Life Cycle Assessment of Energy Production from Solid Waste Valorization and Wastewater Purification: A Case Study of Meat Processing Industry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal

2.2. … and Scope

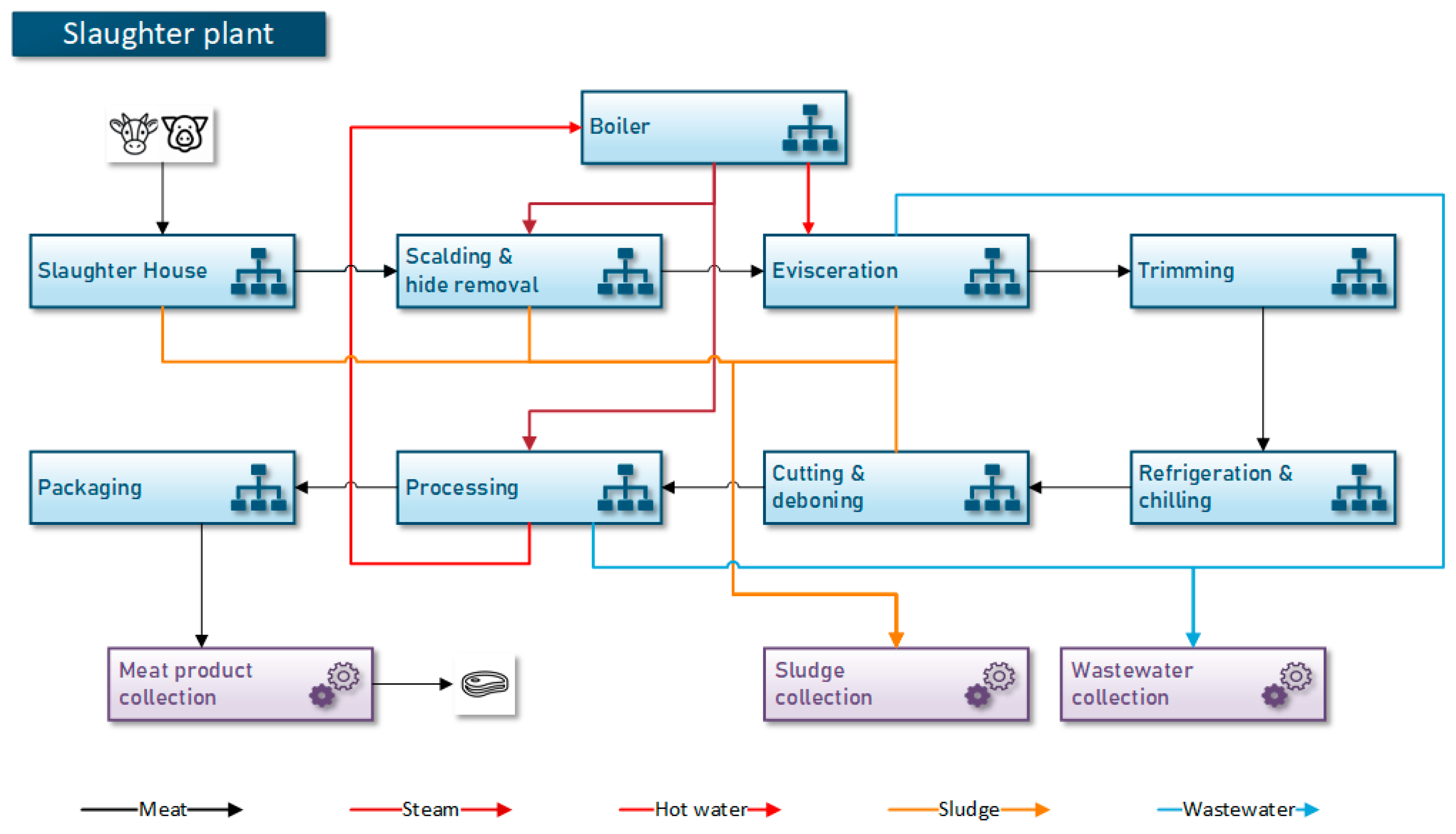

2.2.1. Product System

- Slaughter house;

- Scalding and hide removal;

- Evisceration;

- Trimming;

- Refrigeration and chilling;

- Cutting and deboning;

- Processing;

- Packaging of the final products.

