Online Prediction of Electric Vehicle Battery Failure Using LSTM Network

Abstract

1. Introduction

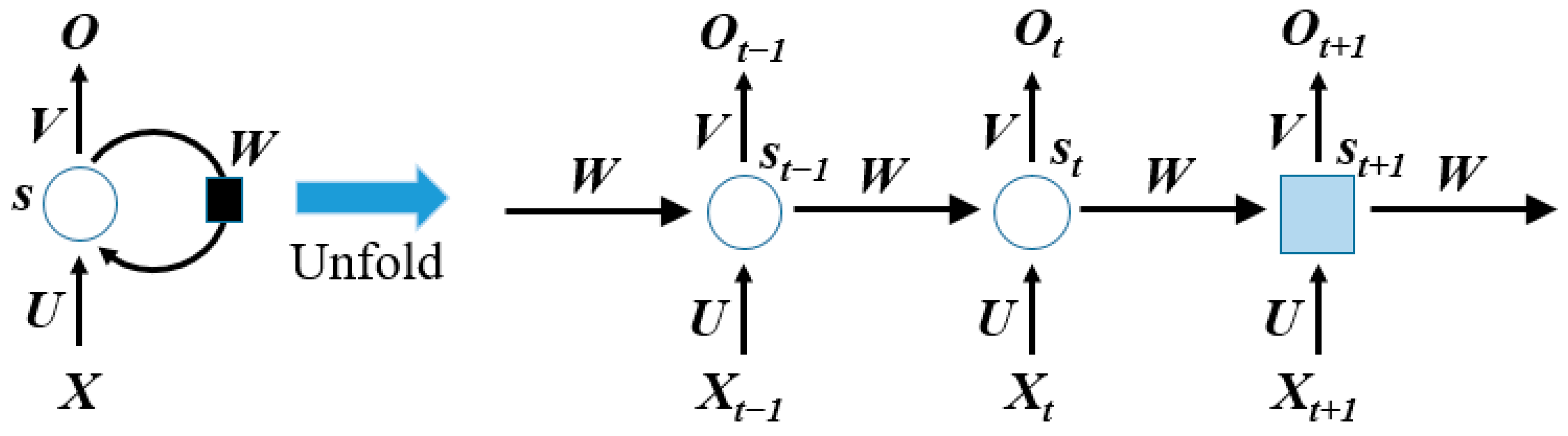

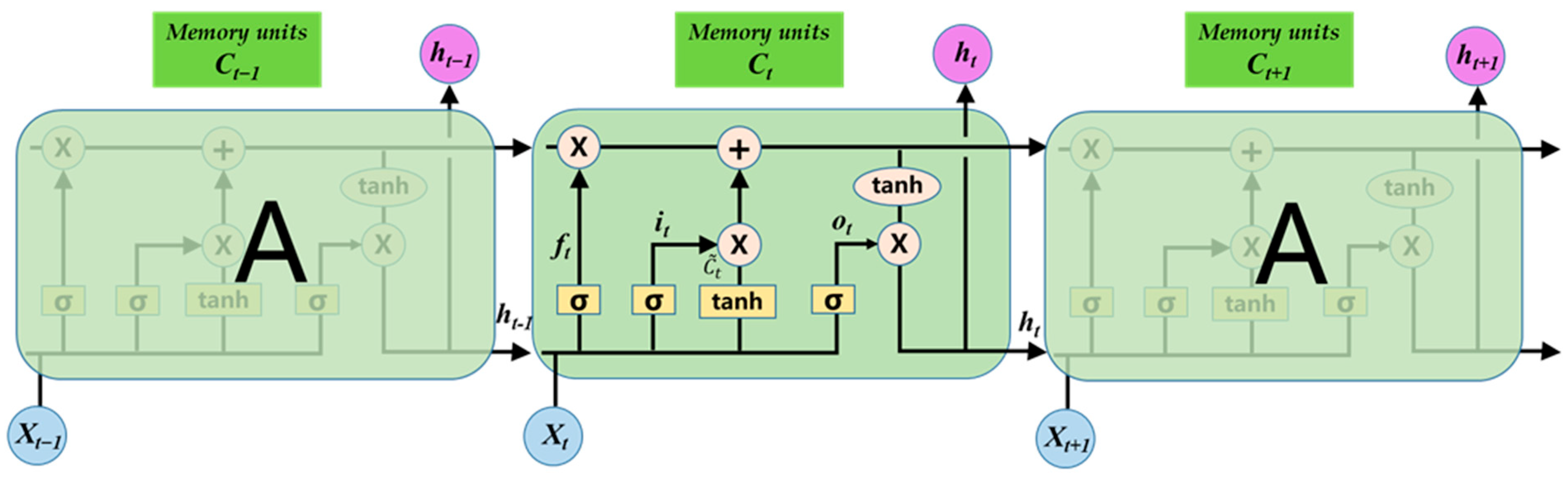

2. LSTM Principle Methodology and Model Building

2.1. Introduction of the LSTM Principle

- (1)

