Thermoelectric Materials and Applications: A Review

Abstract

:1. Introduction

2. Commercial Thermoelectric Modules

2.1. Characteristics and Manufacturing

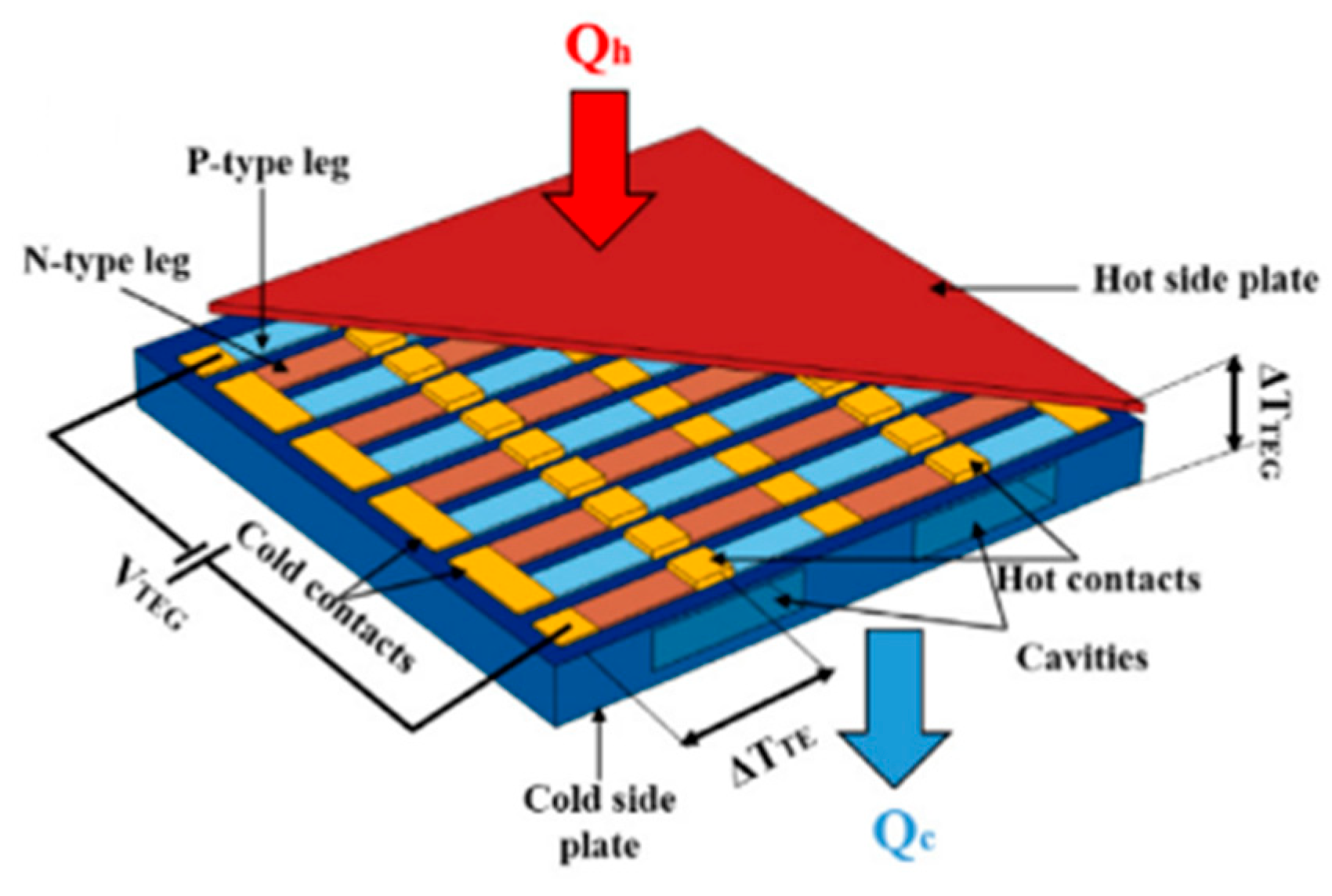

- Planar design: thermoelectric legs are deposited in such a way that all the cold ends are located on one side of the substrate, and the hot ends on the other one; therefore, the temperature gradient for thermoelectric generation (ΔTTEG) is applied along the substrate surface. This configuration never reached real commercialization because it does not fit most commercial applications. A generic thermoelectric module in planar configuration is shown in Figure 3.

- Vertical design: in this configuration, the cold ends are located at the opposite sides of the substrate, while the hot ends are in intermediate positions; the deposited thermoelectric legs are shorter and larger in number. In this case, ΔTTEG is perpendicular to the ceramic substrate. This configuration is the most commercialized one and may be found in many appliances. A generic thermoelectric module in vertical configuration is shown in Figure 4.

- Mixed design: this configuration is considered “mixed” because ΔTTEG is located perpendicularly to the module basal plane (vertical design) but the temperature gradient for thermoelectric refrigeration (ΔTTE) is vertical (planar design). Today, this configuration is commercialized for TE refrigeration; however, thanks to its good applicability, it is currently being studied for other applications. A generic mixed configurated TE module is represented in Figure 5 [22,23,37].

- Large (or bulk) TEGs: these devices have millimetric sizes and can provide power up to hundreds of Watts when subjected to large heat ranges. TE modules in this category are used for industrial applications.

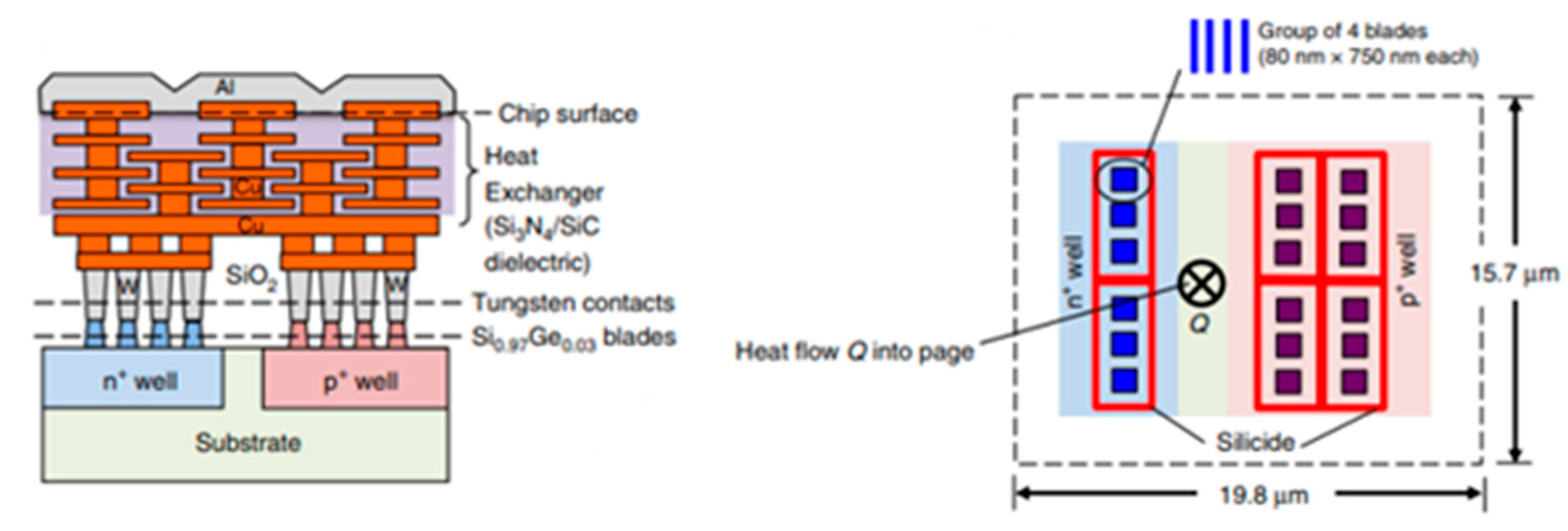

- Silicon technology (SiO2-based substrates): these substrates are used to fabricate micro-TEGs. The most commonly used materials in these substrates are Si-Ge and Bi-Sb-Te alloys. Given the high temperature resistance and the diffusion shield capacity of silicon dioxide (SiO2), these devices are used for electronics, and more specifically integrated circuits (IC) technology [21,41,42]. The TE n- and p-legs in this case are called n+-wells and p+-wells; often the materials are doped with implantation of arsenic (As) and phosphorus (P) ions for the n+-wells and boron (B) ions for the p+-wells [21,43,44].

- Alumina (Al2O3): this substrate is often used for high density multi-layered bulk TEGs. Due to the low cost, time-effectiveness, simplicity, and good chemical and temperature resistance, it is used in the industry at high temperatures for high electrical current generation. These substrates can also be used for the fabrication of micro-generators but are more practical for bulk generators [21,45,46].

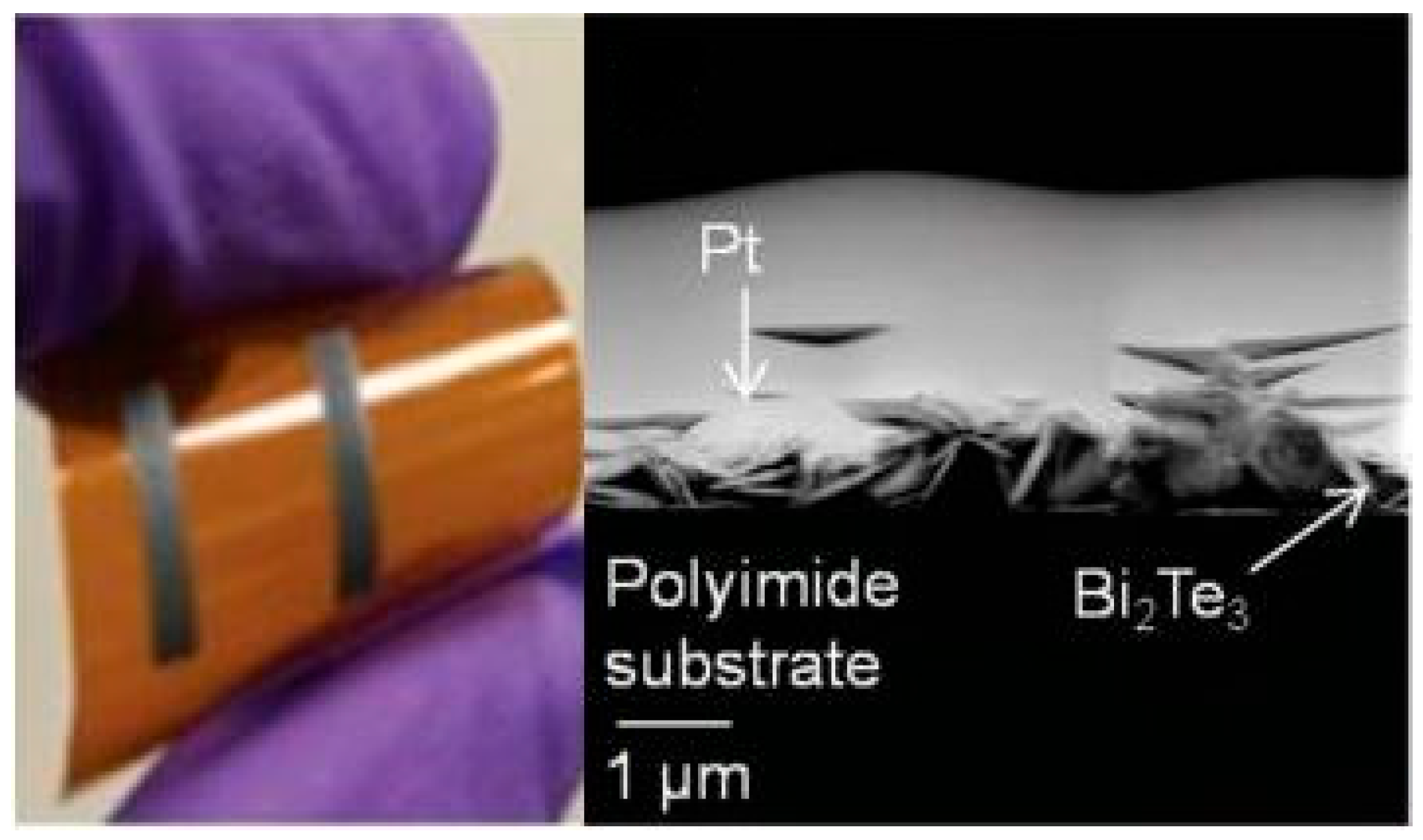

- Polymers: the most common polymer used for this application is polyimide (PI), cellulose fibers-based materials are also often used. These materials are characterized by a low chemical and thermal resistance while demonstrating high flexibility; micro-generators are fabricated using such substrates for near room temperature applications such as wearable devices or health monitoring applications [21,47,48].

- Fabrication of the thermoelectric piles (current and promising methods are discussed in Section 4): in industrial plants, it takes place by hot extrusion of thermoelectric materials.

- The side surfaces of the TE legs are treated to have protection over the environment: a polymeric coating (e.g., water-based paint with fluorine rubber) is deposited by electrodeposition.

- The TE piles are washed and cured, and then cut to fit a certain module design.

- Lithography and electrodeposition are used to deposit on the thermopiles surface:

- ○

- The metal contacts (usually a single Ni layer)

- ○

- The anti-diffusion layer (one Ni layer or two stacked Sn + Ag layers)

- ○

- Cu interconnects are often deposited to increase the electrical contact in the circuit (it is a single thick film which does not exceed 5 µm in thickness)

- The TE modules are assembled by soldering using the applied coating in the form of a tin alloy and gold alloy and using alumina plates as supports [49].

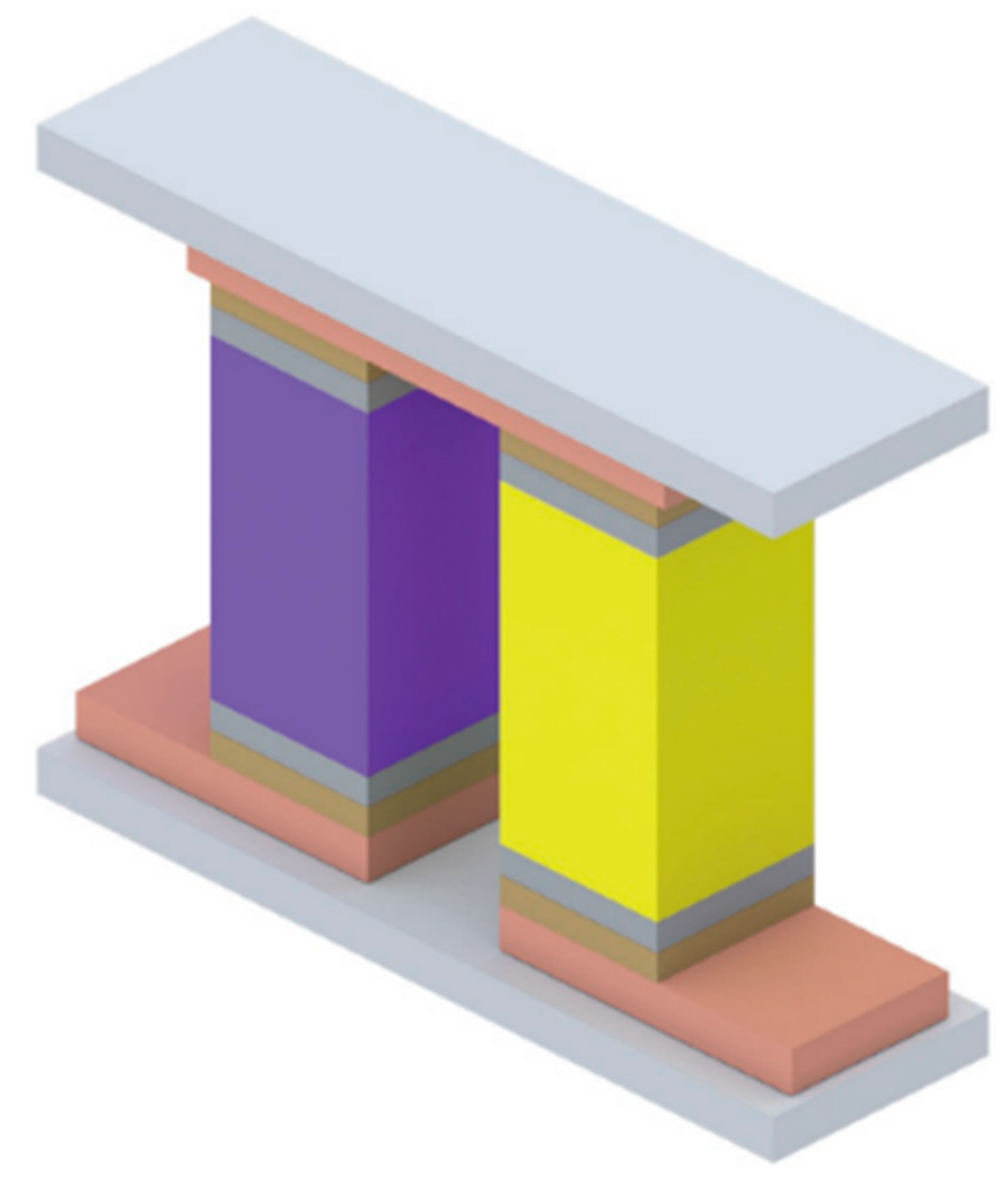

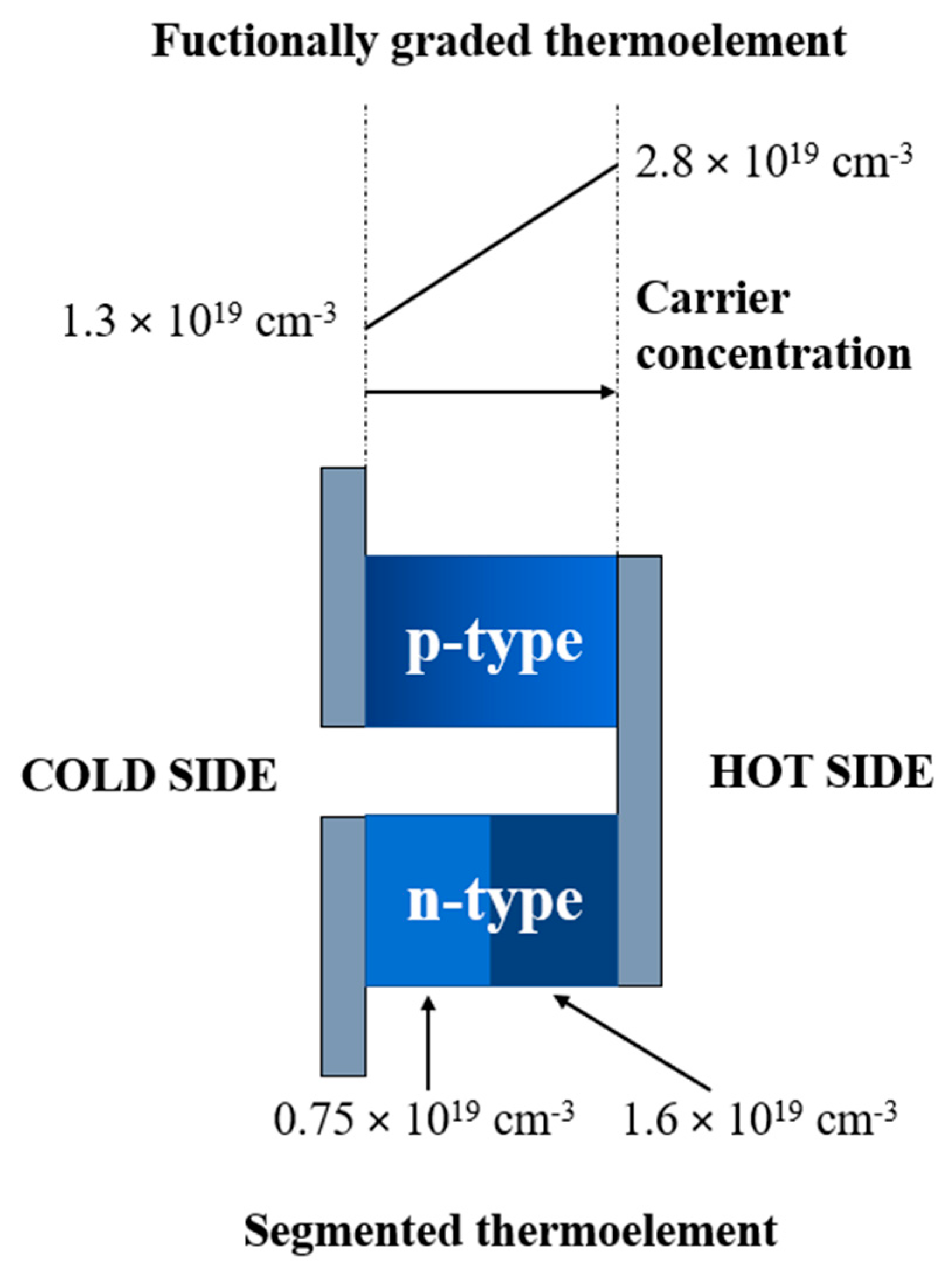

2.2. Functionally Graded and Segmented Thermoelements

- Functionally graded TE elements: during the material fabrication, a gradient of dopants is introduced to have a different carrier concentration in the material; specifically, higher towards the hot side to favor the TEG performance. Fabrication of these thermoelements is carried out with the Bridgman technique. This solution proved useful with non-crystal structured TE materials (e.g., bismuth telluride alloys) exploiting the double doping technique.

