Animal Manure as an Alternative Bioenergy Resource in Rural Sub-Saharan Africa: Present Insights, Challenges, and Prospects for Future Advancements

Abstract

:1. Introduction

2. Animal Manure as an Alternative Source of Energy in Rural SSA

2.1. Present State of Knowledge and Use of Animal Manure for Energy in Rural SSA

2.2. Opportunities and Challenges

2.3. Prospects for Future Advancements

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tomala, J.; Mierzejewski, M.; Urbaniec, M.; Martinez, S. Towards Sustainable Energy Development in Sub-Saharan Africa: Challenges and Opportunities. Energies 2021, 14, 6037. [Google Scholar] [CrossRef]

- Rahman, K.M.; Harder, M.K.; Woodard, R. Energy Yield Potentials from the Anaerobic Digestion of Common Animal Manure in Bangladesh. Energy Environ. 2018, 29, 1338–1353. [Google Scholar] [CrossRef]

- Copinschi, P. Energy and the Economy in Sub-Saharan Africa. In The Palgrave Handbook of International Energy Economics; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Hanif, I. Impact of Economic Growth, Nonrenewable and Renewable Energy Consumption, and Urbanization on Carbon Emissions in Sub-Saharan Africa. Environ. Sci. Pollut. Res. 2018, 25, 15057–15067. [Google Scholar] [CrossRef] [PubMed]

- Bekun, F.V.; Alola, A.A. Determinants of Renewable Energy Consumption in Agrarian Sub-Sahara African Economies. Energy Ecol. Environ. 2022, 7, 227–235. [Google Scholar] [CrossRef]

- Lawal, A.I. Determinants of Renewable Energy Consumption in Africa: Evidence from System GMM. Energies 2023, 16, 2136. [Google Scholar] [CrossRef]

- Szymajda, A.; Łaska, G.; Joka, M. Assessment of Cow Dung Pellets as a Renewable Solid Fuel in Direct Combustion Technologies. Energies 2021, 14, 1192. [Google Scholar] [CrossRef]

- Tucho, G.T.; Nonhebel, S. Bio-Wastes as an Alternative Household Cooking Energy Source in Ethiopia. Energies 2015, 8, 9565–9583. [Google Scholar] [CrossRef]

- Wardle, J.M.; Fischer, A.; Tesfaye, Y.; Smith, J. Seasonal Variability of Resources: The Unexplored Adversary of Biogas Use in Rural Ethiopia. Curr. Res. Environ. Sustain. 2021, 3, 100072. [Google Scholar] [CrossRef] [PubMed]

- Michoud, B.; Hafner, M. Energy Access in Sub-Saharan Africa: General Context. In Financing Clean Energy Access in Sub-Saharan Africa; Springer: Berlin/Heidelberg, Germany, 2021; pp. 7–26. [Google Scholar]

- Dovie, D.B.K.; Witkowski, E.T.F.; Shackleton, C.M. The Fuelwood Crisis in Southern Africa-Relating Fuelwood Use to Livelihoods in a Rural Village. GeoJournal 2004, 60, 123–133. [Google Scholar] [CrossRef]

- Washaya, S.; Washaya, D.D. Benefits, Concerns and Prospects of Using Goat Manure in Sub-Saharan Africa. Pastoralism 2023, 13, 28. [Google Scholar] [CrossRef]

- Mmusi, K.; Mudiwa, J.; Rakgati, E.; Vishwanathan, V. Biogas a Sustainable Source of Clean Energy in Sub Saharan Africa: Challenges and Opportunities. J. Appl. Mater. Sci. Eng. Res. 2021, 5, 7–12. [Google Scholar]

- Liebetrau, J.; O’Shea, R.; Wellisch, M.; Lyng, K.-A.; Bochmann, G.; McCab, B.K.; Harris, P.W.; Lukehurst, C.; Kornatz, P.; Murphy, J.D. Potential and Utilization of Manure to Generate Biogas in Seven Countries; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Mensah, T.N.O.; Oyewo, A.S.; Breyer, C. The Role of Biomass in Sub-Saharan Africa’s Fully Renewable Power Sector—The Case of Ghana. Renew. Energy 2021, 173, 297–317. [Google Scholar] [CrossRef]

