Experimental Study of the Performance of Turbo-Charged Gasoline Direct-Injection Engine Based on Different Pre-Chamber Structures

Abstract

:1. Introduction

2. Experimental Design

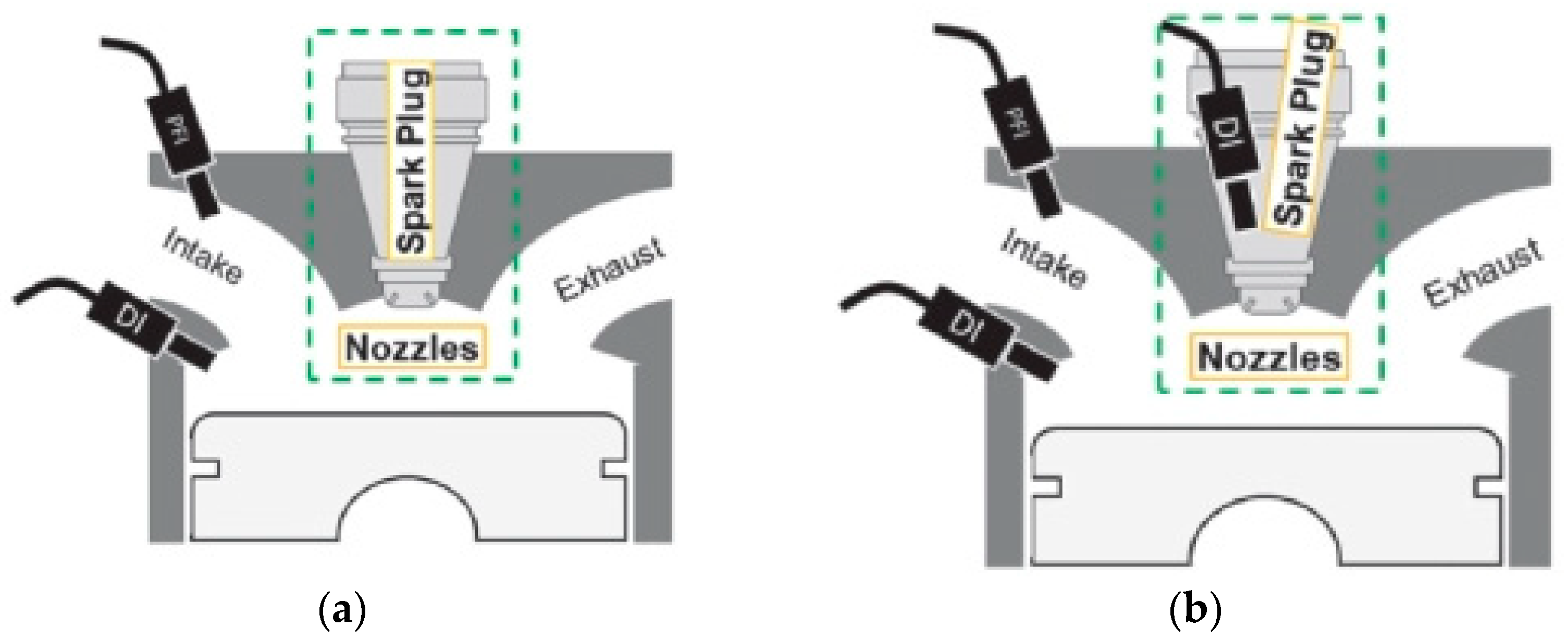

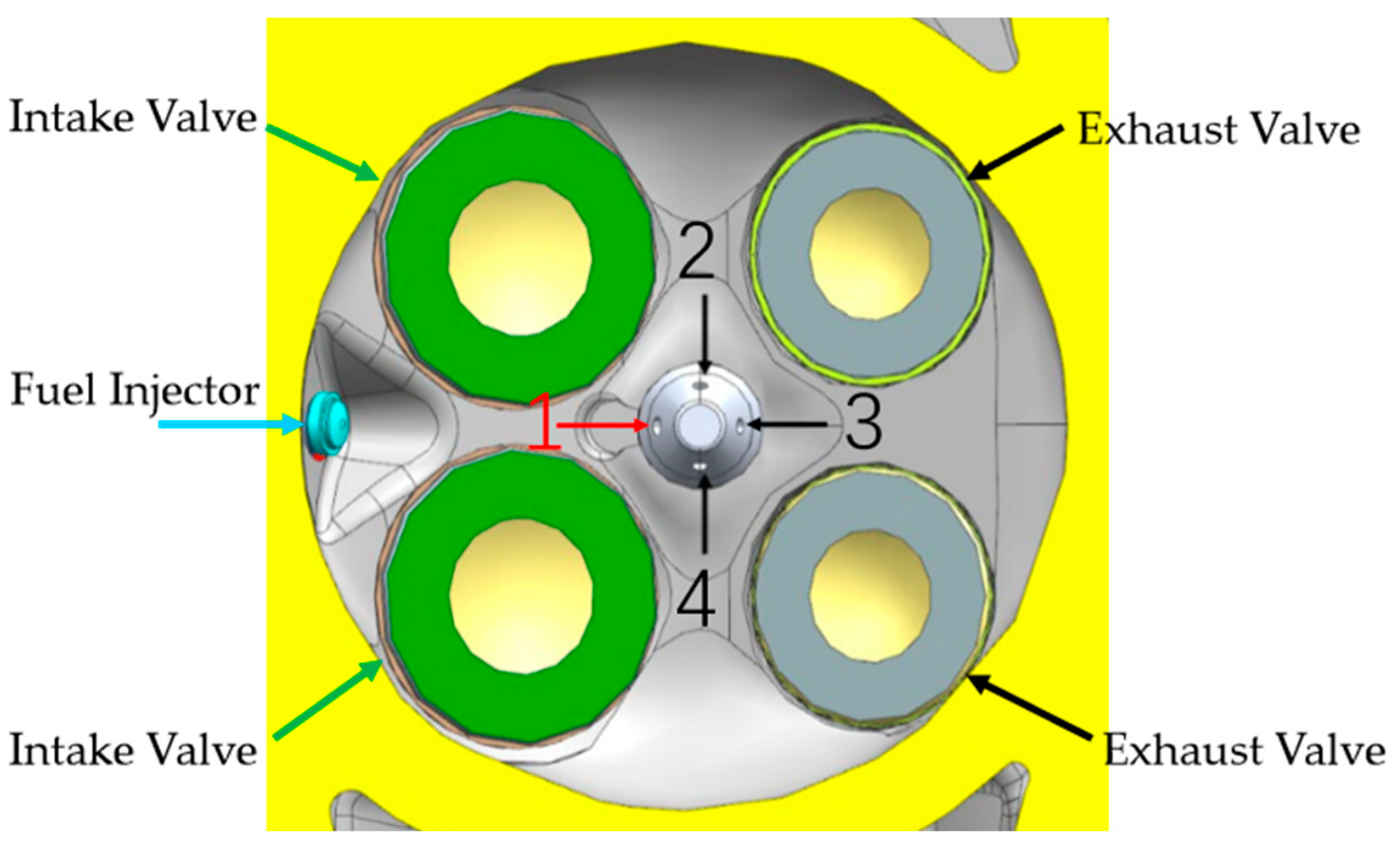

2.1. Experimental Engine

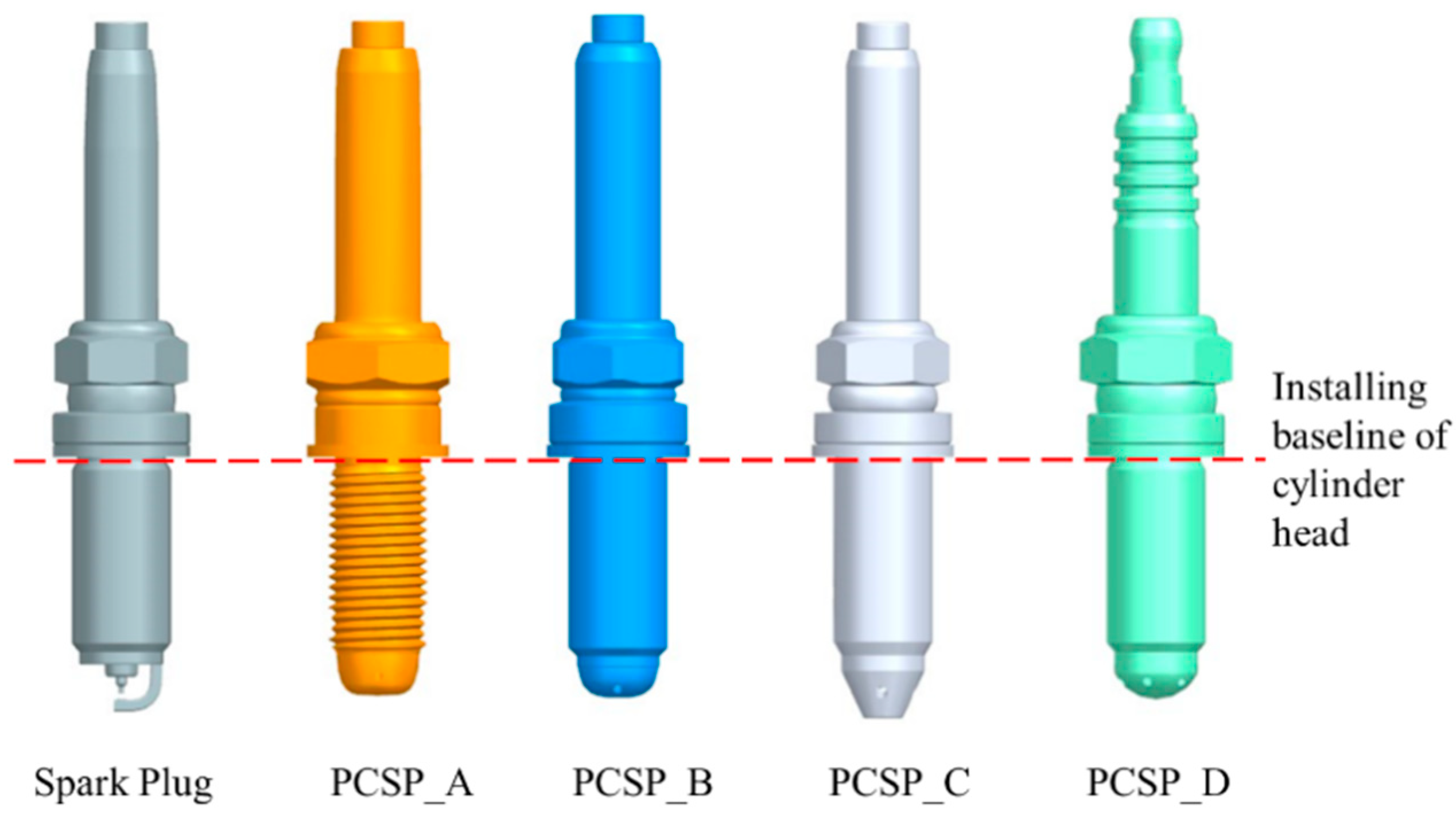

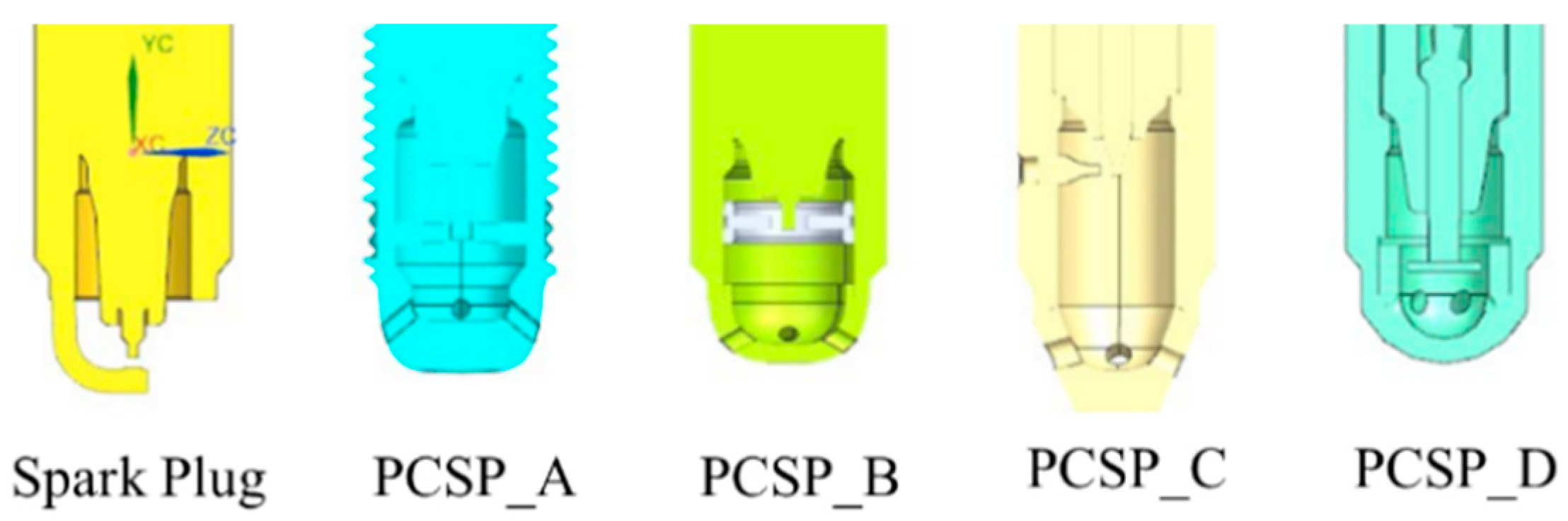

2.2. Pre-Chamber Spark Plugs

2.3. Test Setup

2.4. Test Conditions and Methods

- (1)

- Load characterization tests were performed at 2000 r/min speed; the load started from BMEP 2 bar up to 20 bar and WOT condition.