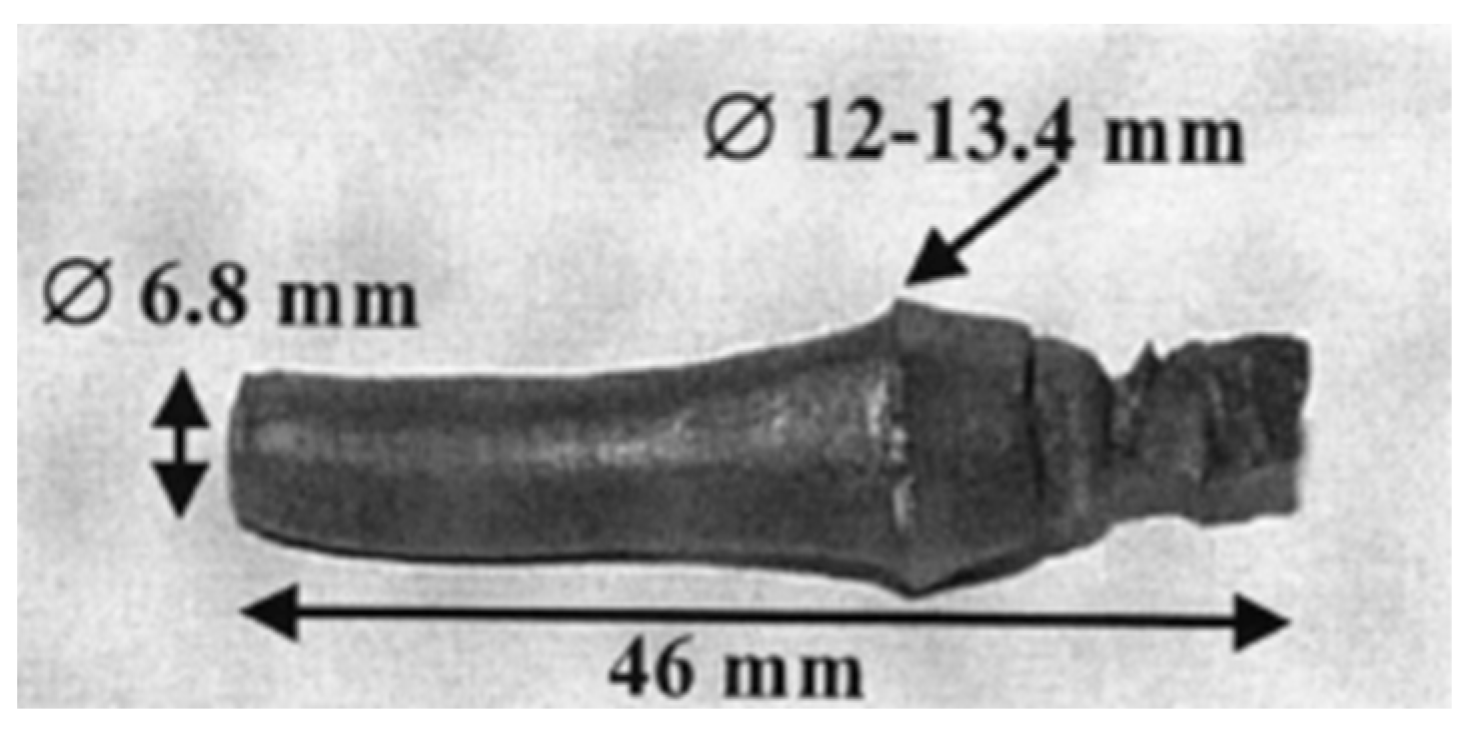

- Segmented elements: This solution consists of joining two different thermoelectric materials with different carrier concentration, obtaining the same results as above. This is done with crystal TE materials because grading is not enough to achieve this properties gradient (e.g., skutterudites); currently, these elements are fabricated via sintering of pressed powders [22,23].

2.3. Applications of Thermoelectric Modules

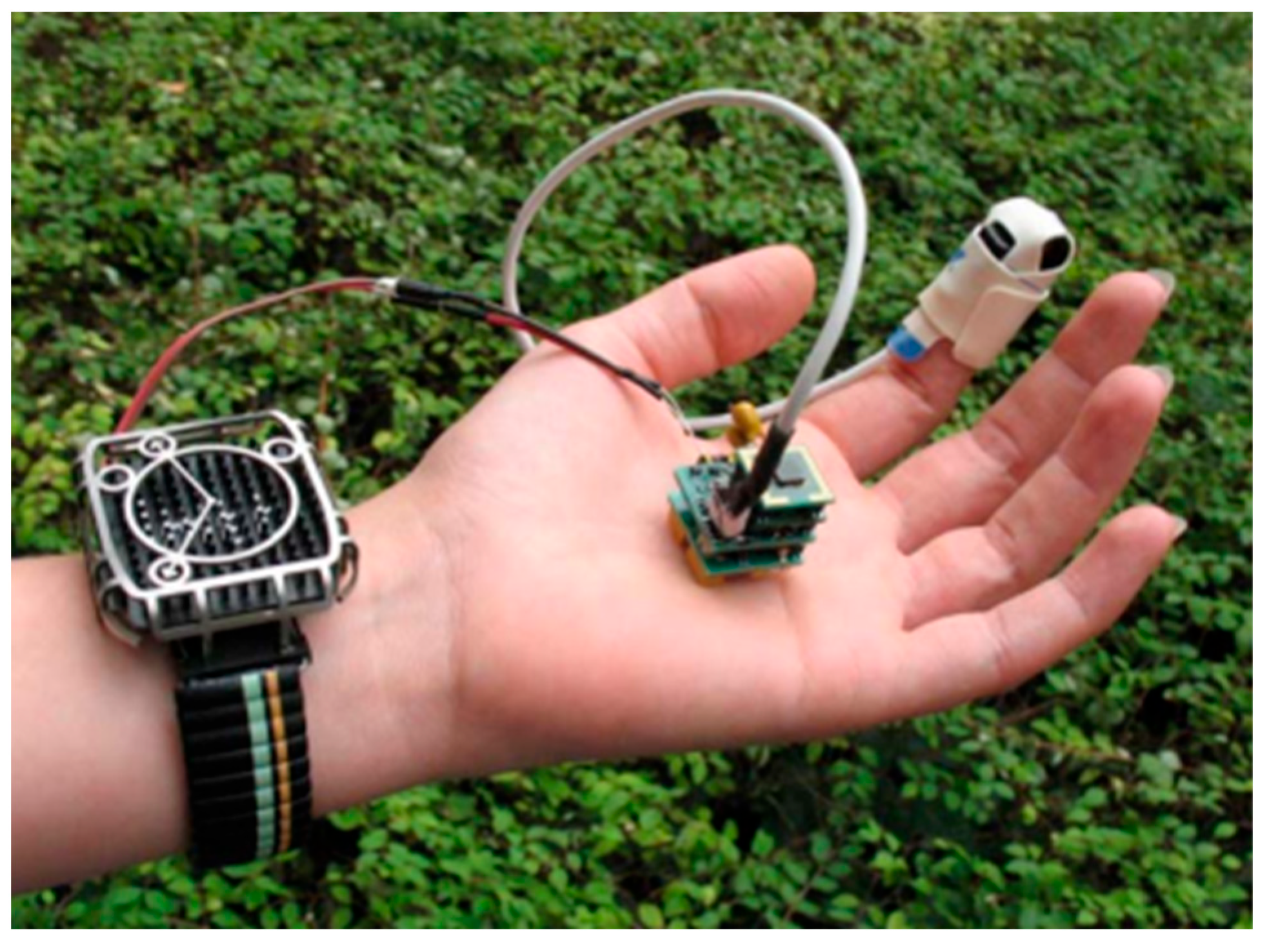

2.3.1. Medical and Wearable Devices

2.3.2. Wireless Sensor Networks (WSNs)

2.3.3. Automotive

2.3.4. Aerospace

2.3.5. Electronic and Micro-Electronic Devices

- Airside: these are the conventional cooling technologies, including rotary fans and heat sinks. The main application of heat sinks is in laptops and located at the heat transfer interface between the heat source and the rotary fans. More innovative solutions in this group are piezoelectric fans and electrostatic fluid accelerators (EFAs).

- Heat transporters: these solutions were designed for higher heat flux applications. The most common solutions are heat pipes, vapor chambers, cold plates, and liquid and spray cooling; they are always used with rotary fans for thermal management of laptops and computer servers.

- Active solid-state heat spreader: Thermoelectric devices are part of this group, along with thermotunneling and thermoionic devices. Currently, used TE devices are thermoelectric coolers (Peltier effect usage); however, these are used for niche applications because of their high price. In this field, TE materials are also studied as TEGs, thus using waste heat as source for electrical energy generation: not only by powering other components of the electronic device but also by supplying current to the cooling fans, being active thanks to the waste heat dispersed by their own system.

- Passive thermal interface material: these solutions are used for cooling by heat transfer and include greases (the most common one based on a silicon matrix), gels, adhesives, and graphene. These materials have extremely lower thermal resistance than air or commercial materials for such purposes (e.g., silver epoxy) and therefore allow for interface cooling [21,79].

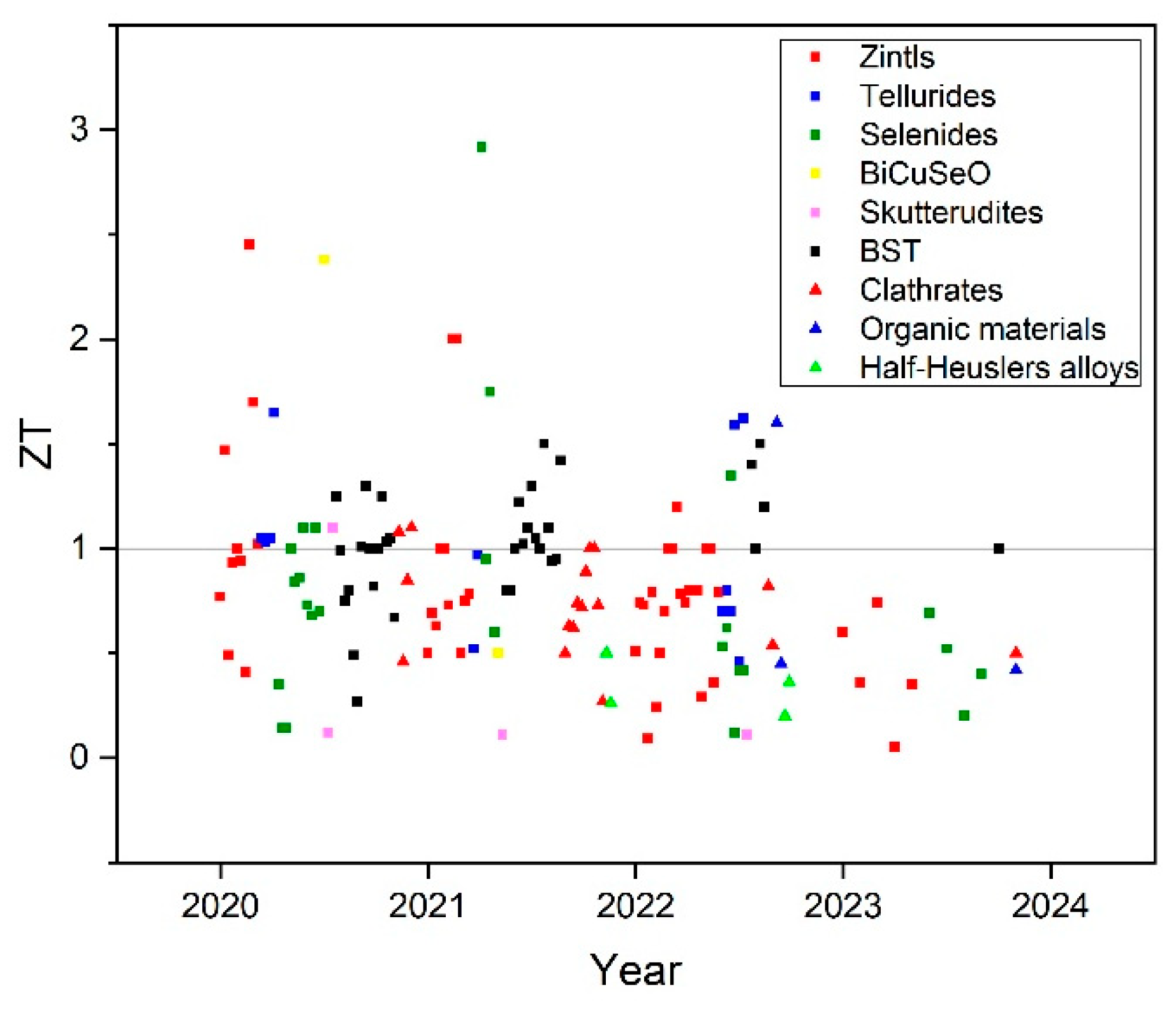

3. Thermoelectric Materials

- Low temperature range (up to 600 K): common low temperature applications are wearable and medical devices, where the devices are working near room temperature (Section 2.3.2). Microelectronics applications, such as nodes for WSN devices, may be included in this category due to the low heating of such utilities (Section 2.3.1 and Section 2.3.5).

- Medium temperature range (from 600 to 1000 K): thermoelectric materials are commonly employed in this range in automotive and in industries, where waste heat can be converted into electrical current directly from the engine in the former case and from plants (e.g., heat pipes) in the latter (Section 2.3.3).