- Forget gate: The inputs and are used, and the activation function determines which information is lost and retained in the LSTM memory cell, calculated as follows:

- (2)

- Input gate: The information in the memory cell is updated using the following expressions:

- (3)

- Final output gate: The output information is determined using the following expression:

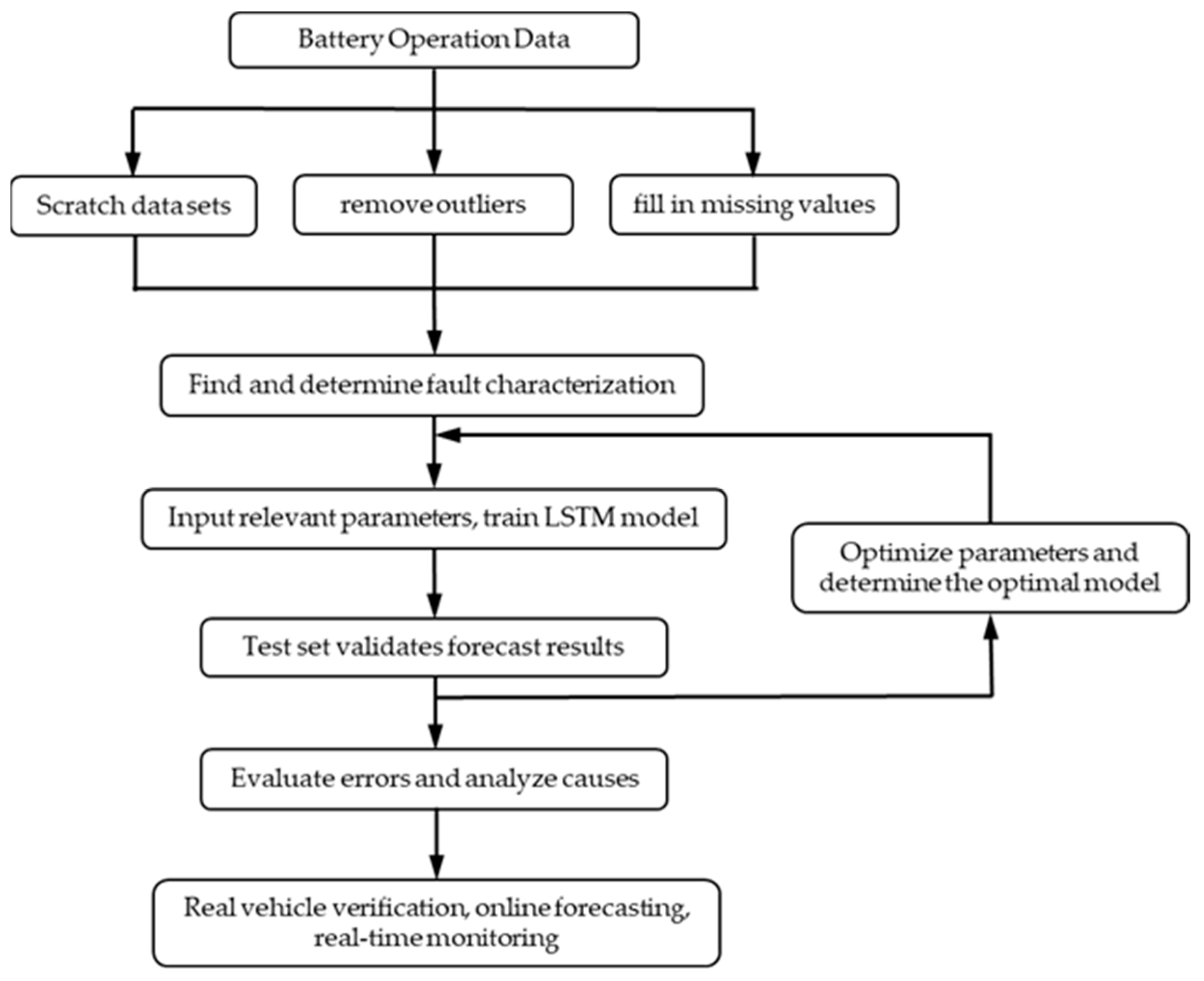

2.2. Fault Prediction Model Building

3. Data Processing and Characterization

3.1. Data Description and Pre-Processing

- (1)

- Data merging: The six-month real-time operation data of each vehicle are sorted and merged, and the data sets are extracted according to vehicle status, charging status and other working conditions.

- (2)

- Removal of abnormal values: The same vehicle operation data are checked after merging. There are some missing data, e.g., there is total battery voltage, but no individual cell voltage. By drawing the SOC curve over time, we find that there are a few abnormal SOC jumps in the sample set. These jumps may consist of a value equal to 0 at one time instant and return to a normal value at the next time instant. As there is a small amount of abnormal data, the deletion operation is performed directly.

