Analysis of NVH Behavior of Synchronous Reluctance Machine for EV Applications

Abstract

:1. Introduction

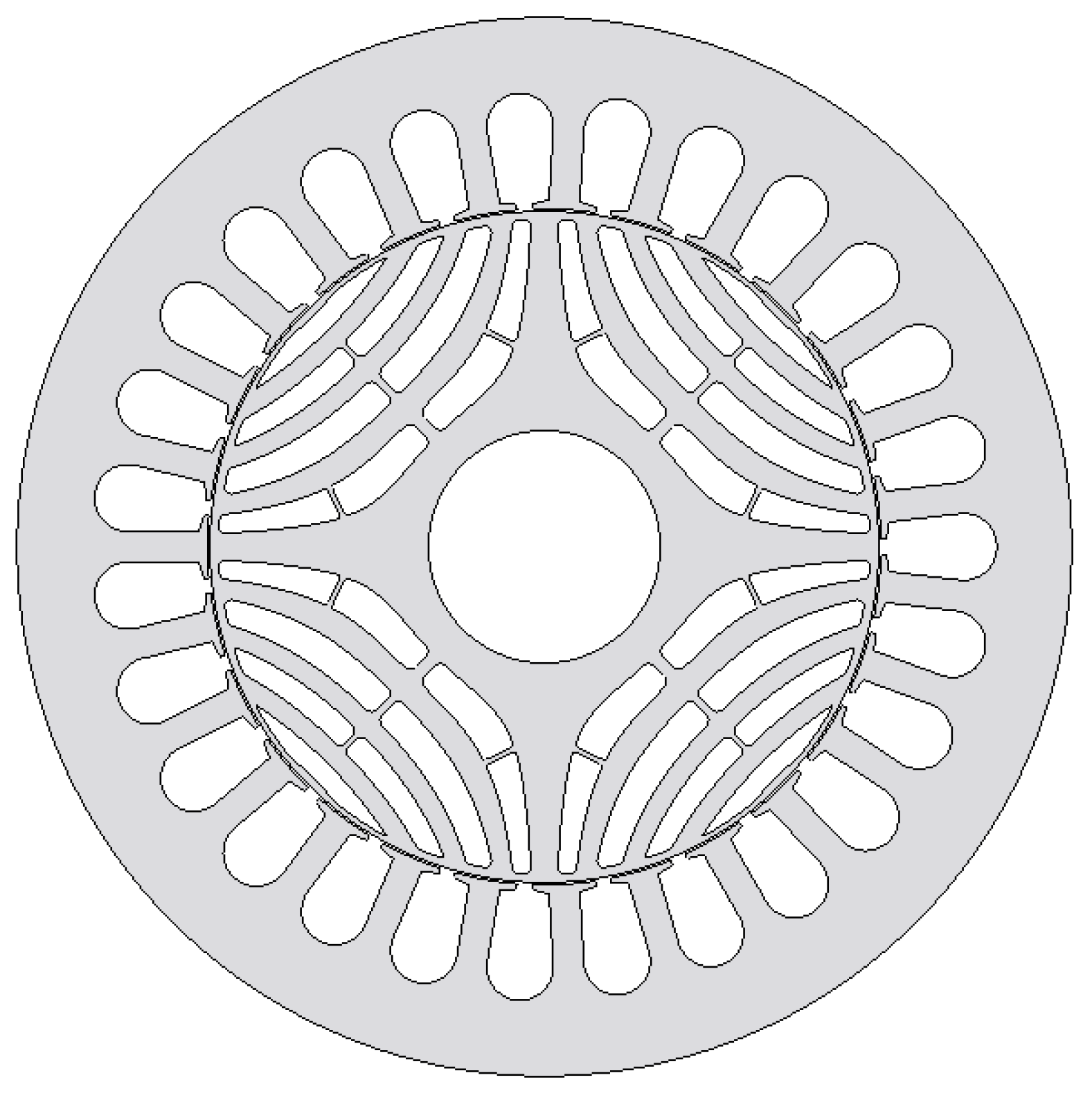