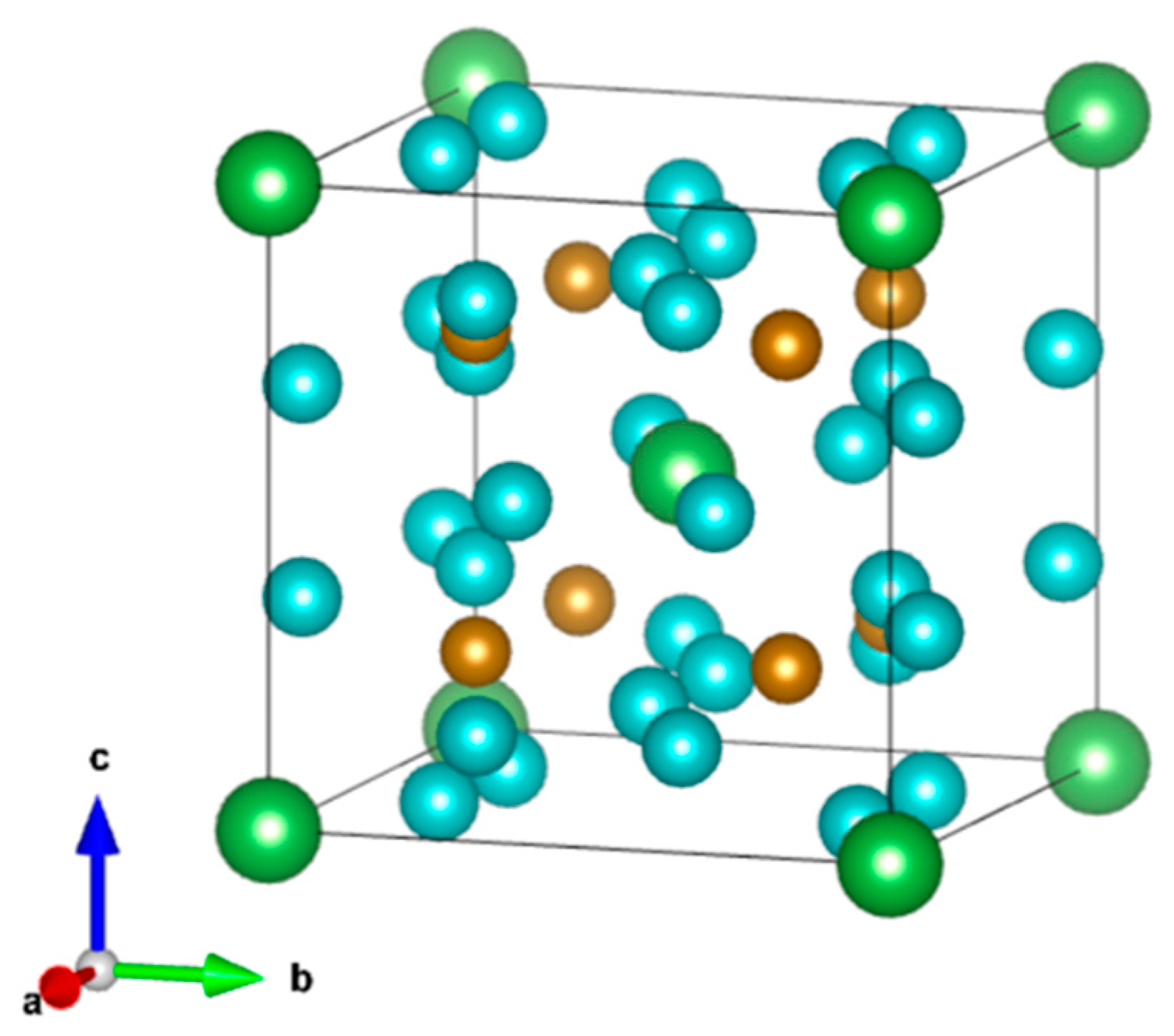

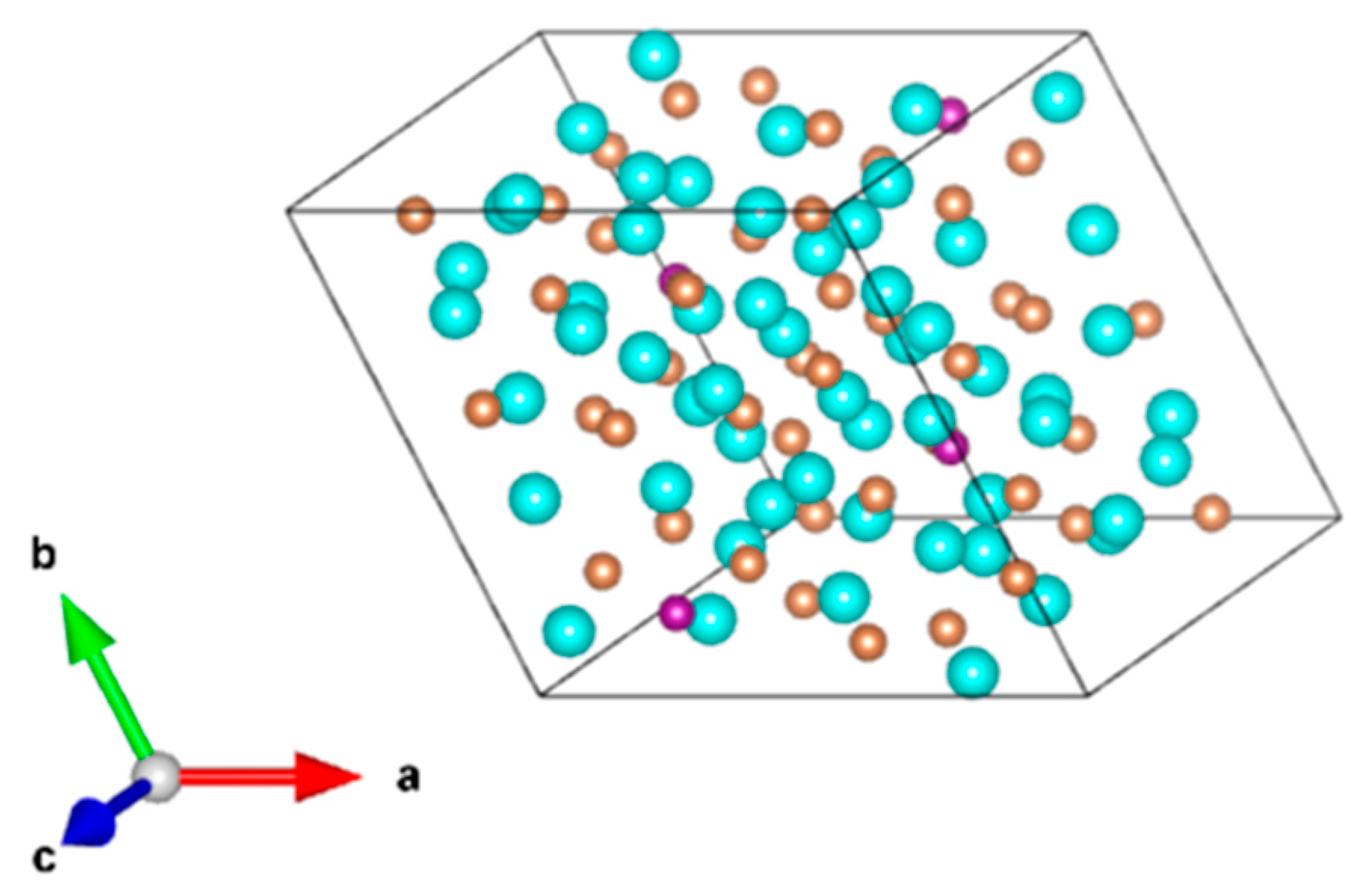

3.1. Skutterudites

3.1.1. n-Type Yb-Partially Filled Skutterudites—Medium Temperature Range

3.1.2. p-Type DD-Based Skutterudites—Medium Temperature Range

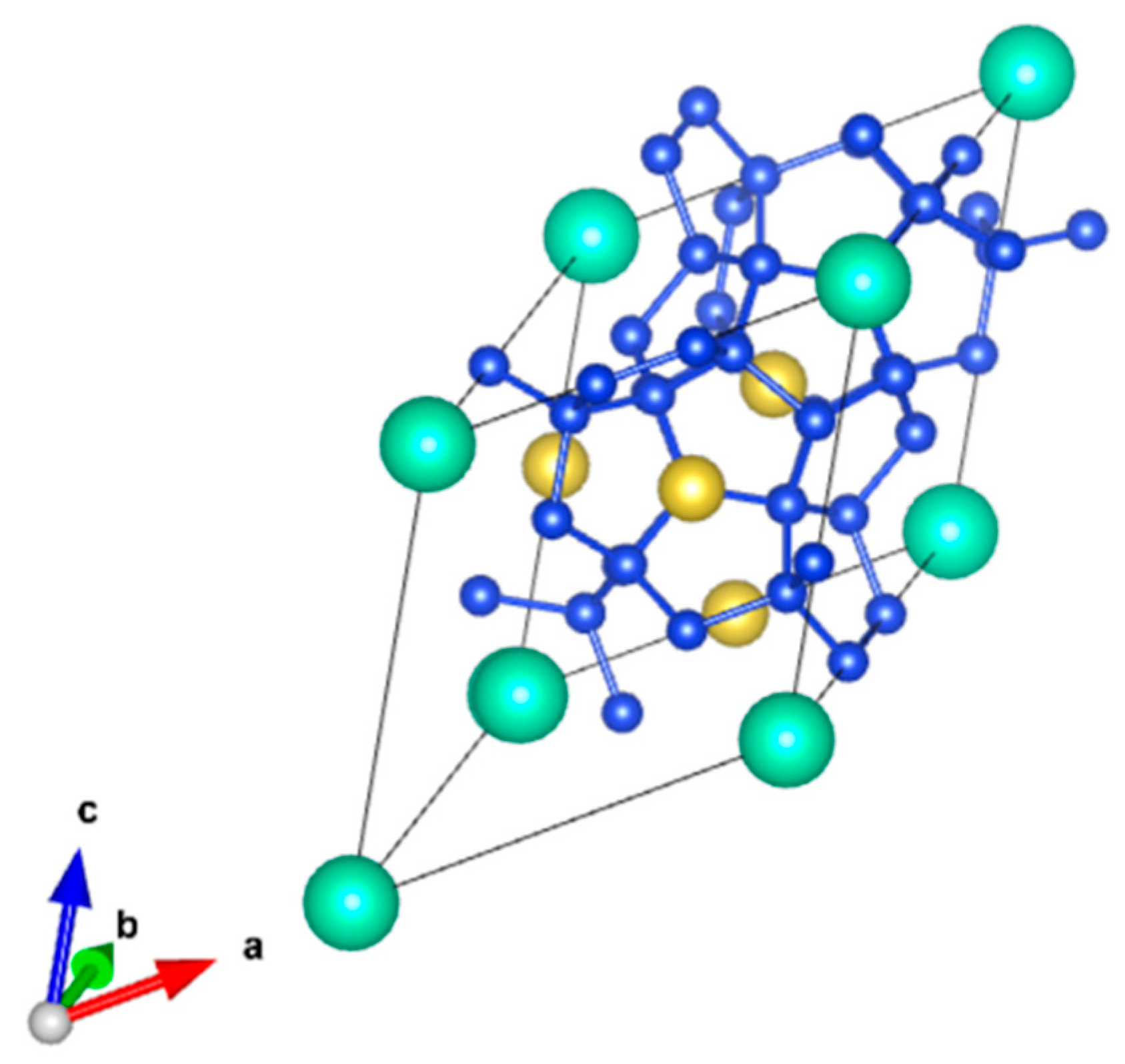

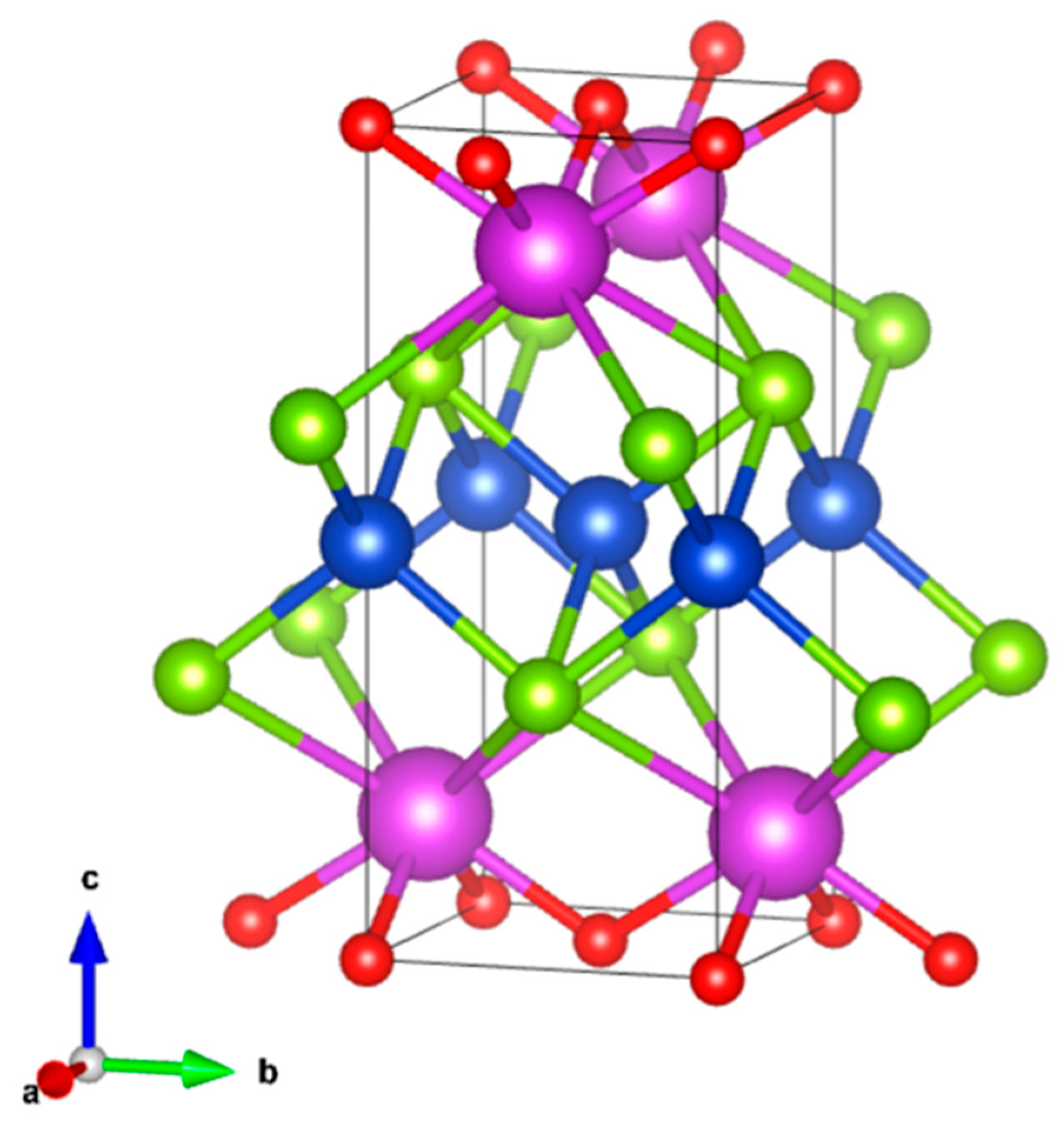

3.2. Half-Heusler Alloys

3.2.1. p-Type XVFeSb—High Temperature range

3.2.2. n-Type XIVNiSn—Medium Temperature Range

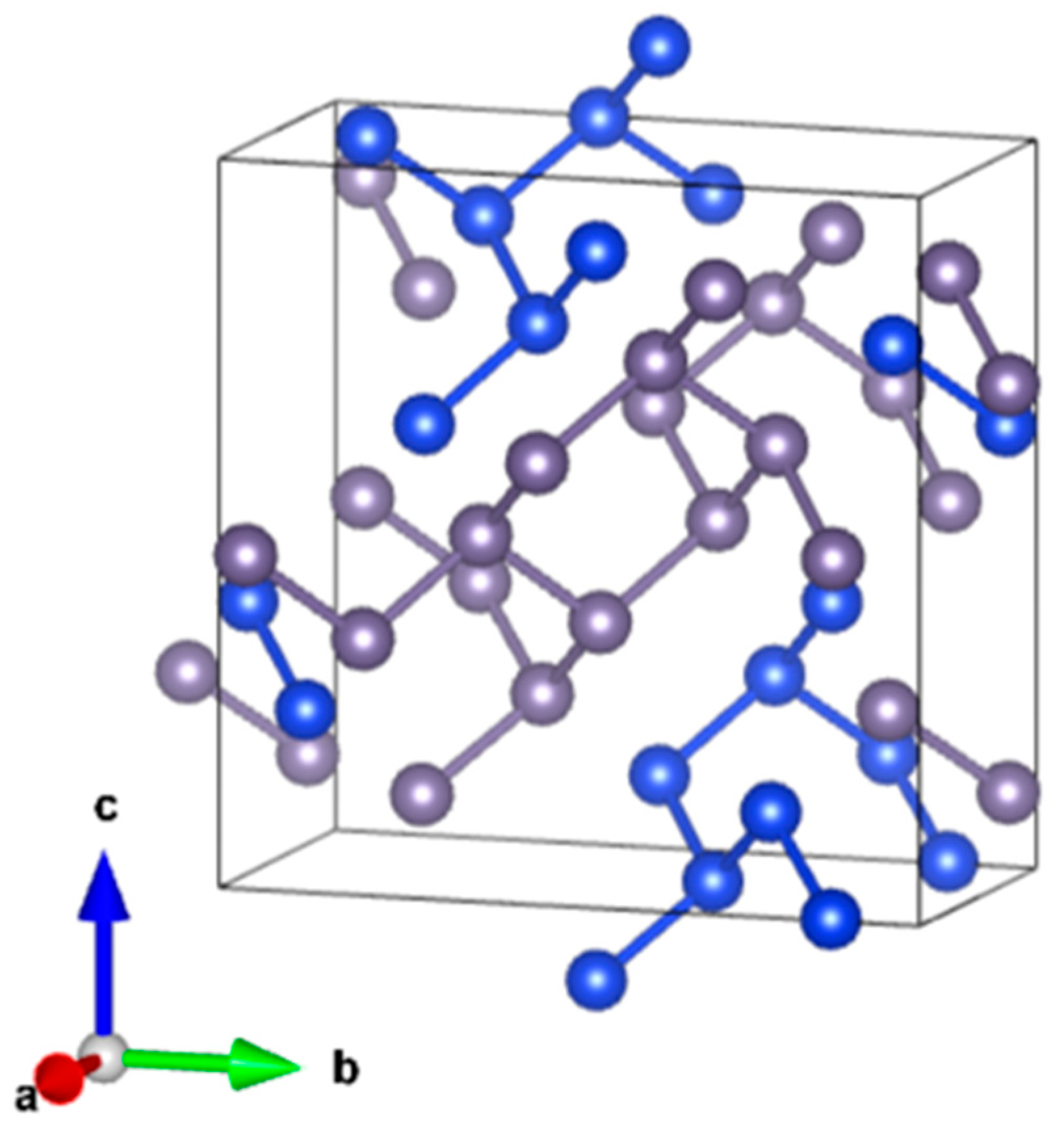

3.3. Clathrates

3.4. Zintls

3.5. Oxyselenides

3.6. Silicon–Germanium (Si1−xGex)—High Temperature Range

3.7. Organic and Hybrid Materials

3.7.1. Conducting Polymers—Low Temperature Range

3.7.2. Carbon-Based TE Materials—Low Temperature Range

3.7.3. Organic Hybrids Materials—Low Temperature Range

3.8. Chalcogenides

3.8.1. Lead Telluride (PbTe) and Its Alloys—Medium Temperature Range

3.8.2. Tin Telluride (SnTe) and Its Alloys—Medium Temperature Range

3.8.3. Germanium Telluride (GeTe) and Its Alloys—Medium Temperature Range

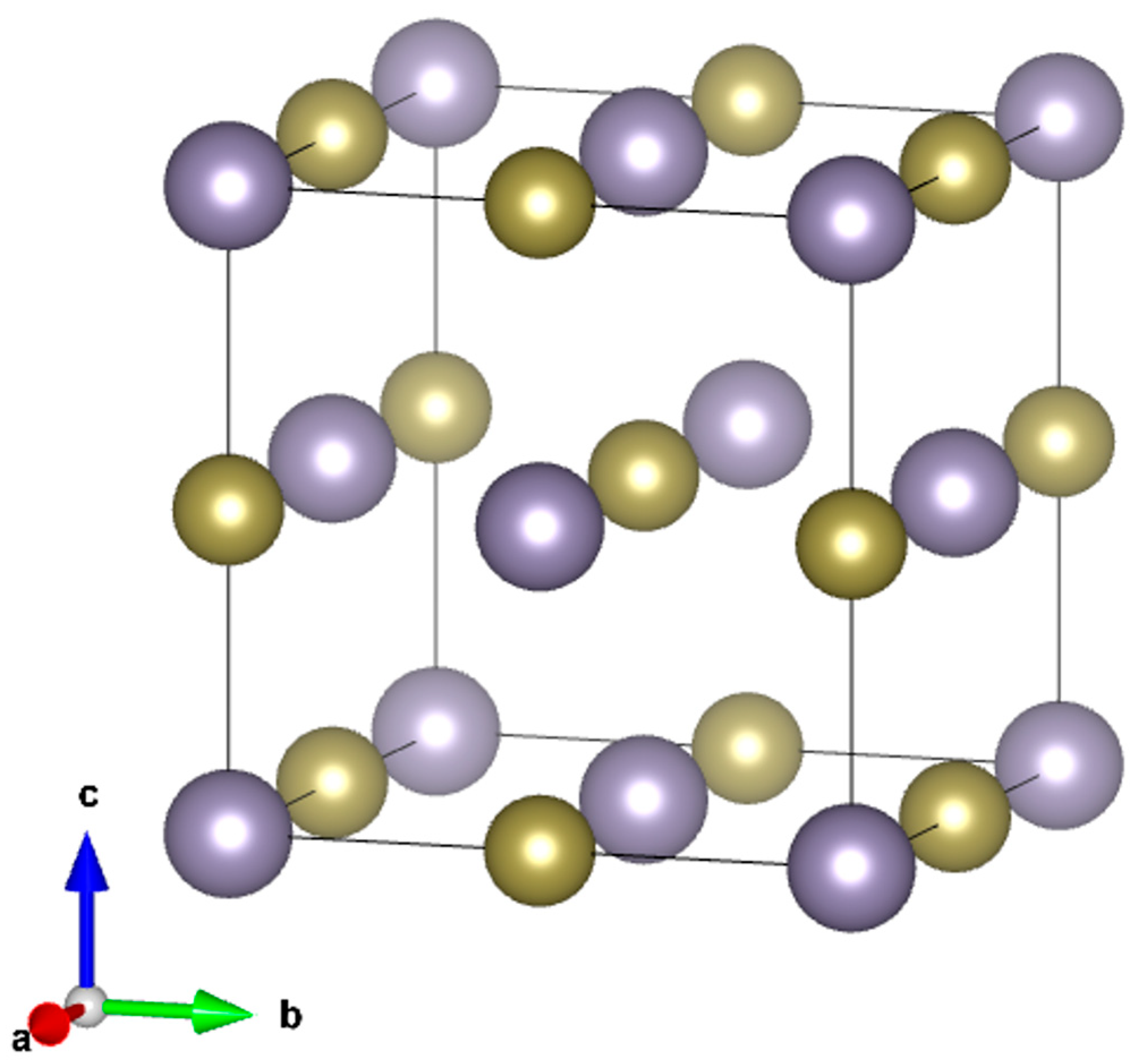

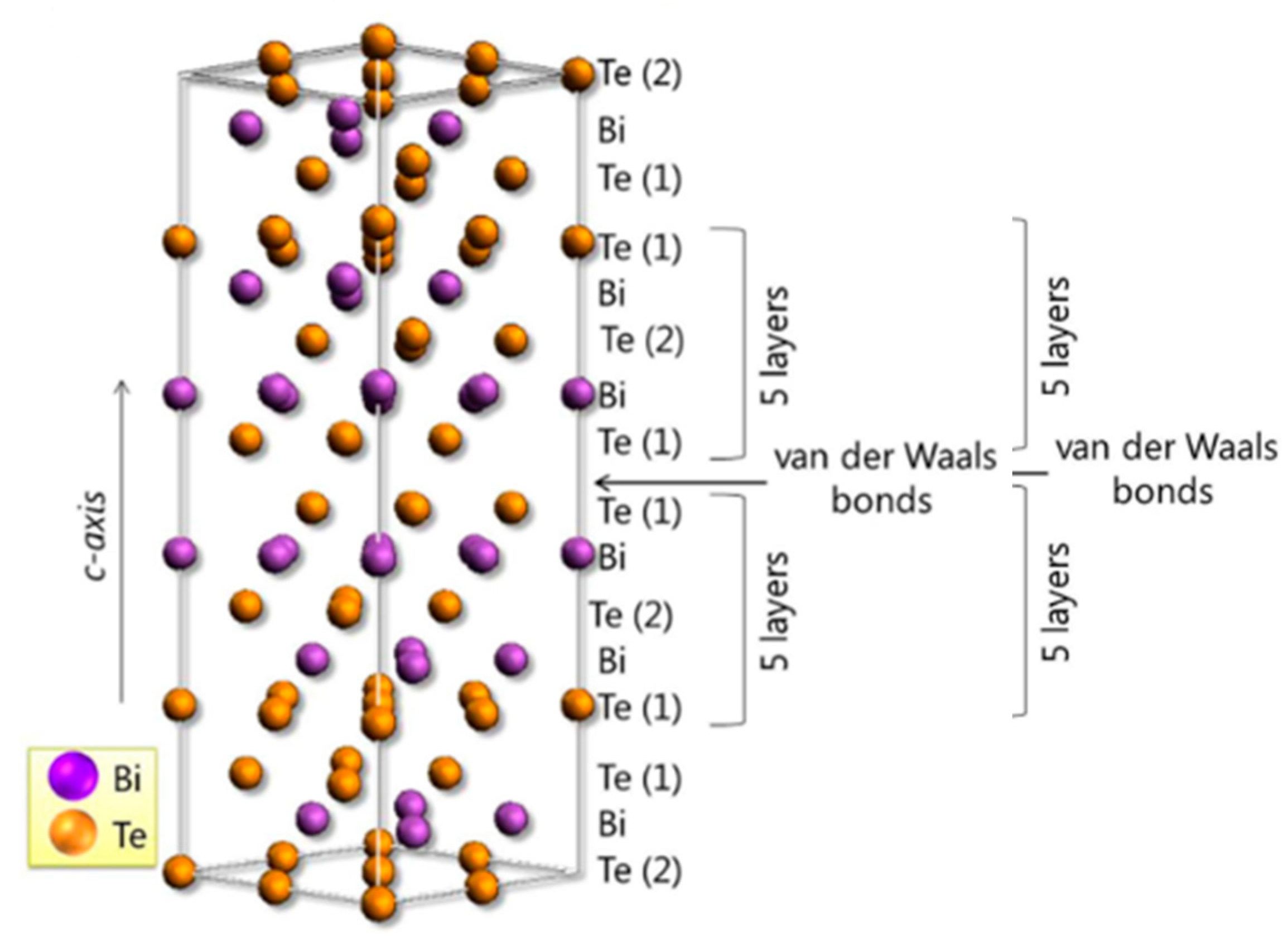

3.8.4. Bismuth Telluride and Its Alloys—Low and Medium Temperature Range

4. Manufacturing Methods

- Microstructural control: nucleation and growth of the grains is totally different in thin films and bulk materials. Typical bulk materials are products of high temperature shaping and consolidation steps. During thin film fabrication, high nucleation rate of grains is shown due to the condensed vapors at low temperatures, leading to smaller grains; bulk materials and thin films average grain sizes are around 30 and 0.1 µm, respectively. Properties such as electrical and thermal conductivity are greatly enhanced by lower grain size and higher microstructural homogeneity.

- Size effect and layered structure: films show unique properties that do not have any counterpart in bulk materials. Extremely thin or multi-layered materials (e.g., superlattices) show these properties: in such cases, the surface atoms are predominant in determining the material behavior with respect to bulk atoms. Most studied effects are electron scattering from the surface, quantum effects, and non-linear diffusion effects. These phenomena are influencing charges and phonons movements, crucial for thermoelectric properties [1,193,194].

- Slow solidification in the furnace (free cooling to RT).

- Rapid solidification carried out with a planar flow casting apparatus forming Yb0.25Co4Sb12 ribbons 20 to 30 µm thick.

- Grain size was hundreds of times higher for the ingots than the ribbons: tens of micrometers against a grain size around tenths of micrometers.

- The ingot samples showed higher microporosity due to lack of compaction between grains, thus being source of inhomogeneities. Ribbons samples reached 95% relative density.

- The ingot samples showed more secondary phases rather than ribbons.

4.1. Processing Technologies: Single Crystal Growth

4.2. Bulk Technologies: Powder Synthesis

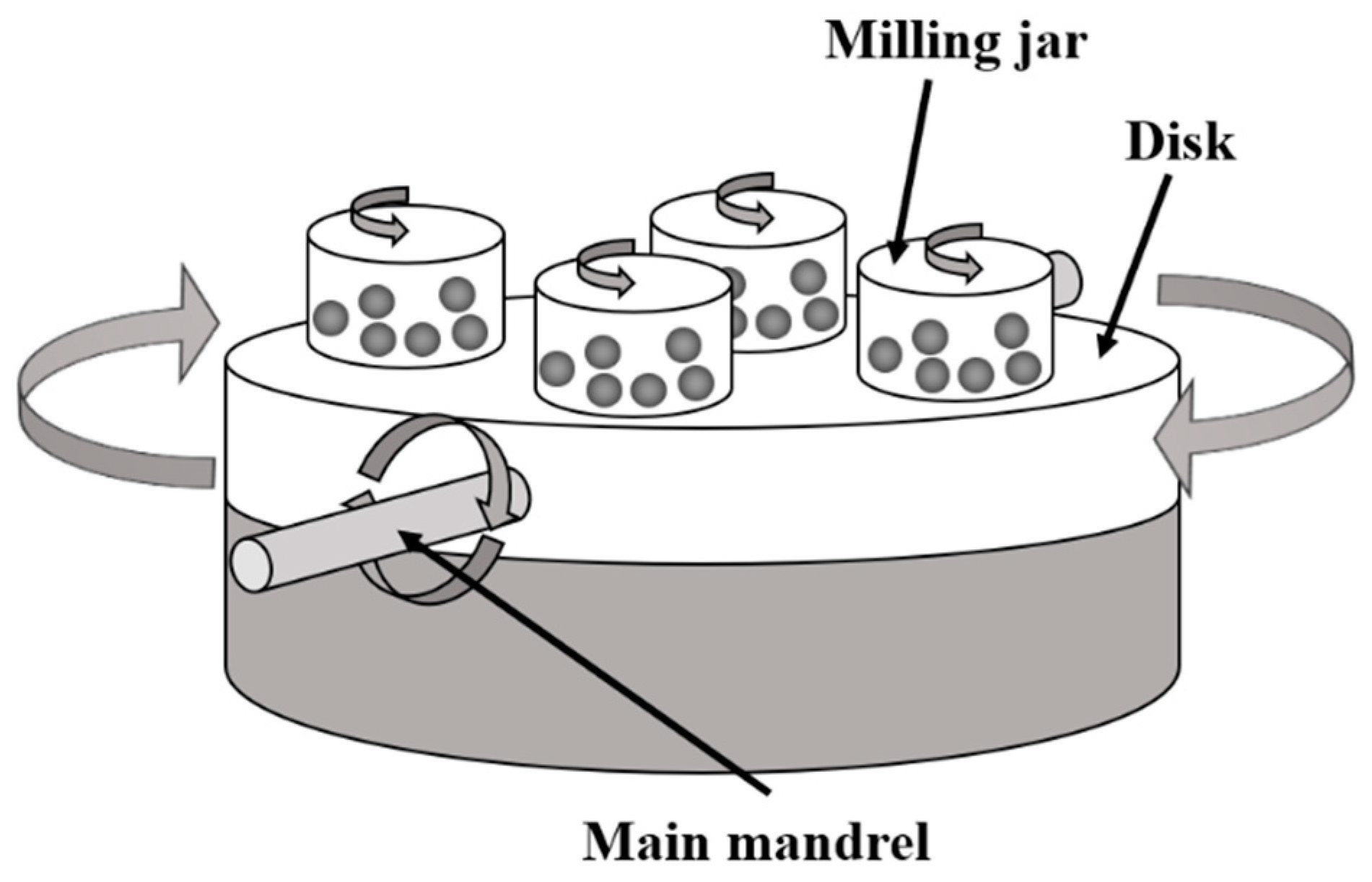

4.2.1. Mechanical Alloying

4.2.2. Melting

4.3. Film Technologies: Chemical and Physical Methods

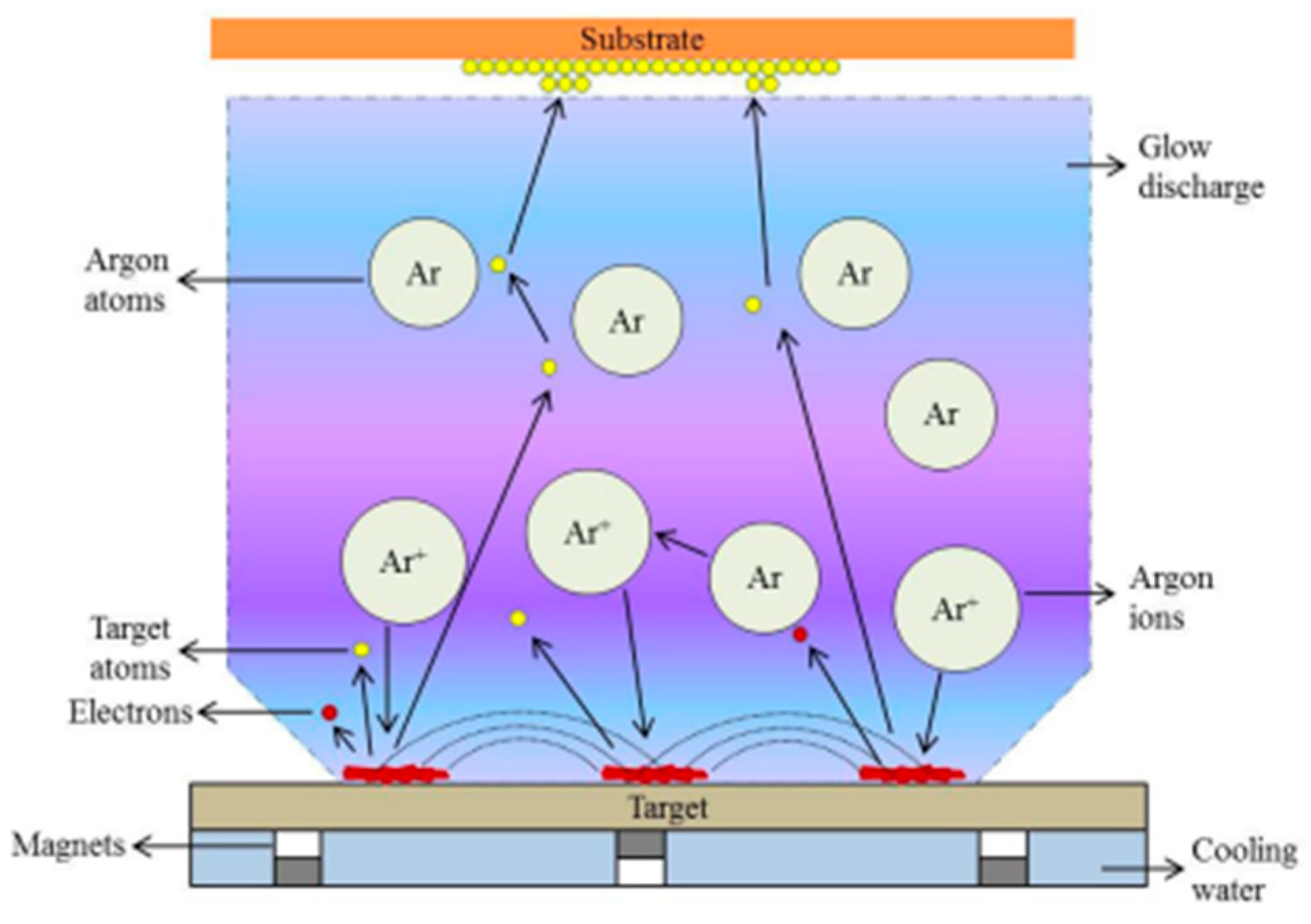

4.3.1. Magnetron Sputtering

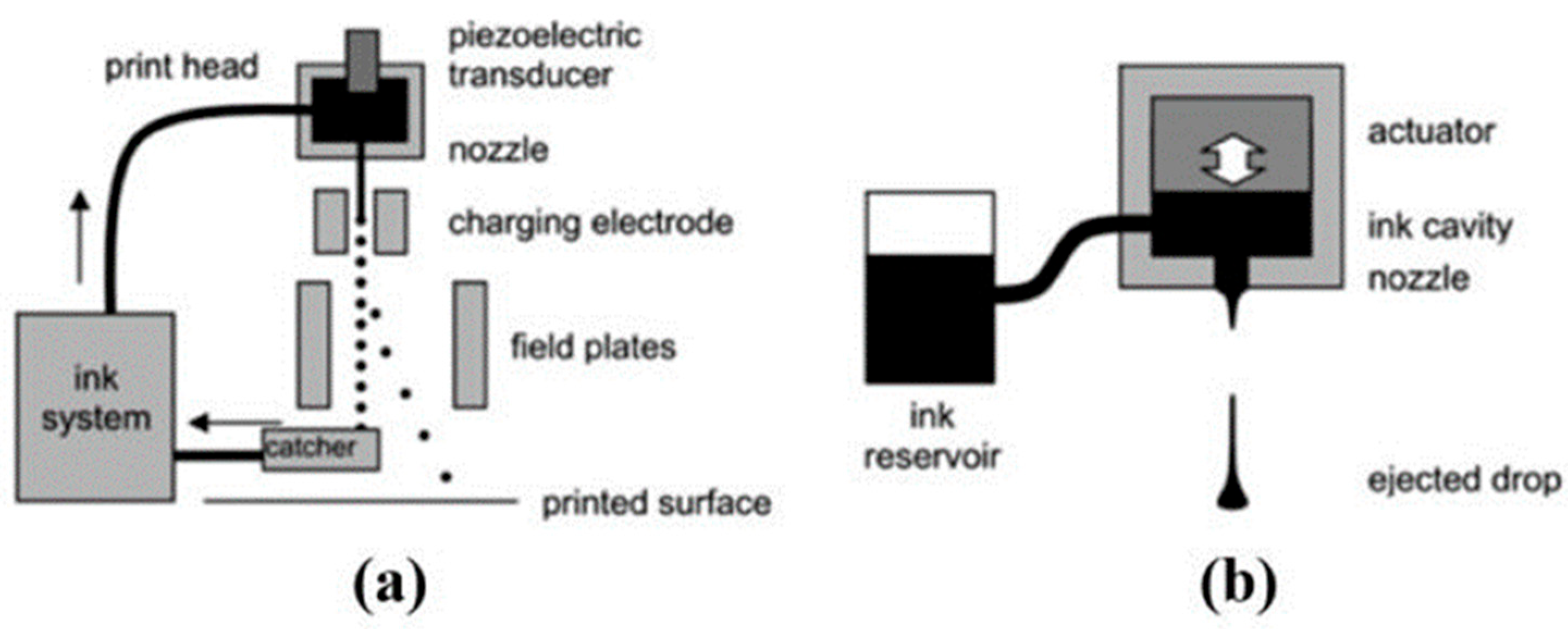

4.3.2. Inkjet Printing (IJP)

4.3.3. Aerosol Jet Printing (AJP)

- Atomization: the functional ink is transformed into an aerosol through pneumatic or ultrasonic atomization.

- ○

- Pneumatic atomization: a piston is partially immersed in the ink. Aerosolization is achieved using an atomizing gas (usually N2) that hits the ink through the piston, splashing the droplets.

- ○

- Ultrasonic atomization: commercial aerosol jet printers usually use this system. High frequency (MHz) ultrasound sets up a capillary wave on the ink surface, leading droplets to break off with a well-defined size distribution.

