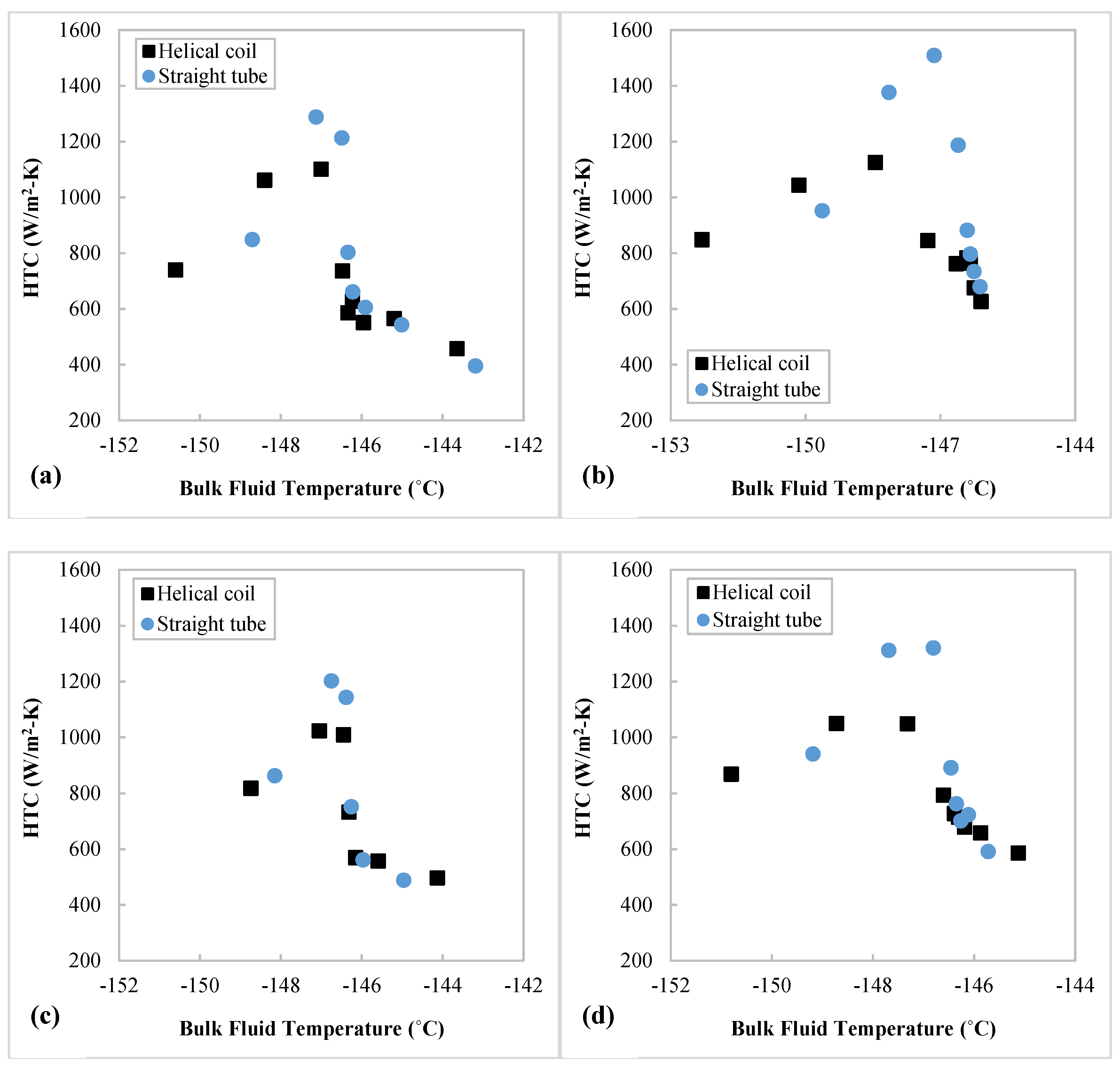

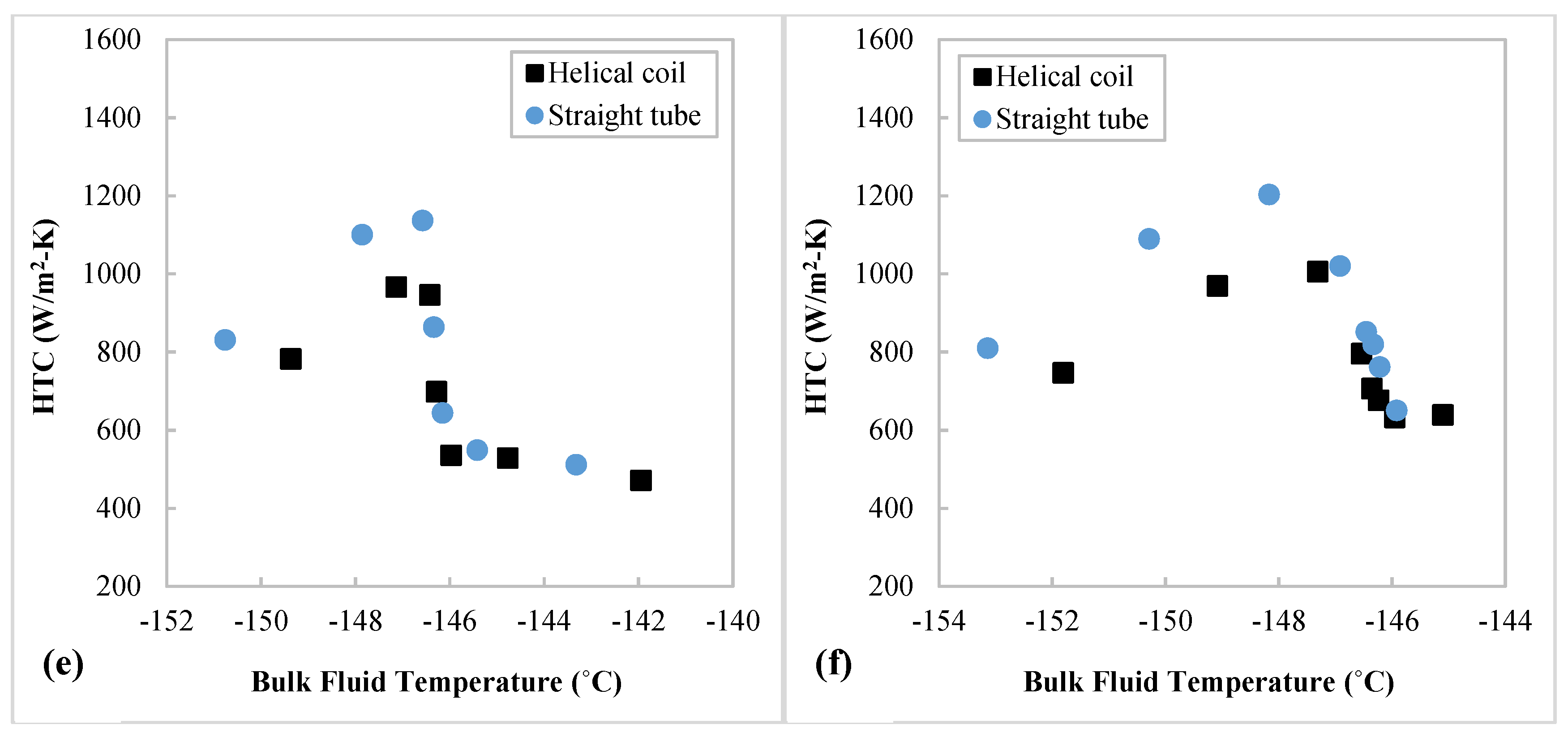

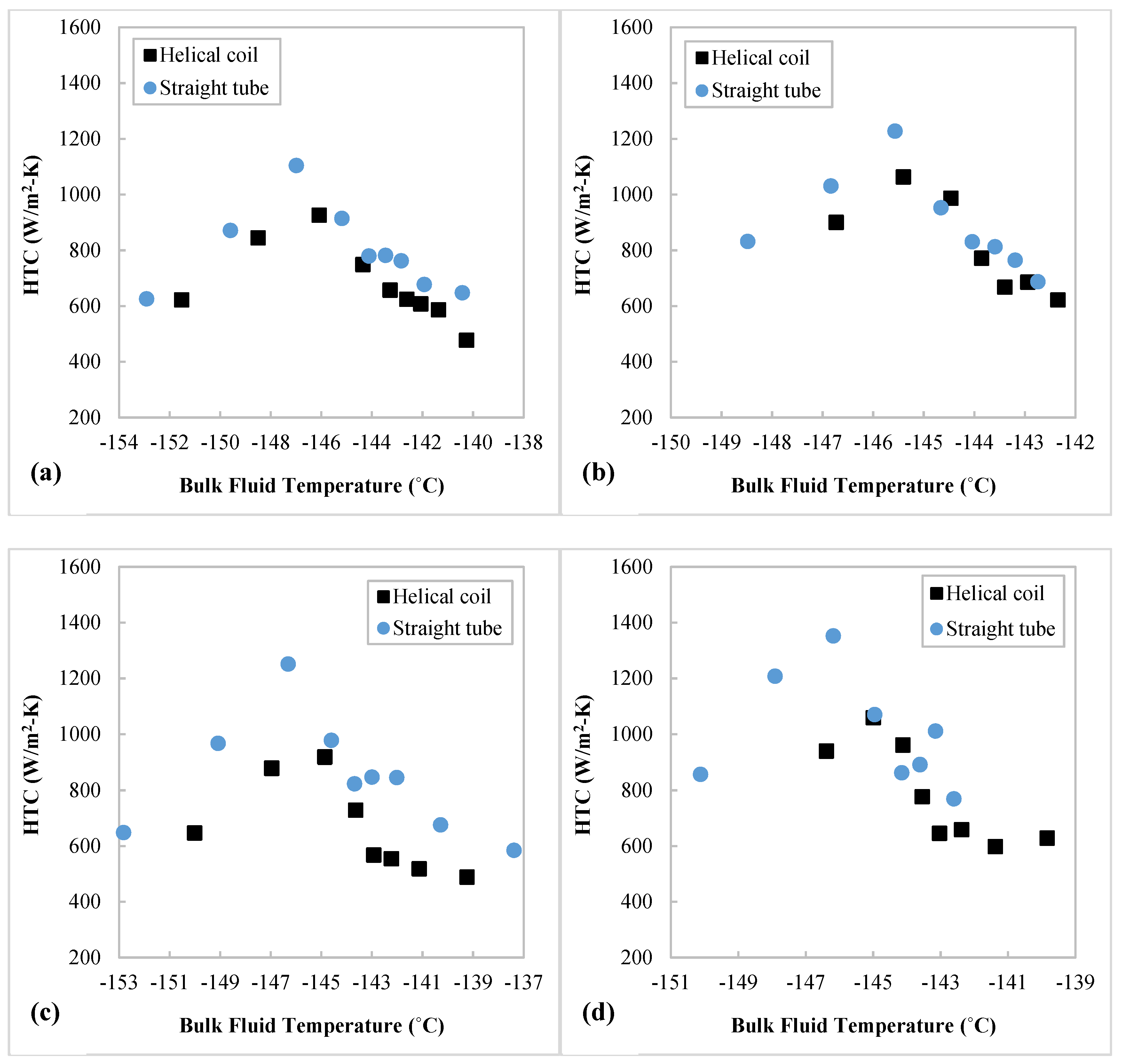

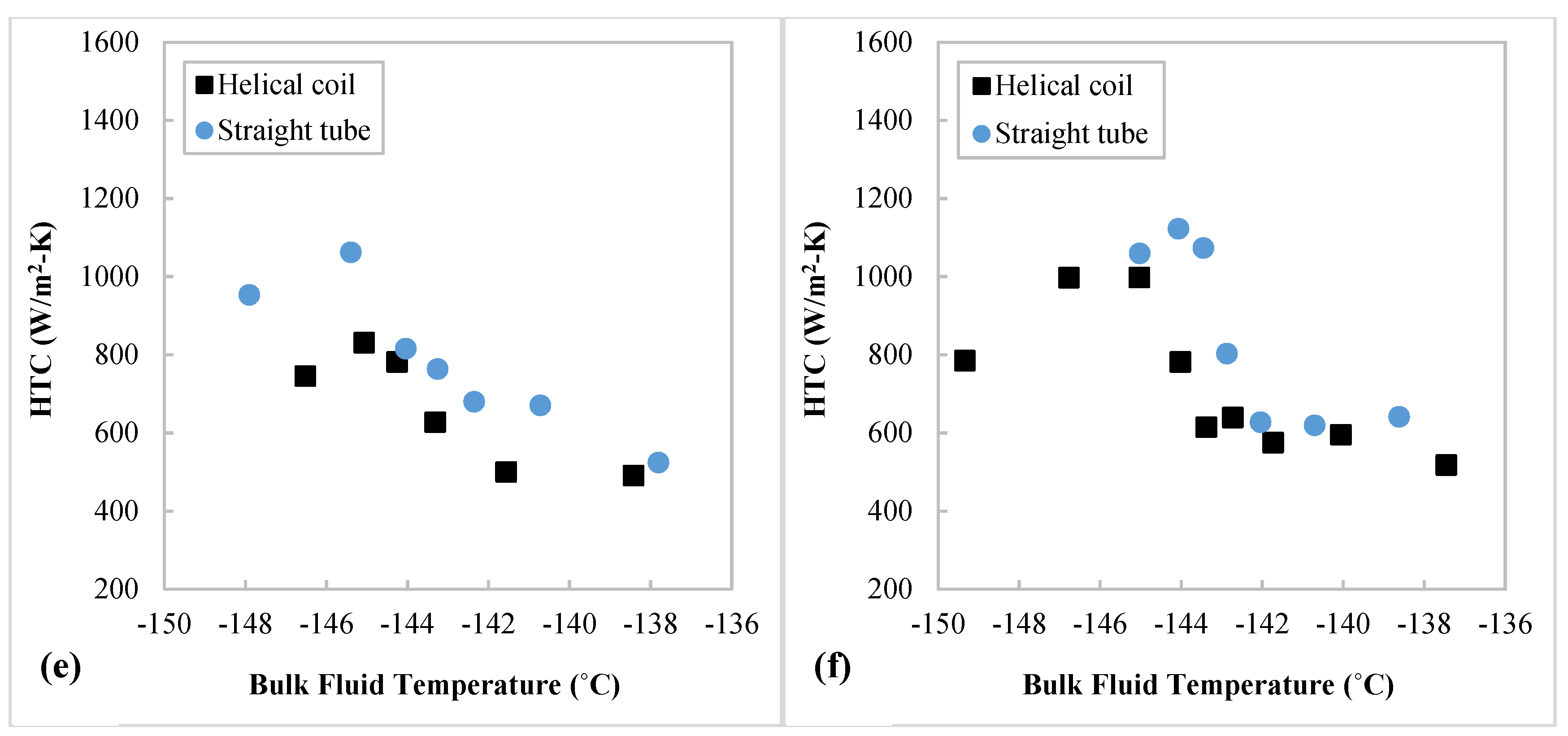

3.3. Comparison between Heat Transfer in Helically Coiled Tube and Straight Tube

4. Conclusions

- The heat transfer coefficients (HTCs) of near pseudocritical nitrogen increase with the increase in mass flux but decrease with the increment in heat flux and pressure in the helically coiled tube.

- The local HTCs of the nitrogen follow the same trend as other supercritical fluids, such as water and CO2—that is, they first increase to a peak value in the vicinity of the pseudocritical point but then dramatically drop as the fluid temperature keeps increasing.

- The local HTCs are highest at the bottom measuring position of a local coil cross section at fluid temperatures below the pseudocritical temperature featuring the buoyancy effect, but they are at the outside position for higher fluid temperatures as the fluid accelerates, and thereby the curvature-induced centrifugal effect starts to have stronger impact.

- The values of dimensionless number Ψ, which is a ratio between the effect of buoyance and curvature, indicate the mixed convection nature of near pseudocritical N2 heat transfer in the helically coiled tube—i.e., depending on the dual effect of buoyancy and curvature. The Ψ values are much greater than 1 at fluid temperatures below the pseudocritical temperature, suggesting that the heat transfer is dominated by the buoyancy effect while the Ψ values are getting close to 1 at fluid temperatures above, showing that the coil curvature-induced centrifugal effect plays a more important role in the dual effect at higher temperatures.

