Combustion of Lean Methane/Propane Mixtures with an Active Prechamber Engine in Terms of Various Fuel Distribution

Abstract

:1. Introduction

2. Aim and Scope of the Study

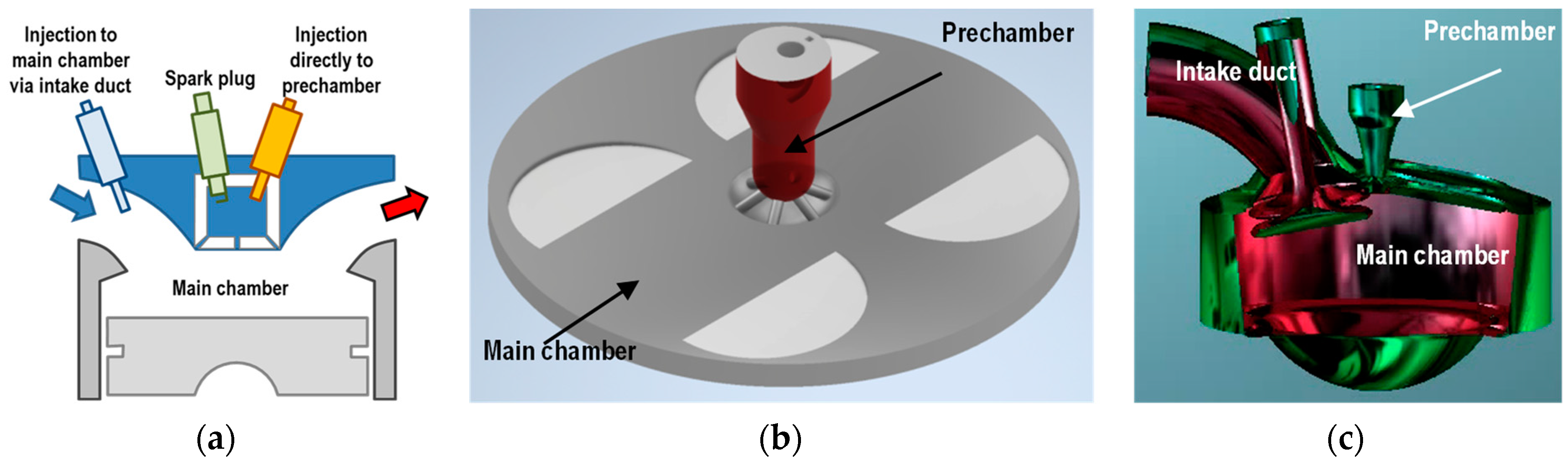

3. Materials and Methods

3.1. Test Stand

- Variable control parameters:

- Excess air ratio (λ = 1.3; 1.5; 1.8);

- Dose of fuel to prechamber: energy value of fuel for prechamber: 10; 20; 30; 40; 45; 50; and 60 J (while keeping the total energy value of fuel supplied to the engine constant).

- Constant control parameters:

- Engine speed: n = 1500 rpm;

- Total fuel dose: qo = 13.5 mg (energy = 675 J).

3.2. Method of Analyzing Research Results

- Heat release ratewhere P is the instantaneous cylinder pressure, α is the crank angle, γ is the ratio of the specific heats, and V is the instantaneous cylinder volume.

- Indicative power (Ni):where Vs—engine displacement, n—engine speed, and τ—cyclicality of engine operation.

- Specific fuel consumption (gi):where G—fuel consumption in the main chamber (MC) and prechamber (PC), respectively.

- Indicative efficiency (ηi):where LHV—heating value of methane.

- Specific emissions of exhaust components (ei):where i = CO, THC, NO, Ci—concentration; CO, THC, NO, Ga—air consumption; GMC, GPC—fuel consumption in both chambers; ai—density ratios (CO = 0.000966; CTHC = 0.000479, CNO = 0.001587) [28].