- Bedi, A.S.; Pellegrini, L.; Tasciotti, L. The Effects of Rwanda’s Biogas Program on Energy Expenditure and Fuel Use. World Dev. 2015, 67, 461–474. [Google Scholar] [CrossRef]

- Gadirli, G.; Pilarska, A.A.; Dach, J.; Pilarski, K.; Kolasa-Więcek, A.; Borowiak, K. Fundamentals, Operation and Global Prospects for the Development of Biogas Plants—A Review. Energies 2024, 17, 568. [Google Scholar] [CrossRef]

- Biodun, M.B.; Fayomi, O.S.I.; Okeniyi, J.O. The Possibility of Biogas Production in Nigeria from Organic Waste Material: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1107, 012166. [Google Scholar] [CrossRef]

- Tolessa, A.; Zantsi, S.; Louw, T.M.; Greyling, J.C.; Goosen, N.J. Estimation of Biomass Feedstock Availability for Anaerobic Digestion in Smallholder Farming Systems in South Africa. Biomass Bioenergy 2020, 142, 105798. [Google Scholar] [CrossRef]

- Kunatsa, T.; Xia, X. Co-Digestion of Water Hyacinth, Municipal Solid Waste and Cow Dung: A Methane Optimised Biogas–Liquid Petroleum Gas Hybrid System. Appl. Energy 2021, 304, 117716. [Google Scholar] [CrossRef]

- Mulinda, C.; Hu, Q.; Pan, K. Dissemination and Problems of African Biogas Technology. Energy Power Eng. 2013, 5, 506–512. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Atnaw, S.M.; Desta, M. The Biogas Technology Development in Ethiopia: The Status, and the Role of Private Sectors, Academic Institutions, and Research Centers. In Lecture Notes in Energy; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2023; Volume 92, pp. 227–243. [Google Scholar]

- Shane, A.; Gheewala, S.H.; Kasali, G. Potential, Barriers and Prospects of Biogas Production in Zambia. J. Sustain. Energy Environ. 2015, 6, 21–27. [Google Scholar]

- Mwirigi, J.; Balana, B.B.; Mugisha, J.; Walekhwa, P.; Melamu, R.; Nakami, S.; Makenzi, P. Socio-Economic Hurdles to Widespread Adoption of Small-Scale Biogas Digesters in Sub-Saharan Africa: A Review. Biomass Bioenergy 2014, 70, 17–25. [Google Scholar] [CrossRef]

- Kalina, M.; Ogwang, J.Ò.; Tilley, E. From Potential to Practice: Rethinking Africa’s Biogas Revolution. Humanit. Soc. Sci. Commun. 2022, 9, 374. [Google Scholar] [CrossRef]

- ESMAP. The Power of Dung: Lessons Learned from On-Farm Biodigester Programs in Africa; World Bank: Washington, DC, USA, 2019. [Google Scholar]

- Manala, C.; Madyira, D.; Mbohwa, C.; Shuma, R. Summary-View: Biomass Anaerobic Respiration Technology in South Africa. In Proceedings of the 7th International Conference on Appropriate Technology, Victoria Falls, Zimbabwe, 23–26 November 2016; pp. 27–41. [Google Scholar]

- Rota, A.; Sehgal, K. FlexiBiogas—A Climate Change Adaptation and Mitigation Technology; IFAD Rural: Rome, Italy, 2014. [Google Scholar]

- Onwosi, C.O.; Ozoegwu, C.G.; Nwagu, T.N.; Nwobodo, T.N.; Eke, I.E.; Igbokwe, V.C.; Ugwuoji, E.T.; Ugwuodo, C.J. Cattle Manure as a Sustainable Bioenergy Source: Prospects and Environmental Impacts of Its Utilization as a Major Feedstock in Nigeria. Bioresour. Technol. Rep. 2022, 19, 101151. [Google Scholar] [CrossRef]