- Transport: following atomization, the carrier gas (often nitrogen N2) carries ink droplets through the mist tube to the deposition head. The process can take around 10 s under typical operating conditions. Large droplets are separated from small droplets before collimation: the large ones go back to the jar; the small ones are part of the aerosol.

- Collimation: while entering the deposition head, the aerosol gas (which contains ink droplets) is surrounded by a flowing sheath gas (usually N2). This collimates the beam and prevents ink accumulation on the deposition nozzle walls.

- Aerodynamic focusing: sheath gas allows volume displacement to collimate the aerosol inside the deposition head. Aerodynamic focusing makes it possible to better collimate the aerosol gas. Therefore, the focusing offered by the sheath gas is coupled with the mechanical focusing of the nozzle (the nozzle diameter can vary from 100 to 400 µm).

- Impact: the aerosol jet hits the substrate, and it gets deposited following a pattern defined in a 2D environment software (e.g., KEWA software for Ceradrop AJ printers). Droplets with a size smaller than average will not impact the substrate; droplets sized larger than the critical dimension will impact the substrate but overspreading on the surface [252,269,272].

- Ink mass density, ρp (g·cm−3)

- Ink viscosity, η (cP)

- Ink surface tension, γs (N·m−1)

- Atomizer gas flow, FG (sccm)

- Carrier gas flow, FC (sccm)

- Sheath gas flow, FS (sccm)

- Ink temperature, T (K)

- Deposition nozzle diameter, D (µm)

- System geometry (e.g., diameter of the mist tube)

- Deposition velocity, v (mm⸱s−1)

- Gravitational sedimentation: it is generally associated with larger droplets. It consists in settling before deposition of larger droplets during transportation.

- Small dp (St < 1): low focusing, diffusion takes place.

- High dp (St > 1): over-focusing, gravitational sedimentation occurs.

- Optimal focusing: St ~ 1

- Wide ink viscosity (η) acceptability range (η can range from 1 to 1000 cP for AJ printer installed with pneumatic atomizers), permitting the utilization of different materials.

- High resolution printing (<5 µm × 5 µm) [274].

- The thickness range of a single pass layer is from 100 nm to 10 µm. The ink solid fraction is a crucial parameter for this dimension: higher nanoparticles concentration means higher thickness.

- Simple geometry control thanks to aerosol jet printing systems configuration and to aerodynamic focusing.

- In comparison to other AM technologies (e.g., inkjet printing), clogging is less likely to take place thanks to the sheath gas utilization.

- Due to the large number of parameters, defining optimal conditions is a hard and long process. This is also related to the difficult reproducibility of the process.

- Films often lack homogeneity and property uniformity, and high pore volume fraction (vol%) can be detrimental (in good proportions, porosity is favorable for thermal conductivity reduction, whereas in unfavorable proportions, it is detrimental for electrical conductivity enhancement). Optimal printing conditions can solve such issues.

- Overspray: the ink is deposited on unintended areas of the substrate, usually around the actual printed material. The problem can be reduced by matching the conditions of optimal focusing.

5. Conclusions

5.1. Printing of Bismuth Telluride-Based Thermoelectric (BT-TE) Materials through Aerosol Jet Printing (AJP)

- Platen temperature: 313 K

- Carrier gas flow: 35 sccm

- Nozzle diameter: 200 µm

- Stand-off: 3 mm

- Platen temperature: 348 K

- Carrier gas flow (N2): 470 sccm

- Nozzle diameter: 300 µm

- Stand-off: 3 mm

5.2. Final Remarks

- AJP process optimization: achieving process reproducibility would enable the definition of process windows depending on ink formulation.