- When compared with the HTCs of supercritical N2 in a straight tube under similar experimental conditions, the HTCs in the helical coil are ~13% lower at fluid temperatures below the pseudocritical temperature but close to the straight tube values (<±6%) at higher fluid temperatures, as the effects of curvature and improved turbulent mixing are moderated by the effect of buoyance at fluid temperatures below the pseudocritical temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Latin symbols | |||

| Cp | specific heat, J/(kg∙K) | T | temperature, °C |

| d | coil tube inner diameter, mm | U | a given function of independent variables Xn |

| D | coil curvature diameter, mm | x | local axial location, mm |

| De* | modified Dean number | Δx | tube wall thickness, mm |

| fb | buoyancy force, N | Xn | nth independent variable |

| fc | centrifugal force, N | q″ | heat flux, W/m2 |

| g | gravitational acceleration, m/s2 | ||

| G | mass flux, kg/(m2∙s) | Greek symbols | |

| Gr | Grashof number | Ψ | the ratio of gravitational buoyancy to curvature effect |

| Grg | gravitational Grashof number | α | the incline angle of secondary vortices symmetric line, ° |

| h | heat transfer coefficient, W/(m2∙K) | σ | uncertainty of a certain variable |

| H | specific enthalpy, kJ/kg | ρ | density, kg/m3 |

| HTC | heat transfer coefficient | μ | dynamic viscosity, Pa∙s |

| Hin | inlet specific enthalpy, kJ/kg | v | kinematic viscosity, m2/s |

| k | thermal conductivity, W/(m∙K) | ||

| L | length, m | Subscripts | |

| N2 | nitrogen | b | bulk fluid |

| P | pressure, Pa | local | local value along test tube axis |

| p | coil pitch, mm | outer | outer tube wall |

| R | coil curvature radius, mm | pc | pseudocritical point |

| Re | Reynolds number | w | tube wall |

Appendix A

| HTCtop Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 11.28% | 11.02% | 10.75% | 11.40% | 11.28% | 10.84% |

| Min. | 10.39% | 10.27% | 10.24% | 10.84% | 10.52% | 10.37% |

| Mean | 10.80% | 10.62% | 10.46% | 11.18% | 10.89% | 10.60% |

| Std. | 0.26% | 0.28% | 0.21% | 0.18% | 0.23% | 0.15% |

| HTCbottom Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 13.30% | 12.24% | 11.58% | 13.02% | 12.40% | 11.57% |

| Min. | 10.48% | 10.33% | 10.28% | 10.90% | 10.65% | 10.43% |

| Mean | 11.46% | 11.04% | 10.74% | 11.74% | 11.35% | 10.87% |

| Std. | 1.03% | 0.74% | 0.52% | 0.70% | 0.65% | 0.40% |

| HTCinside Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 12.01% | 11.53% | 11.12% | 12.07% | 11.77% | 11.16% |

| Min. | 10.41% | 10.29% | 10.24% | 10.90% | 10.55% | 10.36% |

| Mean | 11.09% | 10.79% | 10.57% | 11.45% | 11.09% | 10.74% |

| Std. | 0.54% | 0.46% | 0.33% | 0.32% | 0.39% | 0.27% |

| HTCoutside Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 12.06% | 11.65% | 11.08% | 12.28% | 11.83% | 11.32% |

| Min. | 10.59% | 10.33% | 10.29% | 10.98% | 10.70% | 10.45% |

| Mean | 11.28% | 10.90% | 10.65% | 11.59% | 11.17% | 10.80% |

| Std. | 0.50% | 0.46% | 0.31% | 0.36% | 0.33% | 0.25% |

| HTCtop Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 11.12% | 11.00% | 10.73% | 11.12% | 11.44% | 11.13% |

| Min. | 10.45% | 10.31% | 10.22% | 10.45% | 10.52% | 10.39% |

| Mean | 10.83% | 10.64% | 10.40% | 10.83% | 10.92% | 10.70% |

| Std. | 0.23% | 0.26% | 0.18% | 0.23% | 0.31% | 0.24% |

| HTCbottom Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 12.18% | 11.96% | 11.06% | 12.18% | 12.55% | 11.79% |