2. Noise and Vibration in Synchronous Reluctance Machine

2.1. General Information

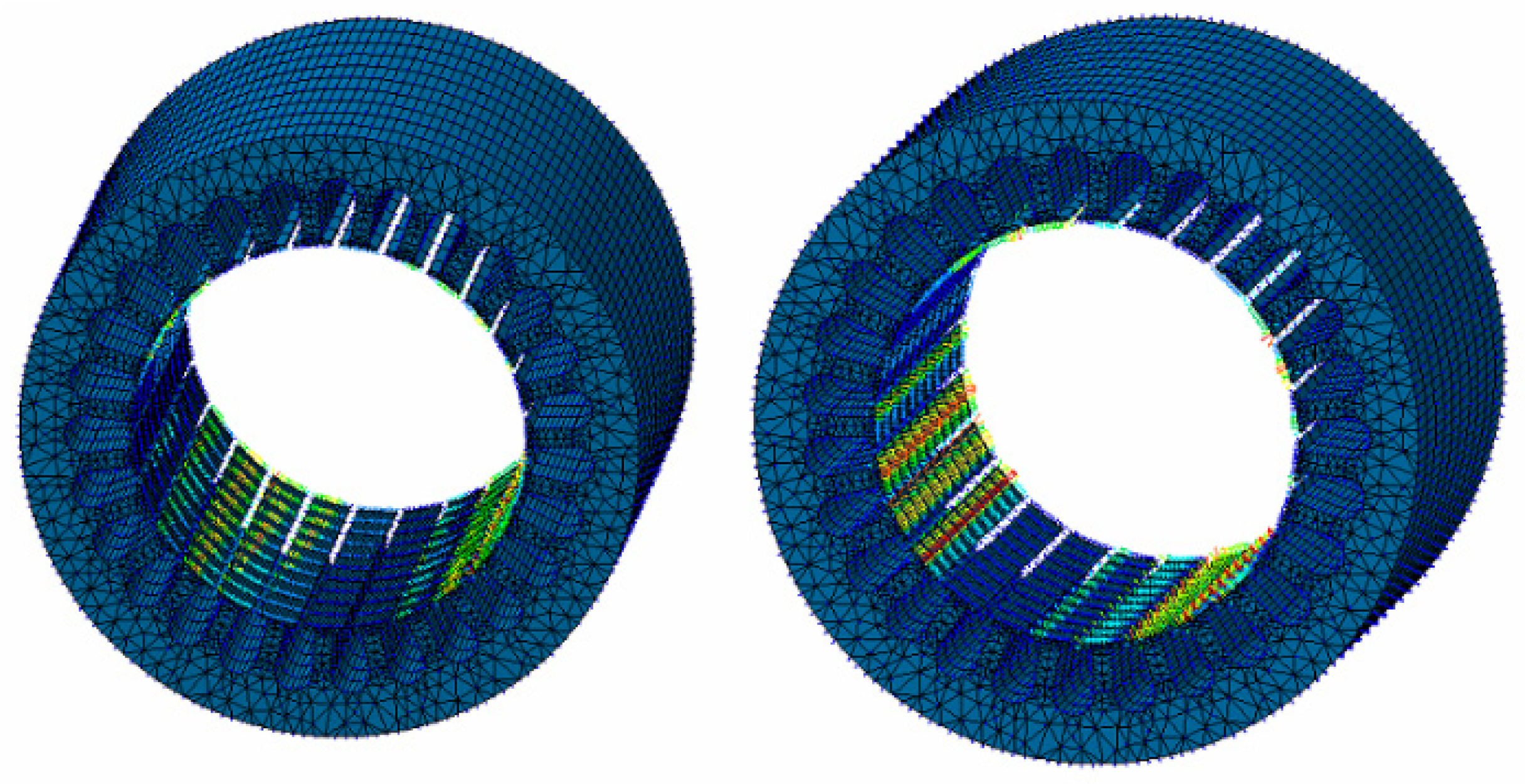

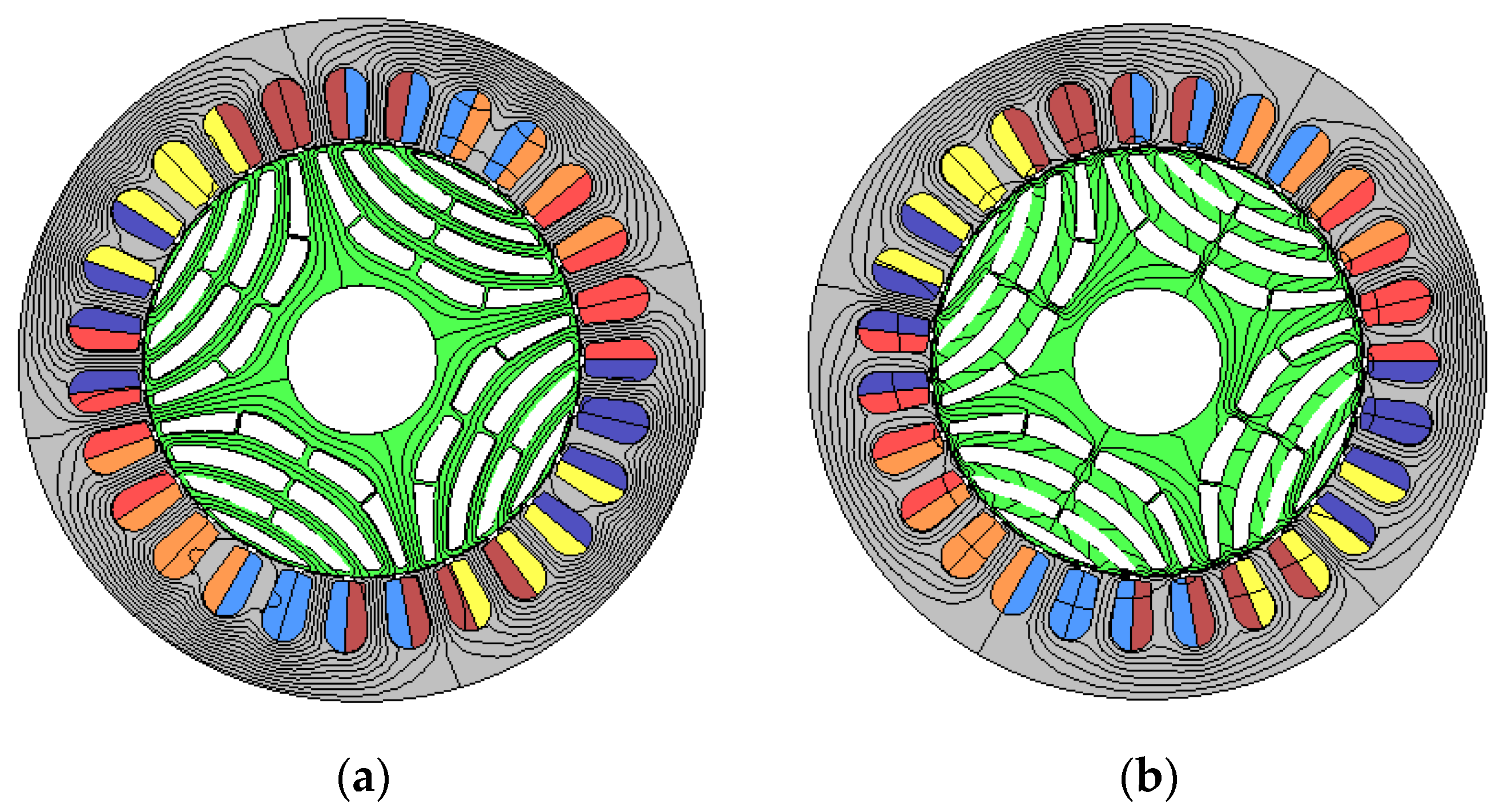