- (3)

- Interpolation method to complete the data: To fill the vacant data rows after the removal of outliers and those already existing in the data set, interpolation is used to improve the sample set. This interpolation is carried out using 10 data points before and after the vacancy row.

- (4)

- Dimensionless processing: After completing the above processing, the data dimensions are removed to ensure the consistency of the data and to avoid the impact of different data units on the model’s learning.

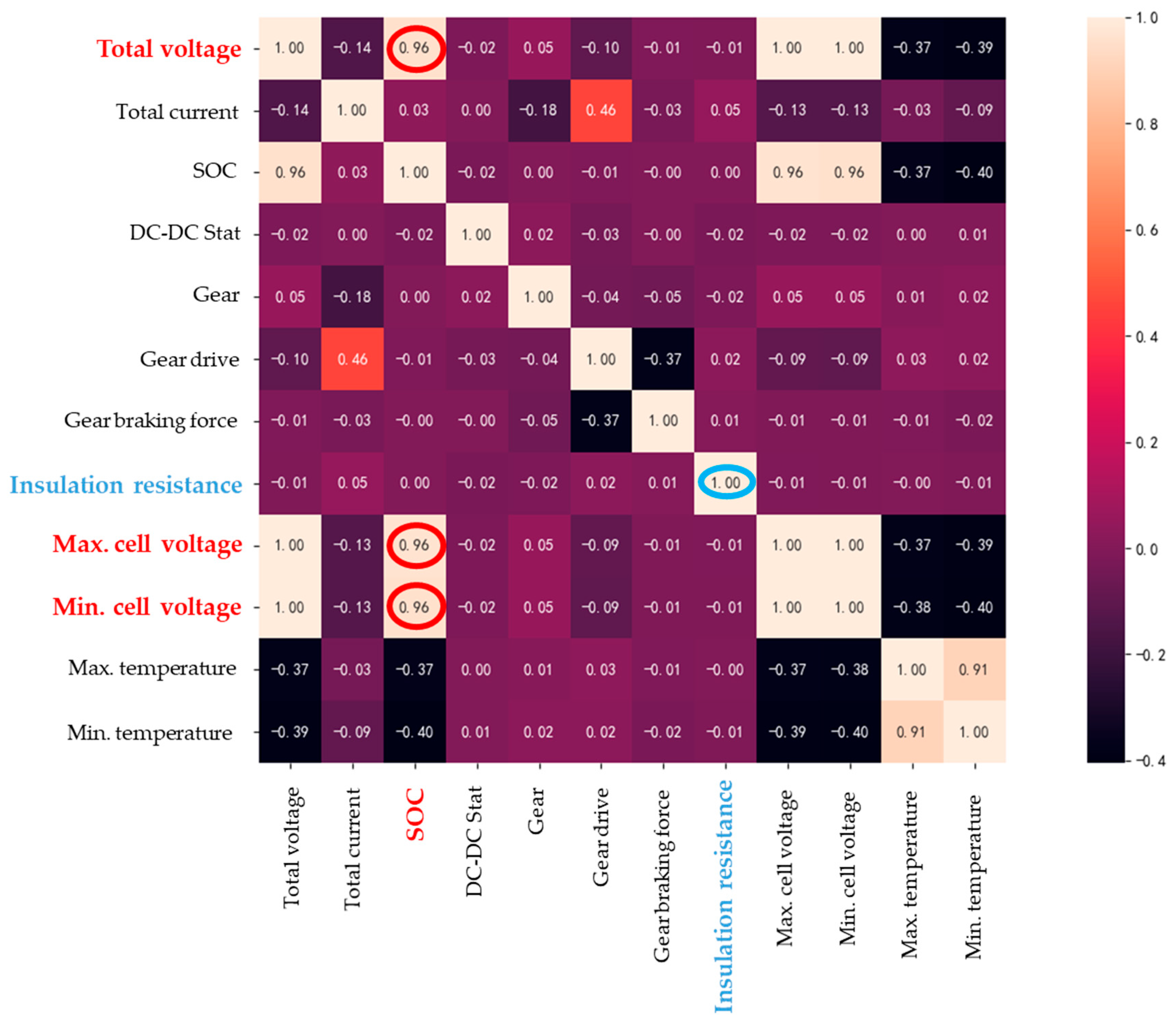

3.2. Relevance Analysis

3.3. Fault Characterization

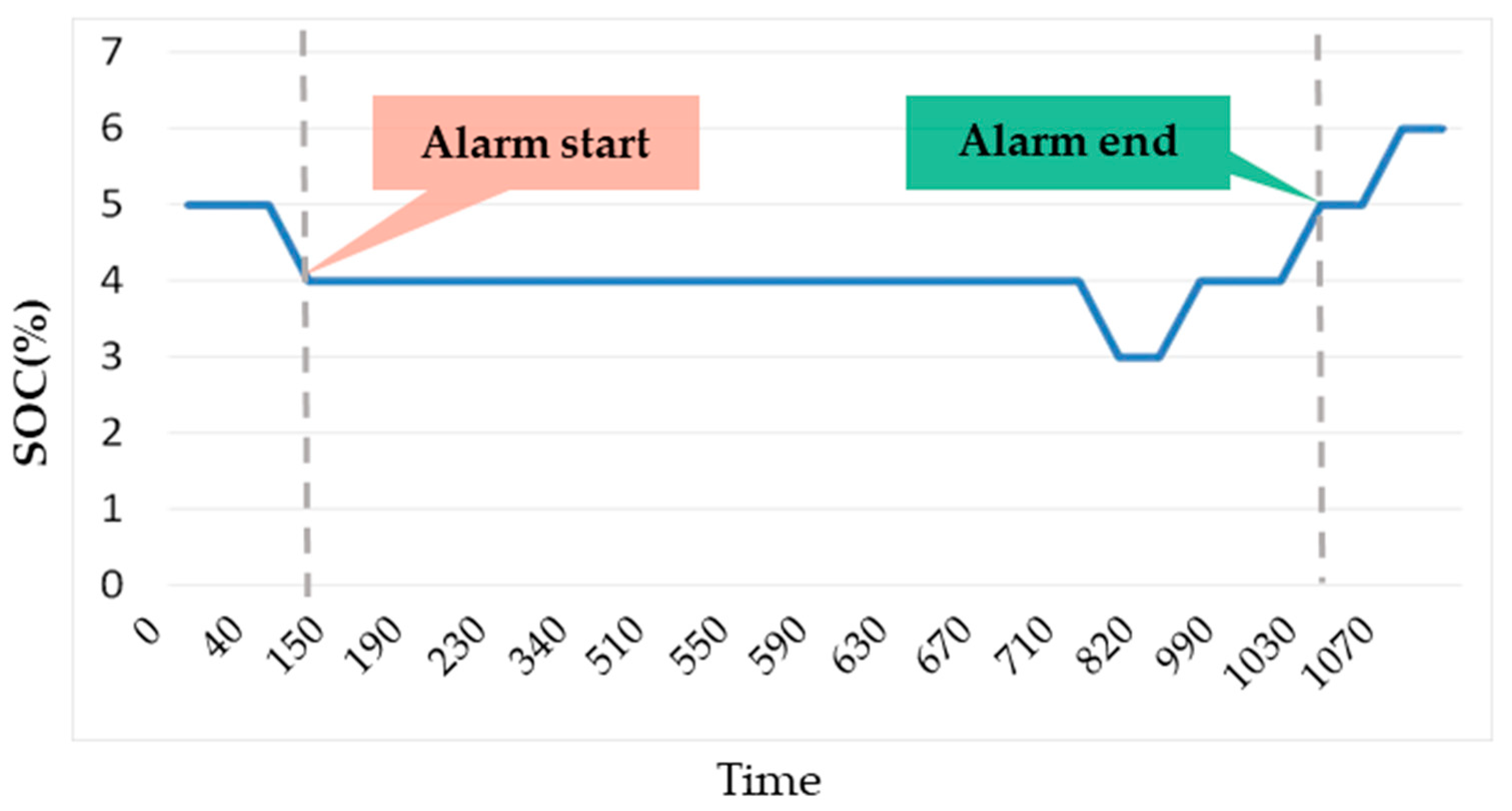