- Utilization of BT-TE inks prepared from powder synthesized by high energy ball milling: this would couple innovation with future process scalability.

Funding

Conflicts of Interest

References

- Mamur, H.; Bhuiyan, M.R.A.; Korkmaz, F.; Nil, M. A Review on Bismuth Telluride (Bi2Te3) Nanostructure for Thermoelectric Applications. Renew. Sustain. Energy Rev. 2018, 82, 4159. [Google Scholar] [CrossRef]

- Sajid, M.; Hassan, I.; Rahman, A. An Overview of Cooling of Thermoelectric Devices. Renew. Sustain. Energy Rev. 2017, 78, 15. [Google Scholar] [CrossRef]

- Gupta, M. Review on Heat Recovery Unit with Thermoelectric Generators. Power 2014, 4, 2021. [Google Scholar]

- Narducci, M.; Castellero, D.; Fanciulli, A.; Puglia, C.; Gobbato, F.; Bennetti, P. Materiali Termoelettrici e Tecnologie per Il Recupero di Calore Disperso, in Materiali Termoelettrici e Tecnologie per Il Recupero di Calore Disperso-Associazione Italiana Metallurigia (AIM) (2021), p. 2021. Available online: https://www.aimnet.it/manifestazione.php?id=698&idc= (accessed on 13 June 2023).

- Polozine, A.; Sirotinskaya, S.; Schaeffer, L. History of Development of Thermoelectric Materials for Electric Power Generation and Criteria of Their Quality. Mater. Res. 2014, 17, 1260. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A Review of the State of the Science on Wearable Thermoelectric Power Generators (TEGs) and Their Existing Challenges. Renew. Sustain. Energy Rev. 2017, 73, 730. [Google Scholar] [CrossRef]

- Burmester, D.; Rayudu, R.; Seah, W.; Akinyele, D. A Review of Nanogrid Topologies and Technologies. Renew. Sustain. Energy Rev. 2017, 67, 760. [Google Scholar] [CrossRef]

- Schwall, M.; Balke, B. Phase separation as a key to a thermoelectric high efficiency. Phys. Chem. Chem. Phys. 2012, 15, 1868–1872. [Google Scholar] [CrossRef] [PubMed]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Dehkordi, A.M.; Zebarjadi, M.; He, J.; Tritt, T.M. Thermoelectric Power Factor: Enhancement Mechanisms and Strategies for Higher Performance Thermoelectric Materials. Mater. Sci. Eng. R Rep. 2015, 97, 1. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, Heating, Generating Power, and Recovering Waste Heat with Thermoelectric Systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef]

- Yan, X.; Liu, W.; Wang, H.; Chen, S.; Shiomi, J.; Esfarjani, K.; Wang, H.; Wang, D.; Chen, G.; Ren, Z. Stronger phonon scattering by larger differences in atomic mass and size in p-type half-Heuslers Hf1−xTixCoSb0.8Sn0.2. Energy Environ. Sci. 2012, 5, 7543–7548. [Google Scholar] [CrossRef]

- Kempf, N.; Zhang, Y. Design and Optimization of Automotive Thermoelectric Generators for Maximum Fuel Efficiency Improvement. Energy Convers. Manag. 2016, 121, 224. [Google Scholar] [CrossRef]

- Ahiska, R.; Mamur, H. Development and Application of a New Power Analysis System for Testing of Geothermal Thermoelectric Generators. Int. J. Green Energy 2016, 13, 672. [Google Scholar] [CrossRef]

- He, R.; Schierning, G.; Nielsch, K. Thermoelectric Devices: A Review of Devices, Architectures, and Contact Optimization. Adv. Mater. Technol. 2018, 3, 1700256. [Google Scholar] [CrossRef]

- Mamur, H.; Ahiska, R. Application of a DC-DC Boost Converter with Maximum Power Point Tracking for Low Power Thermoelectric Generators. Energy Convers. Manag. 2015, 97, 265. [Google Scholar] [CrossRef]

- Rausch, E.; Balke, B.; Deschauer, T.; Ouardi, S.; Felser, C. Charge Carrier Concentration Optimization of Thermoelectric P-Type Half-Heusler Compounds. APL Mater. 2015, 3, 041516. [Google Scholar] [CrossRef]

- Huen, P.; Daoud, W.A. Advances in Hybrid Solar Photovoltaic and Thermoelectric Generators. Renew. Sustain. Energy Rev. 2017, 72, 1295. [Google Scholar] [CrossRef]

- Hossain, S.; Li, T.; Yu, Y.; Yong, J.; Bahk, J.-H.; Skafidas, E. Recent advances in printable thermoelectric devices: Materials, printing techniques, and applications. RSC Adv. 2020, 10, 8421–8434. [Google Scholar] [CrossRef]

- Wei, J.; Yang, L.; Ma, Z.; Song, P.; Zhang, M.; Ma, J.; Yang, F.; Wang, X. Review of current high-ZT thermoelectric materials. J. Mater. Sci. 2020, 55, 12642–12704. [Google Scholar] [CrossRef]

- Jaziri, N.; Boughamoura, A.; Müller, J.; Mezghani, B.; Tounsi, F.; Ismail, M. A Comprehensive Review of Thermoelectric Generators: Technologies and Common Applications. Energy Rep. 2020, 6, 264. [Google Scholar] [CrossRef]

- Rowe, D. Thermoelectrics and Its Energy Harvesting; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Rowe, D.M. Thermoelectrics Handbook Macro to Nano; Rowe, D.M., Ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Shi, X.L.; Zou, J.; Chen, Z.G. Advanced Thermoelectric Design: From Materials and Structures to Devices. Chem. Rev. 2020, 120, 7399. [Google Scholar] [CrossRef] [PubMed]

- Thermoelectric Materials Market By Product Type, By Distribution Channel, By Application, Forecasts to 2027. Available online: https://www.emergenresearch.com/industry-report/thermoelectric-materials-market (accessed on 13 June 2023).

- Li, K.; Garrison, G.; Zhu, Y.; Horne, R.; Petty, S. Cost Estimation of Thermoelectric Generators, 46th Work. Geotherm. Reserv. Eng. 2021, 1, 3–5. [Google Scholar]

- Karthick, K.; Suresh, S.; Hussain, M.M.M.; Ali, H.M.; Kumar, C.S. Evaluation of solar thermal system configurations for thermoelectric generator applications: A critical review. Sol. Energy 2019, 188, 111–142. [Google Scholar] [CrossRef]

- Ahiska, R.; Dislitas, S.; Omer, G. A new method and computer-controlled system for measuring the time constant of real thermoelectric modules. Energy Convers. Manag. 2012, 53, 314–321. [Google Scholar] [CrossRef]

- Harman, T.C.; Taylor, P.J.; Walsh, M.P.; LaForge, B.E. Quantum Dot Superlattice Thermoelectric Materials and Devices. Science 2002, 297, 2229. [Google Scholar] [CrossRef]

- Joshi, G.; He, R.; Engber, M.; Samsonidze, G.; Pantha, T.; Dahal, E.; Dahal, K.; Yang, J.; Lan, Y.; Kozinsky, B.; et al. NbFeSb-Based p-Type Half-Heuslers for Power Generation Applications. Energy Environ. Sci. 2014, 7, 4070. [Google Scholar] [CrossRef]

- Siouane, S.; Jovanović, S.; Poure, P. Fully Electrical Modeling of Thermoelectric Generators with Contact Thermal Resistance Under Different Operating Conditions. J. Electron. Mater. 2017, 46, 40. [Google Scholar] [CrossRef]

- Shi, Y.; Sturm, C.; Kleinke, H. Chalcogenides as thermoelectric materials. J. Solid State Chem. 2019, 270, 273–279. [Google Scholar] [CrossRef]

- Hicks, L.D.; Dresselhaus, M.S. Effect of quantum-well structures on the thermoelectric figure of merit. Phys. Rev. B 1993, 47, 12727–12731. [Google Scholar] [CrossRef]

- Hicks, L.D.; Dresselhaus, M.S. Thermoelectric figure of merit of a one-dimensional conductor. Phys. Rev. B 1993, 47, 16631–16634. [Google Scholar] [CrossRef]

- Liu, W.; Ren, Z.; Chen, G. Nanostructured Thermoelectric Materials. Springer Ser. Mater. Sci. 2013, 182, 255. [Google Scholar]

- Chen, Z.-G.; Han, G.; Yang, L.; Cheng, L.; Zou, J. Nanostructured thermoelectric materials: Current research and future challenge. Prog. Nat. Sci. Mater. Int. 2012, 22, 535. [Google Scholar] [CrossRef]

- Liu, D.W.; Li, J.F.; Chen, C.; Zhang, B.P.; Li, L. Fabrication and Evaluation of Microscale Thermoelectric Modules of Bi2Te3-Based Alloys. J. Micromechanics Microengineering 2010, 20, 125031. [Google Scholar] [CrossRef]

- Ashalley, E.; Chen, H.; Tong, X.; Li, H.; Wang, Z.M. Bismuth telluride nanostructures: Preparation, thermoelectric properties and topological insulating effect. Front. Mater. Sci. 2015, 9, 103–125. [Google Scholar] [CrossRef]

- Goldsmid, H.J. Bismuth Telluride and Its Alloys as Materials for Thermoelectric Generation. Materials 2014, 7, 2577–2592. [Google Scholar] [CrossRef]

- Liu, S.; Hu, B.; Liu, D.; Li, F.; Li, J.-F.; Li, B.; Li, L.; Lin, Y.-H.; Nan, C.-W. Micro-thermoelectric generators based on through glass pillars with high output voltage enabled by large temperature difference. Appl. Energy 2018, 225, 600–610. [Google Scholar] [CrossRef]

- Li, J.-F.; Tanaka, S.; Umeki, T.; Sugimoto, S.; Esashi, M.; Watanabe, R. Microfabrication of thermoelectric materials by silicon molding process. Sens. Actuators A Phys. 2003, 108, 97–102. [Google Scholar] [CrossRef]

- Kao, P.-H.; Shih, P.-J.; Dai, C.-L.; Liu, M.-C. Fabrication and Characterization of CMOS-MEMS Thermoelectric Micro Generators. Sensors 2010, 10, 1315. [Google Scholar] [CrossRef]

- Dhawan, R.; Madusanka, P.; Hu, G.; Debord, J.; Tran, T.; Maggio, K.; Edwards, H.; Lee, M. Si0.97Ge0.03 Microelectronic Thermoelectric Generators with High Power and Voltage Densities. Nat. Commun. 2020, 11, 4362. [Google Scholar] [CrossRef]

- Hu, G.; Edwards, H.; Lee, M. Silicon integrated circuit thermoelectric generators with a high specific power generation capacity. Nat. Electron. 2019, 2, 300–306. [Google Scholar] [CrossRef]

- Thelemann, T.; Thust, H.; Hintz, M. Using LTCC for microsystems. Microelectron. Int. 2002, 19, 19–23. [Google Scholar] [CrossRef]

- Markowski, P.M. Multilayer thick-film thermoelectric microgenerator based on LTCC technology. Microelectron. Int. 2016, 33, 155–161. [Google Scholar] [CrossRef]

- Park, T.; Lim, H.; Hwang, J.U.; Na, J.; Lee, H.; Kim, E. Roll Type Conducting Polymer Legs for Rigid-Flexible Thermoelectric Generator. APL Mater. 2017, 5, 074106. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, Z.; Jia, L. Design and Fabrication of 3D Flexible Thermoelectric Energy Generator Using Chemical Vapor Deposition Method Based on Paper Substrate. In Proceedings of the 2018 International Symposium in Sensing and Instrumentation in IoT Era (ISSI), Shanghai, China, 5–6 September 2018; pp. 1–4. [Google Scholar]

- Grishin, V.I. Method for Manufacturing Semiconductive Branches for a Thermoelectric Module, and Thermoelectric Module. US Patent 20170012195, 24 February 2014. [Google Scholar]

- Crane, D.T.; Lagrandeur, J.W. Progress Report on BSST-Led US Department of Energy Automotive Waste Heat Recovery Program. J. Electron. Mater. 2010, 39, 2142. [Google Scholar] [CrossRef]

- Orr, B.; Akbarzadeh, A.; Lappas, P. An exhaust heat recovery system utilising thermoelectric generators and heat pipes. Appl. Therm. Eng. 2017, 126, 1185–1190. [Google Scholar] [CrossRef]

- Nozariasbmarz, A.; Kishore, R.A.; Poudel, B.; Saparamadu, U.; Li, W.; Cruz, R.; Priya, S. High Power Density Body Heat Energy Harvesting. ACS Appl. Mater. Interfaces 2019, 11, 40107. [Google Scholar] [CrossRef]

- Torfs, T.; Leonov, V.; Vullers, R.J.M. Pulse Oximeter Fully Powered by Human Body Heat. Senosors Transducers J. 2007, 80, 1230. [Google Scholar]

- Torfs, T.; Leonov, V.; Yazicioglu, R.F.; Merken, P.; Van Hoof, C.; Vullers, R.J.M.; Gyselinckx, B. Wearable Autonomous Wireless Electro-Encephalography System Fully Powered by Human Body Heat. Proc. IEEE Sens. 2008, 2008, 1269. [Google Scholar]

- Patidar, S. Applications of Thermoelectric Energy: A Review. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 1992–1996. [Google Scholar] [CrossRef]

- Merriam-Webster, Oximeter Definition & Meaning—Merriam-Webster. Available online: https://www.merriam-webster.com/dictionary/oximeter (accessed on 13 June 2023).

- Leonov, V.; van Andel, Y.; Wang, Z.; Vullers, R.J.M.; van Hoof, C. Micromachined Polycrystalline Si Thermopiles in a T-Shirt. Sens. Transducers 2011, 127, 15. [Google Scholar]

- Liu, Y.; Yin, L.; Zhang, W.; Wang, J.; Hou, S.; Wu, Z.; Zhang, Z.; Chen, C.; Li, X.; Ji, H.; et al. A Wearable Real-Time Power Supply with a Mg3Bi2-Based Thermoelectric Module. Cell Reports Phys. Sci. 2021, 2, 100412. [Google Scholar] [CrossRef]

- Dilhac, J.-M.; Monthéard, R.; Bafleur, M.; Boitier, V.; Durand-Estèbe, P.; Tounsi, P. Implementation of Thermoelectric Generators in Airlinersfor Powering Battery-Free Wireless Sensor Networks. J. Electron. Mater. 2014, 43, 2444. [Google Scholar] [CrossRef]

- Iezzi, B.; Ankireddy, K.; Twiddy, J.; Losego, M.D.; Jur, J.S. Printed, Metallic Thermoelectric Generators Integrated with Pipe Insulation for Powering Wireless Sensors. Appl. Energy 2017, 208, 758. [Google Scholar] [CrossRef]

- Lin, Q.; Chen, Y.C.; Chen, F.; DeGanyar, T.; Yin, H. Design and Experiments of a Thermoelectric-Powered Wireless Sensor Network Platform for Smart Building Envelope. Appl. Energy 2022, 305, 117791. [Google Scholar] [CrossRef]

- Wang, W.; Cionca, V.; Wang, N.; Hayes, M.; O′Flynn, B.; O′Mathuna, C. Thermoelectric Energy Harvesting for Building Energy Management Wireless Sensor Networks. Int. J. Distrib. Sens. Netw. 2013, 2013, 9. [Google Scholar] [CrossRef]

- Lineykin, S.; Sitbon, M.; Kuperman, A. Design and optimization of low-temperature gradient thermoelectric harvester for wireless sensor network node on water pipelines. Appl. Energy 2021, 283, 116240. [Google Scholar] [CrossRef]

- Shen, Z.-G.; Tian, L.-L.; Liu, X. Automotive exhaust thermoelectric generators: Current status, challenges and future prospects. Energy Convers. Manag. 2019, 195, 1138–1173. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, S.; Liu, Z.; Mu, E.; Hu, Z. Thermoelectric converter: Strategies from materials to device application. Nano Energy 2021, 91, 106692. [Google Scholar] [CrossRef]

- Temizer, I.; Ílkılıç, C. The performance and analysis of the thermoelectric generator system used in diesel engines. Renew. Sustain. Energy Rev. 2016, 63, 141–151. [Google Scholar] [CrossRef]

- Yu, C.; Chau, K. Thermoelectric automotive waste heat energy recovery using maximum power point tracking. Energy Convers. Manag. 2009, 50, 1506–1512. [Google Scholar] [CrossRef]

- LaGrandeur, J. Automotive Waste Heat Conversion to Electric Power Using Skutterudites, TAGS, PbTe and Bi2Te3 Discussion Outline Discussion Outline Background Program Information and System Architecture System Modeling (Bumper to Bumper Vehicle Model Inclusive of Ther, 1 (2006). Available online: https://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2010/solid-state_energy_conv/ace051_lagrandeur_2010_o.pdf (accessed on 13 June 2023).