- Nayal, F.S.; Mammadov, A.; Ciliz, N. Environmental Assessment of Energy Generation from Agricultural and Farm Waste through Anaerobic Digestion. J. Environ. Manag. 2016, 184, 389–399. [Google Scholar] [CrossRef] [PubMed]

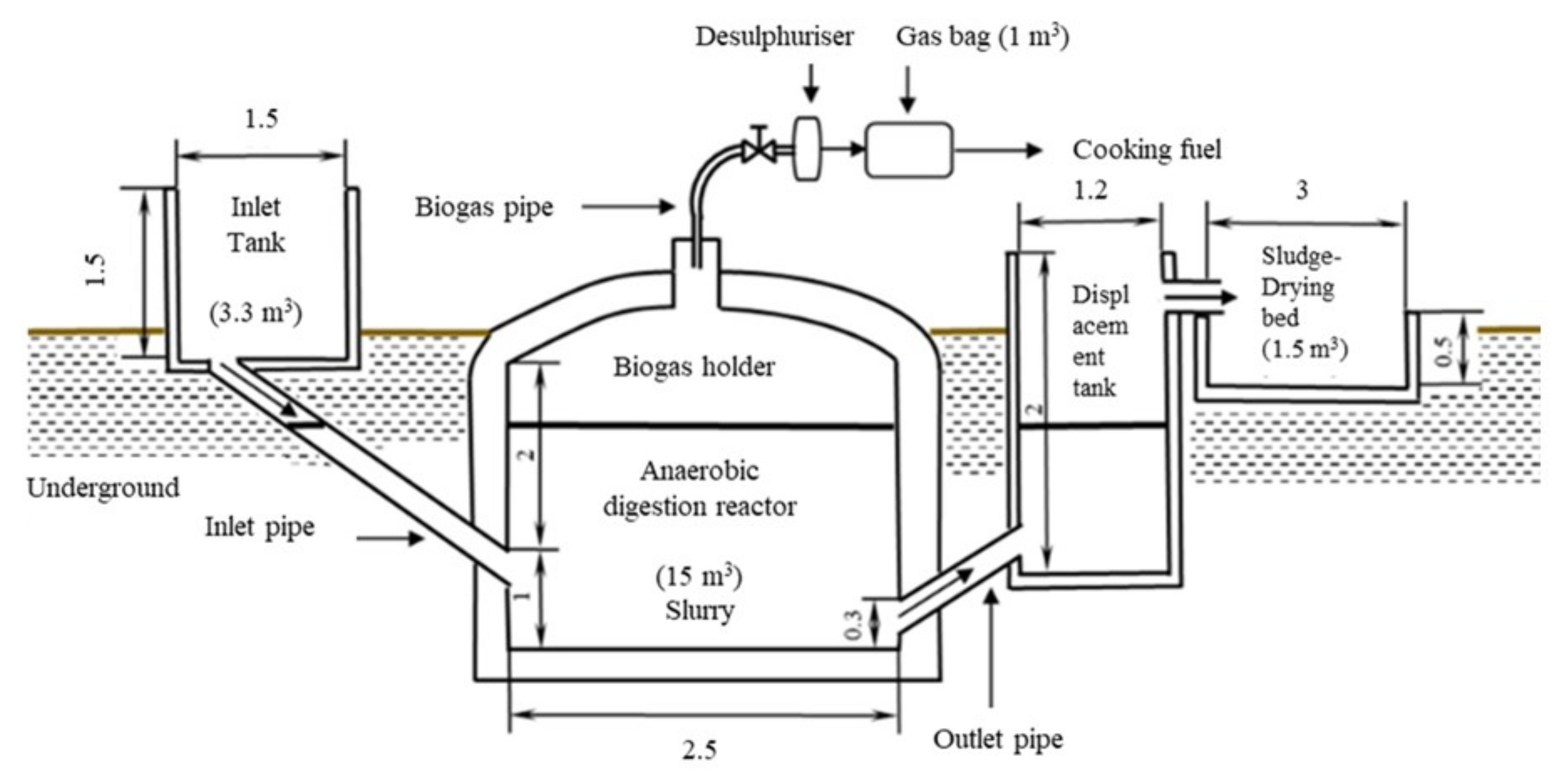

- Akhator, P.; Musa, B. Anaerobic Co-Digestion of Food Waste and Cow Dung in a Pilot Fixed-Dome Bio-Digester for Biogas Production. Int. J. Eng. Sci. Appl. 2022, 6, 56–64. [Google Scholar]

- Liang, J.; Zhang, R.; Chang, J.; Chen, L.; Nabi, M.; Zhang, H.; Zhang, G.; Zhang, P. Rumen Microbes, Enzymes, Metabolisms, and Application in Lignocellulosic Waste Conversion—A Comprehensive Review. Biotechnol. Adv. 2024, 71, 108308. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Fang, W.; Wang, Q.; Zubair, M.; Zhang, G.; Ma, W.; Cai, Y.; Zhang, P. Metagenomic Analysis of Community, Enzymes and Metabolic Pathways during Corn Straw Fermentation with Rumen Microorganisms for Volatile Fatty Acid Production. Bioresour. Technol. 2021, 342, 126004. [Google Scholar] [CrossRef]

- Gupta, K.K.; Aneja, K.R.; Rana, D. Current Status of Cow Dung as a Bioresource for Sustainable Development. Bioresour. Bioprocess. 2016, 3, 28. [Google Scholar] [CrossRef]

- Nkosi, S.M.; Lupuleza, I.; Sithole, S.N.; Zelda, Z.R.; Matheri, A.N. Renewable Energy Potential of Anaerobic Mono-and Co-Digestion of Chicken Manure, Goat Manure, Potato Peels and Maize Pap in South Africa. S. Afr. J. Sci. 2021, 117, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Ratminingsih; Jumadi, J. A Study on the Potential of Cow Dung Waste as an Environmentally Friendly Alternative Energy Source. Adv. Soc. Sci. Educ. Humanit. Res. 2021, 528, 76–80. [Google Scholar]

