Electric Vehicles—An Overview of Current Issues—Part 1—Environmental Impact, Source of Energy, Recycling, and Second Life of Battery

Abstract

:1. Introduction

- Are EVs environmentally friendly over their entire life cycle?

- Can EVs be considered zero-emission vehicles?

- Can maximum efficiency be achieved while reclaiming the critical raw materials (CRMs) from spent EV batteries?

- Will solutions like ‘second-life batteries’ reduce the negative impact of EVs on the environment?

- The environmentally friendly electric vehicles assessment significantly depends on the emission assessment method used,

- A small share of renewable energy sources in the electricity production structure has a significant impact on the environmental friendliness of electric vehicles,

- Recycling of electric vehicle batteries should ensure maximum recovery of rare earth metals,

- There is a need to develop second-life solutions used on a global scale that will extend the life of electric vehicle batteries.

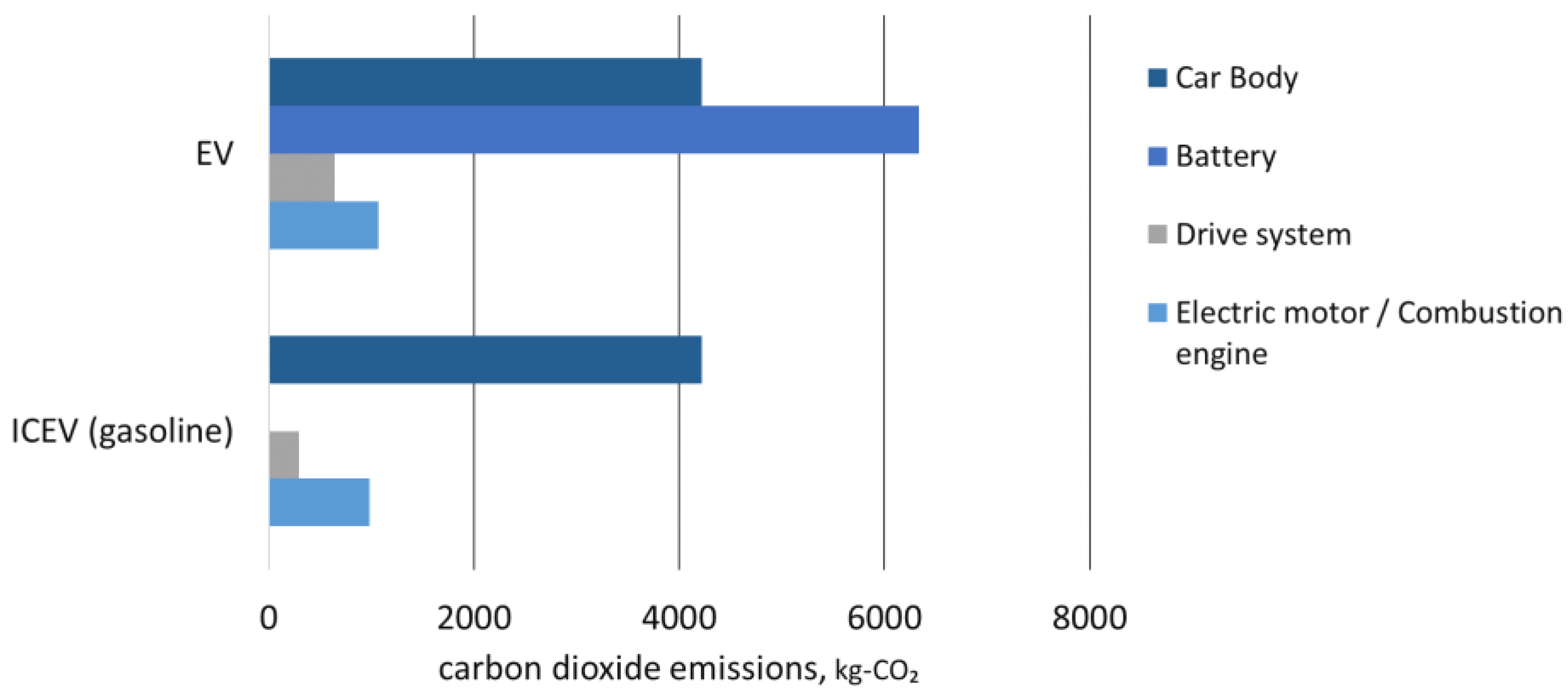

2. Assessment of the Environmental Impact of EVs

- Design stage;

- The manufacturing stage, which also includes the extraction of raw materials, the manufacture of components and parts;

- The stage of assembling the vehicle and transporting it to the storage facility or the end user;

- The operational phase, consisting of the use and maintenance of the vehicle;

- The disposal stage, including dismantling, sorting, partial reuse, recycling, or landfilling.

3. The Energy Mix

4. EV Battery Recycling and Second-Life

4.1. Selected EU Legal Regulations

4.2. Recycling

- Lithium compounds: 2–6%;

- Cobalt: 5–20%;

- Nickel: 5–15%;

- Copper: 3–10%;

- Aluminum: 1–5%;

- Iron: 1–5%;

- Manganese: 2–10%;

- Residue: graphite with flakes of iron, aluminum, and copper.