- (2)

- Characteristic point tests were performed at 3000 r/min speed; the characteristic point loads were BMEP 10 bar and 20 bar, respectively.

- (3)

- Characteristic point tests were conducted at 3200 r/min speed; the characteristic point load at 3200 r/min was BMEP 12 bar, which is the optimum fuel consumption point.

- (4)

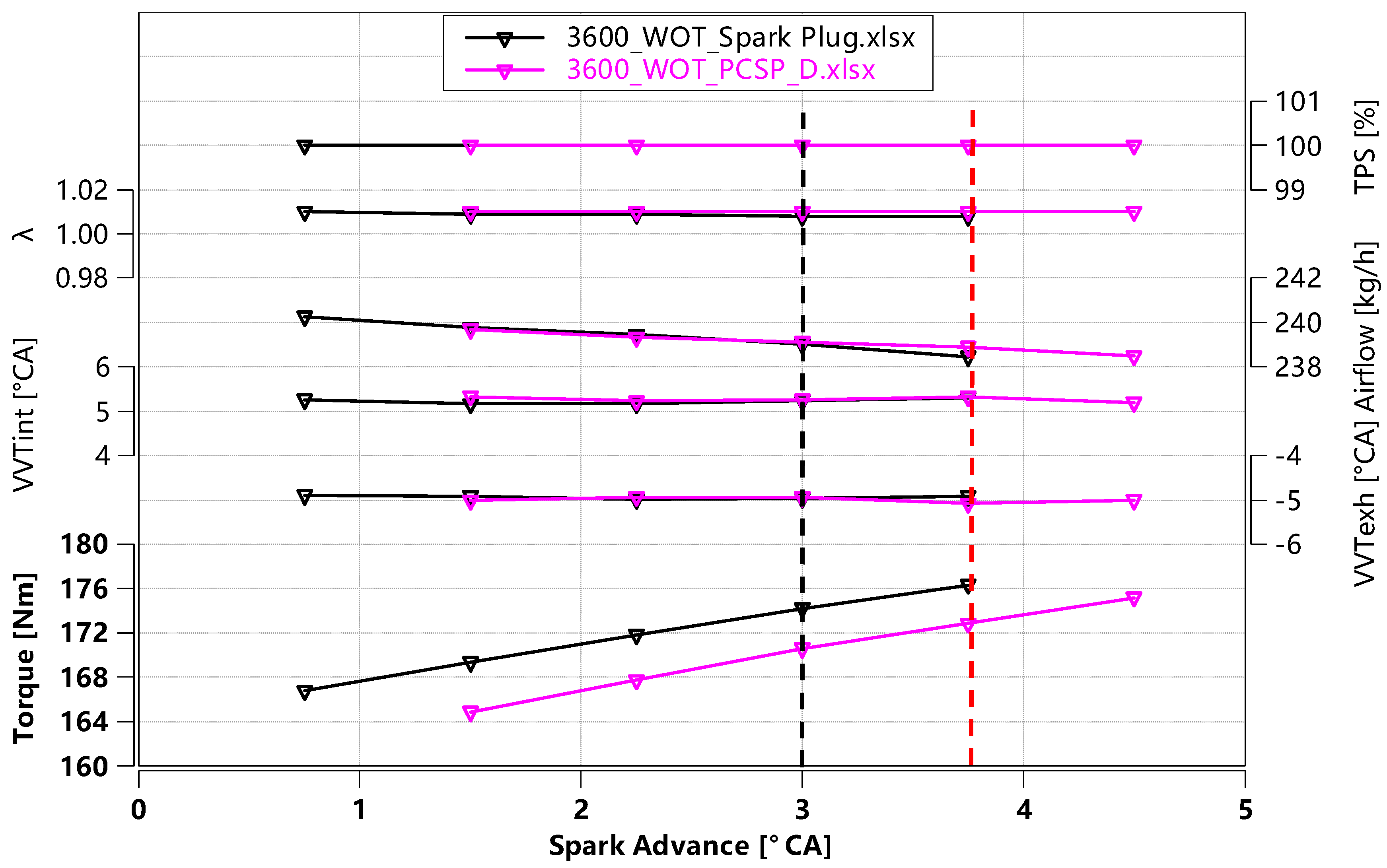

- Spark angle scans for WOT conditions were performed at 3600 r/min speed to compare the dynamics performance of pre-chamber spark plug D and conventional spark plug.