| Min. | 10.56% | 10.34% | 10.26% | 10.56% | 10.63% | 10.47% |

| Mean | 11.24% | 10.94% | 10.55% | 11.24% | 11.35% | 10.98% |

| Std. | 0.52% | 0.58% | 0.31% | 0.52% | 0.70% | 0.50% |

| HTCinside Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 11.53% | 11.43% | 10.84% | 11.53% | 11.85% | 11.33% |

| Min. | 10.49% | 10.31% | 10.23% | 10.49% | 10.52% | 10.40% |

| Mean | 11.07% | 10.80% | 10.46% | 11.07% | 11.03% | 10.80% |

| Std. | 0.36% | 0.40% | 0.24% | 0.36% | 0.47% | 0.32% |

| HTCoutside Uncertainty | 38.1 kg/m2-s, 8.1 kW/m2 | 38.1 kg/m2-s, 9.3 kW/m2 | 38.1 kg/m2-s, 11.2 kW/m2 | 50.8 kg/m2-s, 8.1 kW/m2 | 50.8 kg/m2-s, 9.3 kW/m2 | 50.8 kg/m2-s, 11.2 kW/m2 |

|---|---|---|---|---|---|---|

| Max. | 11.81% | 11.57% | 10.78% | 11.81% | 11.90% | 11.39% |

| Min. | 10.52% | 10.33% | 10.26% | 10.52% | 10.60% | 10.46% |

| Mean | 11.10% | 10.83% | 10.48% | 11.10% | 11.19% | 10.86% |

| Std. | 0.40% | 0.42% | 0.19% | 0.40% | 0.45% | 0.30% |

References

- Fsadni, A.M.; Whitty, J.P. A review on the two-phase heat transfer characteristics in helically coiled tube heat exchangers. Int. J. Heat Mass Transf. 2016, 95, 551–565. [Google Scholar] [CrossRef]

- Brown, C.S.; Cassidy, N.J.; Egan, S.S.; Griffiths, D. Thermal and Economic Analysis of Heat Exchangers as Part of a Geothermal District Heating Scheme in the Cheshire Basin, UK. Energies 2022, 15, 1983. [Google Scholar] [CrossRef]

- Assad, M.E.H.; Nazari, M.A. Chapter 3—Heat Exchangers and Nanofluids. In Design and Performance Optimization of Renewable Energy Systems; Academic Press: London, UK, 2021; pp. 33–42. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, B.; Zhang, H.; Zhu, K.; Kong, B.; Guo, J.; Li, F. Accuracy and efficient solution of helical coiled once-through steam generator model using JFNK method. Ann. Nucl. Eng. 2021, 159, 108290. [Google Scholar] [CrossRef]

- Kumar, E.P.; Solanki, A.K.; Kumar, M.M.J. Numerical investigation of heat transfer and pressure drop characteristics in the micro-fin helically coiled tubes. Appl. Therm. Eng. 2021, 182, 116093. [Google Scholar] [CrossRef]

- Pakdaman, M.F.; Akhavan-Behabadi, M.; Razi, P. An experimental investigation on thermo-physical properties and overall performance of MWCNT/heat transfer oil nanofluid flow inside vertical helically coiled tubes. Exp. Therm. Fluid Sci. 2012, 40, 103–111. [Google Scholar] [CrossRef]

- Sreejith, K.; Sreesastha Ram, T.R.; Varghese Jaivin, A.; Francis Manoj Mossas, V.J.; Nidhin, M.J.; Nithil, E.S.; Sushmitha, S. Experimental investigation of a helical coil heat exchanger. Int. J. Eng. Sci. 2015, 5, 1–5. [Google Scholar]

- Kong, M.; Alvarado, J.L.; Terrell, W.; Thies, C. Performance characteristics of microencapsulated phase change material slurry in a helically coiled tube. Int. J. Heat Mass Transf. 2016, 101, 901–914. [Google Scholar] [CrossRef]

- Jayakumar, J.; Mahajani, S.; Mandal, J.; Iyer, K.N.; Vijayan, P. CFD analysis of single-phase flows inside helically coiled tubes. Comput. Chem. Eng. 2010, 34, 430–446. [Google Scholar] [CrossRef]

