Hygrothermal Performance of the Hemp Concrete Building Envelope

Abstract

:1. Introduction

2. Numerical Simulations

- ✓

- Energy conservation balance

- ✓

- Mass conservation balance

2.1. Model Verification: Materials and Methods

2.1.1. Validation of WUFI Pro 6.2 Models

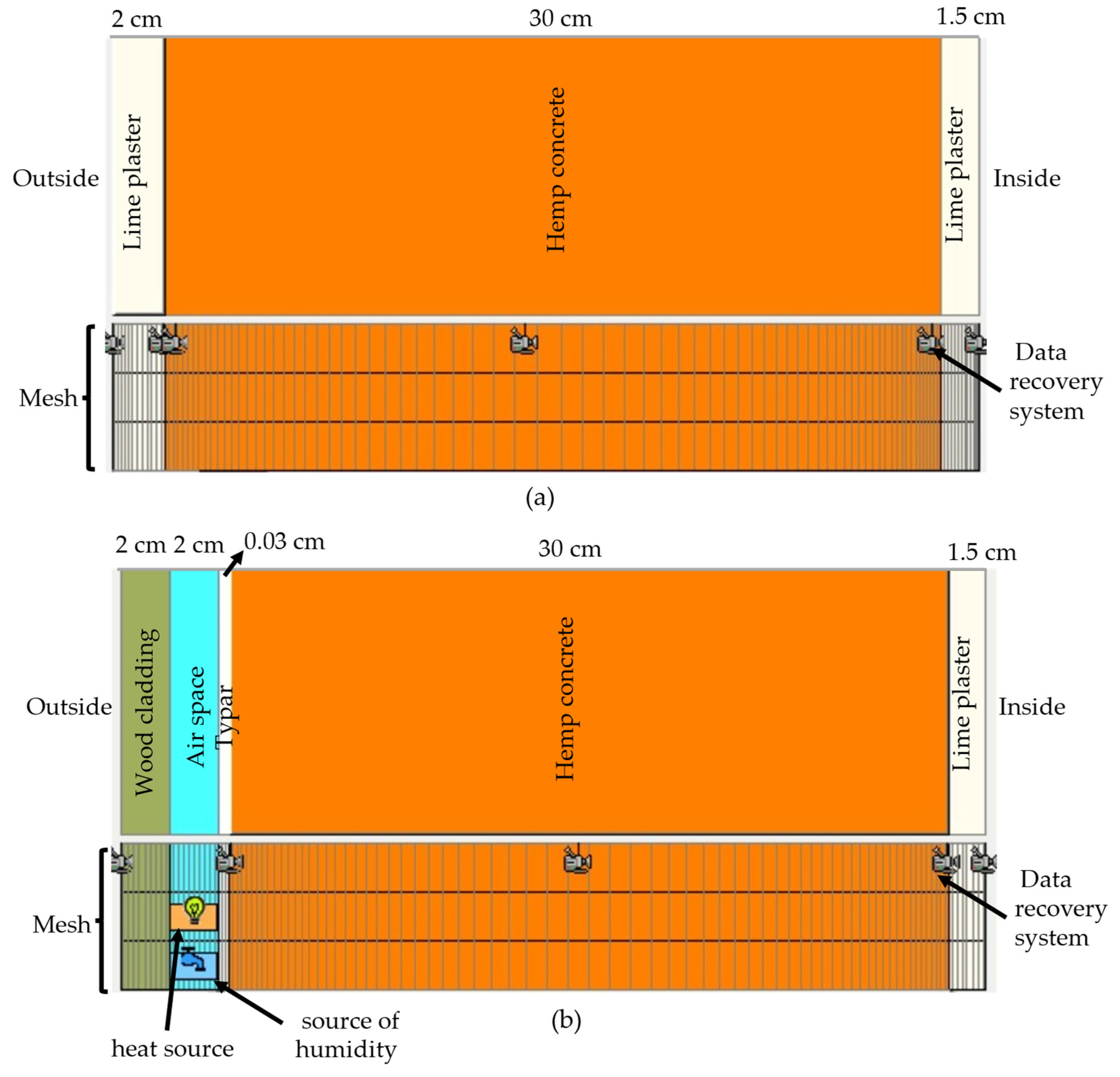

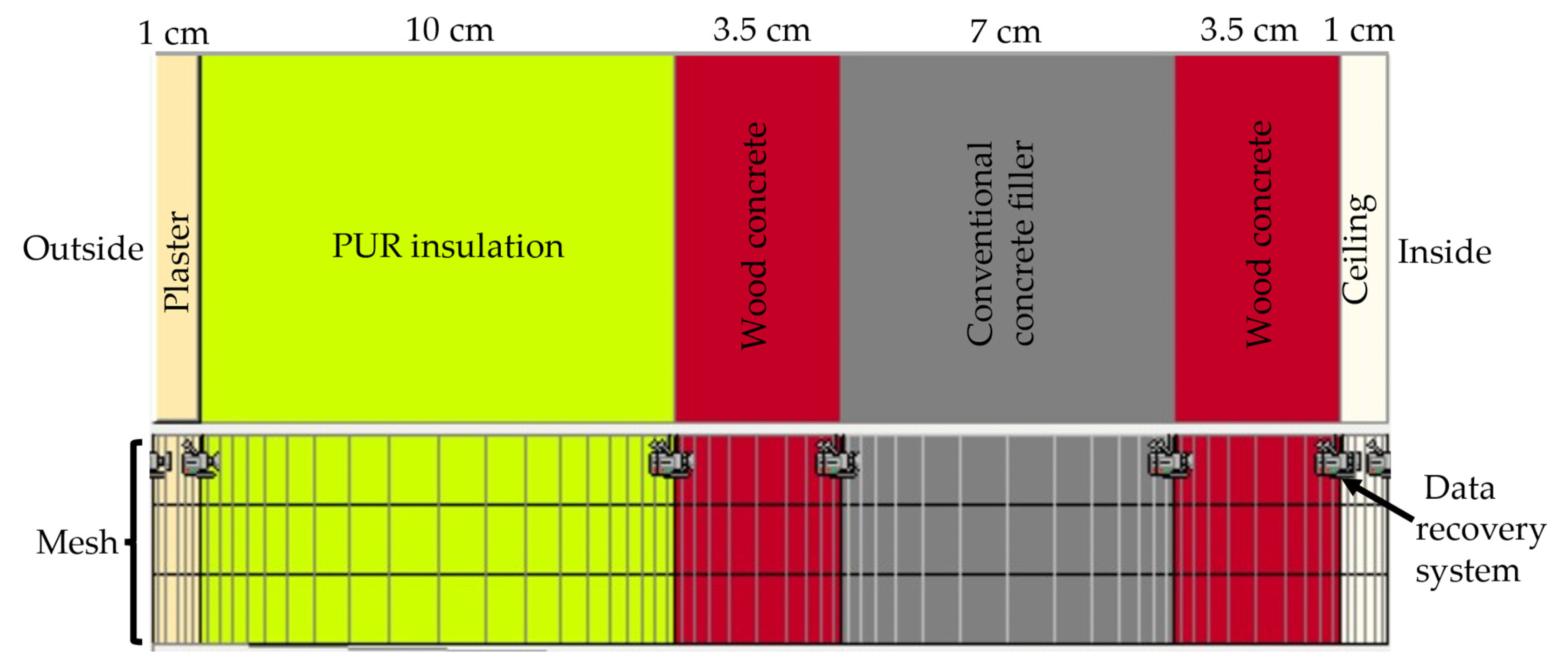

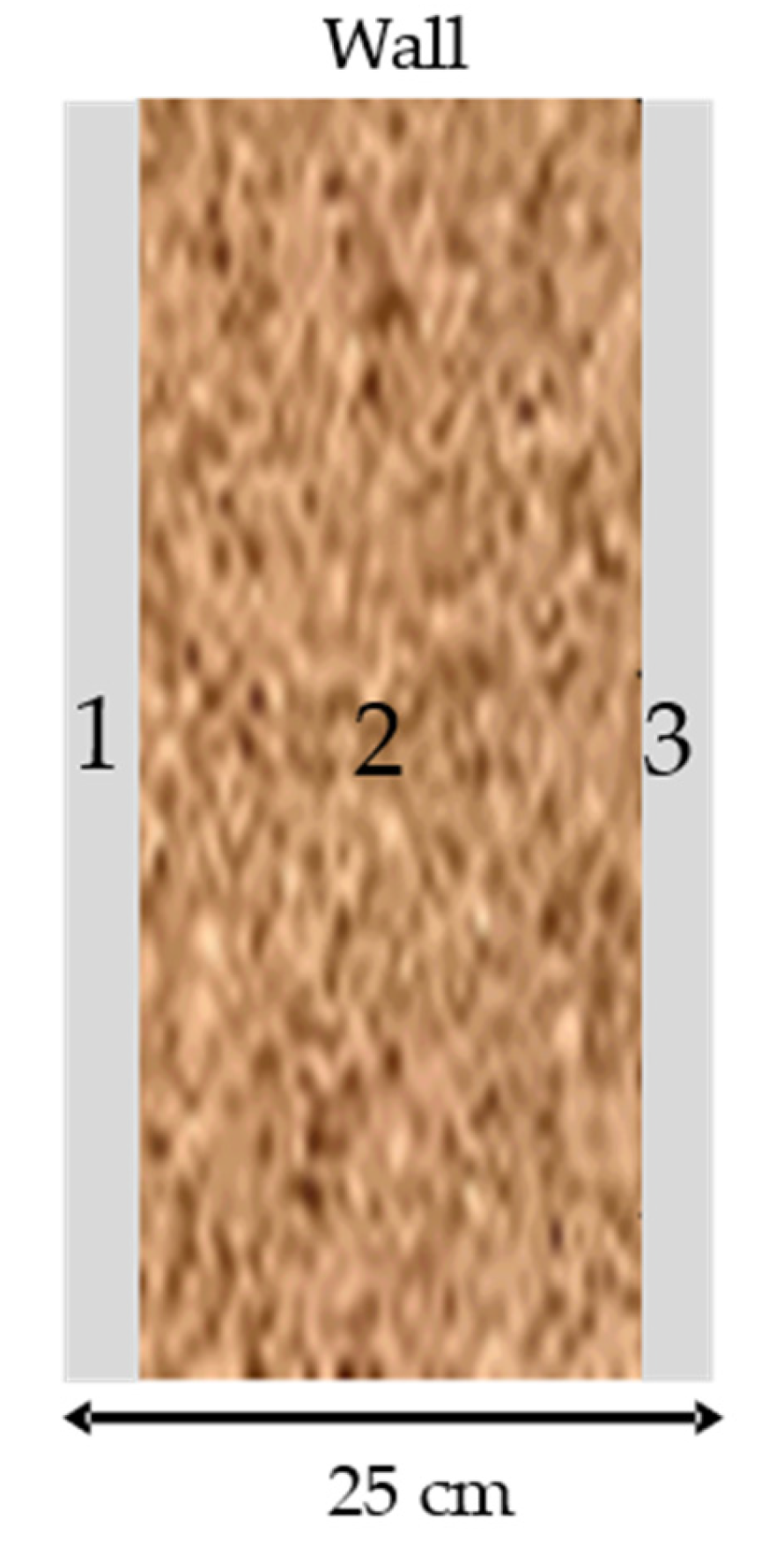

2.1.2. Wall Assembly Configuration for Validation

- For the City of Toronto defined by Dhakal [30]