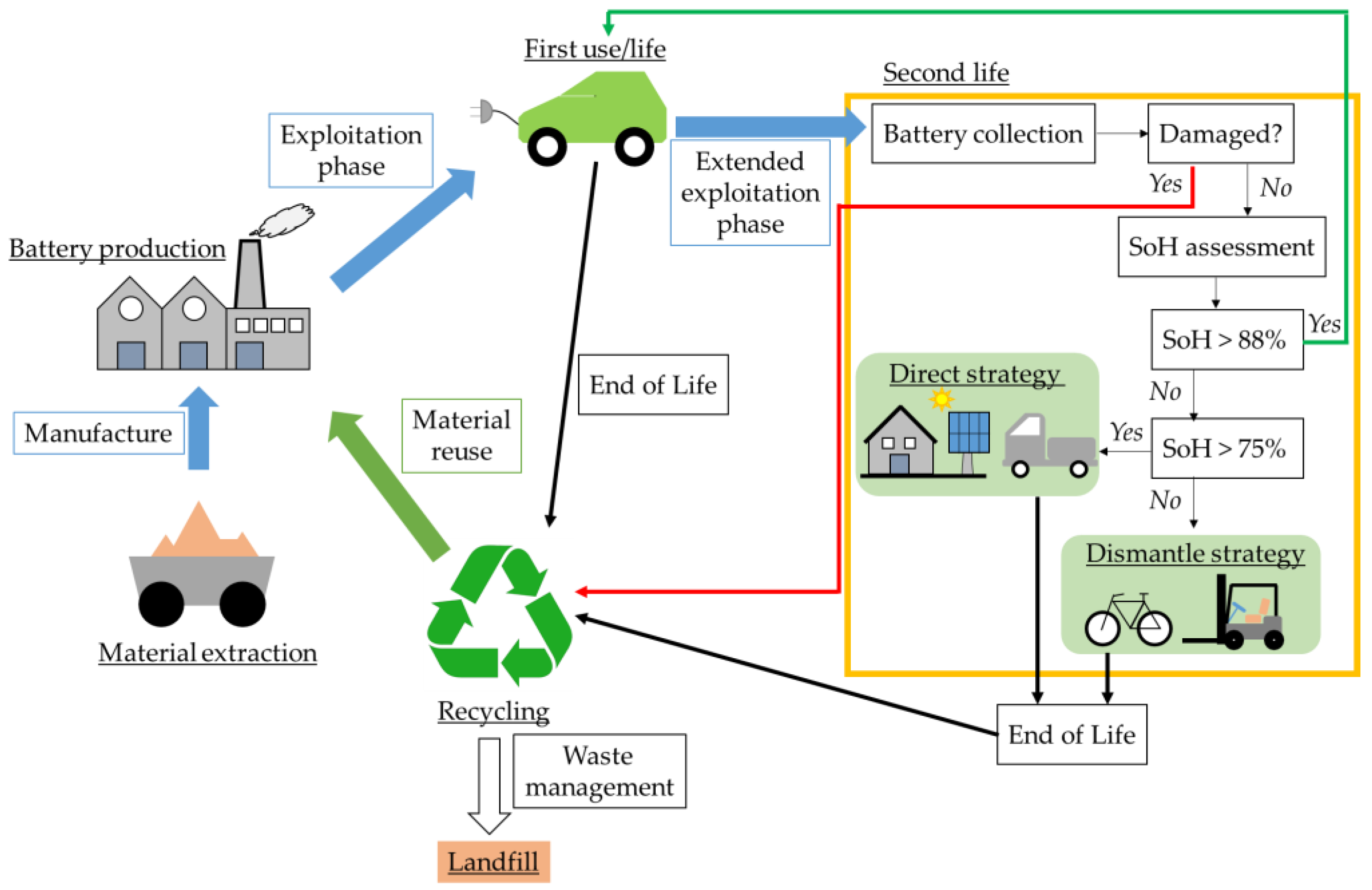

4.3. The Second Life of a Battery

- Extending the product’s service life;

- Avoiding waste generation;

- Re-use and second life;

- Recycling.

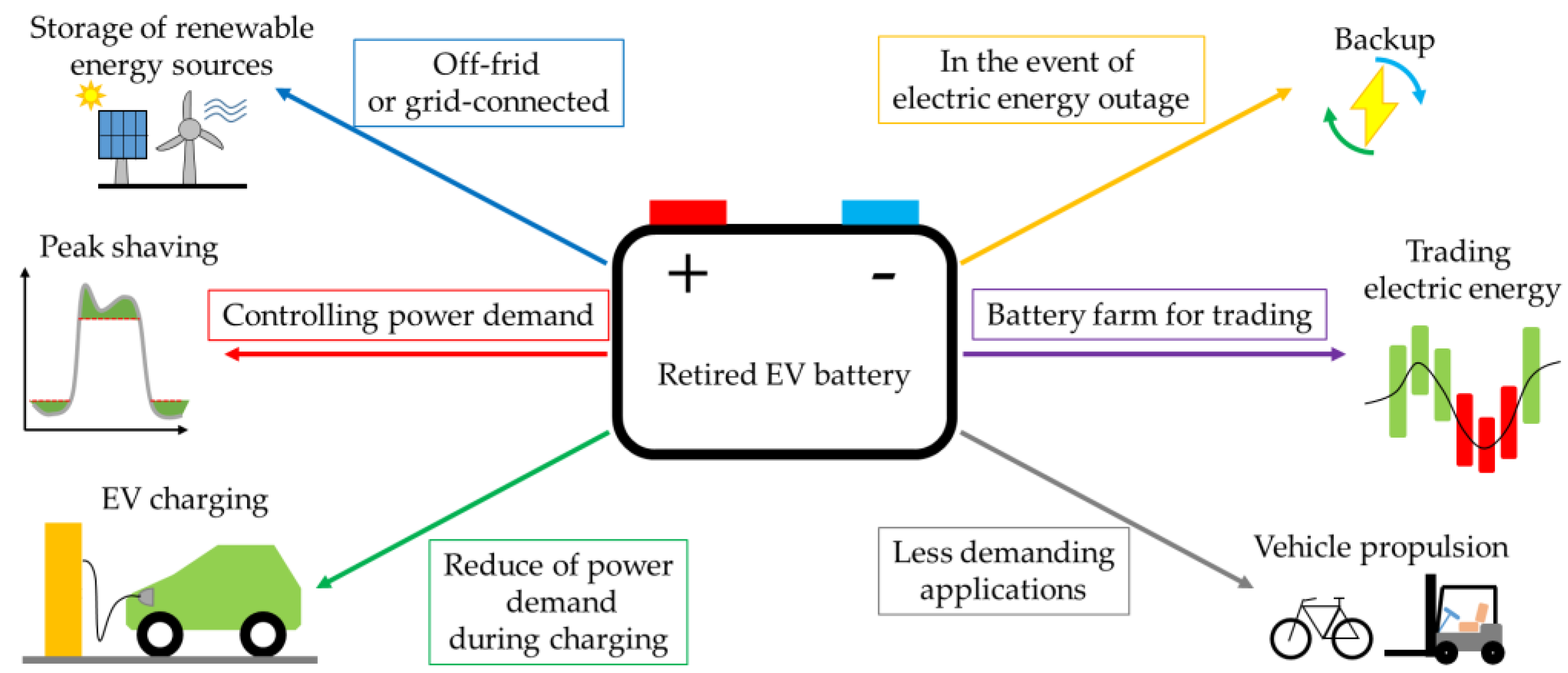

- Stationary storage applications of second-life batteries (electricity storage);

- Vehicle-to-grid (V2G), in which a battery remains in the vehicle and is used for energy storage to be returned to the grid.