3.3.1. SOC Low Alarm Fault Characteristics

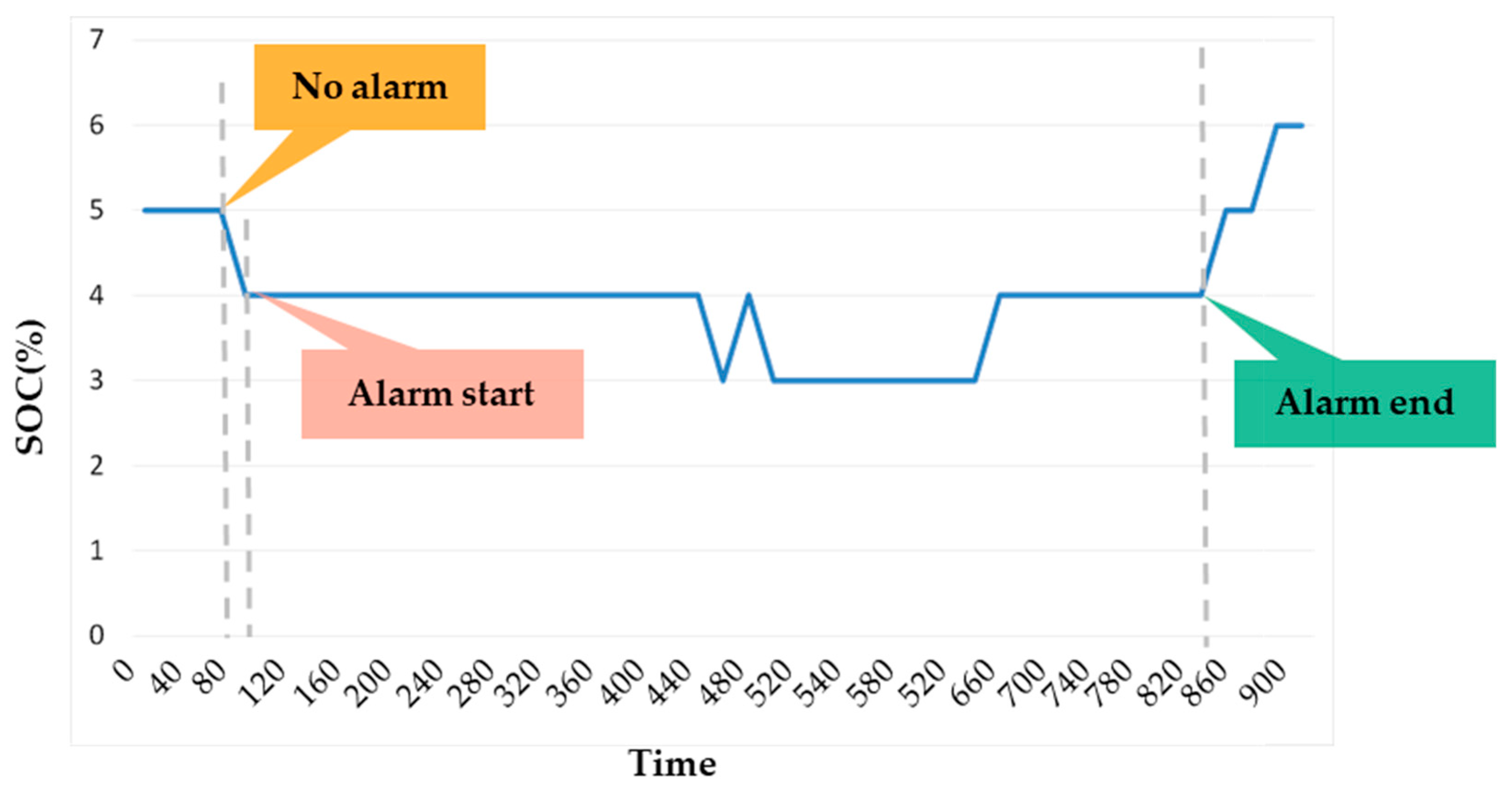

3.3.2. Insulation Alarm Fault Characteristics

4. Experimental Verification and Analysis

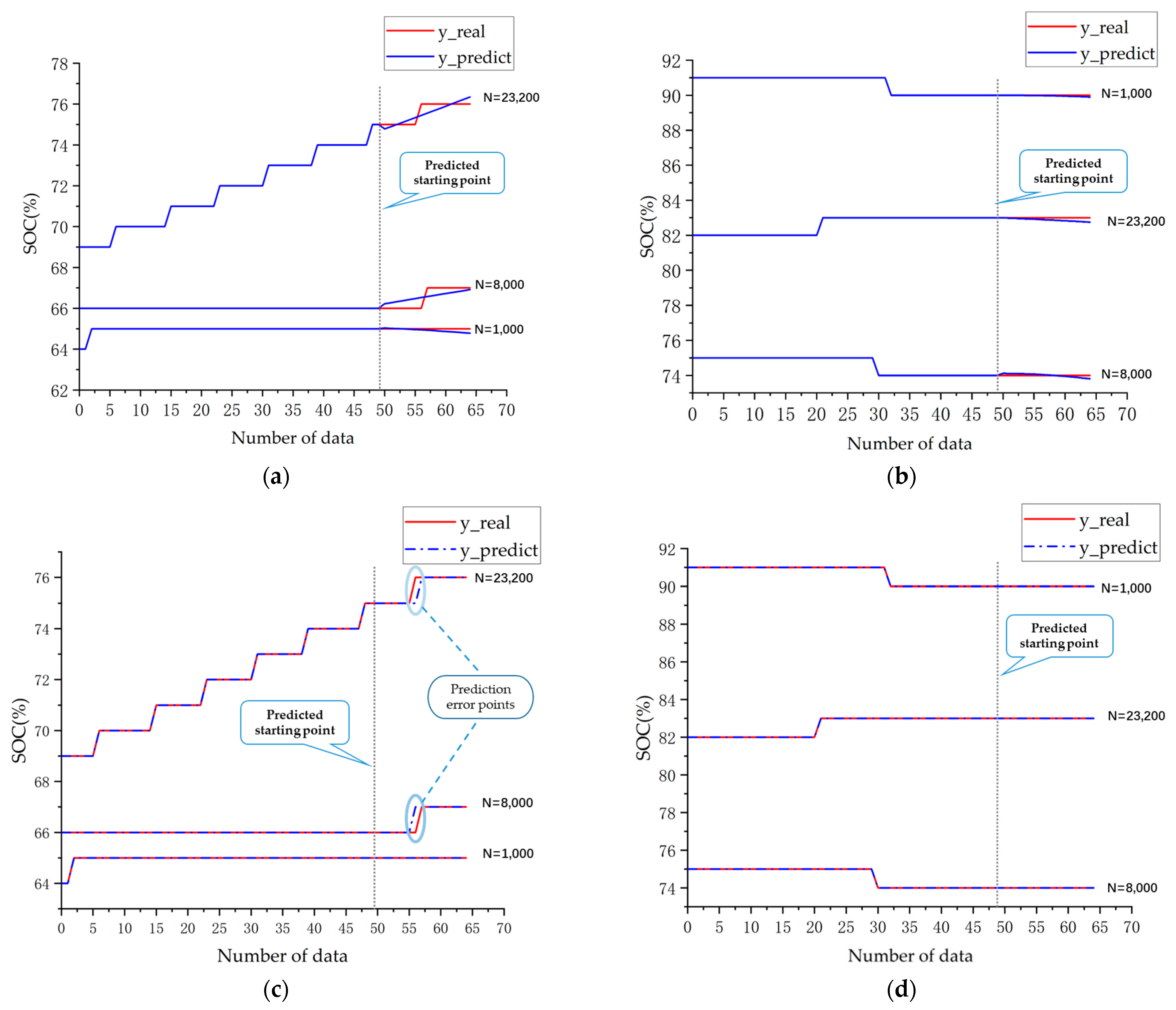

4.1. Low SOC Alarm Fault Prediction

4.1.1. Model Training and Validation

4.1.2. Evaluation and Analysis