2.2.2. Functional Unit

2.2.3. System Boundaries

2.2.4. Data Requirements

2.2.5. Assumptions and Limitations

2.3. Life Cycle Inventory

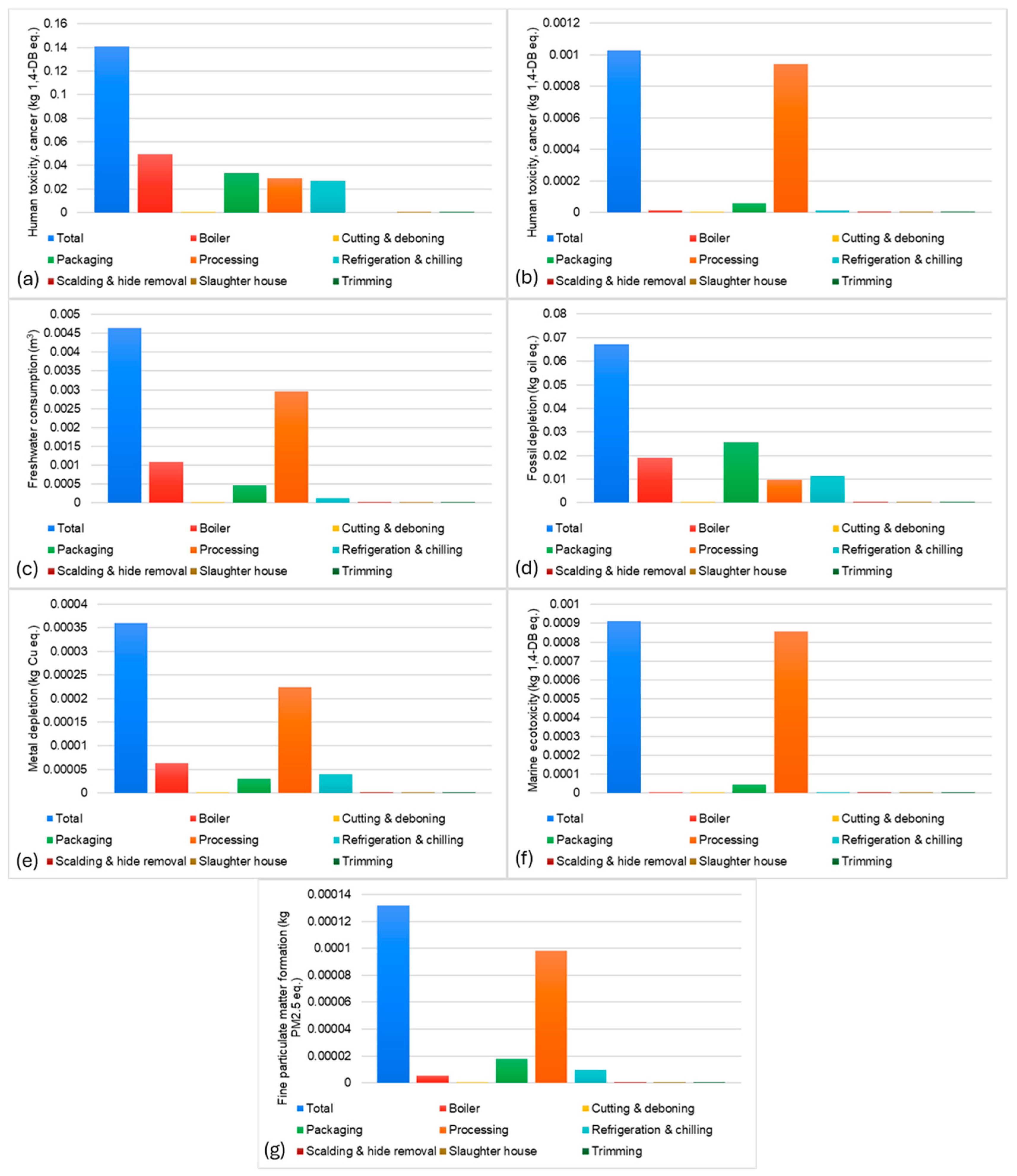

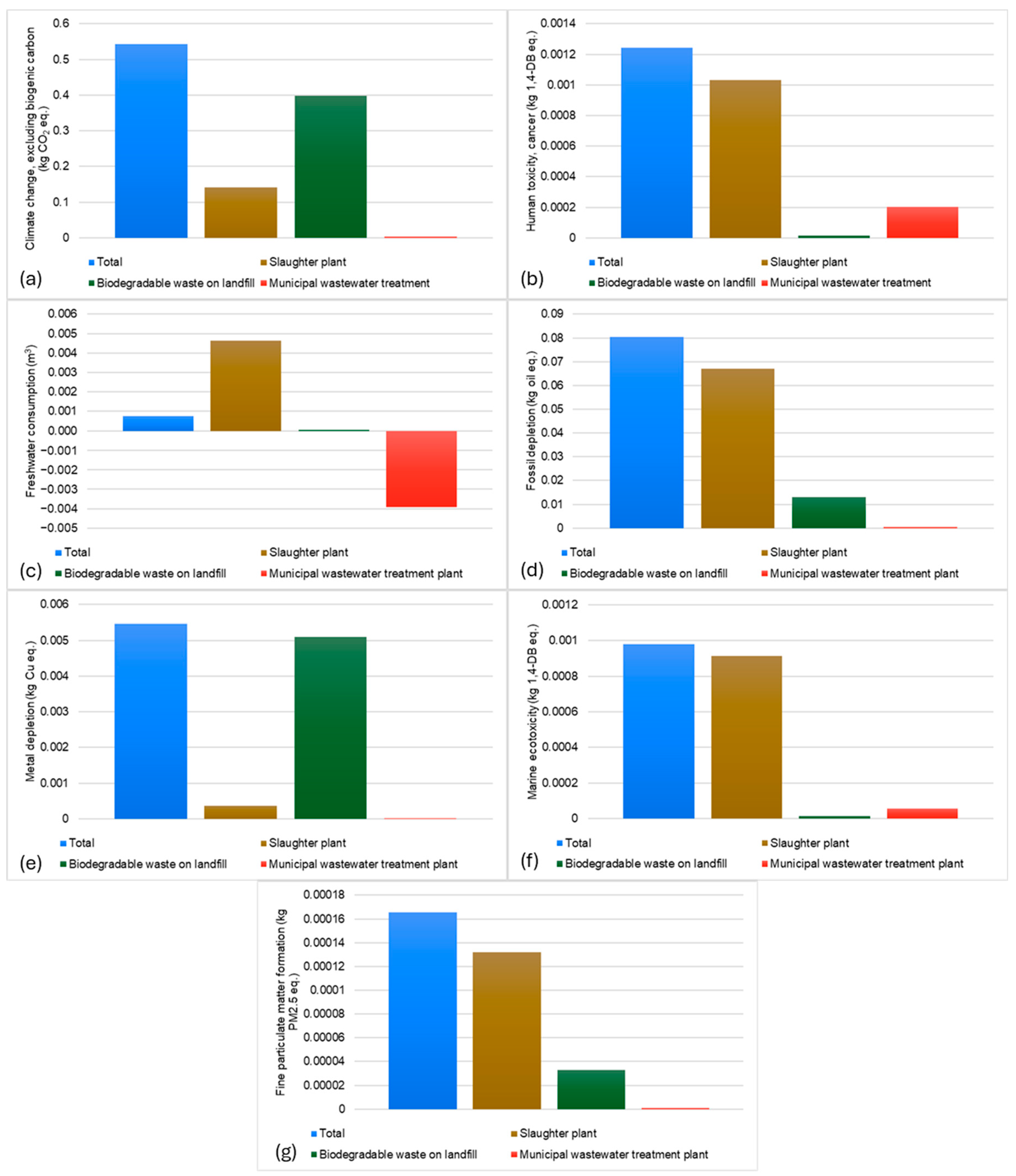

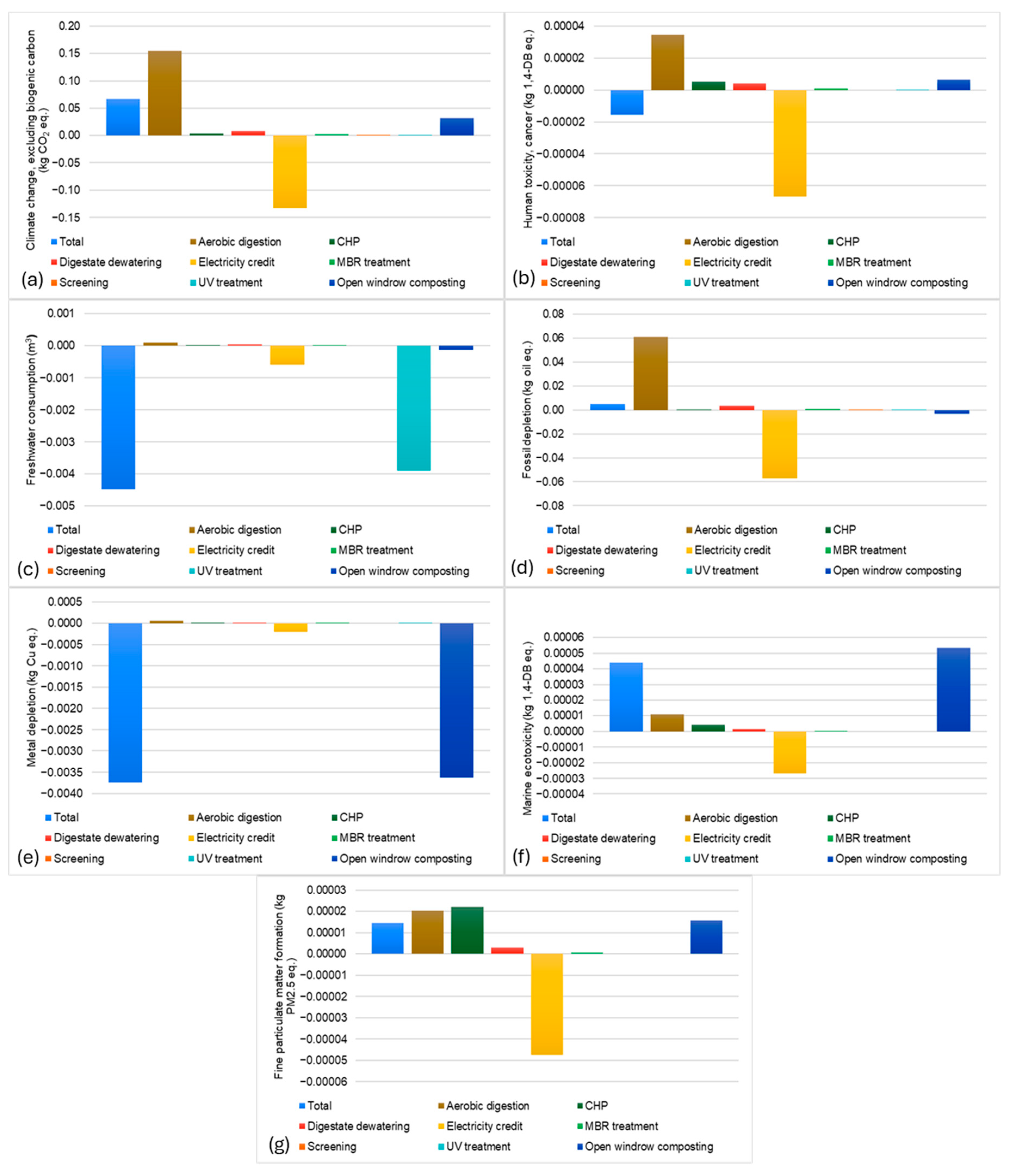

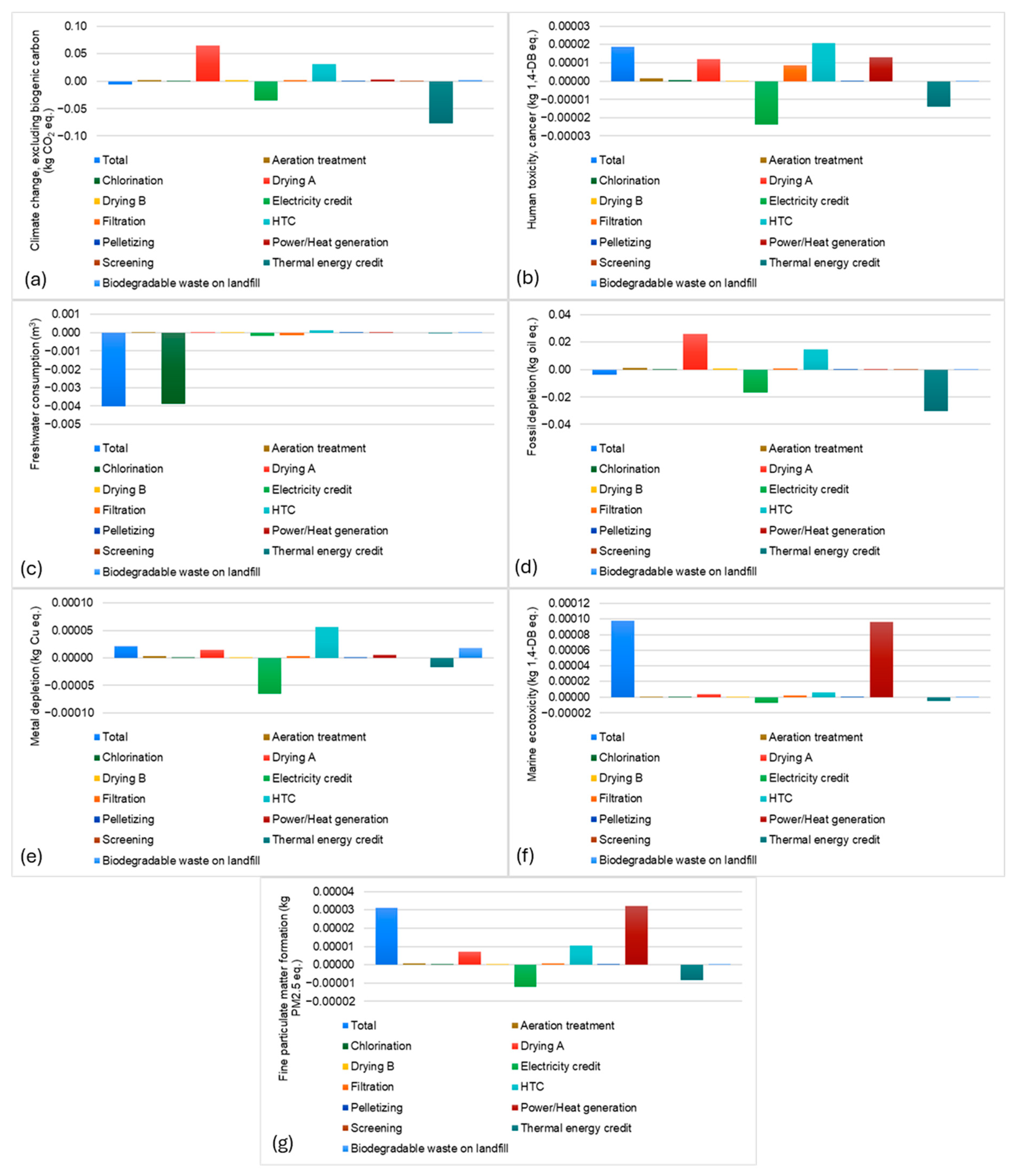