- Fernández-Yáñez, P.; Armas, O.; Kiwan, R.; Stefanopoulou, A.G.; Boehman, A.L. A Thermoelectric Generator in Exhaust Systems of Spark-Ignition and Compression-Ignition Engines. A Comparison with an Electric Turbo-Generator. Appl. Energy 2018, 229, 80. [Google Scholar] [CrossRef]

- Furlong, R.R.; Wahlquist, E.J.U.S. Space Missions Using Radioisotope Power Systems. Nucl. News 1999, 42, 26–35. [Google Scholar]

- Streb, A.J. Radioisotope Power Systems for Manned Space Stations Presented as Preprint 64-711 at the AIAA Third Biennial Aerospace Power Systems Conference, Philadelphia, PA, 1–4 September 1964; Academic Press Inc.: Cambridge, MA, USA, 1966; Volume 16. [Google Scholar]

- Pourkiaei, S.M.; Ahmadi, M.H.; Sadeghzadeh, M.; Moosavi, S.; Pourfayaz, F.; Chen, L.; Yazdi, M.A.P.; Kumar, R. Thermoelectric Cooler and Thermoelectric Generator Devices: A Review of Present and Potential Applications, Modeling and Materials. Energy 2019, 186, 115849. [Google Scholar] [CrossRef]

- Wang, X.; Liang, R.; Fisher, P.; Chan, W.; Xu, J. Critical Design Features of Thermal-Based Radioisotope Generators: A Review of the Power Solution for Polar Regions and Space. Renew. Sustain. Energy Rev. 2020, 119, 109572. [Google Scholar] [CrossRef]

- Hammel, T.E.; Bennett, R.; Otting, W.; Fanale, S. Multi-Mission Radioisotope Thermoelectric Generator (MMRTG) and Performance Prediction Model. In Proceedings of the 7th International Energy Conversion Engineering Conference, Denver, Colorado, 2–5 August 2009. [Google Scholar]

- Bennett, G.L.; Whitmore, C.W.; Amos, W.R. On the Development of the Power Sources for the Ulysses and Galileo Missions; European Space Agency: Paris, France, 1989. [Google Scholar]

- O’Brien, R.C.; Ambrosi, R.M.; Bannister, N.P.; Howe, S.D.; Atkinson, H.V. Safe Radioisotope Thermoelectric Generators and Heat Sources for Space Applications. J. Nucl. Mater. 2008, 377, 506. [Google Scholar] [CrossRef]

- Holgate, T.C.; Bennett, R.; Hammel, T.; Caillat, T.; Keyser, S.; Sievers, B. Increasing the Efficiency of the Multi-Mission Radioisotope Thermoelectric Generator. J. Electron. Mater. 2015, 44, 1814. [Google Scholar] [CrossRef]

- Zhou, Y.; Paul, S.; Bhunia, S. Harvesting Wasted Heat in a Microprocessor Using Thermoelectric Generators: Modeling, Analysis and Measurement. In Proceedings of the 2008 Design, Automation and Test in Europe, Munich, Germany, 10–14 March 2008. [Google Scholar]

- Wang, H.C.; Jewell-Larsen, N.E.; Mamishev, A.V. Thermal Management of Microelectronics with Electrostatic Fluid Accelerators. Appl. Therm. Eng. 2013, 51, 190. [Google Scholar] [CrossRef]

- Solbrekken, G.L.; Yazawa, K.; Bar-Cohen, A. Thermal Management of Portable Electronic Equipment Using Thermoelectric Energy Conversion. Thermomechanical Phenom. Electron. Syst. Proc. Intersoc. Conf. 2004, 1, 276. [Google Scholar]

- Huang, I.Y.; Lin, J.C.; She, K.D.; Li, M.C.; Chen, J.H.; Kuo, J.S. Development of Low-Cost Micro-Thermoelectric Coolers Utilizing MEMS Technology. Sensors Actuators A Phys. 2008, 148, 176. [Google Scholar] [CrossRef]

- Chen, Y.-W.; Wu, C.-C.; Hsu, C.-C.; Dai, C.-L. Fabrication and Testing of Thermoelectric CMOS-MEMS Microgenerators with CNCs Film. Appl. Sci. 2018, 8, 1047. [Google Scholar] [CrossRef]

- Kuang, N.; Zuo, Z.; Wang, W.; Liu, R.; Zhao, Z. Optimized thermoelectric properties and geometry parameters of annular thin-film thermoelectric generators using n-type Bi2Te2.7Se0.3 and p-type Bi0.5Sb1.5Te3 thin films for energy harvesting. Sens. Actuators A Phys. 2021, 332, 113030. [Google Scholar] [CrossRef]

- Kobayashi, A.; Konagaya, R.; Tanaka, S.; Takashiri, M. Optimized structure of tubular thermoelectric generators using n-type Bi2Te3 and p-type Sb2Te3 thin films on flexible substrate for energy harvesting. Sens. Actuators A Phys. 2020, 313, 112199. [Google Scholar] [CrossRef]

- Jeong, S.H.; Cruz, F.J.; Chen, S.; Gravier, L.; Liu, J.; Wu, Z.; Hjort, K.; Zhang, S.; Zhang, Z. Stretchable Thermoelectric Generators Metallized with Liquid Alloy. ACS Appl. Mater. Interfaces 2017, 9, 15791–15797. [Google Scholar] [CrossRef]

- Nie, G.; Suzuki, S.; Tomida, T.; Sumiyoshi, A.; Ochi, T.; Mukaiyama, K.; Kikuchi, M.; Guo, J.Q.; Yamamoto, A.; Obara, H. Performance of Skutterudite-Based Modules. J. Electron. Mater. 2017, 46, 2640. [Google Scholar] [CrossRef]

- Nam, W.H.; Cho, J.Y. A Brief Review of CoSb3-Based Thermoelectric Materials and Modules for Mid-Temperature Power Generation. Ceramist 2021, 24, 213. [Google Scholar] [CrossRef]

- Chen, L.; Zeng, X.; Tritt, T.M.; Poon, S.J. Half-Heusler Alloys for Efficient Thermoelectric Power Conversion. J. Electron. Mater. 2016, 45, 5554. [Google Scholar] [CrossRef]

- Dolyniuk, J.-A.; Owens-Baird, B.; Wang, J.; Zaikina, J.V.; Kovnir, K. Clathrate thermoelectrics. Mater. Sci. Eng. R Rep. 2016, 108, 1–46. [Google Scholar] [CrossRef]

- Christensen, M.; Johnsen, S.; Iversen, B.B. Thermoelectric clathrates of type I. Dalton Trans. 2009, 39, 978–992. [Google Scholar] [CrossRef]

- Zheng, L.; Li, W.; Sun, C.; Shi, X.; Zhang, X.; Pei, Y. Ternary thermoelectric AB2C2 Zintls. J. Alloys Compd. 2019, 821, 153497. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Wang, C.; Zhou, B.; Zheng, L.; Gao, B.; Chen, Y.; Pei, Y. Orbital Alignment for High Performance Thermoelectric YbCd2Sb2 Alloys. Chem. Mater. 2018, 30, 5339. [Google Scholar] [CrossRef]

- Kumar, S.R.S.; Cha, D.; Alshareef, H.N. Lattice dynamics and substrate-dependent transport properties of (In, Yb)-doped CoSb3 skutterudite thin films. J. Appl. Phys. 2011, 110, 083710. [Google Scholar] [CrossRef]

- Basu, R.; Singh, A. High temperature Si–Ge alloy towards thermoelectric applications: A comprehensive review. Mater. Today Phys. 2021, 21, 100468. [Google Scholar] [CrossRef]

- Xie, K.; Gupta, M.C. High-Temperature Thermoelectric Energy Conversion Devices Using Si-Ge Thick Films Prepared by Laser Sintering of Nano/Micro Particles. IEEE Trans. Electron Devices 2020, 67, 2113–2119. [Google Scholar] [CrossRef]

- Toshima, N.; Ichikawa, S. Conducting Polymers and Their Hybrids as Organic Thermoelectric Materials. J. Electron. Mater. 2014, 44, 384–390. [Google Scholar] [CrossRef]

- Toshima, N. Recent progress of organic and hybrid thermoelectric materials. Synth. Met. 2017, 225, 3–21. [Google Scholar] [CrossRef]

- Furdyna, J.K.; Dong, S.N.; Lee, S.; Liu, X.; Dobrowolska, M. The Ubiquitous Nature of Chalcogenides in Science and Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Rogl, G.; Rogl, P. Skutterudites, a most promising group of thermoelectric materials. Curr. Opin. Green Sustain. Chem. 2017, 4, 50–57. [Google Scholar] [CrossRef]

- Izumi, K.M.F. VESTA 3 for Three-Dimensional Visualization of Crystal, Volumetric and Morphology Data. J. Appl. Cryst. 2011, 44, 1272–1276. [Google Scholar]

- Holgate, T.C.; Song, Y.; Bennett, R.; Keyser, S.; Hammel, T.; Siever, R.; Caillat, T.; Fleurial, J.P. Enhancement of the Multi-Mission Radioisotope Thermoelectric Generator with Efficient Skutterudite Thermoelectric Couples: Current Status of the Skutterudite Technology Maturation Program. In Proceedings of the 14th International Energy Conversion Engineering Conference, Salt Lake City, UT, USA, 25–27 July 2016; p. 1. [Google Scholar]

- Salvador, J.R.; Waldo, R.A.; Wong, C.A.; Tessema, M.; Brown, D.N.; Miller, D.J.; Wang, H.; Wereszczak, A.A.; Cai, W. Thermoelectric and mechanical properties of melt spun and spark plasma sintered n-type Yb- and Ba-filled skutterudites. Mater. Sci. Eng. B 2013, 178, 1087–1096. [Google Scholar] [CrossRef]

- Tomida, T.; Sumiyoshi, A.; Nie, G.; Ochi, T.; Suzuki, S.; Kikuchi, M.; Mukaiyama, K.; Guo, J.Q. Fabrication of 200 mm Diameter Sintering Body of Skutterudite Thermoelectric Material by Spark Plasma Sintering. J. Electron. Mater. 2016, 46, 2944–2949. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Rogl, P.; Peranio, N.; Bauer, E.; Zehetbauer, M.; Eibl, O. N-Type Skutterudites (R,Ba,Yb)YCo4Sb12 (R = Sr, La, Mm, DD, SrMm, SrDD) Approaching ZT ≈ 2.0. Acta Mater. 2014, 63, 30. [Google Scholar] [CrossRef]

- Liang, G.; Zheng, Z.; Li, F.; Luo, J.; Jin, H.; Zhang, X.; Fan, P. Nano Structure Ti-Doped Skutterudite CoSb3 Thin Films through Layer Inter-Diffusion for Enhanced Thermoelectric Properties. J. Eur. Ceram. Soc. 2019, 39, 4842. [Google Scholar] [CrossRef]

- Nolas, G.S.; Kaeser, M.; IV, R.T.L.; Tritt, T.M. High Figure of Merit in Partially Filled Ytterbium Skutterudite Materials. Appl. Phys. Lett. 2000, 77, 1855. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Falmbigl, M.; Bauer, E.; Rogl, P.; Zehetbauer, M.; Gelbstein, Y. Thermoelectric Properties of P-Type Didymium (DD) Based Skutterudites DDy(Fe1−xNix)4Sb12 (0.13⩽x⩽0.25, 0.46⩽y⩽0.68). J. Alloys Compd. 2012, 537, 242. [Google Scholar] [CrossRef]

- Mei, Z.G.; Yang, J.; Pei, Y.Z.; Zhang, W.; Chen, L.D.; Yang, J. Alkali-Metal-Filled CoSb3 Skutterudites as Thermoelectric Materials: Theoretical Study. Phys. Rev. B Condens. Matter Mater. Phys. 2008, 77, 1. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Rogl, P.; Bauer, E.; Zehetbauer, M.J. Enhanced Thermoelectric Figure of Merit in P-Type DDy(Fe1−XCox)4Sb12. Solid State Phenom. 2011, 170, 240. [Google Scholar] [CrossRef]

- Casper, F.; Graf, T.; Chadov, S.; Balke, B.; Felser, C. Half-Heusler Compounds: Novel Materials for Energy and Spintronic Applications. Semicond. Sci. Technol. 2012, 27, 063001. [Google Scholar] [CrossRef]

- Quinn, R.J.; Bos, J.-W.G. Advances in half-Heusler alloys for thermoelectric power generation. Mater. Adv. 2021, 2, 6246–6266. [Google Scholar] [CrossRef]

- Kittel, C.; McEuen, P. Introduction to Solid State Physics, 8th ed.; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Zhu, H.; He, R.; Mao, J.; Zhu, Q.; Li, C.; Sun, J.; Ren, W.; Wang, Y.; Liu, Z.; Tang, Z.; et al. Discovery of ZrCoBi based half Heuslers with high thermoelectric conversion efficiency. Nat. Commun. 2018, 9, 2497. [Google Scholar] [CrossRef] [PubMed]

- Nozariasbmarz, A.; Saparamadu, U.; Li, W.; Kang, H.B.; Dettor, C.; Zhu, H.; Poudel, B.; Priya, S. High-performance half-Heusler thermoelectric devices through direct bonding technique. J. Power Sources 2021, 493, 229695. [Google Scholar] [CrossRef]

- Fu, C.; Bai, S.; Liu, Y.; Tang, Y.; Chen, L.; Zhao, X.; Zhu, T. Realizing high figure of merit in heavy-band p-type half-Heusler thermoelectric materials. Nat. Commun. 2015, 6, 8144. [Google Scholar] [CrossRef]

- Kang, H.B.; Poudel, B.; Li, W.; Lee, H.; Saparamadu, U.; Nozariasbmarz, A.; Kang, M.G.; Gupta, A.; Heremans, J.J.; Priya, S. Decoupled phononic-electronic transport in multi-phase n-type half-Heusler nanocomposites enabling efficient high temperature power generation. Mater. Today 2020, 36, 63–72. [Google Scholar] [CrossRef]

- Nolas, G.S.; Slack, G.A.; Schujman, S.B. Chapter 6 Semiconductor clathrates: A phonon glass electron crystal material with potential for thermoelectric applications. Semiconductors and Semimetals 2001, 69, 255–300. [Google Scholar]

- Sales, B.C.; Mandrus, D.G.; Chakoumakos, B.C. Chapter 1 Use of Atomic Displacement Parameters in Thermoelectric Materials Research. In Semiconductors and Semimetals; Elsevier: Amsterdam, The Netherlands, 2001; Volume 70. [Google Scholar]

- Toberer, E.S.; Christensen, M.; Iversen, B.B.; Snyder, G.J. High Temperature Thermoelectric Efficiency in Ba8Ga16Ge30. Phys. Rev. B Condens. Matter Mater. Phys. 2008, 77, 1. [Google Scholar] [CrossRef]

- Cederkrantz, D.; Saramat, A.; Snyder, G.J.; Palmqvist, A.E.C. Thermal Stability and Thermoelectric Properties of p-Type Ba8Ga16Ge30 Clathrates. J. Appl. Phys. 2009, 106, 074509. [Google Scholar] [CrossRef]

- Chakoumakos, B.C.; Sales, B.C.; Mandrus, D.G.; Nolas, G.S. Structural Disorder and Thermal Conductivity of the Semiconducting Clathrate Sr8Ga16Ge30. J. Alloys Compd. 2000, 296, 80. [Google Scholar] [CrossRef]

- Sarukura, N.; Nawata, T.; Ishibashi, H.; Ishii, M.; Fukuda, T. 4—Czochralski Growth of Oxides and Fluorides. In Handbook of Crystal Growth, 2nd, ed.; Elsevier: Boston, MA, USA, 2015; pp. 131–168. [Google Scholar]

- Duffar, T.; Sylla, L. Vertical Bridgman Technique and Dewetting. In Crystal Growth Processes Based on Capillarity: Czochralski, Floating Zone, Shaping and Crucible Techniques; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Saramat, A.; Svensson, G.; Palmqvist, A.E.C.; Stiewe, C.; Mueller, E.; Platzek, D.; Williams, S.G.K.; Rowe, D.M.; Bryan, J.D.; Stucky, G.D. Large Thermoelectric Figure of Merit at High Temperature in Czochralski-Grown Clathrate Ba8Ga16Ge30. J. Appl. Phys. 2006, 99, 023708. [Google Scholar] [CrossRef]

- Bux, S.K.; Zevalkink, A.; Janka, O.; Uhl, D.; Kauzlarich, S.; Snyder, J.G.; Fleurial, J.P. Glass-like Lattice Thermal Conductivity and High Thermoelectric Efficiency in Yb9Mn4.2Sb9. J. Mater. Chem. A 2014, 2, 215. [Google Scholar] [CrossRef]

- Brown, S.R.; Kauzlarich, S.M.; Gascoin, F.; Snyder, G.J. Yb14MnSb11: New High Efficiency Thermoelectric Material for Power Generation. Chem. Mater. 2006, 18, 1873. [Google Scholar] [CrossRef]

- Shuai, J.; Mao, J.; Song, S.; Zhang, Q.; Chen, G.; Ren, Z. Recent progress and future challenges on thermoelectric Zintl materials. Mater. Today Phys. 2017, 1, 74–95. [Google Scholar] [CrossRef]

- Guo, K.; Cao, Q.; Zhao, J. Zintl phase compounds AM2Sb2 (A=Ca, Sr, Ba, Eu, Yb; M=Zn, Cd) and their substitution variants: A class of potential thermoelectric materials. J. Rare Earths 2013, 31, 1029–1038. [Google Scholar] [CrossRef]

- Fang, S.; Li, J.; Zou, K.; Shuai, H.; Xu, L.; Deng, W.; Zou, G.; Hou, H.; Ji, X. Zintl Chemistry: Current Status and Future Perspectives. Chem. Eng. J. 2021, 433, 133841. [Google Scholar] [CrossRef]

- Toberer, E.S.; Zevalkink, A.; Crisosto, N.; Snyder, G.J. The Zintl Compound Ca5Al2Sb6 for Low-Cost Thermoelectric Power Generation. Adv. Funct. Mater. 2010, 20, 4375. [Google Scholar] [CrossRef]

- Zheng, L.; Li, W.; Wang, X.; Pei, Y. Alloying for Orbital Alignment Enables Thermoelectric Enhancement of EuCd2Sb2. J. Mater. Chem. A 2019, 7, 12773. [Google Scholar] [CrossRef]

- Pei, Y.L.; He, J.; Li, J.F.; Fuli; Liu, Q.; Pan, W.; Barreteau, C.; Berardan, D.; Dragoe, N.; Zhao, L.D.. High Thermoelectric Performance of Oxyselenides: Intrinsically Low Thermal Conductivity of Ca-Doped BiCuSeO. NPG Asia Mater. 2013, 5, e47. [Google Scholar] [CrossRef]

- Zhao, L.D.; He, J.; Berardan, D.; Lin, Y.; Li, J.F.; Nan, C.W.; Dragoe, N. BiCuSeO Oxyselenides: New Promising Thermoelectric Materials. Energy Environ. Sci. 2014, 7, 2900. [Google Scholar] [CrossRef]

- Li, J.; Sui, J.; Pei, Y.; Meng, X.; Berardan, D.; Dragoe, N.; Cai, W.; Zhao, L.D. The Roles of Na Doping in BiCuSeO Oxyselenides as a Thermoelectric Material. J. Mater. Chem. A 2014, 2, 4903. [Google Scholar] [CrossRef]

- Singh, R. 12—Advances in the Applications of Thermoelectric Materials, in Woodhead Publishing Series in Electronic and Optical Materials; Kumar, R., Singh, A.T.M., Eds.; Woodhead Publishing: Sawston, UK, 2021; pp. 313–337. [Google Scholar]

- Li, J.; Sui, J.; Pei, Y.; Barreteau, C.; Berardan, D.; Dragoe, N.; Cai, W.; He, J.; Zhao, L.D. A High Thermoelectric Figure of Merit ZT > 1 in Ba Heavily Doped BiCuSeO Oxyselenides. Energy Environ. Sci. 2012, 5, 8543. [Google Scholar] [CrossRef]

- Farooq, M.U.; Butt, S.; Gao, K.; Zhu, Y.; Sun, X.; Pang, X.; Khan, S.U.; Mohmed, F.; Mahmood, A.; Mahmood, N.; et al. Cd-doping a facile approach for better thermoelectric transport properties of BiCuSeO oxyselenides. RSC Adv. 2016, 6, 33789–33797. [Google Scholar] [CrossRef]

- National Aeronautics and Space Administration, Multi-Mission Radioisotope Thermoelectric Generator (MMRTG). Natl. Aeronaut. Sp. Adm. 2013, 2950.