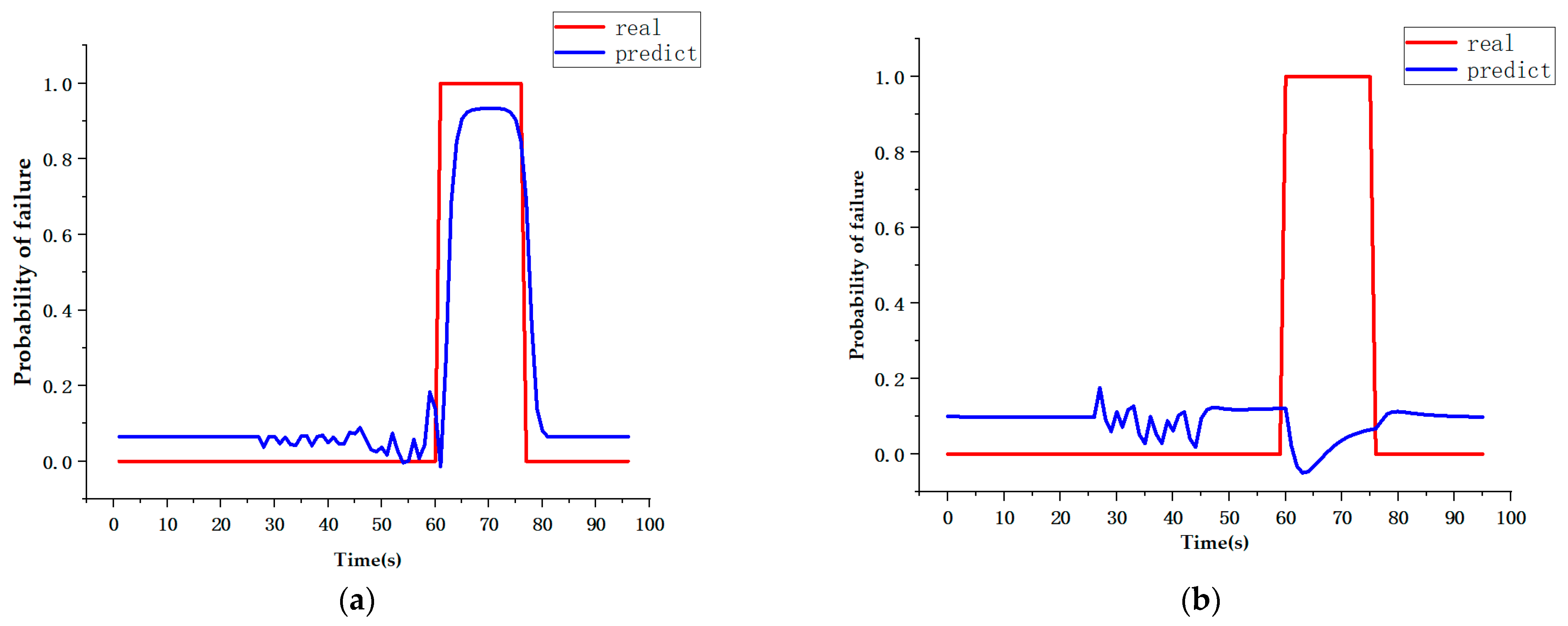

4.2. Insulation Alarm Fault Prediction

4.2.1. Model Training and Validation

4.2.2. Evaluation and Analysis

5. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yao, L. New energy vehicle sales exceed 6.8 million units in 2022. Auto Rev. 2023, 2, 106–107. (In Chinese) [Google Scholar]