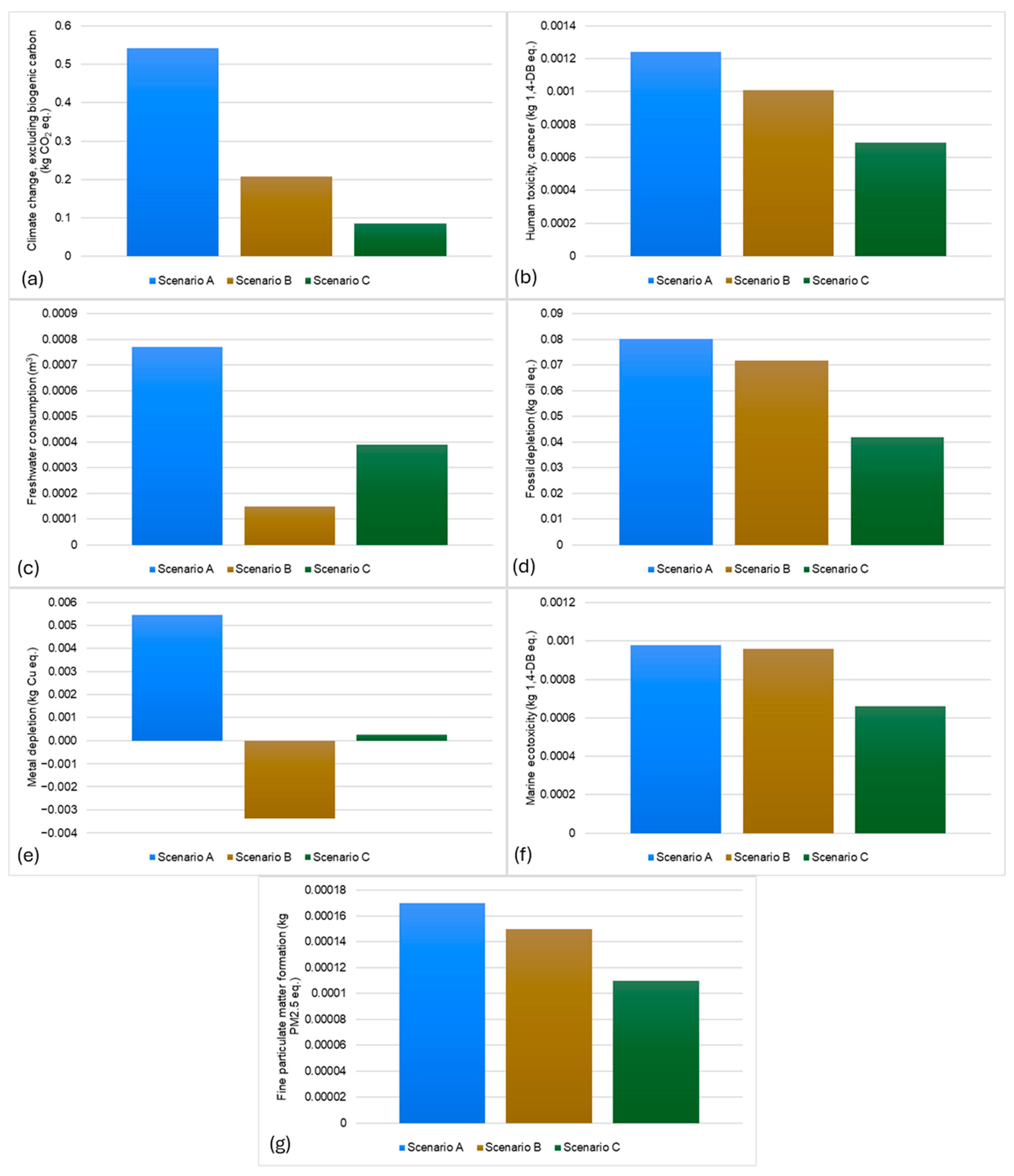

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baker, P.; Machado, P.; Santos, T.; Sievert, K.; Backholer, K.; Hadjikakou, M.; Russell, C.; Huse, O.; Bell, C.; Scrinis, G.; et al. Ultra-Processed Foods and the Nutrition Transition: Global, Regional and National Trends, Food Systems Transformations and Political Economy Drivers. Obes. Rev. 2020, 21, e13126. [Google Scholar] [CrossRef] [PubMed]

- Djekic, I. Environmental Impact of Meat Industry—Current Status and Future Perspectives. Procedia Food Sci. 2015, 5, 61–64. [Google Scholar] [CrossRef]