- Direct reuse—lower costs, no or little adaptability to connect to other batteries;

- Battery dismantling to the module level—versatile reuse options; a new battery management system (BMS) and control systems need to be used;

- Battery dismantling to the cell level—most often implemented by regeneration companies, high versatility of applications, high costs (more labor-intensive processes), selection of cells depending on their SoH.

- 13 MWh energy storage installed at a recycling facility in Lünen (Germany) [107,108,109]—in 2015, Daimler AG, The Mobility House, GETEC, and REMONDIS started the 13 MWh battery storage project. The stationary storage unit is composed of over 1000 used batteries from electric vehicles The installation is the demonstrator of potential secondary use.

- Nissan Leaf batteries used for commercial distributed stationary energy storage systems [101,110,111,112]—in 2010; Nissan in cooperation with Sumitomo Corporation established 4R ENERGY Corporation (joint venture) to reuse battery packs from the Nissan Leaf for stationary storage systems. According to the companies, the second life of batteries is aimed at increasing sustainability and is referred to as “4R business” (Reuse, Refabricate, Resell, Recycle). In 2015, Nissan Motor Company and Green Charge Networks (commercial energy storage systems supplier) collaborated to implement commercial energy storage using second-life Nissan Leaf batteries. The first unit of this type was installed at a Nissan supplier to meet peak electricity demand.

- BMW and MINI batteries as mobile power units [113,114]—in 2020, BMW Group UK announced a cooperation with Off-Grid Energy. Retired BMW and MNI batteries, which can no longer efficiently be used in EVs, were adapted to create mobile power units. The first prototype unit has a 40 kWh capacity with a 7.2 kW fast charge.

- Chevrolet Volt batteries used as energy storage for lighting used at the GM’s Enterprise Data Center [115]—in 2015, GM released news about the retired Chevrolet Volt batteries provided electricity to help keep light in the building. The second-life battery application was included in the grid of renewable energy sources (two 2 kW wind turbines and a 74 kW solar array).

- Stationary energy storage based on Renault vehicle batteries [102,116]—in 2018, the Renault Group announced the launch of the stationary energy battery storage project called Advanced Battery Storage. The project is based on retired Renault Group electric vehicle batteries. The stationary energy battery storage acts as a buffer to help manage the discrepancy between the supply and demand of electric energy. The project is set to be deployed in Europe to reach a capacity of 70 MWh.

- Stationary energy storage based on Kia vehicle batteries [117]—automaker Kia and Deutsche Bahn (Germany’s rail and logistics company) have partnered to use retired Kia EV batteries to create efficient and cost-effective energy storage systems. The developed energy storage units are modular and can be used in many different applications, e.g., collecting surplus electricity from photovoltaic systems or, as part of a distributed system, supplying energy throughout the day to Deutsche Bahn depots where trains are prepared for operation. The first pilot project was launched at the EUREF Berlin campus in July 2022.

- The energy storage at EV recharging stations and buildings based on Volvo vehicle batteries [118]—Volvo Buses, in cooperation with Stena Property and BatteryLoop, have developed energy storage systems based on retired bus batteries used in charging stations and residential buildings. Batteries are used to store renewable energy for residential complexes, e.g., Fyrklövern in Gothenburg.

- Nissan Leaf batteries used for energy storage at Amsterdam ArenA [118]—the energy storage with a capacity of 4 MWh is used to provide appropriate support in crisis situations when events are taking place at the stadium. The storage is powered by renewable energy sources. Previously, diesel generators were used for this purpose.

- BMW i3 batteries as energy storage for renewable energy sources at the manufacturing site where this model is produced [118].

- No. 1—production and use of batteries in the vehicle and recycling of used batteries—Original Equipment Manufacturer (OEM) uses non-standard batteries (not regulated by external regulations). Used batteries after their first life are collected by dismantlers (cooperating with the OEM) and sent for recycling.

- No. 2—production and use of batteries in the vehicle and improved recycling—the recycler collects batteries from workshops or dismantling points. The recycling company uses an automated process to handle large volumes of used batteries.

- No. 3—production and use of batteries in a vehicle, repair and reuse in a vehicle, and recycling—after their first life, batteries are subjected to diagnostics (by the workshop worker) or dismantling to assess their condition and the possibility of reuse. In cooperation with the OEM, the battery is regenerated or repaired and then used in the same or other vehicle (with lower requirements). Batteries that cannot be repaired are sent for recycling.

- No. 4—production and the use of batteries in a vehicle, repair, and reuse in various applications, and recycling—after removing the battery from the vehicle, it is assessed in terms of condition and the possibility of its reuse. Unlike model no. 3, early diagnostics allows you to determine second-life applications, which allows you to reduce maintenance and transportation costs because the reclaimed battery goes to the right place.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zieliński, A. Samochody Osobowe. Dzieje Rozwoju; WKŁ: Warsaw, Poland, 2009. (In Polish) [Google Scholar]

- Zhou, J.; Feng, C.; Su, Q.; Jiang, S.; Fan, Z.; Ruan, J.; Sun, S.; Hu, L. The Multi-Objective Optimization of Powertrain Design and Energy Management Strategy for Fuel Cell-Battery Electric Vehicle. Sustainability 2022, 14, 6320. [Google Scholar] [CrossRef]

- Jia, C.; Zhou, J.; He, H.; Li, J.; Wei, Z.; Li, K.; Shi, M. A novel energy management strategy for hybrid electric bus with fuel cell health and battery thermal-and health-constrained awareness. Energy 2023, 271, 127105. [Google Scholar] [CrossRef]

- Jia, C.; Li, K.; He, H.; Zhou, J.; Li, J.; Wei, Z. Health-aware energy management strategy for fuel cell hybrid bus considering air-conditioning control based on TD3 algorithm. Energy 2023, 283, 128462. [Google Scholar] [CrossRef]