4. Thermodynamic Analysis of System Operation Fueled by Different Fuels

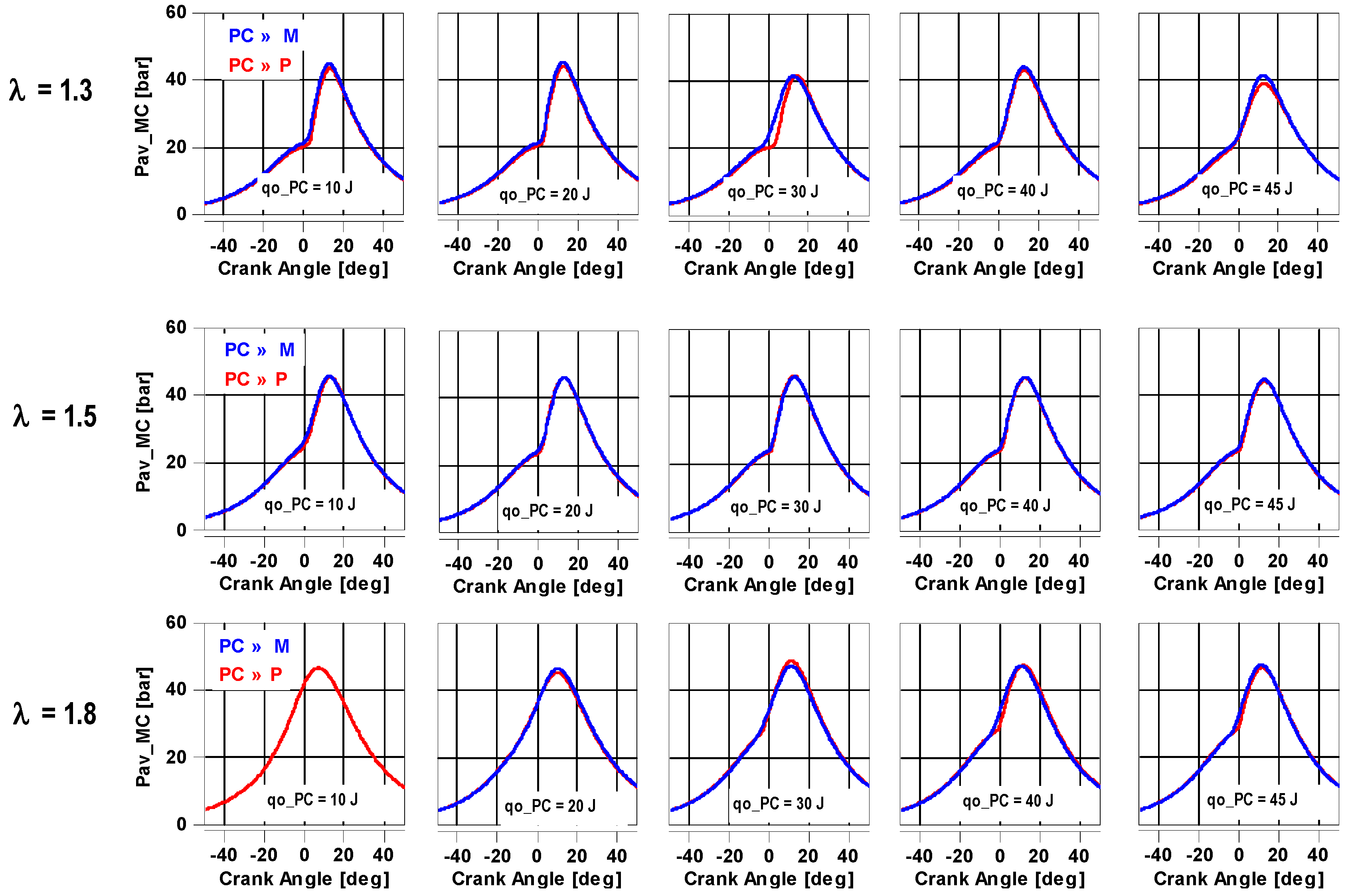

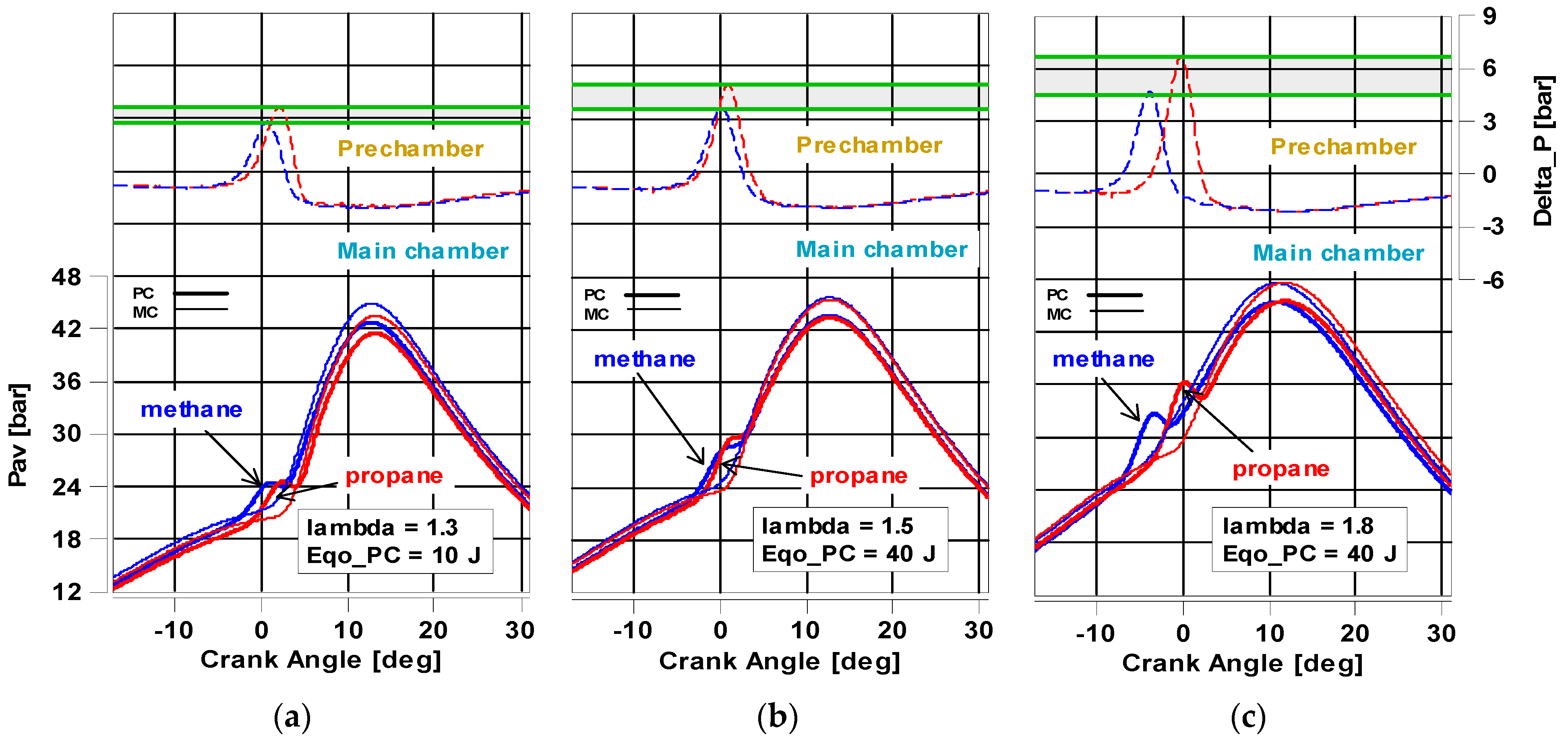

4.1. Cylinder Pressure

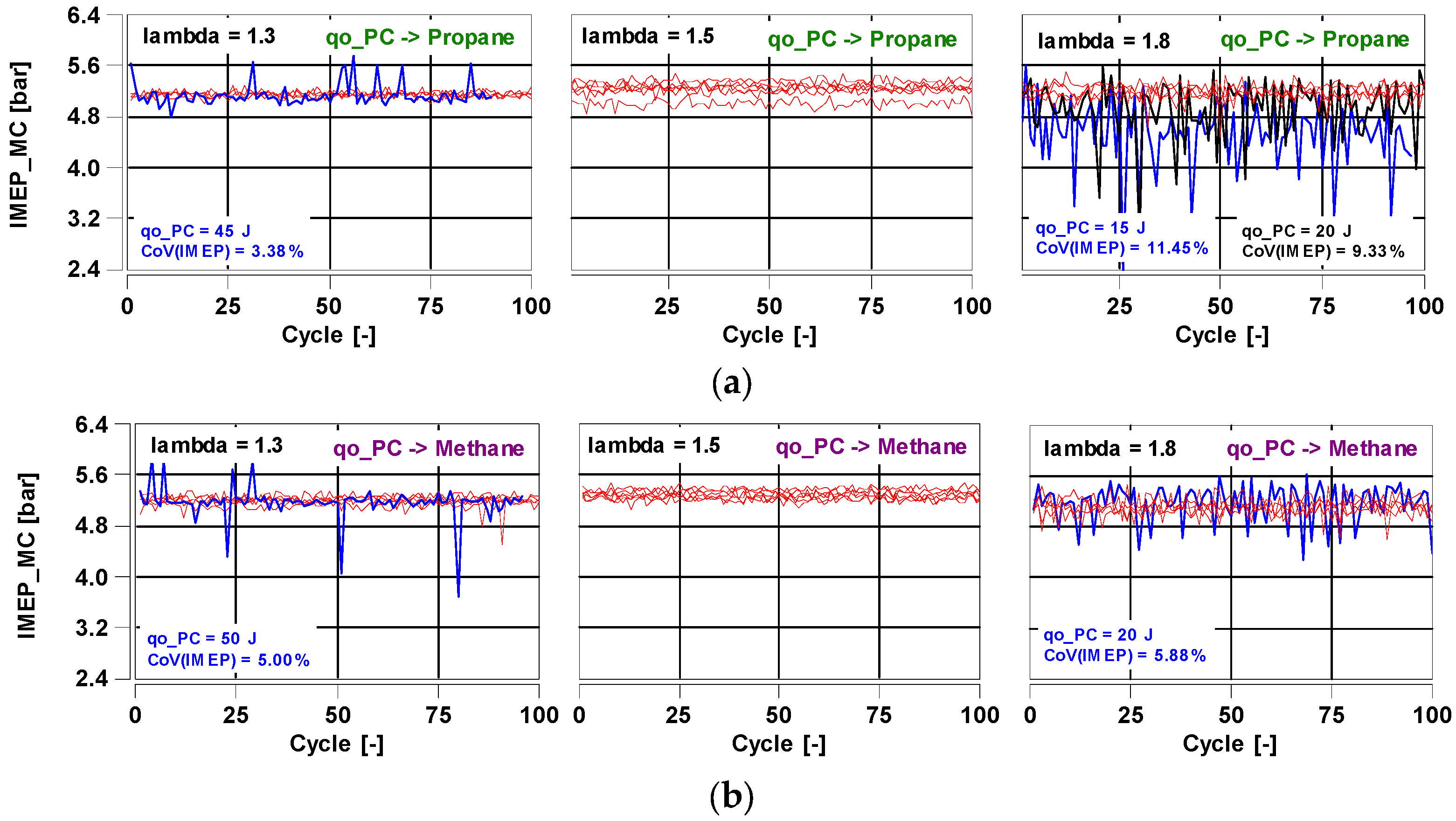

4.2. Analysis of Engine Operation Stability

4.3. Indicators of Engine Operation

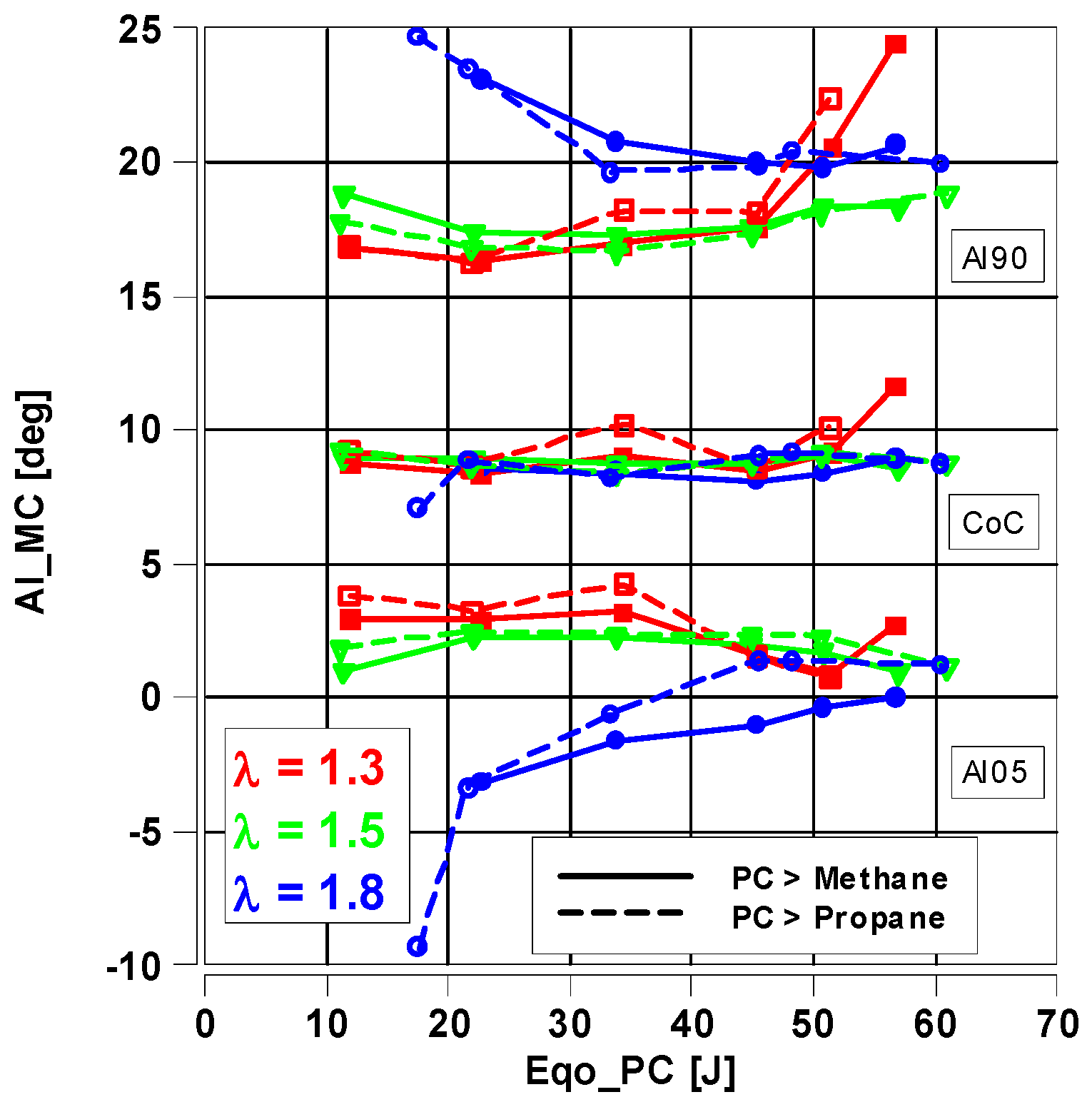

4.3.1. Thermodynamic Indicators

4.3.2. System Efficiency for Methane and Propane Combustion

4.3.3. Analysis of Emission Indexes

5. Conclusions

- Feeding the engine in a single-fuel mode methane (MC) + methane (PC) allows better thermodynamic parameters of the combustion process to be obtained in relation to the dual-fuel mode where propane is supplied to the ignition chamber instead of methane.