- Sayeed, R.; Tiwari, P. Wealth from Meat Industry By-Products and Waste: A Review. In Sustainable Food Waste Management: Concepts and Innovations; Thakur, M., Modi, V.K., Khedkar, R., Singh, K., Eds.; Springer: Singapore, 2020; pp. 191–208. ISBN 978-981-15-8967-6. [Google Scholar]

- Al-Asheh, S.; Bagheri, M.; Aidan, A. Membrane Bioreactor for Wastewater Treatment: A Review. Case Stud. Chem. Environ. Eng. 2021, 4, 100109. [Google Scholar] [CrossRef]

- Skouteris, G.; Rodriguez-Garcia, G.; Reinecke, S.F.; Hampel, U. The Use of Pure Oxygen for Aeration in Aerobic Wastewater Treatment: A Review of Its Potential and Limitations. Bioresour. Technol. 2020, 312, 123595. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, H.; Gao, Y.; Yue, Q.; Gao, B.; Liu, B.; Guo, K.; Xu, X. Pilot-Scale Advanced Treatment of Actual High-Salt Textile Wastewater by a UV/O3 Pressurization Process: Evaluation of Removal Kinetics and Reverse Osmosis Desalination Process. Sci. Total Environ. 2023, 857, 159725. [Google Scholar] [CrossRef] [PubMed]

- Mazhar, M.A.; Khan, N.A.; Ahmed, S.; Khan, A.H.; Hussain, A.; Rahisuddin; Changani, F.; Yousefi, M.; Ahmadi, S.; Vambol, V. Chlorination Disinfection By-Products in Municipal Drinking Water—A Review. J. Clean. Prod. 2020, 273, 123159. [Google Scholar] [CrossRef]

- Gopal, P.M.; Sivaram, N.M.; Barik, D. Chapter 7—Paper Industry Wastes and Energy Generation from Wastes. In Energy from Toxic Organic Waste for Heat and Power Generation; Barik, D., Ed.; Woodhead Publishing: Sawston, UK, 2019; pp. 83–97. ISBN 978-0-08-102528-4. [Google Scholar]

- Salman, C.A.; Schwede, S.; Naqvi, M.; Thorin, E.; Yan, J. Synergistic Combination of Pyrolysis, Anaerobic Digestion, and CHP Plants. Energy Procedia 2019, 158, 1323–1329. [Google Scholar] [CrossRef]

- Shi, L.; Simplicio, W.S.; Wu, G.; Hu, Z.; Hu, H.; Zhan, X. Nutrient Recovery from Digestate of Anaerobic Digestion of Livestock Manure: A Review. Curr. Pollut. Rep. 2018, 4, 74–83. [Google Scholar] [CrossRef]

- Unrean, P.; Lai Fui, B.C.; Rianawati, E.; Acda, M. Comparative Techno-Economic Assessment and Environmental Impacts of Rice Husk-to-Fuel Conversion Technologies. Energy 2018, 151, 581–593. [Google Scholar] [CrossRef]

- McCabe, B.K.; Harris, P.; Antille, D.L.; Schmidt, T.; Lee, S.; Hill, A.; Baillie, C. Toward Profitable and Sustainable Bioresource Management in the Australian Red Meat Processing Industry: A Critical Review and Illustrative Case Study. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2415–2439. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: London, UK, 2006.

- Marathe, K.V.; Chavan, K.R.; Nakhate, P. 8—Life Cycle Assessment (LCA) of PET Bottles. In Recycling of Polyethylene Terephthalate Bottles; Thomas, S., Rane, A., Kanny, K., Abitha, V.K., Thomas, M.G., Eds.; William Andrew Publishing: Norwich, UK, 2019; pp. 149–168. ISBN 978-0-12-811361-5. [Google Scholar]

- Sandin, G.; Peters, G.M.; Svanstrom, M. LCA Methodology. In Life Cycle Assessment of Forest Products: Challenges and Solutions; Springer International Publishing: Cham, Switzerland, 2016; pp. 15–23. ISBN 978-3-319-44027-9. [Google Scholar]

- Stramarkou, M.; Boukouvalas, C.; Koskinakis, S.E.; Serifi, O.; Bekiris, V.; Tsamis, C.; Krokida, M. Life Cycle Assessment and Preliminary Cost Evaluation of a Smart Packaging System. Sustainability 2022, 14, 7080. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current Status of Biogas Upgrading for Direct Biomethane Use: A Review. Renew. Sust. Energ. Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Galib, M.; Elbeshbishy, E.; Reid, R.; Hussain, A.; Lee, H.-S. Energy-Positive Food Wastewater Treatment Using an Anaerobic Membrane Bioreactor (AnMBR). J. Environ. Manag. 2016, 182, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Slaughterhouse Wastewater Characteristics, Treatment, and Management in the Meat Processing Industry: A Review on Trends and Advances. J. Environ. Manag. 2015, 161, 287–302. [Google Scholar] [CrossRef]

- Irshad, A.; Sureshkumar, S.; Raghunath, B.V.; Rajarajan, G.; Mahesh Kumar, G. Treatment of Waste Water from Meat Industry. In Integrated Waste Management in India: Status and Future Prospects for Environmental Sustainability; Prashanthi, M., Sundaram, R., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 251–263. ISBN 978-3-319-27228-3. [Google Scholar]

- Abyar, H.; Nowrouzi, M. Highly Efficient Reclamation of Meat-Processing Wastewater by Aerobic Hybrid Membrane Bioreactor-Reverse Osmosis Simulated System: A Comprehensive Economic and Environmental Study. ACS Sustain. Chem. Eng. 2020, 8, 14207–14216. [Google Scholar] [CrossRef]

- Brandao, M.; Heijungs, R.; Cowie, A. On Quantifying Sources of Uncertainty in the Carbon Footprint of Biofuels: Crop/Feedstock, LCA Modelling Approach, Land-Use Change, and GHG Metrics. Biofuel Res. J. 2022, 9, 1608–1616. [Google Scholar] [CrossRef]

- Brown, H.L.; Hamel, B.B.; Hedman, B.A.; Bruce, A. Hedman Energy Analysis of 108 Industrial Processes; Fairmont Press: Lilburn, GA, USA, 1987. [Google Scholar]

- Huber Technology. Energy-Efficient Mechanical Pre-Treatment. Available online: https://www.huber.de/solutions/centralized-wastewater-treatment/mechanical-pre-treatment.html (accessed on 1 November 2023).