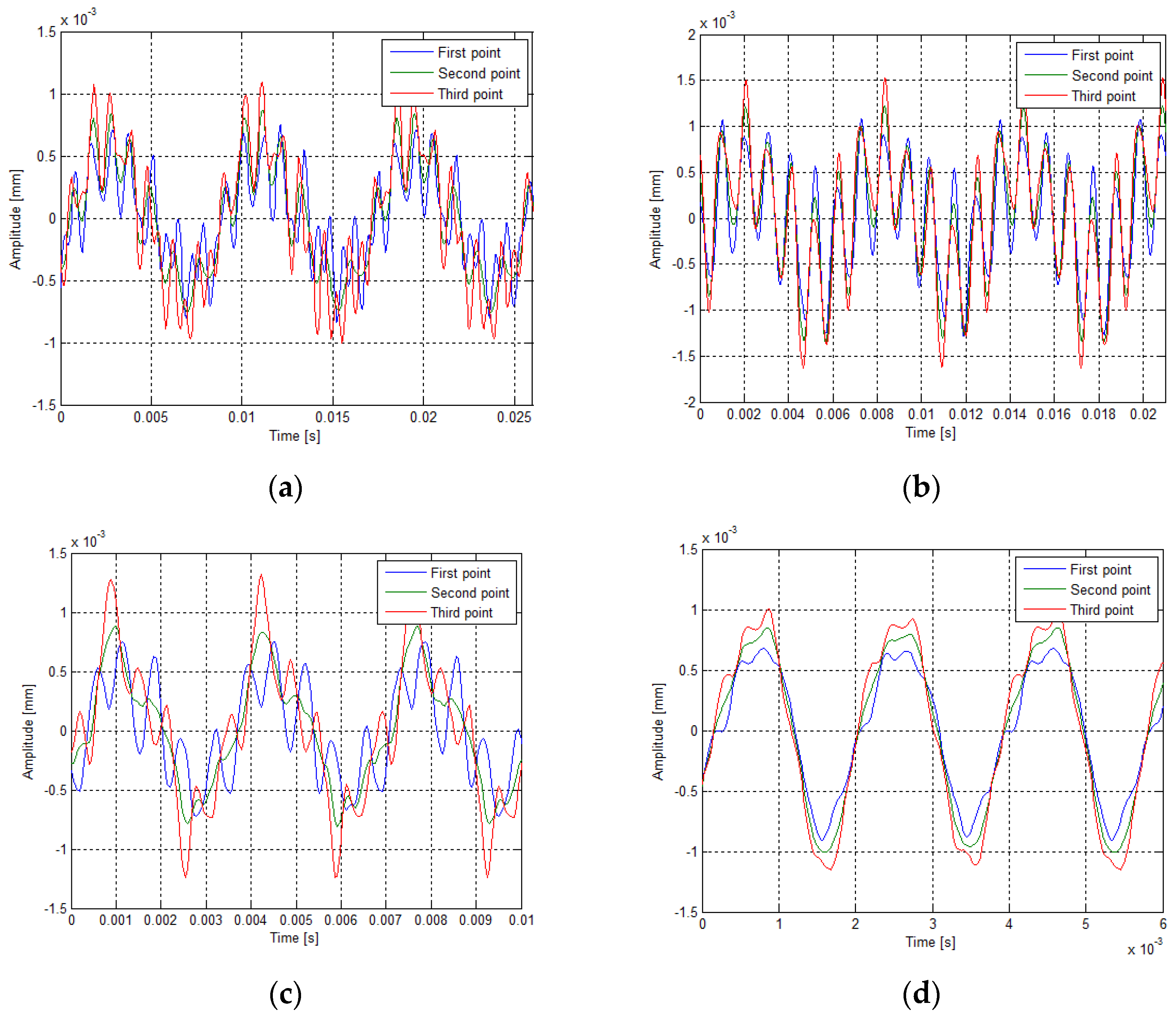

2.2. NVH Simulation

3. Laboratory Tests

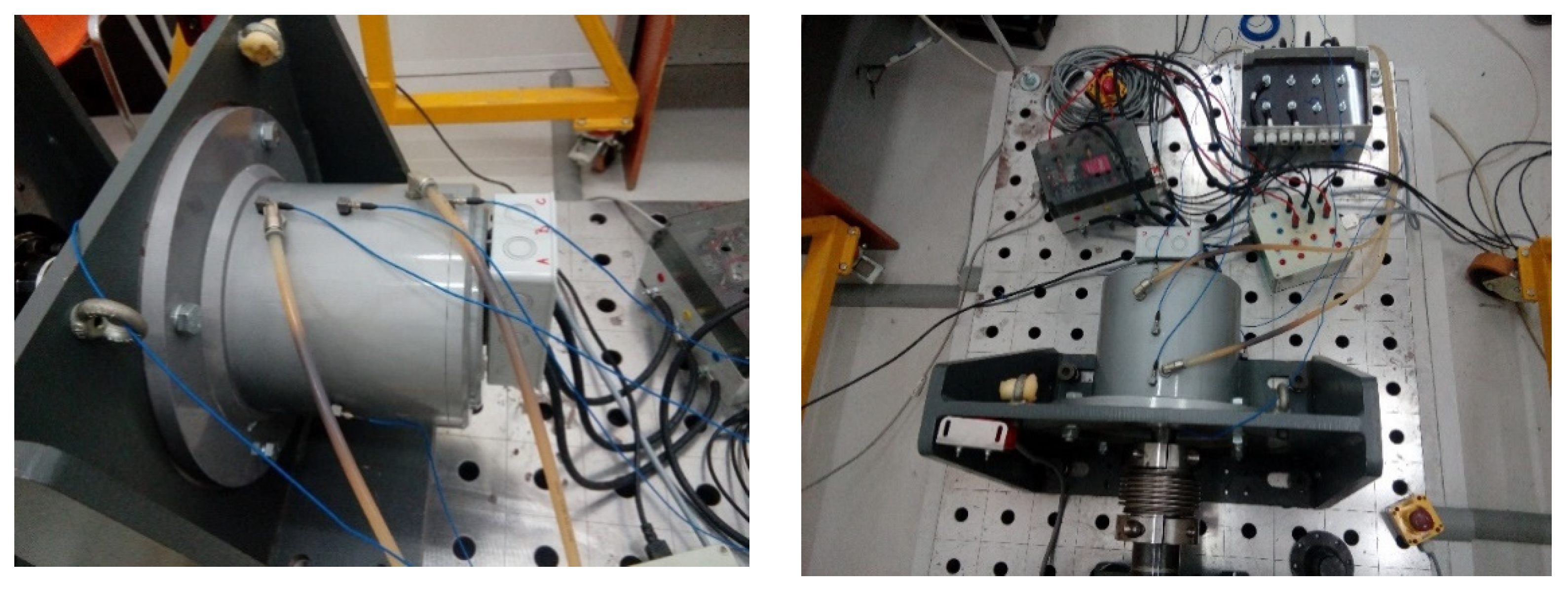

3.1. Laboratory Test Bench