3. Test Results Analysis

3.1. Dynamic Performance Analysis

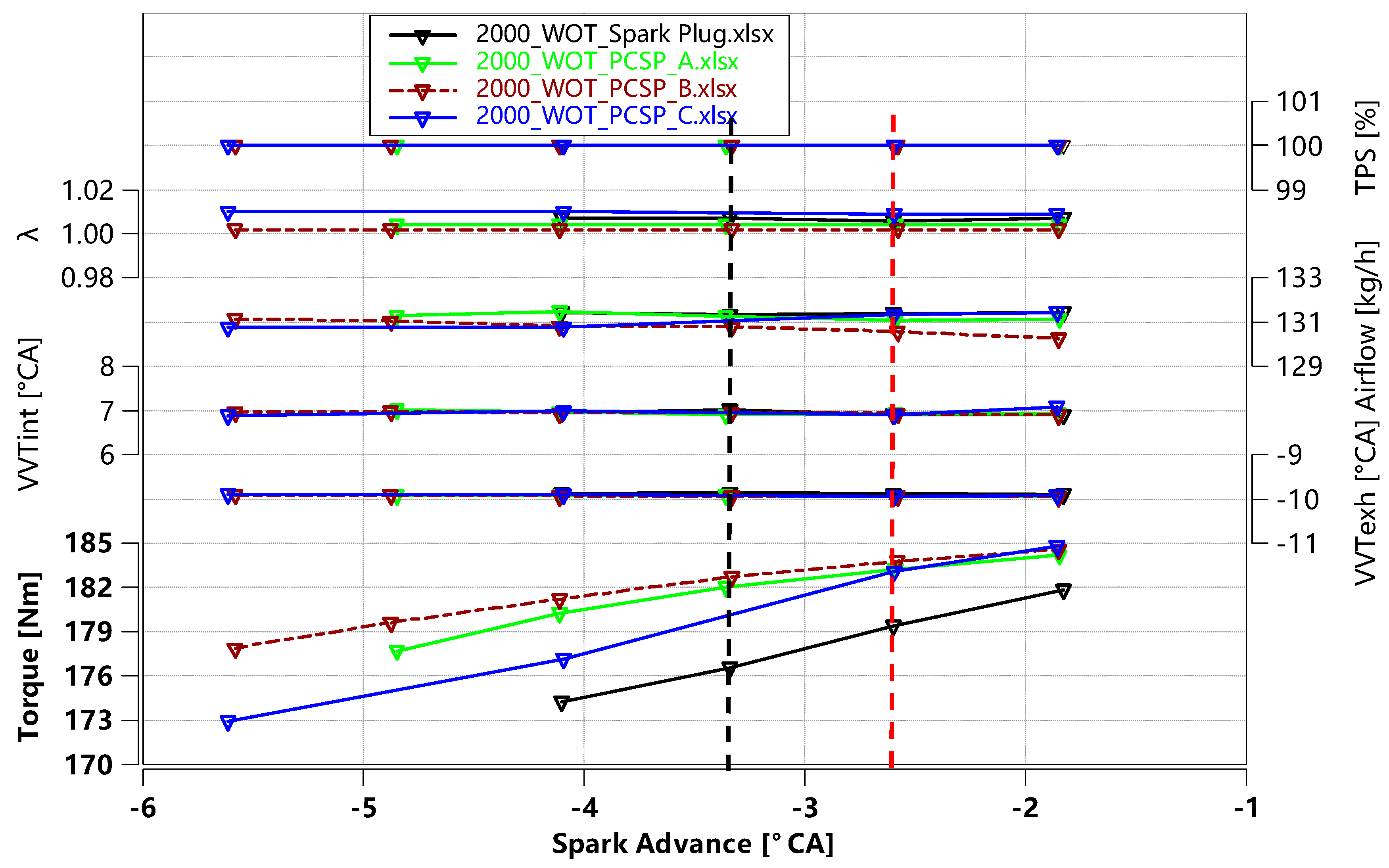

- (1)

- As shown in the performance data at the red dashed line in Figure 8, the dynamics of the pre-chamber spark plug meet the external characteristic torque requirements. Its power is increased by 1.6% relative to a conventional spark plug.

- (2)

- Combining the performance data at the black dashed line shown in Figure 8 and Figure 9, the power under the same spark angle conditions is ranked as follows: B > A > C > Base > D, i.e., pre-chamber spark plugs B, A, and C are more powerful, and D is slightly less powerful compared with conventional spark plugs.

3.2. Economic Analysis

3.2.1. Economy of 2000 r/min and BMEP 2 bar

- (1)

- At a 2 bar load, the fluctuations in the mean effective pressure and relative charge Volumetric Efficiency (VE) of the pre-chamber spark plugs are significantly larger, and the specific fuel consumption is significantly higher compared to the conventional spark plugs.

- (2)

- At a 2 bar load, the exhaust temperature of pre-chamber spark plugs is higher than that of conventional spark plugs.

- (3)

- At a 2 bar load, the economy of the four pre-chamber spark plugs is ranked as C > A > B > D, i.e., the fuel economy of pre-chamber C is the best, and that of D is the worst.

- (4)

- Although pre-chamber C has the best BSFC among the pre-chamber spark plugs, it is still with a 6% deterioration of BSFC. It is a long way from a conventional spark plug.

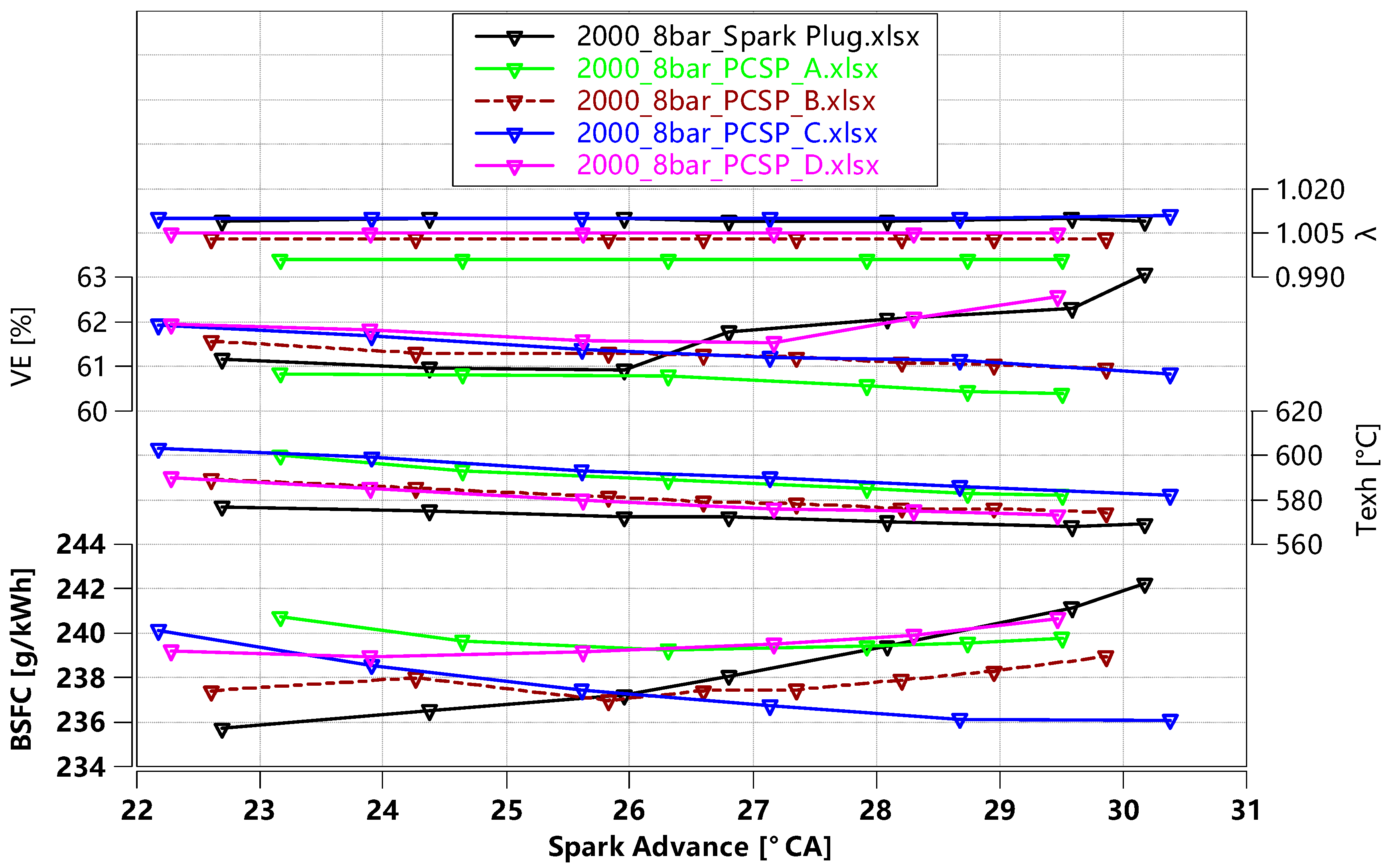

3.2.2. Economy of 2000 r/min and BMEP 8 bar

- (1)

- Compared to 2 bar load, the range of fluctuations in the mean effective pressure and relative charge of pre-chamber spark plugs and the difference in specific fuel consumption relative to ordinary spark plugs were significantly reduced.