- Krzeminski, P.; van der Graaf, J.H.J.M.; van Lier, J.B. Specific Energy Consumption of Membrane Bioreactor (MBR) for Sewage Treatment. Water Sci. Technol. 2012, 65, 380–392. [Google Scholar] [CrossRef] [PubMed]

- Schmalwieser, A.W.; Hirschmann, G.; Cabaj, A.; Sommer, R. Method to Determine the Power Efficiency of UV Disinfection Plants and Its Application to Low Pressure Plants for Drinking Water. Water Supply 2016, 17, 947–957. [Google Scholar] [CrossRef]

- Wang, S.; Sahoo, K.; Jena, U.; Dong, H.; Bergman, R.; Runge, T. Life-Cycle Assessment of Treating Slaughterhouse Waste Using Anaerobic Digestion Systems. J. Clean. Prod. 2021, 292, 126038. [Google Scholar] [CrossRef]

- Czekała, W.; Jasiński, T.; Grzelak, M.; Witaszek, K.; Dach, J. Biogas Plant Operation: Digestate as the Valuable Product. Energies 2022, 15, 8275. [Google Scholar] [CrossRef]

- Kamble, S.; Singh, A.; Kazmi, A.; Starkl, M. Environmental and Economic Performance Evaluation of Municipal Wastewater Treatment Plants in India: A Life Cycle Approach. Water Sci. Technol. 2019, 79, 1102–1112. [Google Scholar] [CrossRef] [PubMed]

- Siatou, A.; Manali, A.; Gikas, P. Energy Consumption and Internal Distribution in Activated Sludge Wastewater Treatment Plants of Greece. Water 2020, 12, 1204. [Google Scholar] [CrossRef]

- Dorca-Preda, T.; Mogensen, L.; Kristensen, T.; Knudsen, M.T. Environmental Impact of Danish Pork at Slaughterhouse Gate—A Life Cycle Assessment Following Biological and Technological Changes over a 10-Year Period. Livest. Sci. 2021, 251, 104622. [Google Scholar] [CrossRef]

- Tetteh, H.; Bala, A.; Fullana-i-Palmer, P.; Balcells, M.; Margallo, M.; Aldaco, R.; Puig, R. Carbon Footprint: The Case of Four Chicken Meat Products Sold on the Spanish Market. Foods 2022, 11, 3712. [Google Scholar] [CrossRef] [PubMed]

- Basu, P. Chapter 2—Biomass Characteristics. In Biomass Gasification and Pyrolysis; Basu, P., Ed.; Academic Press: Boston, MA, USA, 2010; pp. 27–63. ISBN 978-0-12-374988-8. [Google Scholar]

- Raghuvanshi, S.; Bhakar, V.; Sowmya, C.; Sangwan, K.S. Waste Water Treatment Plant Life Cycle Assessment: Treatment Process to Reuse of Water. Procedia CIRP 2017, 61, 761–766. [Google Scholar] [CrossRef]

- Timonen, K.; Sinkko, T.; Luostarinen, S.; Tampio, E.; Joensuu, K. LCA of Anaerobic Digestion: Emission Allocation for Energy and Digestate. J. Clean. Prod. 2019, 235, 1567–1579. [Google Scholar] [CrossRef]

- Mondello, G.; Salomone, R.; Ioppolo, G.; Saija, G.; Sparacia, S.; Lucchetti, M.C. Comparative LCA of Alternative Scenarios for Waste Treatment: The Case of Food Waste Production by the Mass-Retail Sector. Sustainability 2017, 9, 827. [Google Scholar] [CrossRef]