- No-load test

- Different level of loads

- Different speed/torque profiles

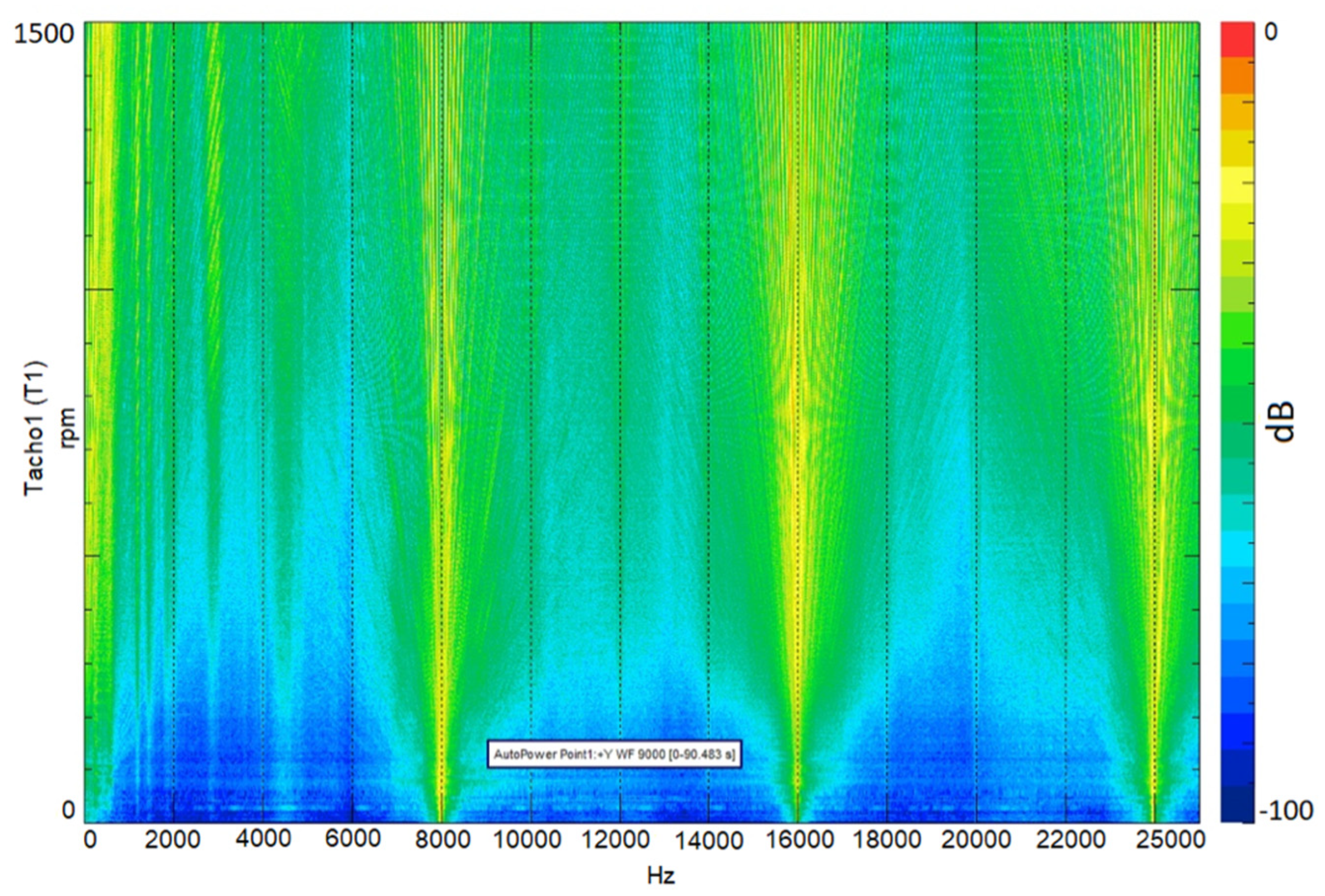

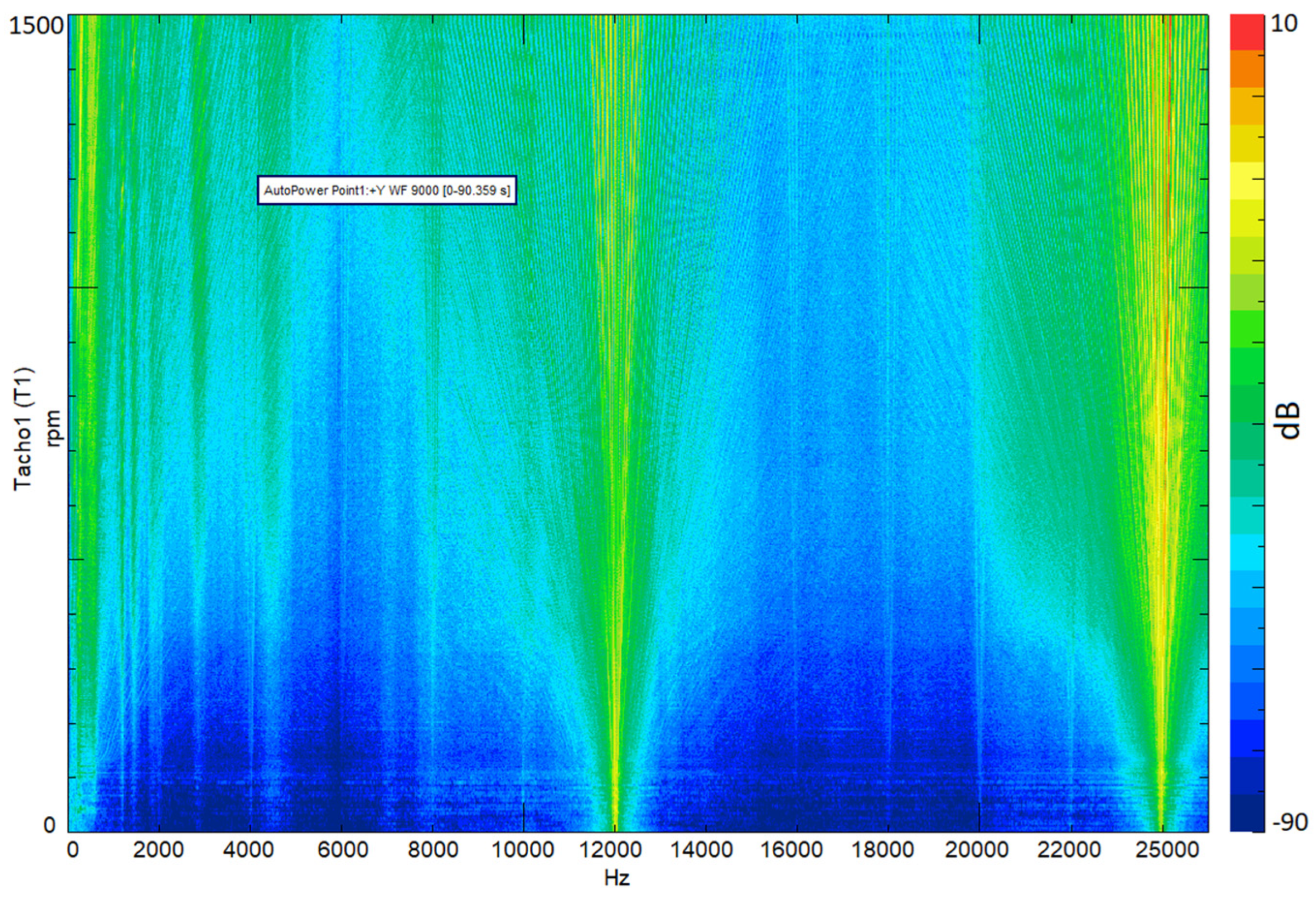