- Smith, J.; Balana, B.B.; Black, H.; von Blottnitz, H.; Casson, E.; Glenk, K.; Langan, S.; Matthews, R.; Mugisha, J.; Smith, P.; et al. The Potential of Small-Scale Biogas Digesters to Alleviate Poverty and Improve Long Term Sustainability of Ecosystem Services in Sub-Saharan Africa. In Proceeding of the 1st World Sustainability Forum, Online, 13–15 September 2021; Volume 5, pp. 2911–2942. [Google Scholar]

- Wardle, J.; Dionisi, D.; Smith, J.; Wardle, J.; Smith, J. Investigating the Challenges of Biogas Provision in Water Limited Environments through Laboratory Scale Biodigesters. Int. J. Sustain. Energy 2023, 42, 829–844. [Google Scholar] [CrossRef]

- Libaisi, J.; Njenga, M. Biogas as a Smart Investment for Women’s Empowerment and Livelihood Enhancement. In Recovering Bioenergy in Sub-Saharan Africa: Gender Dimensions, Lessons and Challenges; CGIAR: Bogor Barat, Indonesia, 2020; pp. 33–38. [Google Scholar]

- Amigun, B.; Von Blottnitz, H. Capacity-Cost and Location-Cost Analyses for Biogas Plants in Africa. Resour. Conserv. Recycl. 2010, 55, 63–73. [Google Scholar] [CrossRef]

- Dahunsi, O.S.; Shoyombo, A.; Fagbiele, O. Biofuel Development in Sub-Saharan Africa. In Anaerobic Digestion; IntechOpen: London, UK, 2019; pp. 1–13. [Google Scholar]