| Process | Input/Output | Flow | Unit | Value |

|---|---|---|---|---|

| Slaughter house | In | Feedstock | kg | 1.53 |

| In | Electricity | kJ | 7.43 | |

| Out | Feedstock | kg | 1.47 | |

| Out | Blood (sludge) | kg | 0.06 | |

| Scalding and hide removal | In | Feedstock | kg | 1.47 |

| In | Steam | kg | 0.06 | |

| In | Electricity | kJ | 3.62 | |

| Out | Feedstock | kg | 1.41 | |

| Out | Hide (sludge) | kg | 0.01 | |

| Out | Fur (sludge) | kg | 0.05 | |

| Out | Water vapor | kg | 0.06 | |

| Evisceration | In | Feedstock | kg | 1.41 |

| In | Hot water | kg | 1.02 | |

| Out | Carcass | kg | 0.94 | |

| Out | Viscera and inedible parts (sludge) | kg | 0.34 | |

| Out | Meat prod. 1 | kg | 0.12 | |

| Out | Wastewater | kg | 1.02 | |

| Trimming | In | Carcass | kg | 0.94 |

| In | Electricity | kJ | 2.90 | |

| Out | Carcass | kg | 0.90 | |

| Out | Meat prod. 2 | kg | 0.04 | |

| Refrigeration and chilling | In | Carcass | kg | 0.90 |

| In | Electricity | kJ | 262.62 | |

| In | Cooling water | kg | 16.35 | |

| Out | Carcass | kg | 0.62 | |

| Out | Meat prod. 3 | kg | 0.28 | |

| Out | Cooling water | kg | 16.35 | |

| Cutting and deboning | In | Carcass | kg | 0.62 |

| In | Electricity | kJ | 5.43 | |

| Out | Other meat | kg | 0.47 | |

| Out | Meat prod. 4 | kg | 0.07 | |

| Out | Bones and inedible parts (sludge) | kg | 0.08 | |

| Processing | In | Other meat | kg | 0.47 |

| In | Steam | kg | 0.02 | |

| In | Electricity | kJ | 53.97 | |

| In | Fuel (diesel) | kJ | 243.42 | |

| In | Water | kg | 2.90 | |

| Out | Other meat | kg | 0.47 | |

| Out | Condensate | kg | 0.02 | |

| Out | Wastewater | kg | 2.90 | |

| Packaging | In | Other meat | kg | 0.47 |

| In | PP (tray) | kg | 0.02 | |

| In | Electricity (packaging) | kJ | 102.33 | |

| In | Electricity (tray) | kJ | 42.75 | |

| Out | Meat prod. 5 | kg | 0.49 | |

| Boiler | In | Condensate | kg | 0.02 |

| In | Water (deionized) | kg | 1.08 | |

| In | Fuel (natural gas) | kJ | 721.01 | |

| Out | Steam | kg | 0.08 | |

| Out | Hot water | kg | 1.02 | |

| Total meat products | In | Meat prod. 1 | kg | 0.12 |

| In | Meat prod. 2 | kg | 0.04 | |

| In | Meat prod. 3 | kg | 0.28 | |

| In | Meat prod. 4 | kg | 0.07 | |

| In | Meat prod. 5 | kg | 0.49 | |

| Out | Meat products | kg | 1.00 |

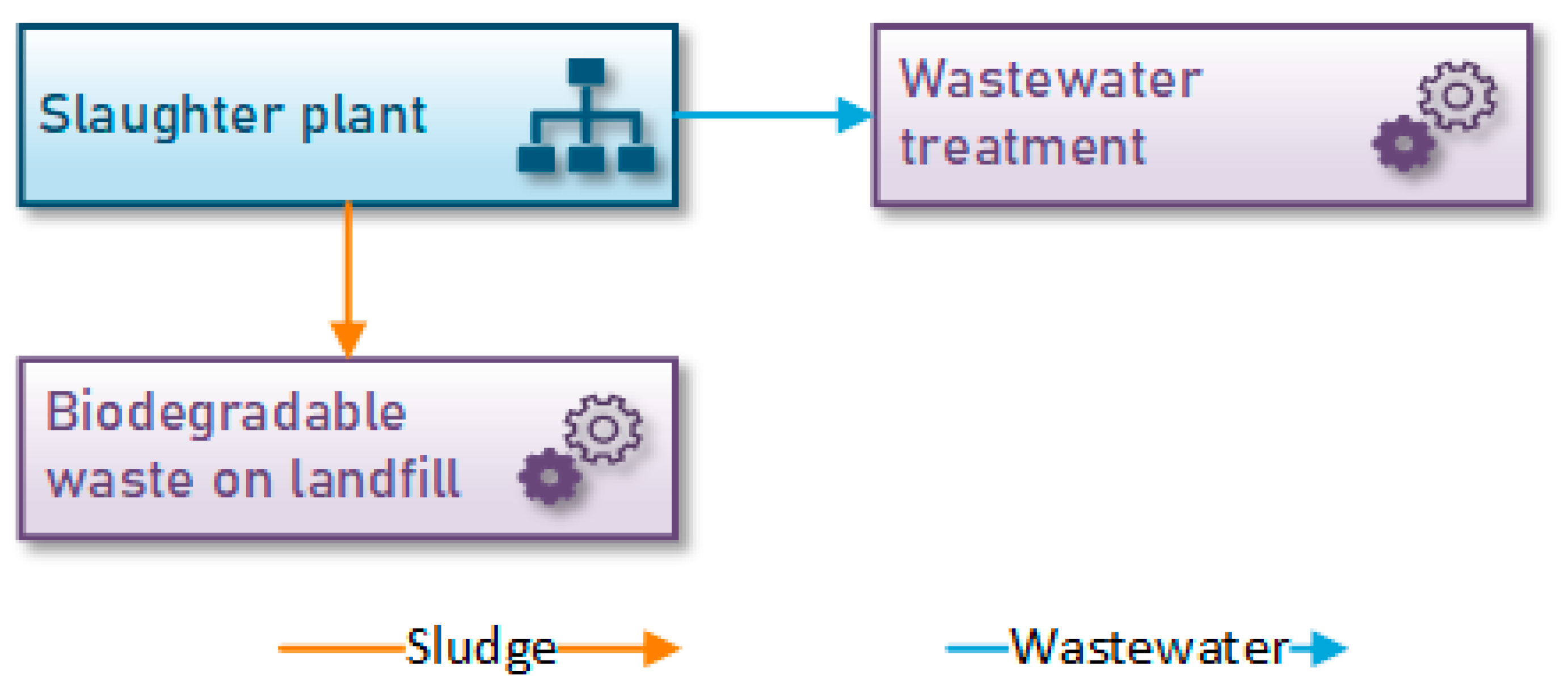

| Process | Input/Output | Flow | Unit | Value |

|---|---|---|---|---|

| Municipal wastewater treatment | In | Wastewater from evisceration | kg | 1.02 |