- For the City of Liège defined by Lamalle [48]

2.1.3. Simulation Assumptions

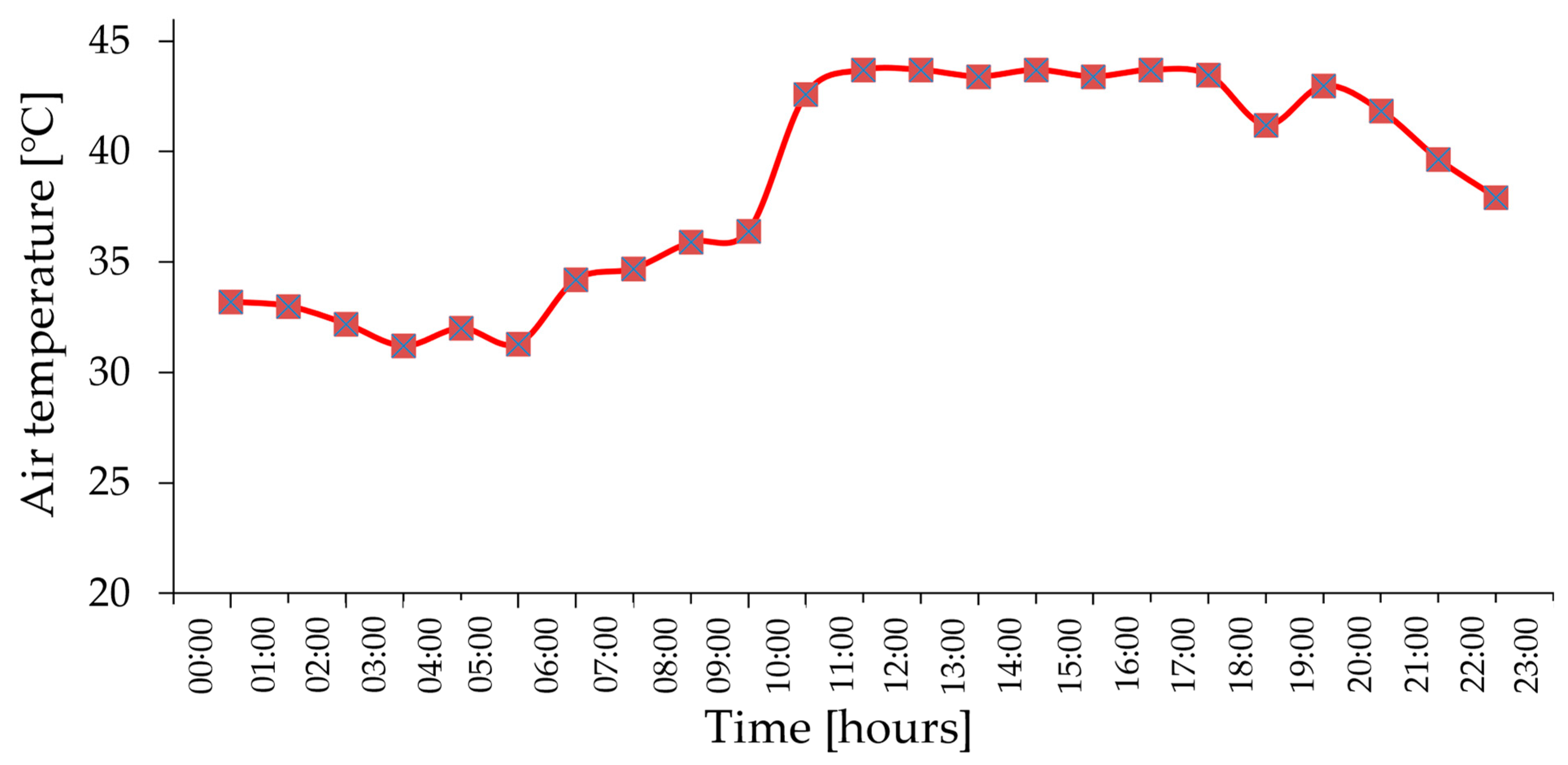

2.1.4. Boundary Conditions for Simulation

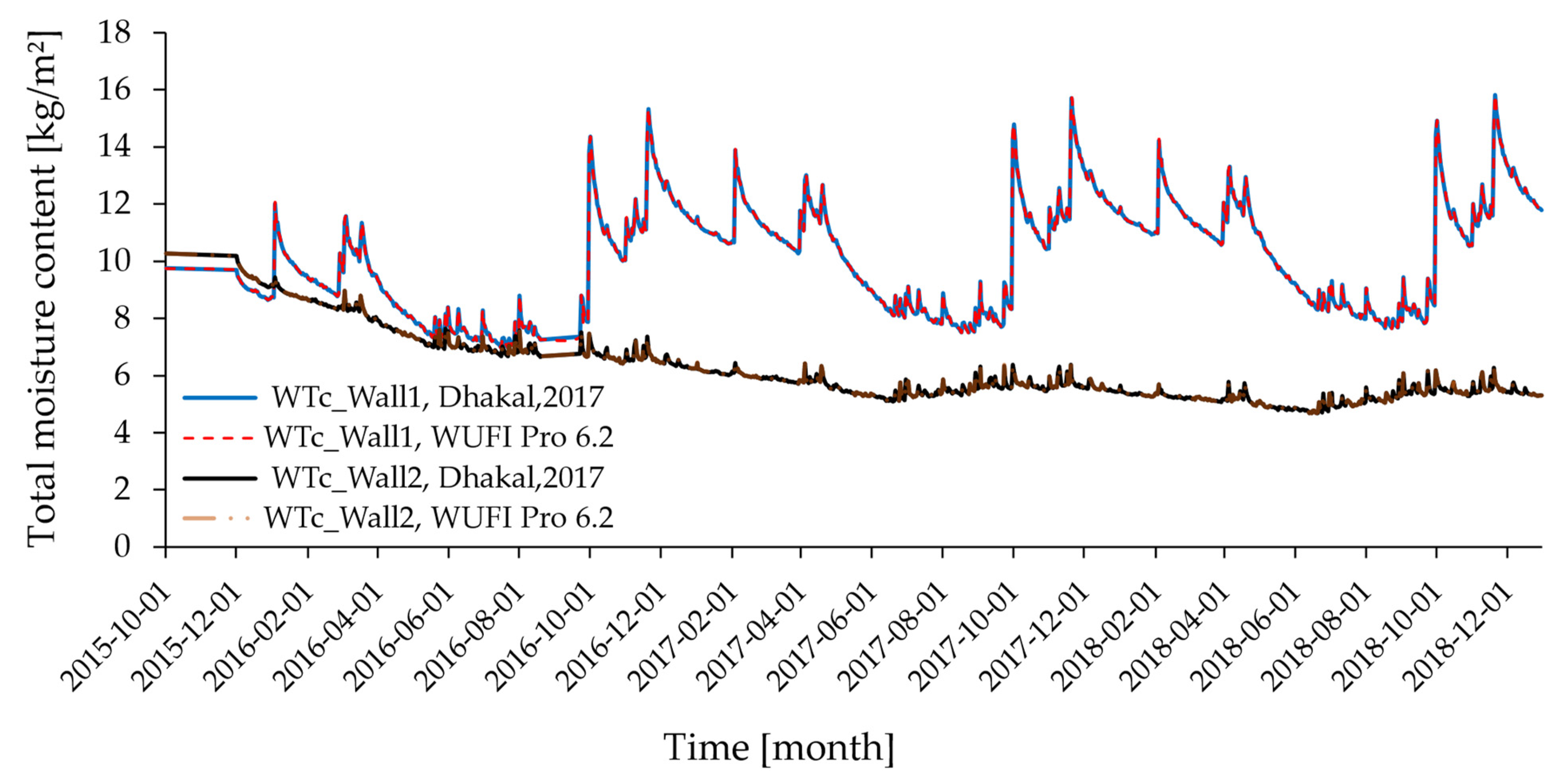

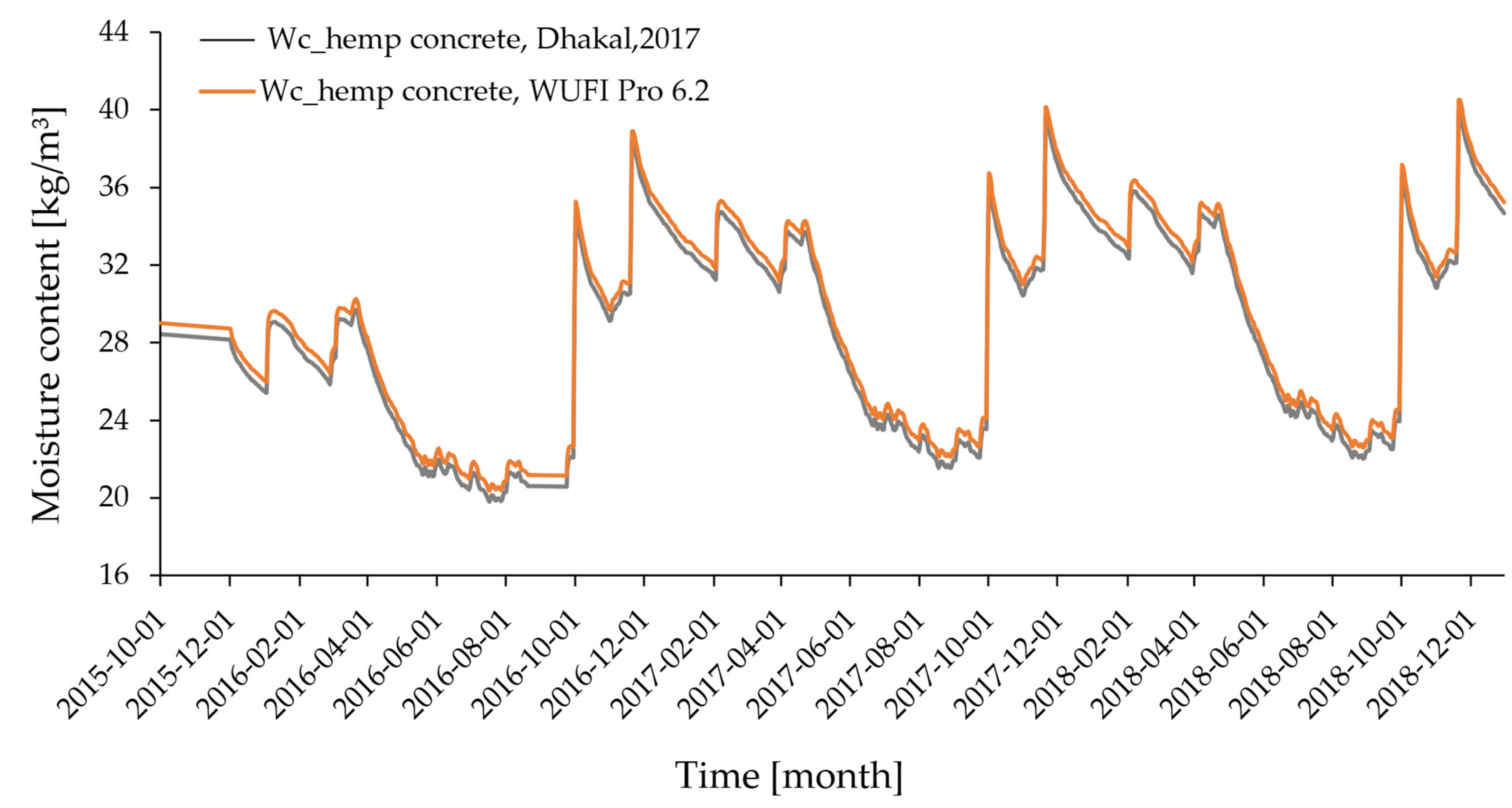