- Haghighi, A.; Maleki, A.; Assad, M.E.H.; Chen, L.; Nazari, M.A.; Shadloo, M.S. A review on heat transfer characteristics of cryogenic heat pipes. J. Therm. Anal. Calorim. 2021. [Google Scholar] [CrossRef]

- Stougie, L.; Van Der Kooi, H.J. Exergy Efficient Application of LNG Cold. In Proceedings of the ECOS2010 23rd International Conference on Efficiency, Cost, Optimization, Simulation, and Environmental Impact of Energy Systems, Lausanne, Switzerland, 14–17 June 2010; Favrat, D., Maréchal, F., Eds.; 2010; Volume 2, pp. 441–446. [Google Scholar]

- Arif, H.; Aydelott, J.C.; Chato, D. Evaluation of Supercritical Cryogen Storage and Transfer Systems for Future NASA Missions. J. Propuls. Power 1992, 8, 332–338. [Google Scholar] [CrossRef]

- Dondapati, R.S. Role of Supercritical Nitrogen (SCN) on the hydraulic and thermal characteristics of futuristic High Temperature Superconducting (HTS) cables. Cryogenics 2020, 111, 103166. [Google Scholar] [CrossRef]

- Zhang, P.; Huang, Y.; Shen, B.; Wang, R.Z. Flow and heat transfer characteristics of supercritical nitrogen in a vertical mini-tube. Int. J. Therm. Sci. 2011, 50, 287–295. [Google Scholar] [CrossRef]

- Dimitrov, D.; Zahariev, A.; Kovachev, V.; Wawryk, R. Forced convective heat transfer to supercritical nitrogen in a vertical tube. Int. J. Heat Fluid Flow 1989, 10, 278–280. [Google Scholar] [CrossRef]

- Negoescu, C.C.; Li, Y.; Al-Duri, B.; Ding, Y. Heat Transfer Behaviour of Supercritical Nitrogen in the Large Specific Heat Region Flowing in a Vertical Tube. Energy 2017, 134, 1096–1106. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Lu, T.; Drögemüller, P.; Yu, Q.; Ding, Y.; Li, Y. Enhancing deteriorated heat transfer of supercritical nitrogen in a vertical tube with wire matrix insert. Int. J. Heat Mass Transf. 2020, 162, 120358. [Google Scholar] [CrossRef]

- Yamagata, K.; Nishikawa, K.; Hasegawa, S.; Fujii, T.; Yoshida, S. Forced convective heat transfer to supercritical water flowing in tubes. Int. J. Heat Mass Transf. 1972, 15, 2575–2593. [Google Scholar] [CrossRef]

- Mokry, S.J.; Kirillov, P.L.; Pioro, I.L.; Gospodinov, Y.K. Supercritical-water Heat Transfer in a Vertical Bare Tube. Nucl. Eng. Des. 2010, 240, 568–576. [Google Scholar] [CrossRef]

- Bae, Y.Y.; Kim, H.Y.; Kang, D.J. Forced and mixed convection heat transfer to supercritical CO2 vertically flowing in a uniformly-heated circular tube. Exp. Therm. Fluid Sci. 2010, 34, 1295–1308. [Google Scholar] [CrossRef]

- Li, Z.H.; Jiang, P.X.; Zhao, C.R.; Zhang, Y. Experimental investigation of convection heat transfer of CO2 at supercritical pressures in a vertical circular tube. Exp. Therm. Fluid Sci. 2010, 34, 1162–1171. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1, Created 7 May 2013, updated 19 February 2017. Available online: https://www.nist.gov/publications/nist-standard-reference-database-23-reference-fluid-thermodynamic-and-transport-0?pub_id=50520 (accessed on 16 May 2021).