- (2)

- The economy of the four pre-chamber spark plugs is ranked as C > B > A > D, i.e., the fuel economy of pre-chamber C is the best, and that of D is the worst.

- (3)

- The economy of pre-chamber C is the best among the pre-chamber spark plugs, reaching a level comparable to that of conventional spark plugs.

3.2.3. Economy of 2000 r/min and BMEP 16 bar

- (1)

- At this load, pre-chamber spark plugs outperform conventional spark plugs.

- (2)

- Similar to that at 2 bar and 8 bar loads, the fuel consumption of pre-chamber C remains the best, and that of pre-chamber D is the worst.

- (1)

- At a small load like 2 bar, the ignition economy of the pre-chamber is not as satisfactory as that of conventional spark plugs, with a 6% difference.

- (2)

- At a medium load like 8 bar, both are economically comparable.

- (3)

- At a large load like 16 bar, the fuel economy of the pre-chamber is more satisfactory.

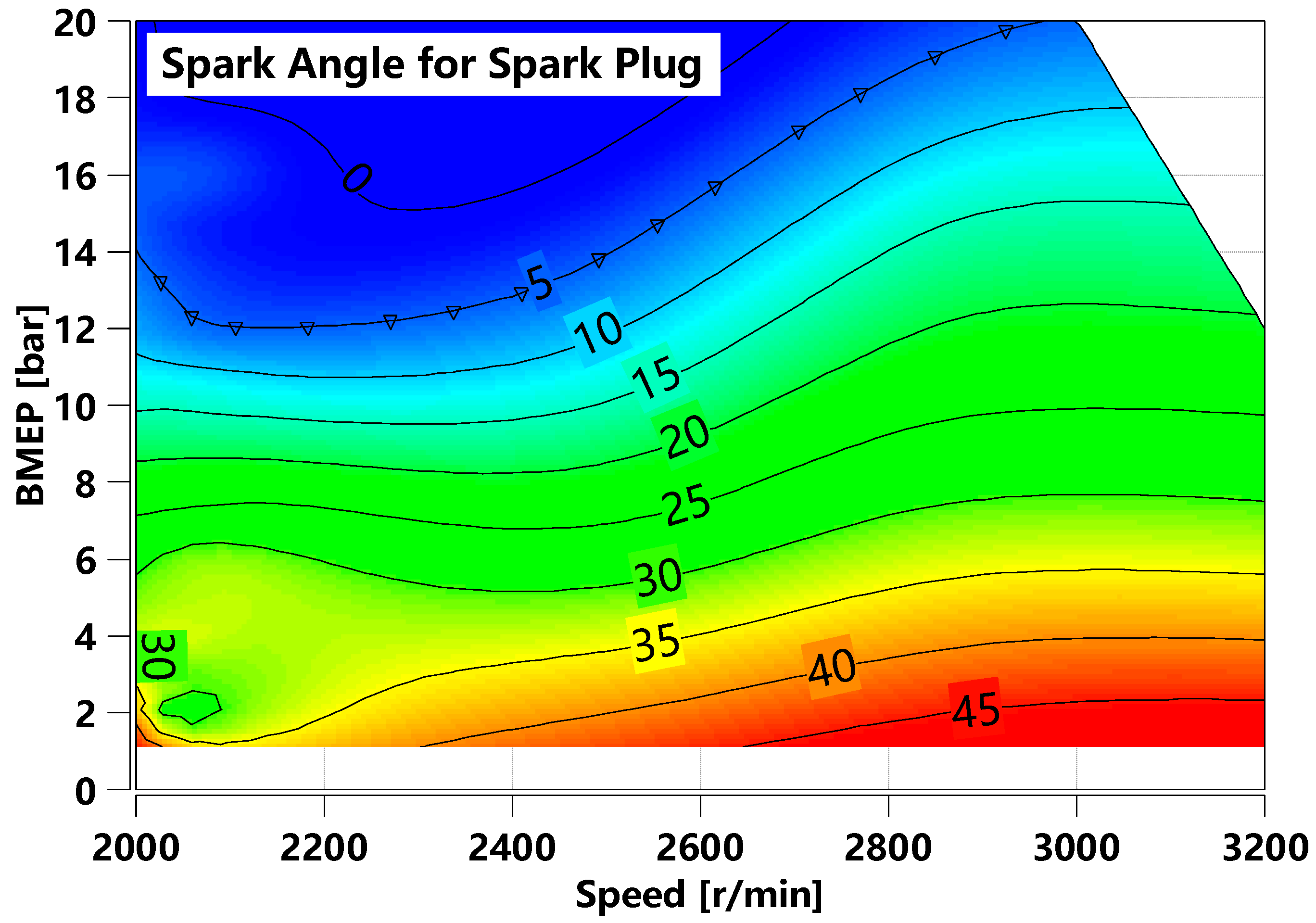

3.2.4. Engine Spark Angle MAP Diagram

- (1)

- The spark angle change pattern of pre-chamber spark plugs is similar to that of conventional spark plugs; i.e., under the same rotational speed, the small load corresponds to the large spark angle, the large load corresponds to the small spark angle, and the spark angle decreases with the increase in load, which is in line with the general law of engines. This is due to the fact that the pre-chamber volume generally accounts for less than 5% of the whole combustion chamber volume, and pre-chamber combustion only stands as the source for the main combustion chamber, with the latter as the major area for cylinder combustion.

- (2)

- For conventional spark plug, the spark angle is 5 °CA at 2000 r/min and 14 bar, while for pre-chamber spark plugs, the same spark angle corresponds to a load of 16~17 bar, which means that the spark angle can be advanced for pre-chamber spark plugs. Through analysis, the spark angle of pre-chamber spark plugs can be advanced by 2~3 °CA relative to conventional spark plugs.

- (3)

- For pre-chamber spark plugs, in terms of the 30 °CA spark angle contour located in the low- and medium-load area, it can be seen that the 30 °CA contour of pre-chamber C occupies the largest proportion of the working area, followed by pre-chamber B, D, and A in a declining order. This shows that under the same conditions, pre-chamber C features a larger spark angle at the same rotational speed and load. Combined with the structure of pre-chamber C and the orientation of its jet holes in the engine, the design of the pre-chamber structure needs to take into account the direction of the in-cylinder airflow and needs to be matched with the design of the combustion chamber.