- Szumska, E.; Jurecki, R.; Pawełczyk, M. Evaluation of the use of hybrid electric powertrain system in urban traffic conditions. Eksploat. I Niezawodn.—Maint. Reliab. 2020, 22, 154–160. [Google Scholar] [CrossRef]

- Szumska, E.M.; Jurecki, R. The Analysis of Energy Recovered during the Braking of an Electric Vehicle in Different Driving Conditions. Energies 2022, 15, 9369. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- ISO 14044:2006; Environmental Management Life Cycle Assessment Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Farzaneh, F.; Jung, S. Lifecycle carbon footprint comparison between internal combustion engine versus electric transit vehicle: A case study in the US. J. Clean. Prod. 2023, 390, 136111. [Google Scholar] [CrossRef]

- Hung, C.R.; Völler, S.; Agez, M.; Majeau-Bettez, G.; Strømman, A.H. Regionalized climate footprints of battery electric vehicles in Europe. J. Clean. Prod. 2021, 322, 129052. [Google Scholar] [CrossRef]

- Morfeldt, J.; Kurland, S.D.; Johansson, D.J. Carbon footprint impacts of banning cars with internal combustion engines. Transp. Res. Part D Transp. Environ. 2021, 95, 102807. [Google Scholar] [CrossRef]

- Neugebauer, M.; Żebrowski, A.; Esmer, O. Cumulative Emissions of CO2 for Electric and Combustion Cars: A Case Study on Specific Models. Energies 2022, 15, 2703. [Google Scholar] [CrossRef]

- Qiao, Q.; Zhao, F.; Liu, Z.; Jiang, S.; Hao, H. Comparative study on life cycle CO2 emissions from the production of electric and conventional vehicles in China. Energy Procedia 2017, 105, 3584–3595. [Google Scholar] [CrossRef]

- Gan, Y.; Lu, Z.; Wu, Q.; He, X.; Dai, Q.; Kelly, J.C.; Anhathi, S.K.; Wang, M. Cradle-to-grave mercury emissions of light-duty gasoline and electric vehicles in China. Resources Conserv. Recycl. 2023, 190, 106736. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative environmental life cycle assessment of conventional and electric vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Jones, B.; Elliott, R.J.; Nguyen-Tien, V. The EV revolution: The road ahead for critical raw materials demand. Appl. Energy 2020, 280, 115072. [Google Scholar] [CrossRef] [PubMed]

- Jones, B.; Nguyen-Tien, V.; Elliott, R.J. The electric vehicle revolution: Critical material supply chains, trade and development. World Econ. 2023, 46, 2–26. [Google Scholar] [CrossRef]

- The Role of Critical Minerals in Clean Energy Transitions. Available online: https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions (accessed on 5 July 2023).

- Cimprich, A.; Bach, V.; Helbig, C.; Thorenz, A.; Schrijvers, D.; Sonnemann, G.; Young, S.B.; Sonderegger, T.; Berger, M. Raw material criticality assessment as a complement to environmental life cycle assessment: Examining methods for product-level supply risk assessment. J. Ind. Ecol. 2019, 23, 226–1236. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Gausen, O.M.; Strømman, A.H. Environmental impacts of hybrid and electric vehicles—A review. Int. J. Life Cycle Assess. 2012, 17, 997–1014. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.M.; Ljunggren Söderman, M.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—What can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Castro, M.B.G.; Remmerswaal, J.A.M.; Reuter, M.A. Life cycle impact assessment of the average passenger vehicle in the Netherlands. Int. J. LCA 2003, 8, 297–304. [Google Scholar] [CrossRef]

- Faria, R.; Marques, P.; Moura, P.; Freire, F.; Delgado, J.; De Almeida, A.T. Impact of the electricity mix and use profile in the life-cycle assessment of electric vehicles. Renew. Sustain. Energy Rev. 2013, 24, 271–287. [Google Scholar] [CrossRef]

- Shafique, M.; Azam, A.; Rafiq, M.; Luo, X. Life cycle assessment of electric vehicles and internal combustion engine vehicles: A case study of Hong Kong. Res. Transp. Econ. 2022, 91, 101112. [Google Scholar] [CrossRef]

- Yu, A.; Wei, Y.; Chen, W.; Peng, N.; Peng, L. Life cycle environmental impacts and carbon emissions: A case study of electric and gasoline vehicles in China. Transp. Res. Part D Transp. Environ. 2018, 65, 409–420. [Google Scholar] [CrossRef]

- Held, M.; Schücking, M. Utilization effects on battery electric vehicle life-cycle assessment: A case-driven analysis of two commercial mobility applications. Transp. Res. Part D Transp. Environ. 2019, 75, 87–105. [Google Scholar] [CrossRef]

- Messagie, M.; Boureima, F.-S.; Coosemans, T.; Macharis, C.; Mierlo, J.V. A Range-Based Vehicle Life Cycle Assessment Incorporating Variability in the Environmental Assessment of Different Vehicle Technologies and Fuels. Energies 2014, 7, 1467–1482. [Google Scholar] [CrossRef]

- Yue, K. Comparative analysis of scrap car recycling management policies. Procedia Environ. Sci. 2012, 16, 44–50. [Google Scholar] [CrossRef]

- Nakano, K.; Shibahara, N. Comparative assessment on greenhouse gas emissions of end-of-life vehicles recycling methods. J. Mater. Cycles Waste 2017, 19, 505–515. [Google Scholar] [CrossRef]

- Venkatesan, M.; Baskaran, R. An Inclusive and Effective End-of-Life Vehicle Recycling System in India: Balancing Economy and Ecology from Grave to Cradle. Iran. J. Chem. Chem. Eng. 2022, 41, 1501–1511. [Google Scholar]

- Ferrao, P.; Amaral, J. Assessing the economics of auto recycling activities in relation to European Union Directive on end of life vehicles. Technol. Forecast. Soc. Chang. 2006, 73, 277–289. [Google Scholar] [CrossRef]

- Fleischer, J.; Gerlitz, E.; Ries, S.; Coutandin, S.; Hofmann, J. Concepts and requirements for flexible disassembly systems for drive train components of electric vehicles. Procedia CIRP 2021, 98, 577–582. [Google Scholar] [CrossRef]