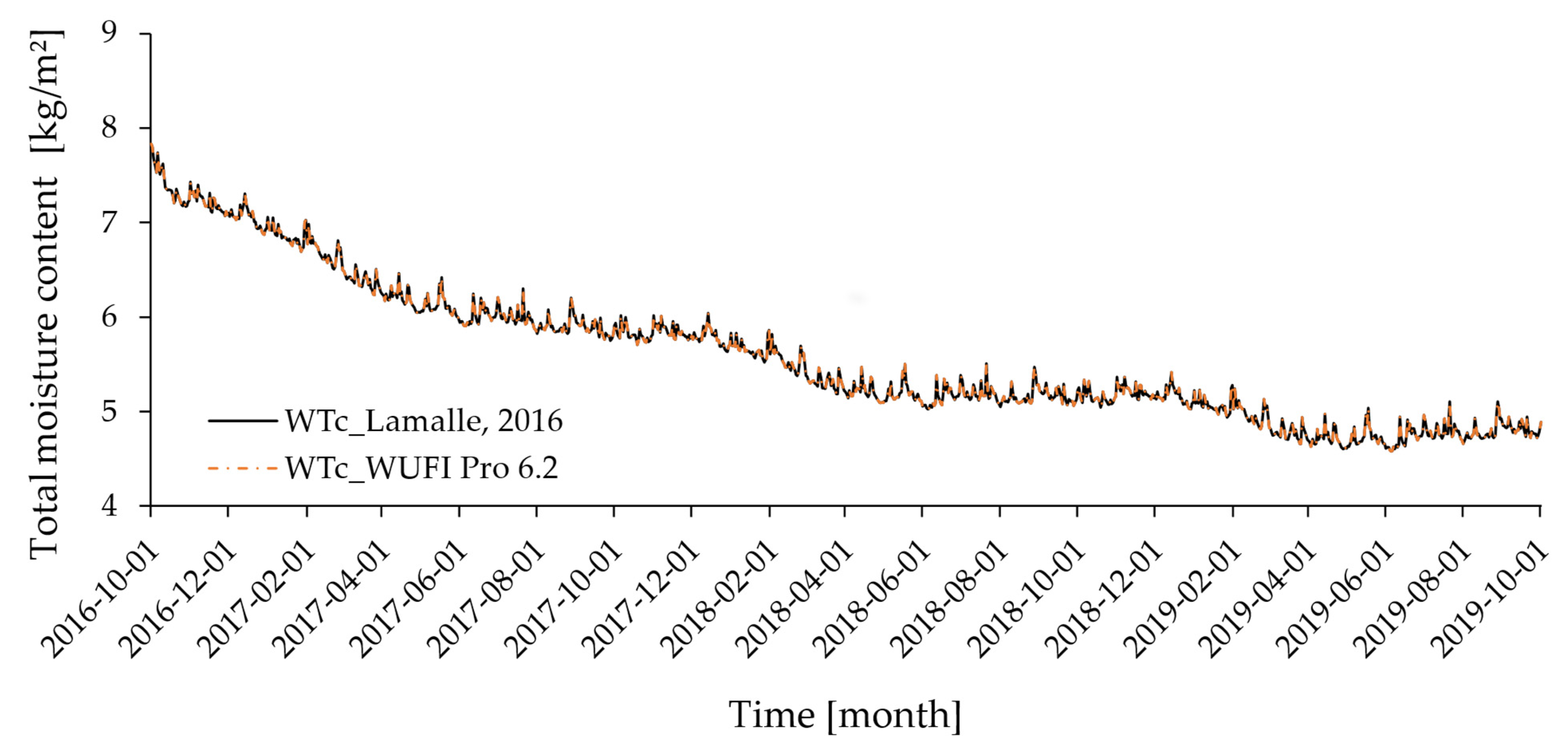

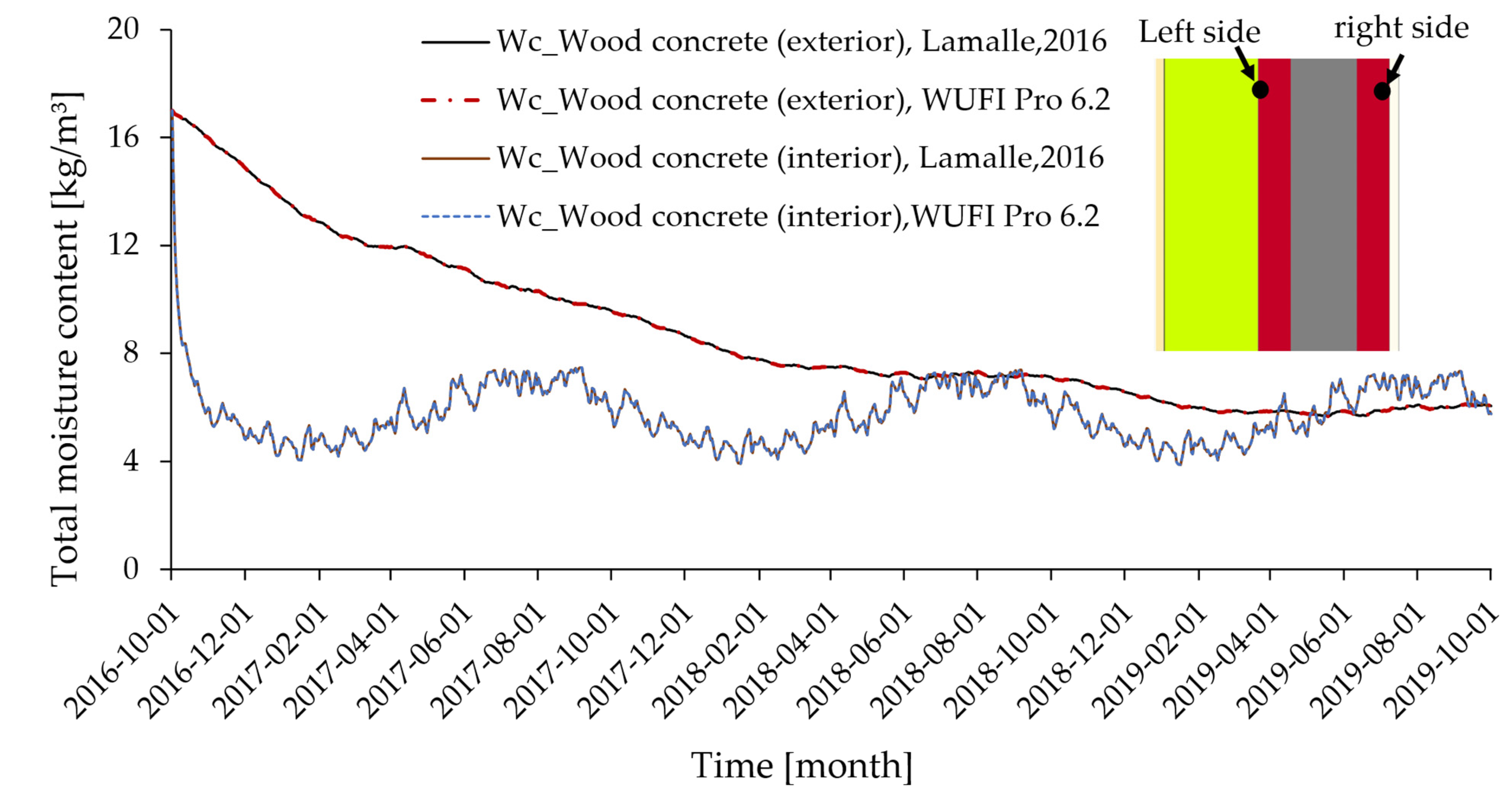

2.1.5. Conformity Check: WUFI Pro 6.2 Results Compared to Dhakal and Lamalle

- Conformity of WUFI Pro 6.2 results with those of Dhakal

- Conformity of WUFI Pro 6.2 results with those of Lamalle [48]