- NDP. South African Renewable Energy Masterplan (SAREM): An Industrial and Inclusive Development Plan for the Renewable Energy and Storage Value Chains by 2030; WDB: Pretoria, South Africa, 2023. [Google Scholar]

- Kaifa, J.; Parawira, W. A Study of the Current State of Biogas Production in Zimbabwe: Lessons for Southern Africa. Biotechnol. Microbiol. 2019, 13, 60–68. [Google Scholar] [CrossRef]

- Kajau, G.; Madyira, D.M. Analysis of the Zimbabwe Biodigester Status. In Proceedings of the Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 35, pp. 561–566. [Google Scholar]

- Tesfay, A.H.; Hailu, M.H.; A Gebrerufael, F.; Adaramola, M.S. Implementation and Status of Biogas Technology in Ethiopia- Case of Tigray Region. Momona Ethiop. J. Sci. 2021, 12, 257–273. [Google Scholar] [CrossRef]

- Surroop, D.; Bundhoo, Z.M.A.; Raghoo, P. Waste to Energy through Biogas to Improve Energy Security and to Transform Africa’s Energy Landscape. Curr. Opin. Green. Sustain. Chem. 2019, 18, 79–83. [Google Scholar] [CrossRef]

- Mukeshimana, M.C.; Zhao, Z.Y.; Ahmad, M.; Irfan, M. Analysis on Barriers to Biogas Dissemination in Rwanda: AHP Approach. Renew. Energy 2021, 163, 1127–1137. [Google Scholar] [CrossRef]

- Hewitt, J.; Holden, M.; Robinson, B.L.; Jewitt, S.; Clifford, M.J. Not Quite Cooking on Gas: Understanding Biogas Plant Failure and Abandonment in Northern Tanzania. Renew. Sustain. Energy Rev. 2022, 165, 112600. [Google Scholar] [CrossRef]

- Lohani, S.P.; Dhungana, B.; Horn, H.; Khatiwada, D. Small-Scale Biogas Technology and Clean Cooking Fuel: Assessing the Potential and Links with SDGs in Low-Income Countries—A Case Study of Nepal. Sustain. Energy Technol. Assess. 2021, 46, 101301. [Google Scholar] [CrossRef]

- Bansal, V.; Tumwesige, V.; Smith, J.U. Water for Small-Scale Biogas Digesters in Sub-Saharan Africa. GCB Bioenergy 2017, 9, 339–357. [Google Scholar] [CrossRef]

- Ndambi, O.A.; Pelster, D.E.; Owino, J.O.; de Buisonjé, F.; Vellinga, T. Manure Management Practices and Policies in Sub-Saharan Africa: Implications on Manure Quality as a Fertilizer. Front. Sustain. Food Syst. 2019, 3, 29. [Google Scholar] [CrossRef]

- Graham, M.W.; Butterbach-Bahl, K.; du Toit, C.J.L.; Korir, D.; Leitner, S.; Merbold, L.; Mwape, A.; Ndung’u, P.W.; Pelster, D.E.; Rufino, M.C.; et al. Research Progress on Greenhouse Gas Emissions from Livestock in Sub-Saharan Africa Falls Short of National Inventory Ambitions. Front. Soil Sci. 2022, 2, 927452. [Google Scholar] [CrossRef]

- Benti, N.E.; Gurmesa, G.S.; Argaw, T.; Aneseyee, A.B.; Gunta, S.; Kassahun, G.B.; Aga, G.S.; Asfaw, A.A. The Current Status, Challenges and Prospects of Using Biomass Energy in Ethiopia. Biotechnol. Biofuels 2021, 14, 209. [Google Scholar] [CrossRef]

- Rasimphi, T.E.; Tinarwo, D. Relevance of Biogas Technology to Vhembe District of the Limpopo Province in South Africa. Biotechnol. Rep. 2020, 25, e00412. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ghimire, S.; Wang, J.; Dong, R.; Li, Q. Alternative Management Systems of Beef Cattle Manure for Reducing Nitrogen Loadings: A Case-Study Approach. Animals 2021, 11, 574. [Google Scholar] [CrossRef]