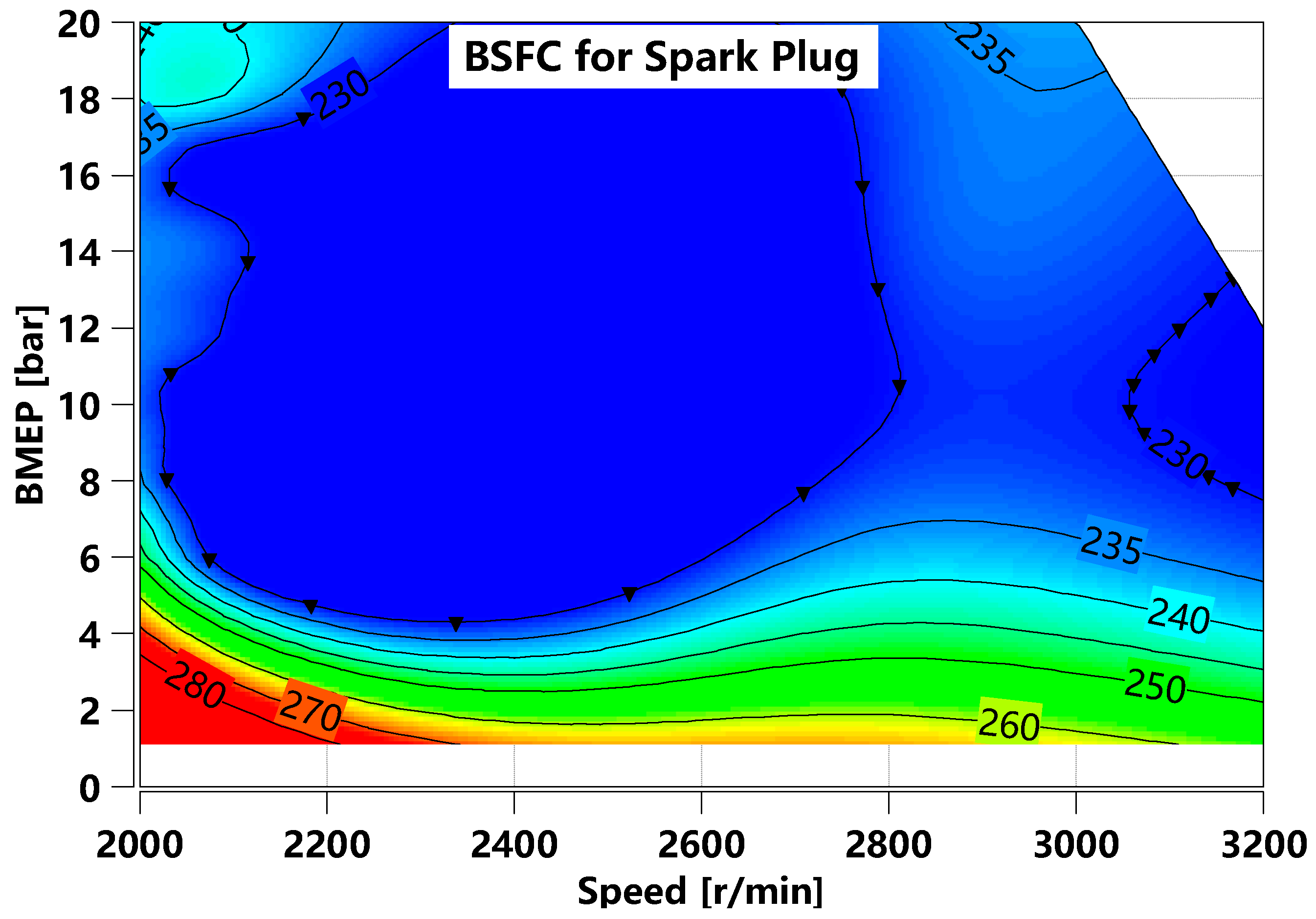

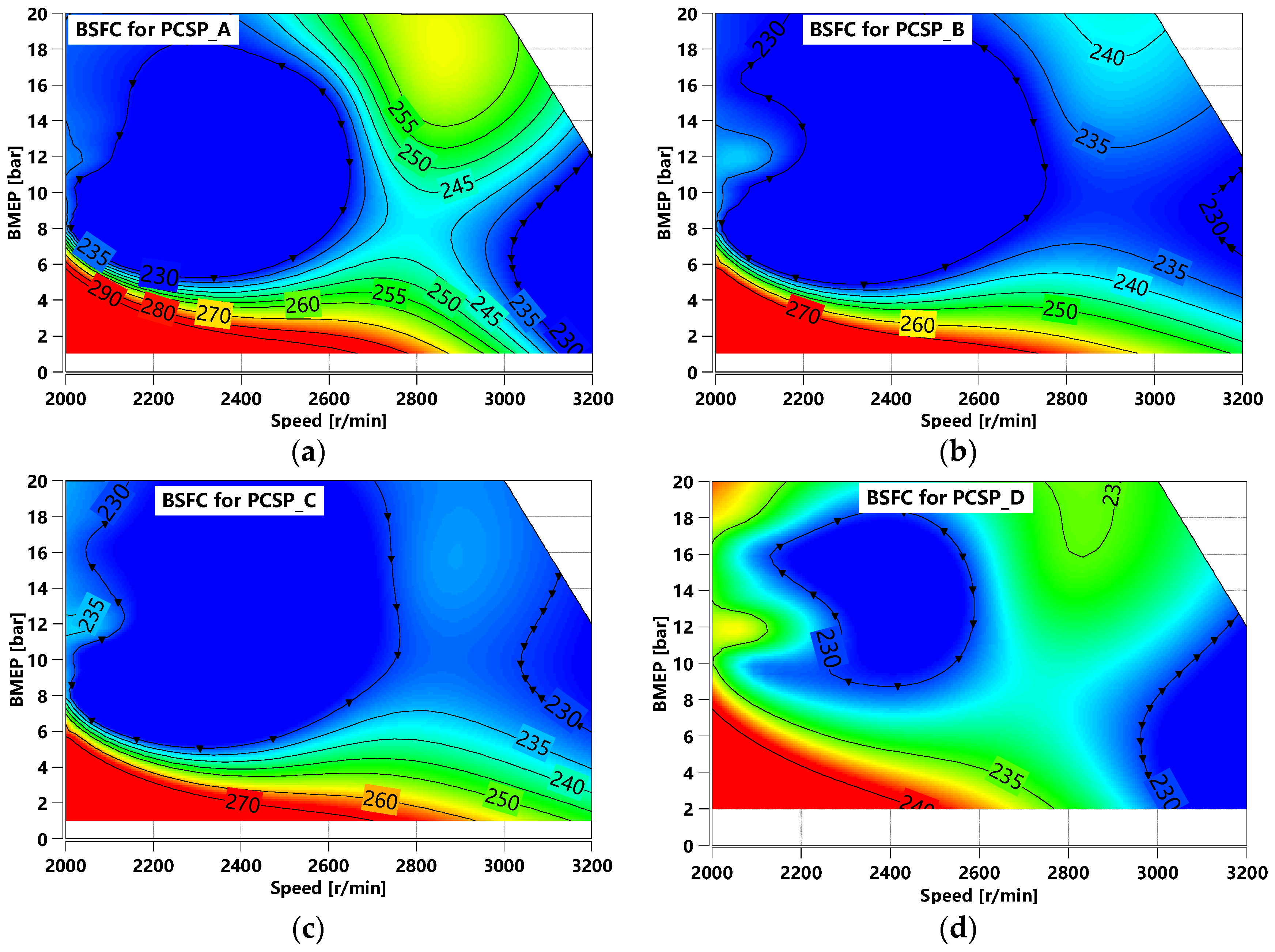

3.2.5. Engine Fuel Economy MAP Diagram

- (1)

- As shown in Figure 16, pre-chamber C has the largest area enclosed by the 230 g/kWh contour, and pre-chamber T is the smallest. The areas enclosed by the spark plugs of the four pre-chambers are ranked as C > B > A > D. Therefore, in terms of the economy represented by the specific fuel consumption, the economy of the four pre-chamber structures is ranked as C > B > A > D. This is consistent with the results of the pre-chambers at 2000 r/ min and 8 bar.

- (2)

- To analyze the economy of the spark plugs of pre-chamber C and conventional spark plugs, the 230 g/(kW·h) specific fuel consumption curve is still used as a reference. Figure 15 shows that the 230 g/(kW·h) curve is close to 5 bar through the low-load region of the conventional spark plugs. Figure 16c indicates that the 230 g/(kW·h) curve is close to 6 bar through the low-load region of pre-chamber C. Thus, for the low-load region, the pre-chamber spark plugs are less economical than the conventional ones. Based on the distribution pattern of specific fuel consumption contour, it can be seen that this gap is 5~10 g/(kW·h) in the low-load region. Similarly, the economy at 20 bar in the high-load region is analyzed. From Figure 16, the fuel consumption curve of pre-chamber spark plug C crosses the speed range roughly from 2100 r/min to 2700 r/min, while that of the conventional spark plug covers the speed range roughly from 2400 r/min to 2700 r/min. It can be concluded that the speed range covered by the pre-chamber spark plug C is wider than that of the conventional spark plug, i.e., the economy of pre-chamber spark plug C is better than that of the conventional spark plug in the high-load region.