- Basu, R.; Bhattacharya, S.; Bhatt, R.; Roy, M.; Ahmad, S.; Singh, A.; Navaneethan, M.; Hayakawa, Y.; Aswal, D.K.; Gupta, S.K. Improved thermoelectric performance of hot pressed nanostructured n-type SiGe bulk alloys. J. Mater. Chem. A 2014, 2, 6922–6930. [Google Scholar] [CrossRef]

- Wang, X.W.; Lee, H.; Lan, Y.C.; Zhu, G.H.; Joshi, G.; Wang, D.Z.; Yang, J.; Muto, A.J.; Tang, M.Y.; Klatsky, J.; et al. Enhanced thermoelectric figure of merit in nanostructured n-type silicon germanium bulk alloy. Appl. Phys. Lett. 2008, 93, 193121. [Google Scholar] [CrossRef]

- Mackey, J.; Dynys, F.; Sehirlioglu, A. Si/Ge–WSi 2 composites: Processing and thermoelectric properties. Acta Mater. 2015, 98, 263–274. [Google Scholar] [CrossRef]

- Bathula, S.; Jayasimhadri, M.; Gahtori, B.; Singh, N.K.; Tyagi, K.; Srivastava, A.K.; Dhar, A. The Role of Nanoscale Defect Features in Enhancing the Thermoelectric Performance of P-Type Nanostructured SiGe Alloys. Nanoscale 2015, 7, 12474. [Google Scholar] [CrossRef] [PubMed]

- Masoumi, S.; O’Shaughnessy, S.; Pakdel, A. Organic-Based Flexible Thermoelectric Generators: From Materials to Devices. Nano Energy 2022, 92, 106774. [Google Scholar] [CrossRef]

- Fan, Z.; Du, D.; Guan, X.; Ouyang, J. Polymer Films with Ultrahigh Thermoelectric Properties Arising from Significant Seebeck Coefficient Enhancement by Ion Accumulation on Surface. Nano Energy 2018, 51, 481. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Zhang, X.; Wu, H.; Shen, J.; Chen, R.; Xiong, Y.; Li, J.; Guo, S. Progress on the Layer-by-Layer Assembly of Multilayered Polymer Composites: Strategy, Structural Control and Applications. Prog. Polym. Sci. 2019, 89, 76. [Google Scholar] [CrossRef]

- Bai, B.; Leng, J.; Wei, M. A Comprehensive Review of In-Situ Polymer Gel Simulation for Conformance Control. Pet. Sci. 2021, 19, 189–202. [Google Scholar] [CrossRef]

- Phan, D.-N.; Khan, M.Q.; Nguyen, N.-T.; Phan, T.-T.; Ullah, A.; Khatri, M.; Kien, N.N.; Kim, I.-S. A review on the fabrication of several carbohydrate polymers into nanofibrous structures using electrospinning for removal of metal ions and dyes. Carbohydr. Polym. 2020, 252, 117175. [Google Scholar] [CrossRef]

- Nguyen, N.-T. Fabrication Technologies; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Mengistie, D.A.; Chen, C.H.; Boopathi, K.M.; Pranoto, F.W.; Li, L.J.; Chu, C.W. Enhanced Thermoelectric Performance of PEDOT:PSS Flexible Bulky Papers by Treatment with Secondary Dopants. ACS Appl. Mater. Interfaces 2015, 7, 94. [Google Scholar] [CrossRef]

- Bubnova, O.; Khan, Z.U.; Malti, A.; Braun, S.; Fahlman, M.; Berggren, M.; Crispin, X. Optimization of the Thermoelectric Figure of Merit in the Conducting Polymer Poly(3,4-Ethylenedioxythiophene). Nat. Mater. 2011, 10, 429. [Google Scholar] [CrossRef]

- Baalousha, M.; How, W.; Valsami-Jones, E.; Lead, J. Rerview of Environmental Nanoscience, in Nanoscience and the Environment; Lead, J.R., Valsami-Jones, E.B., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 7, pp. 1–54. [Google Scholar]

- dos Santos, M.C.; Maynart, M.C.; Aveiro, L.R.; da Paz, E.C.; Pinheiro, V.D.S. Carbon-Based Materials: Recent Advances, Challenges, and Perspectives; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Paul, R. Chapter 18—Prospects of Carbon Nanomaterials for Energy Storage and Conversion, in Micro and Nano Technologies; Paul, R., Etacheri, V., Wang, Y., Lin, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 423–430. [Google Scholar]

- Nonoguchi, Y.; Ohashi, K.; Kanazawa, R.; Ashiba, K.; Hata, K.; Nakagawa, T.; Adachi, C.; Tanase, T.; Kawai, T. Systematic Conversion of Single Walled Carbon Nanotubes into N-Type Thermoelectric Materials by Molecular Dopants. Sci. Rep. 2013, 3, 1. [Google Scholar] [CrossRef]

- Zhou, W.; Fan, Q.; Zhang, Q.; Cai, L.; Li, K.; Gu, X.; Yang, F.; Zhang, N. High-Performance and Compact-Designed Flexible Thermoelectric Modules Enabled by a Reticulate Carbon Nanotube Architecture. Nat. Commun. 2017, 8, 14886. [Google Scholar] [CrossRef]

- Fukumaru, T.; Fujigaya, T.; Nakashima, N. Development of N-Type Cobaltocene-Encapsulated Carbon Nanotubes with Remarkable Thermoelectric Property. Sci. Rep. 2015, 5, 1. [Google Scholar] [CrossRef] [PubMed]

- Li, L.-J.; Khlobystov, A.N.; Wiltshire, J.G.; Briggs, G.A.D.; Nicholas, R.J. Diameter-Selective Encapsulation of Metallocenes in Single-Walled Carbon Nanotubes. Nat. Mater. 2005, 4, 481. [Google Scholar] [CrossRef] [PubMed]

- Ou, C.; Zhang, L.; Jing, Q.; Narayan, V.; Kar-Narayan, S. Compositionally Graded Organic–Inorganic Nanocomposites for Enhanced Thermoelectric Performance. Adv. Electron. Mater. 2020, 6, 1900720. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Liu, Y.; Wang, B.; Fang, L.; Qiu, J.; Zhang, K.; Wang, S. Exceptional Thermoelectric Properties of Flexible Organic−inorganic Hybrids with Monodispersed and Periodic Nanophase. Nat. Commun. 2018, 9, 3817. [Google Scholar] [CrossRef]

- Li, C.; Qin, X.; Li, Y.; Li, D.; Zhang, J.; Guo, H.; Xin, H.; Song, C. Simultaneous Increase in Conductivity and Phonon Scattering in a Graphene Nanosheets/(Bi2Te3)0.2(Sb2Te3)0.8 Thermoelectric Nanocomposite. J. Alloys Compd. 2016, 661, 389. [Google Scholar] [CrossRef]

- Wölfing, B.; Kloc, C.; Teubner, J.; Bucher, E. High Performance Thermoelectric Tl9BiTe6 with an Extremely Low Thermal Conductivity. Phys. Rev. Lett. 2001, 86, 4350. [Google Scholar] [CrossRef]

- Duong, A.T.; Nguyen, V.Q.; Duvjir, G.; Duong, V.T.; Kwon, S.; Song, J.Y.; Lee, J.K.; Lee, J.E.; Park, S.; Min, T.; et al. Achieving ZT=2.2 with Bi-doped n-type SnSe single crystals. Nat. Commun. 2016, 7, 13713. [Google Scholar] [CrossRef]

- Sharma, P.K.; Senguttuvan, T.D.; Sharma, V.K.; Chaudhary, S. Revisiting the Thermoelectric Properties of Lead Telluride. Mater. Today Energy 2021, 21, 100713. [Google Scholar] [CrossRef]

- Su, C.H. Design, Growth and Characterization of PbTe-Based Thermoelectric Materials. Prog. Cryst. Growth Charact. Mater. 2019, 65, 47. [Google Scholar] [CrossRef]

- Girard, S.N.; He, J.; Zhou, X.; Shoemaker, D.; Jaworski, C.M.; Uher, C.; Dravid, V.P.; Heremans, J.P.; Kanatzidis, M.G. High Performance Na-Doped PbTe-PbS Thermoelectric Materials: Electronic Density of States Modification and Shape-Controlled Nanostructures. J. Am. Chem. Soc. 2011, 133, 16588. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Chen, Z.; Nan, P.; Xiong, F.; Lin, S.; Zhang, X.; Chen, Y.; Chen, L.; Ge, B.; Pei, Y. Lattice Strain Advances Thermoelectrics. Joule 2019, 3, 1276. [Google Scholar] [CrossRef]

- Basic Information about Lead Air Pollution. Available online: https://www.epa.gov/lead-air-pollution/basic-information-about-lead-air-pollution (accessed on 13 June 2023).

- Alushllari, M. Negative Effects of Lead in Environment Ecosystems and Human Health. J. Int. Environ. Appl. Sci. 2016, 14, 108. [Google Scholar]

- Bhat, D.K.; Shenoy, U.S. Enhanced Thermoelectric Performance of Bulk Tin Telluride: Synergistic Effect of Calcium and Indium Co-Doping. Mater. Today Phys. 2018, 4, 12. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Shuai, J.; Tang, X.; Tan, G. Lead-Free SnTe-Based Compounds as Advanced Thermoelectrics. Mater. Today Phys. 2021, 19, 100405. [Google Scholar] [CrossRef]

- Li, W.; Zheng, L.; Ge, B.; Lin, S.; Zhang, X.; Chen, Z.; Chang, Y.; Pei, Y. Promoting SnTe as an Eco-Friendly Solution for p-PbTe Thermoelectric via Band Convergence and Interstitial Defects. Adv. Mater. 2017, 29, 1605887. [Google Scholar] [CrossRef]

- He, J.; Xu, J.; Tan, X.; Liu, G.Q.; Shao, H.; Liu, Z.; Jiang, H.; Jiang, J. Synthesis of SnTe/AgSbSe2 Nanocomposite as a Promising Lead-Free Thermoelectric Material. J. Mater. 2016, 2, 165. [Google Scholar]

- Tang, J.; Gao, B.; Lin, S.; Li, J.; Chen, Z.; Xiong, F.; Li, W.; Chen, Y.; Pei, Y. Manipulation of Band Structure and Interstitial Defects for Improving Thermoelectric SnTe. Adv. Funct. Mater. 2018, 28, 1803586. [Google Scholar] [CrossRef]

- Zhang, X.; Bu, Z.; Lin, S.; Chen, Z.; Li, W.; Pei, Y. GeTe Thermoelectrics. Joule 2020, 4, 986. [Google Scholar] [CrossRef]

- Qiu, X.; Zheng, Q.; Lu, X.; Fan, S.; Zhou, X.; Wang, L.; Jiang, W. Effect of Bi Doping on Thermoelectric Properties of Ge0.90−xPb0.10BixTe Compounds. Mater. Sci. Semicond. Process. 2020, 109, 104955. [Google Scholar] [CrossRef]

- Chen, I.N.; Chong, C.W.; Wong, D.P.; Lyu, L.M.; Chien, W.L.; Anbalagan, R.; Aminzare, M.; Chen, Y.F.; Chen, L.C.; Chen, K.H. Improving the Thermoelectric Performance of Metastable Rock-Salt GeTe-Rich Ge–Sb–Te Thin Films through Tuning of Grain Orientation and Vacancies. Phys. Status Solidi Appl. Mater. Sci. 2016, 213, 3122. [Google Scholar] [CrossRef]

- Yuan, J.; Zhu, R. A Fully Self-Powered Wearable Monitoring System with Systematically Optimized Flexible Thermoelectric Generator. Appl. Energy 2020, 271, 115250. [Google Scholar] [CrossRef]

- Goldsmid, H.J. The Thermal Conductivity of Bismuth Telluride. Proc. Phys. Soc. Sect. B 1956, 69, 203. [Google Scholar] [CrossRef]

- Feutelais, Y.; Legendre, B.; Rodier, N.; Agafonov, V. A study of the phases in the bismuth—Tellurium system. Mater. Res. Bull. 1993, 28, 591–596. [Google Scholar] [CrossRef]

- Manzano, C.V.; Abad, B.; Rojo, M.M.; Koh, Y.R.; Hodson, S.L.; Martinez, A.M.L.; Xu, X.; Shakouri, A.; Sands, T.D.; Borca-Tasciuc, T.; et al. Anisotropic Effects on the Thermoelectric Properties of Highly Oriented Electrodeposited Bi2Te3 Films. Sci. Rep. 2016, 6, srep19129. [Google Scholar] [CrossRef]

- Hasanova, G.S.; Aghazade, A.I.; Imamaliyeva, S.Z.; Yusibov, Y.A.; Babanly, M.B. Refinement of the Phase Diagram of the Bi-Te System and the Thermodynamic Properties of Lower Bismuth Tellurides. JOM 2021, 73, 1511–1521. [Google Scholar] [CrossRef]

- Nozariasbmarz, A.; Krasinski, J.S.; Vashaee, D. N-Type Bismuth Telluride Nanocomposite Materials Optimization for Thermoelectric Generators in Wearable Applications, Materials. Materials 2019, 12, 1529. [Google Scholar] [CrossRef]

- Devi, N.; Ray, S.S. Performance of bismuth-based materials for supercapacitor applications: A review. Mater. Today Commun. 2020, 25, 101691. [Google Scholar] [CrossRef]

- Lee, J.S.; Richardella, A.; Rench, D.W.; Fraleigh, R.D.; Flanagan, T.C.; Borchers, J.A.; Tao, J.; Samarth, N. Ferromagnetism and Spin-Dependent Transport in SnS-Type Mn-Doped Bismuth Telluride Thin Films. Phys. Rev. B 2014, 89, 174425. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, L.; Tan, Q.; Li, J.-F. Thermoelectric Properties of Pb-Doped Bismuth Telluride Thin Films Deposited by Magnetron Sputtering. J. Alloys Compd. 2014, 590, 362. [Google Scholar] [CrossRef]

- Bohra, A.K.; Bhatt, R.; Singh, A.; Bhattacharya, S.; Basu, R.; Meshram, K.N.; Sarkar, S.K.; Bhatt, P.; Patro, P.K.; Aswal, D.K.; et al. Transition from n- to p-type conduction concomitant with enhancement of figure-of-merit in Pb doped bismuth telluride: Material to device development. Mater. Des. 2018, 159, 127–137. [Google Scholar] [CrossRef]

- Shen, J.-J.; Zhu, T.-J.; Zhao, X.-B.; Zhang, S.-N.; Yang, S.-H.; Yin, Z.-Z. Recrystallization induced in situ nanostructures in bulk bismuth antimony tellurides: A simple top down route and improved thermoelectric properties. Energy Environ. Sci. 2010, 3, 1519–1523. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; The, K.; Kanatzidis, G.; Zt, T.; Vining, B. Thin-Film Thermoelectric Devices with High Room-Temperature Figures of Merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef]

- Lv, H.Y.; Liu, H.J.; Shi, J.; Tang, X.F.; Uher, C. Optimized thermoelectric performance of Bi2Te3 nanowires. J. Mater. Chem. A 2013, 1, 6831–6838. [Google Scholar] [CrossRef]

- Draft Assessment T. Thermoelectric Materials, Devices and Systems: Technology Assessment; US Department of Energy: Washington, DC, USA, 2015. [Google Scholar]

- Zheng, Z.-H.; Niu, J.-Y.; Ao, D.-W.; Jabar, B.; Shi, X.-L.; Li, X.-R.; Li, F.; Liang, G.-X.; Chen, Y.-X.; Chen, Z.-G.; et al. In-situ growth of high-performance (Ag, Sn) co-doped CoSb3 thermoelectric thin films. J. Mater. Sci. Technol. 2021, 92, 178–185. [Google Scholar] [CrossRef]

- Morgan, K.; Zeimpekis, I.; Feng, Z.; Hewak, D. Enhancing thermoelectric properties of bismuth telluride and germanium telluride thin films for wearable energy harvesting. Thin Solid Film. 2021, 741, 139015. [Google Scholar] [CrossRef]

- Ohring, M. Why Are Thin Films Different from the Bulk? Proc. SPIE 1994, 2114, 624. [Google Scholar]

- Søndergaard, R.R.; Hösel, M.; Krebs, F.C. Roll-to-Roll fabrication of large area functional organic materials. J. Polym. Sci. Part B: Polym. Phys. 2012, 51, 16–34. [Google Scholar] [CrossRef]

- Stark, I.; Stordeur, M. New Micro Thermoelectric Devices Based on Bismuth Telluride-Type Thin Solid Films. In Proceedings of the International Conference on Thermoelectrics, Baltimore, MD, USA, 29 August–2 September 1999; p. 465. [Google Scholar]

- Aversano, F.; Branz, S.; Bassani, E.; Fanciulli, C.; Ferrario, A.; Boldrini, S.; Baricco, M.; Castellero, A. Effect of Rapid Solidification on the Synthesis and Thermoelectric Properties of Yb-Filled Co4Sb12 Skutterudite. J. Alloys Compd. 2019, 796, 33–41. [Google Scholar] [CrossRef]

- Mukherjee, S.; Ghosh, S.; Chattopadhyay, K. Ultralow thermal conductivity and high thermoelectric figure of merit in Cu2Te–Ag2Te composites. J. Alloy. Compd. 2020, 848, 156540. [Google Scholar] [CrossRef]

- Chang, C.; Wu, M.; He, D.; Pei, Y.; Wu, C.-F.; Wu, X.; Yu, H.; Zhu, F.; Wang, K.; Chen, Y.; et al. 3D charge and 2D phonon transports leading to high out-of-plane ZT in n-type SnSe crystals. Science 2018, 360, 778–783. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-C.; Lydia, R.; Yun, J.H.; Lee, H.S.; Rhyee, J.S. Extremely Low Lattice Thermal Conductivity and Point Defect Scattering of Phonons in Ag-Doped (SnSe)1–x(SnS)x Compounds. Chem. Mater. 2017, 29, 5344. [Google Scholar] [CrossRef]

- Agarwal, A.; Patel, P.D.; Lakshminarayana, D. Single Crystal Growth of Layered Tin Monoselenide Semiconductor Using a Direct Vapour Transport Technique. J. Cryst. Growth 1994, 142, 344. [Google Scholar] [CrossRef]

- Patel, S.; Chaki, S.H.; Vinodkumar, P.C. Thermal Analysis of Direct Vapour Transport Technique Grown Tin Selenide Single Crystals, Thermochim. Acta 2020, 689, 178614. [Google Scholar]

- Patel, H.M.; Patel, P.B.; Desai, H.N.; Sikligar, S.P.; Dhimmar, J.M.; Modi, B.P. Synthesis and Characterization of Direct Vapour Transport Grown Sb2Se3 Crystals. Mater. Today Proc. 2021, 47, 583. [Google Scholar] [CrossRef]

- Yin, Y.; Cai, J.; Wang, H.; Xiao, Y.; Hu, H.; Tan, X.; Liu, G.-Q.; Jiang, J. Single-Crystal Growth of n-Type SnS0.95 by the Temperature-Gradient Technique. Vacuum 2020, 182, 109789. [Google Scholar] [CrossRef]

- Aoki, M.; Yamane, H.; Shimada, M.; Sarayama, S.; Iwata, H.; DiSalvo, F.J. Single Crystal Growth of GaN by the Temperature Gradient Na Flux Method. J. Cryst. Growth 2004, 266, 461. [Google Scholar] [CrossRef]

- Ohara, S.; Tan, Z.Q.; Yamamoto, K.; Qiu, N.; Hashishin, T. Collision-Friction Synthesis of Carbon Nanomaterials by a High-Speed Ball-Milling Process; Fujii, W., Ed.; Woodhead Publishing: Sawston, UK, 2013; pp. 509–510. [Google Scholar]

- Takacs, L. Ball Milling-Induced SHS; Borovinskaya, I.P., Gromov, A.A., Levashov, E.A., Maksimov, Y.M., Mukasyan, A.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 27–28. [Google Scholar]

- Thambiliyagodage, C.; Wijesekera, R. Ball milling—A green and sustainable technique for the preparation of titanium based materials from ilmenite. Curr. Res. Green Sustain. Chem. 2021, 5, 100236. [Google Scholar] [CrossRef]

- El-Eskandarany, M.S. 4—Controlling the Powder-Milling Process; William Andrew Publishing: Amsterdam, The Netherlands, 2020; pp. 55–92. [Google Scholar]

- Duroudier, J.-P. 3—Ball and Rod Mills; Elsevier: Amsterdam, The Netherlands, 2016; pp. 73–97. [Google Scholar]

- Kun, C. Mechanical Alloying Process during High Energy Ball Milling. Met. Powder Rep. 1997, 51, 36. [Google Scholar] [CrossRef]

- Lin, S.S.; Liao, C.N. Effect of Ball Milling and Post Treatment on Crystal Defects and Transport Properties of Bi2(Se,Te)3 Compounds. J. Appl. Phys. 2011, 110, 093707-7. [Google Scholar] [CrossRef]

- Lu, M.P.; Liao, C.N. Mechanical and Thermal Processing Effects on Crystal Defects and Thermoelectric Transport Properties of Bi2(Se,Te)3 Compounds. J. Alloys Compd. 2013, 571, 178. [Google Scholar] [CrossRef]

- Campbell, J. Chapter 14—Melting; Butterworth-Heinemann: Boston, MA, USA, 2015; p. 769. [Google Scholar]

- Grandfield, J.F. 5—Ingot Casting and Casthouse Metallurgy of Aluminium and Its Alloys; Woodhead Publishing Series in Metals and Surface Engineering; Lumley, A.M., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 83–140. [Google Scholar]

- Nakajima, K. Chapter 3—Growth of Si Multicrystalline Ingots Using the Conventional Cast Method; Nakajima, S.C.U.C.F., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 101–154. [Google Scholar]