- Zhang, H.; Li, S.; Chen, F.; Pan, X.; Feng, H.; Sun, Y. Battery voltage fault diagnosis for electric vehicles considering driving condition variation. IET Intell. Transp. Syst. 2022, 1–17. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- GERS F. Long Short-Term Memory in Recurrent Neural Networks; Universität Hannover: Germany, 2001; pp. 11–14. [Google Scholar]

- Liwicki, M.; Graves, A.; Fernandez, S.; Bunke, H.; Schmidhuber, J. A novel approach to on-line handwriting recognition based on bidirectional long short-term memory networks. In Proceedings of the 9th International Conference on Document Analysis and Recognition, ICDAR 2007, Curitiba, Brazil, 23–26 September 2007. [Google Scholar]

- Sutskever, I.; Vinyals, O.; Le, Q.V.V. Sequence to sequence learning with neural networks. Adv. Neural Inf. Process. Syst. 2014, 27, 3104–3112. [Google Scholar]

- Palangi, H.; Deng, L.; Shen, Y.; Gao, J.; He, X.; Chen, J.; Song, X.; Ward, R. Deep Sentence Embedding Using the Long Short Term Memory Network: Analysis and Application to Information Retrieval. arXiv 2015, arXiv:1502.06922. [Google Scholar] [CrossRef]

- Karpathy, A.; Fei-Fei, L. Deep visual-semantic alignments for generating image descriptions. arXiv 2014, arXiv:1412.2306. [Google Scholar]

- Mao, J.; Xu, W.; Yang, Y.; Wang, J.; Huang, Z.; Yuille, A. Deep captioning with multimodal recurrent neural networks (m-rnn). arXiv 2014, arXiv:1412.6632. [Google Scholar]

- Vinyals, O.; Toshev, A.; Bengio, S.; Erhan, D. Show and tell: A neural image caption generator. arXiv 2014, arXiv:1411.4555. [Google Scholar]

- Liu, T.; Bao, J.; Wang, J.; Zhang, Y. A Hybrid CNN–LSTM Algorithm for Online Defect Recognition of CO2 Welding. Sensors 2018, 18, 4369. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, X.; Wang, W.; Zhao, X.; Wei, M. Image caption model of double LSTM with scene factors. Image Vis. Comput. 2019, 86, 38–44. [Google Scholar] [CrossRef]

- Wang, C.; Yang, H.; Meinel, C. Image captioning with deep bidirectional LSTMs and multi-task learning. ACM Trans. Multimed. Comput. Commun. Appl. (TOMM) 2018, 14, 1–20. [Google Scholar] [CrossRef]

- Tan, Y.H.; Chan, C.S. Phrase-based image caption generator with hierarchical LSTM network. Neurocomputing 2019, 333, 86–100. [Google Scholar] [CrossRef]

- Wen, S.; Wei, H.; Yang, Y.; Guo, Z.; Zeng, Z.; Huang, T.; Chen, Y. Memristive LSTM network for sentiment analysis. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 1794–1804. [Google Scholar] [CrossRef]

- Behera, R.K.; Jena, M.; Rath, S.K.; Misra, S. Co-LSTM: Convolutional LSTM model for sentiment analysis in social big data. Inf. Process. Manag. 2021, 58, 102435. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Liang, B.; Zhou, Q.; Xu, B. Gated hierarchical LSTMs for target-based sentiment analysis. Int. J. Softw. Eng. Knowl. Eng. 2018, 28, 1719–1737. [Google Scholar] [CrossRef]

- Jiang, H.; Jiao, R.; Wang, Z.; Zhang, T.; Wu, L. Construction and analysis of emotion computing model based on LSTM. Complexity 2021, 2021, 8897105. [Google Scholar] [CrossRef]

- Huang, F.; Li, X.; Yuan, C.; Zhang, S.; Zhang, J.; Qiao, S. Attention-emotion-enhanced convolutional LSTM for sentiment analysis. IEEE Trans. Neural Netw. Learn. Syst. 2021, 33, 4332–4345. [Google Scholar] [CrossRef]

- Saadatnejad, S.; Oveisi, M.; Hashemi, M. LSTM-based ECG classification for continuous monitoring on personal wearable devices. IEEE J. Biomed. Health Inform. 2019, 24, 515–523. [Google Scholar] [CrossRef]

- Wójcikowski, M. Real-time PPG signal conditioning with long short-term memory (LSTM) network for wearable devices. Sensors 2021, 22, 164. [Google Scholar] [CrossRef]

- Ye, Z.; Yu, J. Health condition monitoring of machines based on long short-term memory convolutional autoencoder. Appl. Soft Comput. 2021, 107, 107379. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, W.; Wu, X.; Zhang, S.; Chen, D. Study on Health Indicator Construction and Health Status Evaluation of Hydraulic Pumps Based on LSTM–VAE. Processes 2022, 10, 1869. [Google Scholar] [CrossRef]