- Meng, K.; Xu, G.; Peng, X.; Youcef-Toumi, K.; Li, J. Intelligent disassembly of electric-vehicle batteries: A forward-looking overview. Resour. Conserv. Recycl. 2022, 182, 106207. [Google Scholar] [CrossRef]

- Ma, X.; Ma, Y.; Zhou, J.; Xiong, S. The recycling of spent power battery: Economic benefits and policy suggestions. IOP Conf. Ser. Earth Environ. Sci. 2018, 159, 012017. [Google Scholar] [CrossRef]

- Mohr, M.; Peters, J.F.; Baumann, M.; Weil, M. Toward a cell-chemistry specific life cycle assessment of lithium-ion battery recycling processes. J. Ind. Ecol. 2020, 24, 1310–1322. [Google Scholar] [CrossRef]

- Tarabay, B.; Milovanoff, A.; Abdul-Manan, A.F.; McKechnie, J.; MacLean, H.L.; Posen, I.D. New cathodes now. recycling later: Dynamic scenarios to reduce battery material use and greenhouse gas emissions from US light-duty electric vehicle fleet. Resour. Conserv. Recycl. 2023, 196, 107028. [Google Scholar] [CrossRef]

- Hao, H.; Qiao, Q.; Liu, Z.; Zhao, F. Impact of recycling on energy consumption and greenhouse gas emissions from electric vehicle production: The China 2025 case. Resour. Conserv. Recycl. 2017, 122, 114–125. [Google Scholar] [CrossRef]

- Kastanaki, E.; Giannis, A. Dynamic estimation of end-of-life electric vehicle batteries in the EU-27 considering reuse. remanufacturing and recycling options. J. Clean. Prod. 2023, 393, 136349. [Google Scholar] [CrossRef]

- Xu, C.; Dai, Q.; Gaines, L.; Hu, M.; Tukker, A.; Steubing, B. Future material demand for automotive lithium-based batteries. Commun. Mater. 2020, 1, 99. [Google Scholar] [CrossRef]

- Innovation/Innovation-Needs-in-the-Sustainable-Development-Scenario. Available online: https://www.iea.org/reports/clean-energy-innovation/innovation-needs-in-the-sustainable-development-scenario (accessed on 15 April 2023).

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Heymans, C.; Walker, S.B.; Young, S.B.; Fowler, M. Economic analysis of second use electric vehicle batteries for residential energy storage and load-levelling. Energy Policy 2014, 71, 22–30. [Google Scholar] [CrossRef]

- Picatoste, A.; Justel, D.; Mendoza, J.M.F. Circularity and life cycle environmental impact assessment of batteries for electric vehicles: Industrial challenges. Best practices and research guidelines. Renew. Sustain. Energy Rev. 2022, 169, 112941. [Google Scholar] [CrossRef]

- Bauer, C.; Hofer, J.; Althaus, H.J.; Del Duce, A.; Simons, A. The environmental performance of current and future passenger vehicles: Life cycle assessment based on a novel scenario analysis framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Naranjo, G.P.S.; Bolonio, D.; Ortega, M.F.; García-Martínez, M.J. Comparative life cycle assessment of conventional. Electric and hybrid passenger vehicles in Spain. J. Clean. Prod. 2021, 291, 125883. [Google Scholar] [CrossRef]

- Messagie, M. Life Cycle Analysis of the Climate Impact of Electric Vehicles. Available online: https://scholar.google.com/scholar_lookup?title=Life%20cycle%20analysis%20of%20the%20climate%20impact%20of%20electric%20vehicles&author=M.%20Messagie&publication_year=2017 (accessed on 2 May 2023).

- Bouter, A.; Hache, E.; Ternel, C.; Beauchet, S. Comparative environmental life cycle assessment of several powertrain types for cars and buses in France for two driving cycles: “Worldwide harmonized light vehicle test procedure” cycle and urban cycle. Int. J. Life Cycle Assess. 2020, 25, 1545–1565. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Sullivan, J.; Wang, M.Q. Impact of recycling on cradle-to-gate energy consumption and greenhouse gas emissions of automotive lithium-ion batteries. Environ. Sci. Technol. 2012, 46, 12704–12710. [Google Scholar] [CrossRef] [PubMed]

- Lei, C.; Aldous, I.; Hartley, J.M.; Thompson, D.L.; Scott, S.; Hanson, R.; Anderson, P.A.; Kendrick, E.; Sommerville, R.; Ryder, K.S.; et al. Lithium ion battery recycling using high-intensity ultrasonication. Green. Chem. 2021, 23, 4710–4715. [Google Scholar] [CrossRef]

- Leroutier, M.; Quirion, P. Air pollution and CO2 from daily mobility: Who emits and Why? Evidence from Paris. Energy Econ. 2022, 109, 105941. [Google Scholar] [CrossRef]

- Brand, C.; Boardman, B. Taming of the few—The unequal distribution of greenhouse gas emissions from personal travel in the UK. Energy Policy 2008, 36, 224–238. [Google Scholar] [CrossRef]

- Ko, J.; Park, D.; Lim, H.; Hwang, I.C. Who produces the most CO2 emissions for trips in the Seoul metropolis area? Transp. Res. Part D Transp. Environ. 2011, 16, 358–364. [Google Scholar] [CrossRef]

- Eurostat. Energy Sources. Available online: https://ec.europa.eu/eurostat/web/interactive-publications/energy-2023#energy-environment (accessed on 7 June 2023).

- Shrestha, A.; Mustafa, A.A.; Htike, M.M.; You, V.; Kakinaka, M. Evolution of energy mix in emerging countries: Modern renewable energy, traditional renewable energy, and non-renewable energy. Renew. Energy 2022, 199, 419–432. [Google Scholar] [CrossRef]

- Global Energy Review 2021. Electricity. Available online: https://www.iea.org/reports/global-energy-review-2021/electricity, (accessed on 20 July 2023).