- Zhang, Z.; Fu, S.; Aversano, F.; Bortolotti, M.; Zhang, H.; Hu, C.; Grasso, S. Arc Melting: A Novel Method to Prepare Homogeneous Solid Solutions of Transition Metal Carbides (Zr, Ta, Hf). Ceram. Int. 2019, 45, 9316. [Google Scholar] [CrossRef]

- Nayak, B.B.; Dash, T.; Pradhan, S. Spectroscopic Evaluation of Tungsten Carbide-Titanium Carbide Composite Prepared by Arc Plasma Melting. J. Electron Spectros. Relat. Phenom. 2020, 245, 146993. [Google Scholar] [CrossRef]

- Singh, M.K.; Singh, A. Chapter 2—Fiber Extrusion Melt-Spinning; The Textile Institute Book Series; Singh, M.K., Singh, F., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 29–65. [Google Scholar]

- Yang, W.-J.; Mochizuki, S.; Nishiwaki, N. Chapter 10—Melting and solidification; Transport Processes in Engineering; Yang, W.-J., Mochizuki, S., Nishiwaki, M.P., Eds.; Elsevier: Oxford, UK, 1994; pp. 117–135. [Google Scholar]

- Flemings, M.C. Solidification Processing at Near-Rapid and Rapid Rates (Keynote Paper). In Proceedings of the Metallurgical Society of Canadian Institute of Mining and Metallurgy, Hamilton, ON, USA, 26–30 August 1999; Lait, J.E., Samarasekera, S.P., Eds.; Pergamon: Oxford, UK, 1990; pp. 173–194. [Google Scholar]

- Jin, M.; Jiang, J.; Li, R.; Wang, X.; Chen, Y.; Zhang, R.; Chen, Y. Growth of Large Size SnSe Single Crystal and Comparison of Its Thermoelectric Property with Polycrystal. Mater. Res. Bull. 2019, 114, 156. [Google Scholar] [CrossRef]

- Lee, K.; Kim, S. Design and Preparation of High-Performance Bulk Thermoelectric Materials with Defect Structures. J. Korean Ceram. Soc. 2017, 54, 75. [Google Scholar] [CrossRef]

- Aversano, F.; Ferrario, A.; Boldrini, S.; Fanciulli, C.; Baricco, M.; Castellero, A. Thermoelectric Properties of TiNiSn Half Heusler Alloy Obtained by Rapid Solidification and Sintering. J. Mater. Eng. Perform. 2018, 27, 6306. [Google Scholar] [CrossRef]

- Harmer, M.P. Hot Pressing: Technology and Theory; Pergamon Press: Oxford, UK, 1991. [Google Scholar]

- Hack, K., II. 6—Hot Isostatic Pressing of Al–Ni Alloys. In Woodhead Publishing Series in Metals and Surface Engineering; Hack, E., Ed.; Woodhead Publishing: Sawston, UK, 2008; pp. 118–122. [Google Scholar]

- Hu, C.; Li, F.; Qu, D.; Wang, Q.; Xie, R.; Zhang, H.; Peng, S.; Bao, Y.; Zhou, Y. 8—Developments in Hot Pressing (HP) and Hot Isostatic Pressing (HIP) of Ceramic Matrix Composites; Low, C.M.C., Ed.; Woodhead Publishing: Sawston, UK, 2014; pp. 164–189. [Google Scholar]

- Wang, L.; Zhang, J.; Jiang, W. Recent Development in Reactive Synthesis of Nanostructured Bulk Materials by Spark Plasma Sintering. Int. J. Refract. Met. Hard Mater. 2013, 39, 103. [Google Scholar] [CrossRef]

- Zhezhu, M.; Vasil’ev, A.; Yaprintsev, M.; Ivanov, O.; Novikov, V. Effect of Spark Plasma Sintering Temperature on Microstructure and Thermoelectric Properties of the Cermet Composites Consisting of Bi2Te2.1Se0.9 Matrix and Co@CoTe2 Inclusions. J. Solid State Chem. 2022, 305, 122696. [Google Scholar] [CrossRef]

- Anselmi-Tamburini, U. Spark Plasma Sintering. Encycl. Mater. Tech. Ceram. Glas. 2021, 3, 294. [Google Scholar]

- Mukasyan, A.S.; Rogachev, A.S.; Moskovskikh, D.O.; Yermekova, Z.S. Reactive Spark Plasma Sintering of Exothermic Systems: A Critical Review. Ceram. Int. 2022, 48, 2988–2998. [Google Scholar] [CrossRef]

- Raphel, A.; Singh, A.K.; Vivekanandhan, P.; Kumaran, S. Thermoelectric Performance of Nanostructured PbSnTeSe High Entropy Thermoelectric Alloy Synthesized via Spark Plasma Sintering. Phys. B Condens. Matter 2021, 622, 413319. [Google Scholar] [CrossRef]

- Market, T.; Electronics, M. Deposition Technologies: An Overview, 3rd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Kern, W.; Schuegraf, K.K. 1—Deposition Technologies and Applications: Introduction and Overview; Seshan, E., Ed.; William Andrew Publishing: Norwich, NY, USA, 2001; pp. 11–43. [Google Scholar]

- Everett, R.K. 5—Deposition Technologies for MMC Fabrication; Everett, R.K., Arsenault, I., Eds.; Academic Press: Cambridge, MA, USA, 1991; pp. 103–119. [Google Scholar]

- Leary, M. Chapter 12—Directed Energy Deposition, in Additive Manufacturing Materials and Technologies, Leary, A.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 321–334. [Google Scholar]

- Wördenweber, R. 1—Deposition Technologies, Growth and Properties of High-Tc Films. In Woodhead Publishing Series in Electronic and Optical Materials; Qiu, S., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 3e–38e. [Google Scholar]

- Chen, X.; Zhou, Z.; Lin, Y.-H.; Nan, C. Thermoelectric Thin Films: Promising Strategies and Related Mechanism on Boosting Energy Conversion Performance. J. Mater. 2020, 6, 494. [Google Scholar] [CrossRef]

- Ma, Z.; Wei, J.; Song, P.; Zhang, M.; Yang, L.; Ma, J.; Liu, W.; Yang, F.; Wang, X. Review of Experimental Approaches for Improving ZT of Thermoelectric Materials. Mater. Sci. Semicond. Process. 2021, 121, 105303. [Google Scholar] [CrossRef]

- Vineis, C.J.; Shakouri, A.; Majumdar, A.; Kanatzidis, M.G. Nanostructured Thermoelectrics: Big Efficiency Gains from Small Features. Adv. Mater. 2010, 22, 3970–3980. [Google Scholar] [CrossRef]

- Jia, N.; Cao, J.; Tan, X.Y.; Dong, J.; Liu, H.; Tan, C.K.I.; Xu, J.; Yan, Q.; Loh, X.J.; Suwardi, A. Thermoelectric materials and transport physics. Mater. Today Phys. 2021, 21, 100519. [Google Scholar] [CrossRef]

- Depla, D.; Mahieu, S.; Greene, J.E. Chapter 5—Sputter Deposition Processes; Martin, E., Ed.; William Andrew Publishing: Boston, MA, USA, 2010; pp. 253–296. [Google Scholar]

- Gudmundsson, J.T.; Lundin, D. Introduction to Magnetron Sputtering, In High Power Impulse Magnetron Sputtering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Mattox, D.M. Chapter 4—Physical Sputtering and Sputter Deposition; Mattox, E., Ed.; William Andrew Publishing: Sawston, UK, 2018; pp. 87–149. [Google Scholar]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271. [Google Scholar] [CrossRef]

- Shrivastava, A.; Mukherjee, S.; Chakraborty, S.S. Addressing the Challenges in Remanufacturing by Laser-Based Material Deposition Techniques. Opt. Laser Technol. 2021, 144, 107404. [Google Scholar] [CrossRef]

- Ansari, M.; Jabari, E.; Toyserkani, E. Opportunities and Challenges in Additive Manufacturing of Functionally Graded Metallic Materials via Powder-Fed Laser Directed Energy Deposition: A Review. J. Mater. Process. Technol. 2021, 294, 117117. [Google Scholar] [CrossRef]

- Shah, S.I.; Jaffari, G.H.; Yassitepe, E.; Ali, B. Chapter 4—Evaporation: Processes, Bulk Microstructures, and Mechanical Properties; Martin, E., Ed.; William Andrew Publishing: Boston, MA, USA, 2010; pp. 135–252. [Google Scholar]

- Evans, S.E.; Harrington, T.; Rivero, M.C.R.; Rognin, E.; Tuladhar, T.; Daly, R. 2D and 3D Inkjet Printing of Biopharmaceuticals—A Review of Trends and Future Perspectives in Research and Manufacturing. Int. J. Pharm. 2021, 599, 120443. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet Printing-Process and Its Applications. Adv. Mater. 2010, 22, 673. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Kruse, M.; Xu, B.; Tutika, R.; Zheng, W.; Bartlett, M.D.; Wu, Y.; Claussen, J.C. Flexible Thermoelectric Generators with Inkjet-Printed Bismuth Telluride Nanowires and Liquid Metal Contacts. Nanoscale 2019, 11, 5222. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Kalaitzidou, K.; Yao, D.; Yeo, W.; Harris, T.A.L. Aerosol Jet Printing: Challenges and Advances in Aerosol Jet Printing of Regenerated Silk Fibroin Solutions (Adv. Mater. Interfaces 12/2020). Adv. Mater. Interfaces 2020, 7, 2070065. [Google Scholar] [CrossRef]

- Secor, E.B. Principles of Aerosol Jet Printing. Flex. Print. Electron. 2018, 3, 035002. [Google Scholar] [CrossRef]

- Hollar, C.; Lin, Z.; Kongara, M.; Varghese, T.; Karthik, C.; Schimpf, J.; Eixenberger, J.; Davis, P.H.; Wu, Y.; Duan, X.; et al. High-Performance Flexible Bismuth Telluride Thin Film from Solution Processed Colloidal Nanoplates. Adv. Mater. Technol. 2020, 5, 1. [Google Scholar] [CrossRef]

- Ohring, M. Chapter 5—Plasma and Ion Beam Processing of Thin Films; Ohring, E., Ed.; Academic Press: San Diego, CA, USA, 2002; pp. 203–275. [Google Scholar]

- Simon, A.H. Chapter 7—Sputter Processing; Seshan, K., Schepis, E., Eds.; William Andrew Publishing: Sawston, UK, 2018; pp. 195–230. [Google Scholar]

- Singh, M.M.; Vijaya, G.; Ms, K.; Sridhara, B.K.; Shridhar, T.N. Studies on Nanostructure Aluminium Thin Film Coatings Deposited Using DC Magnetron Sputtering Process. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012071. [Google Scholar]

- Sproul, W.D.; Christie, D.J.; Carter, D.C. Control of Reactive Sputtering Processes. Thin Solid Film. 2005, 491, 1. [Google Scholar] [CrossRef]

- Constantin, D.G.; Apreutesei, M.; Arvinte, R.; Marin, A.; Andrei, O.C.; Munteanu, D. Magnetron Sputtering Technique Used for Coatings Deposition; Technologies and Applications. Int. Conf. Mater. Sci. Eng. 2011, 12, 24. [Google Scholar]

- Kelly, P.J.; Arnell, R.D. Magnetron Sputtering: A Review of Recent Developments and Applications. Vacuum 2000, 56, 159. [Google Scholar] [CrossRef]

- Bishop, C.A. Magnetron Sputtering Source Design and Operation. Vac. Depos. Onto Webs. Film. Foils 2015, 371, 297–324. [Google Scholar]

- Maurya, D.K.; Sardarinejad, A.; Alameh, K. Recent Developments in R.F. Magnetron Sputtered Thin Films for PH Sensing Applications—An Overview, Coatings. Coatings 2014, 4, 756–771. [Google Scholar] [CrossRef]

- Kurokawa, T.; Mori, R.; Norimasa, O.; Chiba, T.; Eguchi, R.; Takashiri, M. Influences of Substrate Types and Heat Treatment Conditions on Structural and Thermoelectric Properties of Nanocrystalline Bi2Te3 Thin Films Formed by DC Magnetron Sputtering. Vacuum 2020, 179, 109535. [Google Scholar] [CrossRef]

- Wijshoff, H. Drop Dynamics in the Inkjet Printing Process. Curr. Opin. Colloid Interface Sci. 2018, 36, 20. [Google Scholar] [CrossRef]

- Liu, X.; Tarn, T.-J.; Huang, F.; Fan, J. Recent Advances in Inkjet Printing Synthesis of Functional Metal Oxides. Particuology 2015, 19, 1. [Google Scholar] [CrossRef]

- Guo, Y.; Patanwala, H.S.; Bognet, B.; Ma, A.W.K. Inkjet and Inkjet-Based 3D Printing: Connecting Fluid Properties and Printing Performance. Rapid Prototyp. J. 2017, 23, 562. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive Nanomaterials for Printed Electronics. Small 2014, 10, 3515–3535. [Google Scholar] [CrossRef]

- Hoath, S.D. Fundamentals of Inkjet Printing, Fundamentals of Inkjet Printing, The Science of Inkjet and Droplets; Wiley-VCH: Weinheim, Germany, 2016; pp. 55–60. [Google Scholar]

- Martin, G.D.; Hoath, S.D.; Hutchings, I.M. Inkjet Printing—The Physics of Manipulating Liquid Jets and Drops. J. Phys. Conf. Ser. 2008, 105, 012001. [Google Scholar] [CrossRef]

- Salary, R.; Lombardi, J.P.; Tootooni, M.S.; Donovan, R.; Rao, P.K.; Borgesen, P.; Poliks, M.D. Computational Fluid Dynamics Modeling and Online Monitoring of Aerosol Jet Printing Process. J. Manuf. Sci. Eng. Trans. ASME 2017, 139, 21015. [Google Scholar] [CrossRef]

- Redón, R.; Ruiz-Huerta, L.; Almanza-Arjona, Y.C.; Rojas-Aguirre, Y.; Caballero-Ruiz, A. Nanocomposites for Additive Manufacturing. Am. J. Chem. Res. 2017, 1, 1–5. [Google Scholar]

- Secor, E.B. Guided Ink and Process Design for Aerosol Jet Printing Based on Annular Drying Effects. Flex. Print. Electron. 2018, 3, 35007. [Google Scholar] [CrossRef]

- Wilkinson, N.J.; Smith, M.A.A.; Kay, R.W.; Harris, R.A. A Review of Aerosol Jet Printing—A Non-Traditional Hybrid Process for Micro-Manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 4599. [Google Scholar] [CrossRef]

- Liu, P.S.K.; Deng, R.; Smith, K.A.; Williams, L.R.; Jayne, J.T.; Canagaratna, M.R.; Moore, K.; Onasch, T.B.; Worsnop, D.R.; Deshler, T. Transmission Efficiency of an Aerodynamic Focusing Lens System: Comparison of Model Calculations and Laboratory Measurements for the Aerodyne Aerosol Mass Spectrometer. Aerosol Sci. Technol. 2007, 41, 721. [Google Scholar] [CrossRef]

- Ceradrop, Ceradrop Ceraprinter F-Serie. 2018. Available online: https://www.ceradrop.com/en/products/f-serie/ (accessed on 13 June 2023).

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for Printing Sensors and Electronics over Large Flexible Substrates: A Review. IEEE Sens. J. 2015, 15, 3164. [Google Scholar] [CrossRef]

- Jeong, Y.R.; Kim, J.; Xie, Z.; Xue, Y.; Won, S.M.; Lee, G.; Jin, S.W.; Hong, S.Y.; Feng, X.; Huang, Y.; et al. A skin-attachable, stretchable integrated system based on liquid GaInSn for wireless human motion monitoring with multi-site sensing capabilities. NPG Asia Mater. 2017, 9, e443. [Google Scholar] [CrossRef]

- Varghese, T.V. Additive Manufacturing of High Performance Flexible Thermoelectric Generators Using Nanoparticle Inks; Boise State Univ.: Boise, ID, USA, 2019; p. 1. [Google Scholar]

- Ou, C.; Sangle, A.L.; Datta, A.; Jing, Q.; Busolo, T.; Chalklen, T.; Narayan, V.; Kar-Narayan, S. Fully Printed Organic-Inorganic Nanocomposites for Flexible Thermoelectric Applications. ACS Appl. Mater. Interfaces 2018, 10, 19580. [Google Scholar] [CrossRef]

- Baba, S.; Huang, L.; Sato, H.; Funahashi, R.; Akedo, J. Room-Temperature Fast Deposition and Characterization of Nanocrystalline Bi0.4Sb1.6Te3 Thick Films by Aerosol Deposition. J. Phys. Conf. Ser. 2012, 379. [Google Scholar] [CrossRef]

- Kim, F.; Kwon, B.; Eom, Y.; Lee, J.E.; Park, S.; Jo, S.; Park, S.H.; Kim, B.-S.; Im, H.J.; Lee, M.H.; et al. 3D Printing of Shape-Conformable Thermoelectric Materials Using All-Inorganic Bi2Te3-Based Inks. Nat. Energy 2018, 3, 301. [Google Scholar] [CrossRef]

- Yang, J.Y.; Aizawa, T.; Yamamoto, A.; Ohta, T. Thermoelectric Properties of N-Type (Bi2Se3)x(Bi2Te3)1−x Prepared by Bulk Mechanical Alloying and Hot Pressing. J. Alloys Compd. 2000, 312, 326. [Google Scholar] [CrossRef]

- Li, H.; Jing, H.; Han, Y.; Xu, Y.; Lu, G.-Q.; Xu, L. Microstructure and Transport Properties of Copper-Doped p-Type BiSbTe Alloy Prepared by Mechanical Alloying and Subsequent Spark Plasma Sintering. J. Alloys Compd. 2013, 576, 369. [Google Scholar] [CrossRef]

| Material | Output Power (mW) | ΔT | Application | Location | Ref. |

|---|---|---|---|---|---|

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 100 | \ | Wearable and medical devices | Wrist | [53] |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 0.035 per cm2 | 2.5 | Arm | [52] | |

| n-leg Mg3.2Bi1.498Sb0.5Te0.002 p-leg Bi0.4Sb1.6Te3 | 13.8 per cm2 | 13 | Arm | [58] | |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 0.001 | 22 | Chest | [57] | |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 1.5 | 6 | Wireless Sensor Networks (WSNs) | Building windows | [61] |

| n-leg Ag screen printing ink p-leg Ni screen printing ink | 0.308 | 127 | Pipes insulation systems | [60] | |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 2 | 2 | Water pipes | [63] | |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 0.95 | 4 | Building heating system | [62] | |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 16,600 gasoline 41,600 Diesel | 50 | Automotive | Engine exhaust | [69] |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 37,850 | 50 | Engine exhaust | [51] | |

| n-type half-Heusler (Zr,Hf) p-type Bi2Te3 | 125,000 | 480 | Engine radiator | [50] | |

| n-leg PbTe p-leg Bi2Te3/TAGS alloy | 110,000 | 420 | Aerospace | Energy supply | [77] |

| n-type SiGe p-type SiGe | 285,000 | 430 | Energy supply | [75] | |

| n-leg PbTe p-leg PbSnTe/TAGS-85 | 105,000 | 425 | Energy supply | [77] | |

| n+-wells Si (P, As) p+-wells Si (B) | 0.0002 | 20 | Electronic devices | ICs | [40] |

| n-leg Bi2Se0.3Te2.7 p-leg Bi0.5Sb1.5Te3 | 0.004 per cm2 | 20 | Electronic devices | [85] | |

| n+-wells Si0.97Ge0.03 (P, As) p+-wells Si0.97Ge0.03 (B) | 0.0003 | 15 | ICs | [43] | |

| n-type Bi2Te2.7Se0.3 p-type Bi0.5Sb1.5Te3 | 0.000169 | 23 | WSNs nodes | [83] |