- The effect of dividing the fuel dose between the MC and PC chambers has the greatest impact in the case of combustion of mixtures with excess air ratios of 1.3 and 1.5.

- Better stability of engine operation CoV(IMEP) < 3.5% in the range of small doses of fuel fed to the prechamber and at charges with λ = 1.3–1.5.

- Higher values of indicative mean effective pressure IMEP when burning mixtures with excess air ratio in the range λ = 1.3–1.5; these values are slightly higher when measured in the main chamber than in the prechamber.

- Higher maximum values of heat released; at the same time, the combustion of minimum doses in the prechamber resulted in maximum values of heat released in relation to the other values of energy supplied to the PC.

- Better thermodynamic performance of combustion in the prechamber at small doses fed to the PC and at λ = 1.3 and 1.5 in the range up to 30 J. The areas of increased propane combustion efficiency in the two-stage system cannot be clearly identified.

- Higher value of the engine’s indicated efficiency reaching more than 40% at a small dose of fuel to the prechamber against 39.3% when propane is fed to the ignition chamber.

- Shorter combustion time; the combustion time increases with an increase in λ and with an increase in the dose delivered to the prechamber.

- Ignitability of the mixture at high λ and low fuel doses (no ignitability when using methane).

- Reduction in CO and HC emissions when burning leaner loads.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gracz, W.; Marcinkowski, D.; Golimowski, W.; Szwajca, F.; Strzelczyk, M.; Wasilewski, J.; Krzaczek, P. Multifaceted comparison efficiency and emission characteristics of multi-fuel power generator fueled by different fuels and biofuels. Energies 2021, 14, 3388. [Google Scholar] [CrossRef]

- Davis, G.C.; Krieger, R.B.; Tabaczynski, R.J. Analysis of the Flow and Combustion Processes of a Three-Valve Stratified Charge Engine with a Small Prechamber; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1974. [Google Scholar] [CrossRef]

- Adams, T. Torch Ignition for Combustion Control of Lean Mixtures; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1979. [Google Scholar] [CrossRef]

- Alvarez, C.E.C.; Couto, G.E.; Roso, V.R.; Thiriet, A.B.; Valle, R.M. A review of prechamber ignition systems as lean combustion technology for SI engines. Appl. Therm. Eng. 2018, 128, 107–120. [Google Scholar] [CrossRef]

- Pielecha, I.; Szwajca, F. Lean methane mixtures in turbulent jet ignition combustion system. Energies 2023, 16, 1236. [Google Scholar] [CrossRef]

- Zhu, S.; Akehurst, S.; Lewis, A.; Yuan, H. A review of the pre-chamber ignition system applied on future low-carbon spark ignition engines. Renew. Sustain. Energy Rev. 2022, 154, 111872. [Google Scholar] [CrossRef]

- Allison, P.M.; de Oliveira, M.; Giusti, A.; Mastorakos, E. Pre-chamber ignition mechanism: Experiments and simulations on turbulent jet flame structure. Fuel 2018, 230, 274–281. [Google Scholar] [CrossRef]