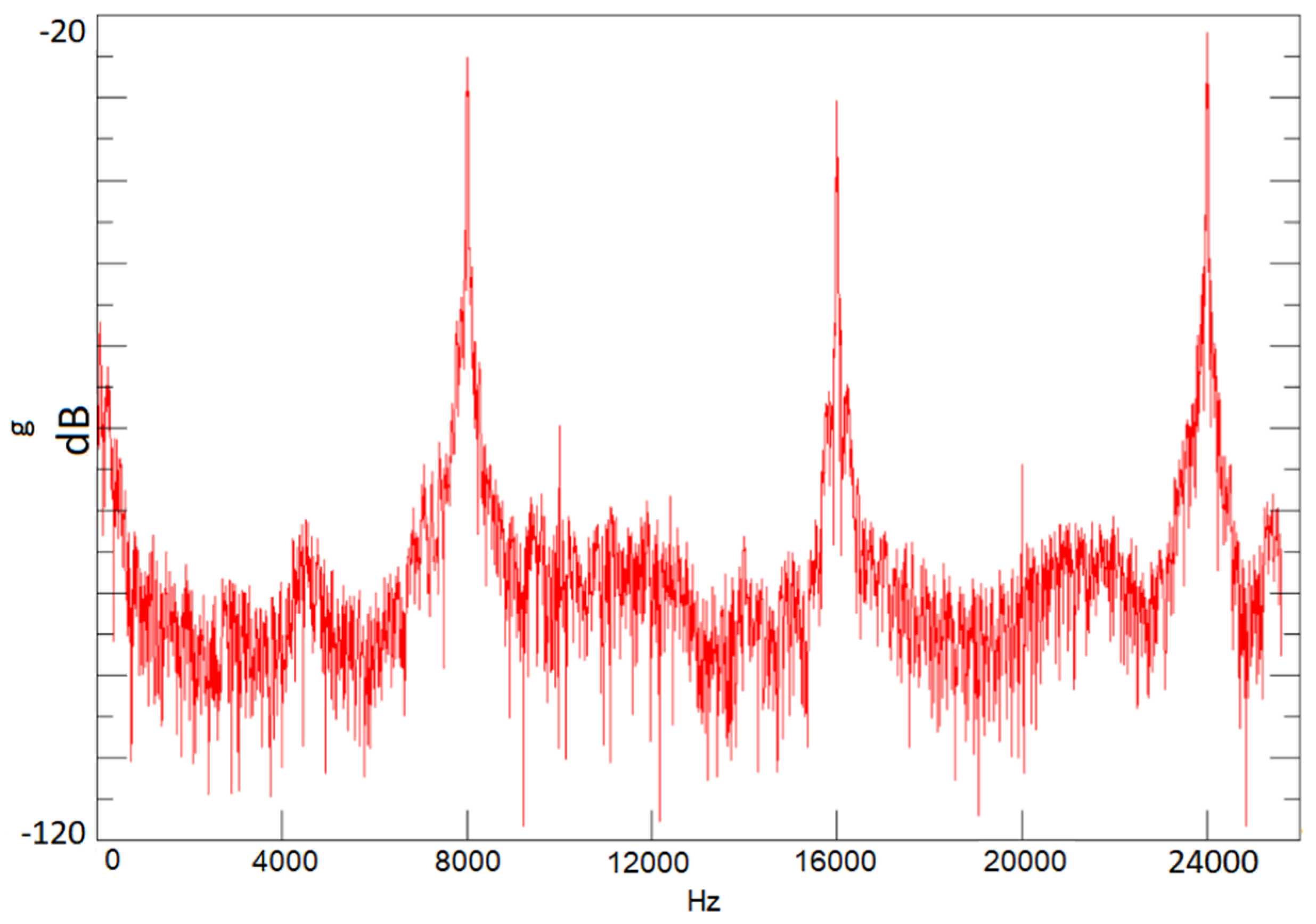

3.2. Experimental Results

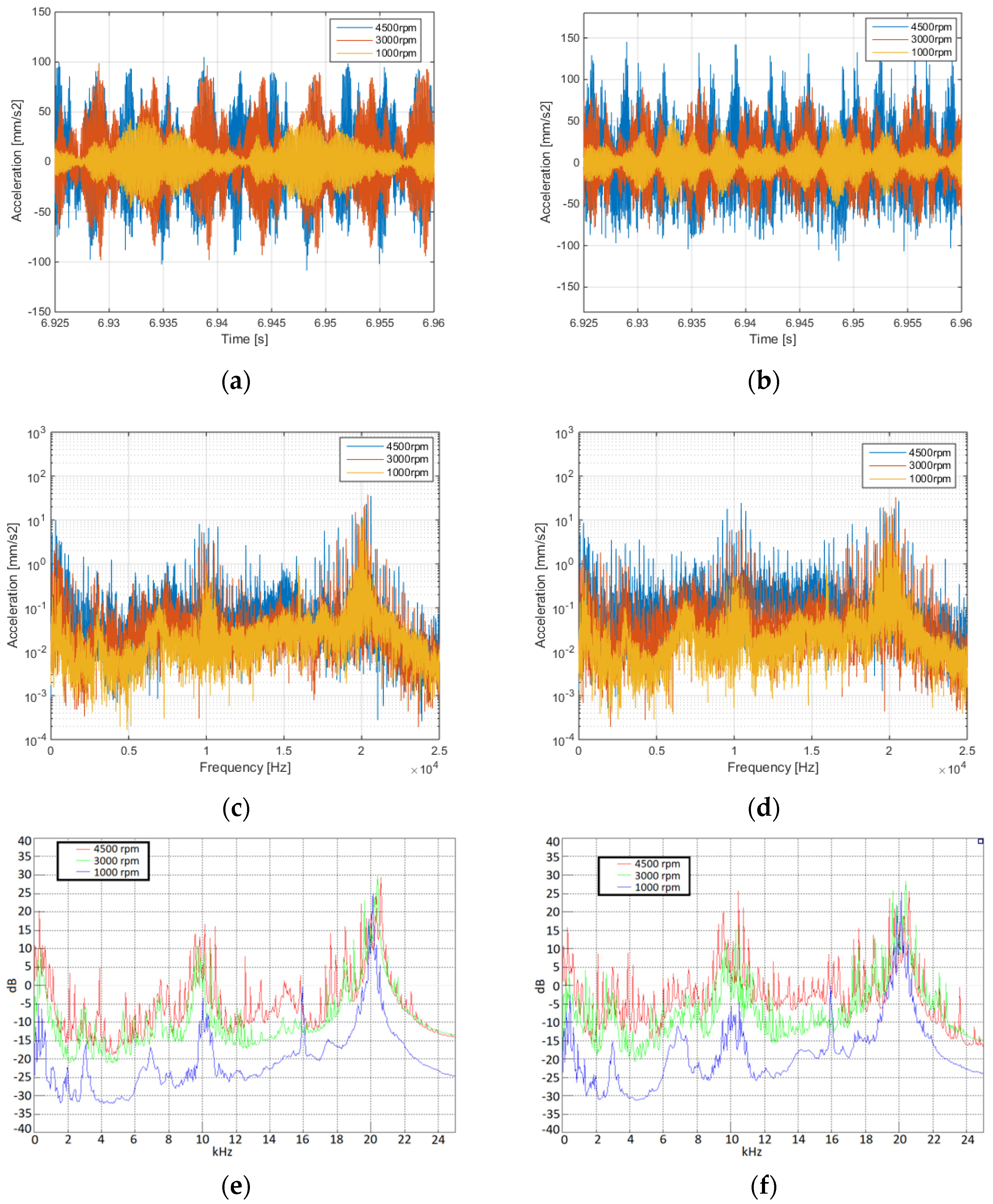

- Investigation of noise and vibration level;