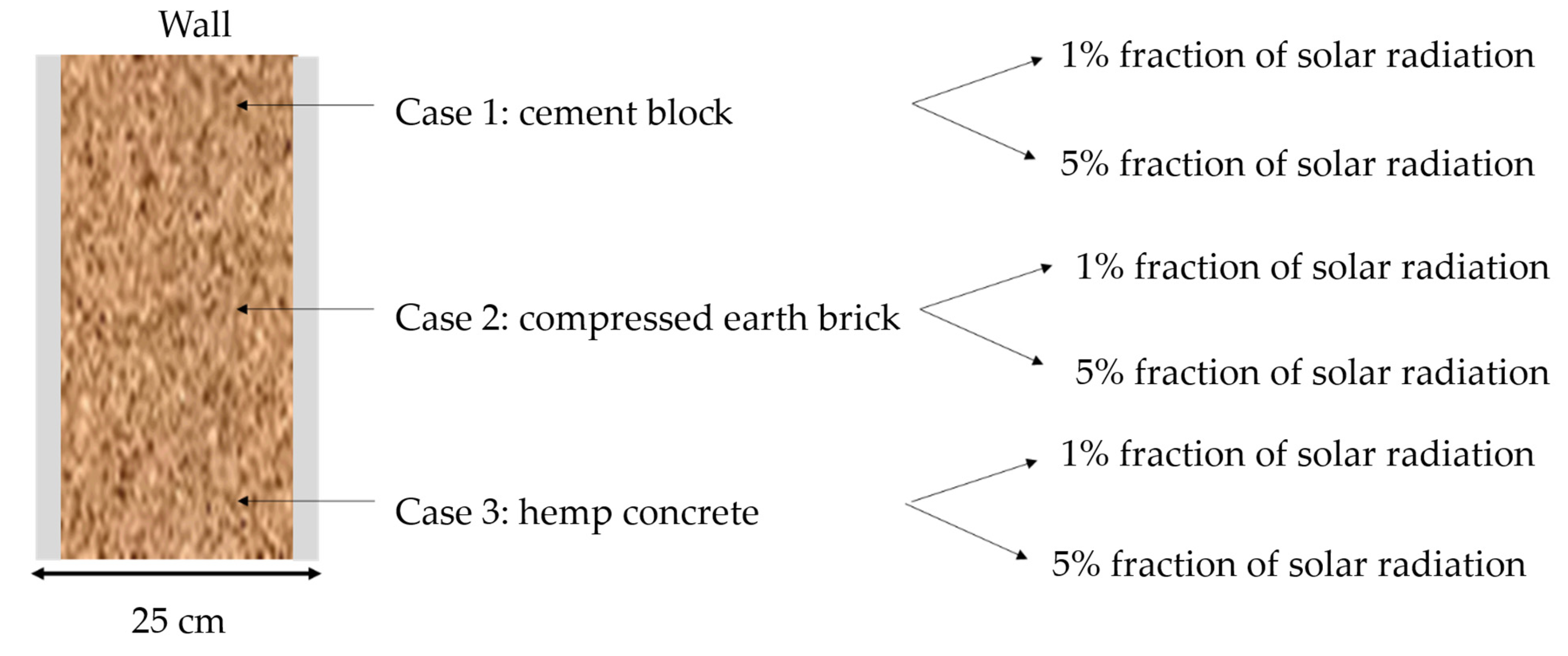

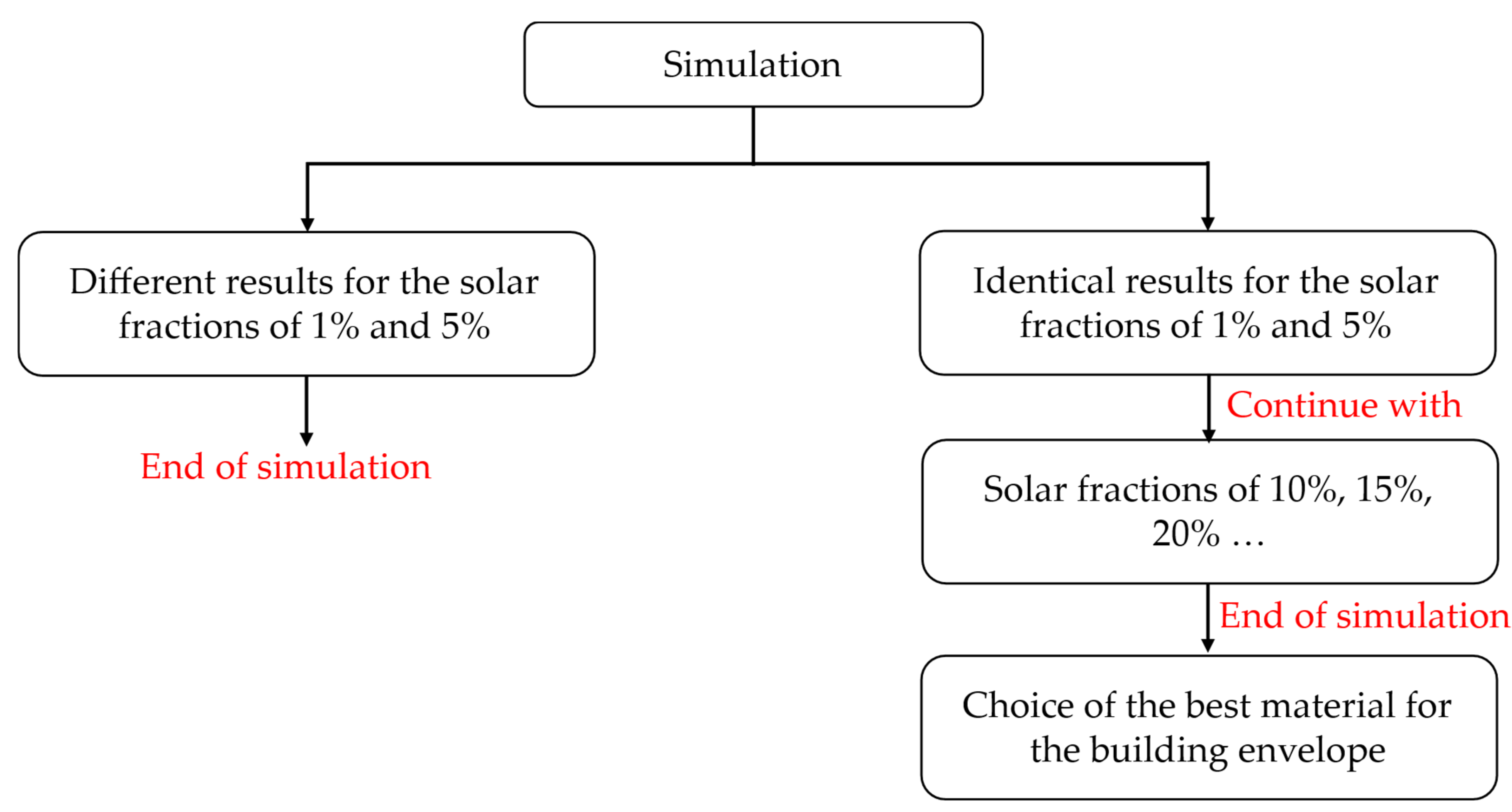

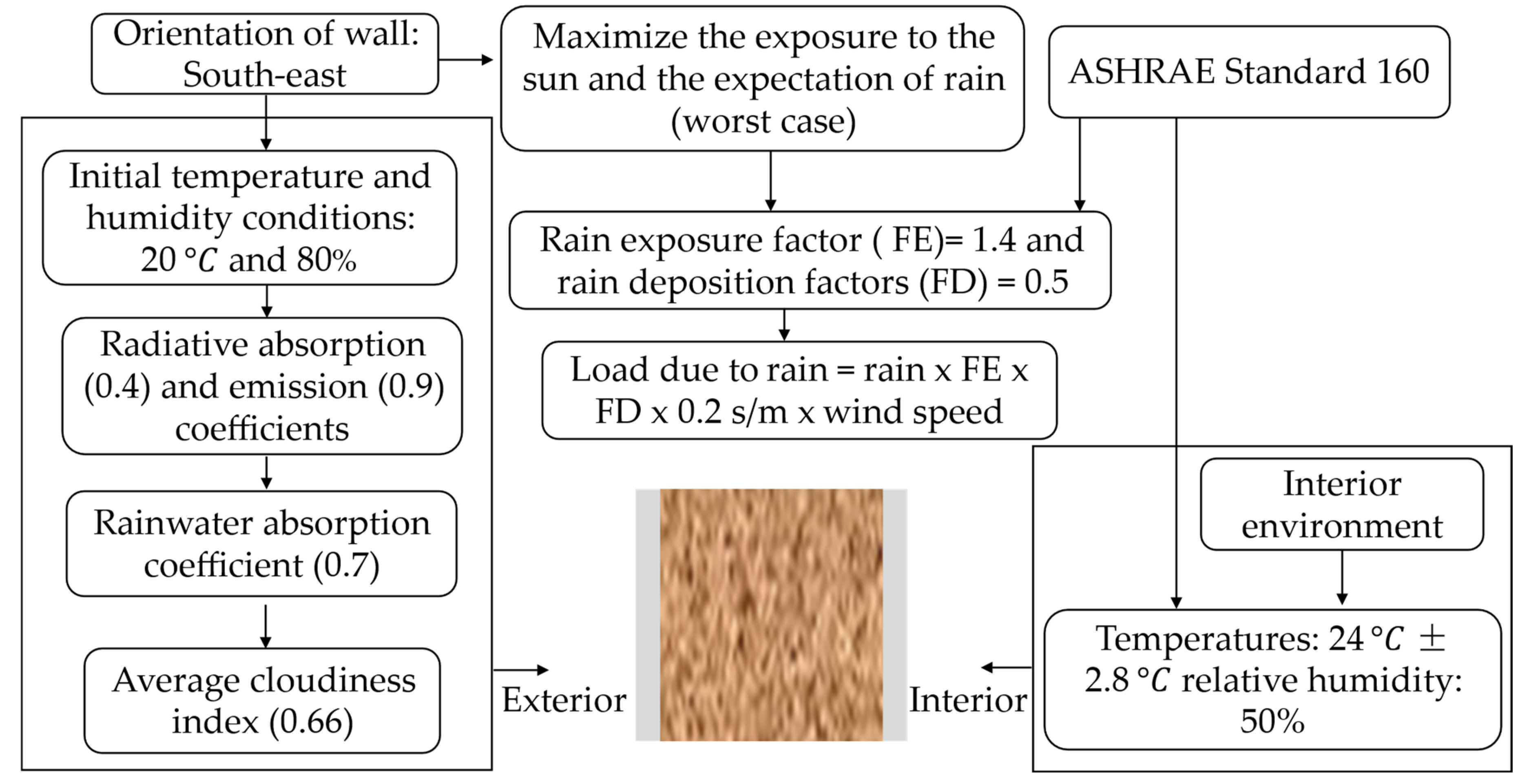

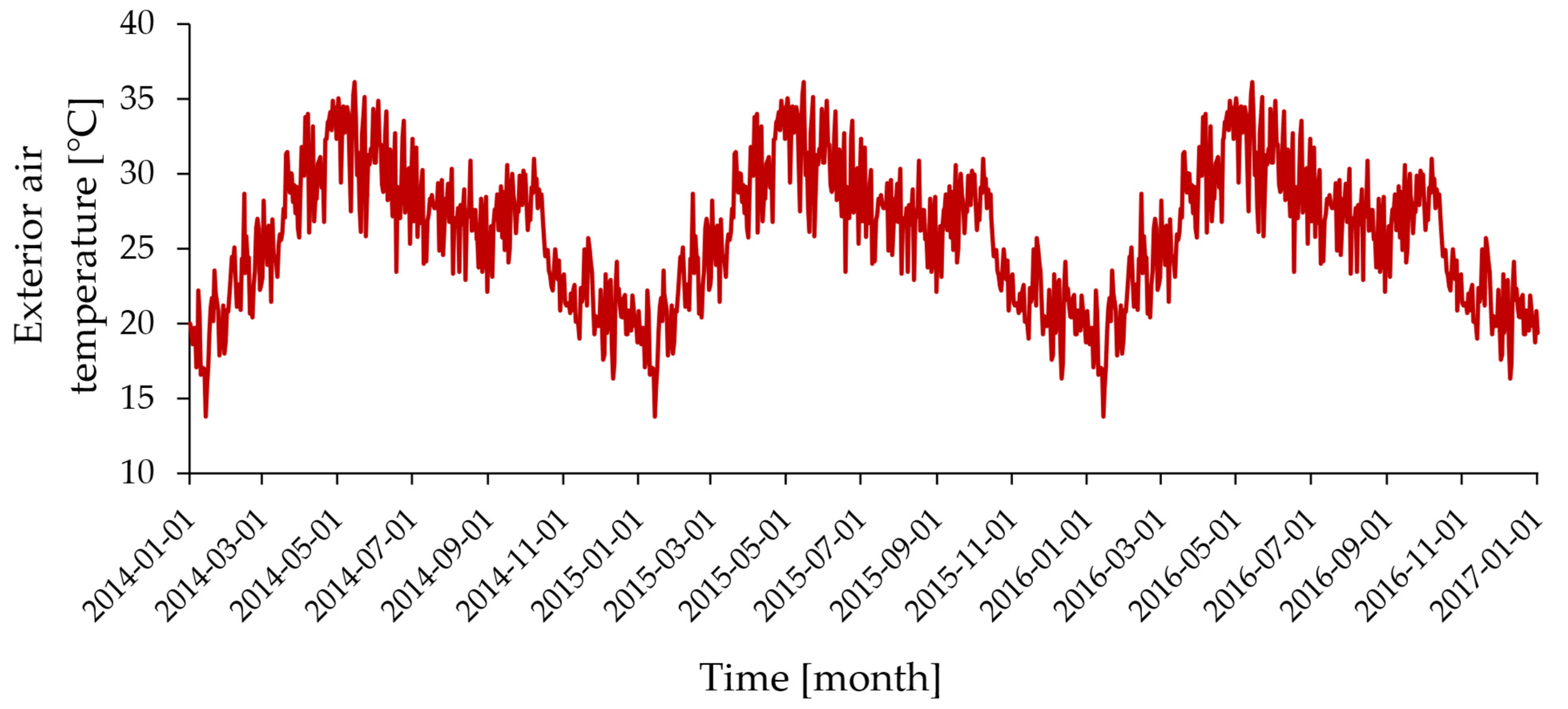

2.2. Case of Our Study: Materials and Methods

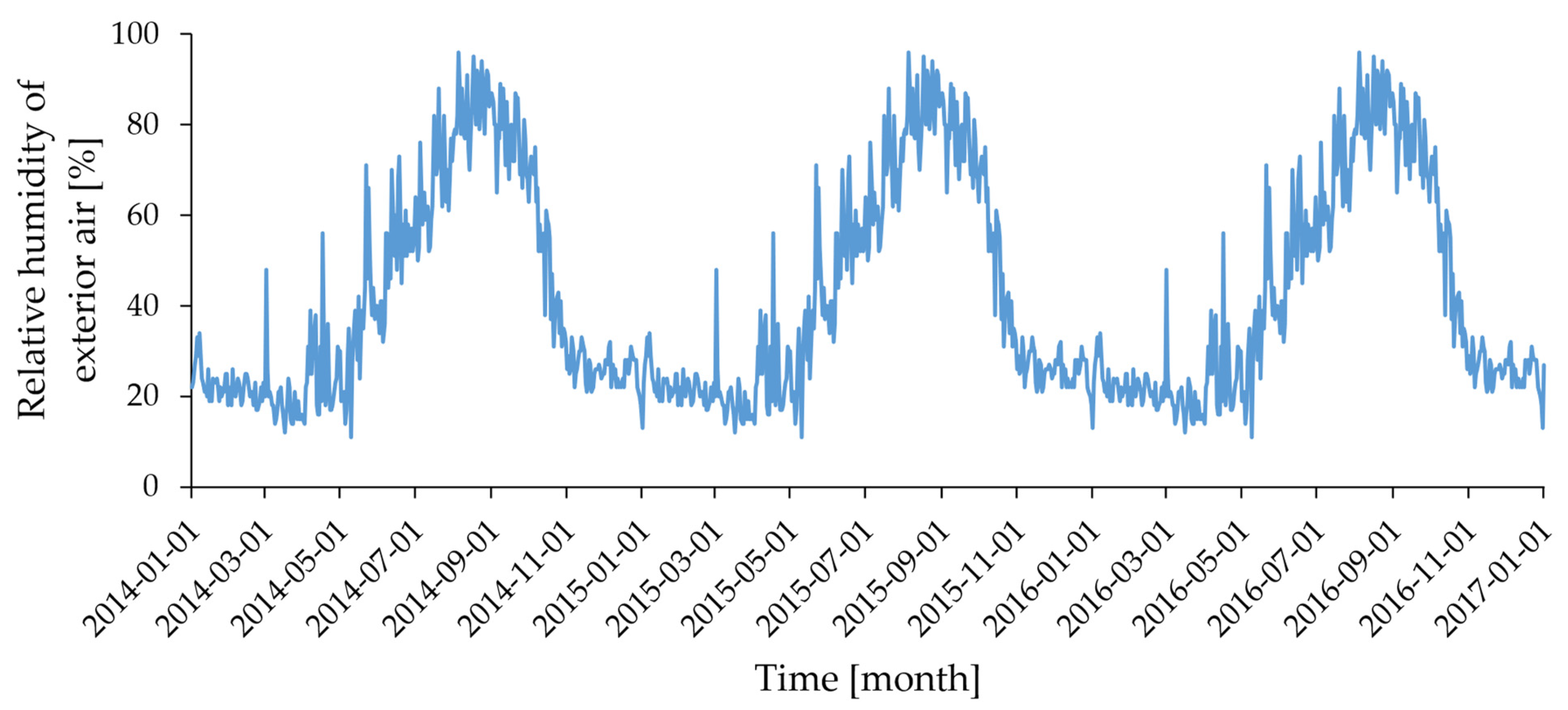

2.2.1. Boundary Conditions and Assumptions

2.2.2. Assumptions Made for the Study

- No water infiltration in the wall, except due to Wind-Driven Rain (WDR),

- The simulation considers that the airtightness is well achieved.

