1. Introduction

State of the art. The shortage of in fossil fuels and the increasing environmental challenges have increased the need for the development of electric cars as potential means of transportation and the adoption of different types of renewable energy sources (photovoltaic, wind, tidal, etc.) as primary sources of energy. The rapid integration of electric vehicles nowadays and the continuous increase in the number of photovoltaic (PV) installations pose a serious challenge to the electricity grid. This may lead to a lack of capacity to deliver peaks of energy when its required or a lack of capacity to store a surplus of solar energy when it is not needed. Currently, there are three levels of charging stations for electrical vehicles: AC level 1 (1–2 kW), AC level 2 (up to 19 kW) and higher-power DC level 3 (up to 300 kW). To accommodate these new trends, it may not be economically feasible to upgrade the grid’s infrastructure [

1]. A possible way to enable the high penetration of electrical vehicles while keeping the current infrastructure is to develop solar-powered charging stations with local battery storage. These solar chargers can also be used to enable the fast charging of electrical vehicles in single-phase households or establishments where the maximum installed power is 3.6 kW.

From the analysis of the current literature, it can be noted that a lot of researchers devote their resources to developing EV charging stations that use different types of renewable energy sources. Photovoltaic energy, being one type of energy that is easily accessible, is one of the most used types in developing renewable-energy charging stations and can be a feasible solution.

The work in [

2] presents an optimal power flow method to manage the energy flow in a PV-battery fast charging station for minimum operation cost. The main objective of the study is to help the penetration of PV-battery systems into the grid. The power management solution is based on a combination between particle swarm optimization and dynamic programing using an optimization cost function based on a combination of electricity grid prices and the battery degradation cost. The algorithm uses forecasted data to find the optimal power management solution.

In [

3], an intelligent energy management system for a grid-connected solar-powered charging station at the workplace is developed. The control strategy is based on Markov’s decision process. It accounts for PV availability, the loading of the grid and the EV charging load data, and controls the power flow between the batteries, PV generator, EV charging station and the grid.

The authors in [

4] develop a home photovoltaic system that integrates the EV battery as an energy store to mitigate the intermittency effects of solar energy. The paper proposes an energy management method to charge the EV battery but at the same time uses the EV battery as an energy storage system, reducing the unexpected peak power demand. This is intended to help and facilitate the implementation of vehicle-to-grid technologies.

In [

5], the authors present a performance study of a grid-connected photovoltaic system that uses battery storage and electrical vehicles connected to a gymnasium building. The proposed charging strategy in this study aims to minimize the peak power demand. It is reported by the authors that the peak grid power was reduced with 51.7%.

The authors in [

6] develop a PV-powered EV charging station with an intelligent energy management strategy. The system uses meteorological data and load statistics to optimize the power flow and managed to reduce the power demand peak by a factor of two.

In [

7,

8], the authors develop a charging station that uses a photovoltaic array, battery storage and a diesel generator. The generator is synchronized to the grid and is always operated at an 80–85% load to obtain optimal fuel efficiency. The charging station regulates the generator’s voltage and frequency without the need of a mechanical speed governor.

In [

9,

10], the authors develop intelligent control strategies for renewable energy microgrids based on artificial neural networks and on a multi-agent decentralized system. The algorithms were proven to be more resilient and more robust than the conventional centralized energy control systems were.

It can be observed that the main focus of the studies in the literature is on the development of different optimization algorithms implemented on different types of renewable energy chargers aimed at reducing the peak power demand or the cost of energy.

The paper is a continuation of the work presented in [

11]. Thus, it presents new research work which follows from the model developed and simulated before, as reported in [

11]. Making use of the previous theoretical background and simulation work, the model has evolved into a further optimized system design, which was developed for hardware implementation. Extensive experimental tests were carried out, which are reported in the paper, validating the novel charger design.