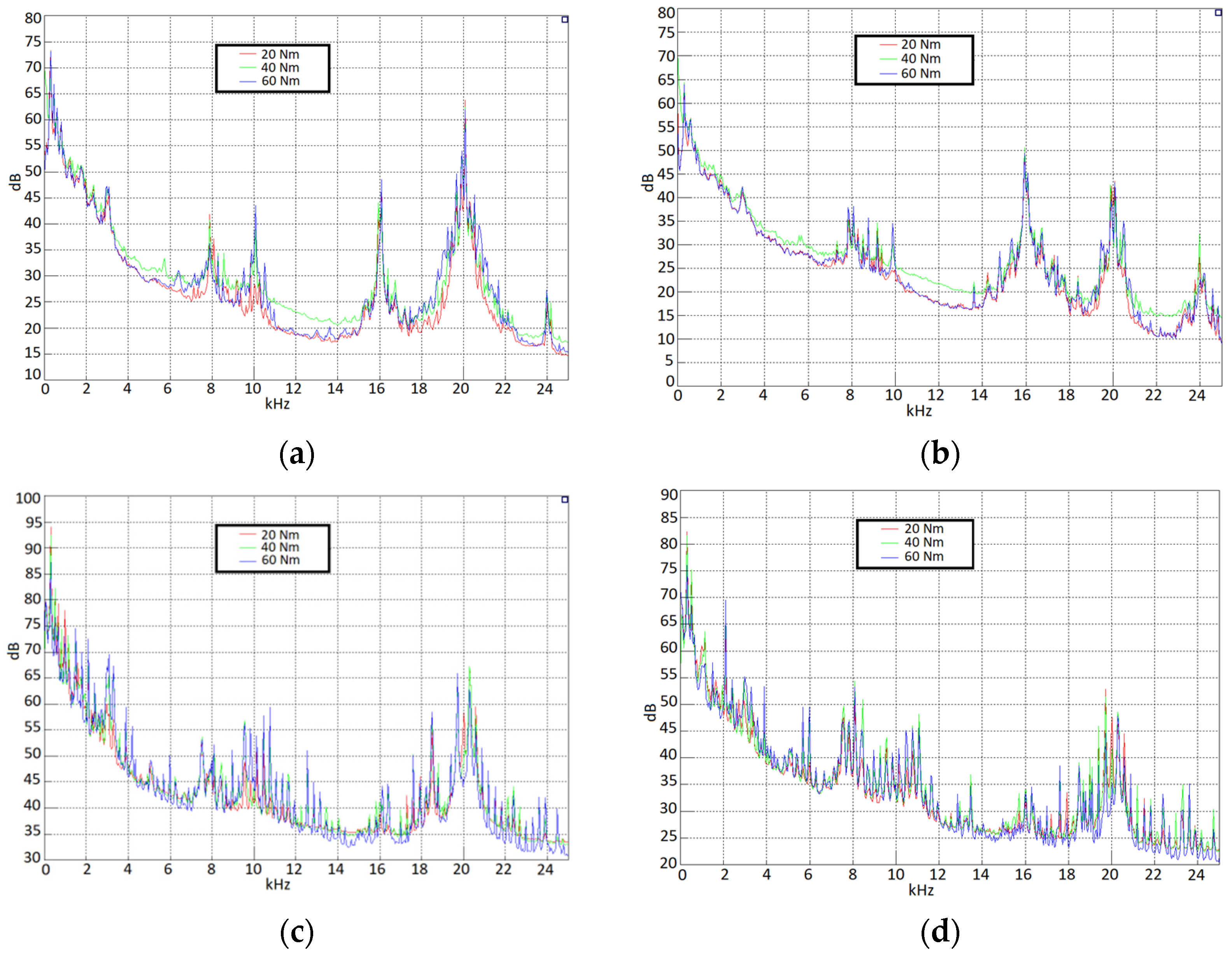

- Investigation of the influence of current angle and load on noise and vibration;