- Díaz, A.; Marrero, G.A.; Puch, L.A.; Rodríguez, J. Economic growth. Energy intensity and the energy mix. Energy Econ. 2019, 81, 1056–1077. [Google Scholar] [CrossRef]

- Toonen, H.M.; Lindeboom, H.J. Dark green electricity comes from the sea: Capitalizing on ecological merits of offshore wind power? Renew. Sustain. Energy Rev. 2015, 42, 1023–1033. [Google Scholar] [CrossRef]

- Dai, H.; Mamkhezri, J.; Arshed, N.; Javaid, A.; Salem, S.; Khan, Y.A. Role of energy mix in determining climate change vulnerability in G7 countries. Sustainability 2022, 14, 2161. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Paramati, S.R.; Ozturk, I.; Bhattacharya, S. The effect of renewable energy consumption on economic growth: Evidence from top 38 countries. Appl. Energy 2016, 162, 733–741. [Google Scholar] [CrossRef]

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast) (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32018L2001 (accessed on 10 May 2023).

- Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en (accessed on 20 April 2023).

- Destek, M.A.; Aslan, A. Renewable and non-renewable energy consumption and economic growth in emerging economies: Evidence from bootstrap panel causality. Renew. Energy 2017, 111, 757–763. [Google Scholar] [CrossRef]

- Tan, X.; Sun, Q.; Wang, M.; Cheong, T.S.; Shum, W.Y.; Huang, J. Assessing the effects of emissions trading systems on energy consumption and energy mix. Appl. Energy 2022, 310, 118583. [Google Scholar] [CrossRef]

- Gambhir, A.; Napp, T.A.; Emmott, C.J.; Anandarajah, G. India’s CO2 emissions pathways to 2050: Energy system, economic and fossil fuel impacts with and without carbon permit trading. Energy 2014, 77, 791–801. [Google Scholar] [CrossRef]

- Marrero, G.A. Greenhouse gases emissions. growth and the energy mix in Europe. Energy Econ. 2010, 32, 1356–1363. [Google Scholar] [CrossRef]

- Müller, N.; Teixidó, J.J. The effect of the EU ETS free allowance allocation on energy mix diversification: The case of Poland’s power sector. Clim. Policy 2021, 21, 804–822. [Google Scholar] [CrossRef]

- Martins, F.; Felgueiras, C.; Smitková, M. Fossil fuel energy consumption in European countries. Energy Procedia 2018, 153, 107–111. [Google Scholar] [CrossRef]

- Michalak, A.; Wolniak, R. The innovativeness of the country and the renewables and non-renewables in the Energy mix on the example of European Union. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100061. [Google Scholar] [CrossRef]

- Eurostat. Energy Environment. Energy 2023. Available online: https://ec.europa.eu/eurostat/web/interactive-publications/energy-2023 (accessed on 2 July 2023).

- Czaplicka-Kolarz, K.; Pyka, I. Miks energetyczny w Unii Europejskiej do 2030 r.-rola paliw rodzimych (Energy mix in the European Union until 2030—The role of domestic fuels). Gór. Geoinż. 2007, 31, 171–178. (In Polish) [Google Scholar]

- Said, Z.; Alshehhi, A.A.; Mehmood, A. Predictions of UAE’s renewable energy mix in 2030. Renew. Energy 2018, 118, 779–789. [Google Scholar] [CrossRef]

- Total Energy Supply (TES) by Source, People’s Republic of China 1990–2020, World Energy Balances 2022. Available online: https://www.iea.org/data-and-statistics/data-product/world-energy-statistics-and-balances (accessed on 30 September 2023).

- Energy Production and Consumption in the United States 2021. Available online: https://www.e-education.psu.edu/ebf301/node/457 (accessed on 1 October 2023).

- 2022 Share of Electricity from Renewable Energy Sources in Japan (Preliminary). Available online: https://energytracker.asia/the-energy-mix-review-in-japan-a-glimpse-of-the-future/ (accessed on 1 October 2023).

- U.S Energy Information Administration, EXECUTIVE SUMMARY. Available online: https://www.eia.gov/international/analysis/country/IND (accessed on 1 October 2023).

- Mi, Z.; Sun, X. Provinces with transitions in industrial structure and energy mix performed best in climate change mitigation in China. Commun. Earth Environ. 2021, 2, 182. [Google Scholar] [CrossRef]

- Baležentis, T.; Štreimikienė, D. Sustainability in the electricity sector through advanced technologies: Energy mix transition and smart grid technology in China. Energies 2019, 12, 1142. [Google Scholar] [CrossRef]

- Hossain, M.R.; Rana, M.J.; Saha, S.M.; Haseeb, M.; Islam, M.S.; Amin, M.R.; Hossain, M.E. Role of energy mix and eco-innovation in achieving environmental sustainability in the USA using the dynamic ARDL approach: Accounting the supply side of the ecosystem. Renew. Energy 2023, 118925. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Selvamanohar, L.; Raju, K.; Rajan Vijayaraghavan, R.; Subburaj, R.; Nurunnabi, M.; Khan, I.A.; Afridhis, S.; Hariharan, A.; Pugazhendhi, R.; et al. A holistic review of the present and future drivers of the renewable energy mix in Maharashtra, State of India. Sustainability 2020, 12, 6596. [Google Scholar] [CrossRef]

- Wójcik, M.; Pawłowska, B.; Stachowicz, F. Przegląd technologii recyklingu zużytych akumulatorów litowo-jonowych (Overview of recycling technologies for used lithium-ion batteries). Zesz. Nauk. Politech. Rzesz. 2017, 89, 107–120. (In Polish) [Google Scholar]

- Abdel-Monem, M.; Hegazy, O.; Omar, N.; Trad, K.; Van den Bossche, P.; Van Mierlo, J. Lithium-ion Batteries: Comprehensive Technical Analysis of Second-Life Batteries for Smart Grid Applications. In Proceedings of the 19th European Conference on Power Electronics and Applications, Warsaw, Poland, 11–14 September 2017. [Google Scholar] [CrossRef]

- Pražanová, A.; Knap, V.; Stroe, D.-I. Literature Review. Recycling of Lithium-Ion Batteries from Electric Vehicles. Part I: Recycling Technology. Energies 2022, 15, 1086. [Google Scholar] [CrossRef]

- Wojciechowski, A.; Łukasik, Z. Recykling pojazdów elektrycznych i hybrydowych (Recycling of electric and hybrid vehicles). Logistyka 2014, 6, 11268–11277. (In Polish) [Google Scholar]

- Re-Use. Recycling and Recovery of Vehicle Parts and Materials. Available online: https://eur-lex.europa.eu/EN/legal-content/summary/re-use-recycling-and-recovery-of-vehicle-parts-and-materials.html (accessed on 16 June 2023).