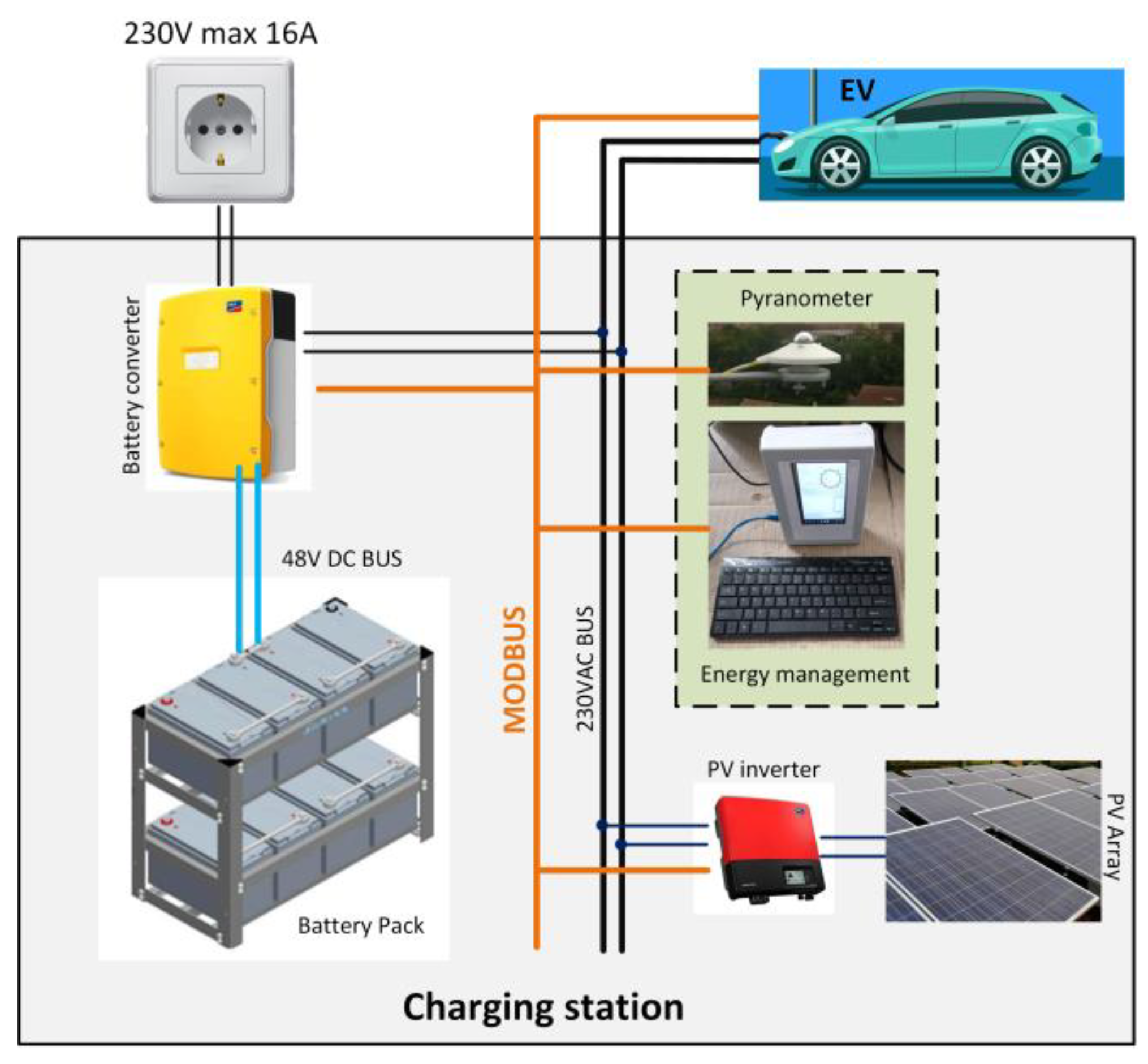

The charger is designed to use converters and inverters that are widely available on the market: Sunny Boy SB3600-TL (3.6 kW) as a solar inverter, Sunny Island as a battery inverter, both from SMA, twelve ET-Solar panels of 250 W, two strings of batteries connected in parallel, each string containing four VRLA 200 AH batteries connected in series for a 48V DC bus and a centralized management system which communicates with the converters through a RS485 network using the Modbus protocol. Sunny Island is the main component of the system. It manages the power flow in the battery charger microgrid based on a set of commands received from the management system. It also deals with the charging and discharging algorithms of the local battery pack. The proposed EV charger is presented in