- Wu, H.; Wang, L.; Wang, X.; Sun, B.; Zhao, Z.; Lee, C.-F.; Liu, F. The effect of turbulent jet induced by pre-chamber sparkplug on combustion characteristics of hydrogen-air pre-mixture. Int. J. Hydrogen Energy 2018, 43, 8116–8126. [Google Scholar] [CrossRef]

- Gholamisheeri, M.; Wichman, I.S.; Toulson, E. A study of the turbulent jet flow field in a methane fueled turbulent jet ignition (TJI) system. Combust. Flame 2017, 183, 194–206. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, L.; Zhong, L.; Wei, H. Enhanced combustion of ammonia engine based on novel air-assisted pre-chamber turbulent jet ignition. Energy Convers. Manag. 2023, 276, 116526. [Google Scholar] [CrossRef]

- Onofrio, G.; Napolitano, P.; Tunestål, P.; Beatrice, C. Combustion sensitivity to the nozzle hole size in an active pre-chamber ultra-lean heavy-duty natural gas engine. Energy 2021, 235, 121298. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, P.; Zhong, L.; Feng, Z.; Wei, H. Experimental observation of lean flammability limits using turbulent jet ignition with auxiliary hydrogen and methane in pre-chamber. Fuel 2021, 305, 121570. [Google Scholar] [CrossRef]

- Bueschke, W.; Szwajca, F.; Wislocki, K. Experimental Study on Ignitability of Lean CNG/Air Mixture in the Multi-Stage Cascade Engine Combustion System; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Vera-Tudela, W.; Merotto, L.; Balmelli, M.; Soltic, P. Experimental study of the ignition of lean methane/air mixtures using inductive and NRPD ignition systems in the pre-chamber and turbulent jet ignition in the main chamber. Energy Convers. Manag. 2022, 252, 115012. [Google Scholar] [CrossRef]

- Arslan, E.; Kahraman, N. Comparison of natural gas and propane addition to combustion air in terms of engine performance in compression ignition engine. Fuel 2022, 312, 122952. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Jang, D.; Lee, M.C. Property-based quantitative risk assessment of hydrogen, ammonia, methane, and propane considering explosion, combustion, toxicity, and environmental impacts. J. Energy Storage 2022, 54, 105344. [Google Scholar] [CrossRef]

- Li, X.; He, B.-Q.; Zhao, H. Effect of direct injection dimethyl ether on the micro-flame ignited (MFI) hybrid combustion characteristics of an optical gasoline engine at ultra-lean conditions. Fuel Process. Technol. 2020, 203, 106383. [Google Scholar] [CrossRef]

- Distaso, E.; Amirante, R.; Cassone, E.; De Palma, P.; Sementa, P.; Tamburrano, P.; Vaglieco, B.M. Analysis of the combustion process in a lean-burning turbulent jet ignition engine fueled with methane. Energy Convers. Manag. 2020, 223, 113257. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, L.; Wei, H. Experimental investigation on the performance of pure ammonia engine based on reactivity controlled turbulent jet ignition. Fuel 2023, 335, 127116. [Google Scholar] [CrossRef]

- Vinod, K.N.; Fang, T. Experimental characterization of spark ignited ammonia combustion under elevated oxygen concentrations. Proc. Combust. Inst. 2022. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, J.; Cui, Z.; Xiong, S.; Yin, S.; Wang, Q.; Long, W. Visualization study on the effects of pre-chamber jet ignition and methane addition on the combustion characteristics of ammonia/air mixtures. Fuel 2023, 338, 127204. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, L.; Zhong, L.; Wei, H. Reactivity controlled turbulent jet ignition (RCTJI) for ammonia engine. Int. J. Hydrogen Energy 2023, 48, 12519–12522. [Google Scholar] [CrossRef]

- Lee, M.C.; Seo, S.B.; Yoon, J.; Kim, M.; Yoon, Y. Experimental study on the effect of N2, CO2, and steam dilution on the combustion performance of H2 and CO synthetic gas in an industrial gas turbine. Fuel 2012, 102, 431–438. [Google Scholar] [CrossRef]