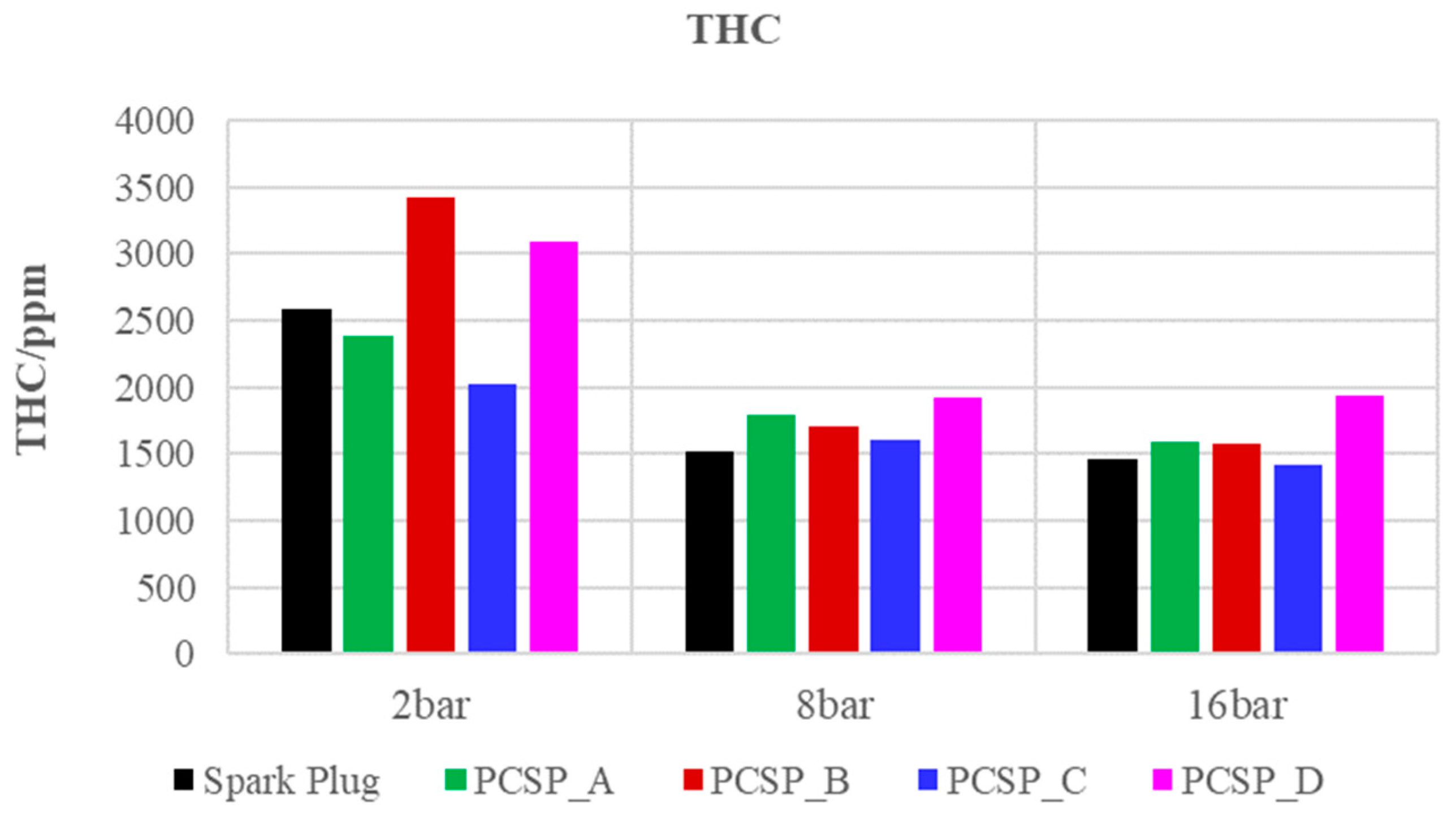

3.3. Emission Characteristic Analysis

3.3.1. THC Emission Characteristics

- (1)

- THC emissions are load-dependent and significantly higher at small loads than at medium and large loads.

- (2)

- THC emissions from the pre-chambers are overall comparable to those of conventional spark plugs.

- (3)

- THC emissions of pre-chambers with different structures are similar, with pre-chamber C having the lowest THC emissions at all loads.

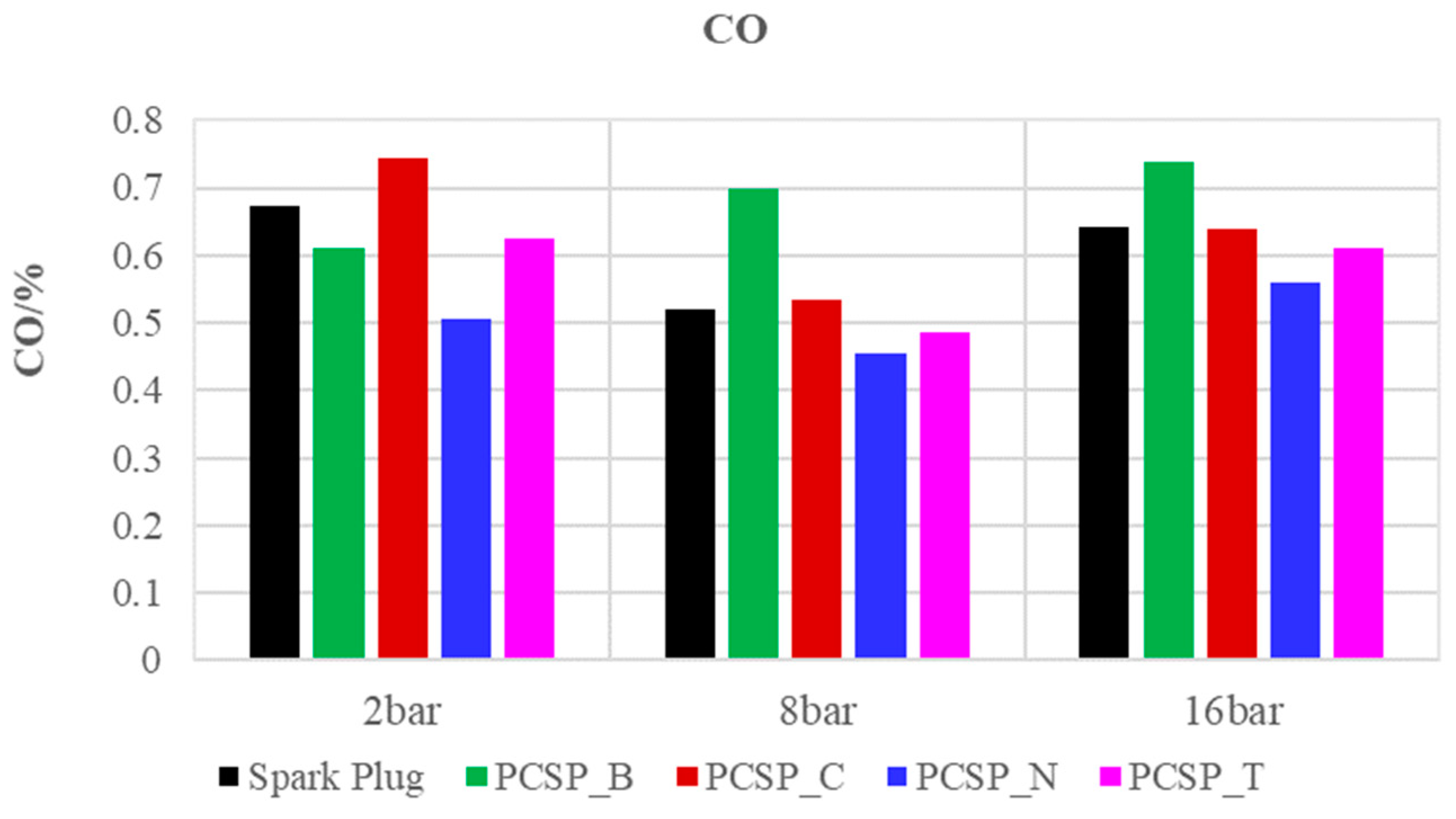

3.3.2. CO Emission Characteristics

- (1)

- CO emissions are independent of load, with no significant emission difference at small, medium, and large loads.

- (2)

- CO emissions from the pre-chambers are overall comparable to those of conventional spark plugs.

- (3)

- CO emissions of pre-chambers with different structures are similar, with pre-chamber N having the lowest CO emissions at all loads.

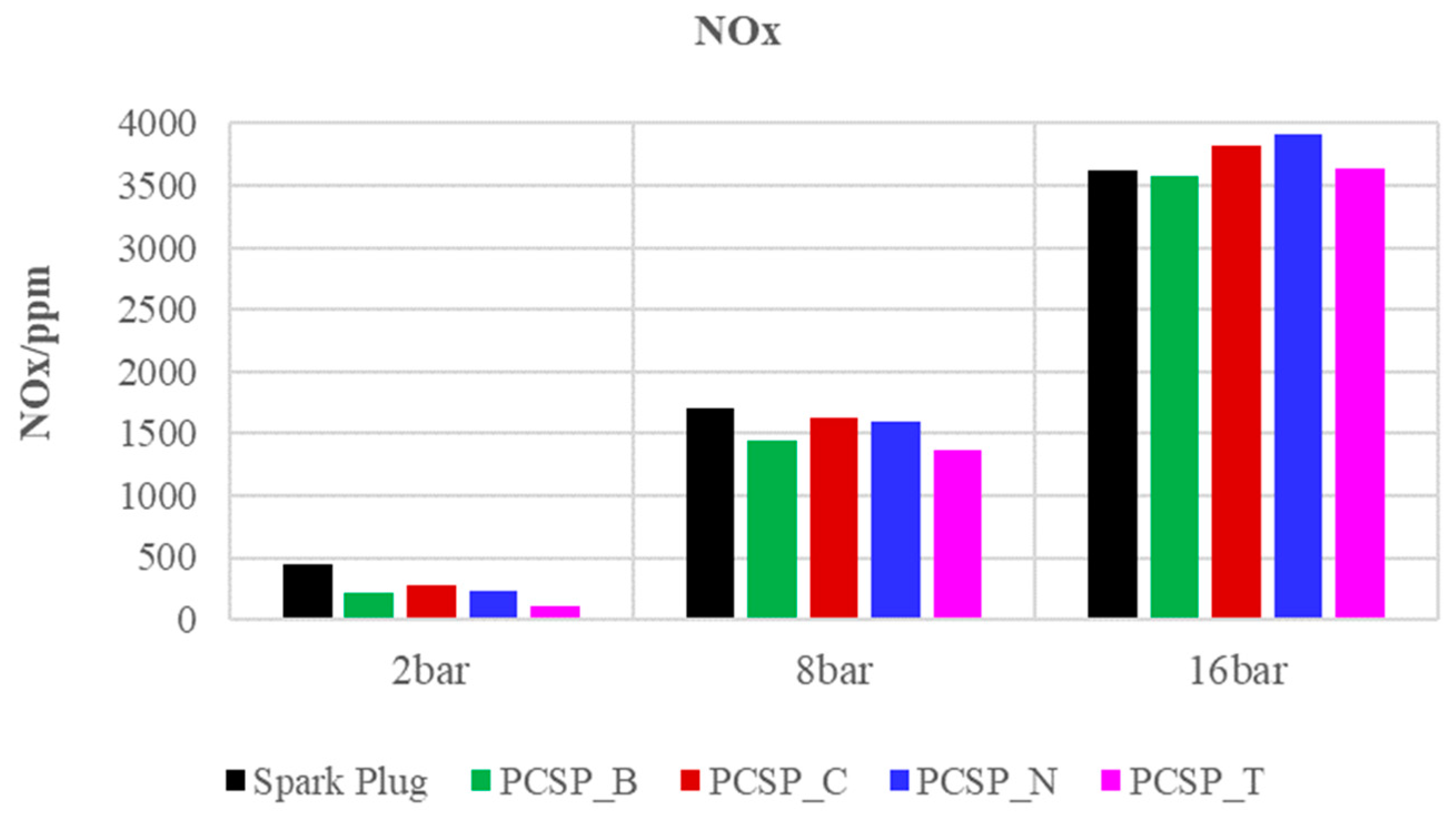

3.3.3. NOx Emission Characteristics

- (1)

- NOx emissions are strongly correlated with load and increase with load.