- Kim, H.; Kwon, Y.; Choi, Y. Assessing the impact of public rental housing on the housing prices in proximity: Based on the regional and local level of price prediction models using long short-term memory (LSTM). Sustainability 2020, 12, 7520. [Google Scholar] [CrossRef]

- Bathla, G.; Rani, R.; Aggarwal, H. Stocks of year 2020: Prediction of high variations in stock prices using LSTM. Multimed. Tools Appl. 2023, 82, 9727–9743. [Google Scholar] [CrossRef]

- Li, R.; Hu, Y.; Liang, Q. T2F-LSTM method for long-term traffic volume prediction. IEEE Trans. Fuzzy Syst. 2020, 28, 3256–3264. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Yao, Y. Fault prognosis of battery system based on accurate voltage abnormity prognosis using long short-term memory neural networks. Appl. Energy 2019, 251, 113381. [Google Scholar] [CrossRef]

- Zhang, H.; Niu, G.; Zhang, B.; Miao, Q. Cost-effective lebesgue sampling long short-term memory networks for lithium-ion batteries diagnosis and prognosis. IEEE Trans. Ind. Electron. 2021, 69, 1958–1967. [Google Scholar] [CrossRef]

- Ding, X.; Cui, Z.; Yuan, H.; Cui, N. Diagnosis of connection fault for parallel-connected lithium-ion batteries based on long short-term memory networks. J. Energy Storage 2022, 55, 105552. [Google Scholar] [CrossRef]

- Trivedi, M.; Kakkar, R.; Gupta, R.; Agrawal, S.; Tanwar, S.; Niculescu, V.C.; Raboaca, M.S.; Alqahtani, F.; Saad, A.; Tolba, A. Blockchain and Deep Learning-Based Fault Detection Framework for Electric Vehicles. Mathematics 2022, 10, 3626. [Google Scholar] [CrossRef]

| Field Name | Example | |||

|---|---|---|---|---|

| Max. alarm level | 0 | 1 | … | 3 |

| Vehicle speed (km/h) | 68.6 | 101.2 | … | 0 |

| Vehicle status | 1 | 2 | … | 1 |

| Mileage (km) | 27,326.3 | 27,341.4 | … | 27,356 |

| Total voltage (V) | 358 | 355 | … | 360 |

| Total current (A) | 156.4 | −9.7 | … | −19.1 |

| SOC (%) | 78 | 78 | … | 5 |

| Insulation resistance (kΩ) | 1000 | 1000 | … | 11 |

| Max. cell voltage (V) | 3.943 | 4.001 | … | 3.921 |

| Min. cell voltage (V) | 3.926 | 3.99 | … | 3.909 |

| Alarm information | 0 | 16 | … | 2048 |

| Vehicle Type | Start Point Position | ME | MSE | RMSE |

|---|---|---|---|---|

| A | 1000 | 0.220 | 0.0126 | 0.1121 |

| 8000 | 0.525 | 0.1105 | 0.3324 | |

| 23,200 | 0.558 | 0.0731 | 0.2704 | |

| B | 1000 | 0.102 | 0.0022 | 0.0468 |

| 8000 | 0.192 | 0.0096 | 0.0979 | |

| 23,200 | 0.251 | 0.0199 | 0.1419 |

| True Value Category | Predicted Value Is Positive Example | Predicted Value Is Negative Example |

|---|---|---|

| Positive Example | TP | FN |

| Negative Example | FP | TN |

| True Value Category | Predicted Value Is Positive Example | Predicted Value Is Negative Example |

|---|---|---|

| Positive Example | 14 | 2 |

| Negative Example | 1 | 63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Chang, H.; Wei, R.; Huang, S.; Chen, S.; He, Z.; Ouyang, D. Online Prediction of Electric Vehicle Battery Failure Using LSTM Network. Energies 2023, 16, 4733. https://doi.org/10.3390/en16124733

Li X, Chang H, Wei R, Huang S, Chen S, He Z, Ouyang D. Online Prediction of Electric Vehicle Battery Failure Using LSTM Network. Energies. 2023; 16(12):4733. https://doi.org/10.3390/en16124733

Chicago/Turabian StyleLi, Xuemei, Hao Chang, Ruichao Wei, Shenshi Huang, Shaozhang Chen, Zhiwei He, and Dongxu Ouyang. 2023. "Online Prediction of Electric Vehicle Battery Failure Using LSTM Network" Energies 16, no. 12: 4733. https://doi.org/10.3390/en16124733

APA StyleLi, X., Chang, H., Wei, R., Huang, S., Chen, S., He, Z., & Ouyang, D. (2023). Online Prediction of Electric Vehicle Battery Failure Using LSTM Network. Energies, 16(12), 4733. https://doi.org/10.3390/en16124733