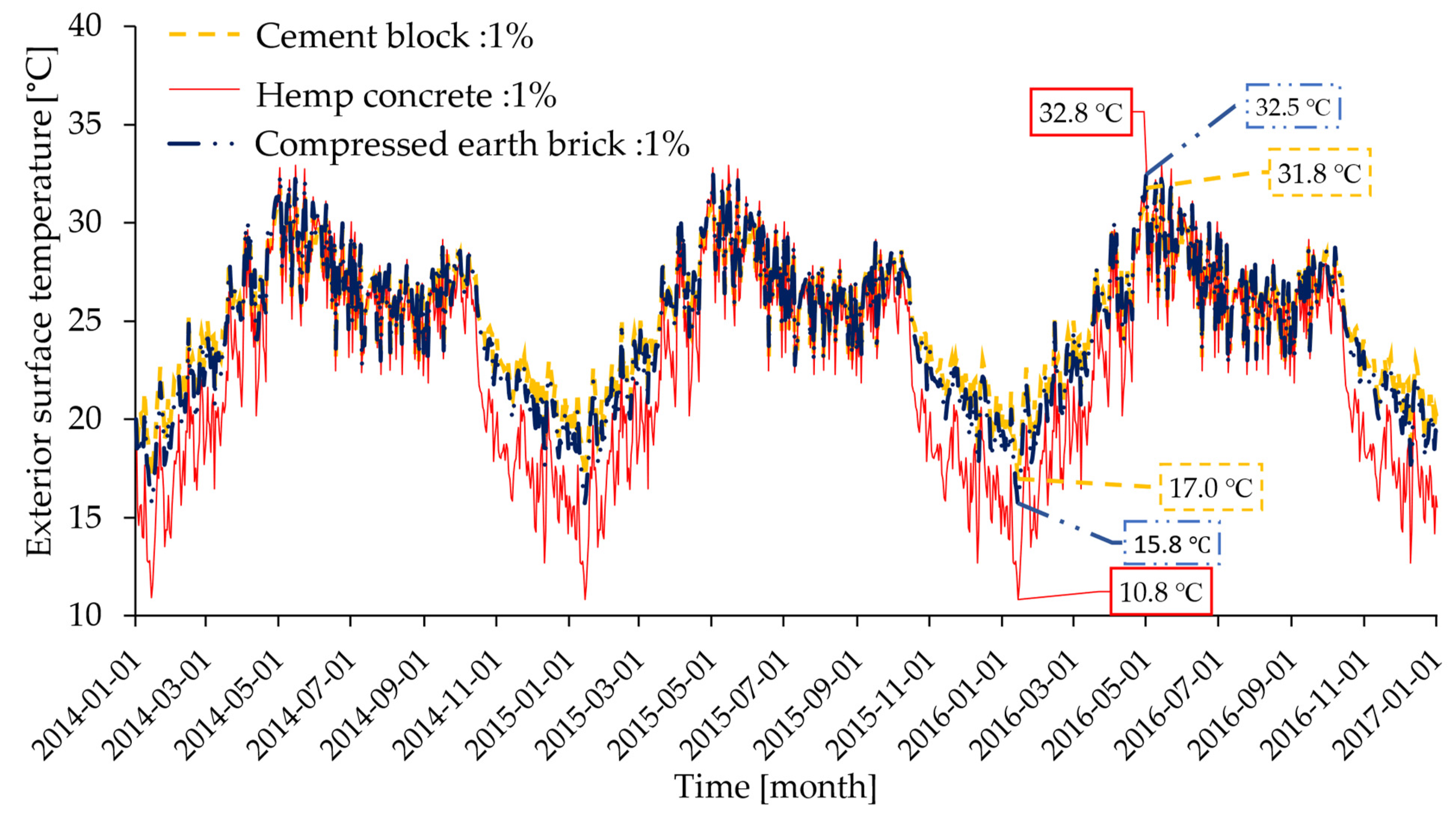

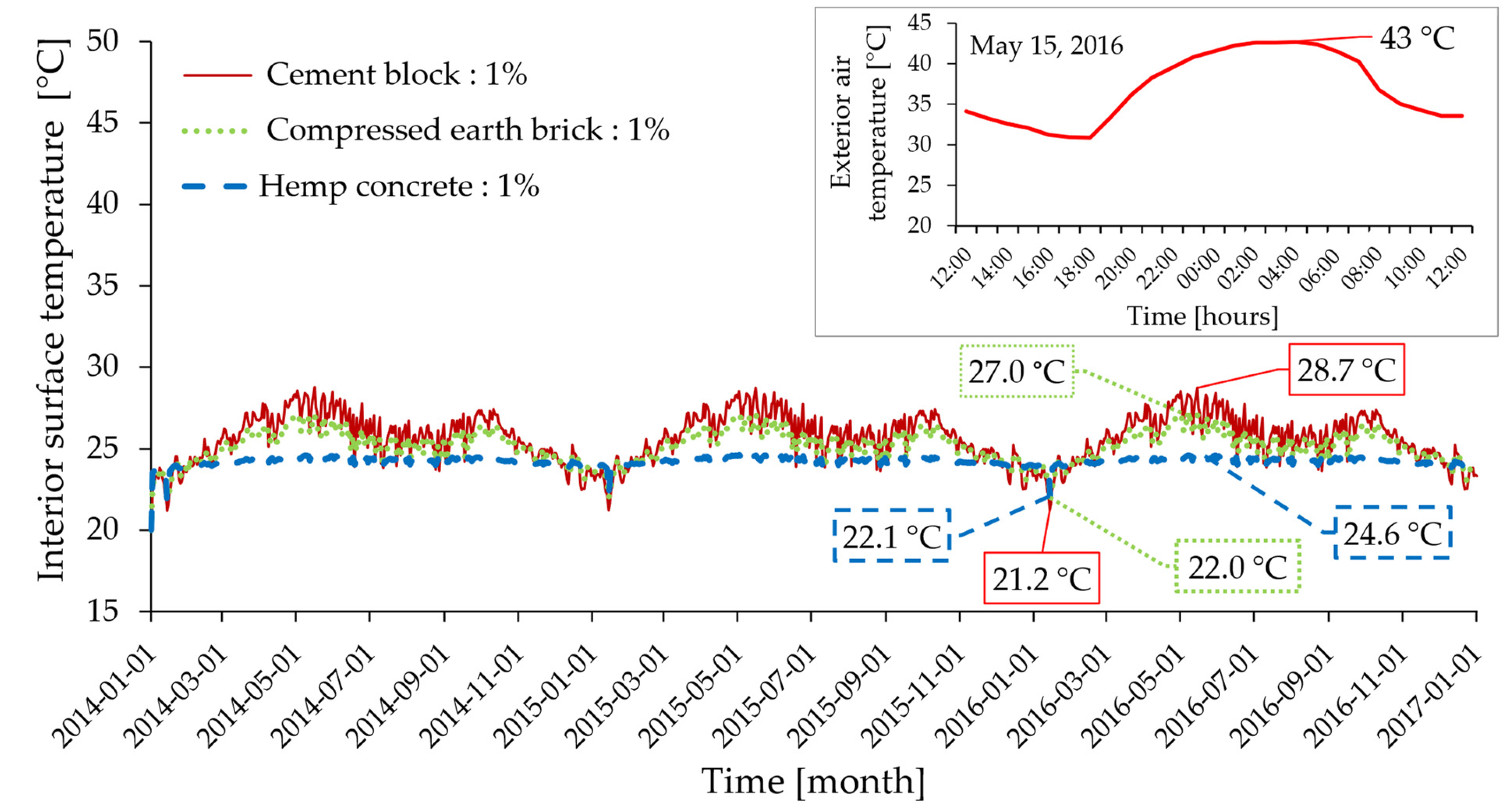

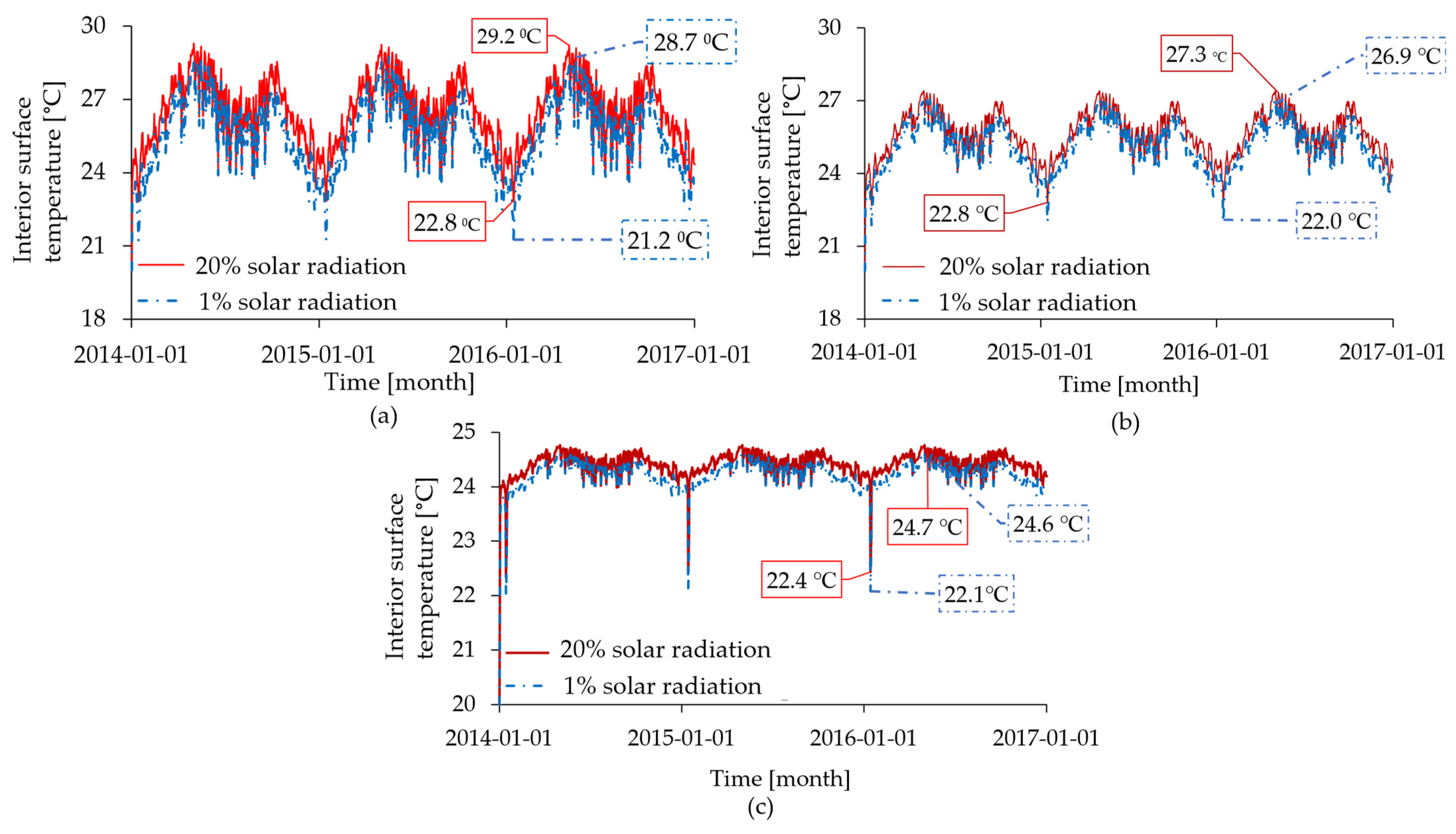

3. Results

4. Discussion

5. Conclusions

- Cement block walls and compressed earth brick walls display maximum interior temperatures of 29.2 °C and 27.3 °C, respectively, surpassing the set temperature of 24 °C, necessitating the use of air conditioning.

- Hemp concrete stands out for its low thermal conductivity (0.085 W/mK), enabling effective control of interior temperature. Simulations indicate variations in interior temperature between 22 °C and 24.6 °C, thereby avoiding the need for air conditioning.

- The hemp concrete wall accumulates more heat on its exterior surface in summer than the other walls, with significant temperature variations between winter and summer. The application of incident solar radiation fractions of 1% and 5% resulted in similar interior temperatures, indicating that the 5% increase in overall solar radiation did not affect the interior temperature of the walls but that of the exterior surface.

- Additionally, with 20% of solar radiation, hemp concrete walls experience only a slight increase of 0.12 °C in maximum interior temperature, while compressed earth brick walls and cement block walls show respective increases of 0.45 °C and 0.50 °C.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thibault, H.; El Habib, E.A.; L’efficacité énergétique dans le bâtiment en Méditerranée. Futuribles 2011, 376, 47–59. Available online: http://planbleu.org/sites/default/files/publications/2-3-fr_futuribles_2011_376_ee.pdf (accessed on 1 March 2023).

- Bakkour, A.; Ouldboukhitine, S.-E.; Biwole, P.; Amziane, S. A review of multi-scale hygrothermal characteristics of plant-based building materials. Constr. Build. Mater. 2024, 412, 134850. [Google Scholar] [CrossRef]

- Commission de Coopération Environnementale. Le Bâtiment Écologique en Amérique du Nord: Débouchés et Défis; Commission de Coopération Environnementale: Montreal, QC, Canada, 2013; p. 80. [Google Scholar]

- William, M.A.; Suárez-López, M.J.; Soutullo, S.; Hanafy, A.A. Building envelopes toward energy-efficient buildings: A balanced multi-approach decision making. Int. J. Energy Res. 2021, 45, 21096–21113. [Google Scholar] [CrossRef]

- Scheifel, G.; Bill, W.J.; Kemptville. La Culture du Chanvre Industriel. 2000. Available online: http://www.omafra.gov.on.ca/french/crops/facts/00-068.htm (accessed on 13 February 2023).

- Berger, J.; Contribution à la Modélisation Hygrothermique des Bâtiments: Application des Méthodes de Réduction de Modèle. Grenoble. 2014, p. 225. Available online: https://theses.hal.science/tel-01127189 (accessed on 13 February 2023).

- ONUDC. Nations Unies, Office Contre la Drogue et le Crime: Le Cannabis en Afrique. 2007. 22p. Available online: www.unodc.org (accessed on 13 February 2023).

- Chamoin, J. Optimisation des Propriétés (Physiques, Mécaniques et Hydriques) de Bétons de Chanvre par la Maîtrise de la Formulation. INSA de Rennes: Rennes, France. 2013. Available online: https://theses.hal.science/tel-00934732 (accessed on 13 February 2023).

- Motamedi, S.; Rousse, D.R.; Promis, G. The evolution of crop-based materials in the built environment: A review of the applications, performance, and challenges. Energies 2023, 16, 5252. [Google Scholar] [CrossRef]

- Fortin, P. Formulation d’un Liant Pouzzolanique Pour la Confection d’un Béton Végétal Hygroscopique; École de Technologie Supérieure: Montreal, QC, Canada, 2022; Available online: https://espace.etsmtl.ca/id/eprint/3095/ (accessed on 19 March 2024).