- Zhang, S.; Xu, X.; Liu, C.; Liu, X.; Zhang, Y.; Dang, C. The heat transfer of supercritical CO2 in helically coiled tube: Trade-off between curvature and buoyancy effect. Energy 2019, 176, 765–777. [Google Scholar] [CrossRef]

- Zhao, H.; Li, X.; Wu, X. Numerical investigation of supercritical water turbulent flow and heat transfer characteristics in vertical helical tubes. J. Supercrit. Fluids 2017, 127, 48–61. [Google Scholar] [CrossRef]

- Xu, J.; Yang, C.; Zhang, W.; Sun, D. Turbulent convective heat transfer of CO2 in a helical tube at near-critical pressure. Int. J. Heat Mass Transf. 2015, 80, 748–758. [Google Scholar] [CrossRef]

- Wang, Y.; Alvarado, J.L.; Terrell, W., Jr. Thermal performance of helical coils with reversed loops and wire coil inserts. Int. J. Heat Mass Transf. 2020, 146, 118723. [Google Scholar] [CrossRef]

- Yu, Q.; Peng, Y.; Negoescu, C.C.; Wang, Y.; Li, Y. Study on Convective Heat Transfer of Supercritical Nitrogen in a Vertical Tube for Liquid Air Energy Storage. Energies 2021, 14, 7773. [Google Scholar] [CrossRef]

- Xu, X.; Liu, C.; Dang, C.; Wu, Y.; Liu, X. Experimental investigation on heat transfer characteristics of supercritical CO2 cooled in horizontal helically coiled tube. Int. J. Refrig. 2016, 67, 190–201. [Google Scholar] [CrossRef]

- Mao, Y.; Guo, L.; Bai, B.; Zhang, X. Convective heat transfer in helical coils for constant-property and variable-property flows with high Reynolds numbers. Front. Energy Power Eng. China 2010, 4, 546–552. [Google Scholar] [CrossRef]

- Li, Z.; Zhai, Y.; Li, K.; Wang, H.; Lu, J. A quantitative study on the interaction between curvature and buoyancy effects in helically coiled heat exchangers of supercritical CO2 Rankine cycles. Energy 2016, 116, 661–676. [Google Scholar] [CrossRef]

- Batista, J.; Trp, A.; Lenic, K. Heat Transfer Enhancement of Crossflow Air-to-Water Fin-and-Tube Heat Exchanger by Using Delta-Winglet Type Vortex Generators. Energies 2022, 15, 2070. [Google Scholar] [CrossRef]

| Measured Parameters | Uncertainties | Instruments | Specifications (Accuracies) |

|---|---|---|---|

| Pressure | ±0.05 Bar | Alicat scientific pressure measuring and controller, PCH-100 PSIA | ±0.125% of read value |

| Power | ±1 W | Elektro-Automatik Analogue, digital bench power supply, EA-PS 9080-120-2U | <0.1% of read value <0.002 Volt <0.08 Ampere |

| T | ±0.5 °C | Thermon Ltd., type-T thermocouple | ±0.5 °C |

| Flow rate | ±0.3 L/min | Omega, FMA-A2323 digital flowmeter | ±1% of full scale ±0.3 SLM |

| L | ±1 mm | SS316 stainless steel tube | ±1 mm of length |

| d | ±0.1 mm | SS316 stainless steel tube | ±0.1 mm of diameter |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Lu, T.; Liu, X.; Sciacovelli, A.; Li, Y. Heat Transfer of Near Pseudocritical Nitrogen in Helically Coiled Tube for Cryogenic Energy Storage. Energies 2022, 15, 2752. https://doi.org/10.3390/en15082752

Wang Y, Lu T, Liu X, Sciacovelli A, Li Y. Heat Transfer of Near Pseudocritical Nitrogen in Helically Coiled Tube for Cryogenic Energy Storage. Energies. 2022; 15(8):2752. https://doi.org/10.3390/en15082752

Chicago/Turabian StyleWang, Yi, Tiejun Lu, Xianglei Liu, Adriano Sciacovelli, and Yongliang Li. 2022. "Heat Transfer of Near Pseudocritical Nitrogen in Helically Coiled Tube for Cryogenic Energy Storage" Energies 15, no. 8: 2752. https://doi.org/10.3390/en15082752

APA StyleWang, Y., Lu, T., Liu, X., Sciacovelli, A., & Li, Y. (2022). Heat Transfer of Near Pseudocritical Nitrogen in Helically Coiled Tube for Cryogenic Energy Storage. Energies, 15(8), 2752. https://doi.org/10.3390/en15082752