| Wastewater from processing | kg | 2.90 | ||

| Total | kg | 3.92 | ||

| Biodegradable waste on landfill | In | Blood | kg | 0.06 |

| Hide | kg | 0.01 | ||

| Fur | kg | 0.05 | ||

| Viscera and inedible parts | kg | 0.3 | ||

| Bones and inedible parts | kg | 0.08 | ||

| Total | kg | 0.54 |

| Process | Input/Output | Flow | Unit | Value |

|---|---|---|---|---|

| Screening [24] | In | Wastewater | kg | 3.92 |

| In | Electricity | kJ | 0.02 | |

| Out | Solids | kg | 0.01 | |

| Out | Wastewater | kg | 3.91 | |

| Membrane bioreactor [25] | In | Wastewater | kg | 3.91 |

| In | Electricity | kJ | 19.70 | |

| Out | Wastewater | kg | 3.90 | |

| Out | Sludge | kg | 0.01 | |

| UV treatment [26] | In | Wastewater | kg | 3.90 |

| In | Electricity | kJ | 0.93 | |

| Out | Clean water | kg | 3.90 | |

| Anaerobic digestion [27] | In | Sludge | kg | 0.54 |

| In | Solid | kg | 0.01 | |

| In | Sludge | kg | 0.01 | |

| In | Wastewater (recycling) | kg | 43.67 | |

| In | Electricity | kJ | 176.50 | |

| In | Fuel (diesel) | kJ | 2051.07 | |

| In | Heat (CHP) | kJ | 1467.09 | |

| Out | Digestate | kg | 44.10 | |

| Out | Biogas | kg | 0.12 | |

| CHP [27] | In | Biogas | kg | 0.12 |

| Out | Heat (CHP) | kJ | 1467.09 | |

| Out | Electricity | kJ | 1304.08 | |

| Digestate thickening [28] | In | Digestate | kg | 44.10 |

| In | Electricity | kJ | 79.37 | |

| Out | To compost | kg | 0.43 | |

| Out | Wastewater (recycling) | kg | 43.67 |

| Process | Input/Output | Flow | Unit | Value |

|---|---|---|---|---|

| Screening [24] | In | Wastewater | kg | 3.92 |

| In | Electricity | kJ | 0.02 | |

| Out | Solids | kg | 0.01 | |

| Out | Wastewater | kg | 3.91 | |

| Aeration treatment [29] | In | Wastewater | kg | 3.91 |

| In | Electricity | kJ | 3.28 | |

| In | Sodium hypochlorite | kg | 4.70 × 10−5 | |

| Out | Wastewater | kg | 3.90 | |

| Out | Sludge | kg | 0.01 | |

| Chlorination [30] | In | Wastewater | kg | 3.90 |

| In | Electricity | kJ | 0.87 | |

| In | Sodium hypochlorite (15%) | kg | 2.94 × 10−4 | |

| Out | Clean water | kg | 3.90 | |

| Drying A [11] | In | Solid wastes | kg | 0.54 |

| In | Sludge | kg | 0.01 | |

| In | Heat | kJ | 960.00 | |

| Out | Solid wastes | kg | 0.24 | |

| Out | Waste vapor | kg | 0.31 | |

| HTC [11] | In | Solid wastes | kg | 0.24 |

| In | Electricity | kJ | 336.10 | |

| Out | Slurry | kg | 2.35 × 10−1 | |

| Out | Exhausted gas | kg | 0.05 × 10−1 | |

| Filtration [11] | In | Slurry | kg | 2.35 × 10−1 |

| In | Electricity | kJ | 20.30 | |

| Out | Solid fuel | kg | 0.97 × 10−1 | |

| Out | Hydrolysates | kg | 1.38 × 10−1 | |

| Drying B [11] | In | Solid fuel | kg | 0.97 × 10−1 |

| In | Heat | kJ | 20.90 | |

| Out | Solid fuel | kg | 0.09 | |

| Out | Waste vapor | kg | 0.01 | |

| Pelletizing [11] | In | Solid fuel | kg | 0.09 |

| In | Electricity | kJ | 2.30 | |

| Out | Pelletized fuel | kg | 0.09 | |

| Pellet power generation [11] | In | Pelletized fuel | kg | 0.09 |

| In | Electricity | kJ | 8.16 | |

| Out | Electricity | kJ | 389.30 | |

| Out | Thermal energy | kJ | 1133.6 | |

| Out | Ash mix | kg | 0.45 × 10−3 |

| Impact Category (×10−3) | Scenario A | Scenario B | Reduction in Scenario B (%) | Scenario C | Reduction in Scenario C (%) |

|---|---|---|---|---|---|

| Climate change (kg CO2 eq.) | 541.30 | 207.70 | 61.63 | 85.41 | 84.22 |

| Human toxicity, cancer (kg 1,4-DB eq.) | 1.24 | 1.01 | 18.55 | 0.69 | 44.35 |

| Freshwater consumption (m3) | 0.77 | 0.15 | 80.52 | 0.39 | 49.35 |

| Fossil depletion (kg oil eq.) | 80.31 | 71.81 | 10.58 | 41.92 | 47.80 |

| Metal depletion (kg Cu eq.) | 5.46 | −3.38 | 161.90 | 0.26 | 95.24 |

| Marine ecotoxicity (kg 1,4-DB eq.) | 0.98 | 0.96 | 2.04 | 0.66 | 32.65 |

| Fine particulate matter formation (kg PM2.5 eq.) | 0.17 | 0.15 | 11.76 | 0.11 | 35.29 |

| Process | Energy Consumed/Generated | Scenario B | Scenario C |

|---|---|---|---|

| Wastewater treatment | Electricity consumed (kJ) | 20.65 | 24.17 |

| Thermal energy consumed (kJ) | 0 | 0 | |

| Electricity generated (kJ) | 0 | 0 | |

| Thermal energy generated (kJ) | 0 | 0 | |

| Solid waste valorization | Electricity consumed (kJ) | 255.87 | 366.86 |

| Thermal energy consumed (kJ) | 3518.16 | 980.90 | |

| Electricity generated (kJ) | 1304.08 | 389.30 | |

| Thermal energy generated (kJ) | 1467.09 | 1133.60 | |

| Energy balance | Electricity (kJ) | 1027.56 | −1.73 |

| Thermal energy (kJ) | −2051.07 | 352.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boukouvalas, C.; Kekes, T.; Oikonomopoulou, V.; Krokida, M. Life Cycle Assessment of Energy Production from Solid Waste Valorization and Wastewater Purification: A Case Study of Meat Processing Industry. Energies 2024, 17, 487. https://doi.org/10.3390/en17020487

Boukouvalas C, Kekes T, Oikonomopoulou V, Krokida M. Life Cycle Assessment of Energy Production from Solid Waste Valorization and Wastewater Purification: A Case Study of Meat Processing Industry. Energies. 2024; 17(2):487. https://doi.org/10.3390/en17020487

Chicago/Turabian StyleBoukouvalas, Christos, Tryfon Kekes, Vasiliki Oikonomopoulou, and Magdalini Krokida. 2024. "Life Cycle Assessment of Energy Production from Solid Waste Valorization and Wastewater Purification: A Case Study of Meat Processing Industry" Energies 17, no. 2: 487. https://doi.org/10.3390/en17020487

APA StyleBoukouvalas, C., Kekes, T., Oikonomopoulou, V., & Krokida, M. (2024). Life Cycle Assessment of Energy Production from Solid Waste Valorization and Wastewater Purification: A Case Study of Meat Processing Industry. Energies, 17(2), 487. https://doi.org/10.3390/en17020487