- Niyigena, C.S.; Variabilité des Performances de Bétons de Chanvre en Fonction des Caractéristiques de la Chènevotte Produite en Auvergne. In Université Blaise Pascal-Clermont-Ferrand II. 2016. Available online: https://theses.hal.science/tel-01487057 (accessed on 25 September 2023).

- Shea, A.; Lawrence, M.; Walker, P. Hygrothermal performance of an experimental hemp–lime building. Constr. Build. Mater. 2012, 36, 270–275. [Google Scholar] [CrossRef]

- ANSI/ASHRAE. Criteria for Moisture-Control Design Analysis in Buildings; ASHRAE: Atlanta, GA, USA, 2016; Available online: https://www.techstreet.com/standards/ashrae-160-2016?product_id=1939166 (accessed on 25 September 2023).

- Łapka, P.; Brzyski, P.; Pietrak, K.; Cieślikiewicz, Ł.; Suchorab, Z. Hygro-thermal characterization of the hemp concrete modified with the gum Arabic admixture. Constr. Build. Mater. 2023, 368, 130392. [Google Scholar] [CrossRef]

- Rahim, M.; Douzane, O.; Le, A.T.; Promis, G.; Langlet, T. Characterization and comparison of hygric properties of rape straw concrete and hemp concrete. Constr. Build. Mater. 2016, 102, 679–687. [Google Scholar] [CrossRef]

- Samri, D. Analyse Physique et Caractérisation Hygrothermique des Matériaux de Construction: Approche Expérimentale et Modélisation Numérique; Ecole Nationale des Travaux Publics de l’Etat: Vaulx-en-Velin, France, 2008; Available online: https://theses.insa-lyon.fr/publication/2008ISAL0067/these.pdf (accessed on 27 September 2023).

- Collet, F.; Pretot, S. Thermal conductivity of hemp concretes: Variation with formulation, density and water content. Constr. Build. Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef]

- Martínez, B.; Mendizabal, V.; Roncero, M.B.; Bernat-Maso, E.; Gil, L. Towards sustainable building solutions: Development of hemp shiv-based green insulation material. Constr. Build. Mater. 2024, 414, 134987. [Google Scholar] [CrossRef]

- Latif, E. Experimental analysis of moisture-dependent thermal conductivity, and hygric properties of novel hemp–shive insulations with numerical assessment of their in-built hygrothermal and energy performance. Materials 2024, 17, 486. [Google Scholar] [CrossRef]

- Bayol, D. Eco-Construction-Bioclimatique-le Beton de Chanvre Vous Permet un Bonus Pour Construire Plus. 2016. Available online: http://db-chanvre.com/la-construction-passive/ (accessed on 27 September 2023).

- Gauthier, G. Art Can-Construction en Chanvre. 2018. Available online: https://maisonenchanvre.com/avantages-du-chanvre (accessed on 27 September 2023).

- Cieski, J. Materiaux Biosourcés, Comportement Hygrothermique d’une Paroi en Beton de Chanvre. Available online: https://seminairemateriaux.files.wordpress.com/2014/06/r9-mc3a9moire.pdf (accessed on 25 April 2023).

- Youssef, A.; Prise en Compte des Apports Mécaniques du Béton de Chanvre Pour le Calcul de Structure Bois/Béton de Chanvre et Métal/Béton de Chanvre. Lorient. 2017. Available online: https://theses.hal.science/tel-01535694 (accessed on 25 April 2023).

- Rahim, M.; Douzane, O.; Le, A.T.; Promis, G.; Laidoudi, B.; Crigny, A.; Dupre, B.; Langlet, T. Characterization of flax lime and hemp lime concretes: Hygric properties and moisture buffer capacity. Energy Build. 2015, 88, 91–99. [Google Scholar] [CrossRef]

- Mazhoud, B.; Collet, F.; Prétot, S.; Lanos, C. Effect of hemp content and clay stabilization on hygric and thermal properties of hemp-clay composites. Constr. Build. Mater. 2021, 300, 123878. [Google Scholar] [CrossRef]

- Pochwała, S.; Makiola, D.; Anweiler, S.; Böhm, M. The heat conductivity properties of hemp–lime composite material used in single-family buildings. Materials 2020, 13, 1011. [Google Scholar] [CrossRef] [PubMed]

- Benmahiddine, F.; Bennai, F.; Charaka, A.; Hamami, A.E.A.; Tahakourt, A.; Belarbi, R. Multi-scale analysis of the effects of hysteresis on the hydrothermal behaviour of bio-based materials: Application to hemp concrete. Constr. Build. Mater. 2024, 411, 134107. [Google Scholar] [CrossRef]

- Boisyvon, A. Comparatif des Performances Envrionnementales du Béton et du Béton de Chanvre-Etude du Cas de Deux batiments D’habitation Construits par Val Touraine Habitat à Nouzilly (37). 2015. 8p. Available online: www.cerema.fr (accessed on 2 April 2023).

- Künzel, H.M.; Germany, F.I. Modeling Air Leakage in Hygrothermal Envelope Simulation. In Proceedings of the BEST 3 Conference, Atlanta, GA, USA, 2–4 April 2012; p. 26. [Google Scholar]

- Dhakal, U.; Berardi, U.; Gorgolewski, M.; Richman, R. Hygrothermal performance of hempcrete for Ontario (Canada) buildings. J. Clean. Prod. 2017, 142, 3655–3664. [Google Scholar] [CrossRef]

- Muhit, I.B.; Omairey, E.L.; Pashakolaie, V.G. A holistic sustainability overview of hemp as building and highway construction materials. Build. Environ. 2024, 256, 11470. [Google Scholar] [CrossRef]

- Wyss, U.; La Construction en” Matériaux locaux”: État d’un Secteur à Potentiel Multiple; Suisse. Direction du Développement et de la Coopération. 2005. Available online: https://jaga.afrique-gouvernance.net/_docs/resource_fr_65911.pdf (accessed on 20 October 2022).

- İlcan, H.; Özkılıç, H.; Tuğluca, M.S.; Şahmaran, M. Interlayer mechanical performance of 3D-printed cementitious systems: A comprehensive study on operational and material parameters. Constr. Build. Mater. 2024, 419, 135463. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Guo, Y.; Kashani, A.; Wang, K.; Ferrara, L.; Agudelo, I. Concrete 3D printing technology in sustainable construction: A review on raw materials, concrete types and performances. Dev. Built Environ. 2024, 17, 100378. [Google Scholar] [CrossRef]

- Li, H.; Addai-Nimoh, A.; Kreiger, E.; Khayat, K.H. Methodology to design eco-friendly fiber-reinforced concrete for 3D printing. Cem. Concr. Compos. 2024, 147, 105415. [Google Scholar] [CrossRef]

- Gamage, K.; Fawzia, S.; Zahra, T.; Teixeira, M.B.F.; Ramli Sulong, N.H. Advancement in Sustainable 3D Concrete Printing: A Review on Materials, Challenges, and Current Progress in Australia. Buildings 2024, 14, 494. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Investigating concrete durability: The impact of natural pozzolan as a partial substitute for microsilica in concrete mixtures. Constr. Build. Mater. 2024, 419, 135491. [Google Scholar] [CrossRef]

- Guangyao, D.; Songmin, L.; Xiaoling, W.; Yazhi, Z.; Qihang, W. Optimal Design of Ecological Concrete Mix Proportion Based on AHP-GWO-BP Neural Network. Int. J. Environ. Res. 2024, 18, 24. [Google Scholar] [CrossRef]

- Mobaraki, B.; Pascual, F.J.C.; Lozano-Galant, F.; Soriano, R.P.; Lozano-Galant, J.A. Characterization of the thermal transmittance in buildings using low-cost temperature sensors. In Proceedings of the International Conference on Building Energy and Environment, Virtual, 25–29 July 2022; pp. 403–412. [Google Scholar] [CrossRef]

- Mobaraki, B.; Komarizadehasl, S.; Castilla Pascual, F.J.; Lozano-Galant, J.A.; Porras Soriano, R. A novel data acquisition system for obtaining thermal parameters of building envelopes. Buildings 2022, 12, 670. [Google Scholar] [CrossRef]

- Bennai, F.; Ferroukhi, M.Y.; Benmahiddine, F.; Belarbi, R.; Nouviaire, A. Assessment of hygrothermal performance of hemp concrete compared to conventional building materials at overall building scale. Constr. Build. Mater. 2022, 316, 126007. [Google Scholar] [CrossRef]

- Sawadogo, M.; Benmahiddine, F.; Godin, A.; Duquesne, M.; Belarbi, R.; Hamami, A. Development and hygrothermal performance analysis of a novel eco-friendly insulating wall under various climatic conditions. Build. Environ. 2023, 245, 110841. [Google Scholar] [CrossRef]

- Birjukovs, M.; Sinka, M.; Jakovics, A.; Bajare, D. Combined in situ and in silico validation of a material model for hempcrete. Constr. Build. Mater. 2022, 321, 126051. [Google Scholar] [CrossRef]

- Jirgensone, B.; Birjukovs, M.; Sinka, M.; Jakovics, A.; Bajare, D. Hygrothermal performance of hempcrete in a multi-layer wall envelope. J. Build. Eng. 2024, 84, 108359. [Google Scholar] [CrossRef]

- Benkhaled, M.; Ouldboukhitine, S.-E.; Bakkour, A.; Amziane, S. Sensitivity analysis of the parameters for assessing a hygrothermal transfer model HAM in bio-based hemp concrete material. Int. Commun. Heat Mass Transf. 2022, 132, 105884. [Google Scholar] [CrossRef]

- Yadav, M.; Saini, A. Opportunities & challenges of hempcrete as a building material for construction: An overview. Mater. Today Proc. 2022, 65, 2021–2028. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. A comprehensive review on the use of hemp in concrete. Constr. Build. Mater. 2022, 341, 127857. [Google Scholar] [CrossRef]

- Lamalle, M. Bloc de Béton de bois, Une alternative au Bloc traditionnel?-Étude des Caractéristiques Mécaniques, Thermiques et Écologiques d’un Bloc de Coffrage en Béton de Bois. In Faculté des Sciences Appliquées; Université de Liége: Liège, Belgium, 2016; p. 172. Available online: http://hdl.handle.net/2268.2/1283 (accessed on 2 January 2022).

- EN15026; Hygrothermal performance of building components and building elements - Assessment of moisture transfer by numerical simulation. European Committee for Standardization (CEN): Brussels, Belgium, 2007.