- Brown, V.J. Biogas a Bright Idea for Africa. Environ. Health Perspect. 2006, 114, A300–A303. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.K.; Mohanty, P.; Mishra, S.; Adhya, T.K. Food Waste Valorisation for Biogas-Based Bioenergy Production in Circular Bioeconomy: Opportunities, Challenges, and Future Developments. Front. Energy Res. 2022, 10, 903775. [Google Scholar] [CrossRef]

- Hanum, F.; Nagahata, M.; Nindhia, T.G.T.; Kamahara, H.; Atsuta, Y.; Daimon, H. Evaluation of a Small-Scale Anaerobic Digestion System for a Cattle Farm under an Integrated Agriculture System in Indonesia with Relation to the Status of Anaerobic Digestion System in Japan. Sustainability 2023, 15, 3833. [Google Scholar] [CrossRef]

- GoZ Ministry of Energy and Power Development National Renewable Energy Policy; Ministry of Energy, Republic of Zimbabwe: Harare, Zimbabwe, 2019; pp. 1–58.

- NEP. The-National-Energy-Policy-2019; The Ministry of Energy: Lusaka, Zambia, 2019; pp. 1–58. [Google Scholar]

- CPP. Cameroon Country Priority Plan and Diagnostic of the Electricity Sector; Government of the Republic of Cameroon: Younde, Cameroon, 2021; pp. 1–54. [Google Scholar]

- GovNamibia. Government of the Republic of Namibia Renewable Energy Policy; Ministry of Mines and Energy: Windhoek, Namibia, 2017; pp. 1–64. [Google Scholar]

- IEA. Outlook for Biogas and Biomethane: Prospects for Organic Growth; International Energy Agency: Paris, France, 2020; pp. 1–93. [Google Scholar]

- Rupf, G.V.; Bahri, P.A.; De Boer, K.; McHenry, M.P. Barriers and Opportunities of Biogas Dissemination in Sub-Saharan Africa and Lessons Learned from Rwanda, Tanzania, China, India, and Nepal. Renew. Sustain. Energy Rev. 2015, 52, 468–476. [Google Scholar] [CrossRef]

- Afzal, I.; Shinwari, Z.K.; Sikandar, S.; Shahzad, S. Plant Beneficial Endophytic Bacteria: Mechanisms, Diversity, Host Range and Genetic Determinants. Microbiol. Res. 2019, 221, 36–49. [Google Scholar] [CrossRef]

- Bhatt, A.H.; Tao, L. Economic Perspectives of Biogas Production via Anaerobic Digestion. Bioengineering 2020, 7, 74. [Google Scholar] [CrossRef]

- Borgström, Y. Pretreatment Technologies to Increase the Methane Yields by Anaerobic Digestion in Relation to Cost Efficiency of Substrate Transportation. Master of Science; Linkoping Institute of Technology: Linkoping, Sweden, 2011. [Google Scholar]

- Klocker, D. Impact of Intermediate and End-Products of Anaerobic Digestion on Sludge Filterability: Understanding Fouling in AnMBRs. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

- Mengistu, M.G.; Simane, B.; Eshete, G.; Workneh, T.S. Factors Affecting Households’ Decisions in Biogas Technology Adoption, the Case of Ofla and Mecha Districts, Northern Ethiopia. Renew. Energy 2016, 93, 215–227. [Google Scholar] [CrossRef]

- Robin, T.; Ehimen, E. Exploring the Potential Role of Decentralised Biogas Plants in Meeting Energy Needs in Sub-Saharan African Countries: A Techno-Economic Systems Analysis. Sustain. Energy Res. 2024, 11, 8. [Google Scholar] [CrossRef]