- (2)

- NOx emissions of pre-chambers are overall comparable to those of conventional spark plugs.

- (3)

- NOx emissions of different pre-chamber structures are similar.

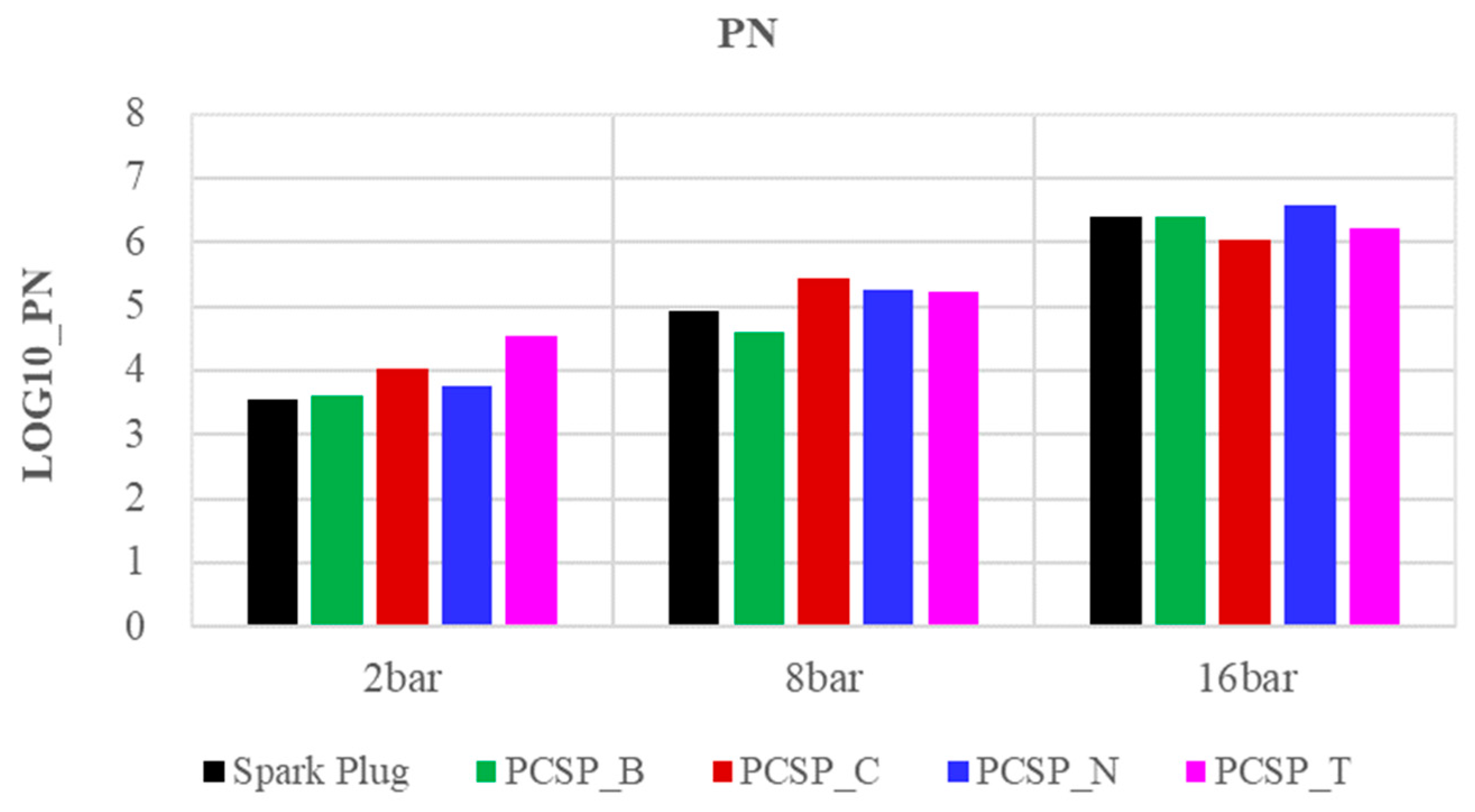

3.3.4. PN Emission Characteristics

- (1)

- PN emissions are positively correlated with load and increase with load.

- (2)

- PN emissions from the pre-chambers are overall comparable to those of conventional spark plugs.

- (3)

- PN emissions of pre-chambers with different structures are similar.

4. Conclusions

- (1)

- The pre-chamber structure has a direct impact on engine performance, and there is a clear load demarcation line for the impact. Under the WOT condition, the dynamics of pre-chamber ignition are 1.6% higher than that of conventional spark plugs. At the small load of 2 bar, the economy of pre-chamber ignition is degraded by 6%; at the medium load of 8 bar, the two have comparable economy; and at the large load of 16 bar, pre-chamber ignition has favorable economy.

- (2)

- The pattern of the spark angle of pre-chamber jet ignition is similar to that of conventional spark plugs; namely, the spark angle decreases with the increase in load at the same rotational speed. By analyzing the MAP diagrams of spark angle, it is derived that the spark angle of pre-chamber spark plugs can be advanced by 2~3 °CA relative to conventional spark plugs.

- (3)

- The pre-chamber needs to be designed with separate ground electrodes to improve ignition reliability. On this basis, the integration of the pre-chamber with the main combustion chamber should be taken into account, especially utilizing the flow field of the main combustion chamber to improve the sweeping of gas in the pre-chamber and to improve the fuel economy and emissions of pre-chamber ignition.

- (4)

- The pre-chamber technology can meet the power requirements of the engine, and the emission level at each load is comparable to that of conventional spark plugs. From the point of view of technology application, pre-chamber ignition technology has potential application prospects.

- (1)

- Fuel economy improvement for small load conditions represented by 2 bar.

- (2)

- The influence of the pre-chamber structure on combustion characteristics; investigation with CFD simulation on the influence of the pre-chamber structure on the in-cylinder flow field, mixture distribution, jet flame spread, and combustion process.

- (3)

- Further study on active pre-chamber to improve poor ignition ability during ultra-lean combustion, especially at low BMEP.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Definitions/Abbreviations

| AC | Active Chamber |

| APS | Acceleration Pedal Position |

| BMEP | Brake Mean Effective Pressure |

| BSFC | Brake-Specific Fuel Consumption |

| °CA | Crank Angle Degree |

| CFD | Computational Fluid Dynamics |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| COV | Coefficient of Variation |

| CR | Compression Ratio |

| EGR | Exhaust Gas Recirculation |

| GDI | Gasoline Direct Injection |

| HC | Hydrocarbons |

| KBL | Knock Boundary Limit |

| λ | Air–Excess ratio |

| MBT | Minimum Advance for Best Torque |

| NOx | Nitrogen Oxides |

| PC | Passive Chamber |

| PCSP | Pre-Chamber Spark Plug |

| PN | Particulate Number |

| RCEM | Rapid Compression Expansion Machine |

| VE | Volumetric Efficiency |

| Texh | Temperature for Exhaust port |

| TJI | Turbulent Jet Ignition |

| TKE | Turbulence Kinetic Energy |

| TPS | Throttle Position Sensor |

| VVTint | Variable Valve Timing for Intake |

| VVTexh | Variable Valve Timing for Exhaust |

| WOT | Wide Open Throttle |

References

- Ayala, F.; Heywood, J. Lean SI Engines: The Role of Combustion Variability in Defining Lean Limits; SAE Tech Paper, 2007-24-0030; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Salvi, B.L.; Subramanian, K.A. Experimental investigation and phenomenological model development of flame kernel growth rate in a gasoline fueled spark ignition engine. Appl. Energy 2015, 139, 93–103. [Google Scholar] [CrossRef]