Figure 1. The battery inverter has an auxiliary input that is used to connect the power outlet. In this way, the management system (EMS) can set the maximum power that can be extracted from the power outlet. As can be seen in

Figure 1, in the best-case scenario the charging power of the EV is the sum of the grid power, the solar power, and the power extracted from the local battery, providing in this situation much greater power than the outlet can provide, making fast charging possible in places where is not possible otherwise.

Figure 2 presents a timeframe of the operation of the proposed charger. It can be observed that the best-case scenario is from 11 o’clock to 16 o’clock. In this time interval, there is a possibility for the fast charging of the EV because there is maximum available solar energy, and the EV can be charged from the grid, local battery, and solar energy. When solar energy is not available, the EV can be charged from the grid and the local battery. The local battery must be recharged at some point.

This can be accomplished during the nighttime through the grid, or if there are no cars charging in the middle of the day then the local battery can be charged from the grid and from solar system.

Motivation. Due to the high integration of renewable energies, the electricity grid nowadays goes through important transformations from a “rigid” grid which involves the centralized generation of electric power, where the power is produced in a central location and then is distributed radially, to a dynamic “flexible” grid which involves decentralized energy production from renewable energy sources. Above all this, the increasing demand of electrical vehicles and their integration poses new challenges for the electricity grid. The electrical vehicle is no longer seen as a passive consumer connected to the grid but an active consumer that also can be used as a storage element connected to the grid.

Considering that the majority of consumers have access to a single-phase grid with a maximum installed power of 3.6 kW, there is a need to install a large number of charging station in order to accommodate the charging of a large number of electrical vehicles. Although it is better to charge EVs during nighttime, when the electricity consumption is low, there will always be consumers who need to charge their electrical cars during periods of time with peak electrical energy consumption. In this regard, there is a need to upgrade transport and distribution networks but this leads to high investment costs and leads to a capacity surplus during normal hours of operation and at night. Also, higher-power transformers are difficult and very expensive to replace. A change in the energy production paradigm is needed so EV charging stations can be coupled with intelligent microgrids that use renewable energies. Additional power generators can work in tandem with the grid to supply charging power to electrical vehicles.

The recent decrease in PV panel and inverter prices and government subsidies has led to the increased penetration of photovoltaic systems into the grid. This reinforces the idea that photovoltaic energy together with energy storage could be a good choice to supplement power to an EV charging station. Not many studies have been conducting on using photovoltaic energy to ease the integration of electrical vehicles into customer markets. The main advantages of this combination of PV–local and battery–grid to charge EVs could be a reduced energy demand from the grid during peak power consumption (peak energy shaving), lower electrical energy costs, the possibility of semi-fast charging where this function cannot be implemented otherwise, the possibility of V2H implementation, modularity (if other technologies become available and more affordable, consumers can easily update the system, adding more power or adding other types of renewable resources).

Considering all the above reasons, the paper proposes a charging station prototype that uses mainly off-the-shelf inverters. It is based on a battery converter which has the purpose of controlling power flow in the charging station’s coupled microgrid. Using this configuration, the energy management system (EMS,

Figure 1) sets the references values for the current extracted from the grid and the power extracted or delivered to the local battery. The solar system will provide the maximum power available. The maximum power charging the EV will be the sum of the solar power, the power provided from the local battery and the power provided by the grid, this being greater than the maximum allowable power from the grid, enabling semi-fast and fast charging modes for EVs.

Paper organization. The rest of the paper is organized as follows:

Section 2 presents the simulation model for the proposed EV charger;

Section 3 presents the test results and discussions. In the

Section 4, simulation and experimental results for each mode of operation are compared demonstrating that the experimental results confirmed the model and validated the proposed charger design. The

Section 5 draws the conclusions.