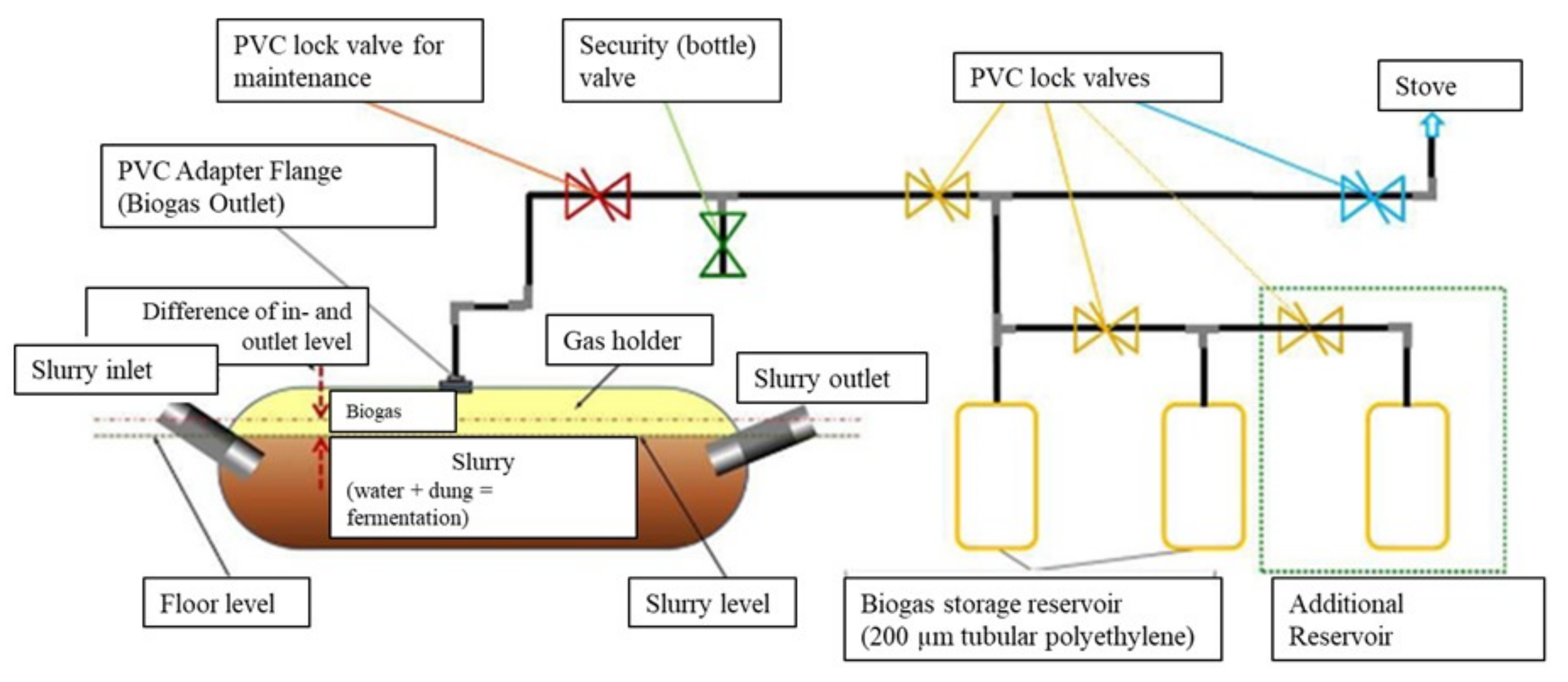

- Lüer, M. Installation Manual for Low-Cost Polyethylene Tube Digesters. Available online: https://energypedia.info/images/1/19/Low_cost_polyethylene_tube_installation.pdf (accessed on 3 April 2024).