- Pires, M.A.M.; Roso, V.R.; Alvarez, C.E.C.; Duarte, V.F.; Santos, N.D.S.A.; Valle, R.M. Effects of Operation Temperature on Exhaust Emissions in a Spark Ignition System Using Pre-Chamber Stratified System; SAE Technical Paper, 2019-36-0130; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Santos, N.D.S.A.; Alvarez, C.E.C.; Roso, V.R.; Baeta, J.G.C.; Valle, R.M. Combustion analysis of a SI engine with stratified and homogeneous pre-chamber ignition system using ethanol and hydrogen. Appl. Therm. Eng. 2019, 160, 113985. [Google Scholar] [CrossRef]

- Toulson, E.; Schock, H.; Attard, W. A Review of Pre-Chamber Initiated Jet Ignition Combustion Systems; SAE Technical Paper 2010-01-2263; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Badawy, T.; Bao, X.C.; Xu, H. Impact of spark plug gap on flame kernel propagation and engine performance. Appl. Energy 2017, 191, 311–327. [Google Scholar] [CrossRef]

- Turkish, M.C. 3-Valve Stratified Charge Engines: Evolvement, Analysis and Progression; SAE Technical Paper 741163; SAE International: Warrendale, PA, USA, 1974. [Google Scholar]

- Sandoval, M.H.B.; Alvarez, C.E.C.; Roso, V.R.; Santos, N.D.S.A.; Valle, R.M. The influence of volume variation in a homogeneous pre-chamber ignition system in combustion characteristics and exhaust emissions. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 72. [Google Scholar] [CrossRef]

- Noguchi, N.; Sanda, S.; Nakamura, N. Development of Toyota Lean Burn Engine; SAE Technical Paper 760757; SAE International: Warrendale, PA, USA, 1976. [Google Scholar]

- Adams, T.G. Torch Ignition for Combustion Control of Lean Mixtures; SAE Technical Paper 790440; SAE International: Warrendale, PA, USA, 1979. [Google Scholar]

- Brandstetter, W. The Volkswagen Lean Burn Pc-Engine Concept; SAE Technical Paper 800456; SAE International: Warrendale, PA, USA, 1980. [Google Scholar]

- Date, T.; Yagi, S. Research and Development of Honda CVCC Engine; SAE Technical Paper 740605; SAE International: Warrendale, PA, USA, 1974. [Google Scholar]

- Alvarez, C.E.; Couto, V.R.; Roso, A.B.; Thiriet; Valle, R.M. A review of pre-chamber ignition systems as lean combustion technology for SI engines. Appl. Therm. Eng. 2018, 128, 107–120. [Google Scholar]

- Yamaguchi, S.; Ohiwa, N.; Hasegawa, T. Ignition and burning process in a divided chamber bomb. Combust. Flame 1985, 59, 177–187. [Google Scholar] [CrossRef]

- Yasuhiro, U.; Takashi, K.; Toru, T. Combustion Technologies for Latest Automobile Engines and the Future Directions. J. Combust. Soc. Jpn. 2018, 60, 18–26. [Google Scholar]

- Attard, W.; Fraser, N.; Parsons, P.; Toulson, E. A Turbulent Jet Ignition Pre-Chamber Combustion System for Large Fuel Economy Improvements in a Modern Vehicle Powertrain; SAE Technical Paper 2010-01-1457; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Attard, W.; Bassett, M.; Parsons, P.; Blaxill, H. A New Combustion System Achieving High Drive Cycle Fuel Economy Improvements in a Modern; SAE Technical Paper 2011-01-0664; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Attard, W.; Bassett, M.; Parsons, P.; Blaxill, H. A Lean Burn Gasoline Fueled Pre-Chamber Jet Ignition Combustion System Achieving High Efficiency and Low NOx at Part Load; SAE Technical Paper 2012-01-1146; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Bunce, M.; Blaxill, H.; Kulatilaka, W.; Jiang, N. The Effects of Turbulent Jet Characteristics on Engine Performance Using a Pre-Chamber Combustor; SAE Technical Paper 201401-1195; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Chinnathambi, P.; Bunce, M.; Cruff, L. RANS Based Multidimensional Modeling of an Ultra-Lean Burn Pre-Chamber Combustion System with Auxiliary Liquid Gasoline Injection; SAE Technical Paper 2015-010386; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Sens, M.; Binder, E.; Benz, A.; Kramer, L.; Schultalbers, M.; Blumenröde, K. Pre-chamber Ignition as a Key Technology for Highly Efficient SI Engines New Approaches and Operating Strategies. In Proceedings of the 39th International Vienna Motor Symposium, Vienna, Austria, 26–27 April 2018. [Google Scholar]

- Sens, M.; Binder, E. Pre-chamber Ignition as a Key Technology for Future Powertrain Fleets. MTZ Worldw. 2019, 80, 44–45. [Google Scholar] [CrossRef]

- Attard, W.P.; Parsons, P. Flame Kernel Development inside a Pre-Chamber of a Turbulent jet Ignition Combustion System in a Modern Vehicle Powertrain; SAE Tech Paper, 2010-01-2260; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Millo, F.; Rolando, L.; Piano, A.; Sementa, P.; Catapano, F.; Di Iorio, S.; Bianco, A. Experimental and Numerical Investigation of a Passive Pre-Chamber Jet Ignition Single-Cylinder Engine; SAE Technical Paper 2021-24-0010; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Frasci, E.; Sementa, P.; Arsie, I.; Jannelli, E.; Vaglieco, B.M. Experimental and Numerical Investigation of a Lean SI Engine to Be Operated as Range Extender for Hybrid Powertrains; SAE Technical Paper 2021-24-0005; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Marquez, M.E.; Hlaing, P.; Houidi, M.B.; Magnotti, G.; Johansson, B.; Cenker, E. Optical Diagnostics of Pre-Chamber Combustion with Flat and Bowl-In Piston Combustion Chamber. Combustion Chamber; SAE Technical Paper 2021-01-0528; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Yu, X.; Zhang, A.; Baur, A.; Engineer, N. The Impact of Pre-Chamber Design on Part Load Efficiency and the Impact of Pre-Chamber Design on Part Load Efficiency and Emissions of a Miller Cycle Light Duty Gasoline Engine; SAE Technical Paper 2021-01-0479; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

| Parameter | Parameter Value |

|---|---|

| Spark Ignition type | Conventional Spark Plug and Pre-chamber Spark Plug |

| Engine displacement | 0.996 L |

| Bore diameter | 72.6 mm |

| Stroke | 80.2 mm |

| Connecting rod length | 141.9 mm |

| Stroke bore ratio | 1.10 |

| Number of valves per cylinder | 4 |

| Compression Ratio (CR) | 10.5 |

| Intake method | exhaust gas turbo-charged |

| Injecting method | Gasoline Direct Injection (GDI) |

| Maximum injection pressure | 350 bar |

| EGR system | Water-cooled EGR |

| Rated power | 85 kW |

| Rated torque | 175 Nm |

| Design Feature | Ground Electrode | Gap | Pre-Chamber Volume | Number | Diameter |

|---|---|---|---|---|---|

| Spark Plug | J-type | 0.75 mm | - | - | - |

| PCSP_A | independent electrode × 2 | 0.3 mm | 376 mm3 | 4 | 1.0 mm |

| PCSP_B | independent electrode × 2 | 0.65 mm | 618 mm3 | 4 | 1.2 mm |

| PCSP_C | independent electrode × 1 | 0.7 mm | 558 mm3 | 4 | one is 1.75 mm, others are 1.5 mm |

| PCSP_D | Pre-chamber inner surface | 0.45 mm | 280 mm3 | 6 | 1.2 mm |

| Measuring Device | Equipment Specification |

|---|---|

| Dynamometer | AC asynchronous dynamometer 202/12 |

| Measurement and control system | PUMA (error: 0.3%) |

| Fuel consumption meter | AVL740 (error: 0.3%) |

| Oil/Cooling Trolley | AVL577 (error: 3 °C) |

| Emissions Analyzer | MEXA-ONED2EGR |

| PN Analyzer | MEXA-2100SPCS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Sun, Y.; Zhang, Z.; Yin, C. Experimental Study of the Performance of Turbo-Charged Gasoline Direct-Injection Engine Based on Different Pre-Chamber Structures. Energies 2024, 17, 1773. https://doi.org/10.3390/en17071773

Zhao X, Sun Y, Zhang Z, Yin C. Experimental Study of the Performance of Turbo-Charged Gasoline Direct-Injection Engine Based on Different Pre-Chamber Structures. Energies. 2024; 17(7):1773. https://doi.org/10.3390/en17071773

Chicago/Turabian StyleZhao, Xiaowei, Yuedong Sun, Zhendong Zhang, and Congbo Yin. 2024. "Experimental Study of the Performance of Turbo-Charged Gasoline Direct-Injection Engine Based on Different Pre-Chamber Structures" Energies 17, no. 7: 1773. https://doi.org/10.3390/en17071773

APA StyleZhao, X., Sun, Y., Zhang, Z., & Yin, C. (2024). Experimental Study of the Performance of Turbo-Charged Gasoline Direct-Injection Engine Based on Different Pre-Chamber Structures. Energies, 17(7), 1773. https://doi.org/10.3390/en17071773