- Zrównoważone Dostawy Surowców Krytycznych Kluczowych dla Przemysłu UE (Sustainable Supply of Critical Raw Materials Key to EU Industry). Available online: https://www.europarl.europa.eu/news/pl/headlines/society/20211118STO17611/zrownowazone-dostawy-surowcow-krytycznych-kluczowych-dla-przemyslu-ue?at_campaign=20234-Economy&at_medium=Google_Ads&at_platform=Search&at_creation=DSA&at_goal=TR_G&at_audience=&at_topic=Raw_batteries&gclid=EAIaIQobChMIrbWmidPH_wIVXAqiAx2TyAdREAAYASAAEgKp6_D_BwE (accessed on 16 June 2023). (In Polish).

- Surowce Strategiczne i Krytyczne Dla Polski i UE (Strategic and Critical Raw Materials for Poland and the EU). Available online: https://www.gov.pl/web/klimat/surowce-strategiczne-i-krytyczne-dla-polski-i-ue (accessed on 16 June 2023). (In Polish)

- Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC (Consolidated Text). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02006L0066-20180704 (accessed on 16 June 2023).

- Communication from the Commission to the European Parliament. The Council. The European Economic and Social Committee and the Committee of the Regions a New Circular Economy Action Plan for a Cleaner and More Competitive Europe. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF (accessed on 16 June 2023).

- Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and waste batteries. Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020PC0798&qid=1608192505371 (accessed on 16 June 2023).

- Łukasik, Z.; Wojciechowski, A. Odzysk materiałowy z części i podzespołów z samochodów EV i HEV wycofanych z eksploatacji (Material recovery from parts and components from end-of-life EVs and HEVs). Elektronika 2015, 4, 63–68. (In Polish) [Google Scholar] [CrossRef]

- Gola-Sienkiewicz, R. Recykling aut elektrycznych i hybrydowych Cz. I (Recycling of electric and hybrid car. Part 1). Recykling 2013, 11, 24–25. (In Polish) [Google Scholar]

- Kotak, Y.; Marchante Fernández, C.; Canals Casals, L.; Kotak, B.S.; Koch, D.; Geisbauer, C.; Trilla, L.; Gómez-Núñez, A.; Schweiger, H.-G. End of Electric Vehicle Batteries: Reuse vs. Recycle. Energies 2021, 14, 2217. [Google Scholar] [CrossRef]

- Batteries for Electric Vehicles. Available online: https://afdc.energy.gov/vehicles/electric_batteries.html (accessed on 21 June 2023).

- Kaminska, S.; Pawlak, P. Analiza ekobilansowa recyklingu zużytych litowo-jonowych akumulatorów samochodowych w technologii Retriev (The ecobalance analysis of the Retriev recycling technology of used car Lithium-ion batteries). Mater. Econ. Logist. J. 2020, 11, 35–44. (In Polish) [Google Scholar] [CrossRef]

- Sonoc, A.; Jeswiet, J.; Soo, V.K. Opportunities to Improve Recycling of Automotive Lithium Ion Batteries. Procedia CIRP 2015, 29, 752–757. [Google Scholar] [CrossRef]

- Duesenfeld Recycling. Available online: https://www.duesenfeld.com/recycling_en.html] (accessed on 22 June 2023).

- What Exactly Is Lithium Battery ‘Black Mass’? Available online: https://aquametals.com/recyclopedia/what-exactly-is-black-mass/ (accessed on 22 June 2023).

- How Are Lithium-Ion Batteries Recycled? Available online: https://aquametals.com/recyclopedia/how-are-lithium-ion-batteries-recycled/ (accessed on 23 June 2023).

- Batteries Europe European Technology and Innovation Platform WG2: Raw Materials and Recycling Roadmap. Available online: https://batterieseurope.eu/wp-content/uploads/2022/09/Roadmap-on-raw-materials-and-recycling-roadmap_WG2.pdf (accessed on 27 June 2023).

- McKinsey & Company. Second-Life EV Batteries: The Newest Value Pool in Energy Storage. Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Automotive%20and%20Assembly/Our%20Insights/Second%20life%20EV%20batteries%20The%20newest%20value%20pool%20in%20energy%20storage/Second-life-EV-batteries-The-newest-value-pool-in-energy-storage.ashx (accessed on 28 June 2023).

- Wood, E.; Alexander, M.; Bradley, T.H. Investigation of battery end-of-life conditions for plug-in hybrid electric vehicles. J. Power Sources 2011, 196, 5147–5154. [Google Scholar] [CrossRef]

- USABC Electric Vehicle Battery Test Procedures Manual Revision 2. 1996. Idaho National Engineering Laboratory. The US. Department of Energy Idaho Field Office. Available online: https://digital.library.unt.edu/ark:/67531/metadc666152/m2/1/high_res_d/214312.pdf (accessed on 28 June 2023).

- Canals Casals, L.; Etxandi-Santolaya, M.; Bibiloni-Mulet, P.A.; Corchero, C.; Trilla, L. Electric Vehicle Battery Health Expected at End of Life in the Upcoming Years Based on UK Data. Batteries 2022, 8, 164. [Google Scholar] [CrossRef]

- Canals Casals, L.; García, B.A.; Cremades, L.V. Electric Vehicle Battery Reuse: Preparing for a Second Life. J. Ind. Eng. Manag. 2017, 10, 266–285. [Google Scholar] [CrossRef]

- Olsson, L.; Fallahi, S.; Schnurr, M.; Diener, D.; Van Loon, P. Circular Business Models for Extended EV Battery Life. Batteries 2018, 4, 57. [Google Scholar] [CrossRef]

- Automakers on Second-Life Batteries for the Grid: ‘We Want a Foot in the Door of This Market’. Available online: https://www.greentechmedia.com/articles/read/automakers-on-second-life-batteries-for-the-grid-we-want-a-foot-in-the-do (accessed on 28 June 2023).

- Germany: 13 MWh “Second Use” Battery Storage Project. Available online: https://www.pv-magazine.com/2015/11/04/germany-13-mwh-second-use-battery-storage-project_100021846/ (accessed on 28 June 2023).