- Wang, K.; Yun, S.; Ke, T.; An, J.; Abbas, Y.; Liu, X.; Zou, M.; Liu, L.; Liu, J. Use of Bag-Filter Gas Dust in Anaerobic Digestion of Cattle Manure for Boosting the Methane Yield and Digestate Utilization. Bioresour. Technol. 2022, 348, 126729. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Zhang, C.; Wang, Y.; Zhu, J.; Huang, X.; Du, T.; Li, X.; Wei, Y. Synergistic Effects of Fe Salts and Composite Additives on Anaerobic Digestion of Dairy Manure. Int. Biodeterior. Biodegrad. 2019, 136, 82–90. [Google Scholar] [CrossRef]

- Adekunle, A.S.; Ibitoye, S.E.; Omoniyi, P.O.; Jilantikiri, L.J.; Sam-Obu, C.V.; Yahaya, T.; Mohammad, B.G.; Olusegun, H.D. Production and Testing of Biogas Using Cow Dung, Jatropha and Iron Filins. J. Bioresour. Bioprod. 2019, 4, 143–148. [Google Scholar] [CrossRef]

- Qi, L.; Liu, X.; Miao, Y.; Chatzisymeon, E.; Yang, P.; Lu, H.; Pang, L. Response of Cattle Manure Anaerobic Digestion to Zinc Oxide Nanoparticles: Methane Production, Microbial Community, and Functions. J. Environ. Chem. Eng. 2021, 9, 106704. [Google Scholar] [CrossRef]

- Yun, S.; Fang, W.; Du, T.; Hu, X.; Huang, X.; Li, X.; Zhang, C.; Lund, P.D. Use of Bio-Based Carbon Materials for Improving Biogas Yield and Digestate Stability. Energy 2018, 164, 898–909. [Google Scholar] [CrossRef]

| Country | No. Installed | Capacity (m3) | Operational (%) | Reference |

|---|---|---|---|---|

| Zambia | 60 | 4–80 | [23] | |

| Zimbabwe | 711 | 50–200 | 15 | [43,44] |

| Ethiopia | 15,738–18,534 | Various | 40 | [24,45,46] |

| Cameroon | 164 * | Various | [46] | |

| Burkina Faso | 10,310 | Various | [46] | |

| Botswana | 15 | Various | [46] | |

| Kenya | 13,000–18,560 | Various | 30 | [24,46,47] |

| Senegal | 875 | Various | [46] | |

| Tanzania | 12,000 | Various | [48] | |

| Uganda | 8000 | Various | [47] | |

| Nepal † | 431,629 | various | 90 | [49] |

| Year of Construction (Phases) | No. Collapsed | No. Functional | No. Non-Functional | No. Yet to Be Fed | No. Abandoned | No. Never Worked | No. under Construction |

|---|---|---|---|---|---|---|---|

| 1980–1990 | 0 | 2 | 21 | 0 | 7 | 2 | 2 |

| 1991–2000 | 0 | 6 | 17 | 0 | 6 | 3 | 0 |

| 2001–2010 | 3 | 5 | 30 | 2 | 13 | 2 | 2 |

| 2011–2012 | 0 | 1 | 0 | 0 | 0 | 0 | 2 |

| Total | 3 | 14 | 68 | 2 | 26 | 7 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sibanda, T.; Uzabakiriho, J.D. Animal Manure as an Alternative Bioenergy Resource in Rural Sub-Saharan Africa: Present Insights, Challenges, and Prospects for Future Advancements. Energies 2024, 17, 1839. https://doi.org/10.3390/en17081839

Sibanda T, Uzabakiriho JD. Animal Manure as an Alternative Bioenergy Resource in Rural Sub-Saharan Africa: Present Insights, Challenges, and Prospects for Future Advancements. Energies. 2024; 17(8):1839. https://doi.org/10.3390/en17081839

Chicago/Turabian StyleSibanda, Timothy, and Jean Damascene Uzabakiriho. 2024. "Animal Manure as an Alternative Bioenergy Resource in Rural Sub-Saharan Africa: Present Insights, Challenges, and Prospects for Future Advancements" Energies 17, no. 8: 1839. https://doi.org/10.3390/en17081839

APA StyleSibanda, T., & Uzabakiriho, J. D. (2024). Animal Manure as an Alternative Bioenergy Resource in Rural Sub-Saharan Africa: Present Insights, Challenges, and Prospects for Future Advancements. Energies, 17(8), 1839. https://doi.org/10.3390/en17081839