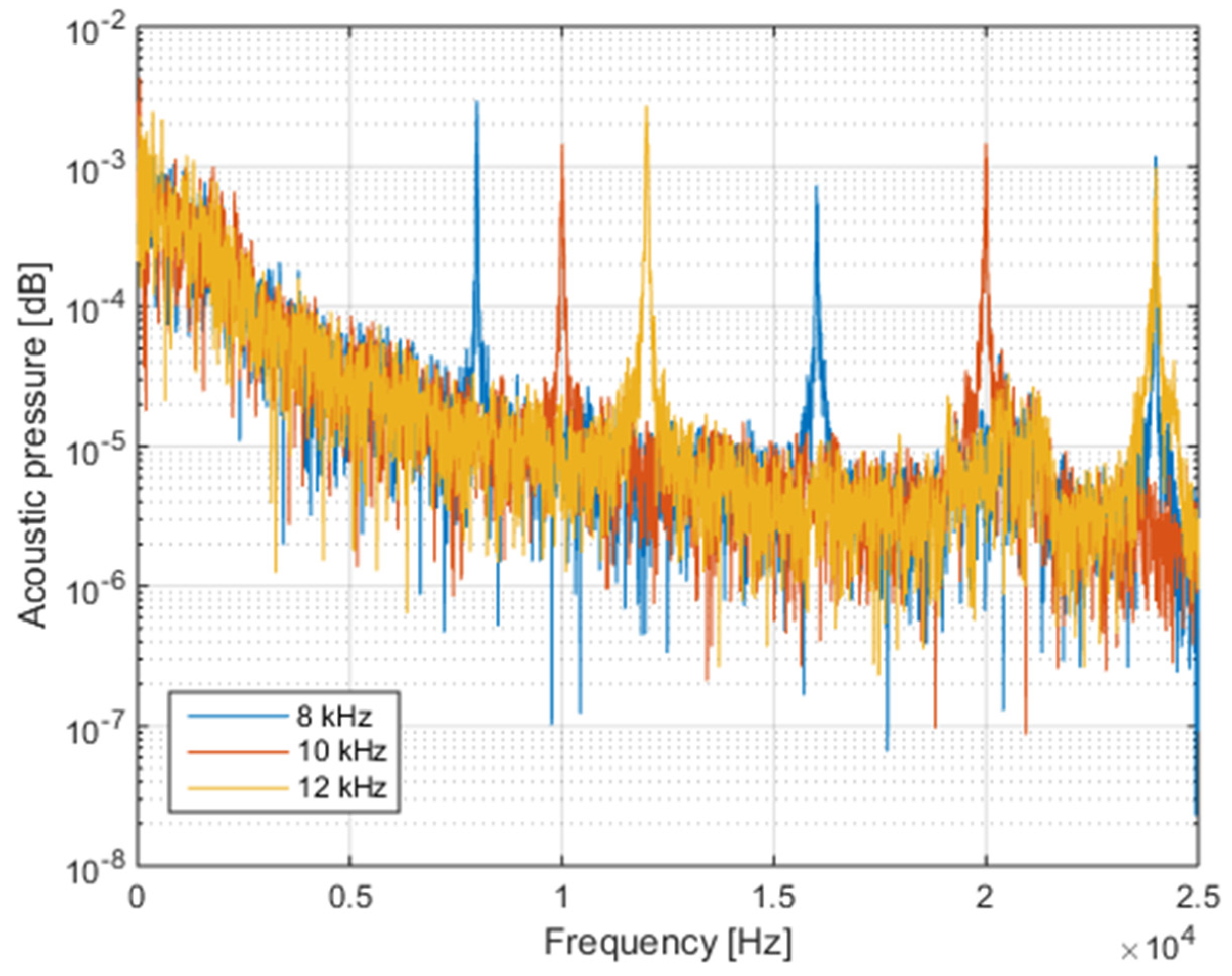

- Investigation of the influence of switching frequency on noise;

- Identification of normal modes and natural frequencies.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tahi, S.; Ibtiouen, R.; Bounekhla, M. Design Optimization of Two Synchronous Reluctance Machine Structures with Maximized Torque and Power Factor. Prog. Electromagn. Res. 2011, 35, 369–387. [Google Scholar] [CrossRef] [Green Version]

- Zhou, E. Magnetic Circuit Analysis and Parametric Calculation of the new Type of Reluctance Motors. Sci. China Ser. A-Math. Phys. Astron. Technol. Sci. 1983, 26, 1218–1230. [Google Scholar]

- Lipo, T.A. Synchronous Reluctance Machines-A Viable Alternative for AC Drives? Electr. Mach. Power Syst. 1991, 19, 659–671. [Google Scholar] [CrossRef]

- Matsuo, T.; Lipo, T. Rotor design optimization of synchronous reluctance machine. IEEE Trans. Energy Convers. 1994, 9, 359–365. [Google Scholar] [CrossRef]

- Kolehmainen, J. Synchronous Reluctance Motor With Form Blocked Rotor. IEEE Trans. Energy Convers. 2010, 25, 450–456. [Google Scholar] [CrossRef]

- Rizk, J.; Nagrial, M.; Hellany, A. Optimum Design Parameters for Synchronous Reluctance Motors. In Proceedings of the 14th International Middle East Power Systems Conference (MEPCON’ 10), Cairo, Egypt, 19–21 December 2010. [Google Scholar]

- Vagati, A.; Canova, A.; Chiampi, M.; Pastorelli, M.; Repetto, M. Design refinement of synchronous reluctance motors through finite-element analysis. IEEE Trans. Ind. Appl. 2000, 36, 1094–1102. [Google Scholar] [CrossRef]

- Bacco, G.; Bianchi, N. Choice of flux-barriers position in synchronous reluctance machines. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 1872–1879. [Google Scholar]

- Barta, J.; Ondrusek, C. Rotor Design and Optimization of Synchronous Reluctance Machine. Sci. J. 2015, 9, 4738358. [Google Scholar] [CrossRef]

- Palmieri, M.; Perta, M.; Cupertino, F.; Pellegrino, G. Effect of the numbers of slots and barriers on the optimal design of synchronous reluctance machines. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Bran, Romania, 22–24 May 2014; pp. 260–267. [Google Scholar]

- Oprea, C.; Dziechciarz, A.; Martis, C. Comparative analysis of different synchronous reluctance motor topologies. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 1904–1909. [Google Scholar]

- Saucy, H.; Dupont, J.-B.; Bouvet, P. Noise radiated by electric motors: Simulation process and overview of the optimization approaches. In Proceedings of the 32nd Electric Vehicle Symposium (EVS32), Lyon, France, 19–22 May 2019. [Google Scholar]

- Verma, S.P. Noise and vibrations of electrical machines and drives; their production and means of reduction. In Proceedings of the International Conference on Power Electronics, Drives and Energy Systems for Industrial Growth, New Delhi, India, 8–11 January 1996. [Google Scholar]

- Kumar, D.; Sambharam, T.; Kottalgi, S.; Mandloi, P.; Kesarkar, O. Electric Vehicle Powertrain Multiphysics NVH Simulation. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018. [Google Scholar]

- Gao, B.; O’Boy, D.J.; Mavros, G. Real-Time Sound and Vibration Modelling for Electric Motor. In Proceedings of the Noise and Vibration Conference & Exhibition, Grand Rapids, MI, USA, 7–10 September 2021. [Google Scholar]

- Saito, A.; Kuroishi, M.; Nakai, H. Vibration Prediction Method of Electric Machines by using Experimental Transfer Function and Magnetostatic Finite Element Analysis. J. Phys. Conf. Ser. 2016, 744, 012088. [Google Scholar] [CrossRef] [Green Version]

- Sarrazin, M.; Gillijns, S.; Anthonis, J.; Janssens, K.; van der Auweraer, H.; Verhaeghe, K. NVH analysis of a 3 phase 12/8 SR motor drive for HEV applications. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013. [Google Scholar]

- Kotter, P.; Oliver, Z.; Konrad, W. Efficient Noise-Vibration-Harshness Modelling of Servo- and Traction Drives. IFAC-PapersOnLine 2016, 49, 330–338. [Google Scholar] [CrossRef]

- Khadersab, A.; Gandhi, S.; Joshi, M.; Dargad, D. Modal Analysis of an Electric Motor Casing-In Comparison with FFT Analyzer. Int. J. Eng. Res. Technol. 2014, 3, IJERTV3IS031520. [Google Scholar]

- Li, H.; Zhang, D.; Xu, P.; Cao, C.; Hu, N.; Yan, X.; Song, Z.; Hu, Z. Analysis on the vibration modes of the electric vehicle motor stator. Vibroengineering Procedia 2019, 22, 81–86. [Google Scholar] [CrossRef]

- Robert, H.; Annabel, S.; Melanie, M.; Barry, J. Integrated approach to NVH analysis in electric vehicle drivetrains. In Proceedings of the 9th International Conference on Power Electronics, Machines and Drives (PEMD 2018), Liverpool, UK, 17–19 April 2019. [Google Scholar]