- Energy Storage: 13 MWh Second-Use Battery for Grid Stabilization in Lünen. Available online: https://www.pveurope.eu/solar-storage/energy-storage-13-mwh-second-use-battery-grid-stabilization-luenen (accessed on 28 June 2023).

- Nissan. Green Charge Networks Turn ‘Second-Life’ EV Batteries into Grid Storage Business. Available online: https://www.greentechmedia.com/articles/read/nissan-green-charge-networks-turn-second-life-ev-batteries-into-grid-storag (accessed on 28 June 2023).

- Nissan and 4R Energy Partner with Green Charge Networks for Commercial Energy Storage Featuring Second-Life Electric Vehicle Batteries. Available online: https://usa.nissannews.com/en-US/releases/nissan-and-4r-energy-partner-with-green-charge-networks-for-commercial-energy-storage-featuring-second-life-electric-vehicle-batteries?selectedTabId=releases# (accessed on 28 June 2023).

- ABB. Nissan to Test Leaf Batteries for Community Storage. Available online: https://www.greentechmedia.com/articles/read/abb-nissan-to-test-leaf-batteries-for-community-storage1 (accessed on 28 June 2023).

- BMW Group UK Second-Life Battery Solution in Partnership with off Grid Energy. Available online: https://www.press.bmwgroup.com/united-kingdom/article/detail/T0318650EN_GB/bmw-group-uk-second-life-battery-solution-in-partnership-with-off-grid-energy?language=en_GB (accessed on 28 June 2023).

- BMW and Mini Batteries to Get Second Life as Mobile Power Units. Available online: https://fleetworld.co.uk/bmw-and-mini-batteries-to-get-second-life-as-mobile-power-units/ (accessed on 28 June 2023).

- Chevy. Nissan Reveal Second-Life Uses for Electric-Car Batteries. Available online: https://www.greencarreports.com/news/1098734_chevy-nissan-reveal-second-life-uses-for-electric-car-batteries (accessed on 28 June 2023).

- Stationary Energy Battery Storage: Three New Projects in Europe. Available online: https://events.renaultgroup.com/en/2022/01/27/stationary-energy-battery-storage-three-new-projects-in-europe/ (accessed on 28 June 2023).

- DB i Kia Dadzą Drugie Życie Zużytym Akumulatorom Samochodów Elektrycznych. Available online: https://motofocus.pl/po-godzinach/106630/db-i-kia-dadza-drugie-zycie-zuzytym-akumulatorom-samochodow-elektrycznych (accessed on 28 June 2023). (In Polish).

- Drugie i Trzecie Życie Baterii z Elektrycznych Samochodów i Autobusów. Available online: https://businessinsider.com.pl/technologie/nowe-technologie/co-sie-dzieje-ze-zuzytymi-bateriami-z-samochodow-elektrycznych-i-autobusow/63wg6gm (accessed on 28 June 2023). (In Polish).

- Jiao, N.; Evans, S. Business Models for Sustainability: The Case of Second-Life Electric Vehicle Batteries. Procedia CIRP 2016, 40, 250–255. [Google Scholar] [CrossRef]

- Cao, J.; Chen, X.; Qiu, R.; Hou, S. Electric vehicle industry sustainable development with a stakeholder engagement system. Technol. Soc. 2021, 67, 101771. [Google Scholar] [CrossRef]

- Ma, Y.; Shi, T.; Zhang, W.; Hao, Y.; Huang, J.; Lin, Y. Comprehensive policy evaluation of NEV development in China, Japan, the United States, and Germany based on the AHP-EW model. J. Clean. Prod. 2019, 214, 389–402. [Google Scholar] [CrossRef]

- Li, W.; Yang, M.; Sandu, S. Electric vehicles in China: A review of current policies. Energy Environ. 2018, 29, 1512–1524. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, L. Can the development of electric vehicles reduce the emission of air pollutants and greenhouse gases in developing countries? Transp. Res. Part D Transp. Environ. 2017, 51, 129–145. [Google Scholar] [CrossRef]

| Nickel–Metal Hydride Battery (NI-MH) | Lithium–Ion Battery (Li-Ion) |

|---|---|

| |

|

|

| Pyrometallurgy | Hydrometallurgy | |

|---|---|---|

| Advantages |

| |

|

| |

| Disadvantages |

|

|

| Method Used | Process/Company Name | State |

|---|---|---|

| Pyrometallurgical, hydrometallurgical | Umicore | Belgium |

| Mechanical | uRecycle | Sweden |

| Electro-hydrometallurgical | AquaMetals | USA |

| Hydrometallurgical | Valibat | France |

| Hydrometallurgical | Brunp | China |

| Mechanical, Hydrometallurgical | Duesenfeld | Germany |

| Mechanical, Hydrometallurgical | Retriev | Canada, USA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzek, M.; Jackowski, J.; Jurecki, R.S.; Szumska, E.M.; Zdanowicz, P.; Żmuda, M. Electric Vehicles—An Overview of Current Issues—Part 1—Environmental Impact, Source of Energy, Recycling, and Second Life of Battery. Energies 2024, 17, 249. https://doi.org/10.3390/en17010249

Guzek M, Jackowski J, Jurecki RS, Szumska EM, Zdanowicz P, Żmuda M. Electric Vehicles—An Overview of Current Issues—Part 1—Environmental Impact, Source of Energy, Recycling, and Second Life of Battery. Energies. 2024; 17(1):249. https://doi.org/10.3390/en17010249

Chicago/Turabian StyleGuzek, Marek, Jerzy Jackowski, Rafał S. Jurecki, Emilia M. Szumska, Piotr Zdanowicz, and Marcin Żmuda. 2024. "Electric Vehicles—An Overview of Current Issues—Part 1—Environmental Impact, Source of Energy, Recycling, and Second Life of Battery" Energies 17, no. 1: 249. https://doi.org/10.3390/en17010249

APA StyleGuzek, M., Jackowski, J., Jurecki, R. S., Szumska, E. M., Zdanowicz, P., & Żmuda, M. (2024). Electric Vehicles—An Overview of Current Issues—Part 1—Environmental Impact, Source of Energy, Recycling, and Second Life of Battery. Energies, 17(1), 249. https://doi.org/10.3390/en17010249