- ANSI/ASHRAE 160; Criteria for Moisture-Control Design Analysis in Buildings. ASHRAE: Atlanta, GA, USA, 2009. Available online: https://www.ashrae.org/file%20library/technical%20resources/standards%20and%20guidelines/standards%20addenda/160_2009_e_201601209.pdf (accessed on 3 April 2022).

- Haik, R.; Peled, A.; Meir, I. The thermal performance of lime hemp concrete (LHC) with alternative binders. Energy Build. 2020, 210, 109740. [Google Scholar] [CrossRef]

- Asli, M.; Brachelet, F.; Sassine, E.; Antczak, E. Thermal and hygroscopic study of hemp concrete in real ambient conditions. J. Build. Eng. 2021, 44, 102612. [Google Scholar] [CrossRef]

- Hachem, C.E.; Moussa, J.; Abahri, K. Thermal Study of Hemp Concrete Behavior when Subjected to High Temperatures by X-ray Microtomography. In Proceedings of the International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of CBMs and Concrete Structures, Milos, Greece, 14–16 June 2023; pp. 1318–1329. [Google Scholar]

- Bennai, F.; Issaadi, N.; Abahri, K.; Belarbi, R.; Tahakourt, A. Experimental characterization of thermal and hygric properties of hemp concrete with consideration of the material age evolution. Heat Mass Transf. 2018, 54, 1189–1197. [Google Scholar] [CrossRef]

- Makaka, G.; Meyer, E. Temperature stability of traditional and low-cost modern housing in the Eastern Cape, South Africa. J. Build. Phys. 2006, 30, 71–86. [Google Scholar] [CrossRef]

- Ouellet-Plamondon, C.; Kaboré, A. Hygrothermal Measurement of Heavy Cob Materials; Springer Nature: Cham, Switzerland, 2023; pp. 1243–1252. [Google Scholar] [CrossRef]

- Le Quéré, C.; Peters, G.P.; Andres, R.J.; Andrew, R.M.; Boden, T.A.; Ciais, P.; Friedlingstein, P.; Houghton, R.A.; Marland, G.; Moriarty, R. Global carbon budget 2013. Earth Syst. Sci. Data 2014, 6, 235–263. [Google Scholar] [CrossRef]

- Tomovska, R.; Radivojević, A. Tracing sustainable design strategies in the example of the traditional Ohrid house. J. Clean. Prod. 2017, 147, 10–24. [Google Scholar] [CrossRef]

- Boyer, D.; Sur L’augmentation de L’albédo des Toitures de Batiments Pour Diminuer la Progressiobs des Changements Climatiques. Supérieures GCH-Proj. D’études 2010, p. 34. Available online: https://www.ecohabitation.com/media/archives/files/Projet%20pour%20combattre%20les%20changements%20climatiques.pdf (accessed on 9 December 2023).

- Costantine, G.; Maalouf, C.; Moussa, T.; Polidori, G. Experimental and numerical investigations of thermal performance of a Hemp Lime external building insulation. Build. Environ. 2018, 131, 140–153. [Google Scholar] [CrossRef]

- Kabore, A.; Maref, W.; Plamondon, C. Hygrothermal performance of the building envelope with low environmental impact: Case of a hemp concrete envelope. In Proceedings of the 8th International Building Physics Conference (IBPC 2021), Copenhagen, Denmark, 25–27 August 2021. [Google Scholar]

| Hygrothermal Property | Values |

|---|---|

| Dry density [kg/m3] | 388 |

| The porosity of the material [-] | 0.66 |

| Specific heat in dry condition [J/kg K] | 1560 |

| Thermal conductivity dry state [W/m K] | 0.1 |

| Dry vapor diffusion resistance factor | 4.85 |

| Moisture-dependent thermal conductivity supplement [% M, %] | 3.34 |

| Maximum water content [kg/m3] | 655 |

| Open water saturation [kg/m3] | 424 |

| Moisture content at 80% [kg/m3] | 29 |

| Liquid absorption coefficient | 0.074 |

| Humidity type of construction [kg/m3] | 286 |

| Layer Name | Material in the Database | Density [kg/m3] | Porosity [-] | Thermal Conductivity [W/m·K] | Resistance to Diffusion [-] |

|---|---|---|---|---|---|

| Plaster | Exterior mineral plaster | 1900 | 0.24 | 0.8 | 25 |

| Polyurethane Rigid Foam (PUR) insulation | PUR | 40 | 0.95 | 0.03 | 50 |

| Wood concrete | Concrete block of expanded clay | 800 | 0.67 | 0.1 | 4 |

| Conventional concrete filler | Concrete E/C = 0.5 | 2300 | 0.18 | 1.6 | 180 |

| Ceiling | Interior ceiling (plaster) | 850 | 0.65 | 0.2 | 8.3 |

| Wood fiber panel | Wood fiber panel | 300 | 0.8 | 0.05 | 12.5 |

| Cellulose insulation | Cellulose fiber | 50 | 0.95 | 0.034 | 1.8 |

| Foamed concrete filler | Cellulose concrete | 500 | 0.77 | 0.12 | 8 |

| Number | Assumptions |

|---|---|

| 1 | Samples—isotropic, homogeneous, and without volumetric variation |

| 2 | No chemical reaction between water in all 3 phases |

| 3 | No energy dissipation during flow |

| 4 | Except for weather, no parameter depends on the time of day |

| 5 | No univalent relationship between water content and relative humidity |

| 6 | No air infiltration (airtight wall) |

| 7 | No relevance of temperature in moisture sorption |

| 8 | No advection |

| 9 | Perfect contact between materials |

| Number | Boundary Conditions |

|---|---|

| 1 | Interior environment: 21 °C ± 1 °C, RH 50 ± 10% (sinusoidal curve for Dhakal and EN 15 026 for Lamalle) |

| 2 | Initial state: 20 °C and 80% RH (constant in the component) for both authors and for WUFI Pro 6.2 |

| 3 | Southeast orientation [30] and west orientation [48] to maximize the combination of sun exposure and rain expectation; vertical surfaces [R1 = 0, R2 = 0.07 m/s; short building—height up to 10 m], with R1 and R2 as the driving rain coefficients that depend strongly on the position of the external façade |

| 4 | Short-wave absorptivity (shiny limestone and untreated spruce) = 0.4 |

| 5 | Rainwater absorption factor αr = 0.7 |

| 6 | No surface coating |

| 7 | ACH-8 for the air layer (ventilated) for assembly 2 [30], and for the rest of the assemblies, there is no air layer, where ACH is the Air Change per Hour |

| 8 | Cloud index or average cloud index: 2.64 for Dhakal and 0.64 for Lamalle (analyzed from weather files) |

| 9 | Simulation period is 3 years each: from 1 October 2015 to 1 October 2018 for Dhakal, and from 1 October 2016 to 1 October 2019 for Lamalle |

| 10 | The others, not mentioned, are taken by default as in the works of Dhakal and Lamalle |

| 11 | Heat transfer coefficients (interior hi and exterior he): program default (constant coefficient), hi = 8.0 W/m2K, he = 17.0 W/m2K |

| Unit | WUFI Pro 6.2 | Dhakal [30] | |

|---|---|---|---|

| Heat flow, left side | [MJ/m2] | −489.01 | −489.01 |

| Heat flow, right side | [MJ/m2] | −487.69 | −487.69 |

| Moisture flow, left side | [kg/m2] | 0.84 | 0.84 |

| Moisture flow, right side | [kg/m2] | 2.62 | 2.62 |

| Total water content (start of the simulation) | [kg/m2] | 9.75 | 9.75 |

| Total water content (end of the simulation) | [kg/m2] | 7.98 | 7.98 |

| Minimum value | [kg/m2] | 7.78 | 7.78 |

| Maximum value | [kg/m2] | 17.57 | 17.57 |

| Case 1: Cement Block Wall | Case 2: Compressed Earth Brick Wall | Case 3: Hemp Concrete Wall |

|---|---|---|

| Plaster: 1 cm Cement block: 23 cm Plaster: 1 cm | Plaster: 1 cm Compressed earth brick: 23 cm Plaster: 1 cm | Plaster: 1 cm HLC2 hemp concrete: 23 cm Plaster: 1 cm |

| Layer Name | Materials in the Database | Density [kg/m3] | Porosity [-] | Thermal Conductivity [W/mK] | Specific Heat [J/kgK] | Diffusion Resistance [-] |

|---|---|---|---|---|---|---|

| Roughcast | Cement plaster | 2000 | 0.3 | 1.2 | 850 | 25 |

| Cement block | Concrete W/C = 0.5 | 2300 | 0.18 | 1.6 | 850 | 180 |

| HLC2 hemp concrete | HLC2 hemp concrete | 317 | 0.79 | 0.085 | 1000 | 3.6 |

| Compressed earth brick | Compressed earth brick | 2100 | 0.24 | 0.8 | 1732 | 10 |

| Painting | Lime plaster | 1600 | 0.3 | 0.7 | 850 | 7 |

| Air blade | 20 mm air blade | 1.3 | 0.999 | 0.071 | 1000 | 0.73 |

| Case of Simulated Wall | Fraction of Incident Solar Radiation (%) | Exterior Wall Surface Temperature [°C] | Temperature in the Middle of the Wall [°C] | Interior Wall Surface Temperature [°C] |

|---|---|---|---|---|

| Cement block wall | 1 | 15 to 35 | 18 to 31 | 20 to 29 |

| 5 | 15 to 37 | 19 to 31 | 20 to 29 | |

| Earth brick wall | 1 | 13 to 37 | 20 to 30 | 21 to 27 |

| 5 | 13 to 38 | 20 to 30 | 22 to 27 | |

| Hemp concrete wall | 1 | 9 to 45 | 18 to 31 | 22 to 24.5 |

| 5 | 9 to 49 | 19 to 31 | 22 to 24.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaboré, A.; Maref, W.; Ouellet-Plamondon, C.M. Hygrothermal Performance of the Hemp Concrete Building Envelope. Energies 2024, 17, 1740. https://doi.org/10.3390/en17071740

Kaboré A, Maref W, Ouellet-Plamondon CM. Hygrothermal Performance of the Hemp Concrete Building Envelope. Energies. 2024; 17(7):1740. https://doi.org/10.3390/en17071740

Chicago/Turabian StyleKaboré, Aguerata, Wahid Maref, and Claudiane M. Ouellet-Plamondon. 2024. "Hygrothermal Performance of the Hemp Concrete Building Envelope" Energies 17, no. 7: 1740. https://doi.org/10.3390/en17071740

APA StyleKaboré, A., Maref, W., & Ouellet-Plamondon, C. M. (2024). Hygrothermal Performance of the Hemp Concrete Building Envelope. Energies, 17(7), 1740. https://doi.org/10.3390/en17071740