- Sathyan, S.; Aydin, U.; Belahcen, A. Acoustic Noise Computation of Electrical Motors Using the Boundary Element Method. Energies 2020, 13, 245. [Google Scholar] [CrossRef] [Green Version]

- Samani, N.; Ganji, B. Noise reduction of switched reluctance motors. In Proceedings of the 2017 8th Power Electronics, Drive Systems & Technologies Conference (PEDSTC), Mashhad, Iran, 14–16 February 2017; pp. 300–304. [Google Scholar] [CrossRef]

- Chauvicourt, F.; Faria, C.; Dziechciarz, A.; Martis, C. Influence of Rotor Geometry on NVH Behavior of Synchronous Reluctance Machine. In Proceedings of the 2015 Tenth International Conference on Ecological Vehicles and Renewable Energies (EVER 2015), Grimaldi Forum, Larotto, Monaco, 31 March–2 April 2015. [Google Scholar]

- Deng, C.; Deng, Q.; Liu, W.; Yu, C.; Hu, J.; Li, X. Analysis of Vibration and Noise for the Powertrain System of Electric Vehicles under Speed-Varying Operating Conditions. Math. Probl. Eng. 2020, 2020, 6617291. [Google Scholar] [CrossRef]

- Khadersab, A. Modal Analysis of Electric Motor Casing. Int. J. Eng. Res. 2014. [Google Scholar]

- Zhang, Z.; Yaman, S.; Mohamad, S.; Suryadev, S.; Chengxiu, C.; Mahesh, K. Effectiveness of Power Electronic Controllers in Mitigating Acoustic Noise and Vibration in High-Rotor Pole SRMs. Energies 2021, 14, 702. [Google Scholar] [CrossRef]

| Range of Voltage | 0–400 VAC/0–600 VDC |

|---|---|

| Maximum current | 200 A (for 2-phase SRM and 3-phase AC machines) 100 A (for 4-phase SRM and 5-phase AC machines) |

| Rated power | 29 kW |

| Max power | 89 kW |

| Rated speed | 4000 rpm |

| Max speed | 12,000 rpm |

| Max torque | 320 Nm |

| Measured signals |

|

| Active axial length | 145 mm |

| Air gap | 0.45 mm |

| Stator outer diameter | 205 mm |

| Stator inner diameter | 131 mm |

| Rotor diameter | 130 mm |

| Shaft diameter | 45 mm |

| Sensitivity (±10%) | 10.2 mV/(m/s2) |

| Measurement range | ±490 m/s2 pk |

| Frequency range (±5%) | 0.5 to 3000 Hz |

| Resonant frequency | ≥40 kHz |

| Phase response (±5°) (at 21 °C) | 2 to 3000 Hz |

| Broadband resolution (1 to 10,000 Hz) | 0.0015 m/s2 rms |

| Non-linearity | ≤1% |

| Transverse sensitivity | ≤5% |

| Frequency range (±1 dB) | 10 to 25 kHz |

| Frequency range (±2 dB) | 5 to 70 kHz |

| Dynamic range lower limit with GRAS preamplifier | 44 dB(A) |

| Dynamic range upper limit with GRAS CCP preamplifier | 168 dB |

| Set sensitivity @ 250 Hz (±3 dB) | 1.45 mV/Pa |

| Output impedance | <50 Ω |

| Temperature range, operation | −30 to 85/−22 to 185 °C/°F |

| Current Angle | Rotational Speed | Torque | |||||

|---|---|---|---|---|---|---|---|

| 20 Nm | 30 Nm | 40 Nm | 50 Nm | 60 Nm | 70 Nm | ||

| 40 deg | 1000 rpm | 63 A | 80 A | 108 A | 132 A | 162 A | 190 A |

| 1500 rpm | 60 A | 78 A | 107 A | 130 A | 160 A | 184 A | |

| 2000 rpm | 58 A | 77 A | 97 A | 122 A | 150 A | 172 A | |

| 3000 rpm | 57 A | 76 A | 97 A | 126 A | 141 A | 159 A | |

| 4500 rpm | 56 A | 76 A | 96 A | 120 A | 143 A | 158 A | |

| 45 deg | 1000 rpm | 58 A | 77 A | 104 A | 126 A | 153 A | 176 A |

| 1500 rpm | 58 A | 78 A | 98 A | 124 A | 151 A | 169 A | |

| 2000 rpm | 58 A | 77 A | 94 A | 122 A | 148 A | 161 A | |

| 3000 rpm | 57 A | 76 A | 97 A | 120 A | 142 A | 162 A | |

| 4500 rpm | 61 A | 80 A | 108 A | 130 A | 149 A | 164 A | |

| 50 deg | 1000 rpm | 59 A | 76 A | 101 A | 124 A | 149 A | 177 A |

| 1500 rpm | 64 A | 78 A | 103 A | 123 A | 148 A | 173 A | |

| 2000 rpm | 60 A | 81 A | 105 A | 124 A | 151 A | 164 A | |

| 3000 rpm | 60 A | 83 A | 116 A | 137 A | 161 A | 182 A | |

| 4500 rpm | 89 A | 121 A | 171 A | 197 A | |||

| 60 deg | 1000 rpm | 65 A | 83 A | 108 A | 133 A | 162 A | 182 A |

| 1500 rpm | 66 A | 91 A | 117 A | 144 A | 176 A | 187 A | |

| 2000 rpm | 77 A | 106 A | 128 A | 158 A | 180 A | 192 A | |

| 3000 rpm | 110 A | 160 A | 184 A | ||||

| 4500 rpm | 118 A | 163 A | 190 A | ||||

| Ovalization | Triangular | Square | |

|---|---|---|---|

| Simulation | 928 Hz | 2485 Hz | 4433 Hz |

| Measurement | 1166 Hz | 2866 Hz | 4451 Hz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziechciarz, A.; Popp, A.; Marțiș, C.; Sułowicz, M. Analysis of NVH Behavior of Synchronous Reluctance Machine for EV Applications. Energies 2022, 15, 2785. https://doi.org/10.3390/en15082785

Dziechciarz A, Popp A, Marțiș C, Sułowicz M. Analysis of NVH Behavior of Synchronous Reluctance Machine for EV Applications. Energies. 2022; 15(8):2785. https://doi.org/10.3390/en15082785

Chicago/Turabian StyleDziechciarz, Arkadiusz, Aron Popp, Claudia Marțiș, and Maciej Sułowicz. 2022. "Analysis of NVH Behavior of Synchronous Reluctance Machine for EV Applications" Energies 15, no. 8: 2785. https://doi.org/10.3390/en15082785

APA StyleDziechciarz, A., Popp, A., Marțiș, C., & Sułowicz, M. (2022). Analysis of NVH Behavior of Synchronous Reluctance Machine for EV Applications. Energies, 15(8), 2785. https://doi.org/10.3390/en15082785