- Cheng, Q.; Kaario, O.; Ahmad, Z.; Vuorinen, V.; Larmi, M. Effect of pilot fuel properties on engine performance and combustion stability in a tri-fuel engine powered by premixed methane-hydrogen and diesel pilot. Int. J. Hydrogen Energy 2021, 46, 37469–37486. [Google Scholar] [CrossRef]

- Jean, M.; Granier, P.; Leroy, T. Combustion stability control based on cylinder pressure for high efficiency gasoline engines. Energies 2022, 15, 2530. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Batool, S.; Naber, J.D.; Shahbakhti, M. Data-driven modeling and control of cyclic variability of an engine operating in low temperature combustion modes. IFAC-PapersOnLine 2021, 54, 834–839. [Google Scholar] [CrossRef]

- Merkisz, J.; Pielecha, J.; Radzimirski, S. New Trends in Emission Control in the European Union; Springer Tracts on Transportation and Traffic; Springer: Cham, Switzerland, 2014; Volume 4. [Google Scholar] [CrossRef]

- Lott, P.; Deutschmann, O. Lean-burn natural gas engines: Challenges and concepts for an efficient exhaust gas aftertreatment system. Emiss. Control Sci. Technol. 2020, 7, 1–6. [Google Scholar] [CrossRef]

- Li, G.; Long, Y.; Zhang, Z.; Liang, J.; Zhang, X.; Zhang, X.; Wang, Z. Performance and emissions characteristics of a lean-burn marine natural gas engine with the addition of hydrogen-rich reformate. Int. J. Hydrogen Energy 2019, 44, 31544–31556. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Engine | – | 1-cyl., 4-valve, SI, TJI |

| Displacement | dm3 | 0.5107 |

| Bore × stroke | mm | 85 × 90 |

| Compression ratio | – | 14.5 |

| Fueling | – | Prechamber: EM injector Main chamber EM injector |

| Prechamber | – | 2.35 cm3 (5.93% of Vc) |

| Air system | – | Naturally aspirated |

| Property | Methane | Propane |

|---|---|---|

| Chemical formula | CH4 | C3H8 |

| Lower flammable limit [%] | 5 | 2.1 |

| Upper flammable limit [%] | 15.4 | 9.5 |

| Flammable range [%] | 10.4 | 7.4 |

| Risk index of explosion [−] | 2.0 | 3.524 |

| Minimum ignition energy [mJ] | 0.21–0.30 | 0.25–0.27 |

| Auto ignition temperature [°C] | 580 | 480 |

| Stoichiometric air/fuel ratio [−] | 17.19 | 15.67 |

| Adiabatic flame temperature [°C] | 1963 | 1980 |

| Laminar burning velocity [cm/s] | 37 | 39–43 |

| Lower heating value [MJ/kg] | 50.0 | 46.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pielecha, I.; Szwajca, F. Combustion of Lean Methane/Propane Mixtures with an Active Prechamber Engine in Terms of Various Fuel Distribution. Energies 2023, 16, 3608. https://doi.org/10.3390/en16083608

Pielecha I, Szwajca F. Combustion of Lean Methane/Propane Mixtures with an Active Prechamber Engine in Terms of Various Fuel Distribution. Energies. 2023; 16(8):3608. https://doi.org/10.3390/en16083608

Chicago/Turabian StylePielecha, Ireneusz, and Filip Szwajca. 2023. "Combustion of Lean Methane/Propane Mixtures with an Active Prechamber Engine in Terms of Various Fuel Distribution" Energies 16, no. 8: 3608. https://doi.org/10.3390/en16083608

APA StylePielecha, I., & Szwajca, F. (2023). Combustion of Lean Methane/Propane Mixtures with an Active Prechamber Engine in Terms of Various Fuel Distribution. Energies, 16(8), 3608. https://doi.org/10.3390/en16083608